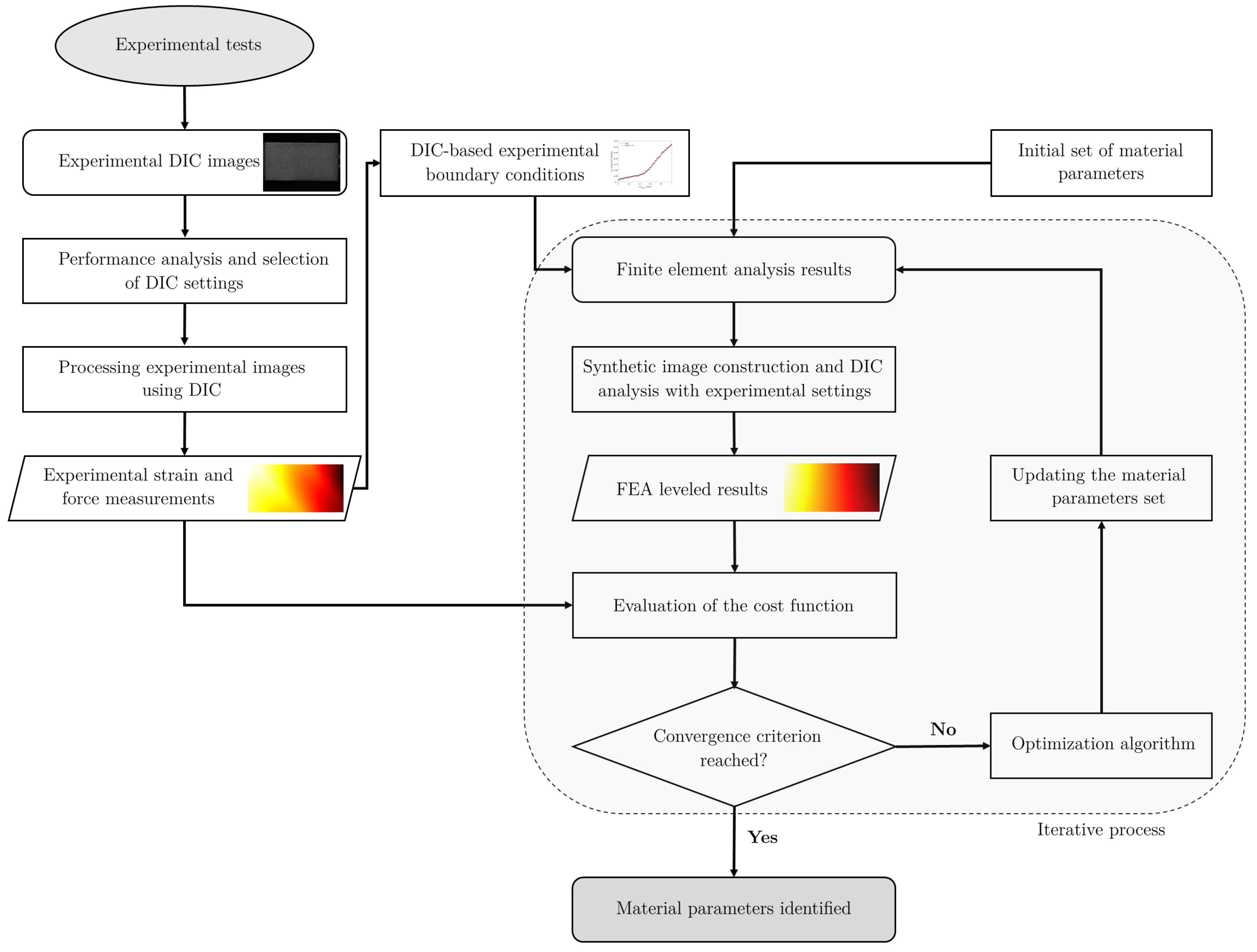

2.2. Compression Tests and Full-Field Measurements

A universal Instron 5848 MicroTester machine (Instron, Barcelona, Spain) was used to carry out the compression tests, with displacement control at a cross-head velocity of 0.5 mm/min. A 2 kN load cell was used to measure the resultant uniaxial load. To minimise friction and avoid excessive barrelling, a lubricant was applied between the specimen and the compression platens. To improve flatness of the compression surfaces, loading and unloading cycles of up to 20 N were performed before testing. Image focusing over the target pattern surface was then adjusted accordingly for stable measurements during the test.

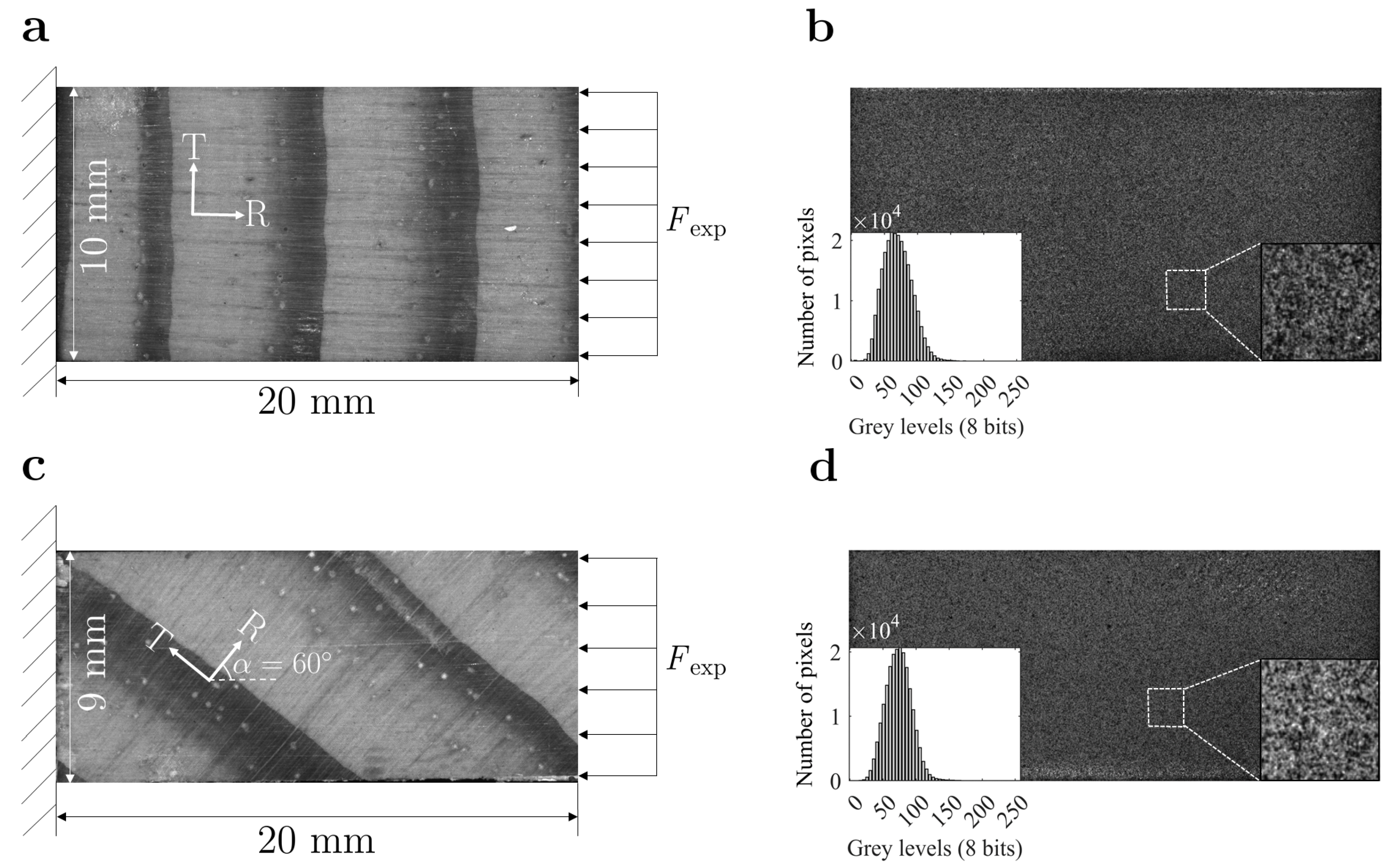

The camera-lens optical system consisted of a Baumer Optronic FWX20 camera (Baumer Optronic GmbH, Radeberg, Germany) coupled with an AF Micro-Nikkor 200 mm f/4D ED-IF lens (Nikon, Portugal). The image field of view covered an area integrating several annual growth rings. The field of view targeted a physical region of about 20.5 × 15.5 mm

2. The surface of the specimens was painted to carry out DIC measurements. The speckle pattern was created by means of an airbrush painting with a 0.18-mm nozzle (IWATA, model CM-B, Anesta Iwata Iberica SL, Barcelona, Spain).

Figure 2b,d show the speckle pattern applied on an on-axis and off-specimen, respectively, as well as the grey level frequency histogram. The lighting system and the exposure time were set to avoid pixel saturation and image blurring during testing. Loading and image recording were synchronized during the test at an acquisition frequency of 1 Hz.

2.3. Digital Image Correlation: Parametric Analysis

In this work, the MatchID subset-based DIC 2D software (Ghent, Belgium [

47]) was used to reconstruct the displacements and strain fields. In this technique, a mathematical correlation criterion is minimised with respect to the unknown parameters of the displacement shape function, by considering, iteratively, a sub-region centred on a pixel in the undeformed image

and searching for the subset transformation on the deformed configuration

[

32]. A square subset can be defined by

pixels, where

N is a positive integer, defining the subset size (SS) or displacement spatial resolution. The size of the subsets may respect the rule of thumb of at least three contrasted pixelated speckles. On the other hand, a single speckle must contain at least three to five pixels to avoid aliasing effects. Therefore, as a first approximation, the subset size can be a multiple of three regarding the average speckle size across the image, providing that a regular pattern is created.

The zero-mean normalized sum-of-squared-differences (ZNSSD) criterion was selected mainly due to its good performance on a wide range of image contrast variations and lightning intensity shifting. DIC uses subset shape functions to match locations in the undeformed image to corresponding positions in the deformed image. The polynomial order of these shape functions determines how the subset can deform throughout the correlation process since this subset must be able to change size, shape and position during the entire deformation in order to be traced back in the deformed image. It is possible to choose between affine, irregular and quadratic shape functions, depending on the local strain gradients. Moreover, the coordinates of points in the deformed subset may be located between pixels. The intensity of these points with sub-pixel positions must be given before assessing the similarity between reference and deformed subsets using the correlation criterion, hence the need for using a sub-pixel interpolation method, such as bilinear, bicubic or bicubic spline interpolation [

48].

In contrast with a finite element mesh, the correlation domains can overlap by sharing gray intensity pixels over the boundaries. The distance between adjacent centroid of the subsets is the step size (ST), which will define the mesh data points to be used in the reconstruction of the strain fields. Nevertheless, when analyzing areas with substantial heterogeneous deformation, this ST should be carefully set to achieve smooth displacement fields in particular close to holes or material transition zones.

The strain fields are then reconstructed from the displacement fields by a suitable filtering and differentiation algorithm. Typically this operation is defined locally across a strain window (SW), embedding some displacement data points

over which a local surface fitting approach is applied on a least-square regression sense [

48]. The polynomial order of these bi-dimensional functions can be defined as bilinear or biquadratic, for instance. It is pointed out that the selected SS and ST parameters in the correlation process will propagate over the strain reconstruction by defining the final spatial resolution. This parameter can be estimated based on the following virtual strain gauge (VSG) measure (units in pixel) [

47]:

Similar to SS, using a larger VSG translates to smoother results. However, the signal measured can be inaccurate in areas with high heterogeneous deformation and gradients properties. A smaller VSG, on the other hand, produces noisier results but with improved strain spatial resolution. Moreover, settings such as the SS, ST and VSG may be easily translated to physical units by means of the magnification factor of the optical system.

The selection of the DIC setting parameters is therefore critical as it influences the measurements and identification results [

2]. On the one hand, using a larger SS increases the resolution, minimising the noise, but decreases the spatial resolution, which is not ideal for measuring strain gradients or heterogeneous strain fields. On the other hand, using smaller SS decreases the resolution of the measurements, however, the spatial resolution is increased.

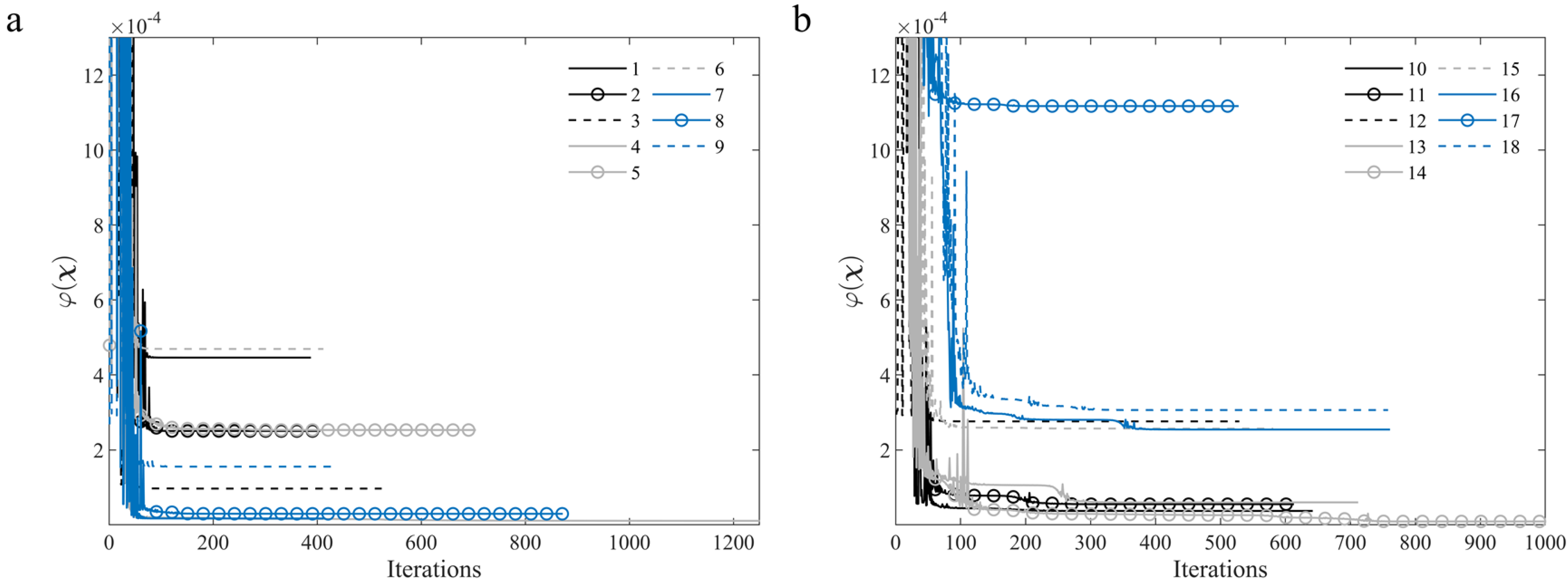

In this work, the selection of the DIC settings was carried out with the support of the performance analysis module within MatchID [

47]. This tool allows performing a large set of DIC analysis by covering a spectrum of different setting combinations at once. This analysis was systematically performed on both on-axis and off-axis specimens (

Figure 2), since the off-axis angle orientation will generate a different mechanical response under the same uniaxial compressive loading. A total of 1800 analyses (900 for each specimen configuration) were performed.

Table 1 reports the different parameters sets used in the parametric analysis.

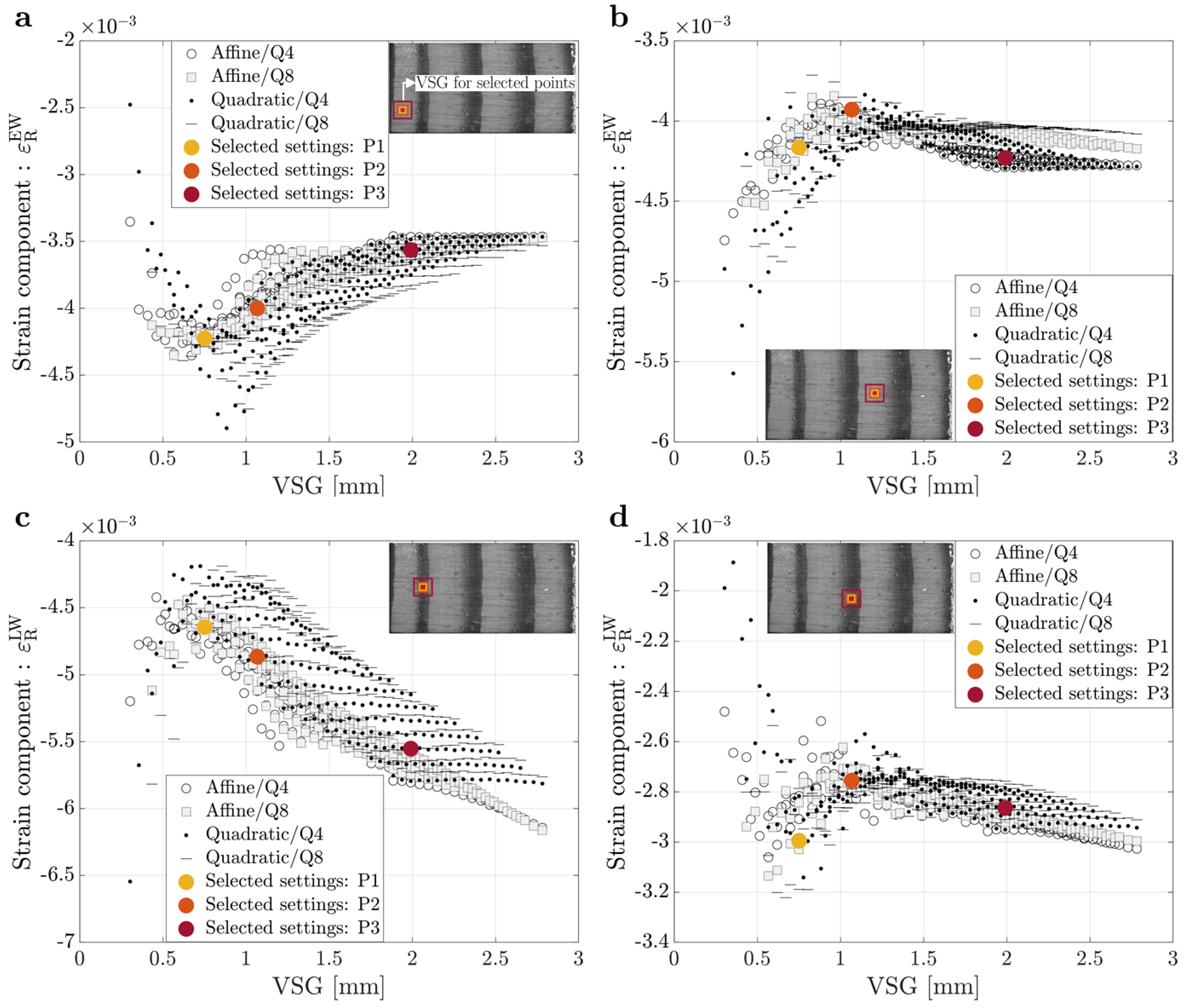

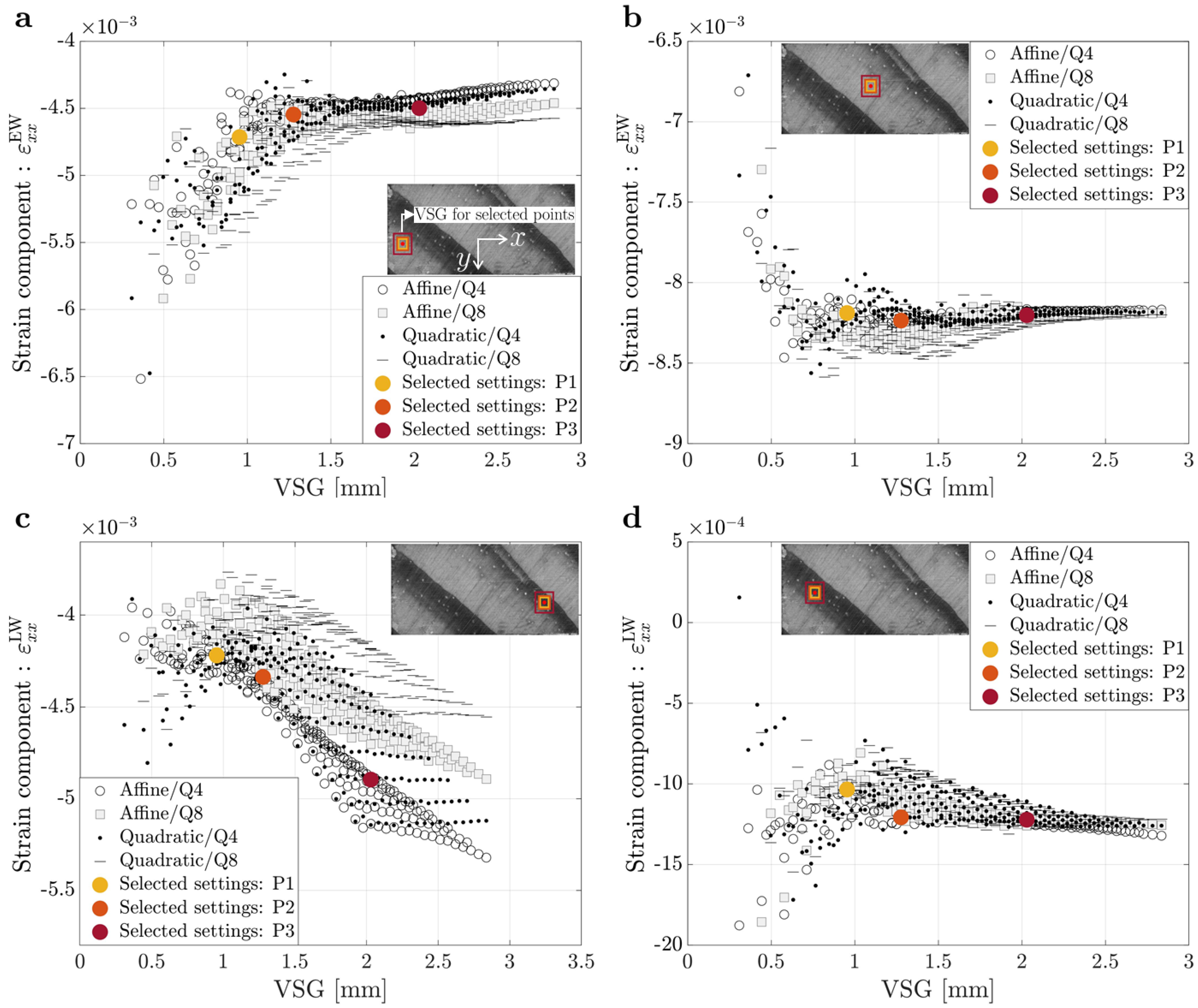

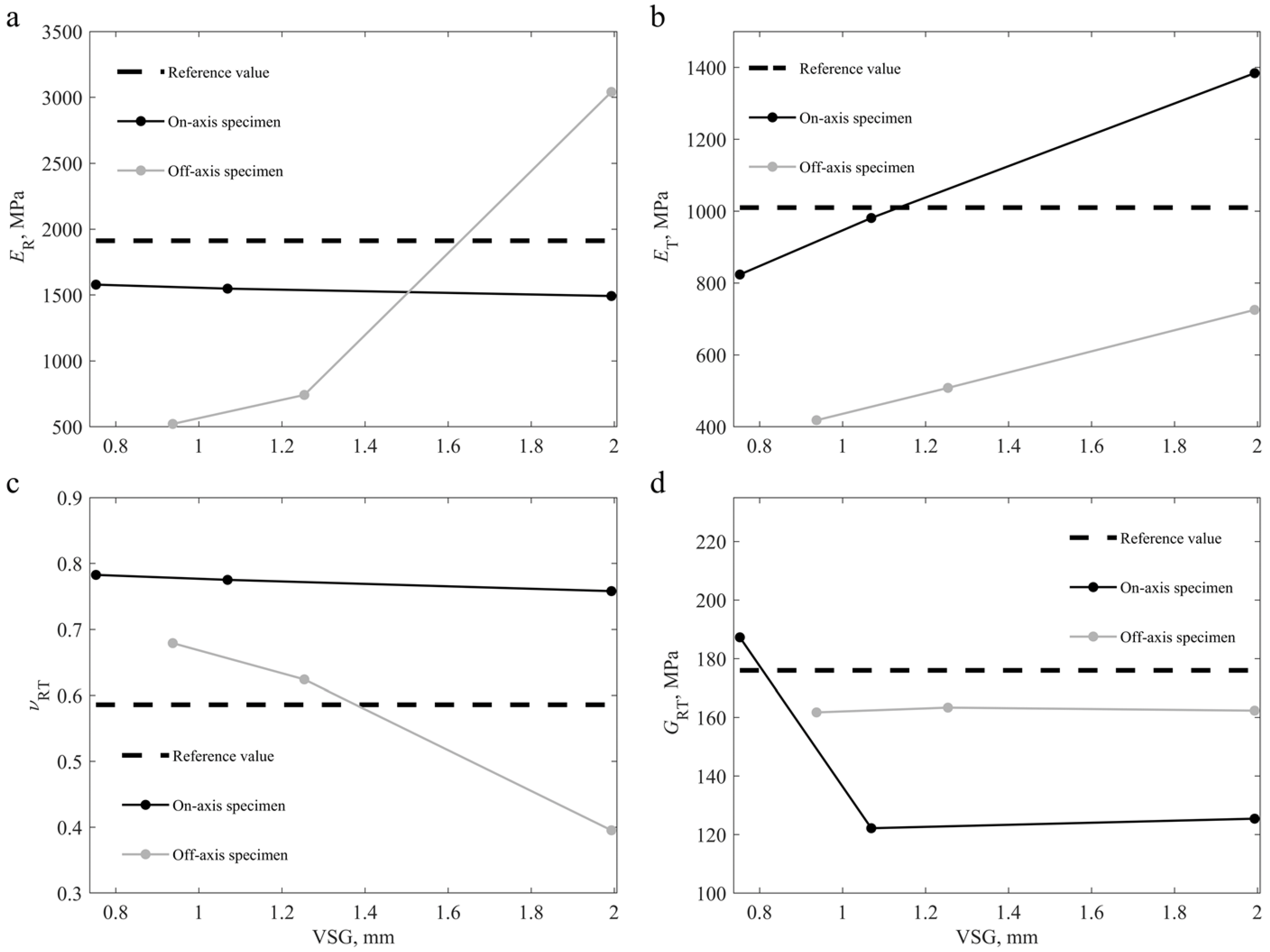

The sets of different DIC settings tested correspond to a VSG range between 23 and 211 pixels, or approximately 0.3 to 2.79 mm. The convergence study performed for the on-axis and off-axis specimens is summarized in

Figure 3 and

Figure 4, respectively, by comparing the signal measured of the strain component on the radial direction (

) for the on-axis specimen and on the

x direction (

) for the off-axis specimen, with the VSG size at four different points: (a) two earlywood points and (b) two latewood points.

A larger VSG smooths the measurements, reducing the built-in noise in the experimental data, but also decreases the strain gradients that are expected in heterogeneous materials like wood, which are created by the growth ring structure [

2]. Furthermore, higher VSG values appear to result in reduced magnitude of the strain signal reconstruction in the earlywood, which is to be expected given the effect of latewood tissue. When looking at the effect of VSG on strain signal reconstruction in latewood tissue, bigger values of VSG appear to lead to a higher strain signal reconstruction, in magnitude, due to the earlywood tissue influence, which is less stiff and deforms more at the same stress value. However, in some results of this parametric analysis, it is also possible to observe that the measured strain signal does not have a significant variation when the VSG increases. This is due to the VSG not being large enough to capture the transition between the earlywood and latewood tissues, which can also be confirmed by the VSG size representations found in

Figure 3 and

Figure 4. Furthermore, the affine and quadratic subset shape functions give comparable measurements, according to the obtained results. Likewise, bilinear and biquadratic strain interpolation, which are used to reconstruct strain fields from displacement measurements, appear to converge, suggesting that, for this analysis, the VSG size has a larger effect on the observations than these parameters. Nevertheless, these results show that when dealing with highly heterogeneous materials, it is important to carefully select the DIC setting parameters to well-balance reconstruct the strain gradients, achieving a balance between spatial resolution and accuracy.

For this work, three different sets of DIC parameters were selected for the on-axis and off-axis specimens to study the influence of spatial resolution and accuracy on the material parameters identification results, which are also represented as differently coloured dots in

Figure 3 and

Figure 4. The different DIC settings were selected according to different trade-offs between accuracy and spatial resolution. The first set of settings selected (P1) is characterized by good spatial resolution due to the lower value of VSG size and, consequently, adequate accuracy. The second set of settings (P2) has a lesser spatial resolution when compared to P1, but slightly improved accuracy due to the higher VSG size. Finally, the third set of setting parameters (P3) is characterized by good accuracy, owing to the high level of smoothing imposed by the larger VSG, but significantly less spatial resolution, which in turn compromises the measurement of strain gradients.

Table 2 lists the 2D-DIC parameters used in this work for the on-axis and off-axis specimens, concerning the three different sets of settings chosen.

2.4. Finite Element Model and Synthetic Images

A FE model was implemented in ANSYS Mechanical APDL software (Pennsylvania, Canonsburg, United States of America [

49]) using DIC-based experimental boundary conditions on the left and right boundaries of the region of interest (ROI), interpolated between the DIC and FEA meshes. Wood was modelled as a homogeneous orthotropic linear elastic material.

According to Hooke’s Law, if a plane stress condition is applied to an orthotropic material, the relationship between stress and strain in the global coordinate system can be expressed by [

50]:

where

are the stiffness matrix components in the global coordinate system, while

and

are the stress and strain fields, respectively, and the subscripts describe the three stress/strain components (

,

and

). The stress/strain relationship described in Equation (

2) can also be expressed regarding the modulus of elasticity,

Poisson’s ratio and shear modulus by the following:

where

is the modulus of elasticity,

is the

Poisson’s ratio,

is the shear modulus and the subscripts represent the different components of the global coordinate system. The

Poisson’s ration in the different components of the global coordinate system can be further related by the following expression:

As presented by Equations (

3) and (

4), the linear elastic orthotropic constitutive model has a total of four independent parameters to calibrate (

,

,

and

). Moreover, the geometry of the FE models was defined considering the real rectangular shape of the specimens based on the reference experimental image. The finite element PLANE182 was selected for meshing, which is a two-dimensional four-node structural solid element. Using plane stress and pure displacement formulation, this element was defined as a plane element with two degrees of freedom at each node, which are the translations in the nodal

x and

y directions. The element size was set to 0.085 mm, and there were roughly 30,300 nodes and 30,000 elements on the on-axis FE models and 25,600 nodes and 25,300 elements on the off-axis FE models.

In the proposed FEMU approach, the main goal is to fit the FEA results with experimental data. However, before doing this comparison, numerous inconsistencies must be handled, including differing coordinate systems, data locations, strain formulations, spatial resolutions and data filtering. To solve these issues, it was proposed to synthetically deform the reference image of the DIC speckle pattern by means of coordinates and nodal displacements of the FE model, creating a set of deformed synthetic images for further evaluation by the DIC approach. The synthetically deformed image can then be processed using the same DIC settings as the experimental images, ensuring that both sets of data have the same filtering, spatial resolution, and strain formulation. Furthermore, using this approach guarantees that both DIC and FEA are subjected to the same calibration and triangulation processes, directly expressing both data meshes inside the same coordinate frame with coincident data point positions, avoiding further interpolation steps between the two meshes. On top of that, the experimental data are accompanied by noise and errors. However, due to this approach, which uses a real DIC reference image, numerous potential error sources associated are inadvertently included in the DIC-levelled FEA data. As a result, some pattern-related image artifacts, such as saturation, aliasing and lightning issues, may be more easily distinguished from actual model problems [

44].

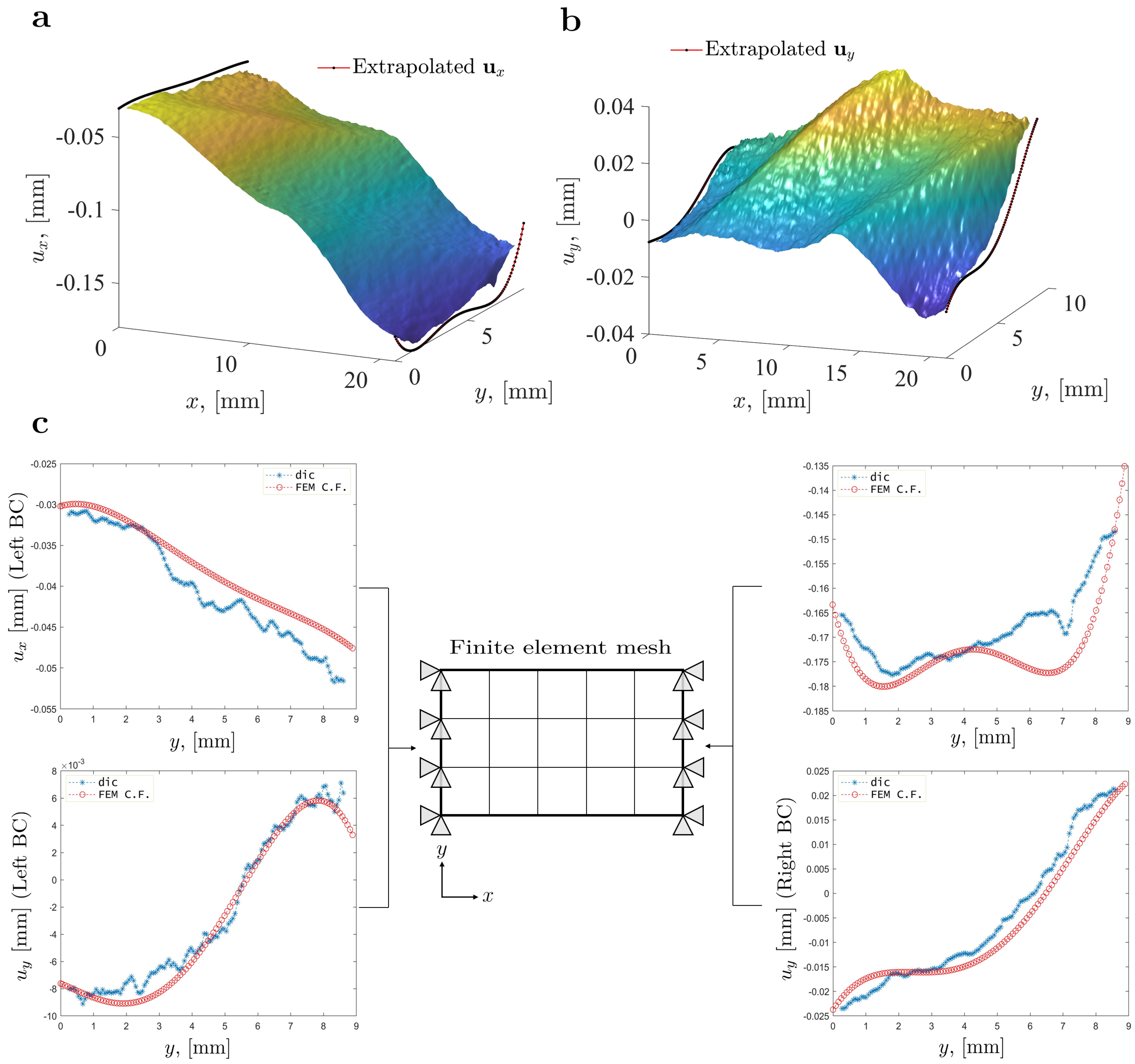

Following this approach, the FE model was implemented considering the whole DIC ROI. The DIC-based experimental boundary conditions were extrapolated from the experimental data points to the left and right edges of the defined ROI.

Figure 5 shows the surface plot of the full-field displacement measurements along the

x axis (

) and

y axis (

), along with the extrapolated boundary conditions, which are applied on the FE model of one of the off-axis specimens under analysis.

This extrapolation approach is required to fully deform a region in the synthetic image that is equal to the experimental DIC ROI, thus ensuring an equal ROI on both the experimental and synthetic images, addressing the data location issue and eliminating extra interpolation processes. For the sake of simplicity,

Figure 5 only shows the extrapolation results for one specimen, although this procedure was individually performed for all the specimens under analysis. The extrapolation was done considering the whole full-field displacement measurements and smoothed by a fourth-order polynomial function.

The mesh and displacement FE fields were then used to synthetically deform the experimental reference image using MatchID FE deformation module [

47], as represented in the workflow in

Figure 1. Afterwards, the MatchID FE validation module [

47] was used to process the synthetic image, using the same DIC software and the same setting parameters used for the experimental data. This approach has increased accuracy since the discrepancies in the processing method between the two sets of data are addressed, especially when compared to the direct interpolation method [

44].

2.5. Finite Element Model Updating Technique

The FEMU is used to find the four orthotropic linear elastic parameters of wood. An optimisation approach is used to continuously update an unknown material parameter set in order to minimise a cost function that reflects the difference between experimental measurements and FEA results. This characterisation method returns the elastic properties, which are defined by the parameter values used in the last numerical simulation of the iterative process when the minimum is reached and the optimisation process converges. Using this method, all the elastic parameters may be determined concurrently from a single experiment, given that the experimental test submits the material to a heterogeneous state of stress and strain. Displacements, stresses, loads and temperatures are all examples of data that may be used in the comparison. Because of its adaptability and simplicity of application, FEMU is a popular inverse identification approach [

33,

51], although the main disadvantage is the high computational time [

52], which is due to the necessity for a FEA and, in this case, the generation of a synthetic image and additional processing with DIC for each objective function (OF) evaluation.

The OF used in this work describes the difference between experimental and FEA results, including the load and strain fields, and can be represented by the following expression:

where

is a vector containing the four unknown material parameters (

,

,

, and

) and

is a weighting coefficient between the strain (

) and force (

) terms. The strain term is characterized as follows:

where the variable

n is the total number of full-field measurement data points, while

and

are the experimental and numerical strain fields, respectively, considering the different components of in-plane strain fields (

,

, and

). The variables

,

,

represent the maximum value of the experimental full-field strain measurements for each correspondent component. Moreover, the force term is defined as:

Similarly, the variables and reflect the experimental and numerical loads for the selected stage, respectively.

To begin the iterative process of FEMU, a starting set of parameters is given to the FEA. The numerical results are then used to generate a synthetic image, which is then processed through DIC with the same setting parameters as the experimental data, matching numerical data locations and experimental data points. The DIC-levelled FEA data are then used to evaluate the cost function and the iterative process continues, by means of an optimisation algorithm, which iteratively updates the material parameter set until a minimum of the cost function is reached.

The Nelder-Mead simplex method, which is a simple direct-search algorithm, was used in the optimisation process. In this method, a simplex is formed with as many vertices as the number of variables plus one, followed by a series of modifications aimed at minimising the OF value at its vertices [

53]. The fminsearch function from MATLAB’s library (Massachusetts, Natick, United States of America [

54]) was used as the optimisation technique. Moreover, the initial starting parameters were considered to be reference values [

2,

55] (see

Table 3).

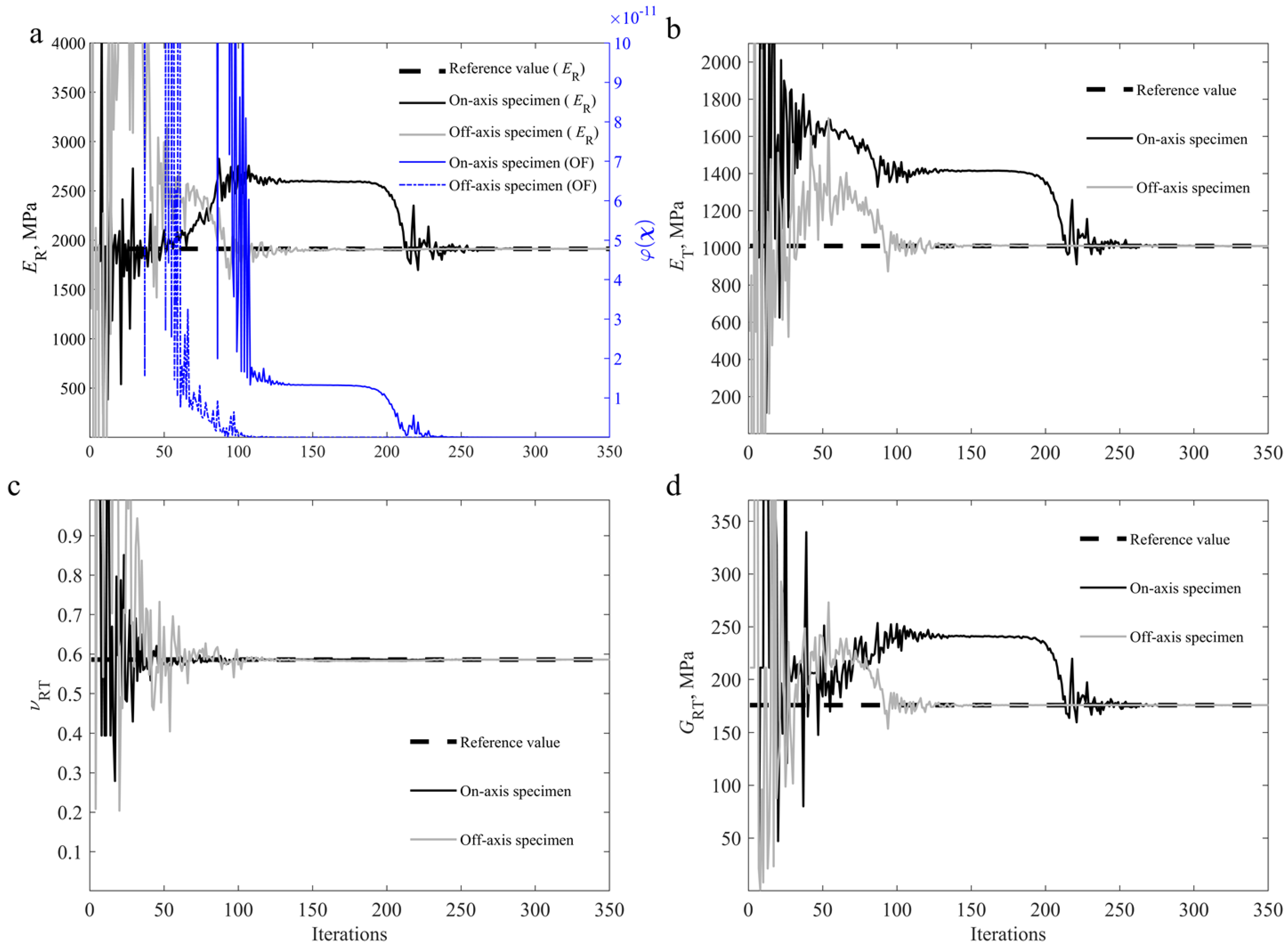

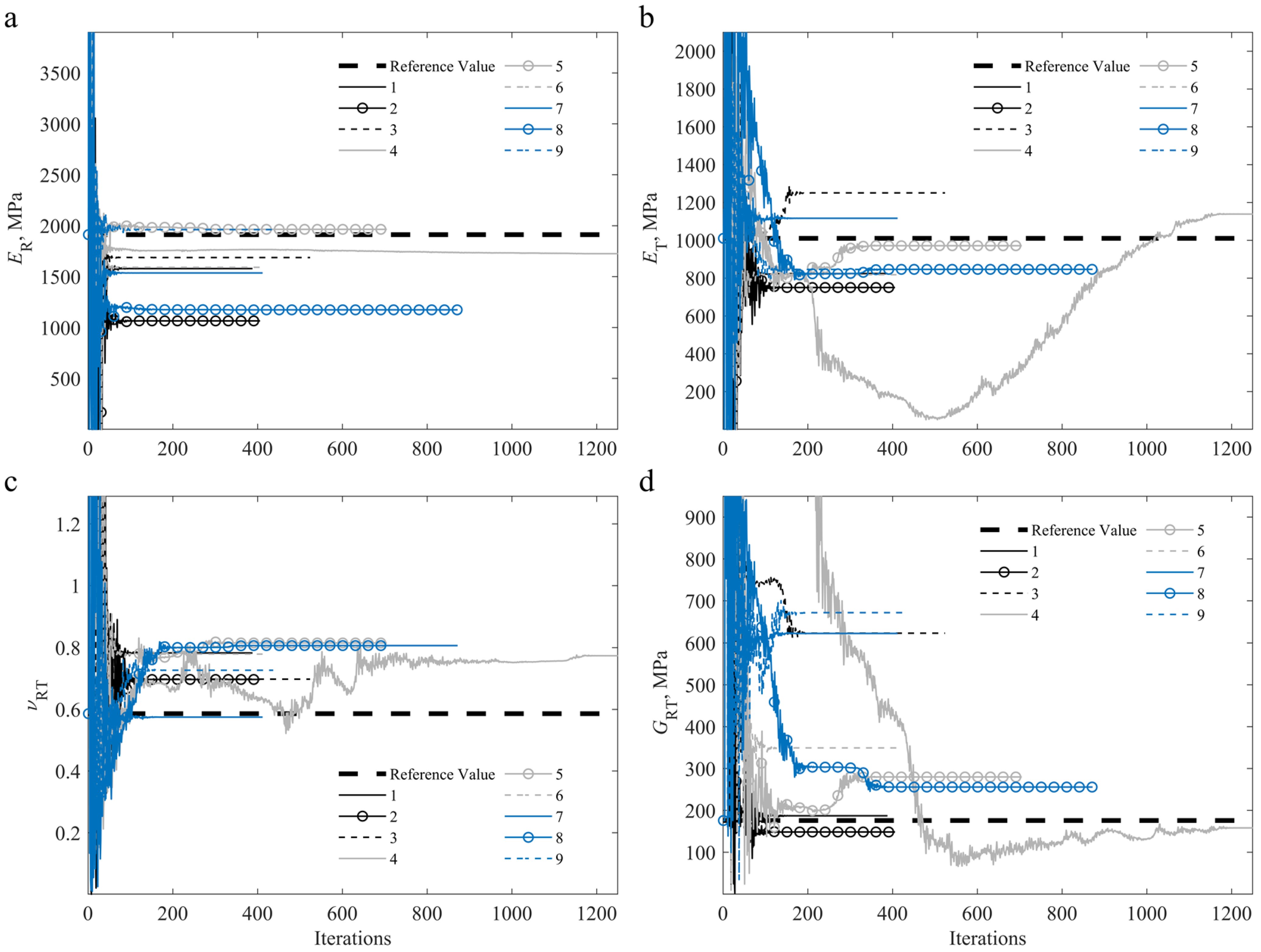

The described methodology is first validated using the DIC-levelled FEA results as our reference in the FEMU technique (

Section 3.1). With this approach, an exact solution for the constitutive parameters is known, and expected to be identified, being the reference parameters given to the FE model (the case of virtual experiments). Moreover, the

used in this method validation approach is

. The

value used on the experimental identification is

, which privileges the strain term minimisation, while also being capable of minimising the difference between the numerical and experimental loads, as is shown on the convergence study for the identified parameters (

Section 3.3). The difference between the

used in both cases is due to the

value, which is lower in the method validation, since we are using the DIC-levelled FEA results as our reference, and therefore the FE model should be able to precisely reproduce the same results in the parameters identification procedure. The

on the experimental identification is higher since there are differences between the experimental observations and the numerical results, coming from the constitutive model used in the FEA, and in this case also owing to the homogeneous modelling of wood used in this work. The

determines a balance between the strain and forces terms, and the goal is to minimise the difference between the strain fields, while also being able to minimise the differences between the experimental and numerical loads. If the

value is low (which is the case for the virtual experiments validation, see

Section 3.1), it means that the

value has also to be low. A lower

value gives more weight to the strain fields differences minimisation and allows the

to converge to a lower value than the

, while also allowing the optimisation method to more easily reach a global minimum instead of a local minimum. However, the

should be carefully selected, because if an overly low value is used for this weight, the force term may not be minimised. As a result, the difference between the experimental and numerical loads should be verified alongside the identification results.

Furthermore, as illustrated in

Figure 2, on the off-axis specimens, the global coordinate systems and fibre coordinates systems are rotated by the off-axis angle (

). This angle was measured for each of the off-axis specimens under analysis and taken into account in the rotation matrix between the two coordinate systems. Therefore, the constitutive parameters of the off-axis specimens were identified on the fibre orientation coordinate system, thus comparable to the reference parameters and the values identified for the on-axis specimens.

Moreover, when the load is increased, the measured displacements rise as well, which improves the signal-to-noise ratio and hence the identification. However, the load cannot be raised above a certain point without deviating from linear elastic behaviour. Therefore, the stage selection for the identification process was performed based on this premise, by selecting a later stage, in order to achieve a good signal-to-noise ratio, while also making sure that the material is still undergoing linear elastic deformation.