Experimental Study of the Dynamic Characteristics of a New Antidrainage Subgrade Structure for High-Speed Railways in Diatomaceous Earth Areas

Abstract

:1. Introduction

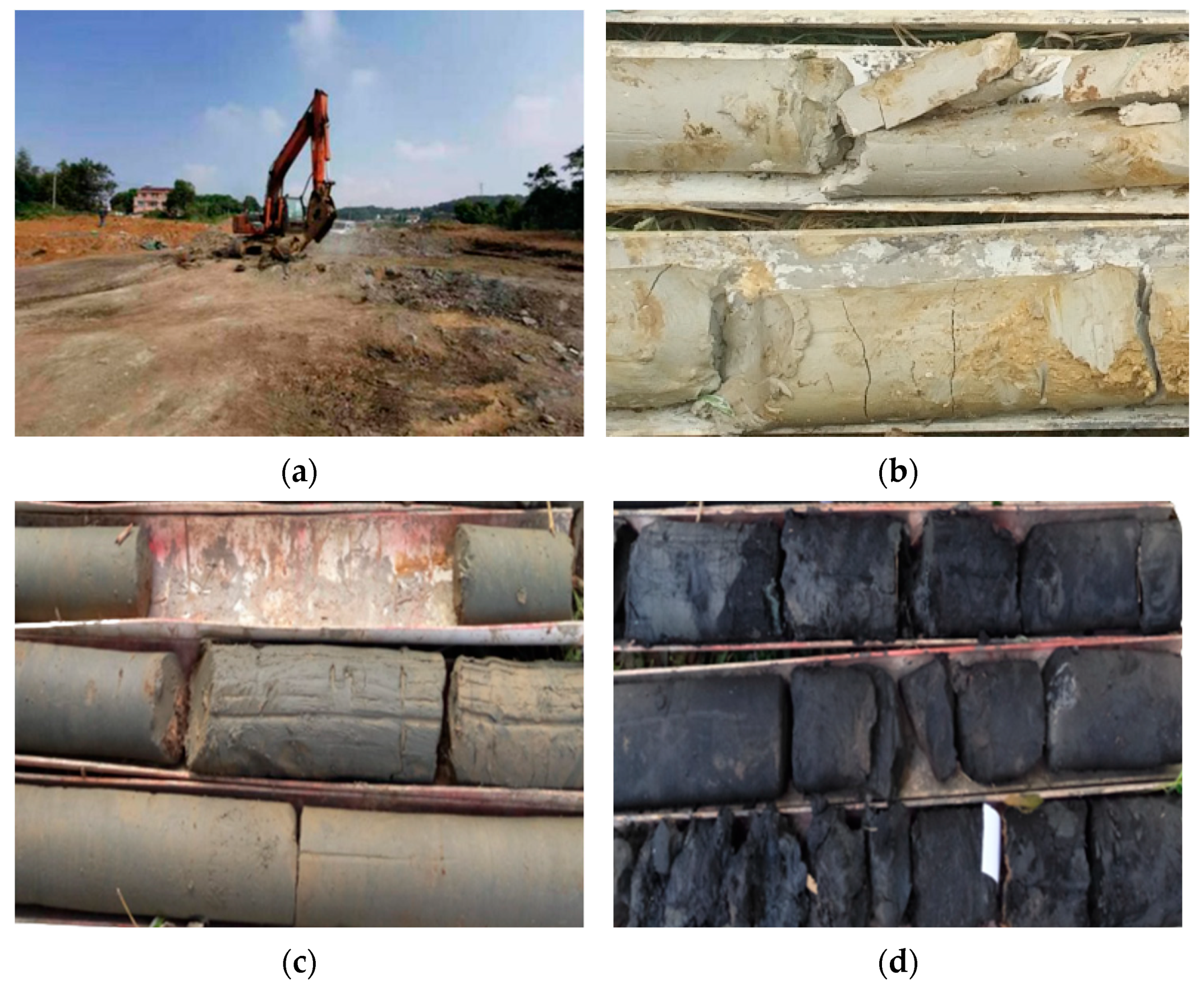

2. Project Overview

3. Hydrophysical and Physical Properties of Diatomaceous Earth

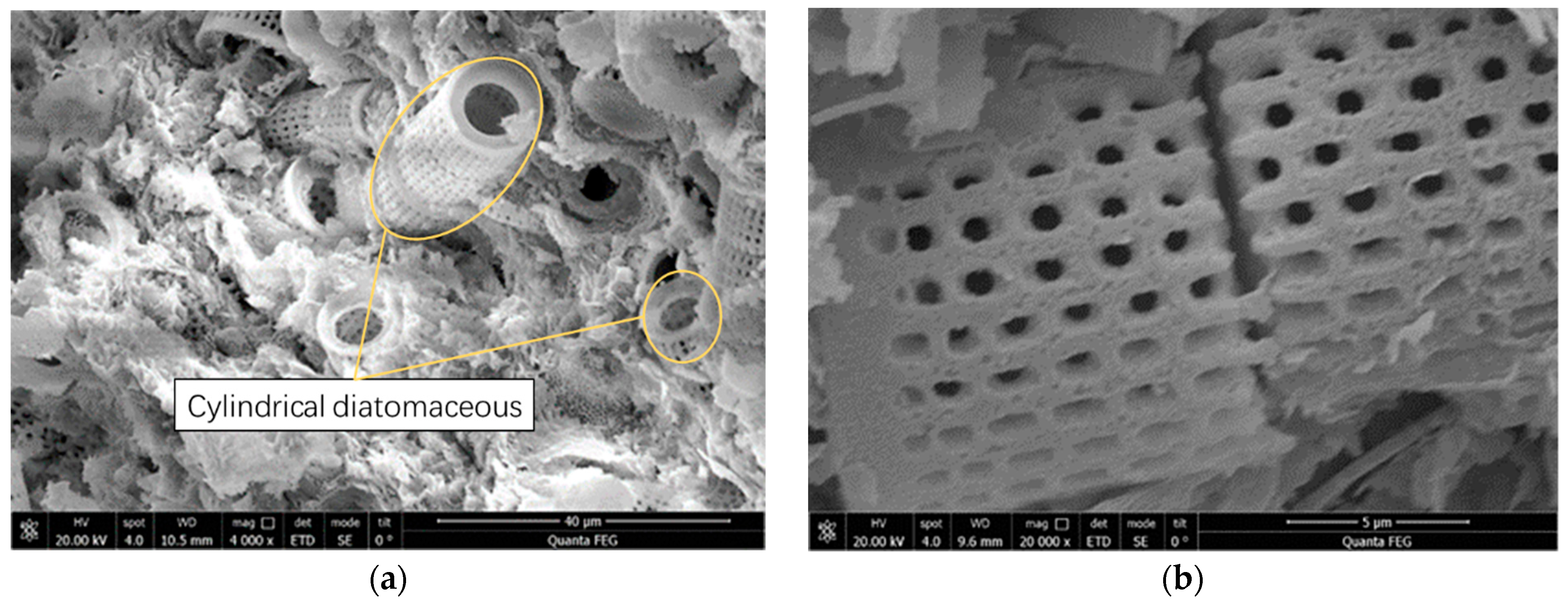

3.1. Basic Physical Properties of Diatomaceous Earth

- The diatomaceous earth contained diatom remains of various shapes that were mainly cylindrical. Because of the dense distribution of extremely small round pores (pore size < 0.2 μm) all along the walls of the diatom remains and the mixed accumulation of the diatom remains, the diatomaceous earth exhibited extremely high porosity and very low density;

- The water content of diatomaceous earth was very high, and the water content of the black diatomaceous earth ranged from 27.5 to 102.2%, with an average water content of 68.02%, which showed that the natural diatomaceous earth exhibited high humidity;

- The diatomaceous earth had very large pore ratios, with an average pore ratio between 1.47 and 1.85, which is an important reason for the high-water content of diatomaceous earth;

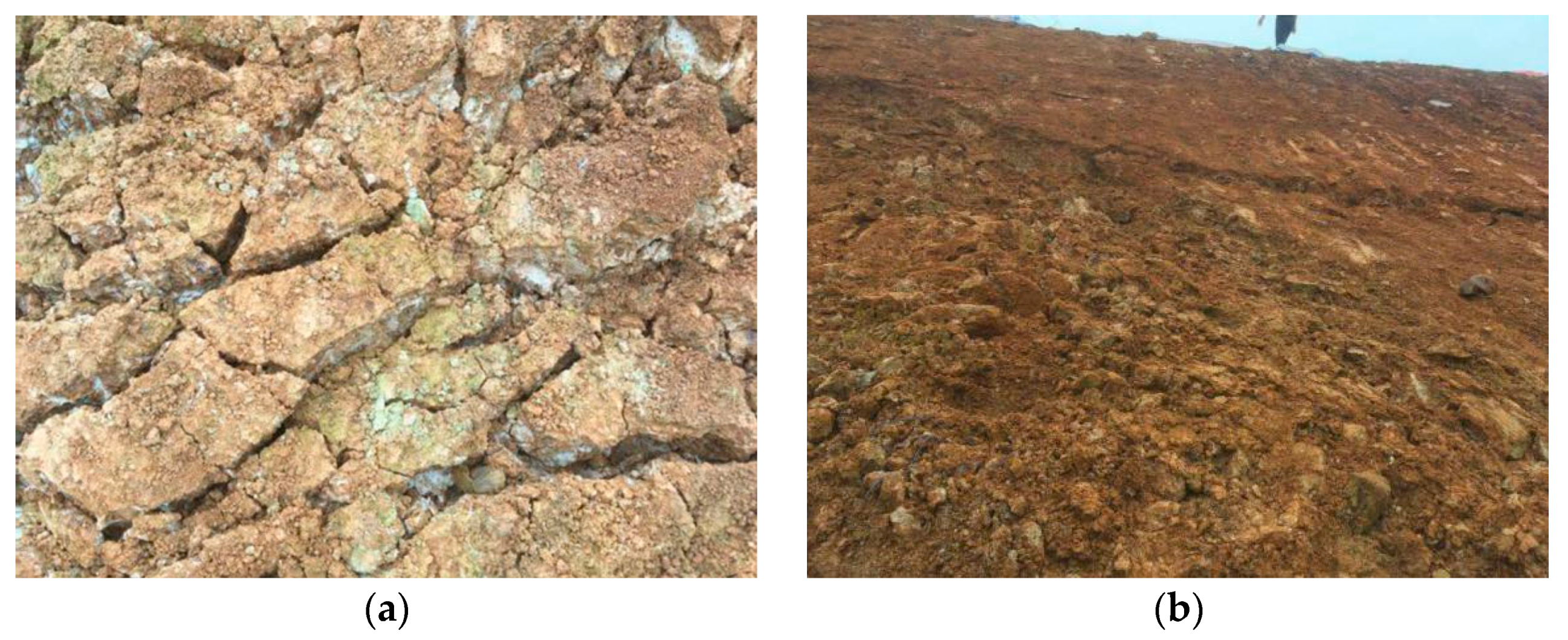

- The results of the tests carried out on samples taken at different depths show that the natural density, the water content, and the pore ratio of the diatomaceous earth tended to decrease at shallow depths and increase at deeper depths. This is related to the fact that the diatomaceous earth located closest to the surface is most affected by changes in the external environment, both wet and dry.

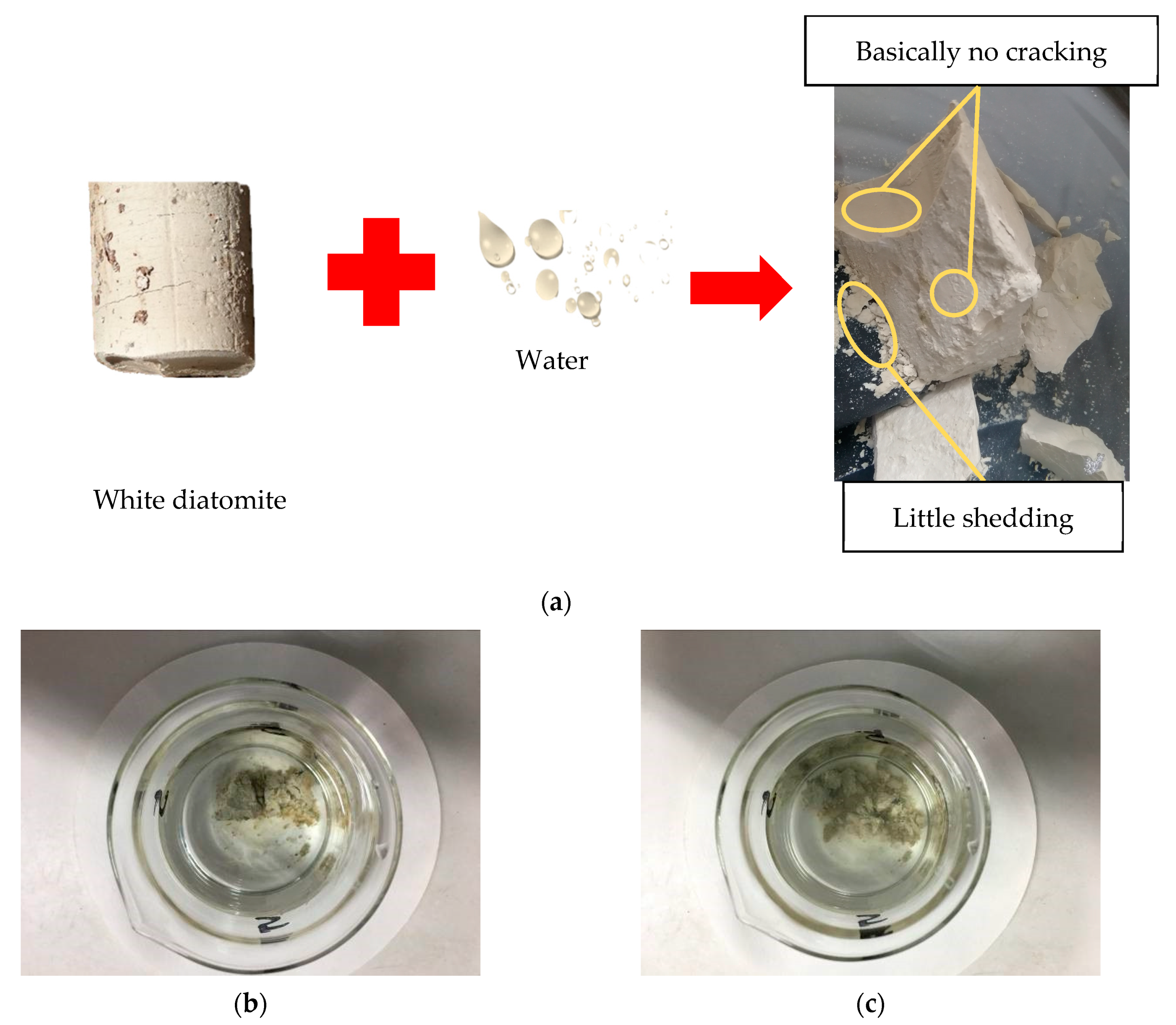

3.2. Observations of the Hydrophysical Properties of Diatomaceous Earth

- Natural diatomaceous earth did not change significantly when immersed in water and was more stable than dry diatomaceous earth, as shown in Figure 4a;

- Because of its low specific gravity, dry diatomaceous earth floated on the surface of the water for a few seconds, and then absorbed the water and sank, rapidly disintegrating into a fine, scaly, powdered form, as shown in Figure 4b,c;

- When natural diatomaceous earth was dried in the shade, fissures developed. When the lower part was immersed in water, the water was preferentially transported through the fissures and transferred to the upper part, which was not immersed in water. The natural diatomaceous earth broke up in blocks and flaps after exposure to the sun.

3.3. Disintegration Characteristics of Diatomaceous Earth

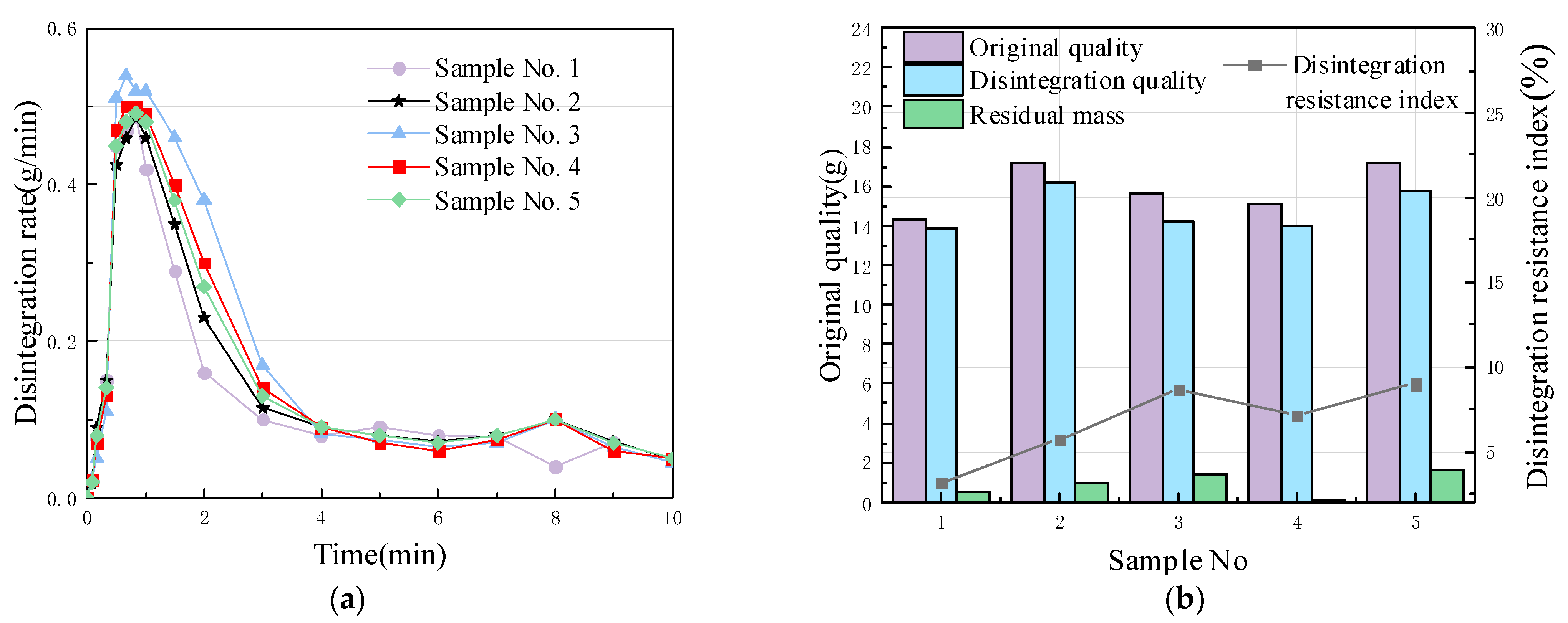

- As shown in Figure 5a, during the first 30 s after the specimen was placed in water, the disintegration rate was low as the water gradually entered the pores of the specimen during this time, and there was still some air enclosed in the pores by water. As the test proceeded, more water entered the pore space, and the gas enclosed in the pore space was further compressed, resulting in the tensile stress of the gas on the soil. When the strengths of certain weak parts of the specimen were less than the tensile stress, fractures were produced. The specimen disintegrated rapidly at 1 to 2 min into the test, after which the disintegration rate decreased and stabilized until the end of the test;

- As shown in Figure 5b, the maximum value of the disintegration resistance index for the five specimens was 9.0%, with almost complete disintegration. The disintegration resistance index ranged from 3.1% to 9.0%, with very weak disintegration resistance and strong disintegration.

4. Antidrainage Measures and Excitation Test Methods

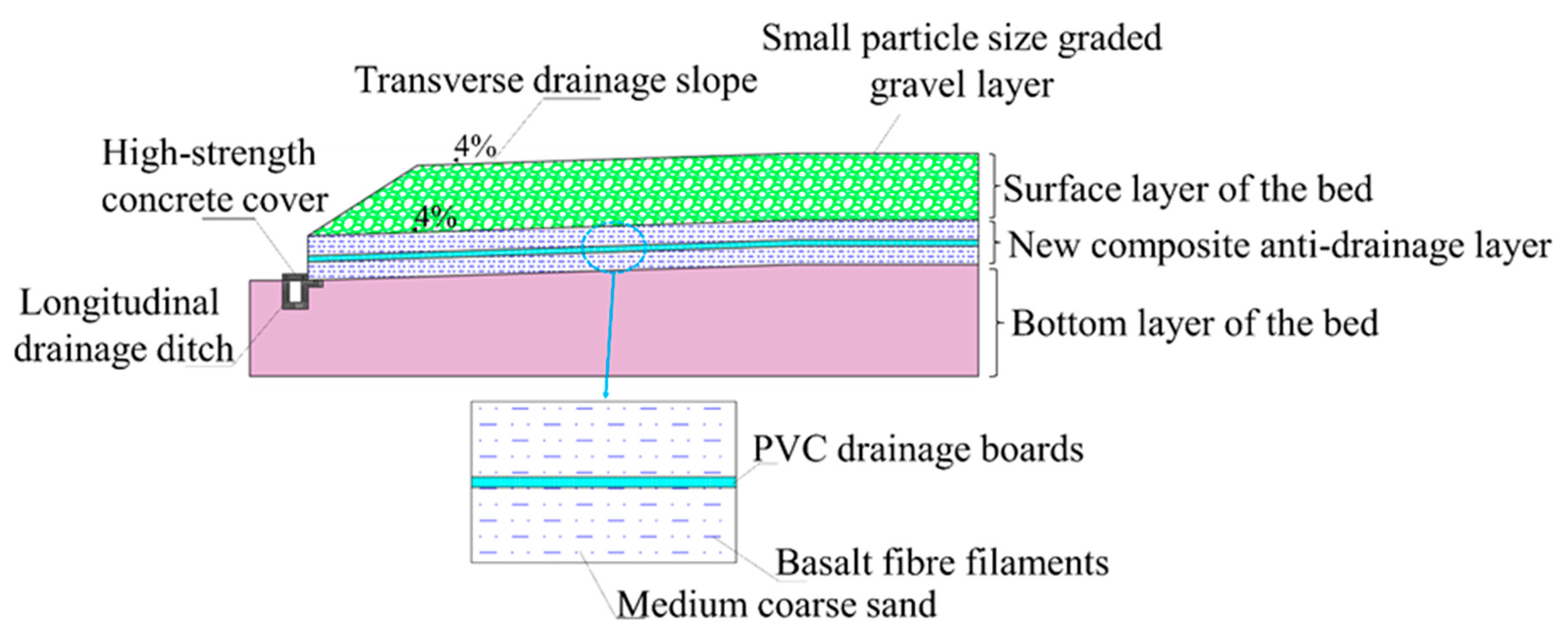

4.1. New Antidrainage Subgrade Structure

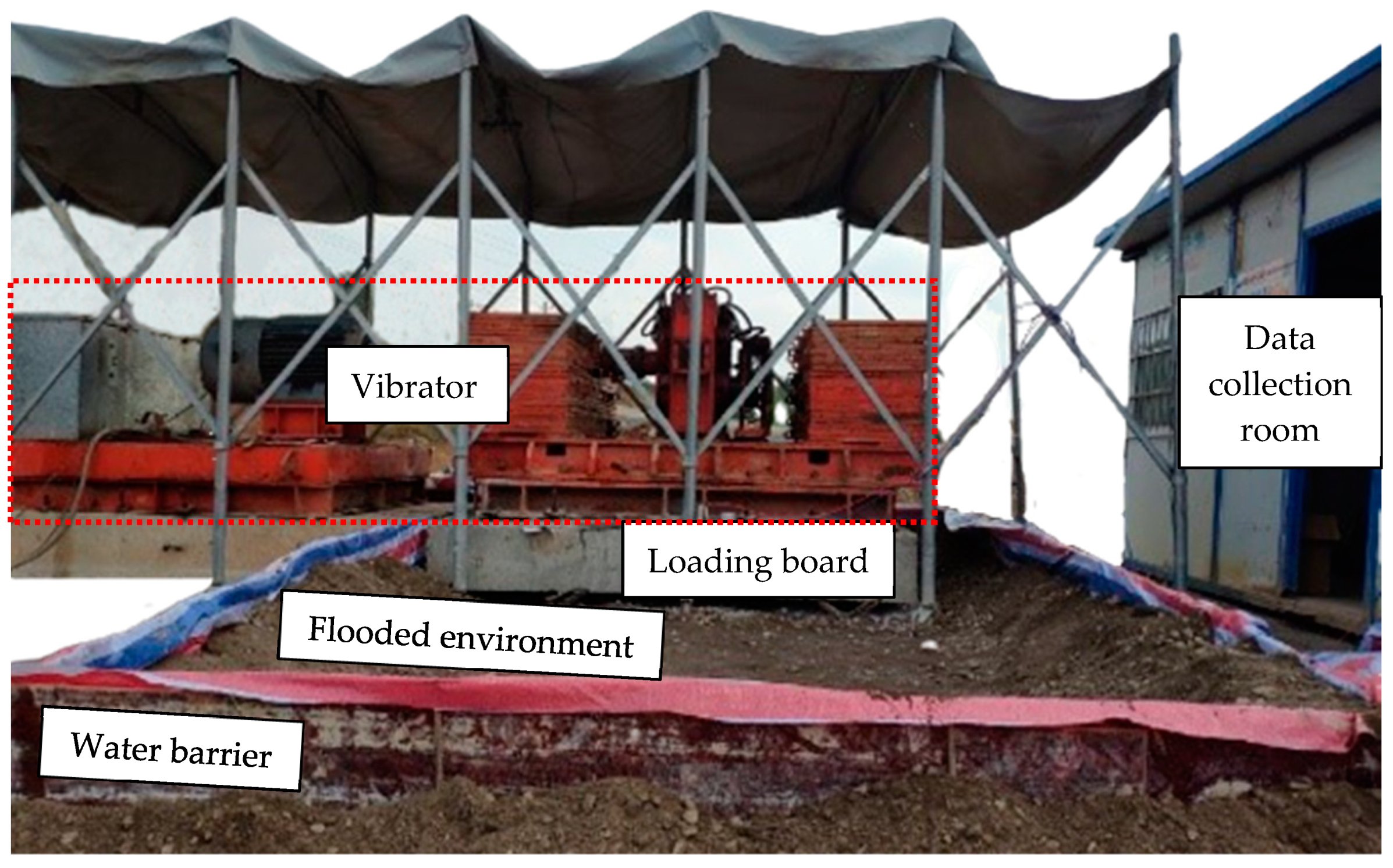

4.2. Simulation of Water Immersion Environments

4.3. Excitation Test Program

4.4. Excitation Test Equipment and Loading Parameters

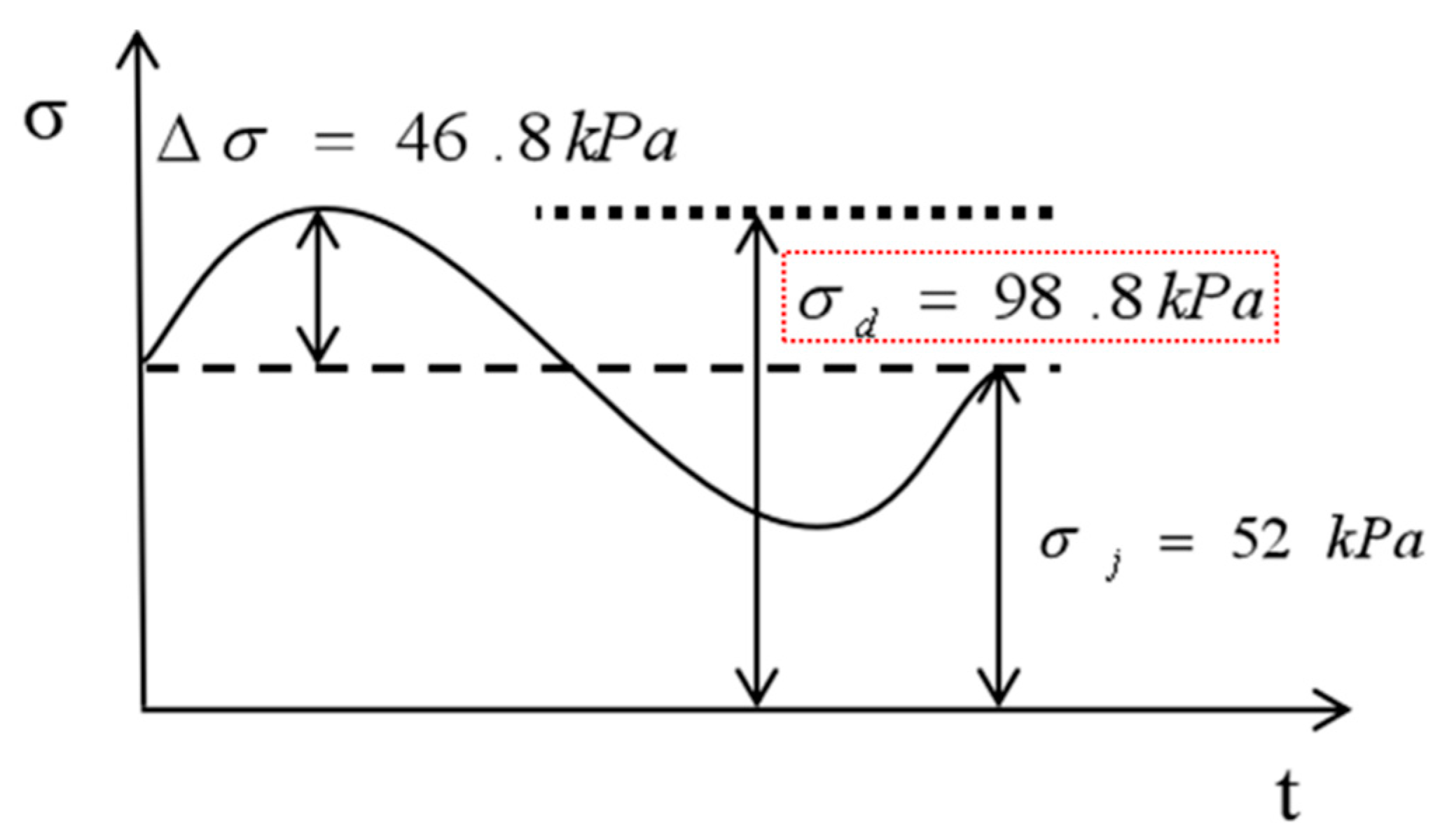

4.4.1. Stress Amplitude

4.4.2. Excitation Frequency

- Static load determination

- 2.

- Dynamic load determination

4.4.3. The Number of Excitations and Frequency of Observations

5. Test Results and Analysis

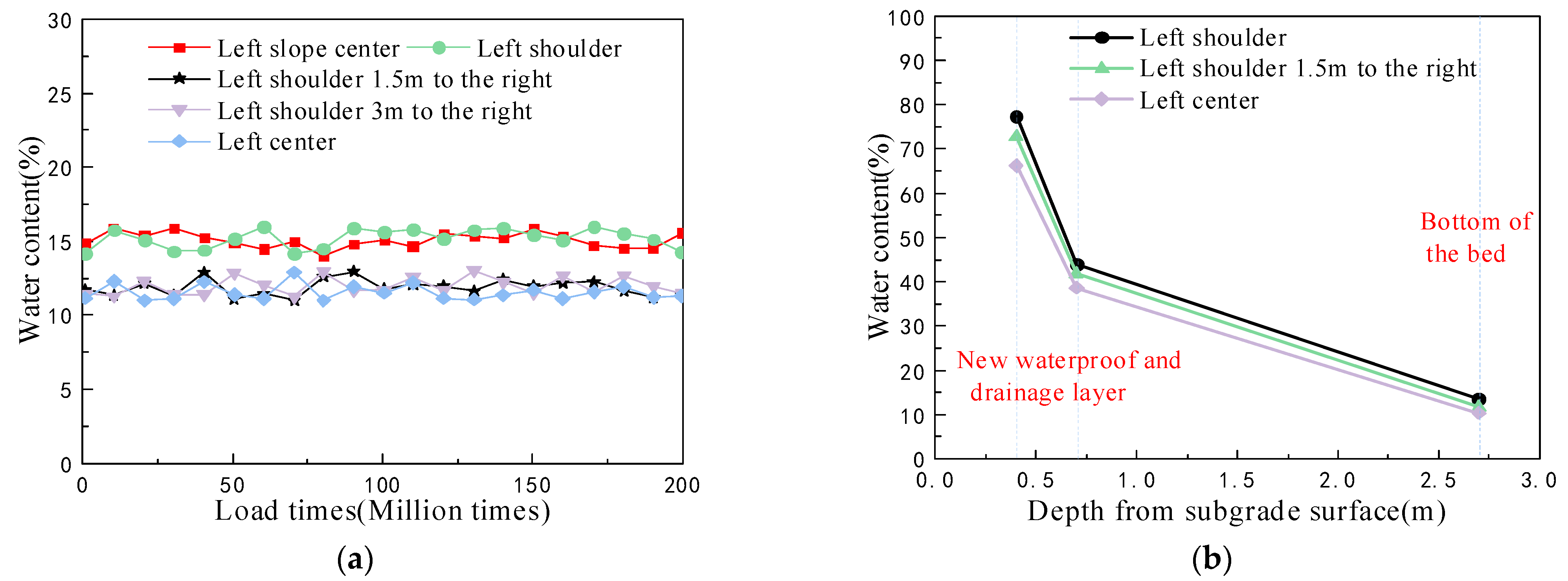

5.1. Water Content Analysis at the Bottom of the Subgrade Bed

5.1.1. Monitoring of the Water Content of Natural Foundation Subgrade Beds during Construction

5.1.2. Monitoring of Subgrade Bed Water Content during Excitation Tests

- Compared with the water content during the construction period, it can be seen that, during the excitation test, the water content at the center of the left slope of the subgrade and the left shoulder position was about 15%, and the water content at the rest of the positions was about 12%. During the loading process, the water content fluctuated very little in each test part of the substrate, which shows that the cyclic dynamic loading has little effect on the performance of the new drainage prevention structure in the substrate, and that the durability of the drainage prevention layer is good;

- After the excitation test, the water content in the surface layer of the bed was much higher than the water content in the bottom layer of the bed below the new antidrainage layer, indicating that the antidrainage structure designed in the bed served as a good water barrier and that it effectively blocked the water in the upper section, and prevented rainwater from seeping down to the diatomaceous earth foundation [33]; this avoided the disintegration and deterioration of the diatomaceous earth and subsequent problems.

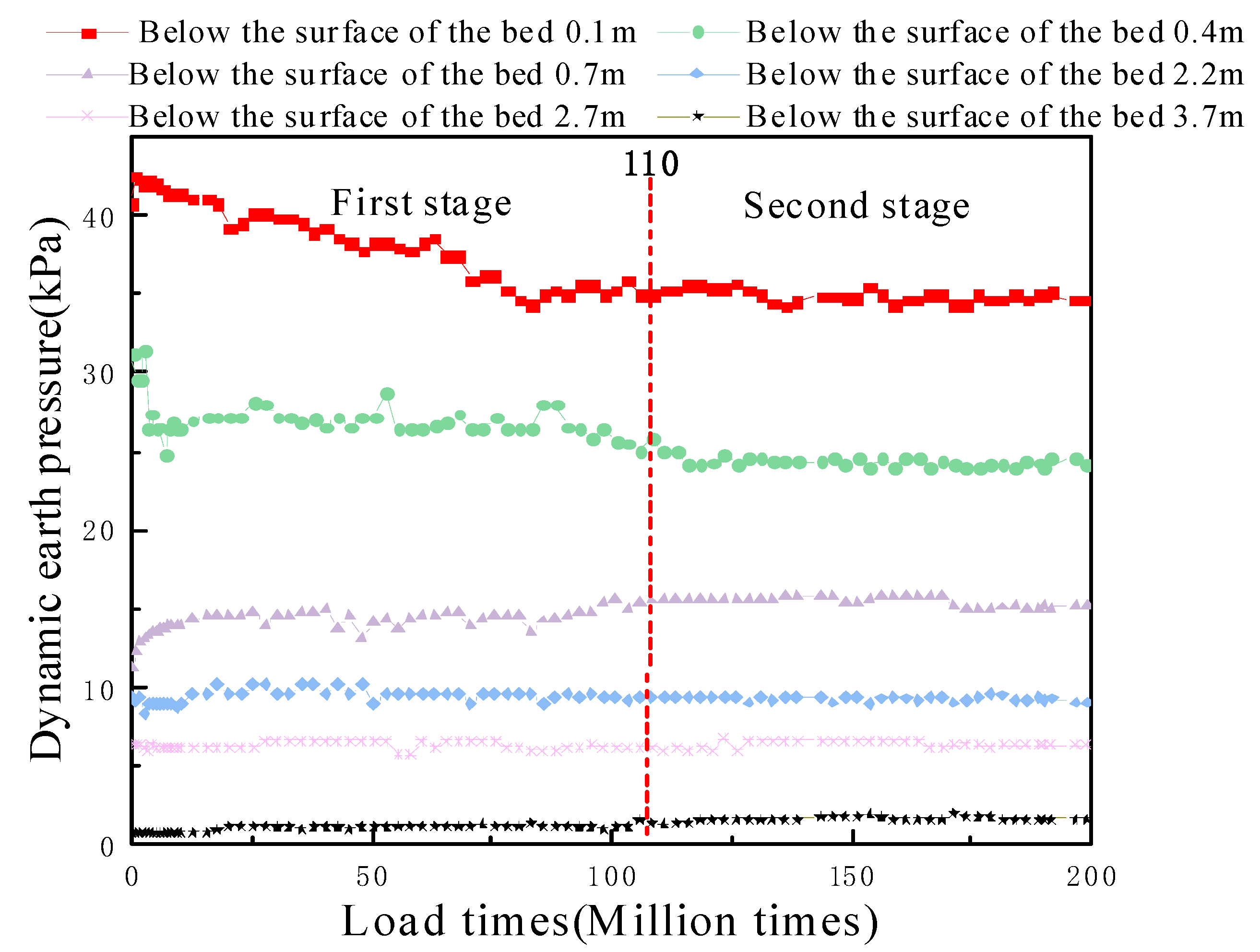

5.2. Dynamic Stress Analysis

5.2.1. Analysis of the Dynamic Stress Changes Based on the Number of Vibrations

5.2.2. Distribution Law of Dynamic Stresses along the Depth Direction

5.2.3. Dynamic Stress Distribution Law along the Transverse Side of the Subgrade Bed

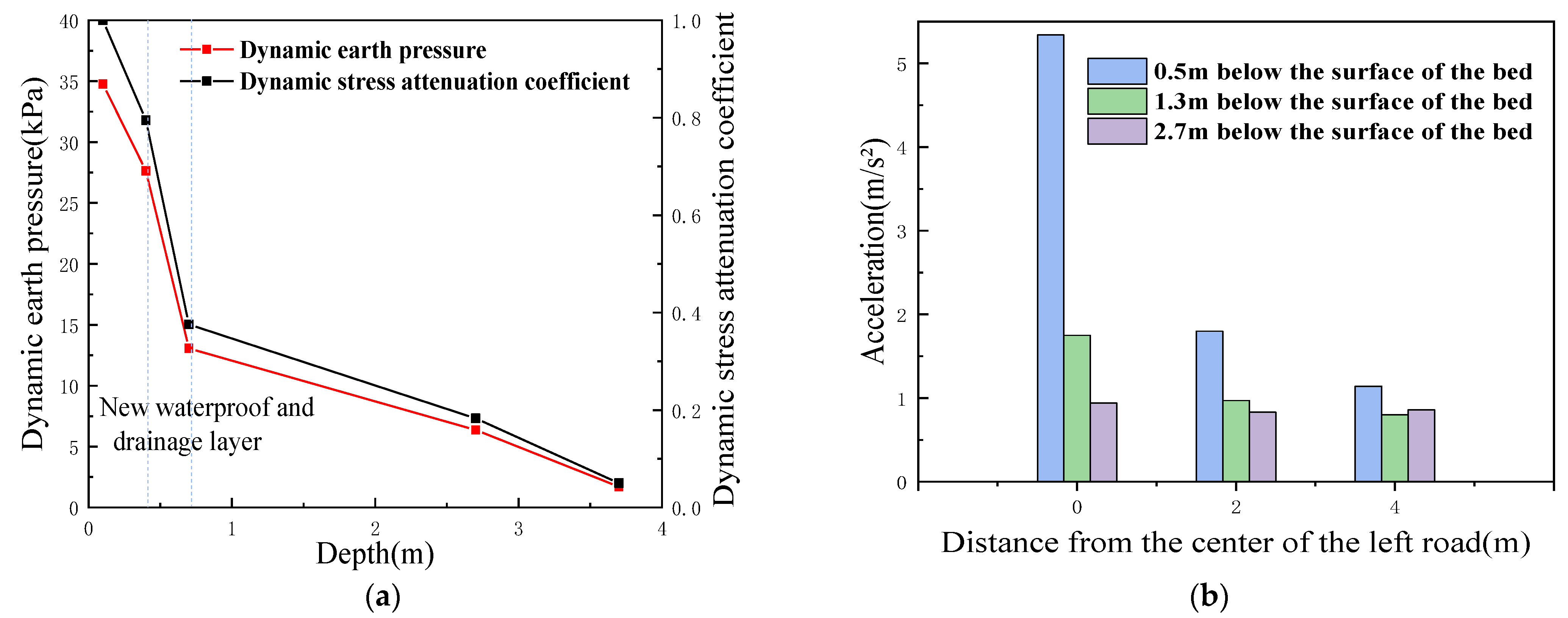

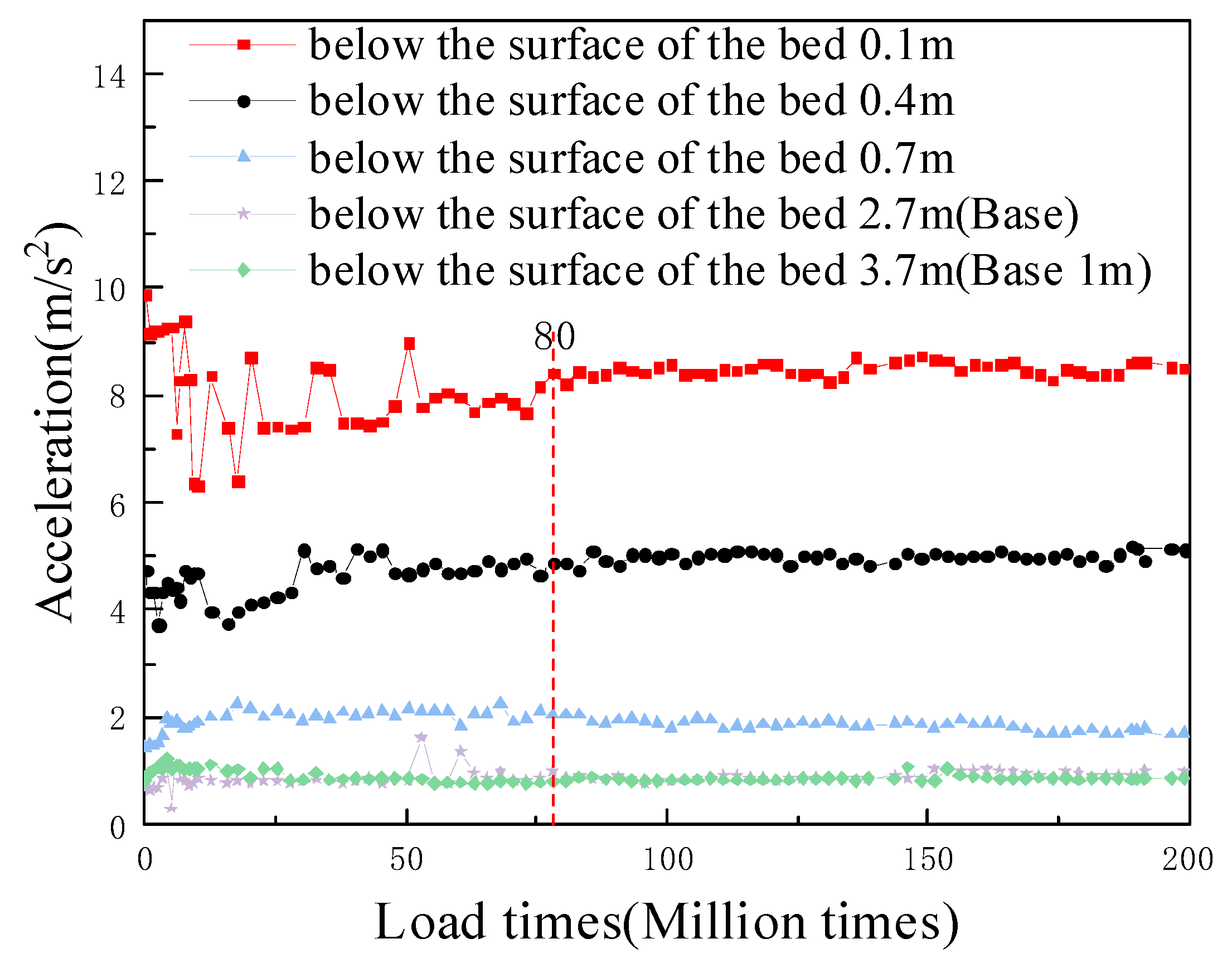

5.3. Analysis of Vibration Acceleration

5.3.1. Analysis of Vibration Acceleration with the Number of Vibrations

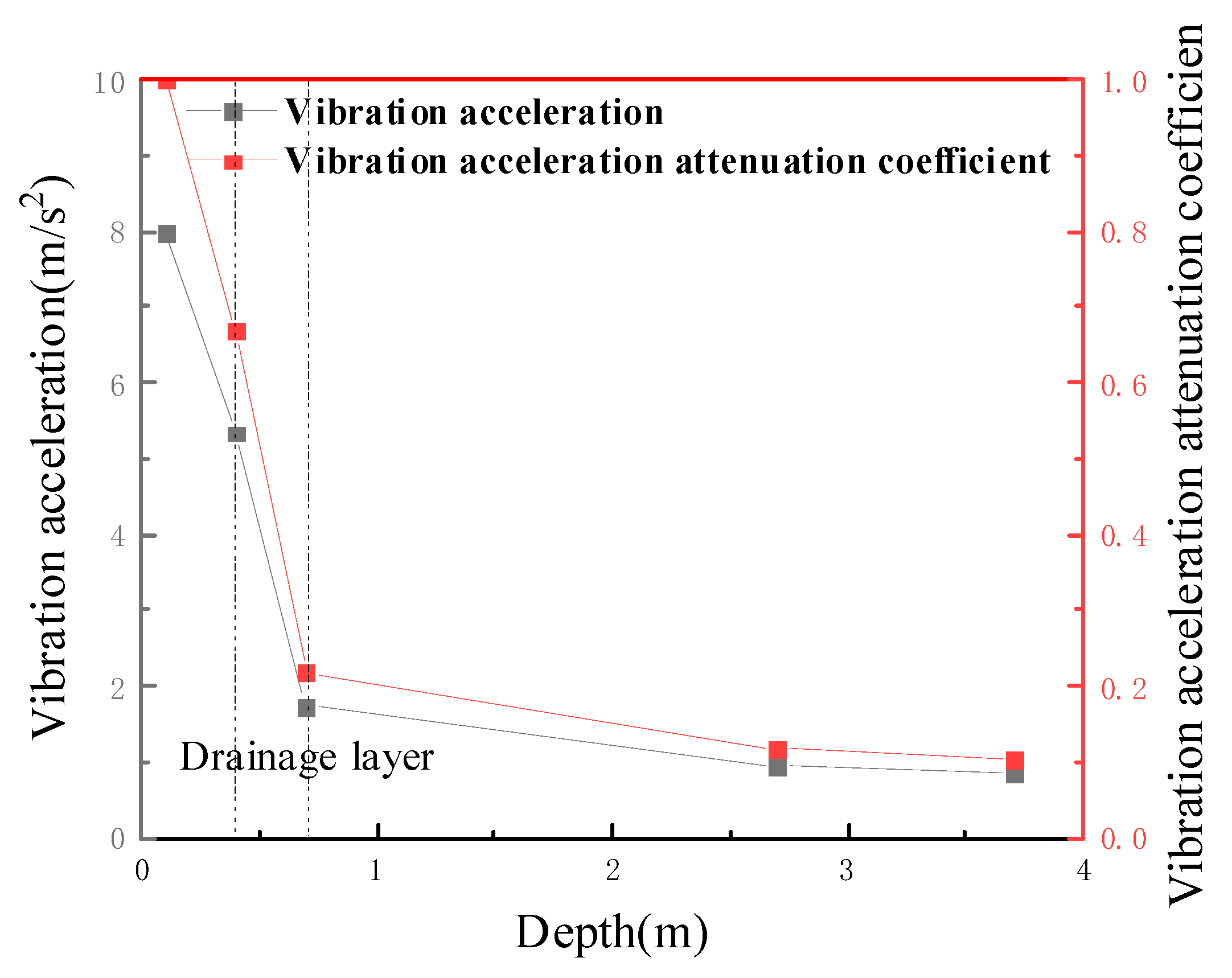

5.3.2. Distribution Law of Vibrational Acceleration with Depth

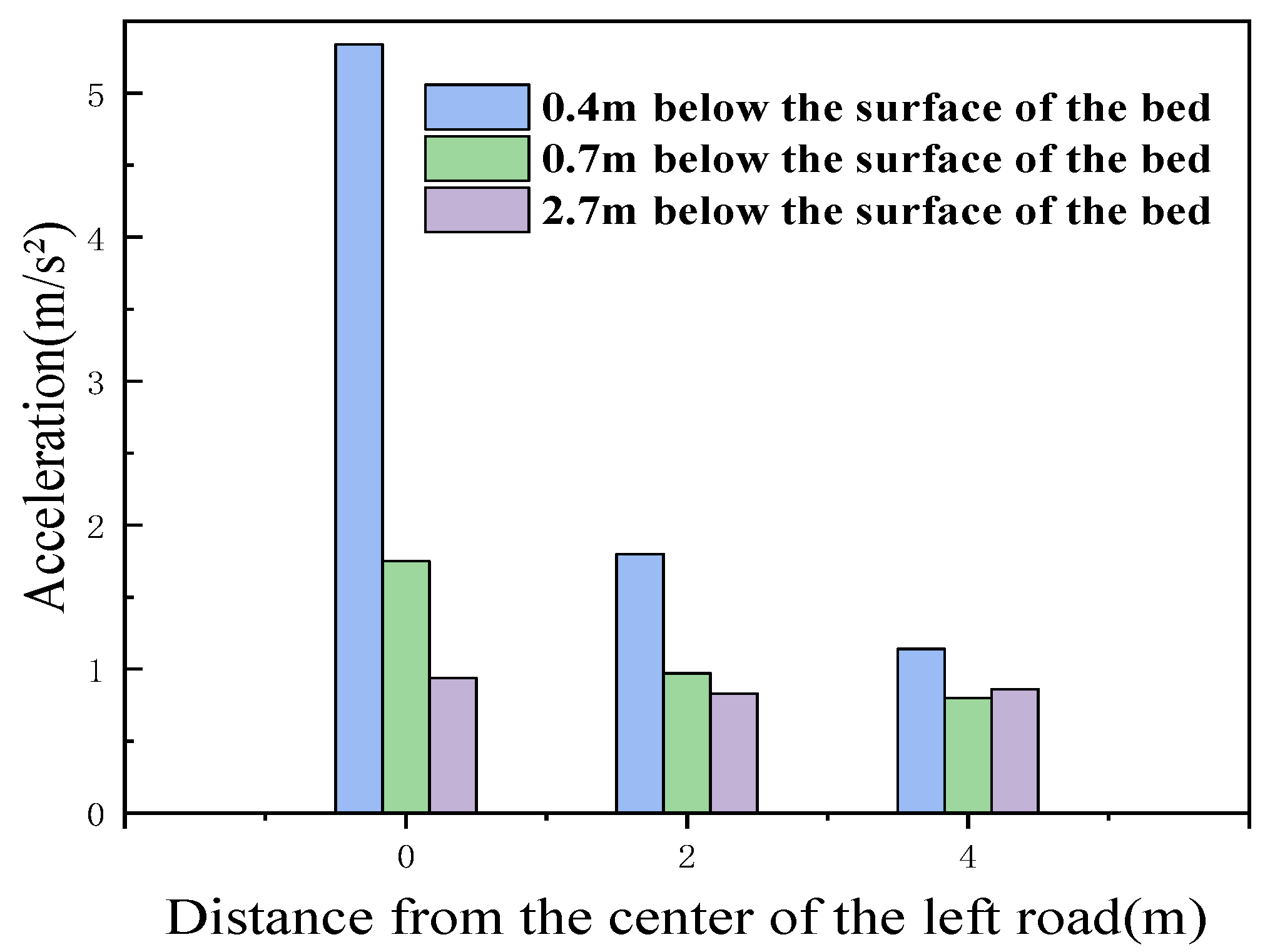

5.3.3. Distribution Law of Vibrational Acceleration along the Transverse Direction of the Subgrade

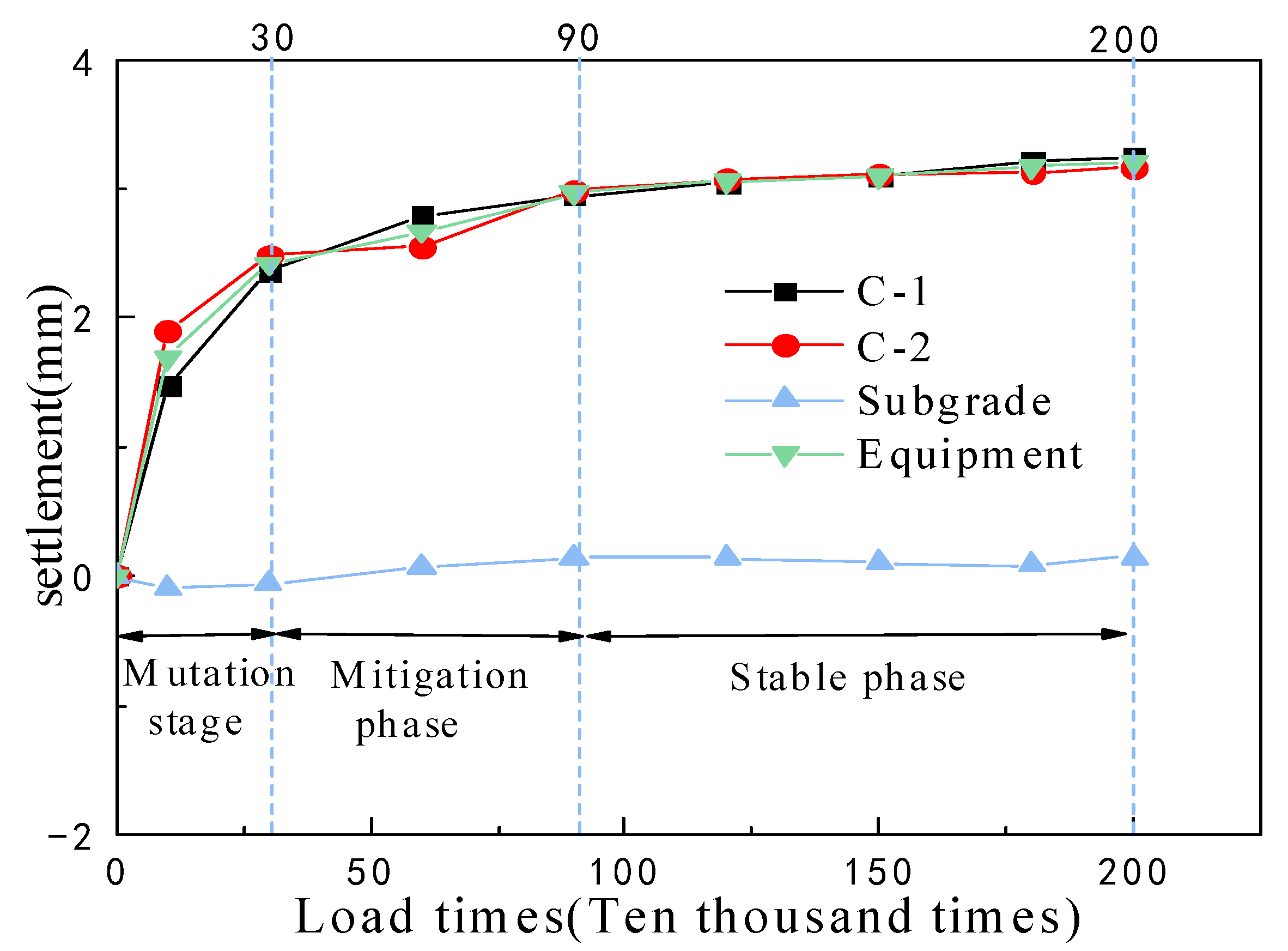

5.4. Analysis of the Cumulative Settlement of the Subgrade

6. Conclusions

- The diatomaceous earth in the Shengzhou area is a regional geotechnical soil with very complex engineering properties. It has very poor hydrophysical properties and was easily disintegrated by water. The disintegration resistance index of the diatomaceous earth specimens ranged from 3.1% to 9.0%, with an average value of 6.05%, which means that they were weakly resistant to disintegration;

- When diatomaceous earth was exposed to the natural environment, it was susceptible to disintegration and deterioration with frequent cycling between wet and dry, which led to problems such as softening and strength reduction, disintegration damage, penetration cracks, and other issues. This affected the strength and settling of the natural diatomaceous earth foundation, and the construction of projects in diatomaceous earth areas must be conducted with measures taken to prevent drainage;

- For the first time, a new antidrainage subgrade structure was proposed for diatomaceous earth areas. During the vibration test, the attenuation of the water content in the new antidrainage layer range was about 30%, and the water contents of the test parts of the substrate fluctuated minimally, and were stable at 12% and 15% near the new waterproof structure under the coupling of the dynamic load, and the water immersion had good water impermeability and fatigue resistance. The dynamic stress and vibration acceleration through the capillary drainage layer ranged, respectively, from 27.64 kPa to 13.06 kPa, and from 5.34 m/s2 to 1.75 m/s2. The new drainage layer for the lower foundation has a certain energy dissipation and protection role;

- Under the coupled effects of dynamic loading and water submersion, when cyclic loading reached 700,000 cycles, the dynamic stress and vibrational acceleration of the surface of the subgrade bed were stabilized at approximately 6.37 kPa and 0.94 m/s2, respectively. When the number of excitations reached 2 million, the settlement of the roadbed under the loading plate, the bed near the loading plate, and the diatomaceous earth foundation were 3.26 mm, 0.15 mm, and 0.08 mm, respectively. The settlement of the dynamic load on the bed was large, while the postwork settlement of the diatomaceous earth foundation caused by the dynamic load was negligible.

- Diatomaceous earth is a regional geotechnical soil, for which the test data accumulated thus far are limited, and the relevant test data are discrete. Therefore, a further improvement of diatomaceous earth test methods is needed;

- In the future, on the basis of the roadbed settlement monitoring data, a prediction model conforming to the settlement law should be proposed, and the long-term stability of the diatomaceous earth roadbed should be studied and analyzed in depth;

- The new Hang Shaotai high-speed railway will soon be operational and open to traffic. Thus, field dynamic tests can be carried out in the future to analyze the dynamic response characteristics of the roadbed structure when high-speed trains pass through the diatomaceous earth section.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Caicedo, B.; Mendoza, C.; López, F.; Lizcano, A. Behavior of diatomaceous soil in lacustrine deposits of Bogotá, Colombia. J. Rock Mech. Geotech. Eng. 2018, 10, 367–379. [Google Scholar] [CrossRef]

- Chaika, C.; Dvorkin, J. Porosity reduction during diagenesis of diatomaceous rocks. AAPG Bull. 2000, 84, 1173–1184. [Google Scholar]

- Díaz-Rodríguez, J.A.; González-Rodríguez, R. Influence of diatom microfossils on soil compressibility. In Proceedings of the 18 th International Conference on Soil Mechanics and Geotechnical Engineering, Paris, France, 2–5 September 2013. [Google Scholar]

- Hong, Z.; Tateishi, Y.; Han, J. Experimental Study of Macro- and Microbehavior of Natural Diatomite. J. Geotech. Geoenviron. Eng. 2006, 132, 603–610. [Google Scholar] [CrossRef]

- Zhou, F.; Li, Z.; Lu, Y.-Y.; Shen, B.; Guan, Y.; Wang, X.-X.; Yin, Y.-C.; Zhu, B.-S.; Lu, L.-L.; Ni, Y.; et al. Diatomite derived hierarchical hybrid anode for high performance all-solid-state lithium metal batteries. Nat. Commun. 2019, 10, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Xu, J.; Xie, Z.; Gao, X.; Zhou, J.; Xiong, Y.; Chen, C.; Zhang, J.; Liu, Z. Diatomite-Templated Synthesis of Freestanding 3D Graphdiyne for Energy Storage and Catalysis Application. Adv. Mater. 2018, 30, e1800548. [Google Scholar] [CrossRef] [PubMed]

- Chu, H.; Cao, D.; Dong, B.; Qiang, Z. Bio-diatomite dynamic membrane reactor for micro-polluted surface water treatment. Water Res. 2010, 44, 1573–1579. [Google Scholar] [CrossRef]

- Liu, D.; Gu, J.; Liu, Q.; Tan, Y.; Li, Z.; Zhang, W.; Su, Y.; Li, W.; Cui, A.; Gu, C.; et al. Metal-Organic Frameworks Reactivate Deceased Diatoms to be Efficient CO2Absorbents. Adv. Mater. 2013, 26, 1229–1234. [Google Scholar] [CrossRef]

- Wang, M.; Xiang, Y.; Zhang, G.; Song, J.; Cai, D.; Wu, Z. A facile approach to improve the quality of diatomite as sulfuric acid catalyst support. Appl. Catal. A Gen. 2013, 466, 185–189. [Google Scholar] [CrossRef]

- He, Y.; Bin Jiang, D.; Chen, J.; Zhang, Y.X. Evaluation of MnO2-templated iron oxide-coated diatomites for their catalytic performance in heterogeneous photo Fenton-like system. J. Hazard. Mater. 2018, 344, 230–240. [Google Scholar] [CrossRef] [PubMed]

- Day, R.W. Engineering properties of diatomaceous fill. J. Geotech. Eng. Div. Am. Civ. Eng. 1995, 121, 908–910. [Google Scholar] [CrossRef]

- Ovalle, C.; Arenaldi-Perisic, G. Mechanical behaviour of undistursubgrade bed diatomaceous soil. Mar. Georesour. Geotechnol. 2021, 39, 623–630. [Google Scholar] [CrossRef]

- Perisic, G.A.; Ovalle, C.; Barrios, A. Compressibility and creep of a diatomaceous soil. Eng. Geol. 2019, 258, 105145. [Google Scholar] [CrossRef]

- Shiwakoti, D.R.; Tanaka, H.; Tanaka, M.; Locat, J. Influences of Diatom Microfossils on Engineering Properties of Soils. Soils Found. 2002, 42, 1–17. [Google Scholar] [CrossRef] [Green Version]

- Kwon, T.-H.; Lee, K.-R.; Cho, G.-C.; Lee, J.Y. Geotechnical properties of deep oceanic sediments recovered from the hydrate occurrence regions in the Ulleung Basin, East Sea, offshore Korea. Mar. Pet. Geol. 2011, 28, 1870–1883. [Google Scholar] [CrossRef]

- Wang, J.; Yazdani, E.; Evans, T.M. Case study of a driven pile foundation in diatomaceous soil. I: Site characterization and engineering properties. J. Rock Mech. Geotech. Eng. 2021, 13, 431–445. [Google Scholar] [CrossRef]

- Zhang, Y.S.; Guo, C.B.; Qu, Y.X.; Yao, X. Research on mechanical properties of swelling diatomite and their geohazard effects. J. Rock Soil Mech. 2013, 34, 23–30. (In Chinese) [Google Scholar]

- Guo, C.B.; Zhang, Y.S.; Meng, Q.W.; Zheng, G.; Li, H.H. Research on shear strength of remolding diatomite by ring shear tests. J. Rock Soil Mech. 2013, 34, 94–100. (In Chinese) [Google Scholar]

- Zhang, Y.; Guo, C.; Yao, X.; Qu, Y.; Zhou, N. Engineering geological characterization of clayey diatomaceous earth deposits encountered in highway projects in the Tengchong region, Yunnan, China. Eng. Geol. 2013, 167, 95–104. [Google Scholar] [CrossRef]

- Wiemer, G.; Kopf, A. Influence of diatom microfossils on sediment shear strength and slope stability. Geochem. Geophys. 2017, 18, 333–345. [Google Scholar] [CrossRef]

- Diaz-Rodríguez, J. Abraham. Diatomaceous soils: Monotonic behavior. In Deformation Characteristics of Geomaterials; IOS Press: Amsterdam, NY, USA, 2011; pp. 865–871. [Google Scholar]

- Burger, C.A.; Shackelford, C.D. Soil-water characteristic curves and dual porosity of sand–diatomaceous earth mixtures. J Geotech. Geoenviron. 2001, 127, 790–800. [Google Scholar] [CrossRef]

- Wiemer, G.; Dziadek, R.; Kopf, A. The enigmatic consolidation of diatomaceous sediment. Mar. Geol. 2017, 385, 173–184. [Google Scholar] [CrossRef]

- Qian, J.; Yao, Y.; Li, J.; Xiao, H.; Luo, S. Resilient properties of soil-rock mixture materials: Preliminary investigation of the effect of composition and structure. Materials 2020, 13, 1658. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Spangenberg, E. A fractal model for physical properties of porous rock: Theoretical formulations and application to elastic properties. J. Geophys. Res. Solid Earth 1998, 103, 12269–12289. [Google Scholar] [CrossRef]

- Ministry of Railways of the People’s Republic of China. Geotechnical Test Procedures for Railroad Engineering (TB10102-2004); China Railway Press: Beijing, China, 2004. (In Chinese)

- Ministry of Railways of the People’s Republic of China. Code for Design of High Speed Railway (TB 10621-2009); China Railway Press: Beijing, China, 2009. (In Chinese)

- Zhang, C.; Jiang, G. Full-scale model testing of the dynamic response of lime-stabilized weathered red mudstone subgrade under railway excitation. Soil Dyn. Earthq. Eng. 2020, 130, 105999. [Google Scholar] [CrossRef]

- Bian, X.; Li, W.; Hu, J.; Liu, H.; Duan, X.; Chen, Y. Geodynamics of high-speed railway. Transp. Geotech. 2018, 17, 69–76. [Google Scholar] [CrossRef]

- Jiang, H.; Bian, X.; Jiang, J.; Chen, Y. Dynamic performance of high-speed railway formation with the rise of water table. Eng. Geol. 2016, 206, 18–32. [Google Scholar] [CrossRef]

- Bian, X.; Jiang, H.; Chen, Y. Preliminary testing on high-speed railway substructure due to water level changes. Procedia Eng. 2016, 143, 769–781. [Google Scholar] [CrossRef] [Green Version]

- Su, Q.; Bai, H.; Huang, J.J.; Li, X.; Zhang, W.C. In-situ tests on long-term dynamic characteristics of low embankment on rigid foundation. J. China Civ. Eng. J. 2011, 44, 147–151. (In Chinese) [Google Scholar]

- Yang, G.L.; Qiu, M.M.; He, X.; Shen, Q. Tests for working property of water-proof layer of cutting subgrade in expansive soil under vibrating load. J. Vib. Shock. 2016, 35, 1–7+20. (In Chinese) [Google Scholar]

- Bian, X.; Jiang, H.; Cheng, C.; Chen, Y.; Chen, R.; Jiang, J. Full-scale model testing on a ballastless high-speed railway under simulated train moving loads. Soil Dyn. Earthq. Eng. 2014, 66, 368–384. [Google Scholar] [CrossRef]

- Li, J.; Chen, S.; Yu, F.; Dai, Z.; Ojekunle, O.V. In situ model tests to investigate the dynamic response of water-softened subgrade under vibrating loads. Soil Dyn. Earthq. Eng. 2020, 138, 106336. [Google Scholar] [CrossRef]

- Wang, L.; Lei, X.; Liu, S. Investigation of immersion influence on dynamic properties of high-speed railway subgrade with semi-rigid waterproof functional layer through field-excitation testing. Can. Geotech. J. 2018, 55, 19–33. [Google Scholar] [CrossRef]

- Hao, B.; Qian, S.; Huang, J. In-situ forced vibration tests on dynamic characteristics of non-embedded pile-board subgrade. J. Rock Soil Mech. 2012, 33, 3753–3759. (In Chinese) [Google Scholar]

- Fu, L.L.; Gong, Q.M.; Wang, Y. Analysis on dynamic transfer characteristics of low geosynthetic-reinforced embankments supported by CFG piles subjected to high-speed railway. In Advanced Materials Research; Trans Tech Publications Ltd.: Bach, Freienbach, Schwyz, Switzerland, 2012; Volume 368, pp. 2575–2580. [Google Scholar]

- Shang, Y.H.; Xu, L.R.; Cai, Y. Study on dynamic characteristics of cement-stabilized expansive soil subgrade of heavy-haul railway under immersed environment. J. Rock Soil Mech. 2020, 41, 2739–2745+2755. (In Chinese) [Google Scholar]

- Yang, G.L.; Duan, J.Y.; Hu, M.; Qiu, M.M. Study on Structure Design of New Waterproof Subgrade in Expansive Soil Cutting for Passenger Dedicated Railway. J. China Rail Soci. 2021, 43, 134–141. (In Chinese) [Google Scholar]

- Wang, L. Vibration characterization of fully-closed high speed railway subgrade through frequency: Sweeping test. Soil Dyn. Earthq. Eng. 2016, 88, 33–44. [Google Scholar] [CrossRef]

- Chen, J.; Zhou, Y.; Zhou, G.; Fu, B. Experimental Vibration Investigation on High-Speed Railway Ballastless Track-Subgrade Structure. Int. J. Struct. Stab. Dyn. 2020, 20, 2050081. [Google Scholar] [CrossRef]

- Li, S.; Wei, L.; Chen, X.; He, Q.; Chen, A. Dynamic characteristics of subgrade-bridge transitions in heavy-haul railways under roller excitation. Transp. Geotech. 2021, 29, 100589. [Google Scholar] [CrossRef]

- Cao, L.; Yang, C.; Zhang, J.; Zeng, P.; Li, S. Earthquake response of the train–slab ballastless track–subgrade system: A shaking table test study. J. Vib. Control 2021, 27, 1979–1990. [Google Scholar] [CrossRef]

| Item | Classification | White Diatomaceous Earth | Black Diatomaceous Earth | Blue Diatomaceous Earth |

|---|---|---|---|---|

| Natural Density | Range | 1.33~1.88 | 1.37~1.91 | 1.30~2.06 |

| Dry Density | Range | 0.64~1.58 | 0.82~1.50 | 0.67~1.62 |

| Water content | Range | 20.5~115.5% | 27.5~102.2% | 21.9~114.0% |

| Average value | 53.73% | 68.02% | 64.71% | |

| Void ratio | Range | 0.69~3.31 | 0.84~2.37 | 0.68~3.09 |

| Average value | 1.47 | 1.71 | 1.85 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Su, Q.; Deng, Z.; Wang, X.; Jia, W.; Niu, Y. Experimental Study of the Dynamic Characteristics of a New Antidrainage Subgrade Structure for High-Speed Railways in Diatomaceous Earth Areas. Materials 2022, 15, 532. https://doi.org/10.3390/ma15020532

Su Q, Deng Z, Wang X, Jia W, Niu Y. Experimental Study of the Dynamic Characteristics of a New Antidrainage Subgrade Structure for High-Speed Railways in Diatomaceous Earth Areas. Materials. 2022; 15(2):532. https://doi.org/10.3390/ma15020532

Chicago/Turabian StyleSu, Qian, Zhixing Deng, Xun Wang, Wenyi Jia, and Yunbin Niu. 2022. "Experimental Study of the Dynamic Characteristics of a New Antidrainage Subgrade Structure for High-Speed Railways in Diatomaceous Earth Areas" Materials 15, no. 2: 532. https://doi.org/10.3390/ma15020532

APA StyleSu, Q., Deng, Z., Wang, X., Jia, W., & Niu, Y. (2022). Experimental Study of the Dynamic Characteristics of a New Antidrainage Subgrade Structure for High-Speed Railways in Diatomaceous Earth Areas. Materials, 15(2), 532. https://doi.org/10.3390/ma15020532