On the Possible Nature of Armchair-Zigzag Structure Formation and Heat Capacity Decrease in MWCNTs

Abstract

:1. Introduction

2. Materials and Methods

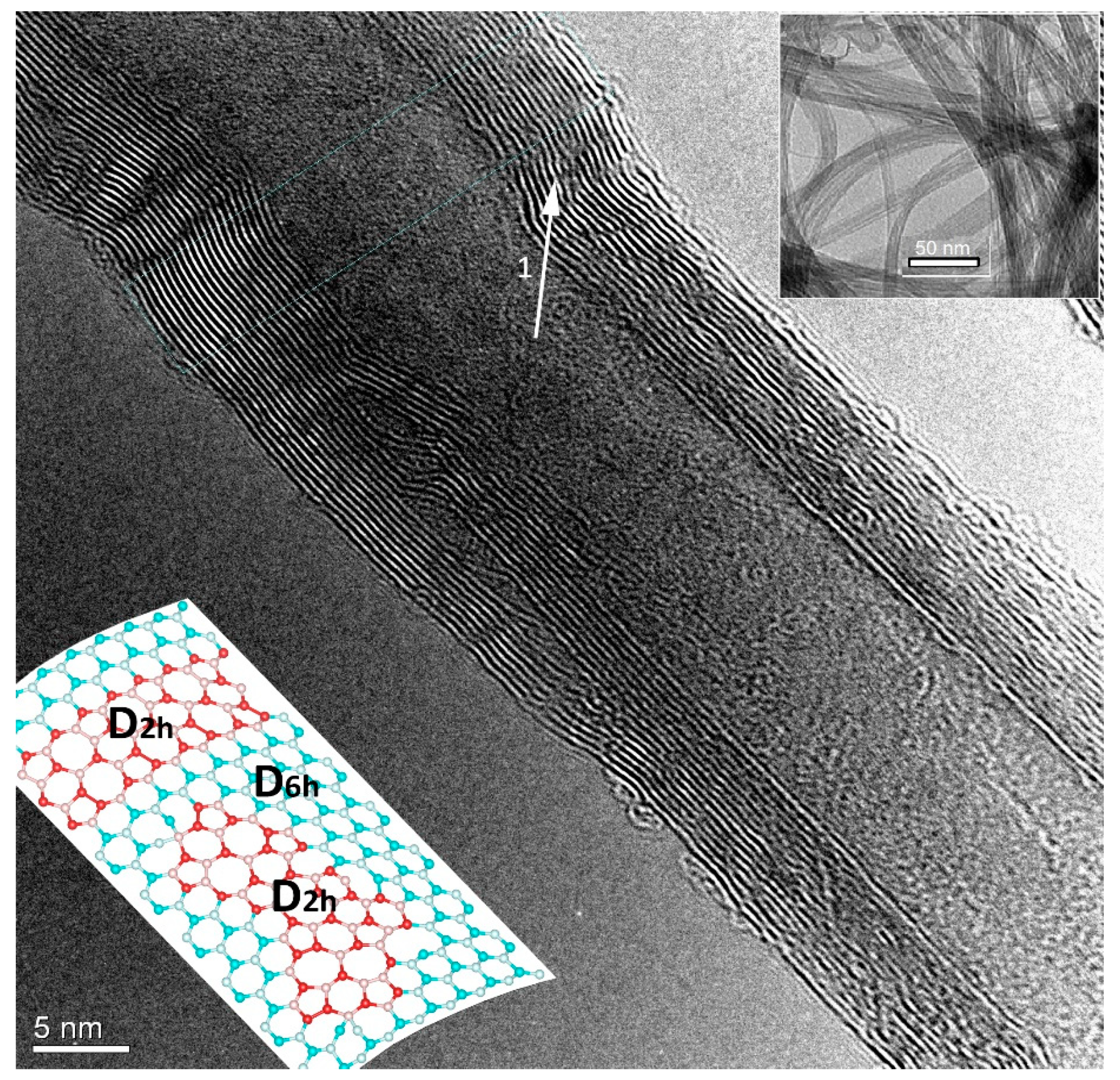

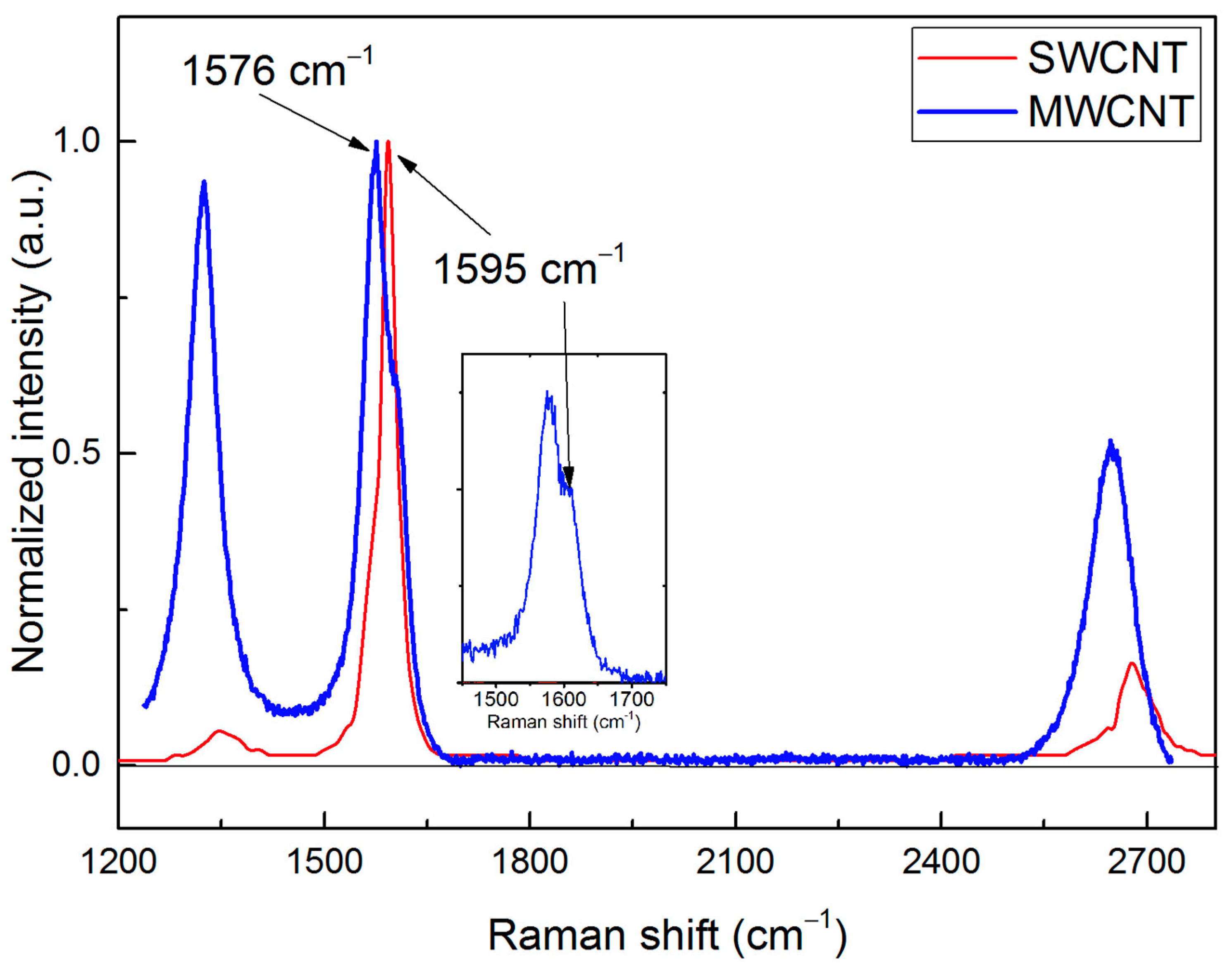

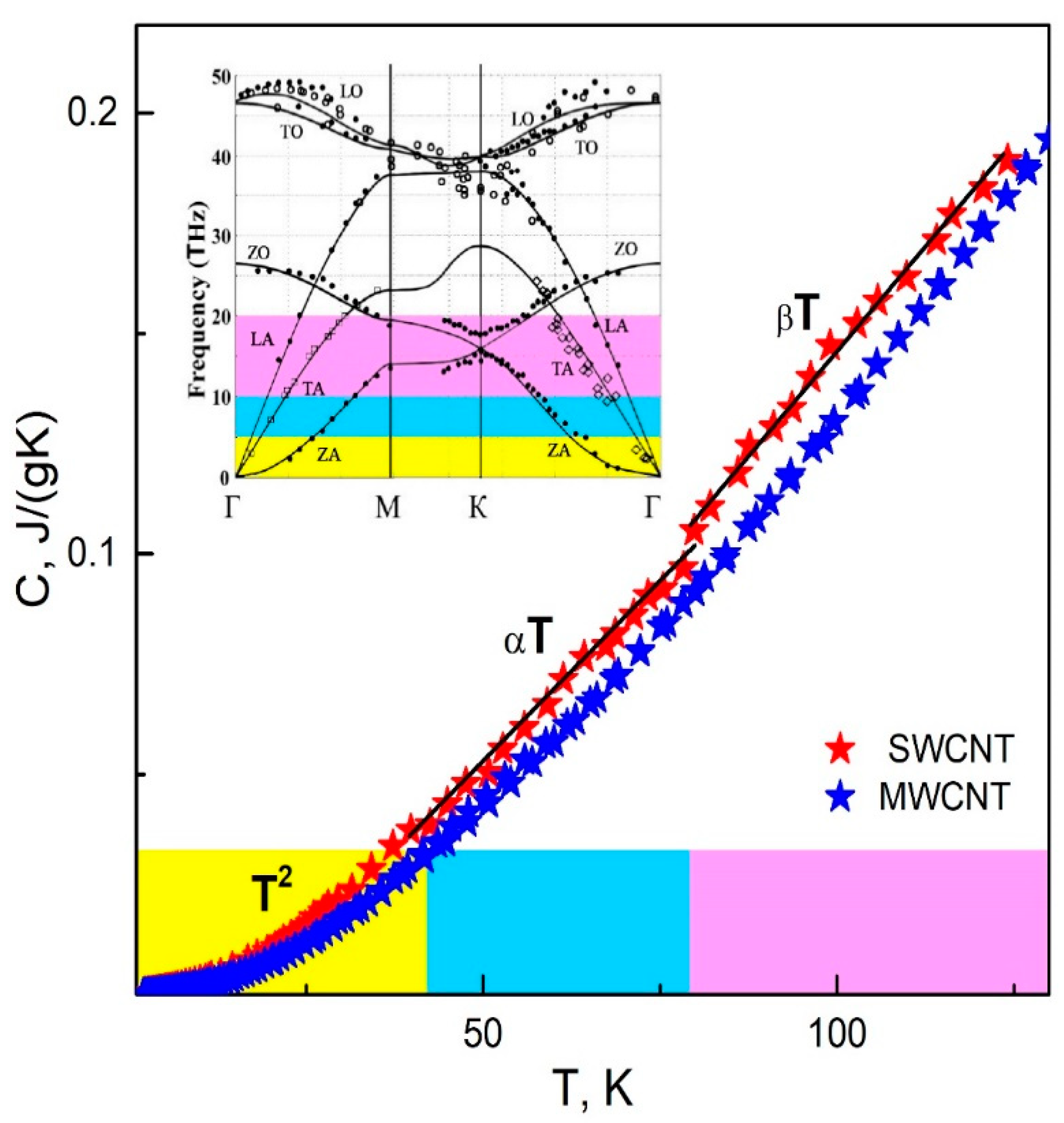

3. Results and Discussion of the Armchair-Zigzag Structure of MWCNTs

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Blackburn, J.L.; Ferguson, A.J.; Cho, C.; Grunlan, J.C. Carbon-nanotube-based thermoelectric materials and devices. Adv. Mater. 2018, 30, 1704386. [Google Scholar] [CrossRef] [PubMed]

- Razeeb, K.M.; Dalton, E.; Cross, G.L.W.; Robinson, A.J. Present and future thermal interface materials for electronic devices. Int. Mater. Rev. 2018, 63, 1–21. [Google Scholar] [CrossRef]

- Lee, J.; Kim, D.; Yoon, Y.J. Specific heat measurements of CNT nanofluids. Int. J. Nanotechnol. 2019, 16, 289. [Google Scholar] [CrossRef]

- Jagadeesan, A.K.; Thangavelu, K.; Dhananjeyan, V. Carbon nanotubes: Synthesis, properties and applications. In 21st Century Surface Science—A Handbook; Pham, P., Goel, P., Kumar, S., Eds.; IntechOpen: London, UK, 2020. [Google Scholar] [CrossRef]

- Shah, K.A.; Tali, B.A. Synthesis of carbon nanotubes by catalytic chemical vapour deposition: A review on carbon sources, catalysts and substrates. Mater. Sci. Semicond. Process. 2016, 41, 67–82. [Google Scholar] [CrossRef]

- Kuznetsov, V.L.; Bokova-Sirosh, S.N.; Moseenkov, S.I.; Ishchenko, A.V.; Krasnikov, D.V.; Kazakova, M.A.; Romanenko, A.I.; Tkachev, E.N.; Obraztsova, E.D. Raman spectra for characterization of defective CVD multi-walled carbon nanotubes. Phys. Status Solidi B Basic Res. 2014, 251, 2444–2450. [Google Scholar] [CrossRef]

- Flygare, M.; Svensson, K. Quantifying crystallinity in carbon nanotubes and its influence on mechanical behaviour. Mater. Today Commun. 2019, 18, 39–45. [Google Scholar] [CrossRef]

- Jang, J.-W. Direct curvature measurement of the compartments in bamboo-shaped multi-walled carbon nanotubes via scanning probe microscopy. Sci. Rep. 2021, 11, 701. [Google Scholar] [CrossRef]

- Zhang, Z.; Yang, Y.; Xu, F.; Wang, L.; Yakobson, B.I. Unraveling the sinuous grain boundaries in graphene. Adv. Funct. Mater. 2015, 25, 367–373. [Google Scholar] [CrossRef]

- Li, Z.L.; Li, Z.M.; Cao, H.Y.; Yang, J.H.; Shu, Q.; Zhang, Y.Y.; Xiang, H.J.; Gong, X.G. What are grain boundary structures in graphene? Nanoscale 2014, 6, 4309–4315. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ovid’ko, I.A. Review on grain boundaries in graphene. Curved poly- and nanocrystalline graphene structures as new carbon allotropes. Rev. Adv. Mater. Sci. 2012, 30, 201–224. [Google Scholar]

- Kumanek, B.; Janas, D. Thermal conductivity of carbon nanotube networks: A review. J. Mater. Sci. 2019, 54, 7397–7427. [Google Scholar] [CrossRef] [Green Version]

- Bagatskii, M.I.; Jeżowski, A.; Szewczyk, D.; Sumarokov, V.V.; Barabashko, M.S.; Kuznetsov, V.L.; Moseenkov, S.I.; Ponomarev, A.N. Size effects in the heat capacity of modified MWCNTs. Therm. Sci. Eng. Prog. 2021, 26, 101097. [Google Scholar] [CrossRef]

- Bagatskii, M.I.; Barabashko, M.S.; Dolbin, A.V.; Sumarokov, V.V.; Sundqvist, B. The specific heat and the radial thermal expansion of bundles of single-walled carbon nanotubes. Low Temp. Phys. 2012, 38, 523–528. [Google Scholar] [CrossRef]

- Muratov, V.B.; Vasil’ev, O.O.; Kulikov, L.M.; Garbuz, V.V.; Nesterenko, Y.V.; Duda, T.I. Thermodynamic properties of multiwalled carbon nanotubes. J. Superhard Mater. 2012, 34, 173–178. [Google Scholar] [CrossRef]

- Barabashko, M.S.; Drozd, M.; Szewczyk, D.; Jeżowski, A.; Bagatskii, M.I.; Sumarokov, V.V.; Dolbin, A.V.; Nesov, S.N.; Korusenko, P.M.; Ponomarev, A.N.; et al. Calorimetric, NEXAFS and XPS studies of MWCNTs with low defectiveness. Fuller. Nanotub. Carbon Nanostruct. 2021, 29, 331–336. [Google Scholar] [CrossRef]

- Sumarokov, V.V.; Jeżowski, A.; Szewczyk, D.; Barabashko, M.S.; Ponomarev, A.N.; Kuznetsov, V.L.; Moseenkov, S.I. The low-temperature specific heat of MWCNTs. Low Temp. Phys. 2019, 45, 347–354. [Google Scholar] [CrossRef]

- Jorge, G.A.; Bekeris, V.; Escobar, M.M.; Goyanes, S.; Zilli, D.; Cukierman, A.L.; Candal, R.J. A specific heat anomaly in multiwall carbon nanotubes as a possible sign of orientational order–disorder transition. Carbon 2010, 48, 525–530. [Google Scholar] [CrossRef]

- Yi, W.; Lu, L.; Dian-lin, Z.; Pan, Z.W.; Xie, S.S. Linear specific heat of carbon nanotubes. Phys. Rev. B Condens. Matter. 1999, 59, R9015–R9018. [Google Scholar] [CrossRef]

- Masarapu, C.; Henry, L.L.; Wei, B. Specific heat of aligned multiwalled carbon nanotubes. Nanotechnology 2005, 16, 1490–1494. [Google Scholar] [CrossRef]

- Lifshits, I.M. On the Thermal Properties of Chain and Layered Structures at Low Temperatures. J. Exp. Theor. Phys. 1952, 22, 475–486. [Google Scholar]

- Tarasov, V.V. Theory of Heat Capacity of Chain and Layered Structures. J. Phys. Chem. 1950, 24, 111–128. [Google Scholar]

- Xia, M.; Song, Y.; Zhang, S. Specific heat of graphene nanoribbons. Phys. Lett. A. 2011, 375, 3726–3730. [Google Scholar] [CrossRef]

- Avramenko, M.V.; Golushko, I.Y.; Myasnikova, A.E.; Rochal, S.B. Vibrational heat capacity of carbon nanotubes at low and ultra-low temperatures. Phys. E Low Dimens. Syst. Nanostruct. 2015, 68, 133–139. [Google Scholar] [CrossRef] [Green Version]

- Hepplestone, S.P.; Ciavarella, A.M.; Janke, C.; Srivastava, G.P. Size and temperature dependence of the specific heat capacity of carbon nanotubes. Surf. Sci. 2006, 600, 3633–3636. [Google Scholar] [CrossRef]

- Savinskii, S.S.; Petrovskii, V.A. Discrete and continuum models for calculating the phonon spectra of carbon nanotubes. Phys. Solid State 2002, 44, 1802–1807. [Google Scholar] [CrossRef]

- Kuznetsov, V.L.; Krasnikov, D.V.; Schmakov, A.N.; Elumeeva, K.V. In situ and ex situ time resolved study of multi-component Fe-Co oxide catalyst activation during MWNT synthesis. Phys. Status Solidi B Basic Res. 2012, 249, 2390–2394. [Google Scholar] [CrossRef]

- Izyumov, Y.A.; Syromyatnikov, V.N. Phase Transitions and Crystal Symmetry; Springer: Dordrecht, The Netherlands, 1990. [Google Scholar]

- Doniach, S.; Sondheimer, E.H. Green’s Functions for Solid State Physicists; World Scientific Publishing Company: London, UK, 1998. [Google Scholar]

- Dresselhaus, M.S.; Dresselhaus, G.; Jorio, A. Group Theory; Springer: Berlin, Germany, 2010. [Google Scholar]

- Paul, R.; Mitra, A.K. Photoluminescence from SWCNT/Cu hybrid nanostructure synthesized by a soft chemical route. ISRN Opt. 2012, 2012, 1–5. [Google Scholar] [CrossRef] [Green Version]

- Singh, D.K.; Iyer, P.K.; Giri, P.K. Diameter dependence of interwall separation and strain in multiwalled carbon nanotubes probed by X-ray diffraction and Raman scattering studies. Diam. Relat. Mater. 2010, 19, 1281–1288. [Google Scholar] [CrossRef]

- Kiang, C.-H.; Endo, M.; Ajayan, P.M.; Dresselhaus, G.; Dresselhaus, M.S. Size effects in carbon nanotubes. Phys. Rev. Lett. 1998, 81, 1869–1872. [Google Scholar] [CrossRef] [Green Version]

- Kim, J.; Lee, N.; Min, Y.H.; Noh, S.; Kim, N.K.; Jung, S.; Joo, M.; Yamada, Y. Distinguishing zigzag and armchair edges on graphene nanoribbons by X-ray photoelectron and Raman spectroscopies. ACS Omega 2018, 3, 17789–17796. [Google Scholar] [CrossRef] [Green Version]

- Cançado, L.G.; Takai, K.; Enoki, T.; Endo, M.; Kim, Y.A.; Mizusaki, H.; Jorio, A.; Coelho, L.N.; Magalhaes-Paniago, R.; Pimenta, M.A. General equation for the determination of the crystallite size La of nanographite by Raman spectroscopy. Appl. Phys. Lett. 2006, 88, 163106. [Google Scholar] [CrossRef]

- Bokova-Sirosh, S.N.; Kuznetsov, V.L.; Romanenko, A.I.; Kazakova, M.A.; Krasnikov, D.V.; Tkachev, E.N.; Yuzyuk, Y.I.; Obraztsova, E.D. Investigation of defectiveness of multiwalled carbon nanotubes produced with Fe–Co catalysts of different composition. J. Nanophotonics 2016, 10, 012526. [Google Scholar] [CrossRef]

- Wang, G.; Dai, Z.; Wang, Y.; Tan, P.; Liu, L.; Xu, Z.; Wei, Y.; Huang, R.; Zhang, Z. Measuring interlayer shear stress in bilayer graphene. Phys. Rev. Lett. 2017, 119, 036101. [Google Scholar] [CrossRef] [PubMed]

- Enyashin, A.N.; Ivanovskii, A.L. Deformation mechanisms for carbon and boron nitride nanotubes. Inorg. Mater. 2006, 42, 1336–1341. [Google Scholar] [CrossRef]

- Sabirov, D.S.; Ori, O. Skeletal Rearrangements of the C240 Fullerene: Efficient Topological Descriptors for Monitoring Stone–Wales Transformations. Mathematics 2020, 8, 968. [Google Scholar] [CrossRef]

- Vuković, T.; Damnjanović, M.; Milošević, I. Interaction between layers of the multi-wall carbon nanotubes. Phys. E 2003, 16, 259–268. [Google Scholar] [CrossRef]

- Askerov, A. Phonon Spectra in Graphene Nanoribbons. Univ. Mold. 2018, 2, 53–59. [Google Scholar]

- Aghaei, A.; Dayal, K.; Elliott, R.S. Anomalous phonon behavior of carbon nanotubes: First-order influence of external load. J. Appl. Phys. 2013, 113, 023503. [Google Scholar] [CrossRef] [Green Version]

- Thébaud, S. Electron and Phonon Transport in Disordered Thermoelectric Materials: Dimensional Confinement, Resonant Scattering and Localization. Ph.D. Thesis, University of Lyon, Lyon, France, 2019. Available online: https://tel.archives-ouvertes.fr/tel-02356350 (accessed on 3 December 2021).

- Landau, L.D.; Pitaevskii, L.P.; Lifshitz, E.M.; Kosevich, A.M. Theory of Elasticity, 3rd ed.; Butterworth-Heinemann: Oxford, UK, 1984. [Google Scholar]

- Xu, C.H.; Hu, J.J.; Rong, D.L. Flexural wave propagation of double-layered graphene sheets based on the Hamiltonian system. Mater. Sci. For. 2020, 975, 121–126. [Google Scholar] [CrossRef]

- Lei, X.; Natsuki, T.; Shi, J.; Ni, Q.-Q. Analysis of carbon nanotubes on the mechanical properties at atomic scale. J. Nanomater. 2011, 2011, 1–10. [Google Scholar] [CrossRef] [Green Version]

| Sample | D (cm−1) | G (cm−1) | ID/IG |

|---|---|---|---|

| SWCNTs | 1344 | 1595 | 0.08 |

| MWCNTs | 1325 | 1576 (1595) | 0.9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ponomarev, A.; Egorushkin, V.; Bobenko, N.; Barabashko, M.; Rezvanova, A.; Belosludtseva, A. On the Possible Nature of Armchair-Zigzag Structure Formation and Heat Capacity Decrease in MWCNTs. Materials 2022, 15, 518. https://doi.org/10.3390/ma15020518

Ponomarev A, Egorushkin V, Bobenko N, Barabashko M, Rezvanova A, Belosludtseva A. On the Possible Nature of Armchair-Zigzag Structure Formation and Heat Capacity Decrease in MWCNTs. Materials. 2022; 15(2):518. https://doi.org/10.3390/ma15020518

Chicago/Turabian StylePonomarev, Alexander, Valeriy Egorushkin, Nadezhda Bobenko, Maksym Barabashko, Anastasiya Rezvanova, and Anna Belosludtseva. 2022. "On the Possible Nature of Armchair-Zigzag Structure Formation and Heat Capacity Decrease in MWCNTs" Materials 15, no. 2: 518. https://doi.org/10.3390/ma15020518

APA StylePonomarev, A., Egorushkin, V., Bobenko, N., Barabashko, M., Rezvanova, A., & Belosludtseva, A. (2022). On the Possible Nature of Armchair-Zigzag Structure Formation and Heat Capacity Decrease in MWCNTs. Materials, 15(2), 518. https://doi.org/10.3390/ma15020518