Non-Destructive Evaluation of Mortar with Ground Granulated Blast Furnace Slag Blended Cement Using Ultrasonic Pulse Velocity

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Mix Designs

2.3. Testing

3. Test Results

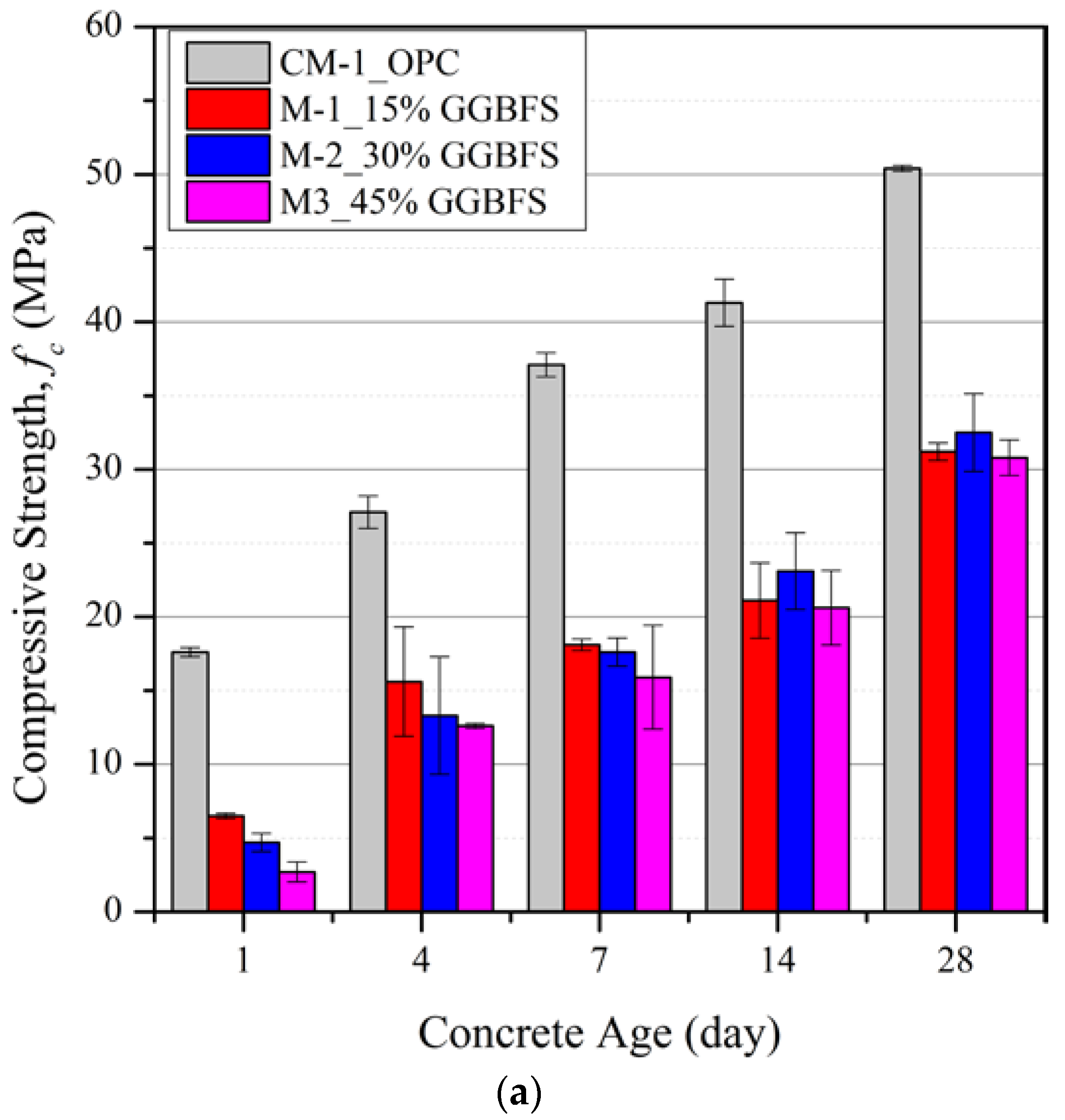

3.1. Mechanical Compressive Strength

3.1.1. Influence of GGBFS as a Partial Replacement of Cement on Compressive Strength

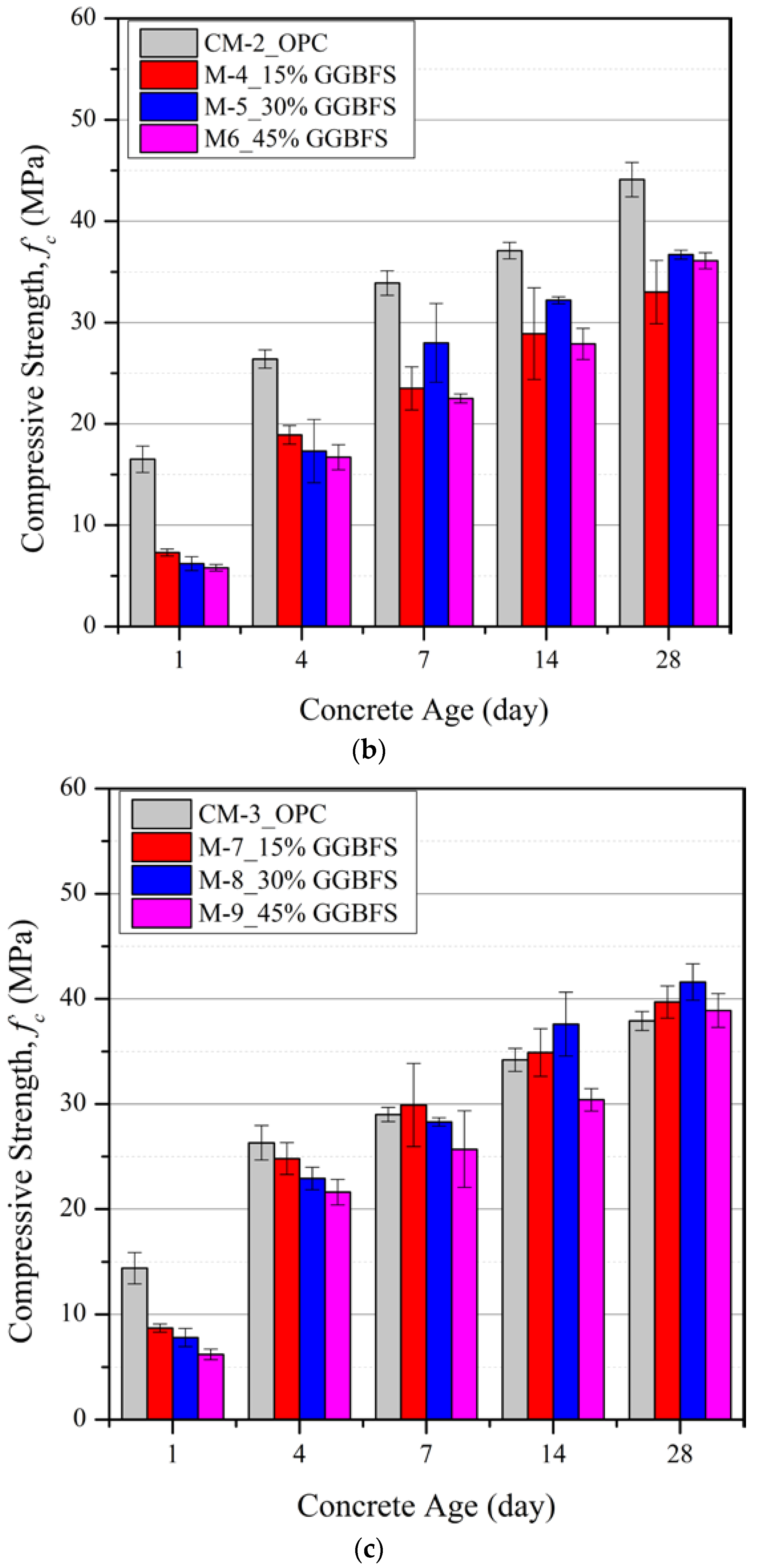

3.1.2. Influence of wc Ratio on Compressive Strength of Slag Blended Mortars

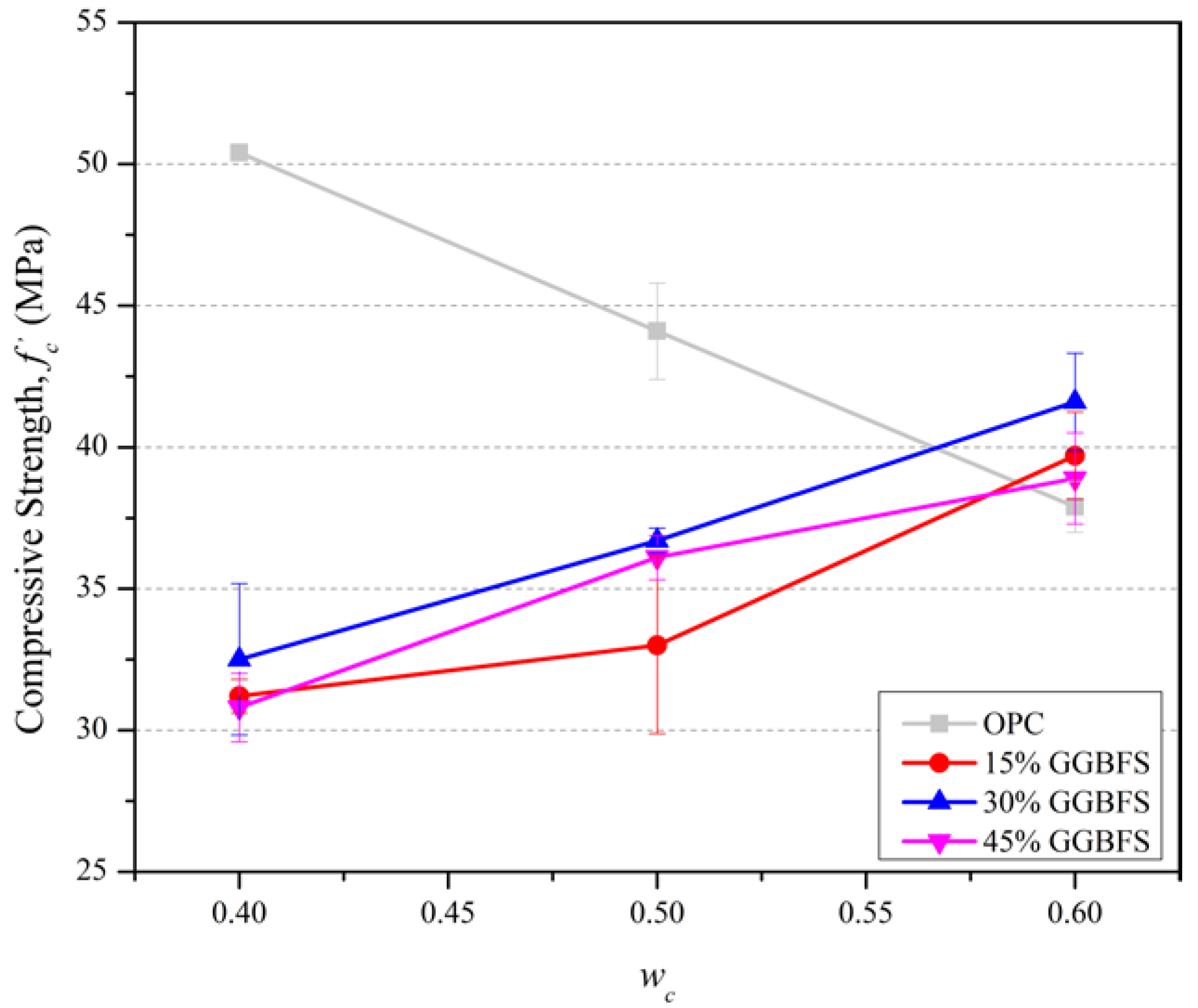

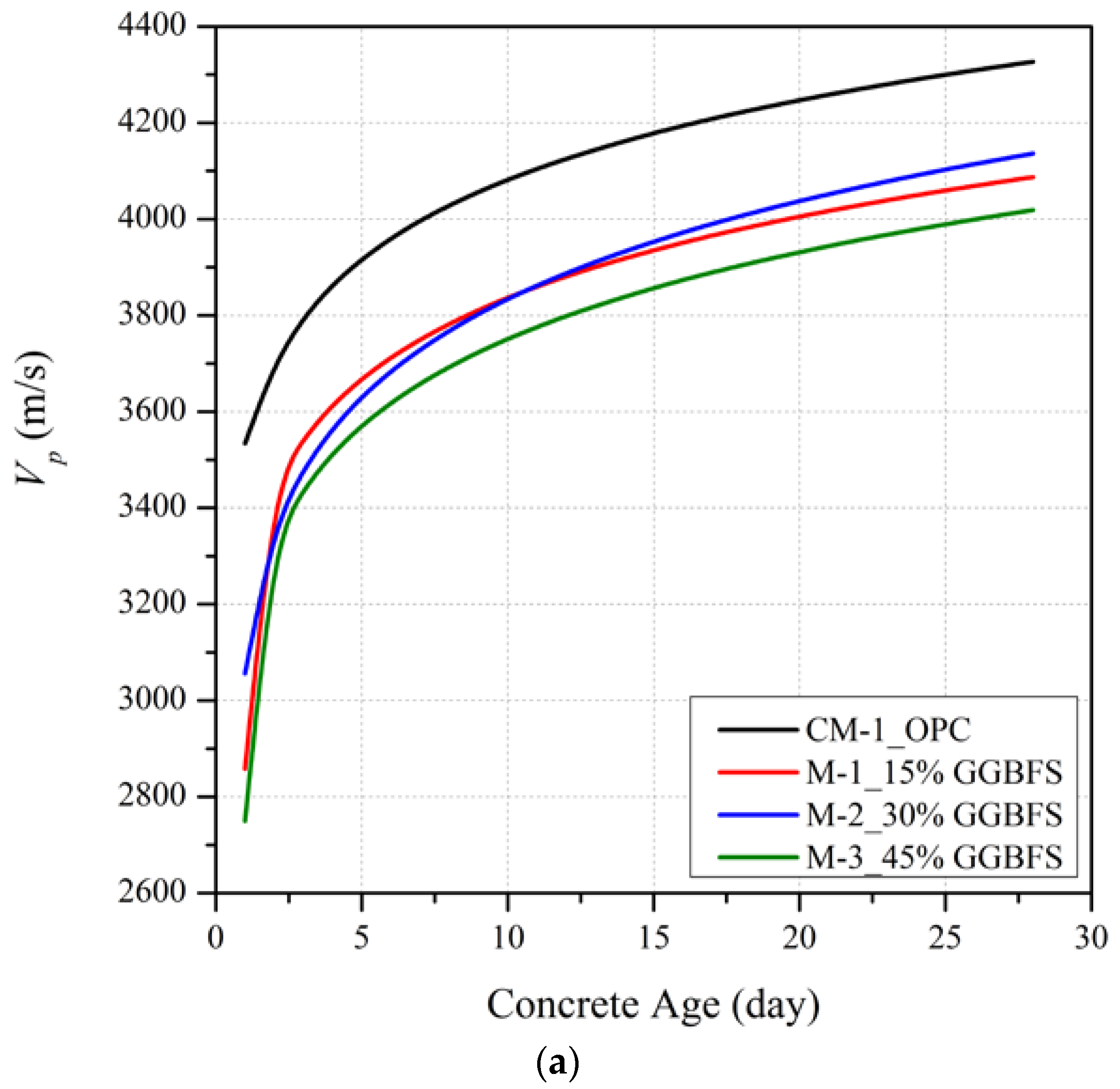

3.2. Ultrasonic Pulse Velocity (Vp)

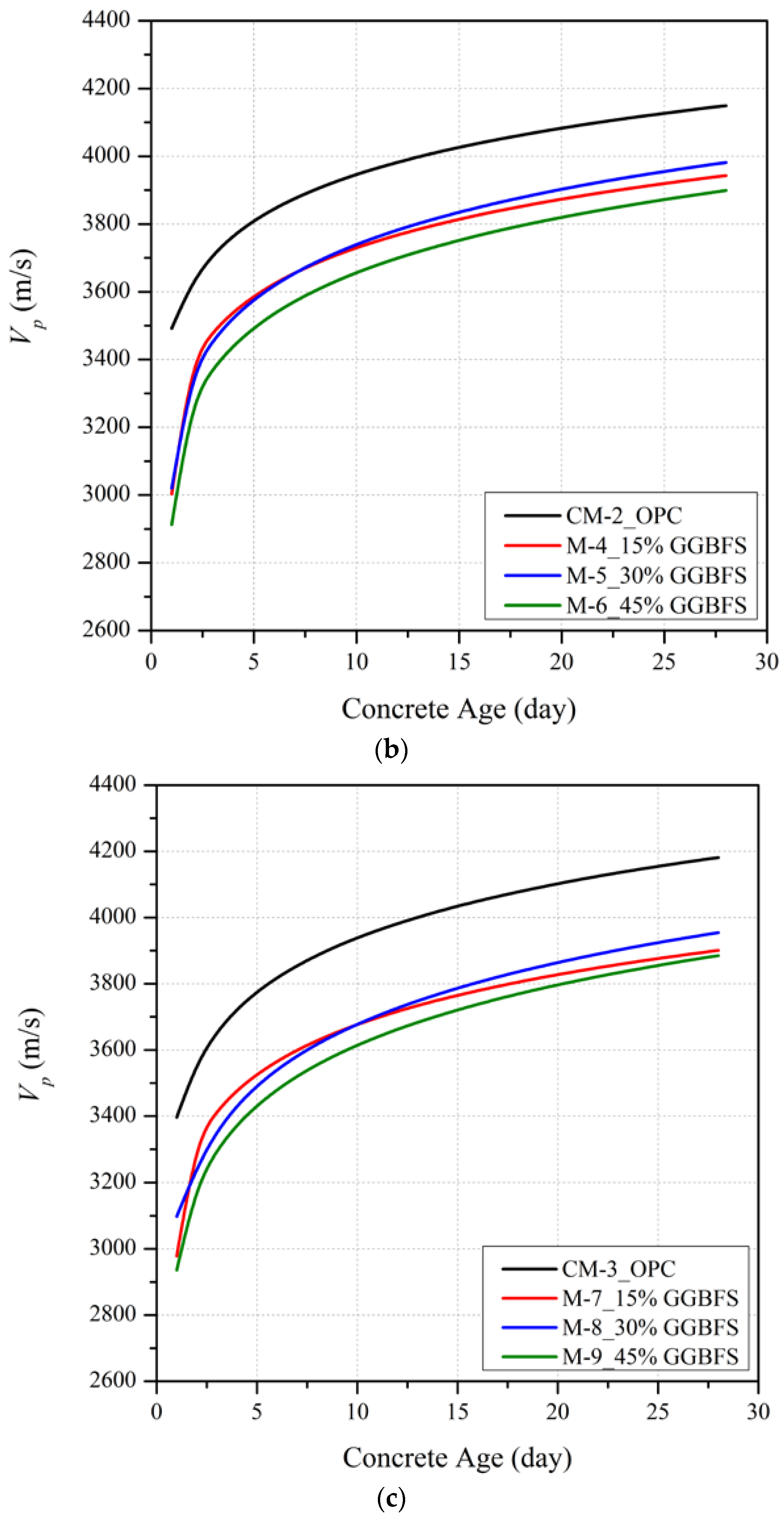

3.2.1. Influence of GGBFS as a Partial Replacement of OPC on Vp

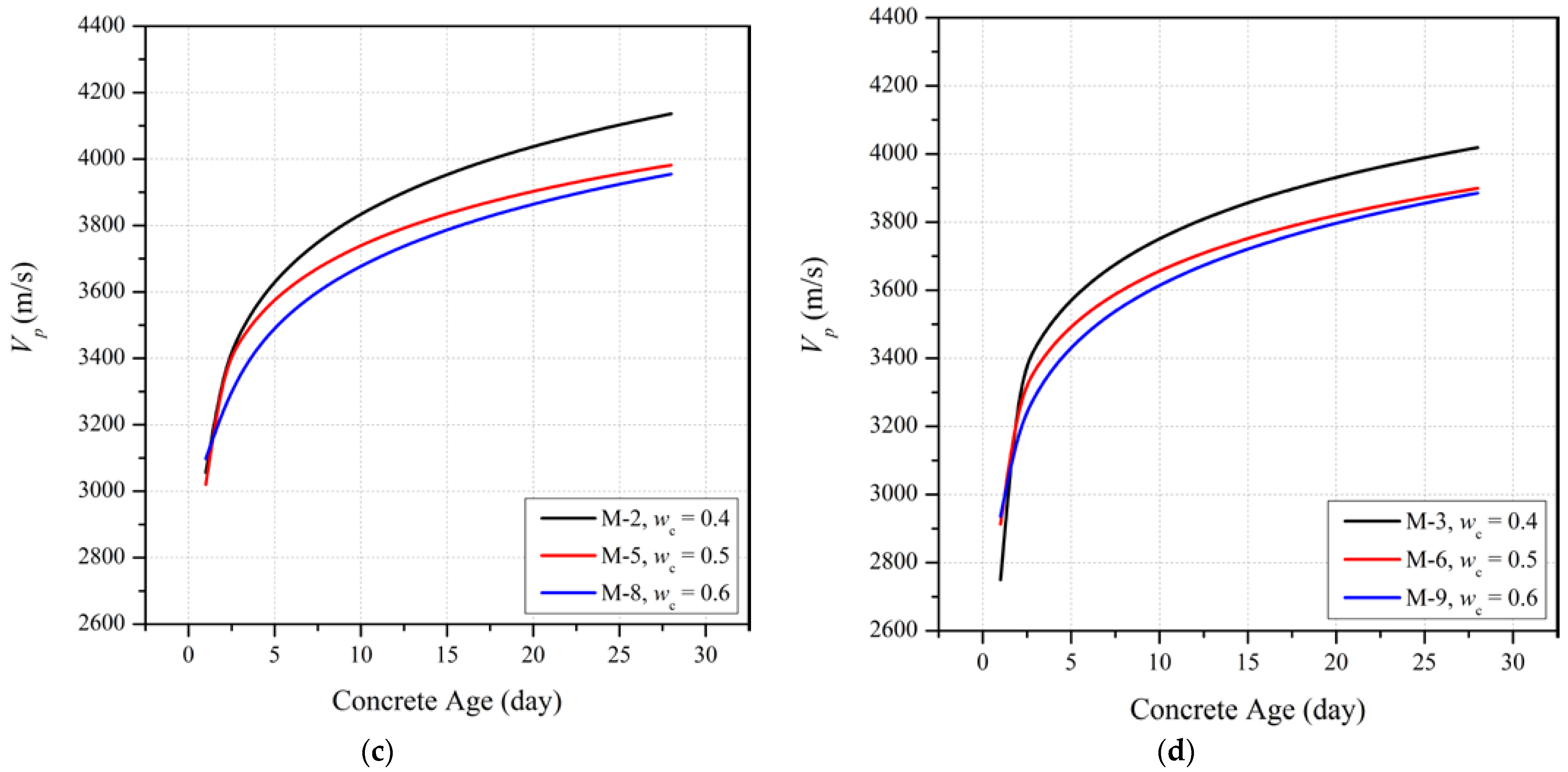

3.2.2. Influence of wc on Vp of Slag Blended Mortars

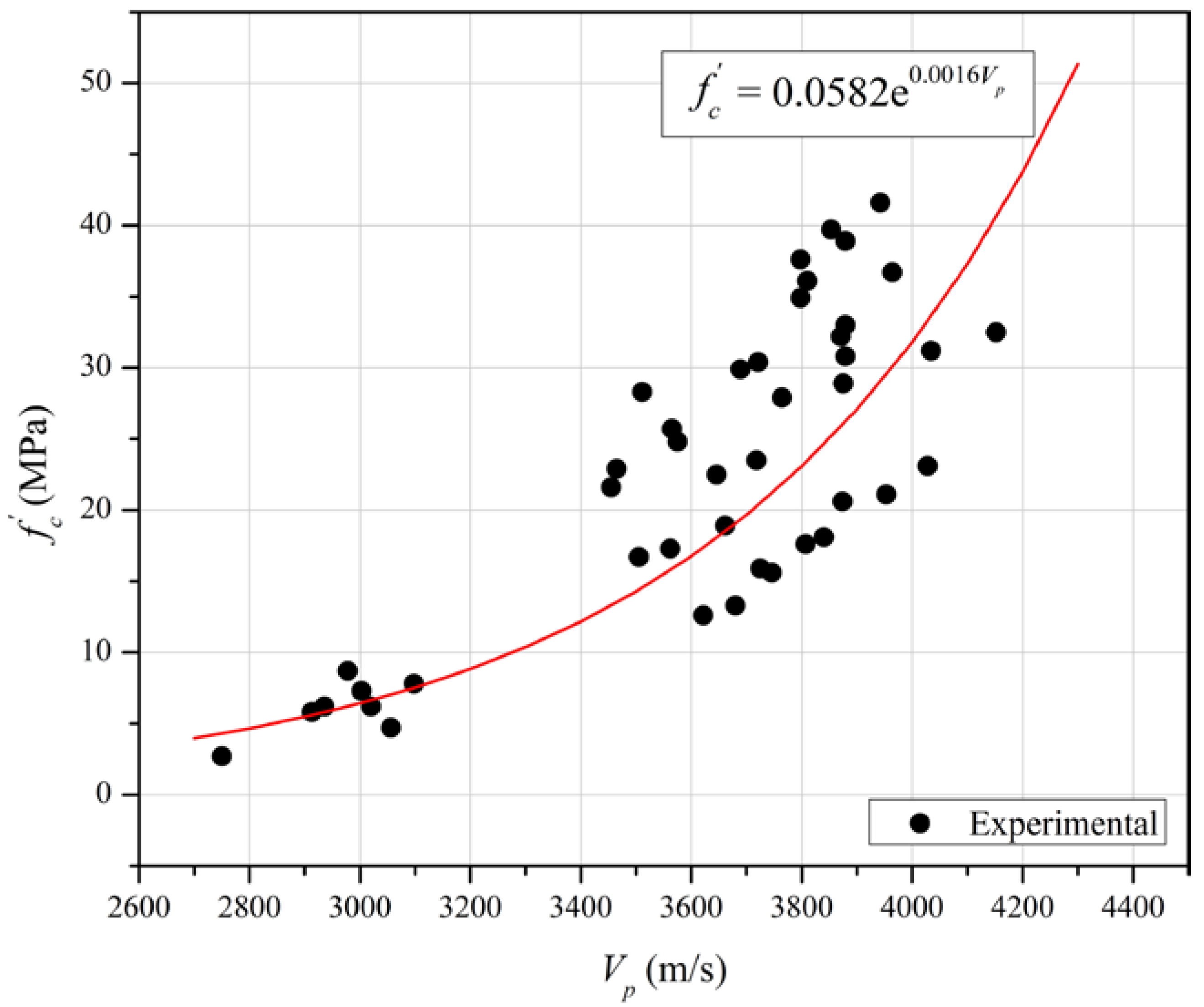

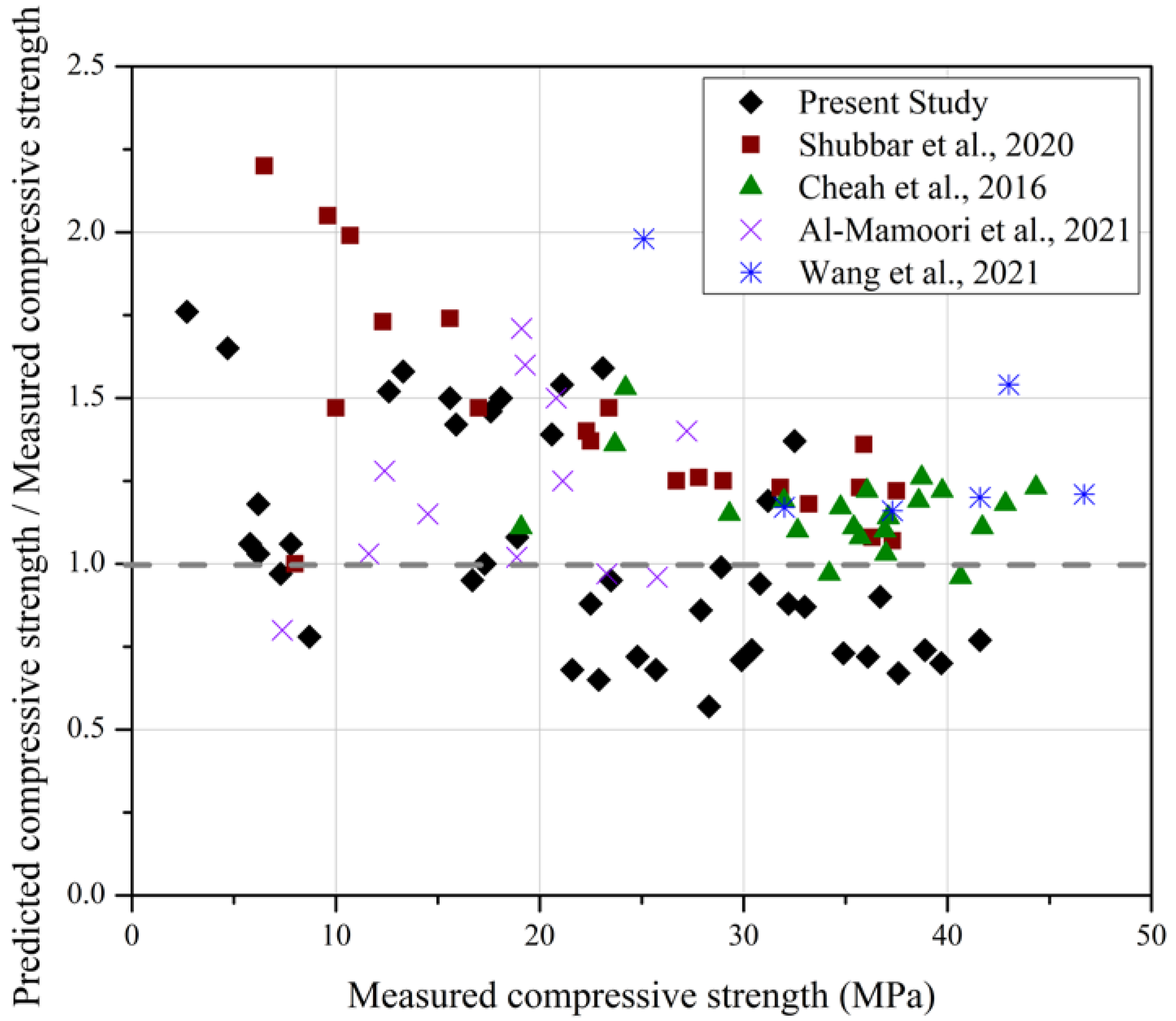

3.3. Correlation between and Vp of Slag Blended Mortars

4. Conclusions

- A slower hydration rate is observed during early ages (1-day to 14-day) but long-term strengths approach those of mortars without GGBFS. Previous research has shown that this is due to the specific characteristics of hydration kinetics of these material types.

- The compressive strength of mortars with GGBFS at a given curing period and water-to-cement ratio is relatively independent of the slag replacement percentage (s) for s values between 15% and 45%.

- The compressive strength of a given mortar mix without slag is well described by an exponential function of the ultrasonic velocity (Vp).

- The exponential relationship between compressive strength and ultrasonic velocity requires the application of a correction factor in mortars with slag replacement, where the correction factor is a function of time and water-to-cement ratio.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chidiac, S.E.; Panesar, D.K. Evolution of mechanical properties of concrete containing ground granulated blast furnace slag and effects on the scaling resistance test at 28days. Cem. Concr. Compos. 2008, 30, 63–71. [Google Scholar] [CrossRef]

- Cyr, M.; Lawrence, P.; Ringot, E. Efficiency of mineral admixtures in mortars: Quantification of the physical and chemical effects of fine admixtures in relation with compressive strength. Cem. Concr. Res. 2006, 36, 264–277. [Google Scholar] [CrossRef]

- Demirboğa, R.; Türkmen, İ.; Karakoç, M.B. Relationship between ultrasonic velocity and compressive strength for high-volume mineral-admixtured concrete. Cem. Concr. Res. 2004, 34, 2329–2336. [Google Scholar] [CrossRef]

- Lawrence, P.; Cyr, M.; Ringot, E. Mineral admixtures in mortars effect of type, amount and fineness of fine constituents on compressive strength. Cem. Concr. Res. 2005, 35, 1092–1105. [Google Scholar] [CrossRef]

- Escalante-García, J.I.; Sharp, J.H. The microstructure and mechanical properties of blended cements hydrated at various temperatures. Cem. Concr. Res. 2001, 31, 695–702. [Google Scholar] [CrossRef]

- Rashad, A.M. An overview on rheology, mechanical properties and durability of high-volume slag used as a cement replacement in paste, mortar and concrete. Constr. Build. Mater. 2018, 187, 89–117. [Google Scholar] [CrossRef]

- Tasdemir, M.A.; Tasdemir, C.; Ozbek, E.; Altay, B. Fineness effect of GGBS on the properties and microstructure of concrete. In Proceedings of the 1st International Symposium on Mineral Admixtures in Cement, Istanbul, Turkey, 22–23 September 1997. [Google Scholar]

- Najim, K.B. Strength evaluation of concrete structures using ISonReb linear regression models: Laboratory and site (case studies) validation. Constr. Build. Mater. 2017, 149, 639–647. [Google Scholar] [CrossRef]

- Sitarz, M.; Hager, I.; Choińska, M. Evolution of Mechanical Properties with Time of Fly-Ash-Based Geopolymer Mortars under the Effect of Granulated Ground Blast Furnace Slag Addition. Energies 2020, 13, 1135. [Google Scholar] [CrossRef]

- Sturrup, V.; Vecchio, F.; Caratin, H. Pulse velocity as a measure of concrete compressive strength. Spec. Publ. 1984, 82, 201–228. [Google Scholar]

- Biswas, R.; Rai, B.; Samui, P. Compressive strength prediction model of high-strength concrete with silica fume by destructive and non-destructive technique. Innov. Infrastruct. Solut. 2021, 6, 65. [Google Scholar] [CrossRef]

- Kheder, G.; Al Gabban, A.; Abid, S. Mathematical model for the prediction of cement compressive strength at the ages of 7 and 28 days within 24 hours. Mater. Struct. 2003, 36, 693–701. [Google Scholar] [CrossRef]

- Rashid, K.; Waqas, R. Compressive strength evaluation by non-destructive techniques: An automated approach in construction industry. J. Build. Eng. 2017, 12, 147–154. [Google Scholar] [CrossRef]

- Saha, A.K.; Majhi, S.; Sarker, P.K.; Mukherjee, A.; Siddika, A.; Aslani, F.; Zhuge, Y. Non-destructive prediction of strength of concrete made by lightweight recycled aggregates and nickel slag. J. Build. Eng. 2021, 33, 101614. [Google Scholar] [CrossRef]

- Atici, U. Prediction of the strength of mineral admixture concrete using multivariable regression analysis and an artificial neural network. Expert Syst. Appl. 2011, 38, 9609–9618. [Google Scholar] [CrossRef]

- Gül, R.; Demirboğa, R.; Güvercin, T. Compressive strength and ultrasound pulse velocity of mineral admixtured mortars. Indian J. Eng. Mater. Sci. 2006, 13, 18–24. [Google Scholar]

- Trtnik, G.; Kavcic, F.; Turk, G. Prediction of concrete strength using ultrasonic pulse velocity and artificial neural networks. Ultrasonics 2009, 49, 53–60. [Google Scholar] [CrossRef]

- Le, D.-H.; Sheen, Y.-N.; Lam, M.N.-T. Fresh and hardened properties of self-compacting concrete with sugarcane bagasse ash–slag blended cement. Constr. Build. Mater. 2018, 185, 138–147. [Google Scholar] [CrossRef]

- Türkmen, I.; Öz, A.; Aydin, A. Characteristics of workability, strength, and ultrasonic pulse velocity of SCC containing zeolite and slag. Sci. Res. Essays 2010, 5, 2055–2064. [Google Scholar]

- Bogas, J.A.; Gomes, M.G.; Gomes, A. Compressive strength evaluation of structural lightweight concrete by non-destructive ultrasonic pulse velocity method. Ultrasonics 2013, 53, 962–972. [Google Scholar] [CrossRef]

- ASTM C109-21; Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in or [50 mm] Cube Specimen). ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM C597-02; Standard Test Method for Pulse Velocity Through Concrete. ASTM International: West Conshohocken, PA, USA, 2002.

- BS 1881-203:1986; Testing Concrete—Recommendations for Measurements of Velocity of Ultrasonic Pulses in Concrete. British Standard International: London, UK, 1986.

- CECS 21-2000; Technical Specification for Inspection of Concrete Defects by Ultrasonic Method. China Association for Engineering Construction Standardization Commitee of the Concrete Structure: Xi’an, China, 2000.

- BS EN 12504-4:2004; Testing Concrete—Determination of Ultrasonic Pulse Velocity. British Standard International: London, UK, 2004.

- ISI 13311-1:1992; Non-Destructive Testing of Concrete—Methods of Test, in Part 1—Ultrasonic Pulse Velocity. Bureau of Indian Standards: New Delhi, India, 1992.

- ISO 1920-7:2004; Testing of Concrete, in Part 7: Non-Destructive Tests on Hardened Concrete. The International Organization for Standardization: Geneva, Switzerland, 2004.

- Palod, R.; Deo, S.V.; Ramtekkar, G.D. Effect on mechanical performance, early age shrinkage and electrical resistivity of ternary blended concrete containing blast furnace slag and steel slag. Mater. Today Proc. 2020, 32, 917–922. [Google Scholar] [CrossRef]

- Xie, W.; Wang, P.; Li, S. Influence of fine slag powder content on the mechanical properties of concrete. J. North China Insitute Water Conserv. Hydroelectr. Power 2012, 33, 62–65. [Google Scholar]

- Lu, Y.; Ma, H.; Li, Z. Ultrasonic monitoring of the early-age hydration of mineral admixtures incorporated concrete using cement-based piezoelectric composite sensors. J. Intell. Mater. Syst. Struct. 2014, 26, 280–291. [Google Scholar] [CrossRef]

- Robeyst, N.; Gruyaert, E.; Grosse, C.U.; de Belie, N. Monitoring the setting of concrete containing blast-furnace slag by measuring the ultrasonic p-wave velocity. Cem. Concr. Res. 2008, 38, 1169–1176. [Google Scholar] [CrossRef]

- Bentz, D.P. Influence of water-cement ratio on hydration kinetics: Simple models based on spatial considerations. Cem. Concr. Res. 2006, 36, 238–244. [Google Scholar] [CrossRef]

- He, H.; Stroeven, P.; Stroeven, M.; Sluys, L.J. Influence of particle packing on elastic properties of concrete. Mag. Concr. Res. 2012, 64, 163–175. [Google Scholar] [CrossRef]

- Hobbs, S.V. A Study of Non-Evaporable Water Content in Cement-Based Mixtures with and without Pozzolanic Materials; Cornell University: Ithaca, NY, USA, 2001. [Google Scholar]

- Zeng, Q.; Li, K.; Fen-Chong, T.; Dangla, P. Pore structure characterization of cement pastes blended with high-volume fly-ash. Cem. Concr. Res. 2012, 42, 194–204. [Google Scholar] [CrossRef]

- Abo-Qudais, S.A. Effect of concrete mixing parameters on propagation of ultrasonic waves. Constr. Build. Mater. 2005, 19, 257–263. [Google Scholar] [CrossRef]

- Aggelis, D.; Polyzos, D.; Philippidis, T. Wave dispersion and attenuation in fresh mortar: Theoretical predictions vs. experimental results. J. Mech. Phys. Solids 2005, 53, 857–883. [Google Scholar] [CrossRef]

- Al-Mamoori, S.F.; Shubbar, A.A.; Al-Khafaji, Z.S.; Nasr, M.S.; Alkhayyat, A.; Al-Rifaie, A.; Hashim, K. Production of ternary blend binder as an alternative to portland cement. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2021. [Google Scholar]

- Cheah, C.B.; Chung, K.Y.; Ramli, M.; Lim, G.K. The engineering properties and microstructure development of cement mortar containing high volume of inter-grinded GGBS and PFA cured at ambient temperature. Constr. Build. Mater. 2016, 122, 683–693. [Google Scholar] [CrossRef]

- Shubbar, A.A.; Jafer, H.; Abdulredha, M.; Al-Khafaji, Z.S.; Nasr, M.S.; Al Masoodi, Z.; Sadique, M. Properties of cement mortar incorporated high volume fraction of GGBFS and CKD from 1 day to 550 days. J. Build. Eng. 2020, 30, 101327. [Google Scholar] [CrossRef]

- Wang, H.Y.; Wang, W.C.; Wang, J.C.; Chen, Y.W. Evaluation of the engineering properties and durability of mortar produced using ground granulated blast-furnace slag and stainless steel reduced slag. Constr. Build. Mater. 2021, 280, 122498. [Google Scholar] [CrossRef]

| Author(s) | Mixture Composition | Range of Compressive Strength | %GGBFS | Expression Type | Strength Prediction Model (R2) |

|---|---|---|---|---|---|

| Bogas et al. [20] | Cement Type I 52.R and I 42.5 R with SF and FA, coarse and fine sand (2:1), gravel and light weight aggregates (<12 mm), wc = 0.3–0.65) | 25–90 MPa (7–28 days) | 0% | Power | (R2 = 0.85) |

| Biswas et al. [11] | Cement Type I with SF in dry densified form (2-15%), coarse aggregates (<20 mm), and fine aggregates, wc = 0.36 | 40–75 MPa (7–28 days) | 0% | Exponential | (R2 = 0.79) |

| Najim [8] | Cement Type I, mineral coarse aggregate (<20 mm), natural sand (<4.75 mm), unspecified wc | 25–50 M Pa (28 days) | 0% | Linear | (R2 = 0.70) |

| Trtnik et al. [17] | CEM II/A-S 42.5 R, CEM I 52.5 R, CEM I 42.5 N, and CEM I 42.5 N SR, with crushed limestone and rounded limestone | 0–50 MPa (1–7 days) | 0% | Exponential | (R2 = 0.64) |

| Demirboga et al. [3] | ASTM Type 1 cement with FA and BFS (50-70%), natural aggregates (<16 mm), and w/b = 0.35 | 2–55 MPa (3–120 days) | 50–70% | Exponential | (R2 = 0.96) |

| Le et al. [18] | ASTM Type I OPC, with coarse aggregates (<20 mm), fine aggregates (<5 mm), FA, GGBFS, and sugarcane bagasse ash (SBA), w/b = 0.45 | 20–35 MPa (7–91 days) | 0–60% | Exponential | (R2 = 0.94) |

| Turkmen et al. [19] | ASTM Type 1 OPC, with coarse aggregate (<16 mm), fine aggregate (<4 mm), and cement substitution using either NZ, or BFS, or both, w/b = 0.4 | 5–50 MPa (3–90 days) | 0–30% | Exponential | (R2 = 0.94) |

| Cement | AFS 45/50 Silica Sand | GGBFS | |||

|---|---|---|---|---|---|

| CaO | 63.4% | SiO2 | 99.9% | S | 0.4% |

| SiO2 | 20.1% | Fe2O3 | 0.01% | SO3 | 2.4% |

| Al2O3 | 4.6% | Al2O3 | 0.02% | MgO | 5.7% |

| Fe2O3 | 2.8% | CaO | 0.00% | Al3O3 | 12.6% |

| SO3 | 2.7% | MgO | 0.00% | FeO | 0.8% |

| MgO | 1.3% | Na2O | 0.00% | MnO | 0.1% |

| Na2O | 0.6% | K2O | 0.00% | Cl | 0.01% |

| Total chloride | 0.02% | TiO2 | 0.03% | Insoluble residue content | 0.2% |

| - | - | MnO | <0.001% | - | - |

| Cement | AFS 45/50 Silica Sand | GGBFS | |||

|---|---|---|---|---|---|

| Specific Gravity | 3.15 | Loss on ignition | 0.01 | Specific gravity | 3.0–3.2 |

| Fineness Index | 390 m2/kg | Water content (at 105 °C) | <0.001 | Relative Water Requirement | 103% |

| Normal Consistency | 27% | AFS fineness number | 47.5 | Loss on Ignition | 0.20% |

| Setting Time Initial | 120 min | - | - | Temperature Rise | 18.8 °C |

| Setting Time Final | 210 min | - | - | Fineness (passing 45 μm) | 98% |

| Soundness | 2 mm | - | - | - | - |

| Loss on Ignition | 3.80% | - | - | - | - |

| Fineness (passing 45 μm) | 95.30% | - | - | - | - |

| Sieve Size (μm) | Percentage Passing |

|---|---|

| 1180 | 100 |

| 600 | 91 |

| 300 | 14.8 |

| 150 | 3.1 |

| 75 | 0 |

| Mix | OPC | Sand | Water | GGBFS | Cement Proportion | GGBFS Proportion | Superplasticizer (mL/kg) |

|---|---|---|---|---|---|---|---|

| CM-1 | 1 | 2 * | 0.4 | 0 | 100% | 0% | 2.55 |

| CM-2 | 1 | 2 | 0.5 | 0 | 100% | 0% | 1.48 |

| CM-3 | 1 | 2 | 0.6 | 0 | 100% | 0% | 0 |

| M-1 | 0.85 | 2 | 0.4 | 0.15 | 85% | 15% | 2.94 |

| M-2 | 0.70 | 2 | 0.4 | 0.30 | 70% | 30% | 2.86 |

| M-3 | 0.55 | 2 | 0.4 | 0.45 | 55% | 45% | 3.64 |

| M-4 | 0.85 | 2 | 0.5 | 0.15 | 85% | 15% | 1.76 |

| M-5 | 0.70 | 2 | 0.5 | 0.30 | 70% | 30% | 1.07 |

| M-6 | 0.55 | 2 | 0.5 | 0.45 | 55% | 45% | 0.91 |

| M-7 | 0.85 | 2 | 0.6 | 0.15 | 85% | 15% | 0 |

| M-8 | 0.70 | 2 | 0.6 | 0.30 | 70% | 30% | 0 |

| M-9 | 0.55 | 2 | 0.6 | 0.45 | 55% | 45% | 0 |

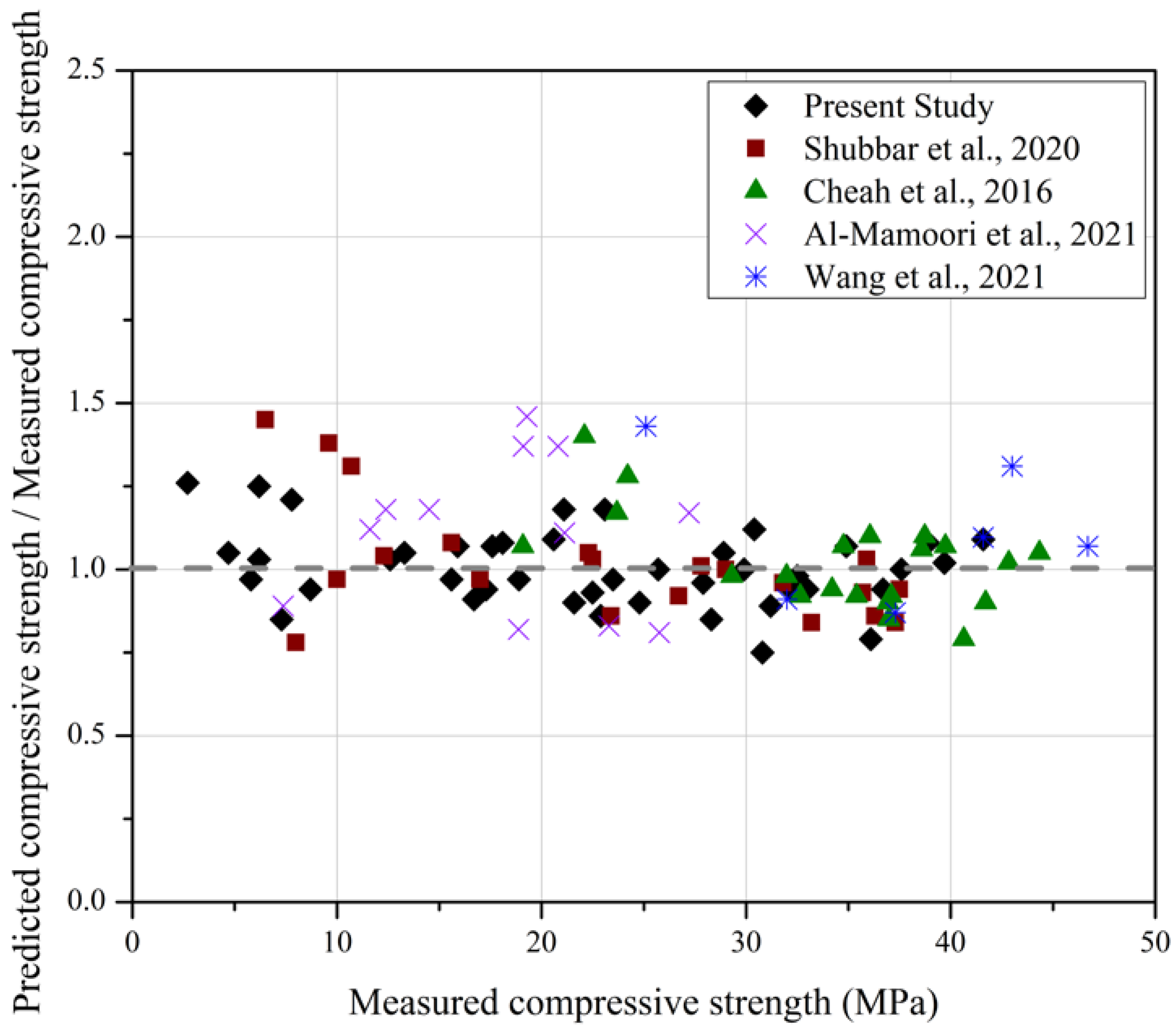

| Concrete Mix Composition | Range of Com-pressive Strength, (MPa) | GGBFS Partial Replacement, s (%) | Specimen Shape and Size | Reference |

|---|---|---|---|---|

| Ordinary Portland cement mortar—partial replacement with GGBFS (10–40%) and CKD (5–25%), fine aggregates (<3.15 mm), wc = 0.4 | Normal strength mortar (5–38 MPa at 1–28 days) | 0–40% | 100 mm cubes | Shubbar et al. [40] |

| Portland limestone cement mortar—partial cement replacement with intergrinded GGBFS (0–80%), and PFA (0–20%), fine aggregates (<5 mm), wc = 0.45 | Normal strength mortar (19–44 MPa at 7–28 days) | 0–80% | 100 mm cubes | Cheah et al. [39] |

| CEM-II / A / LL 32.5-N cement mortar—partial cement replacement with GGBFS (0–35%) and PFA (0–35%), fine aggregates (<4.76 mm), wc = 0.4 | Normal strength mortar (8–32 MPa at 7–28 days) | 0–35% | 100 mm cubes | Al-Mamoori et al. [38] |

| ASTM Type 1 cement mortar—partial cement replacement with GGBFS (0–20%) and SSRS (5–20%), fine aggregates (<4.75 mm), wc = 0.5 | High strength mortar (25–63 MPa at 3–56 days) | 0–20% | 50 mm cubes | Wang et al. [41] |

| a | b | wc | s (%GGBFS) | R2 |

|---|---|---|---|---|

| 0.2114 | 0.0012 | 0.4 | 15 | 0.939 |

| 0.0243 | 0.0017 | 30 | 0.995 | |

| 0.0124 | 0.0019 | 45 | 0.968 | |

| 0.0518 | 0.0016 | 0.5 | 15 | 0.985 |

| 0.0191 | 0.0019 | 30 | 0.976 | |

| 0.0190 | 0.0019 | 45 | 0.989 | |

| 0.0521 | 0.0017 | 0.6 | 15 | 0.993 |

| 0.0232 | 0.0019 | 30 | 0.903 | |

| 0.0210 | 0.0020 | 45 | 0.976 | |

| 0.2982 | 0.0012 | 0.4–0.6 | 0 | 0.900 |

| Source of Variation | SS | MS | F-Value | p-Value |

|---|---|---|---|---|

| t (days) | 5749.14 | 5749.14 | 51.22 | 0 |

| Vp (m/s) | 398,365,031.60 | 398,365,031.60 | 6002.57 | 0 |

| s (%) | 137.82 | 137.82 | 0.66 | 0.42 |

| wc | 17,487.02 | 17,487.02 | 268.309 | 0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Loke, C.K.; Lehane, B.; Aslani, F.; Majhi, S.; Mukherjee, A. Non-Destructive Evaluation of Mortar with Ground Granulated Blast Furnace Slag Blended Cement Using Ultrasonic Pulse Velocity. Materials 2022, 15, 6957. https://doi.org/10.3390/ma15196957

Loke CK, Lehane B, Aslani F, Majhi S, Mukherjee A. Non-Destructive Evaluation of Mortar with Ground Granulated Blast Furnace Slag Blended Cement Using Ultrasonic Pulse Velocity. Materials. 2022; 15(19):6957. https://doi.org/10.3390/ma15196957

Chicago/Turabian StyleLoke, Chi Kang, Barry Lehane, Farhad Aslani, Subhra Majhi, and Abhijit Mukherjee. 2022. "Non-Destructive Evaluation of Mortar with Ground Granulated Blast Furnace Slag Blended Cement Using Ultrasonic Pulse Velocity" Materials 15, no. 19: 6957. https://doi.org/10.3390/ma15196957

APA StyleLoke, C. K., Lehane, B., Aslani, F., Majhi, S., & Mukherjee, A. (2022). Non-Destructive Evaluation of Mortar with Ground Granulated Blast Furnace Slag Blended Cement Using Ultrasonic Pulse Velocity. Materials, 15(19), 6957. https://doi.org/10.3390/ma15196957