Prediction of Mechanical Properties of Highly Functional Lightweight Fiber-Reinforced Concrete Based on Deep Neural Network and Ensemble Regression Trees Methods

Abstract

:1. Introduction

- -

- Revealing the fundamental possibility of predicting the properties of lightweight fiber-reinforced concrete using artificial intelligence methods.

- -

- Determination of the quantitative and qualitative picture of the relationship between the initial data of the formulation and technology and the output parameters expressed in the properties of concrete.

- -

- The fundamental basis of structure formation and the formation of concrete properties, presented for the analysis of the constructed neural network and the issuance of applied forecasts to it on the operational characteristics of concrete.

- -

- Proof of the possibility of neural network control of the structure and properties of concrete and analysis of complex relationships that were previously inaccessible through the manual method.

- -

- Review and analysis of existing literature in the areas of improving the quality of the concrete industry and the introduction of new management and quality control systems in production, as well as a review of existing authors’ methods for the application of artificial intelligence methods in the concrete industry and manufacturing enterprises in general.

- -

- Selection of an empirical base built on physical experiments and accumulated experience with the results of testing concretes and the mutual dependencies between the input parameters of the initial components and the technological and output parameters of the resulting concretes established by us and other authors.

- -

- After processing and applying the data of a physical experiment, it is necessary to develop, train, and test a deep neural network, as well as apply an ensemble model of regression trees to process the empirical base with a further comparison of the results based on the values of the main metrics.

- -

- Evaluate the prospects of applying the developed methods in practice and evaluate the possibility of translating and projecting the results obtained to other types of concrete, as well as developing specific proposals for the construction industry.

2. Materials and Methods

2.1. Materials

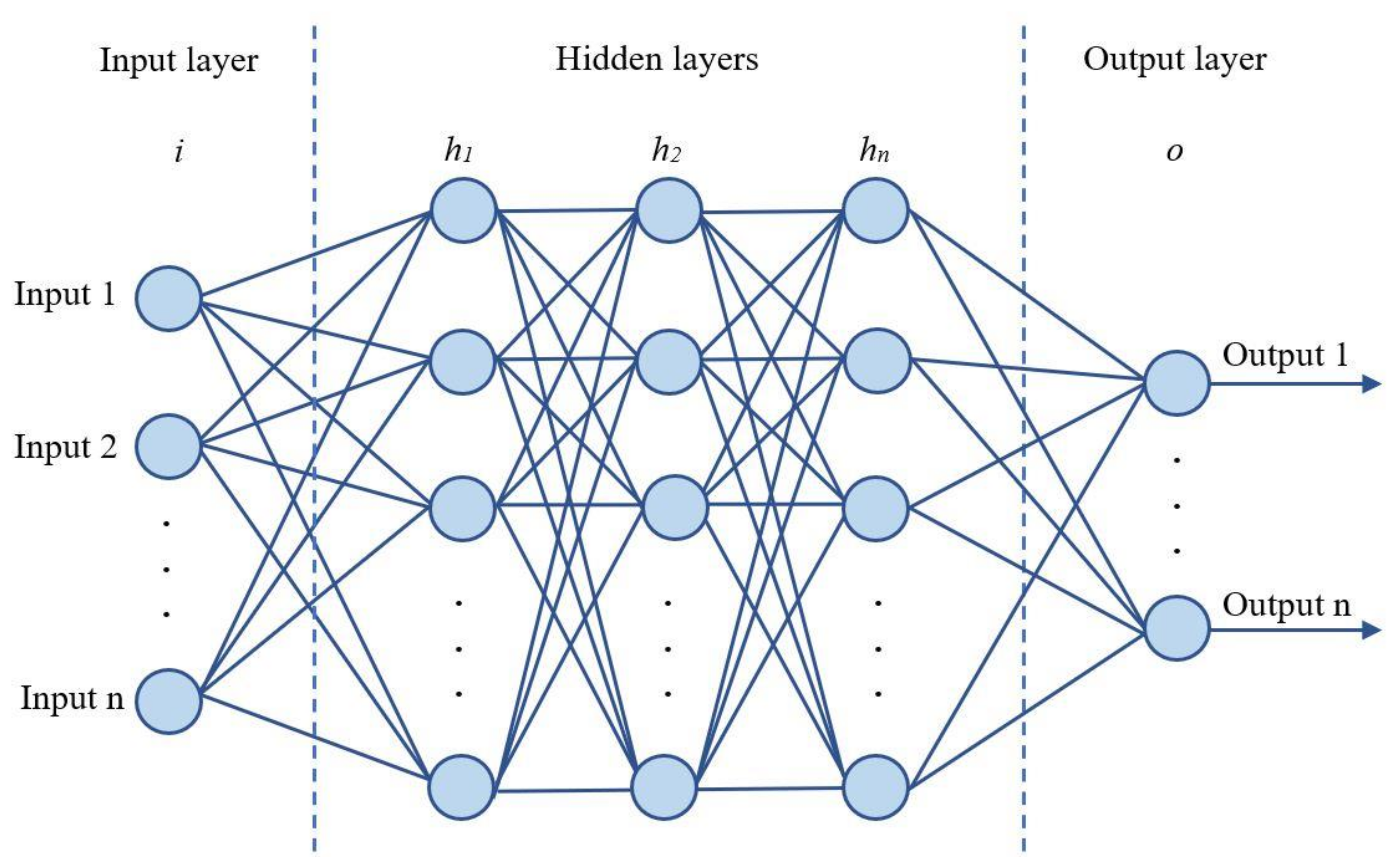

2.2. Deep Learning

2.3. Ensemble of Regression Trees

3. Results

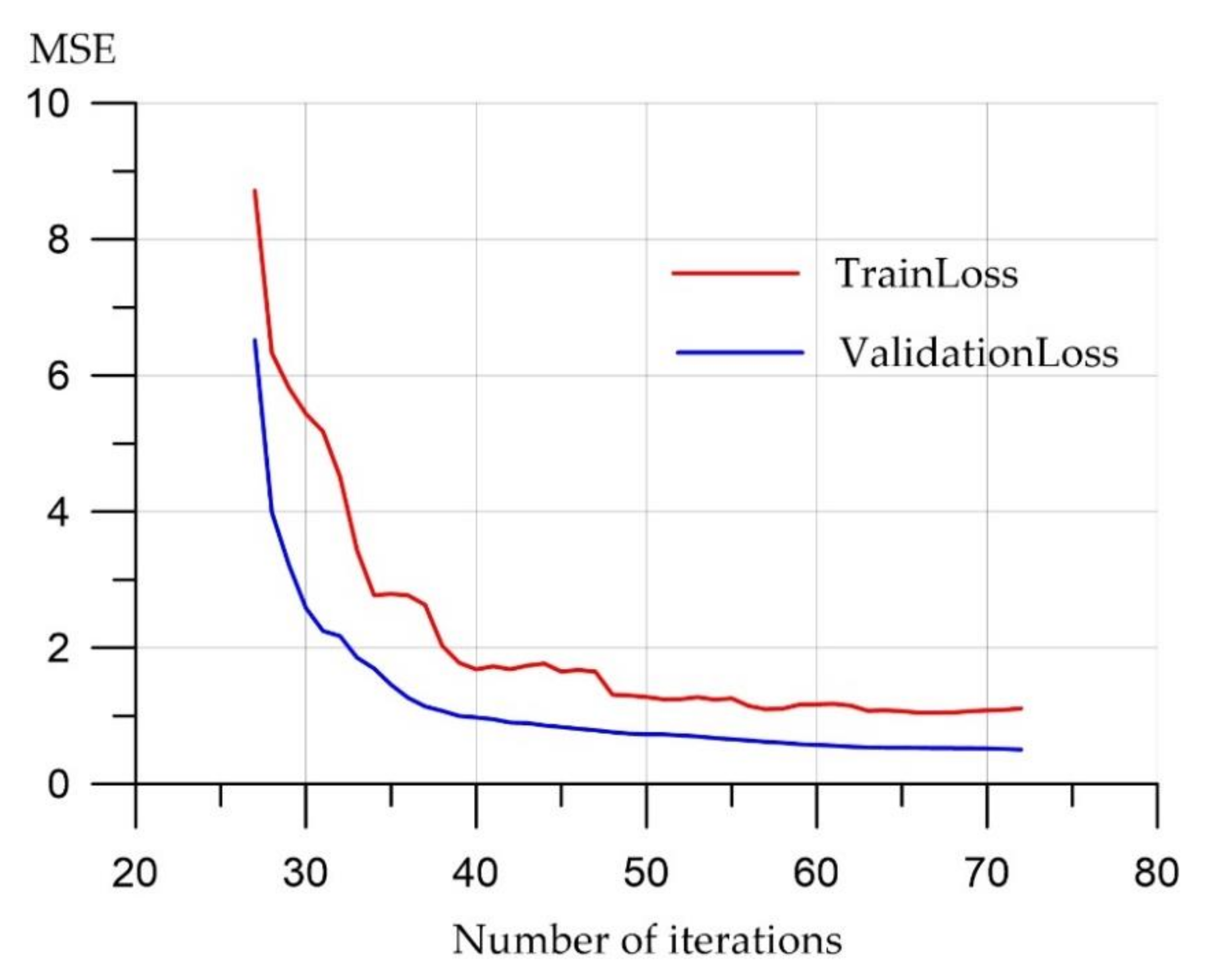

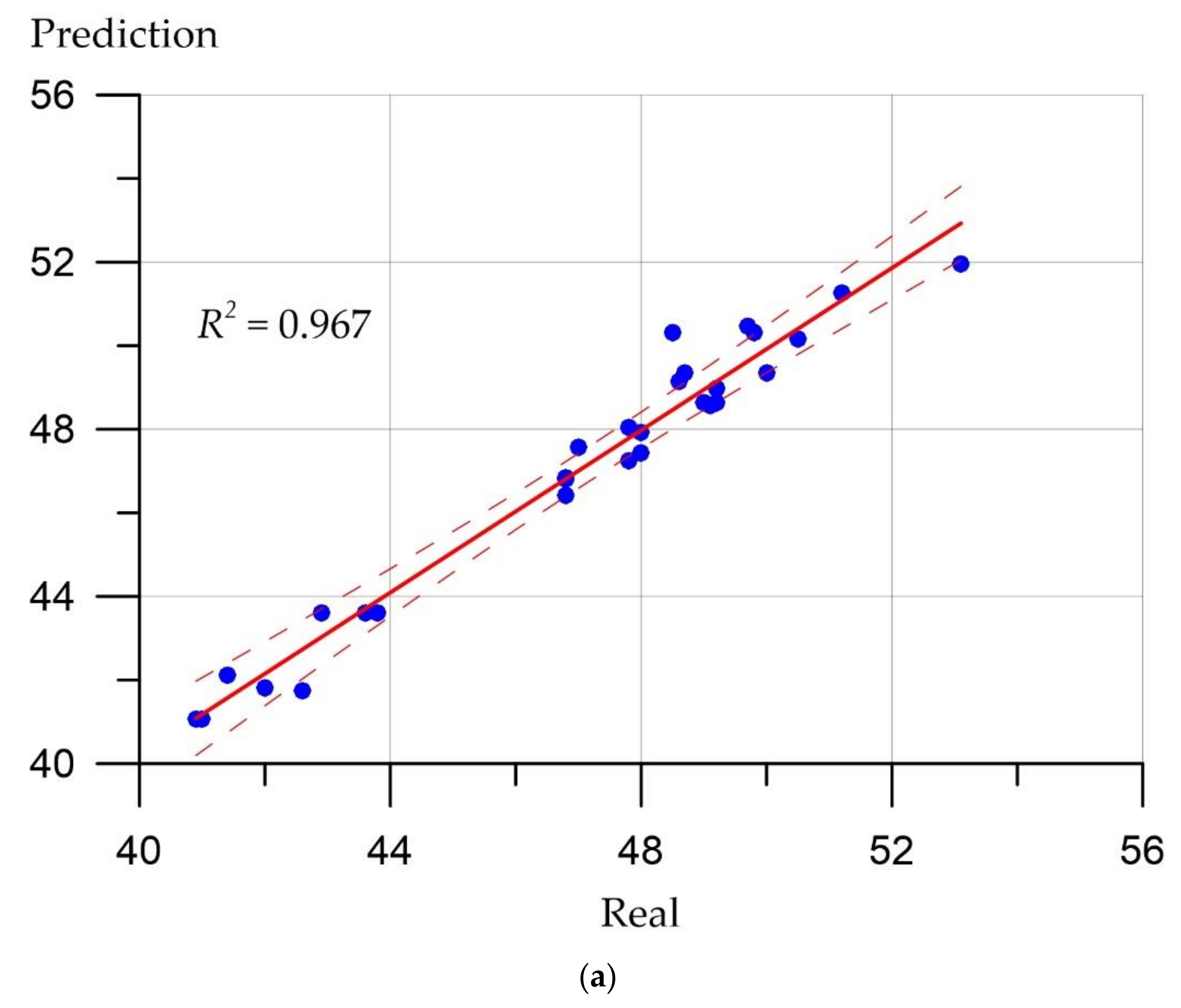

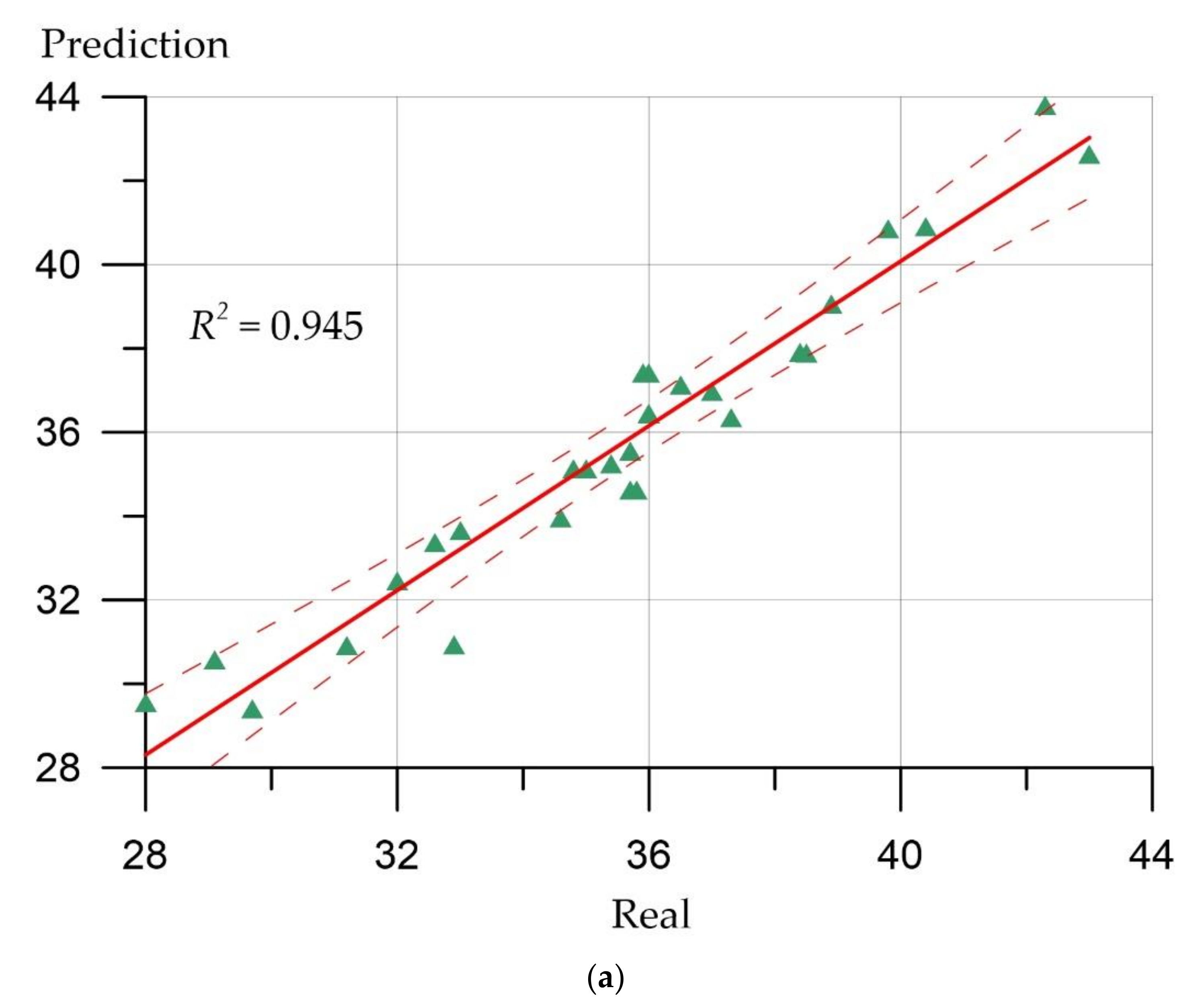

3.1. Results for a Deep Neural Network

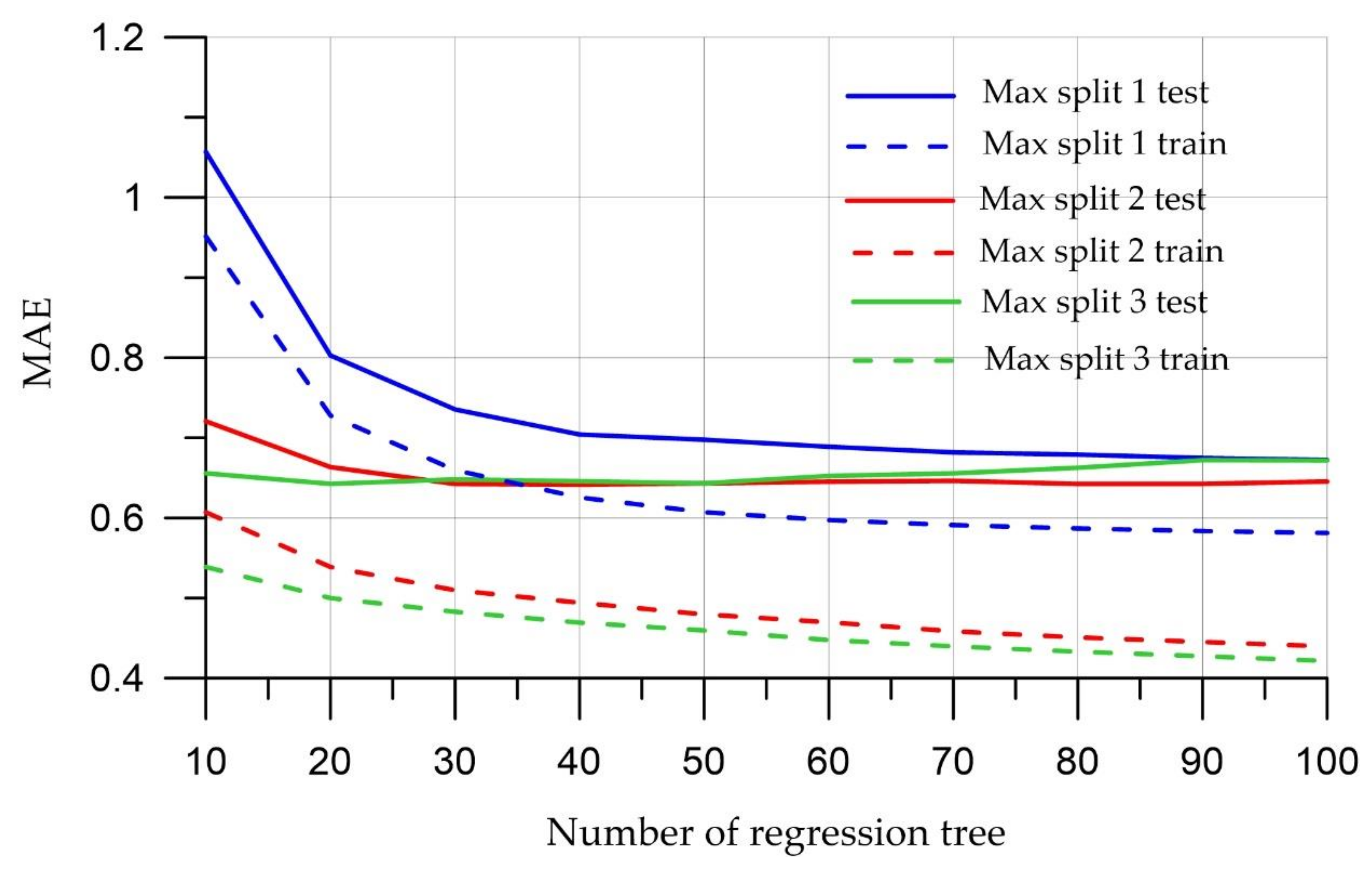

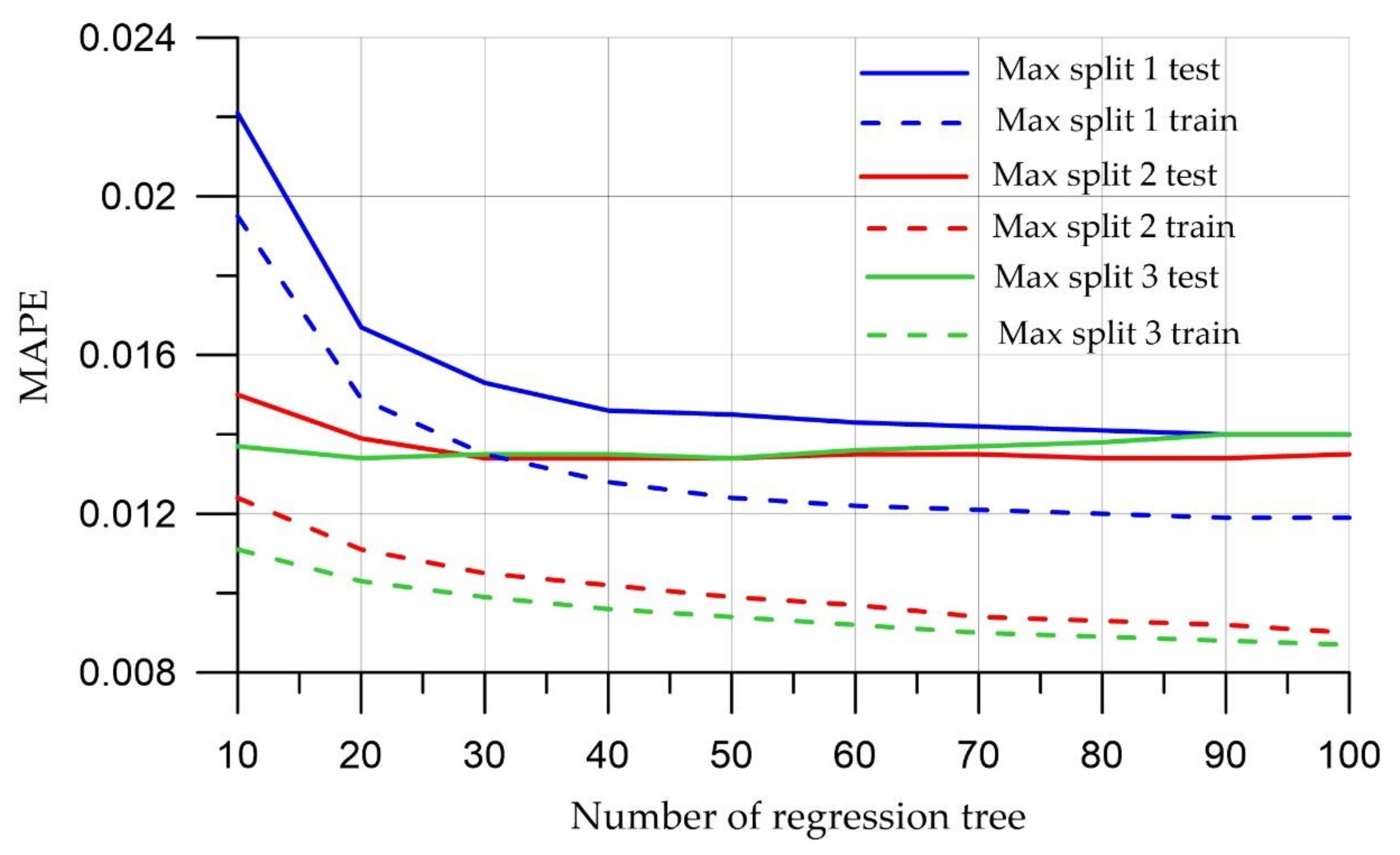

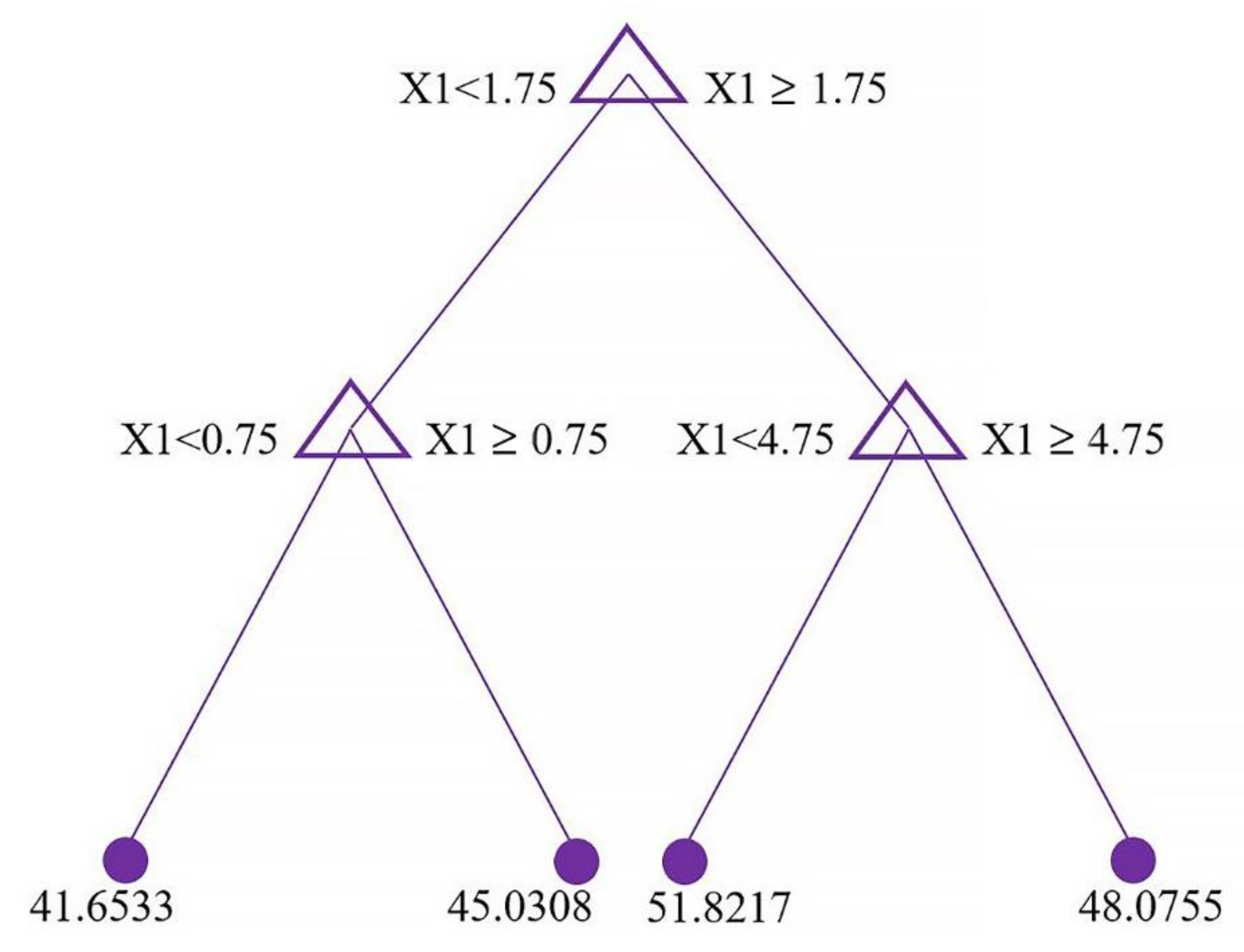

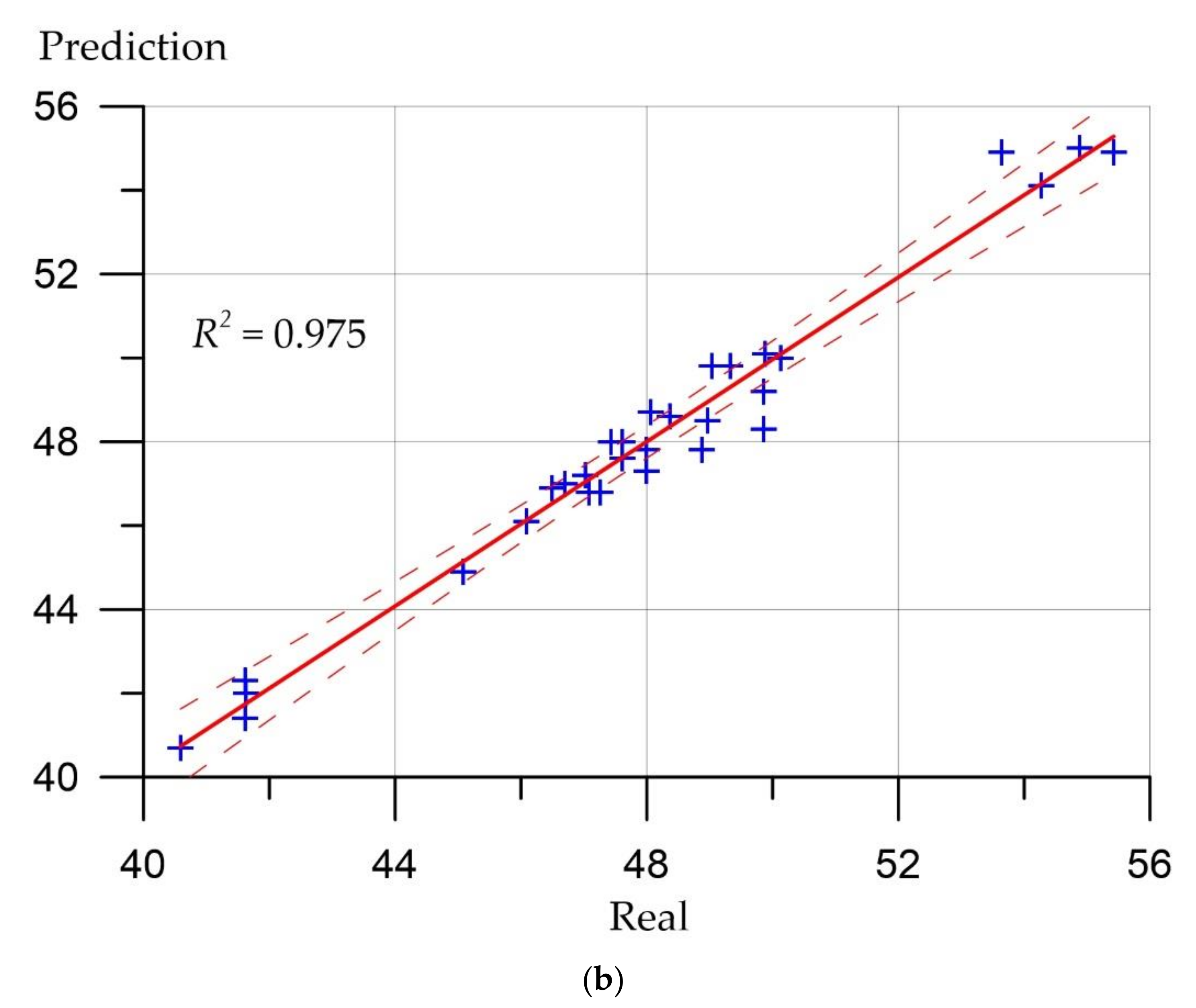

3.2. Results for an Ensemble of Regression Trees

4. Discussion

5. Conclusions

- (1)

- Deep neural network and ensemble regression trees methods can be applied to determine the mechanical properties of highly functional lightweight fiber-reinforced concrete.

- (2)

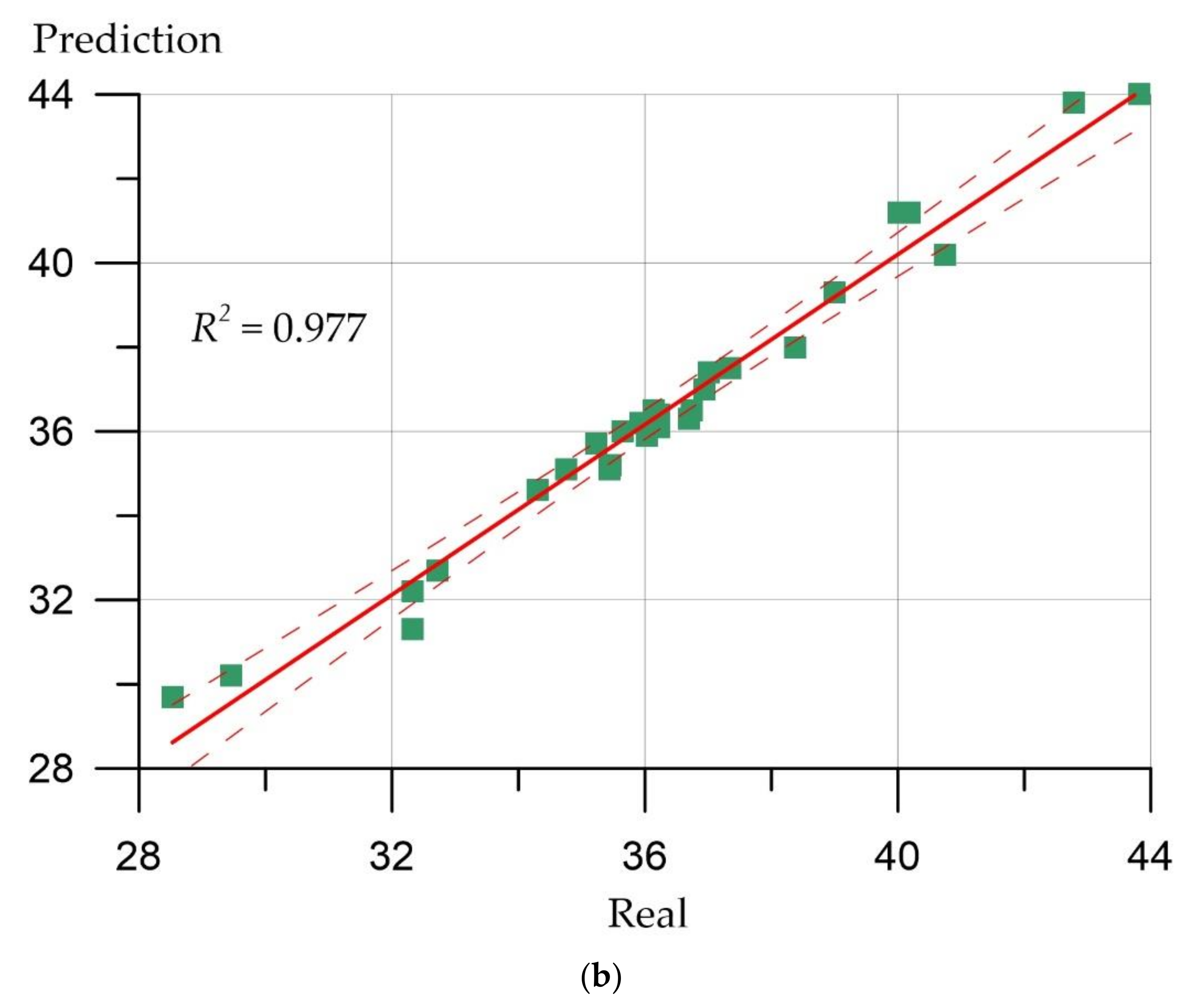

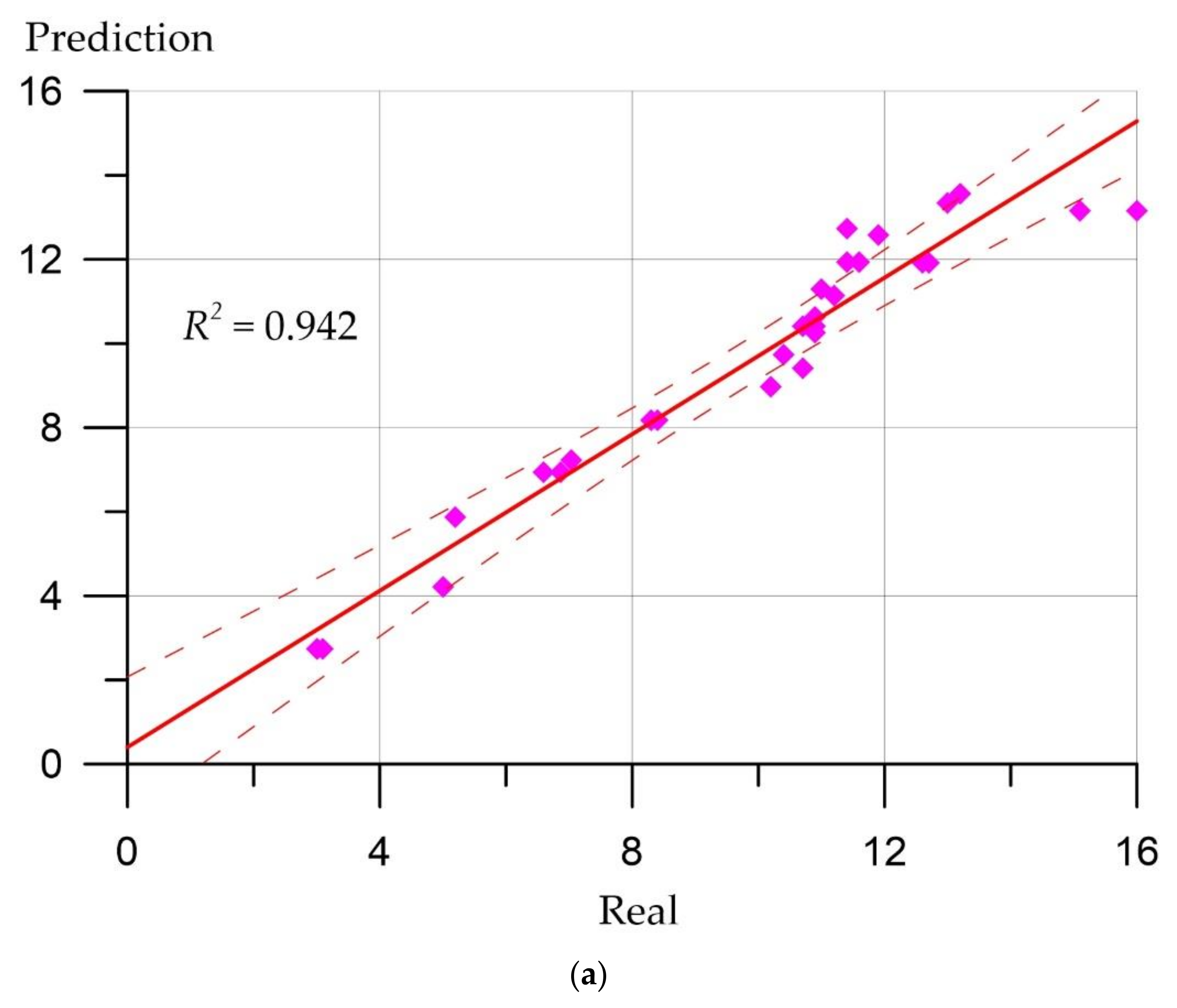

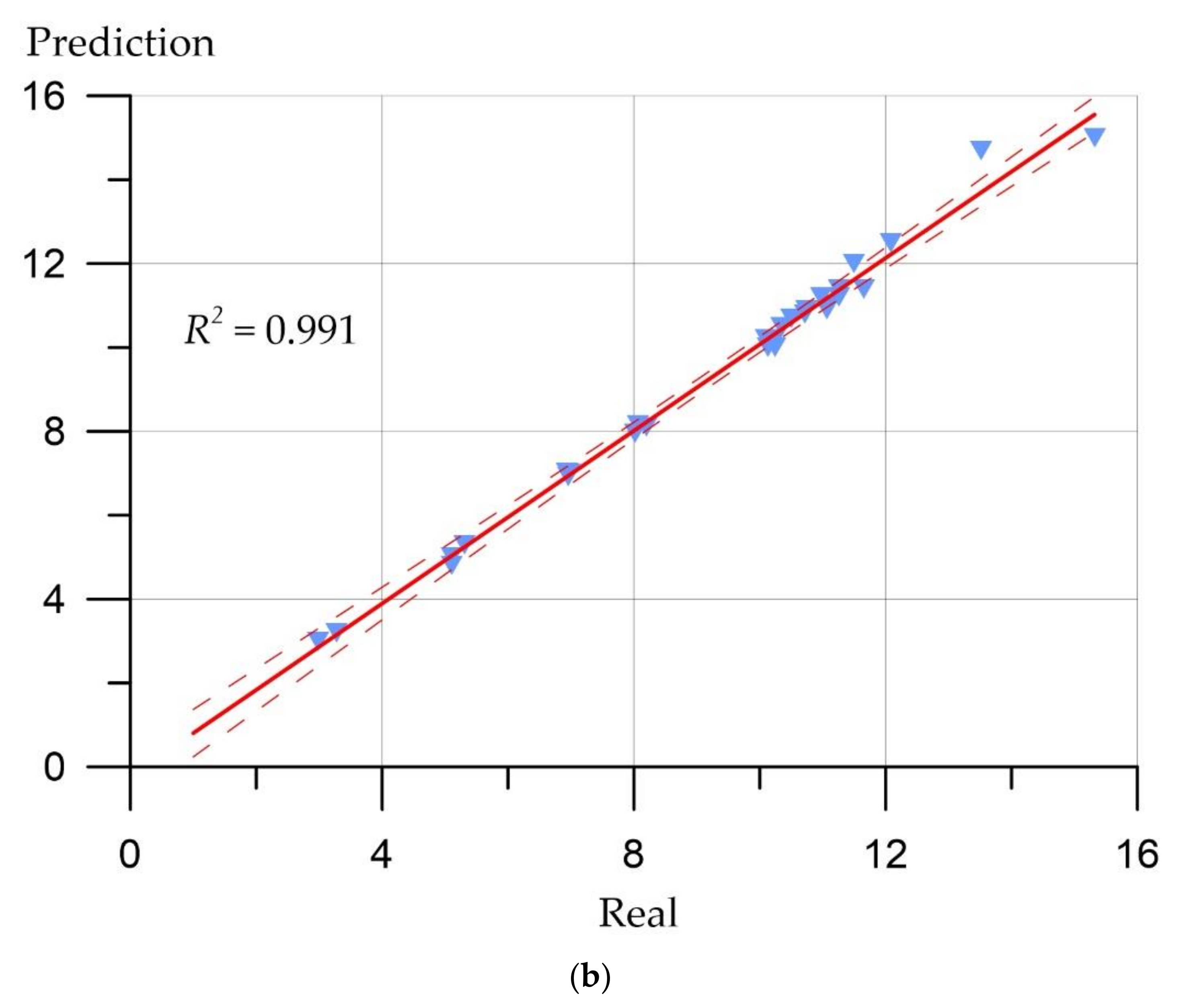

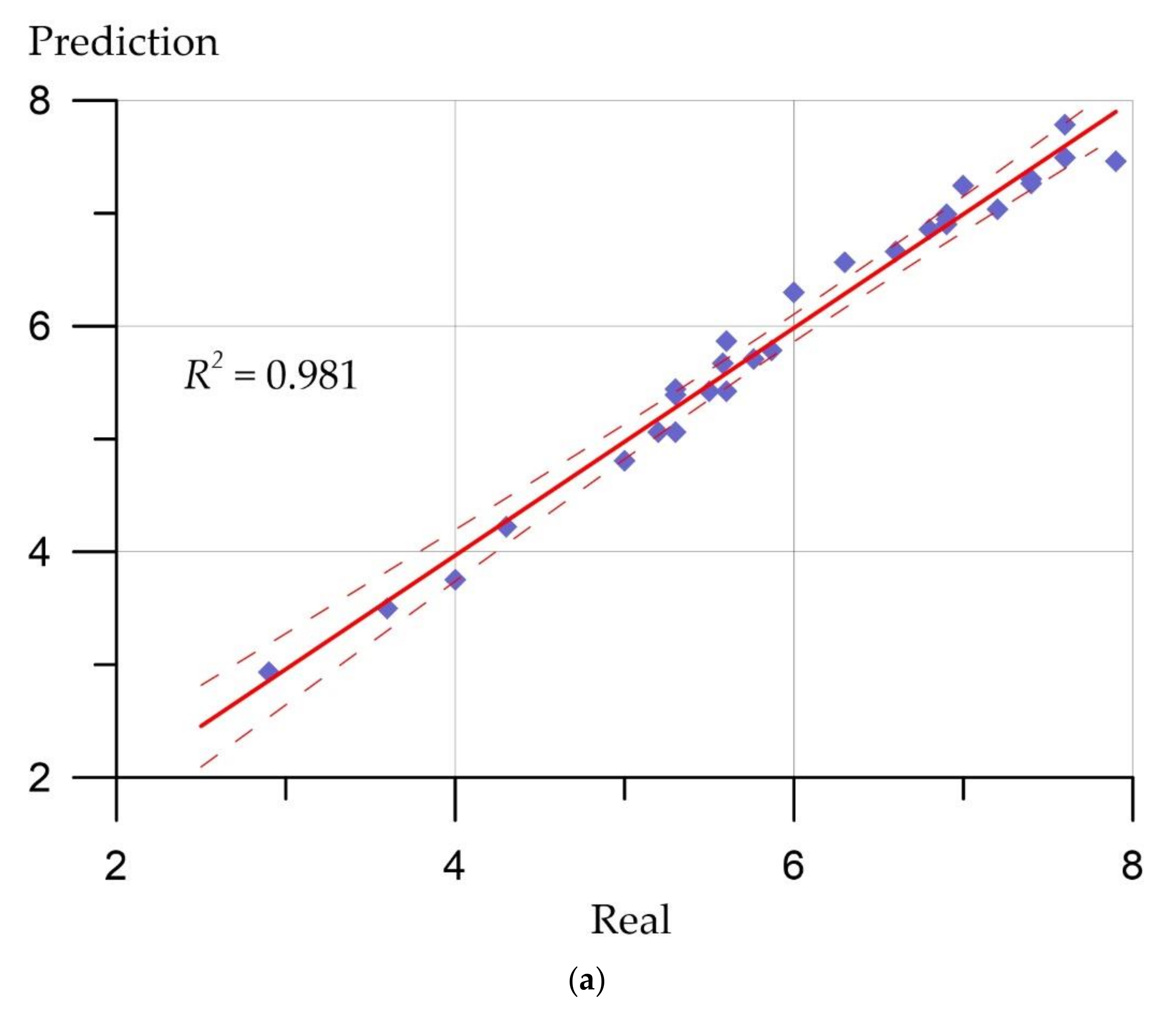

- The developed models are adequate since the distribution of points on the graphs has no patterns and looks like a random scatter of points around zero. The coefficient of determination shows values from 0.94 to 0.99, which indicates a high correspondence of the model to the data.

- (3)

- The ensemble method of regression trees in this implementation demonstrated the best values of metrics compared to the neural network, since it is a more complex algorithm in terms of the number of parameters compared to the neural network. Therefore, the ensemble method of regression trees had more opportunities to adjust to the data.

- (4)

- The quantitative picture of the accuracy of the applied methods for strength characteristics varies: For the deep neural network method, it was from 0.15 to 0.73 (MAE), from 0.17 to 0.89 (RMSE), and from 0.98% to 6.62% (MAPE), and for the ensemble of regression trees, it was from 0.11 to 0.62 (MAE), from 0.15 to 0.80 (RMSE), and from 1.30% to 3.4% (MAPE). Both methods have shown fairly high efficiency in relation to such a hard-to-predict material as concrete, which is very heterogeneous in structure and depends on a large number of factors.

- (5)

- The result obtained in the form of a developed neural network for predicting the properties of lightweight fiber-reinforced concrete allows us to establish the fundamental role of the initial factors, namely the amount of fiber and the method of distribution of fibers in the formation of output parameters—the strength properties of fiber-reinforced concrete. Thus, with the help of the considered methods of artificial intelligence, the role of specific recipe-technological factors, which were previously evaluated only from the point of view of traditional recipes and technology, is revealed. Thus, artificial intelligence methods for building a neural network made it possible to reveal, establish, and manage this fundamental relationship, strengthening the role of the control technologist in the formation and prediction of the properties of specific building materials.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shah, H.A.; Yuan, Q.; Akmal, U.; Shah, S.A.; Salmi, A.; Awad, Y.A.; Shah, L.A.; Iftikhar, Y.; Javed, M.H.; Khan, M.I. Application of Machine Learning Techniques for Predicting Compressive, Splitting Tensile, and Flexural Strengths of Concrete with Metakaolin. Materials 2022, 15, 5435. [Google Scholar] [CrossRef] [PubMed]

- Amin, M.N.; Ahmad, A.; Khan, K.; Ahmad, W.; Ehsan, S.; Alabdullah, A.A. Predicting the Rheological Properties of Super-Plasticized Concrete Using Modeling Techniques. Materials 2022, 15, 5208. [Google Scholar] [CrossRef] [PubMed]

- Dai, L.; Wu, X.; Zhou, M.; Ahmad, W.; Ali, M.; Sabri, M.M.S.; Salmi, A.; Ewais, D.Y.Z. Using Machine Learning Algorithms to Estimate the Compressive Property of High Strength Fiber Reinforced Concrete. Materials 2022, 15, 4450. [Google Scholar] [CrossRef] [PubMed]

- De-Prado-Gil, J.; Zaid, O.; Palencia, C.; Martínez-García, R. Prediction of Splitting Tensile Strength of Self-Compacting Recycled Aggregate Concrete Using Novel Deep Learning Methods. Mathematics 2022, 10, 2245. [Google Scholar] [CrossRef]

- Chen, H.; Sun, Z.; Zhong, Z.; Huang, Y. Fatigue Factor Assessment and Life Prediction of Concrete Based on Bayesian Regularized BP Neural Network. Materials 2022, 15, 4491. [Google Scholar] [CrossRef]

- Candelaria, M.D.E.; Kee, S.-H.; Lee, K.-S. Prediction of Compressive Strength of Partially Saturated Concrete Using Machine Learning Methods. Materials 2022, 15, 1662. [Google Scholar] [CrossRef] [PubMed]

- Ngo, T.Q.L.; Wang, Y.-R.; Chiang, D.-L. Applying Artificial Intelligence to Improve On-Site Non-Destructive Concrete Compressive Strength Tests. Crystals 2021, 11, 1157. [Google Scholar] [CrossRef]

- Shen, Y.; Sun, J.; Liang, S. Interpretable Machine Learning Models for Punching Shear Strength Estimation of FRP Reinforced Concrete Slabs. Crystals 2022, 12, 259. [Google Scholar] [CrossRef]

- Ahmad, A.; Ostrowski, K.A.; Maślak, M.; Farooq, F.; Mehmood, I.; Nafees, A. Comparative Study of Supervised Machine Learning Algorithms for Predicting the Compressive Strength of Concrete at High Temperature. Materials 2021, 14, 4222. [Google Scholar] [CrossRef]

- Kekez, S.; Kubica, J. Application of Artificial Neural Networks for Prediction of Mechanical Properties of CNT/CNF Reinforced Concrete. Materials 2021, 14, 5637. [Google Scholar] [CrossRef]

- Song, H.; Ahmad, A.; Ostrowski, K.A.; Dudek, M. Analyzing the Compressive Strength of Ceramic Waste-Based Concrete Using Experiment and Artificial Neural Network (ANN) Approach. Materials 2021, 14, 4518. [Google Scholar] [CrossRef]

- Tosee, S.V.R.; Faridmehr, I.; Bedon, C.; Sadowski, Ł.; Aalimahmoody, N.; Nikoo, M.; Nowobilski, T. Metaheuristic Prediction of the Compressive Strength of Environmentally Friendly Concrete Modified with Eggshell Powder Using the Hybrid ANN-SFL Optimization Algorithm. Materials 2021, 14, 6172. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, A.; Ahmad, W.; Chaiyasarn, K.; Ostrowski, K.A.; Aslam, F.; Zajdel, P.; Joyklad, P. Prediction of Geopolymer Concrete Compressive Strength Using Novel Machine Learning Algorithms. Polymers 2021, 13, 3389. [Google Scholar] [CrossRef] [PubMed]

- Anysz, H.; Narloch, P. Designing the Composition of Cement Stabilized Rammed Earth Using Artificial Neural Networks. Materials 2019, 12, 1396. [Google Scholar] [CrossRef] [PubMed]

- Beskopylny, A.; Lyapin, A.; Anysz, H.; Meskhi, B.; Veremeenko, A.; Mozgovoy, A. Artificial Neural Networks in Classification of Steel Grades Based on Non-Destructive Tests. Materials 2020, 13, 2445. [Google Scholar] [CrossRef]

- Amiri, M.; Hatami, F. Prediction of mechanical and durability characteristics of concrete including slag and recycled aggregate concrete with artificial neural networks (ANNs). Constr. Build. Mater. 2022, 325, 126839. [Google Scholar] [CrossRef]

- Ahmad, A.; Elchalakani, M.; Elmesalami, N.; El Refai, A.; Abed, F. Reliability analysis of strength models for short-concrete columns under concentric loading with FRP rebars through Artificial Neural Network. J. Build. Eng. 2021, 42, 102497. [Google Scholar] [CrossRef]

- Naderpour, H.; Rafiean, A.H.; Fakharian, P. Compressive strength prediction of environmentally friendly concrete using artificial neural networks. J. Build. Eng. 2018, 16, 213–219. [Google Scholar] [CrossRef]

- Ganasan, R.; Tan, C.G.; Ibrahim, Z.; Nazri, F.M.; Sherif, M.M.; El-Shafie, A. Development of Crack Width Prediction Models for RC Beam-Column Joint Subjected to Lateral Cyclic Loading Using Machine Learning. Appl. Sci. 2021, 11, 7700. [Google Scholar] [CrossRef]

- Nafees, A.; Javed, M.F.; Khan, S.; Nazir, K.; Farooq, F.; Aslam, F.; Musarat, M.A.; Vatin, N.I. Predictive Modeling of Mechanical Properties of Silica Fume-Based Green Concrete Using Artificial Intelligence Approaches: MLPNN, ANFIS, and GEP. Materials 2021, 14, 7531. [Google Scholar] [CrossRef]

- Barkhordari, M.S.; Armaghani, D.J.; Mohammed, A.S.; Ulrikh, D.V. Data-Driven Compressive Strength Prediction of Fly Ash Concrete Using Ensemble Learner Algorithms. Buildings 2022, 12, 132. [Google Scholar] [CrossRef]

- Lyu, Z.; Yu, Y.; Samali, B.; Rashidi, M.; Mohammadi, M.; Nguyen, T.N.; Nguyen, A. Back-Propagation Neural Network Optimized by K-Fold Cross-Validation for Prediction of Torsional Strength of Reinforced Concrete Beam. Materials 2022, 15, 1477. [Google Scholar] [CrossRef] [PubMed]

- Sun, J.; Wang, J.; Zhu, Z.; He, R.; Peng, C.; Zhang, C.; Huang, J.; Wang, Y.; Wang, X. Mechanical Performance Prediction for Sustainable High-Strength Concrete Using Bio-Inspired Neural Network. Buildings 2022, 12, 65. [Google Scholar] [CrossRef]

- Feng, W.; Wang, Y.; Sun, J.; Tang, Y.; Wu, D.; Jiang, Z.; Wang, J.; Wang, X. Prediction of thermo-mechanical properties of rubber-modified recycled aggregate concrete. Constr. Build. Mater. 2022, 318, 125970. [Google Scholar] [CrossRef]

- Mesfin, W.M.; Cho, S.; Lee, J.; Kim, H.-K.; Kim, T. Deep-Learning-Based Segmentation of Fresh or Young Concrete Sections from Images of Construction Sites. Materials 2021, 14, 6311. [Google Scholar] [CrossRef] [PubMed]

- Vu, G.; Timothy, J.J.; Singh, D.S.; Saydak, L.A.; Saenger, E.H.; Meschke, G. Numerical Simulation-Based Damage Identification in Concrete. Modelling 2021, 2, 355–369. [Google Scholar] [CrossRef]

- Wei, W.; Ding, L.; Luo, H.; Li, C.; Li, G. Automated bughole detection and quality performance assessment of concrete using image processing and deep convolutional neural networks. Constr. Build. Mater. 2021, 281, 122576. [Google Scholar] [CrossRef]

- Ni, H.-G.; Wang, J.-Z. Prediction of compressive strength of concrete by neural networks. Cem. Concr. Res. 2000, 30, 1245–1250. [Google Scholar] [CrossRef]

- Khokhar, S.A.; Ahmed, T.; Khushnood, R.A.; Ali, S.M.; Shahnawaz. A Predictive Mimicker of Fracture Behavior in Fiber Reinforced Concrete Using Machine Learning. Materials 2021, 14, 7669. [Google Scholar] [CrossRef]

- Isleem, H.F.; Tayeh, B.A.; Alaloul, W.S.; Musarat, M.A.; Raza, A. Artificial Neural Network (ANN) and Finite Element (FEM) Models for GFRP-Reinforced Concrete Columns under Axial Compression. Materials 2021, 14, 7172. [Google Scholar] [CrossRef] [PubMed]

- Zhou, M.; Wu, Z.; Ouyang, X.; Hu, X.; Shi, C. Mixture design methods for ultra-high-performance concrete—A review. Cem. Concr. Res. 2021, 124, 104242. [Google Scholar] [CrossRef]

- Suescum-Morales, D.; Salas-Morera, L.; Jiménez, J.R.; García-Hernández, L. A Novel Artificial Neural Network to Predict Compressive Strength of Recycled Aggregate Concrete. Appl. Sci. 2021, 11, 11077. [Google Scholar] [CrossRef]

- Xue, J.; Shao, J.F.; Burlion, N. Estimation of constituent properties of concrete materials with an artificial neural network based method. Cem. Concr. Res. 2021, 150, 106614. [Google Scholar] [CrossRef]

- Kurpińska, M.; Kułak, L.; Miruszewski, T.; Byczuk, M. Application of Artificial Neural Networks to Predict Insulation Properties of Lightweight Concrete. Appl. Sci. 2021, 11, 10544. [Google Scholar] [CrossRef]

- Yoon, J.Y.; Kim, H.; Lee, Y.-J.; Sim, S.-H. Prediction Model for Mechanical Properties of Lightweight Aggregate Concrete Using Artificial Neural Network. Materials 2019, 12, 2678. [Google Scholar] [CrossRef] [PubMed]

- Mailyan, L.R.; Beskopylny, A.N.; Meskhi, B.; Stel’makh, S.A.; Shcherban, E.M.; Ananova, O. Optimization of Composition and Technological Factors for the Lightweight Fiber-Reinforced Concrete Production on a Combined Aggregate with an Increased Coefficient of Structural Quality. Appl. Sci. 2021, 11, 7284. [Google Scholar] [CrossRef]

- Shcherban’, E.M.; Stel’makh, S.A.; Beskopylny, A.; Mailyan, L.R.; Meskhi, B.; Varavka, V. Nanomodification of Lightweight Fiber Reinforced Concrete with Micro Silica and Its Influence on the Constructive Quality Coefficient. Materials 2021, 14, 7347. [Google Scholar] [CrossRef]

- Shcherban’, E.M.; Stel’makh, S.A.; Beskopylny, A.; Mailyan, L.R.; Meskhi, B.; Shuyskiy, A. Improvement of Strength and Strain Characteristics of Lightweight Fiber Concrete by Electromagnetic Activation in a Vortex Layer Apparatus. Appl. Sci. 2022, 12, 104. [Google Scholar] [CrossRef]

- Stel’makh, S.A.; Shcherban’, E.M.; Beskopylny, A.N.; Mailyan, L.R.; Meskhi, B.; Butko, D.; Smolyanichenko, A.S. Influence of Composition and Technological Factors on Variatropic Efficiency and Constructive Quality Coefficients of Lightweight Vibro-Centrifuged Concrete with Alkalized Mixing Water. Appl. Sci. 2021, 11, 9293. [Google Scholar] [CrossRef]

- Mailyan, L.R.; Stel’makh, S.A.; Shcherban’, E.M.; Stroev, D.A. Selection of a rational formulation of lightened concretes on combined aggregates. J. Phys. Conf. Ser. 2021, 2124, 012017. [Google Scholar] [CrossRef]

- Stel’makh, S.A.; Shcherban’, E.M.; Beskopylny, A.; Mailyan, L.R.; Meskhi, B.; Varavka, V. Quantitative and Qualitative Aspects of Composite Action of Concrete and Dispersion-Reinforcing Fiber. Polymers 2022, 14, 682. [Google Scholar] [CrossRef] [PubMed]

- GOST 10180 Concretes. Methods for Strength Determination Using Reference Specimens. Available online: http://docs.cntd.ru/document/1200100908 (accessed on 1 April 2021).

- GOST 24452 Concretes. Methods of Prismatic Compressive Strength, Modulus of Elasticity and Poisson’s Ratio Determination. Available online: https://docs.cntd.ru/document/9056198 (accessed on 1 April 2021).

- Rosellini, W.; D’Haese, P.-F. Data is Driving the Future of Neurotargeting with CranialCloud. ONdrugDelivery Mag. 2017, 81, 44–47. [Google Scholar]

- Møller, M.F. A scaled conjugate gradient algorithm for fast supervised learning. Neural Netw. 1993, 6, 525–533. [Google Scholar] [CrossRef]

- Tkalich, S.A.; Taratynov, O.Y. Durability prognostication of ferroconcrete structures on the basis of neural indistinct networks. IOP Conf. Ser. Mater. Sci. Eng. 2019, 537, 22038. [Google Scholar] [CrossRef]

| Reference Number | Methods | Materials | Parameters | Objectives | |

| Input | Variable | ||||

| [6] | Support vector machine (SVM) Gaussian process regression, ANN | Concrete | P- and S-wave velocities, electrical resistivity, density, water-to-binder ratio | Compressive strength | Recommendation of a set of criteria for evaluating the compressive strength of concrete in a marine environment with various saturation and salinity conditions |

| [7] | SVM, Adaptive neural fuzzy inference system (ANFIS), ANN | Concrete | Results from the two non–destructive testing tests | Compressive strength | Using non-destructive testing to improve concrete strength estimation by aI predictive models |

| [8] | Decision tree (DT) Ensemble ML (boosting, Ada Boost) | Fiber reinforced polymer (FRP) | Database of 121 groups of experimental results | Punching shear strength | Build machine learning models to accurately predict the punching shear strength of FRP reinforced concrete slabs |

| [9] | DT, ANN, Gradient boosting | Concrete | Water, cement, coarse aggregate, fine aggregate, fly ash, microsilica, superplasticizers, nanosilica, temperature | Compressive strength | High temperature compressive strength prediction |

| [10] | ANN | Self-sensing concrete, carbon nanotubes/carbon nanofibers (CNT/CNF) reinforced concrete | Parameters of the composition of the concrete mixture | Compressive strength, flexural strength | Approximation of the ANN approach to a range of specific researchers and possible implementation of ANN in civil engineering practice |

| [11] | ANN, DT | Concrete in fresh and hardened states | Dosage of ceramic waste powder 10% and 20% | Compressive strength | Application of ANN and DT to predict compressive strength of concrete containing CWP |

| [13] | ANN, boosting, Ada Boost ML | Geopolymer concrete (GPC) | Parameters of the composition of the concrete mixture | Compressive strength | Using ANN, Boosting and AdaBoost ML approaches based on Python coding to predict the compressive strength of high calcium fly ash based GPCs |

| [17] | ANN | Fiber-reinforced polymers—short concrete columns | Column length, modulus of elasticity of fiberglass, compressive strength of concrete, coefficients of longitudinal and transverse reinforcement, ultimate axial load | Load carrying capacity | Forecasting the bearing capacity of fiberglass short concrete columns |

| [21] | Separate stacking ensemble with the random forest algorithm (SSE-Random Forest) SSE-Bagging, Integrated stacking ensemble (ISE), weighted averaging ensemble (WAE) | Fly Ash Concrete (FAC) | Parameters of the composition of the concrete mixture | Compressive strength | Comparison of ensemble models of deep neural networks, i.e., superlearning algorithm, simple averaging, weighted averaging, integrated summation, as well as individual ensemble summation models and superlearning models. to develop an accurate approach to estimating the FAC compressive strength and to reduce the high variance of the predictive models |

| Variable | Glass Fiber Content | Fiber Distribution Method | Cubic Compressive Strength | Prismatic Compressive Strength | Flexural Tensile Strength | Axial Tensile Strength |

| Unit | % | - | MPa | MPa | MPa | MPa |

| mean | 4.0 | - | 48.41 | 36.78 | 9.41 | 5.76 |

| std | 2.46 | - | 3.98 | 3.71 | 3.12 | 1.56 |

| min | 0.0 | - | 40.20 | 28.0 | 3.0 | 2.80 |

| max | 8.0 | - | 57.80 | 44.10 | 16.0 | 8.90 |

| Parameter Number | Parameter | Value | Description |

| 1 | Network type | Fully Connected Feedforward Neural Network for Solving the Regression Problem | The first fully connected layer of the neural network has a connection from the input of the network, and each subsequent layer has a connection from the previous layer |

| 2 | Number of hidden layers | 5 | 1 hidden layer—40 neurons 2 hidden layer—30 neurons 3 hidden layer—20 neurons 4 hidden layer—30 neurons 5 hidden layer—40 neurons |

| 3 | Activation function for hidden layers | Relu | |

| 4 | Loss function minimization method | LBFGS | Broyden-Fletcher-Goldfarb-Shannot quasi-Newton algorithm with limited memory usage |

| 5 | Regularization method | Early stopping | Scheduled to stop when it starts to deteriorate validation set error |

| Parameter Number | Parameter | Value | Description |

| 1 | Ensemble Aggregation Algorithm | LSBoost | The LSBoost (Least-squares boosting) method uses the least squares method as a loss function |

| 2 | Number of trees | 10…100 with step 10 | The model is a combination of n-decision trees |

| 3 | Tree Complexity Level (Depth) | 1,2,3 | The maximum depth of the tree takes the values 1, 2 and 3 |

| 4 | Limit on the number of objects in leaves (MinLeafSize) | 5 | According to the classics, in regression problems it is recommended to use the value 5 |

| 5 | Minimum number of branch node observations (MinParentSize) | 10 | Each branch node in the tree has at least the MinParentSize of the observation |

| 6 | Learning rate | 1 | Ensemble model learning rate (can take values in the range (0…1]) |

| 7 | Method for estimating the generalizing ability of a model | 10 block cross validation | 10-box cross validation on training data |

| Method | MAE | RMSE | MAPE, % |

|---|---|---|---|

| Deep Neural Network | 0.46 | 0.60 | 0.98 |

| Ensemble of Regression Trees | 0.62 | 0.80 | 1.30 |

| Method | MAE | RMSE | MAPE, % |

|---|---|---|---|

| Deep Neural Network | 0.73 | 0.89 | 2.11 |

| Ensemble of Regression Trees | 0.48 | 0.62 | 1.33 |

| Method | MAE | RMSE | MAPE, % |

|---|---|---|---|

| Deep Neural Network | 0.63 | 0.87 | 6.62 |

| Ensemble of Regression Trees | 0.30 | 0.44 | 3.4 |

| Method | MAE | RMSE | MAPE, % |

| Deep Neural Network | 0.15 | 0.17 | 2.49 |

| Ensemble of Regression Trees | 0.11 | 0.15 | 2.06 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stel’makh, S.A.; Shcherban’, E.M.; Beskopylny, A.N.; Mailyan, L.R.; Meskhi, B.; Razveeva, I.; Kozhakin, A.; Beskopylny, N. Prediction of Mechanical Properties of Highly Functional Lightweight Fiber-Reinforced Concrete Based on Deep Neural Network and Ensemble Regression Trees Methods. Materials 2022, 15, 6740. https://doi.org/10.3390/ma15196740

Stel’makh SA, Shcherban’ EM, Beskopylny AN, Mailyan LR, Meskhi B, Razveeva I, Kozhakin A, Beskopylny N. Prediction of Mechanical Properties of Highly Functional Lightweight Fiber-Reinforced Concrete Based on Deep Neural Network and Ensemble Regression Trees Methods. Materials. 2022; 15(19):6740. https://doi.org/10.3390/ma15196740

Chicago/Turabian StyleStel’makh, Sergey A., Evgenii M. Shcherban’, Alexey N. Beskopylny, Levon R. Mailyan, Besarion Meskhi, Irina Razveeva, Alexey Kozhakin, and Nikita Beskopylny. 2022. "Prediction of Mechanical Properties of Highly Functional Lightweight Fiber-Reinforced Concrete Based on Deep Neural Network and Ensemble Regression Trees Methods" Materials 15, no. 19: 6740. https://doi.org/10.3390/ma15196740

APA StyleStel’makh, S. A., Shcherban’, E. M., Beskopylny, A. N., Mailyan, L. R., Meskhi, B., Razveeva, I., Kozhakin, A., & Beskopylny, N. (2022). Prediction of Mechanical Properties of Highly Functional Lightweight Fiber-Reinforced Concrete Based on Deep Neural Network and Ensemble Regression Trees Methods. Materials, 15(19), 6740. https://doi.org/10.3390/ma15196740