Research on the Mechanical and Physical Properties of Basalt Fiber-Reinforced Pervious Concrete

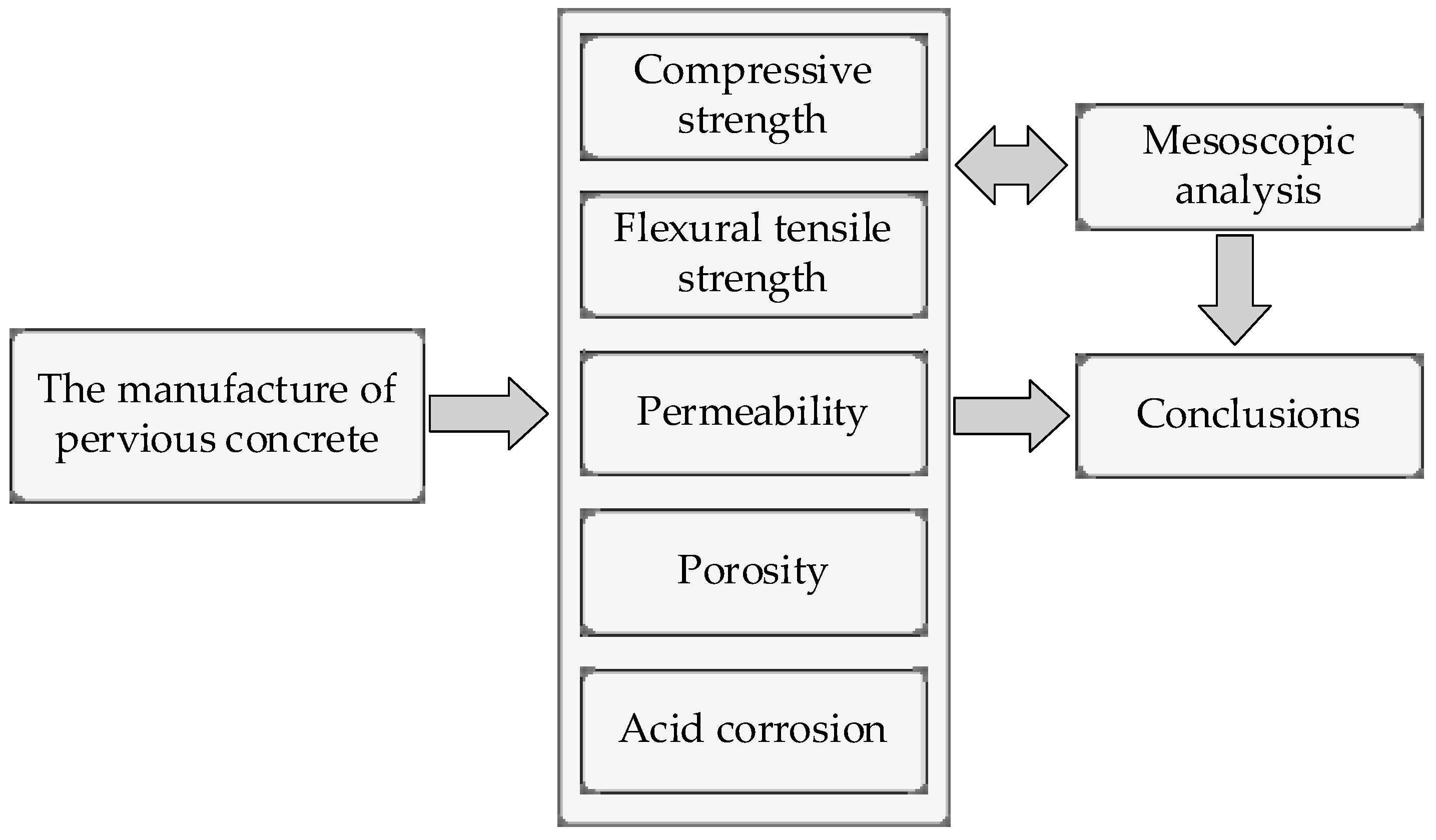

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Cement

2.1.2. Silica Fume

2.1.3. Aggregate

2.1.4. Basalt Fiber

2.1.5. Other Materials

2.2. Mixture Proportion

2.3. Test Method

3. Experiment and Discussion

3.1. Mechanical Properties of Fiber-Reinforced Pervious Concrete

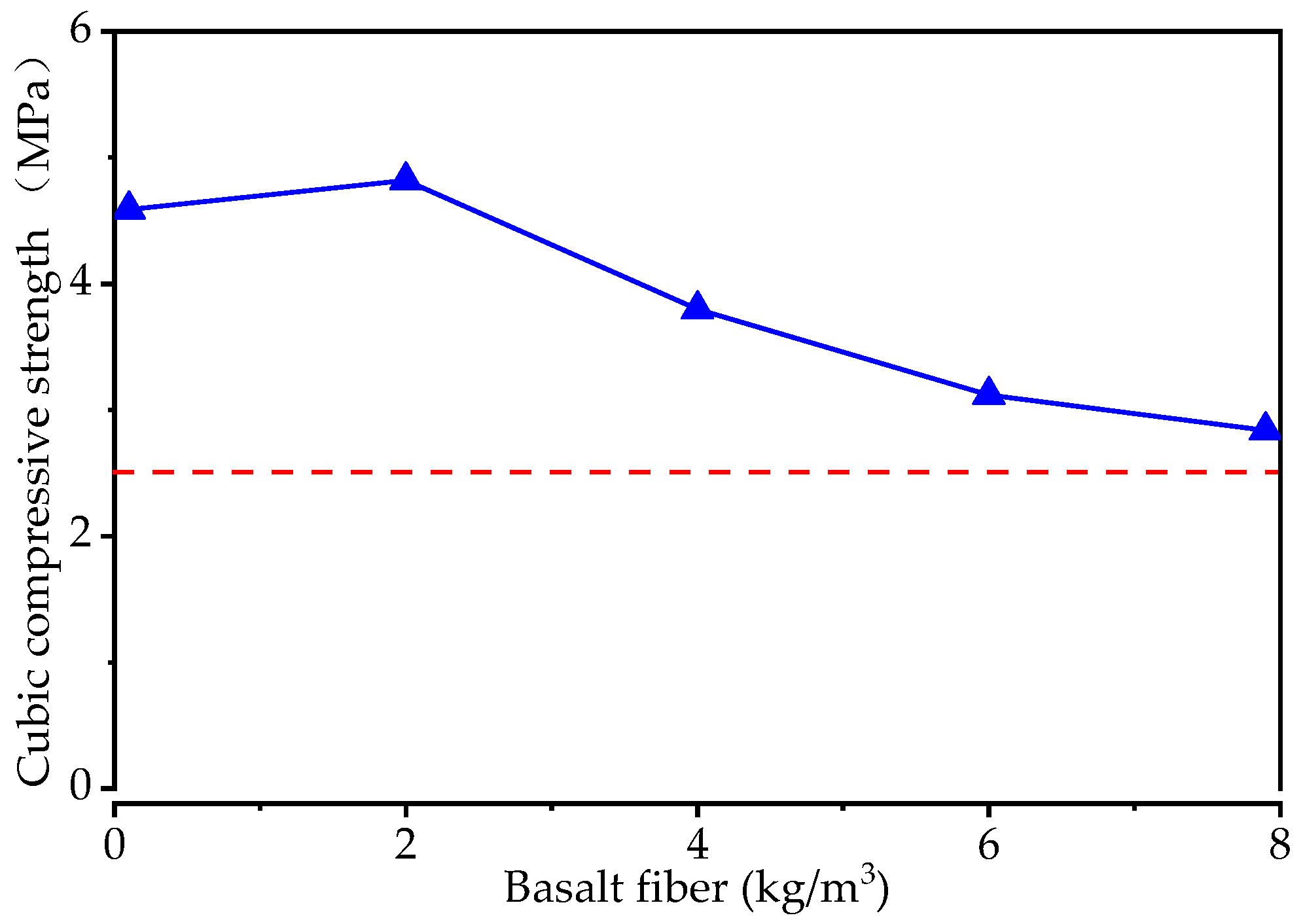

3.1.1. Cubic Compressive Strength

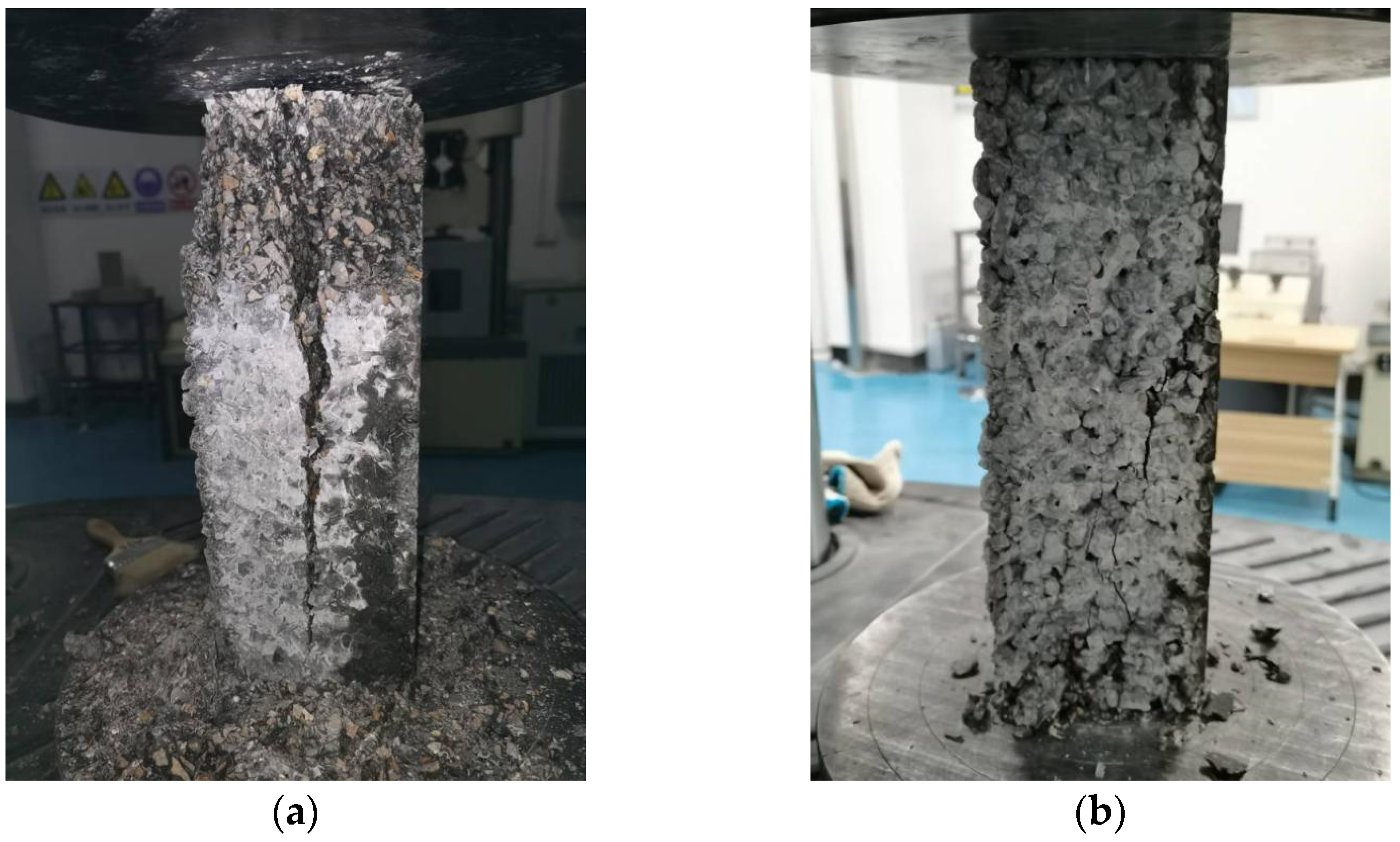

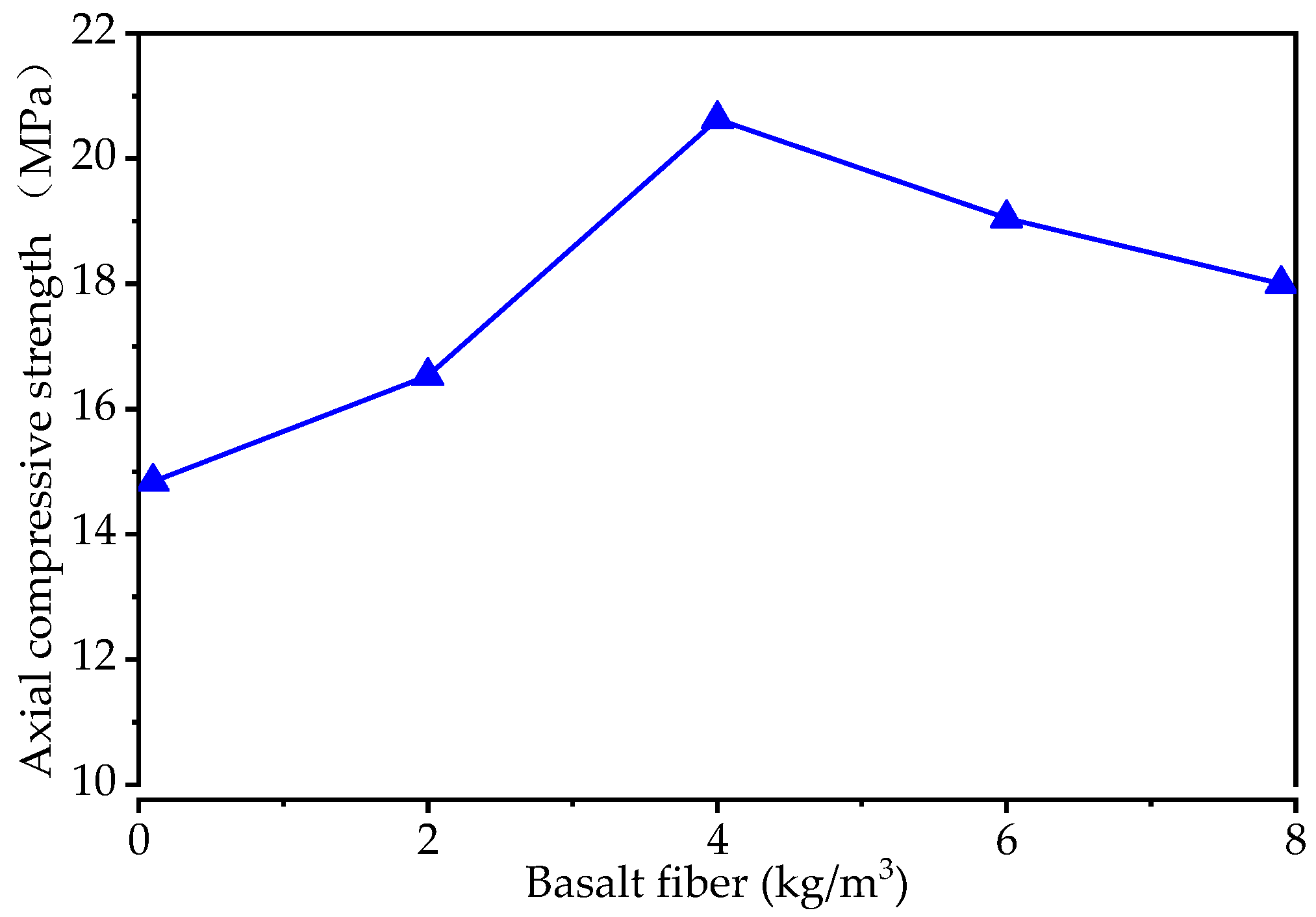

3.1.2. Axial Compressive Strength

3.1.3. Flexural Tensile Strength

3.2. Permeability and Porosity of Fiber-Reinforced Pervious Concrete

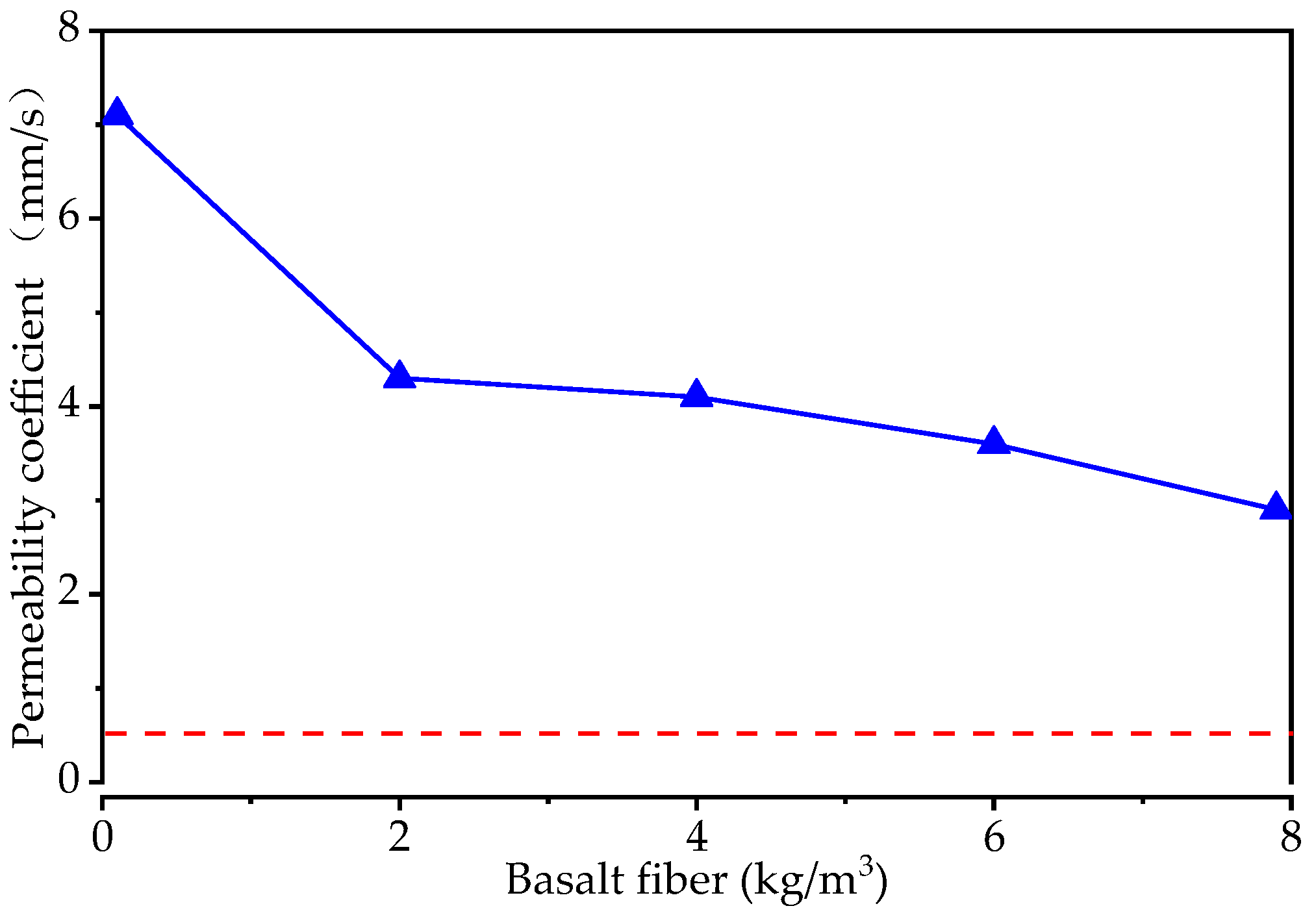

3.2.1. Permeability

3.2.2. Porosity

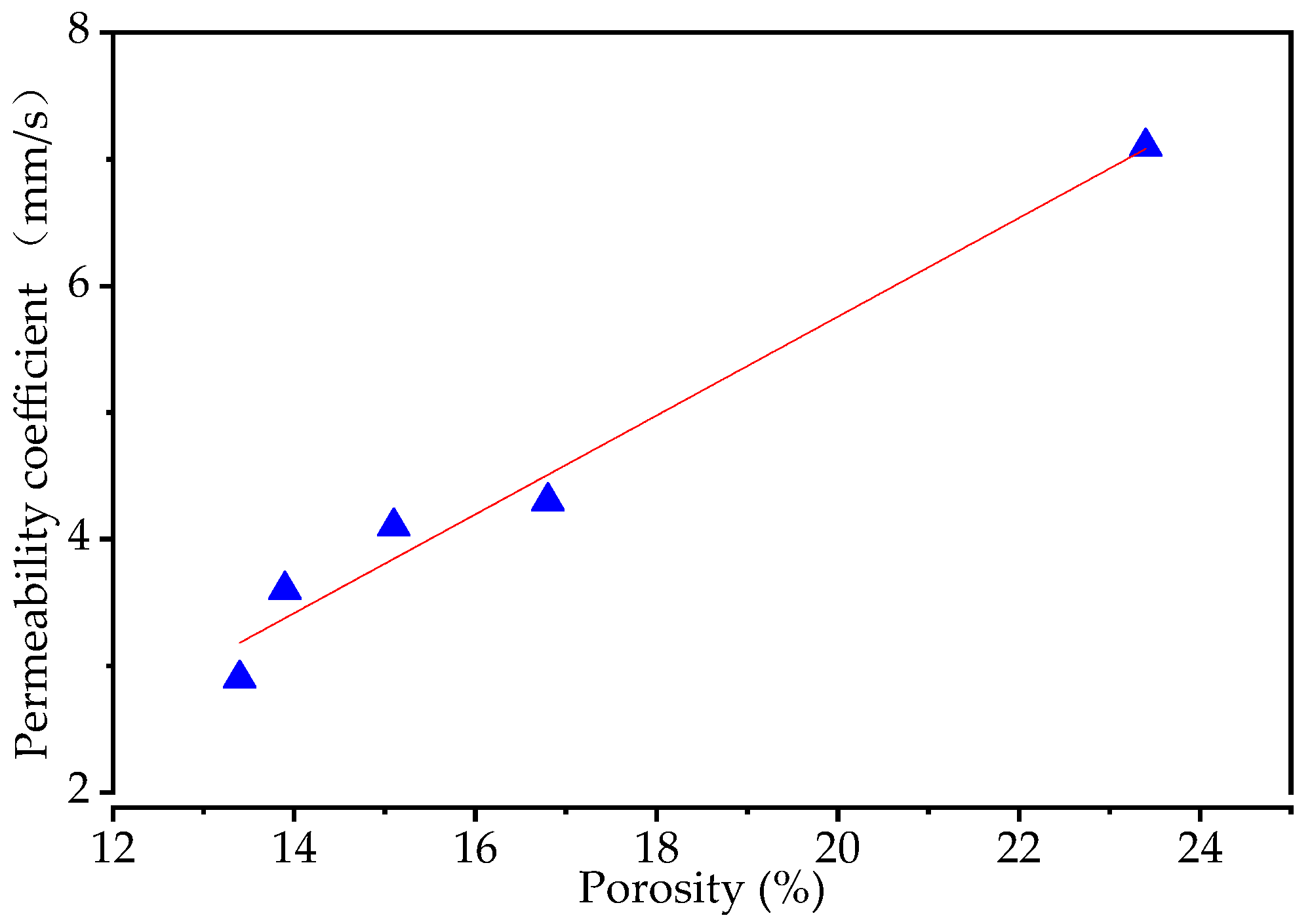

3.2.3. The Relationship between the Permeability and Porosity

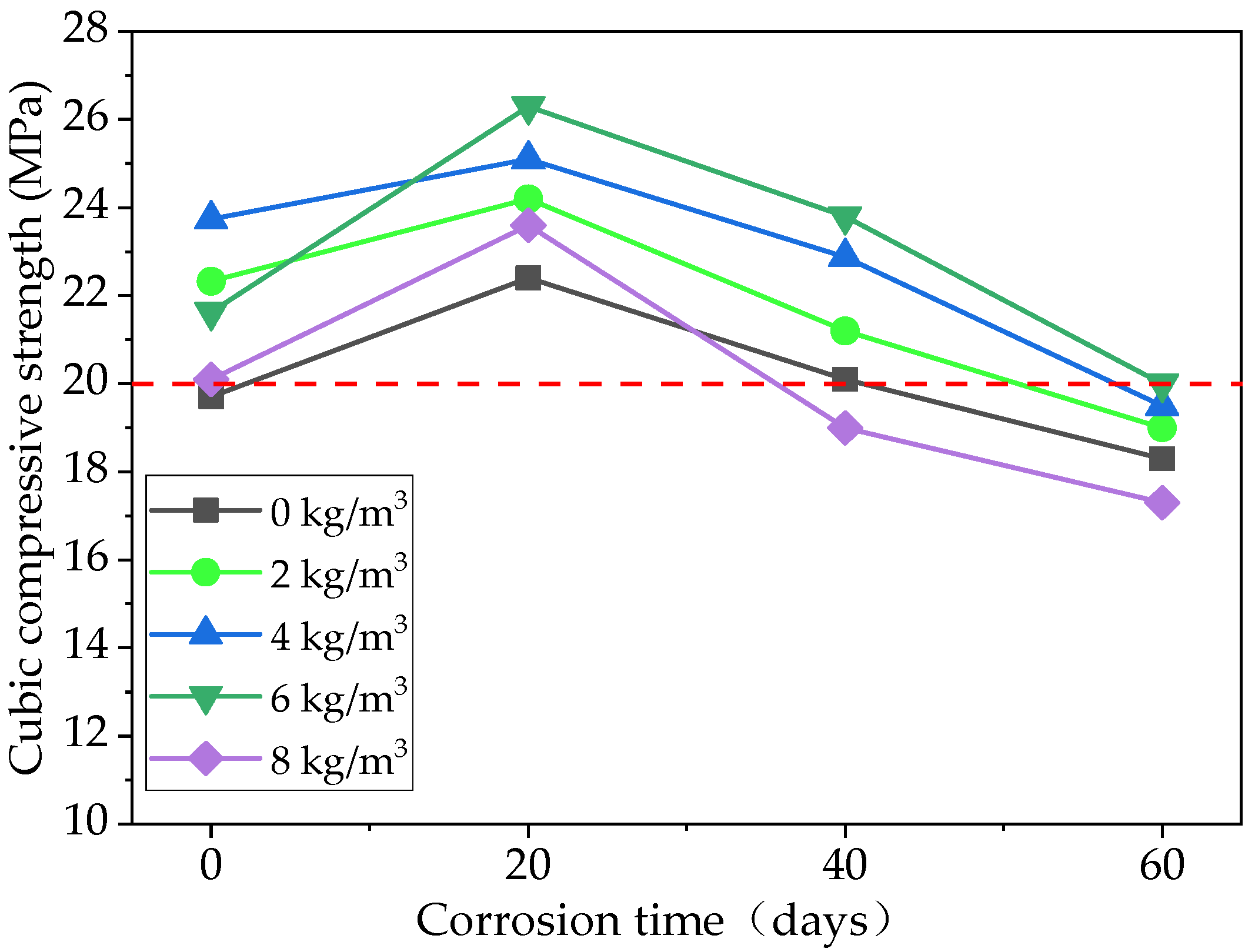

3.3. The Acidic Corrosion Behavior of Fiber-Reinforced Pervious Concrete

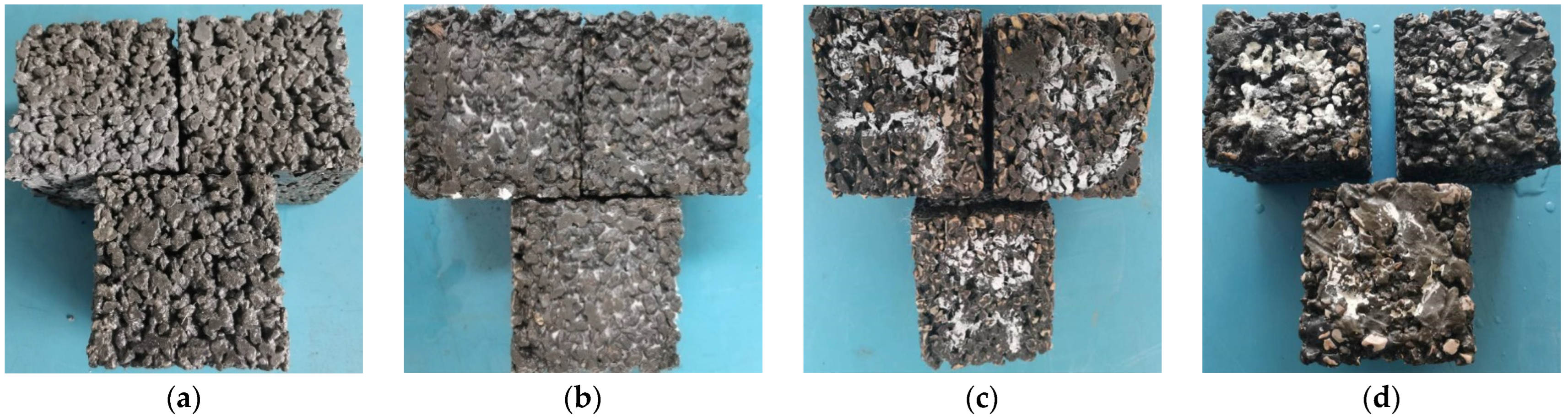

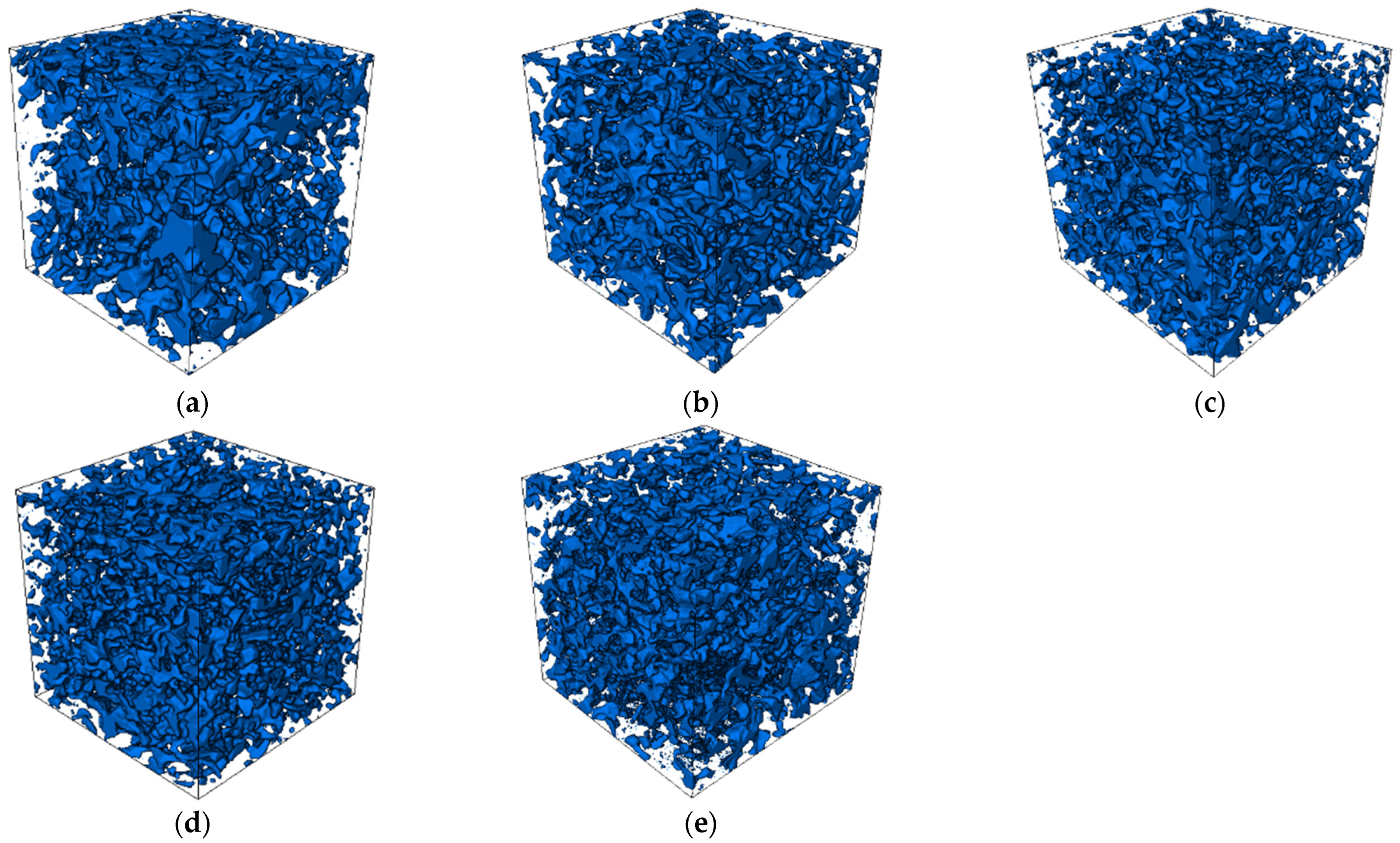

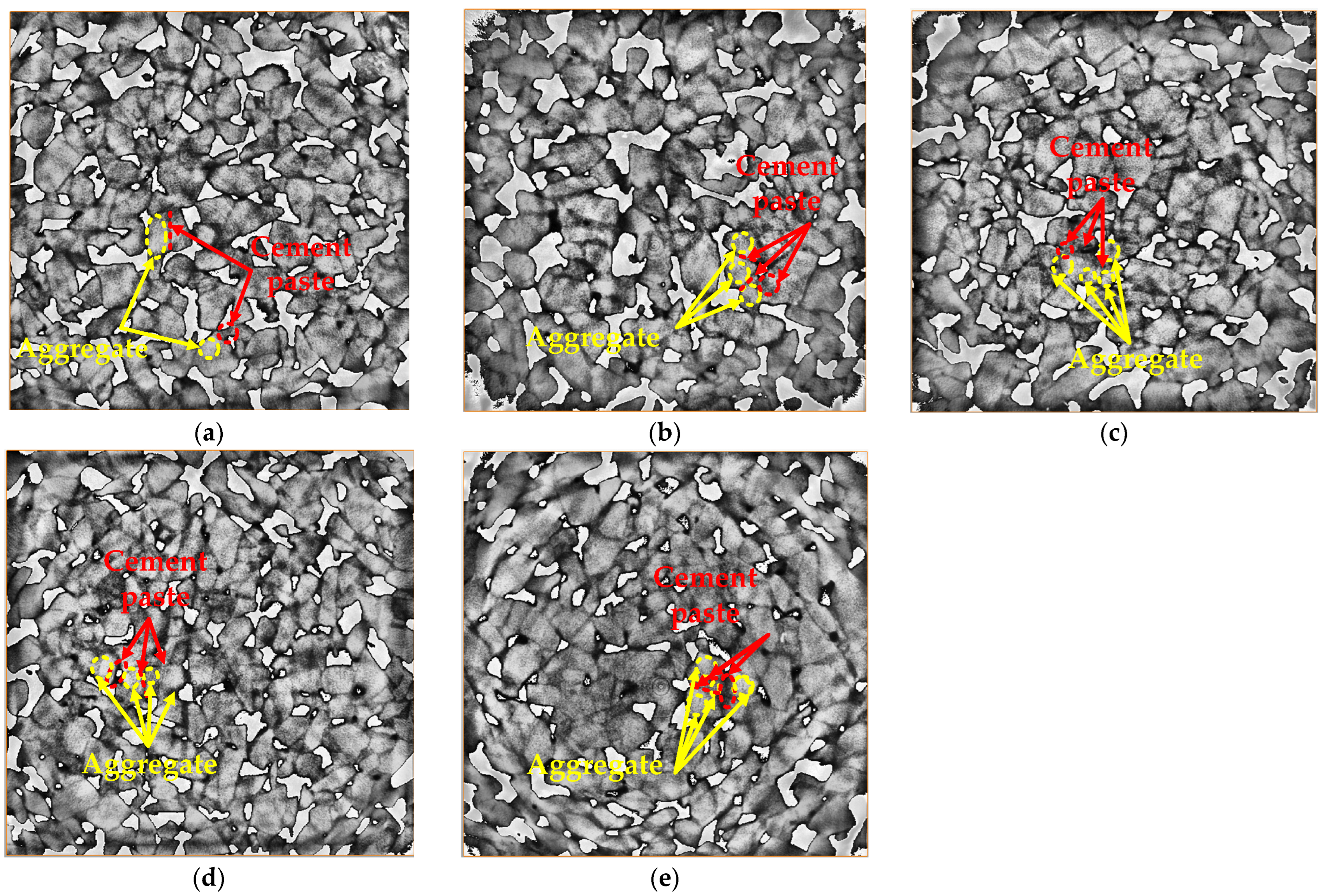

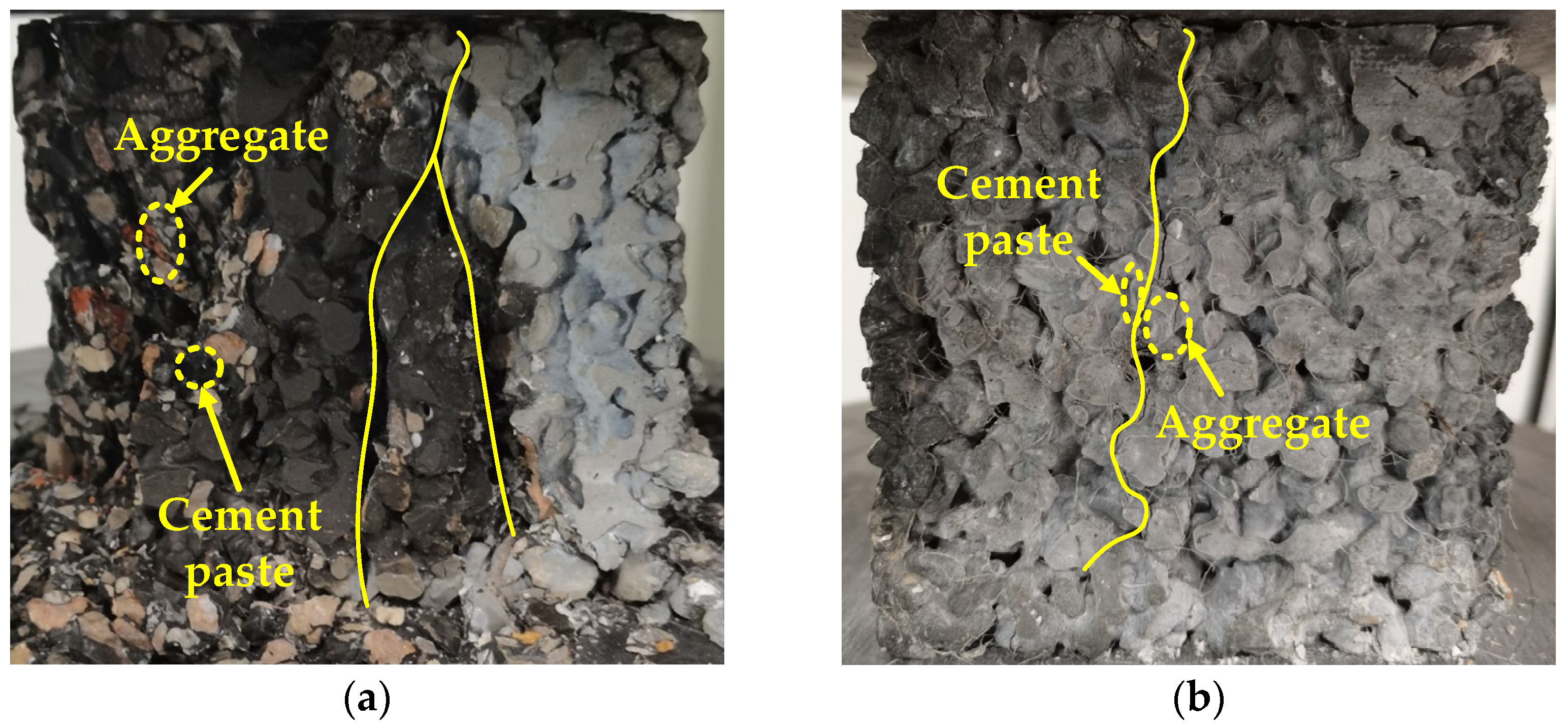

3.4. The Mesostructure of Fiber-Reinforced Pervious Concrete

3.5. Analysis of the Relation between Mechanical Properties and Physical Performance

4. Conclusions

- The incorporation of basalt fiber enhances the cubic and axial compressive strength, and the compressive strength increases and then decreases with the increasing of the basalt fiber content. Compared to the matrix without basalt fiber, the cubic and axial compressive strength of the matrix with a basalt content of 4 kg/m3 increased by 24% and 39%, respectively.

- The contribution of basalt fiber to the flexural strength of the concrete matrix reduces with the increasing of the basalt fiber content. Compared to the control samples, the flexural tensile strength of the matrix with a basalt fiber content of 4 kg/m3 reduces by 17%.

- A pervious concrete matrix incorporating basalt fiber showed a lower permeability and porosity than that of the mix without fiber. Moreover, the permeability coefficient and the porosity of the pervious concrete with a basalt fiber content of 4 kg/m3 were 42% and 35% lower than those of the control samples.

- For the concrete matrix with the basalt fiber content of 4 kg/m3, the cubic compressive strengths of the matrix with acidic corrosion of 0 day, 20 days, 40 days, and 60 days were 21%, 12%, 14%, and 7% higher than those of the control group, respectively. The compressive strength increased and then decreased with the increase in the corrosion time, and the addition of basalt fibers does not change this trend.

- The testing results of ICT scanning indicated that the basalt fiber obviously affects the distribution of the cement paste and aggregate, hence affecting the physical and mechanical properties of the pervious concrete. The optimum basalt fiber content can realize the balance between the cement paste, aggregate, and the ITZ.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Deo, O.; Neithalath, N. Compressive behavior of pervious concretes and a quantification of the influence of random pore structure features. Mater. Sci. Eng. A 2010, 528, 402–412. [Google Scholar] [CrossRef]

- Aslam, F.; Zaid, O.; Althoey, F.; Alyami, S.H.; Qaidi, S.M.; de Prado Gil, J.; Martínez-García, R. Evaluating the influence of fly ash and waste glass on the characteristics of coconut fibers reinforced concrete. Struct. Concr. 2022. early view. [Google Scholar] [CrossRef]

- Akeed, M.H.; Qaidi, S.; Ahmed, H.U.; Faraj, R.H.; Mohammed, A.S.; Emad, W.; Tayeh, B.A.; Azevedo, A.R.G. Ultra-high-performance fiber-reinforced concrete. Part IV: Durability properties, cost assessment, applications, and challenges. Case Stud. Constr. Mat. 2022, 17, e01271. [Google Scholar] [CrossRef]

- Onyelowe, K.C.; Ebid, A.M.; Riofrio, A.; Baykara, H.; Soleymani, A.; Mahdi, H.A.; Jahangir, H.; Ibe, K. Multi-Objective Prediction of the Mechanical Properties and Environmental Impact Appraisals of Self-Healing Concrete for Sustainable Structures. Sustainability 2022, 14, 9573. [Google Scholar] [CrossRef]

- Ho, H.-L.; Huang, R.; Hwang, L.-C.; Lin, W.-T.; Hsu, H.-M. Waste-Based Pervious Concrete for Climate-Resilient Pavements. Materials 2018, 11, 900. [Google Scholar] [CrossRef] [PubMed]

- Huang, J.; Luo, Z.; Khan, M.B.E. Impact of aggregate type and size and mineral admixtures on the properties of pervious concrete: An experimental investigation. Constr. Build. Mater. 2020, 265, 120759. [Google Scholar] [CrossRef]

- Chandrappa, A.K.; Biligiri, K.P. Pervious concrete as a sustainable pavement material—Research findings and future prospects: A state-of-the-art review. Constr. Build. Mater. 2016, 111, 262–274. [Google Scholar] [CrossRef]

- Mahalingam, R.; Mahalingam, S.V. Analysis of pervious concrete properties. J. Croat. Assoc. Civ. Eng. 2016, 68, 493–501. [Google Scholar]

- Joshi, T.; Dave, U. Evaluation of strength, permeability and void ratio of pervious concrete with changing W/C ratio and aggregate size. Int. J. Civ. Eng. Technol. 2016, 7, 276–284. [Google Scholar]

- Yu, F.; Sun, D.; Wang, J.; Hu, M. Influence of aggregate size on compressive strength of pervious concrete. Constr. Build. Mater. 2019, 209, 463–475. [Google Scholar] [CrossRef]

- Wang, H.; Li, H.; Liang, X.; Zhou, H.; Xie, N.; Dai, Z. Investigation on the mechanical properties and environmental impacts of pervious concrete containing fly ash based on the cement-aggregate ratio. Constr. Build. Mater. 2019, 202, 387–395. [Google Scholar] [CrossRef]

- Lori, A.R.; Hassani, A.; Sedghi, R. Investigating the mechanical and hydraulic characteristics of pervious concrete containing copper slag as coarse aggregate. Constr. Build. Mater. 2019, 197, 130–142. [Google Scholar] [CrossRef]

- Lu, G.; Liu, P.; Wang, Y.; Faßbender, S.; Wang, D.; Oeser, M. Development of a sustainable pervious pavement material using recycled ceramic aggregate and bio-based polyurethane binder. J. Clean. Prod. 2019, 220, 1052–1060. [Google Scholar] [CrossRef]

- Zareei, S.A.; Ameri, F.; Bahrami, N.; Shoaei, P.; Moosaei, H.R.; Salemi, N. Performance of sustainable high strength concrete with basic oxygen steel-making (BOS) slag and nano-silica. J. Build. Eng. 2019, 25, 100791. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Soomro, M.; Evangelista, A.C.J. A review of recycled aggregate in concrete applications (2000–2017). Constr. Build. Mater. 2018, 172, 272–292. [Google Scholar] [CrossRef]

- Wongsa, A.; Zaetang, Y.; Sata, V.; Chindaprasirt, P. Properties of lightweight fly ash geopolymer concrete containing bottom ash as aggregates. Constr. Build. Mater. 2016, 111, 637–643. [Google Scholar] [CrossRef]

- Yap, S.P.; Chen, P.Z.C.; Goh, Y.; Ibrahim, H.; Mo, K.H.; Yuen, C.W. Characterization of pervious concrete with blended natural aggregate and recycled concrete aggregates. J. Clean. Prod. 2018, 181, 155–165. [Google Scholar] [CrossRef]

- Lang, L.; Duan, H.; Chen, B. Properties of pervious concrete made from steel slag and magnesium phosphate cement. Constr. Build. Mater. 2019, 209, 95–104. [Google Scholar] [CrossRef]

- Kachouh, N.; El-Hassan, H.; El Maaddawy, T. Effect of steel fibers on the performance of concrete made with recycled concrete aggregates and dune sand. Constr. Build. Mater. 2019, 213, 348–359. [Google Scholar] [CrossRef]

- El-Hassan, H.; Kianmehr, P.; Zouaoui, S. Properties of pervious concrete incorporating recycled concrete aggregates and slag. Constr. Build. Mater. 2019, 212, 164–175. [Google Scholar] [CrossRef]

- Saberian, M.; Li, J.; Nguyen, B.; Wang, G. Permanent deformation behaviour of pavement base and subbase containing recycle concrete aggregate, coarse and fine crumb rubber. Constr. Build. Mater. 2018, 178, 51–58. [Google Scholar] [CrossRef]

- Yaowarat, T.; Horpibulsuk, S.; Arulrajah, A.; Mohammadinia, A.; Chinkulkijniwat, A. Recycled Concrete Aggregate Modified with Polyvinyl Alcohol and Fly Ash for Concrete Pavement Applications. J. Mater. Civ. Eng. 2019, 31, 4019103. [Google Scholar] [CrossRef]

- Lu, J.-X.; Yan, X.; He, P.; Poon, C.S. Sustainable design of pervious concrete using waste glass and recycled concrete aggregate. J. Clean. Prod. 2019, 234, 1102–1112. [Google Scholar] [CrossRef]

- Shilar, F.A.; Ganachari, S.V.; Patil, V.B.; Javed, S.; Khan, T.M.Y.; Baig, R.U. Assessment of Destructive and Nondestructive Analysis for GGBS Based Geopolymer Concrete and Its Statistical Analysis. Polymers 2022, 14, 3132. [Google Scholar] [CrossRef]

- Zamanabadi, S.N.; Zareei, S.A.; Shoaei, P.; Ameri, F. Ambient-cured alkali-activated slag paste incorporating micro-silica as repair material: Effects of alkali activator solution on physical and mechanical properties. Constr. Build. Mater. 2019, 229, 116911. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, K.; Wang, X.; Zhou, W. Strength, fracture and fatigue of pervious concrete. Constr. Build. Mater. 2013, 42, 97–104. [Google Scholar] [CrossRef]

- Adil, G.; Kevern, J.T.; Mann, D. Influence of silica fume on mechanical and durability of pervious concrete. Constr. Build. Mater. 2020, 247, 118453. [Google Scholar] [CrossRef]

- Amornsrivilai, P.; Tia, M.; Lee, M.-G.; Su, Y.-M. Effects of Fly Ash and Silica Fume on Permeability of Concrete Made With Porous Limestone and Non-Porous Aggregates. J. Test. Eval. 2016, 45, 335–345. [Google Scholar] [CrossRef]

- Ztürk, B.; Yilmaz, C. Analytical investigation of effect of retrofit application using FRP on seismic behavior of a monumental building at historical Cappadocia region of Turkey. In Proceedings of the 9th U.S. National and 10th Canadian Conference on Earthquake Engineering, Toronto, ON, Canada, 25–29 July 2010. [Google Scholar]

- Ztürk, B.; Yilmaz, C.; Senturk, T. Effect of FRP retrofitting application on seismic behavior of a historical building at Nigde, Turkey. In Proceedings of the 14th European Conference on Earthquake Engineering, Ohrid, Republic of Macedonia, 30 August–3 September 2010. [Google Scholar]

- Akand, L.; Yang, M.; Wang, X. Effectiveness of chemical treatment on polypropylene fibers as reinforcement in pervious concrete. Constr. Build. Mater. 2018, 163, 32–39. [Google Scholar] [CrossRef]

- Al-Hadithi, A.; Noaman, A.T.; Mosleh, W.K. Mechanical properties and impact behavior of PET fiber reinforced self-compacting concrete (SCC). Compos. Struct. 2019, 224, 111021. [Google Scholar] [CrossRef]

- Mastali, M.; Dalvand, A. Use of silica fume and recycled steel fibers in self-compacting concrete (SCC). Constr. Build. Mater. 2016, 125, 196–209. [Google Scholar] [CrossRef]

- Fiore, V.; Scalici, T.; Di Bella, G.; Valenza, A. A review on basalt fibre and its composites. Compos. Part B Eng. 2015, 74, 74–94. [Google Scholar] [CrossRef]

- Kumutha, R.; Fathima, I.S.; Vijai, D.K. Experimental investigation on properties of basalt fiber reinforced geopolymer concrete. J. Mech. Civil Eng. 2017, 14, 105–109. [Google Scholar] [CrossRef]

- Abbass, M.; Singh, G. Impact strength of rice husk ash and basalt fibre based sustainable geopolymer concrete in rigid pavements. Mater. Today Proc. 2021, 61, 250–257. [Google Scholar] [CrossRef]

- Xu, J.; Kang, A.; Wu, Z.; Xiao, P.; Gong, Y. Effect of high-calcium basalt fiber on the workability, mechanical properties and microstructure of slag-fly ash geopolymer grouting material. Constr. Build. Mater. 2021, 302, 124089. [Google Scholar] [CrossRef]

- Saloni; Parveen; Pham, T.M. Enhanced properties of high-silica rice husk ash-based geopolymer paste by incorporating basalt fibers. Constr. Build. Mater. 2020, 245, 118422. [Google Scholar] [CrossRef]

- Şahin, F.; Uysal, M.; Canpolat, O.; Aygörmez, Y.; Cosgun, T.; Dehghanpour, H. Effect of basalt fiber on metakaolin-based geopolymer mortars containing rilem, basalt and recycled waste concrete aggregates. Constr. Build. Mater. 2021, 301, 124113. [Google Scholar] [CrossRef]

- Yu, H.Y.; Meng, T.; Zhao, Y.X.; Liao, J.P.; Ying, K.J. Effects of basalt fiber powder on mechanical properties and microstructure of concrete. Case Stud. Constr. Mater. 2022, 17, e01286. [Google Scholar] [CrossRef]

- Wang, W.; Zhu, J.; Cheng, X.; Liu, S.; Jiang, D.; Wang, W. Numerical simulation of strength of basalt fiber permeable concrete based on CT technology. Case Stud. Constr. Mater. 2022, 17, e01348. [Google Scholar] [CrossRef]

- GB/T 14685-2011; Pebble and Crushed Stone for Construction. China Construction Industry Press: Beijing, China, 2011.

- CJJ/T 135-2009; Technical Specification for Pervious Cement Concrete Pavement. China Construction Industry Press: Beijing, China, 2009.

- GB/T 50081-2019; Standard for Test Methods of Concrete Physical and Mechanical Properties. China Construction Industry Press: Beijing, China, 2019.

- CJJ/T 253-2016; Technical Specification for Application of Pervious Recycled Aggregate Concrete. China Construction Industry Press: Beijing, China, 2016.

- GB/T 50476-2019; Standard for Design of Concrete Structure Durability. China Construction Industry Press: Beijing, China, 2019.

- Chen, M.C.; Kai, W.; Li, X. Deterioration mechanism of cementitious materials under acid rain attack. Eng. Fail Anal. 2013, 27, 272–285. [Google Scholar] [CrossRef]

- Oni, B.C.; Xia, J.; Liu, M. Mechanical properties of pressure moulded fibre reinforced pervious concrete pavement brick. Case Stud. Constr. Mater. 2020, 13, e00431. [Google Scholar] [CrossRef]

| Initial Setting Time (min) | Final Setting Time (min) | Flexural Strength (MPa) | Compressive Strength (MPa) | ||

|---|---|---|---|---|---|

| 3 d | 28 d | 3 d | 28 d | ||

| 255 | 290 | 5.2 | 8.85 | 24.6 | 48.4 |

| Fire-Resistance Temperature (°C) | Volumetric Weight (kg/m3) | Mean Diameter (µm) | Specific Surface Area (m2) |

|---|---|---|---|

| 1600 | 1650 | 0.2 | 24 |

| Aggregate Size (mm) | Bulk Density (kg/m3) | Apparent Density (kg/m3) | Porosity (%) |

|---|---|---|---|

| 5–10 | 1580 | 2750 | 40.2 |

| Sieve Size (mm) | 2.36 | 4.75 | 9.5 |

|---|---|---|---|

| Accumulated retained percentage (%) | 99 | 95 | 11 |

| Density (kg/m3) | Tensile Strength (MPa) | Elastic Modulus (GPa) | Length (mm) | Diameter (µm) | Elongation (%) |

|---|---|---|---|---|---|

| 2650 | 4800 | 110 | 20 | 15 | 3.1 |

| Number | Material Consumption (kg/m3) | |||||

|---|---|---|---|---|---|---|

| Aggregate | Cement | Water | Silica Fume | Water-Reducing Agent | Basalt Fiber | |

| BF-0 | 1617 | 388 | 121 | 25 | 4.13 | 0 |

| BF-2 | 1617 | 388 | 121 | 25 | 4.13 | 2 |

| BF-4 | 1617 | 388 | 121 | 25 | 4.13 | 4 |

| BF-6 | 1617 | 388 | 121 | 25 | 4.13 | 6 |

| BF-8 | 1617 | 388 | 121 | 25 | 4.13 | 8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, J.; Pang, Q.; Lv, Y.; Zhang, J.; Gao, S. Research on the Mechanical and Physical Properties of Basalt Fiber-Reinforced Pervious Concrete. Materials 2022, 15, 6527. https://doi.org/10.3390/ma15196527

Wu J, Pang Q, Lv Y, Zhang J, Gao S. Research on the Mechanical and Physical Properties of Basalt Fiber-Reinforced Pervious Concrete. Materials. 2022; 15(19):6527. https://doi.org/10.3390/ma15196527

Chicago/Turabian StyleWu, Jian, Qian Pang, Yuanyuan Lv, Jinpeng Zhang, and Shan Gao. 2022. "Research on the Mechanical and Physical Properties of Basalt Fiber-Reinforced Pervious Concrete" Materials 15, no. 19: 6527. https://doi.org/10.3390/ma15196527

APA StyleWu, J., Pang, Q., Lv, Y., Zhang, J., & Gao, S. (2022). Research on the Mechanical and Physical Properties of Basalt Fiber-Reinforced Pervious Concrete. Materials, 15(19), 6527. https://doi.org/10.3390/ma15196527