Compressive Mechanical Properties and Shock-Induced Reaction Behavior of Zr/PTFE and Ti/PTFE Reactive Materials

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material Types

2.2. Preparation of Specimens

- (a)

- The dried powder of Zr, Ti, and PTFE was filled into a chrome steel tank by mass ratio and ground at room temperature;

- (b)

- The grounded powder was placed into a uniaxially pressed mold, the pressure of 30 MPa was held for 5 min, and a cylindrical sample of Φ10 mm × 10 mm was prepared;

- (c)

2.3. Mechanical Property Experiment

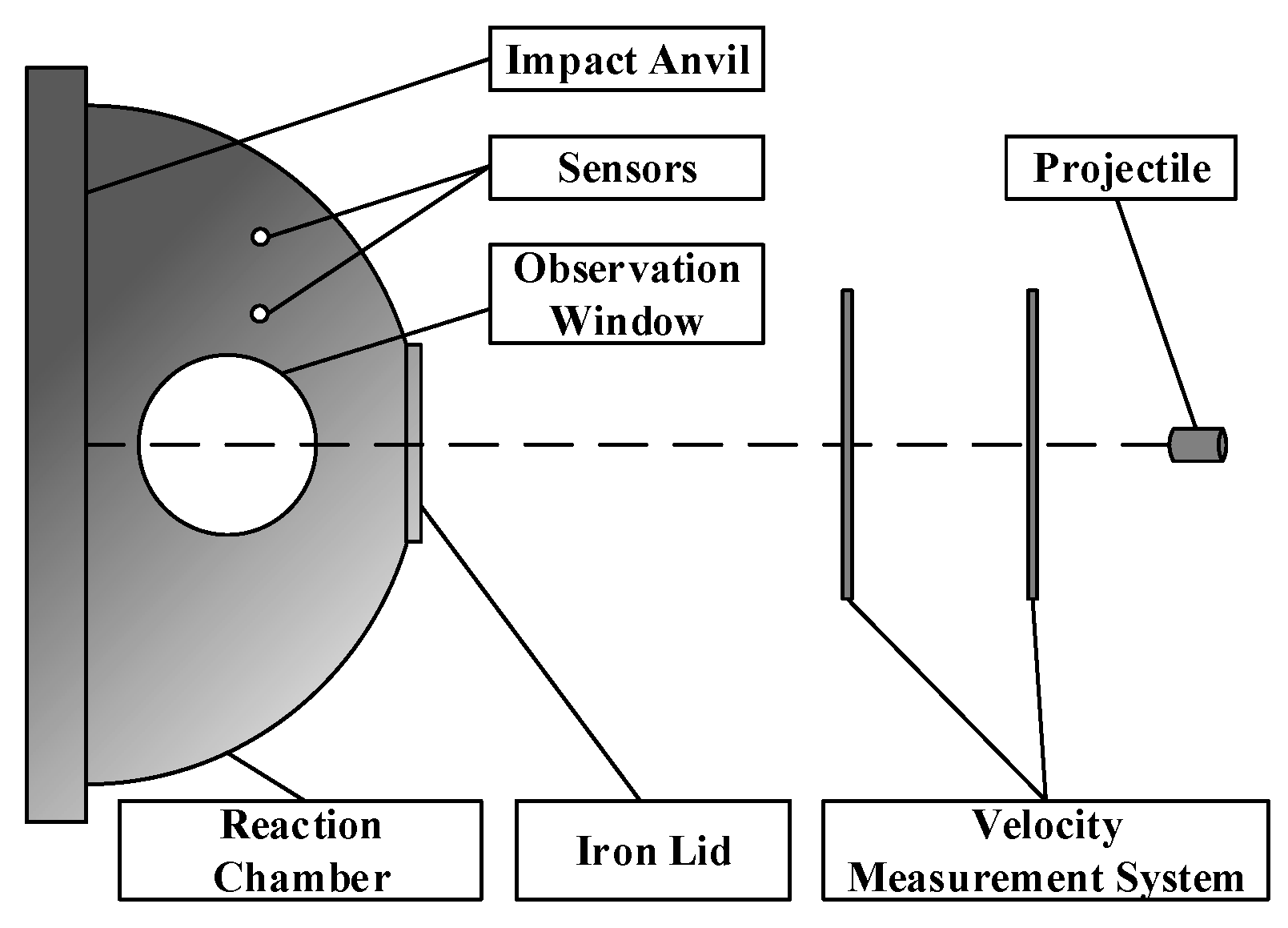

2.4. Quasi-Sealed Chamber Experiment

3. Results

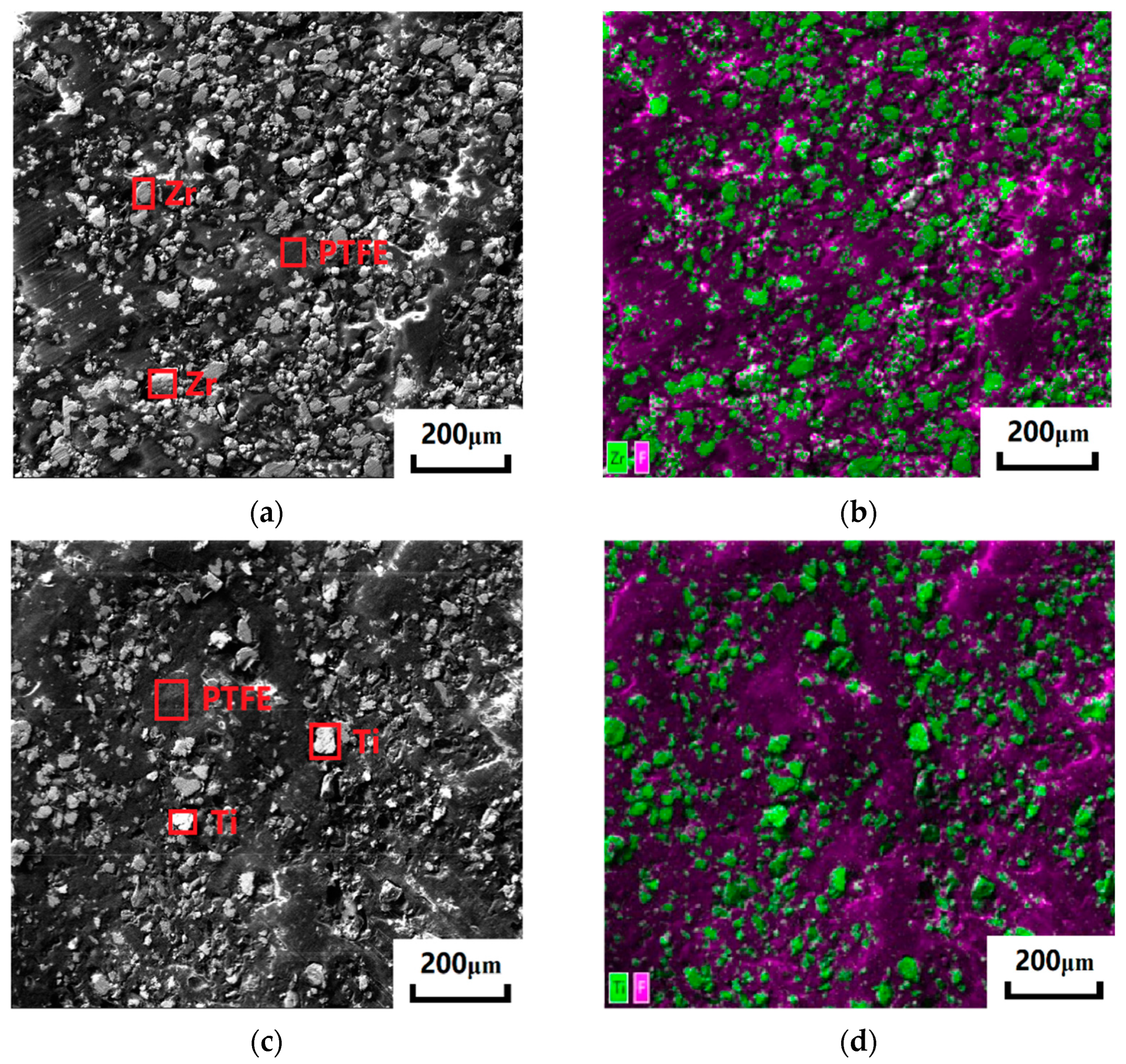

3.1. Microstructure of the Composites

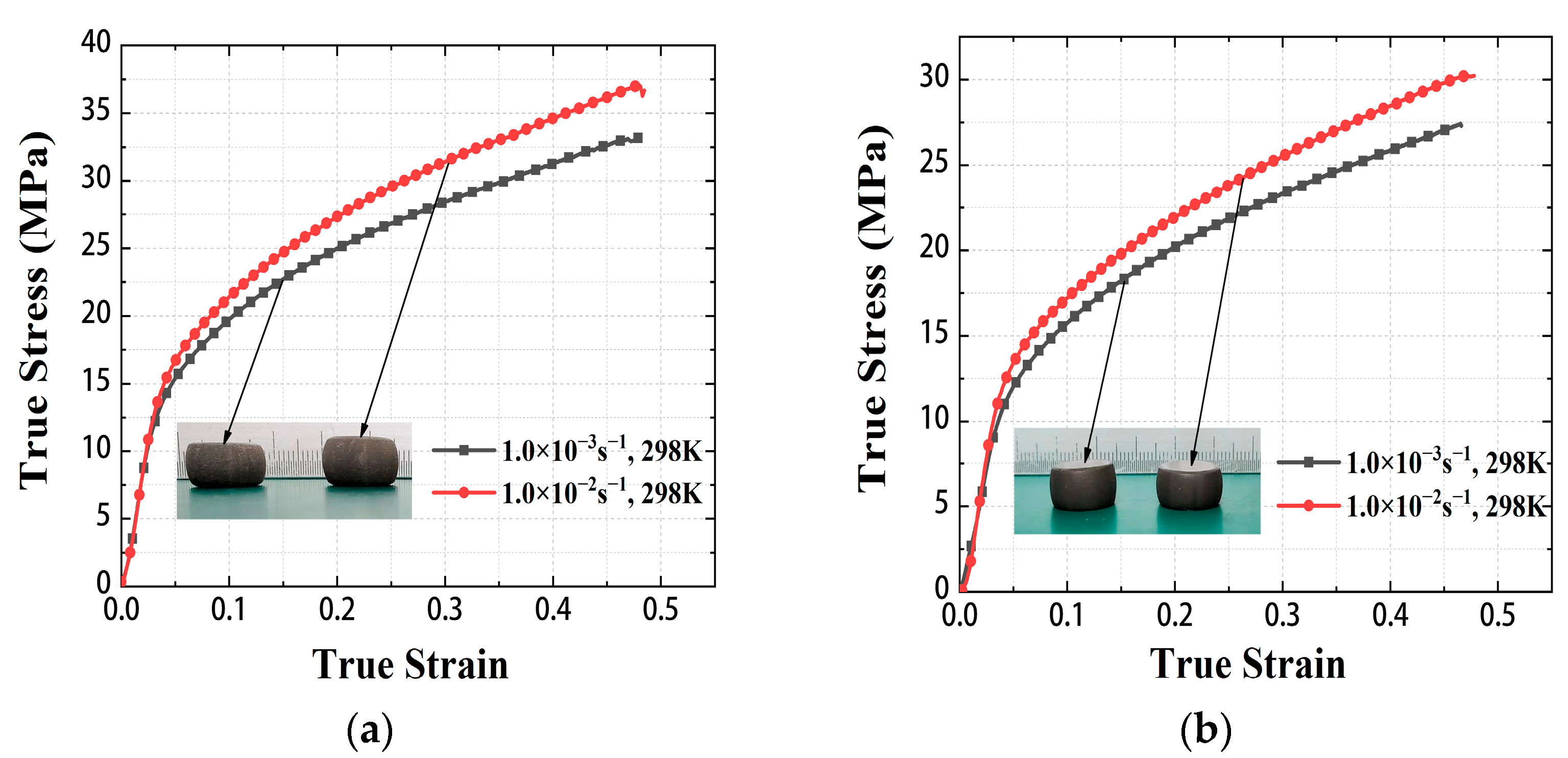

3.2. The Mechanical Property under Quasi-Static Compression

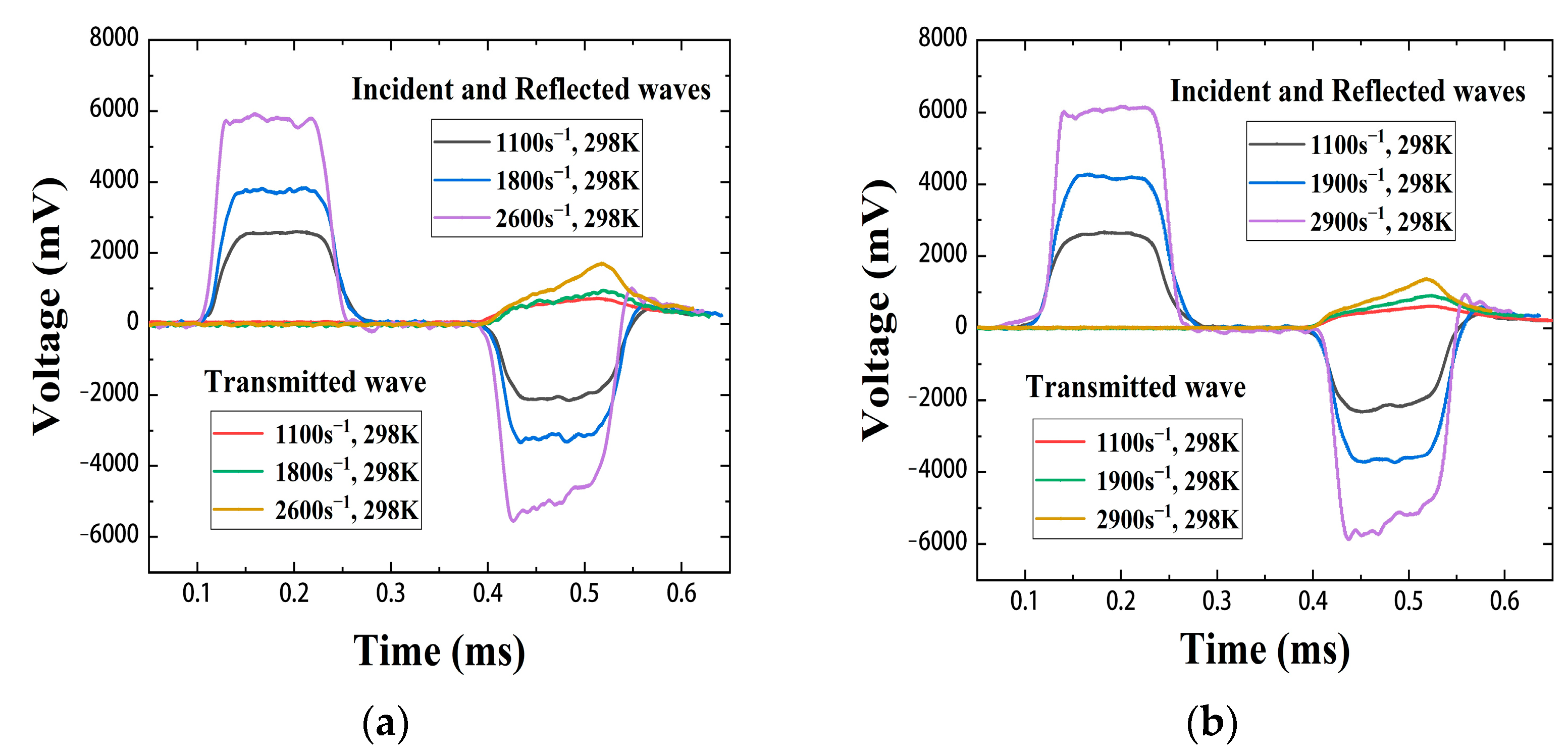

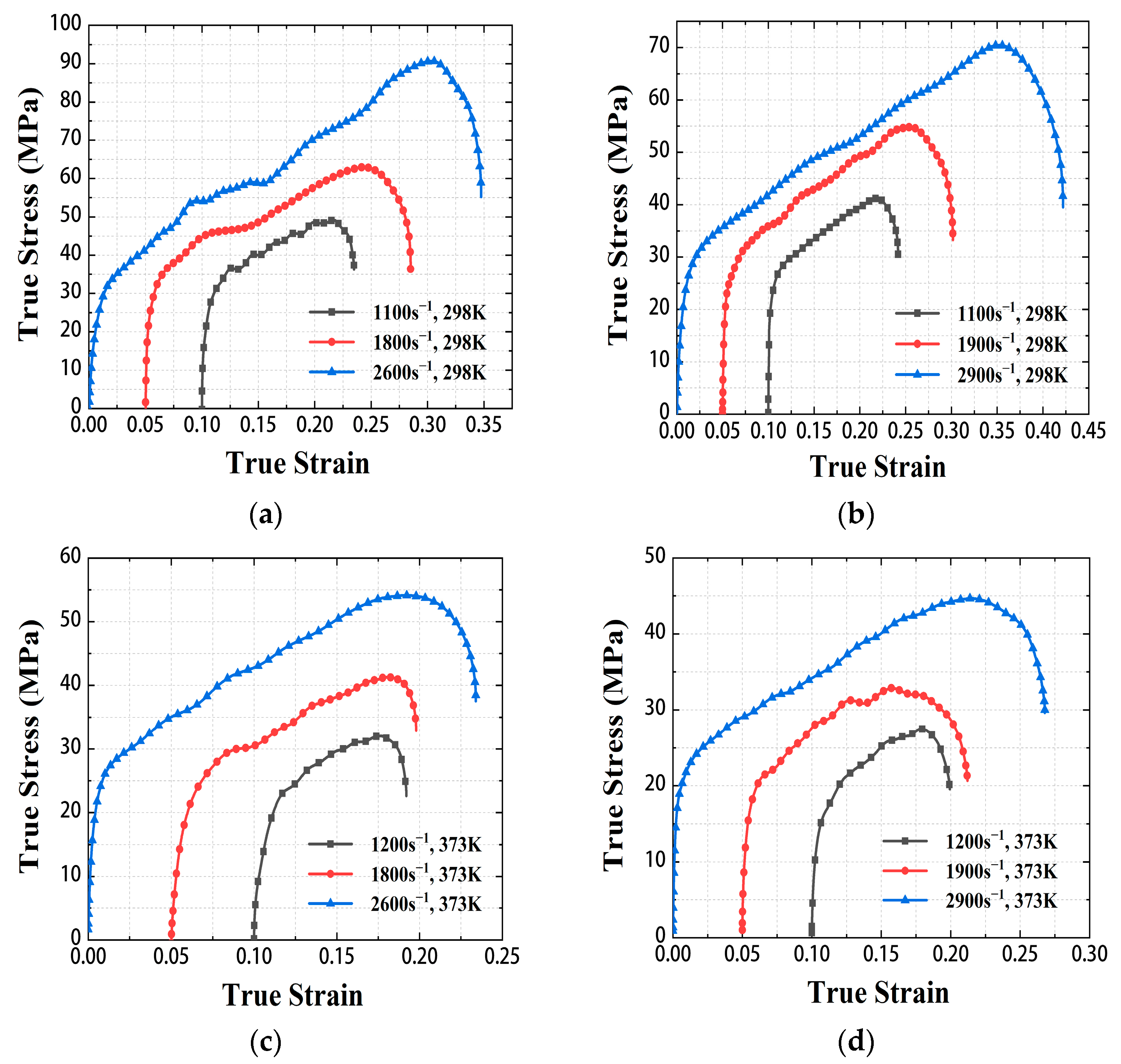

3.3. The Mechanical Property under Dynamic Compression

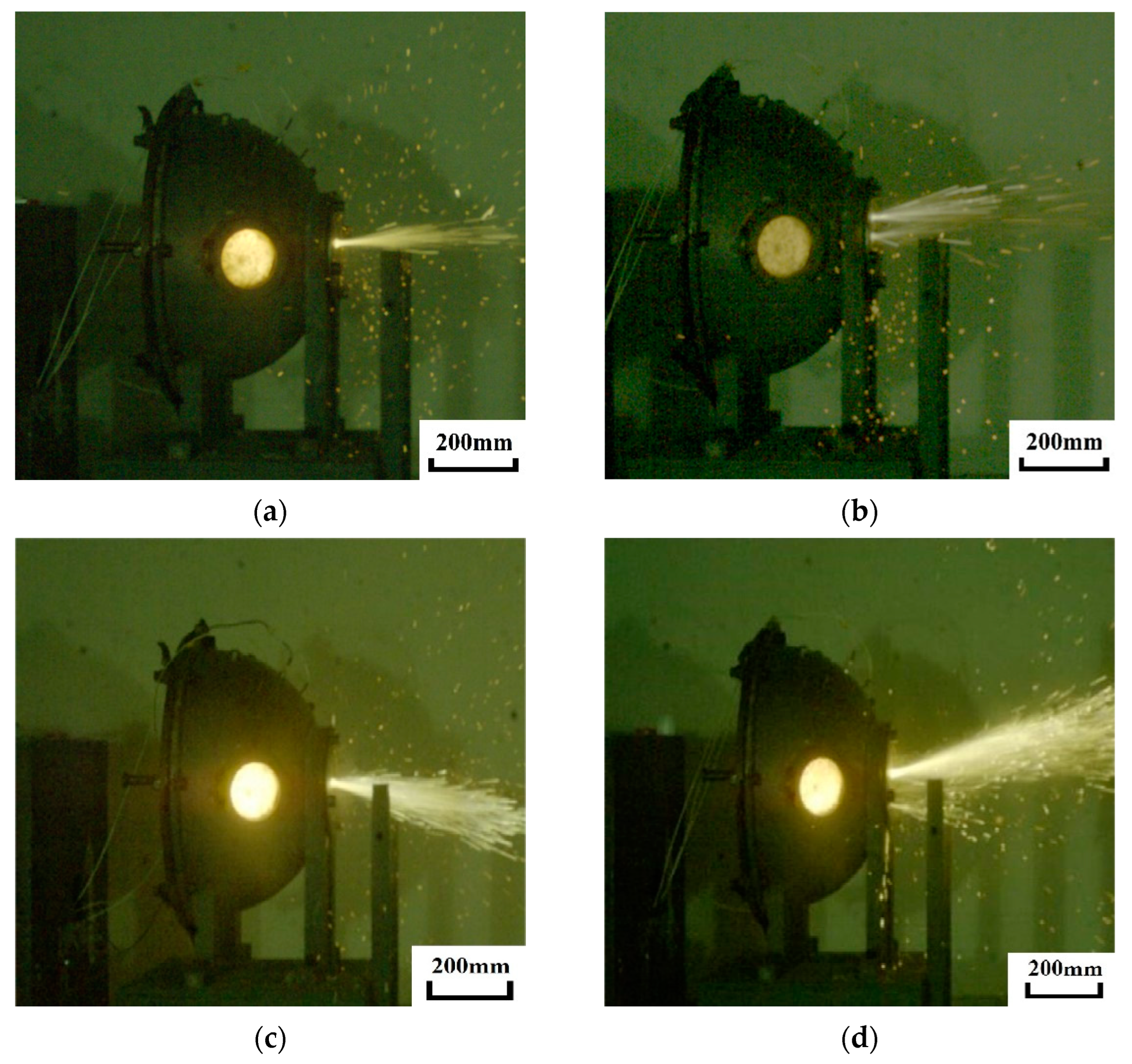

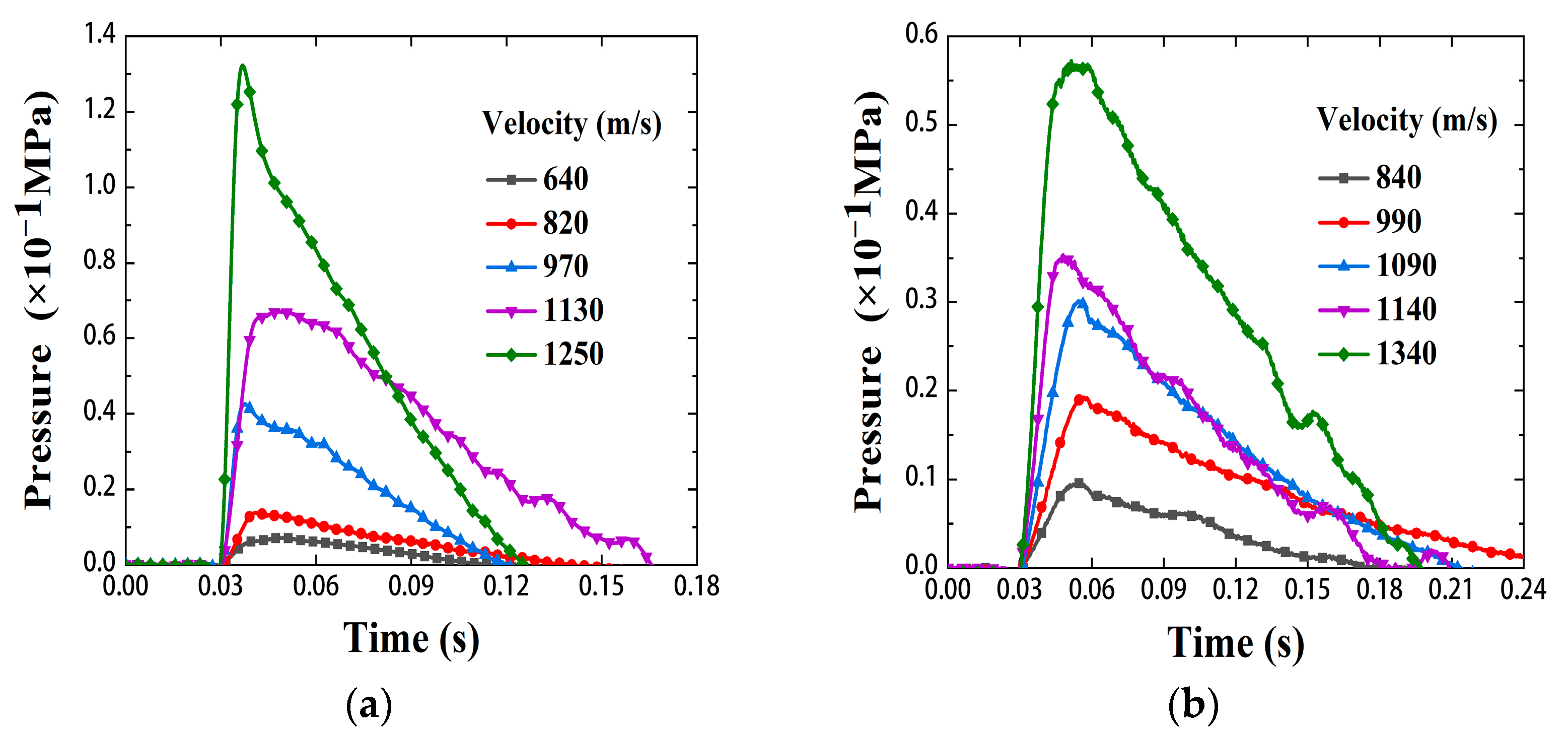

3.4. Shock-Induced Reaction Characteristics

4. Discussion

4.1. Validation of SHPB Test Results

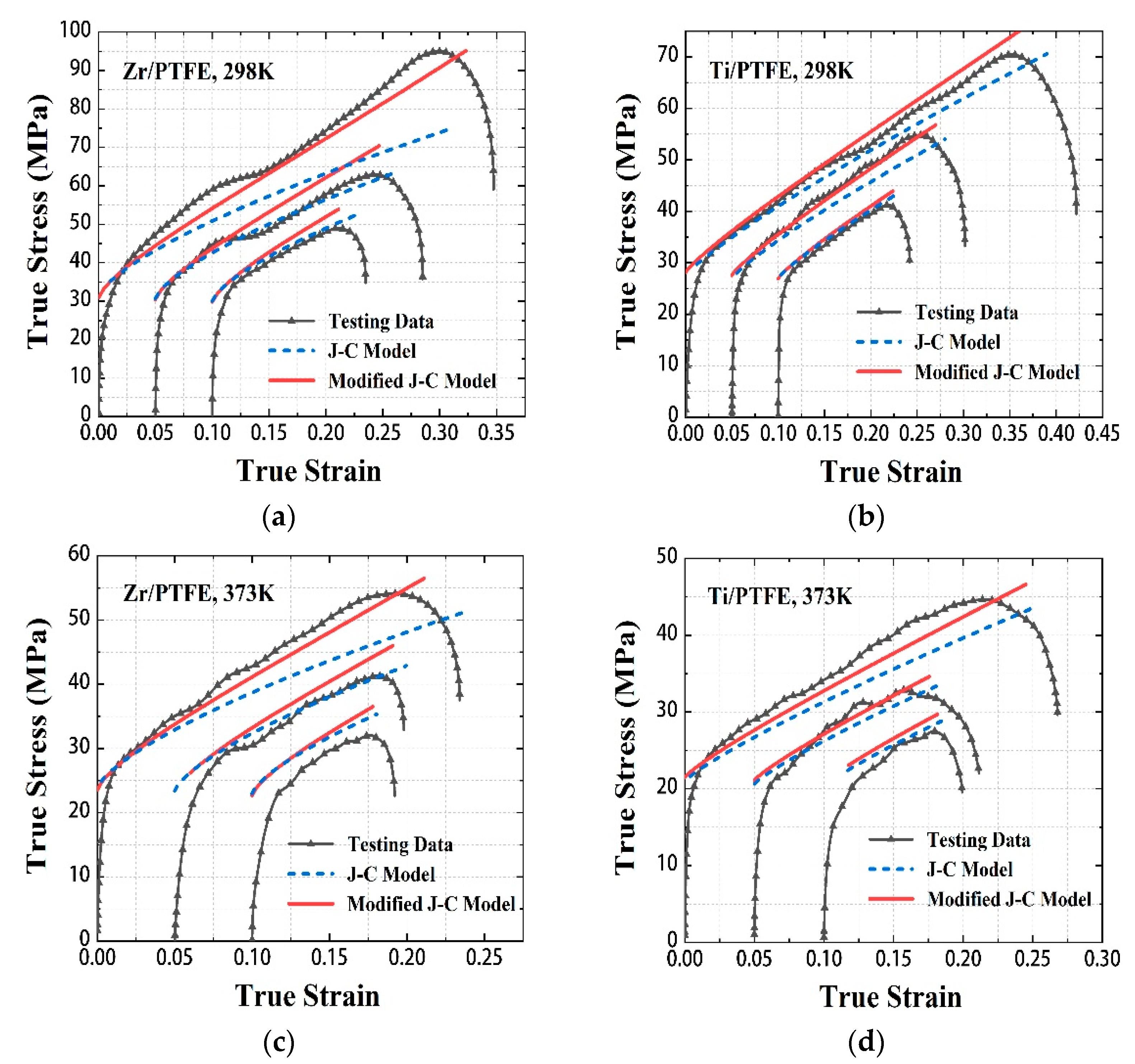

4.2. Constitutive Model Building

4.2.1. Johnson–Cook Constitutive Model

4.2.2. Determination of Parameters in Constitutive Models

4.2.3. Fitting and Modification of Johnson–Cook Constitutive Model

4.2.4. Comparison of the Existing Johnson–Cook Constitutive Model

4.3. Shock-Induced Reaction Behavior

5. Conclusions

- The addition of zirconium and titanium powders improves the strengths of the materials under dynamic load compared to Al/PTFE RMs. The strengths of Zr/PTFE RMs are higher than Ti/PTFE RMs;

- A modified J-C model considering the strain and strain rate coupling was proposed. The parameters of the modified J-C model of Zr/PTFE and Ti/PTFE RMs were determined, which can describe and predict plastic flow stress;

- The test results of the quasi-sealed chamber show that the two materials have violent chemical reactions under the high-velocity impact, and the energy release characteristics will increase with the increase of the impact velocity. At the same impact velocity, the released energy of Zr/PTFE RMs is higher than that of Ti/PTFE RMs.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhou, J.; He, Y.; He, Y.; Wang, C.T. Investigation on impact initiation characteristics of fluoropolymer-matrix reactive materials. Prop. Explos. Pyrotech. 2017, 42, 603–615. [Google Scholar] [CrossRef]

- Wang, C.T.; He, Y.; Ji, C.; He, Y.; Han, W.; Pan, X.C. Investigation on shock-induced reaction characteristics of a Zr-based metallic glass. Intermetallics 2018, 93, 383–388. [Google Scholar] [CrossRef]

- Wang, C.T.; He, Y.; Ji, C.; He, Y.; Guo, L.; Meng, Y.P. Dynamic fragmentation of a Zr-based metallic glass under various impact velocities. J. Mater. Sci. 2021, 56, 2900–2911. [Google Scholar] [CrossRef]

- Nielson, D.B.; Tanner, R.L.; Lund, G.K. High Strength Reactive Materials and Methods of Making. U.S. Patent 2004/0116576 A1, 17 June 2004. [Google Scholar]

- Joshi, V.S. Process for Making Polytetrafluoroethylene-Aluminum Composite and Product Made. U.S. Patent US 6547993 B1, 15 April 2003. [Google Scholar]

- Mock, W.; Holt, W.H. Impact initiation of rods of pressed polytetrafluoroethylene (PTFE) and aluminum powders. In Proceedings of the Conference of the American Physical Society Topical Group on Shock Compression of Condensed Matter, Baltimore, MD, USA, 31 July–5 August 2005. [Google Scholar]

- Raftenberg, M.N.; Mock, W.; Kirby, G.C. Modeling the impact deformation of rods of a pressed PTFE/Al composite mixture. Int. J. Impact Eng. 2008, 35, 1735–1744. [Google Scholar] [CrossRef]

- Ames, R.G. Energy release characteristics of impact-initiated energy materials. In Proceedings of the Materials Research Society Symposium, Boston, MA, USA, 28 November–2 December 2005. [Google Scholar]

- Ames, R.G. Vented chamber calorimetry for impact-initiated energetic materials. In Proceedings of the 43rd AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 10–13 January 2005. [Google Scholar]

- Rack, H.J.; Qazi, J.I. Titanium alloys for biomedical applications. Mater. Sci. Eng. C 2006, 26, 1269–1277. [Google Scholar] [CrossRef]

- Suyalatu; Nomura, N.; Oya, K.; Tanaka, Y.; Kondo, R.; Doi, H.; Tsutsumi, Y.; Hanawa, T. Microstructure and magnetic susceptibility of as-cast Zr–Mo alloys. Acta Biomater. 2010, 6, 1033–1038. [Google Scholar] [CrossRef] [PubMed]

- Feng, Z.H.; Xia, C.Q.; Zhang, X.Y.; Ma, M.Z.; Liu, R.P. Development and applications of zirconium alloys with high strength and toughness. Mater. Sci. Technol. 2018, 26, 1–8. [Google Scholar]

- Wang, L.Y.; Jiang, J.W.; Li, M.; Ma, Y.Y. Experimental research on energy release behavior of W/Zr/Hf Alloy Fragment. Acta Armamentarii 2019, 40, 1603–1608. [Google Scholar]

- Chen, W.; Zhao, W.T.; Wang, J.; Liang, D.; Ge, W.Y.; Xiong, X.S. Study of damaging process for W-Zr alloy fragment. Ordnance Mater. Sci. Eng. 2009, 32, 108–111. [Google Scholar] [CrossRef]

- Guo, Z.P.; Liu, R.; Wang, C.T.; He, Y.; He, Y.; Ma, Y.; Hu, X.B. Compressive Mechanical Properties and Shock-Induced Reaction Behavior of a Ti–29Nb–13Ta–4.6Zr Alloy. Met. Mater. Int. 2019, 26, 1498–1505. [Google Scholar] [CrossRef]

- Li, W.; Ren, H.L.; Ning, J.G.; Hao, L. Dynamic compression characteristics of zirconium/polytetrafluoroethylene reactive material. Acta Armamentarii 2020, 41, 56–62. [Google Scholar]

- Tong, Y.; Wang, Z.C.; Cai, S.Y.; Hu, W.X.; Li, S.Y. Damage Effects of Metal Plates by Ti/W/PTFE Energetic Fragment Impact. J. Ordnance Equip. Eng. 2019, 40, 1–6. [Google Scholar]

- Li, W.; Ren, H.L.; Ning, J.G.; Liu, Y.B. Dynamic mechanical behavior and impact ignition characteristics of Al/PTFE reactive materials. Chin. J. Energ. Mater. 2020, 28, 38–45. [Google Scholar]

- Zhao, R.G.; Chen, C.Z.; Luo, W.B.; Luo, X.Y.; Li, H.C.; Tan, D.H. Key issues in the SHPB experiment of polymer materials. Chin. J. Solid Mech. 2011, 32, 134–144. [Google Scholar]

- Wang, L.L. Stress Wave Basics, 2nd ed.; National Defense Industry Press: Beijing, China, 1985; pp. 52–60. [Google Scholar]

- Tang, W.H.; Zhang, R.Q. Introduction to Theory and Computation of Equations of State, 2nd ed.; Higher Education Press: Beijing, China, 2008; pp. 301–302. [Google Scholar]

- Yang, X.L.; He, Y.; He, Y.; Wang, C.T.; Qi, L.; Guo, Z.P. Study of the effect of interface properties on the dynamic behavior of Al/PTFE composites using experiment and 3D meso-scale modelling. Compos. Interfaces 2020, 27, 401–418. [Google Scholar] [CrossRef]

- Johnson, G.R.; Cook, W.H. A constitutive model and data for materials subjected to large strains, high strain rates, and high temperatures. In Proceedings of the 7th International Symposium on Ballistics, Hague, The Netherlands, 19–21 April 1983. [Google Scholar]

- Wang, Y.; Zhang, C.M.; Zhang, Y. Study on static and dynamic mechanical properties of aviation Al7050 alloy and construction of JC constitutive model. Mater. Rep. 2021, 35, 10096–10102. [Google Scholar]

- Nagy, A.; Ko, W.L.; Lindholm, U.S. Mechanical behavior of foamed materials under dynamic compression. J. Cell. Plast. 1974, 10, 127–134. [Google Scholar] [CrossRef]

- Herbold, E.B.; Cai, J.; Benson, D.J.; Nesterenko, V.F. Simulation of particle size effect on dynamic properties and fracture of PTFE-Al-W composite. AIP Conf. Proc. 2007, 3, 161–173. [Google Scholar]

- Wang, Z. Parameter Calibration of PTFE/Al Reactive Materials and Numerical Simulation Research of Its Impact-Induced Deflagration Behavior. Master’s Thesis, North University of China, Shanxi, China, 2021. [Google Scholar]

- Zhang, J. Study on Dynamic Mechanical Properties of Multifunctional Energetic Structural Materials. Master’s Thesis, Nanjing University of Science and Technology, Nanjing, China, 2013. [Google Scholar]

- Dreizin, E.L. Metal-based reactive nanomaterials. Prog. Energy Combust. Sci. 2009, 35, 141–167. [Google Scholar] [CrossRef]

| Material | A | B | n | C | m | a | b |

|---|---|---|---|---|---|---|---|

| PTFE [26] | 11 | 44 | 1 | 0.12 | 1 | / | / |

| Al/PTFE [7,27] (26.5/73.5) | 8.044~17 | 45.403~250.6 | 0.86659~1.8 | 0.4~0.4873 | 1 | / | / |

| AL/PTFE/W [28] (12/38/50) | 23 | 20.26 | 0.67604 | 0.19707 | / | / | / |

| Zr/PTFE (47.6/52.4) | 11.596 | 37.0508 | 0.7061 | 0.1146 | 0.9536 | 0.0485 | 0.00061 |

| Ti/PTFE (32/68) | 10.227 | 35.7976 | 0.8525 | 0.1134 | 0.937 | 0.0147 | 0.00157 |

| Material | Velocity (m/s) | ∆P (10−1 MPa) | ∆E (J) |

|---|---|---|---|

| Zr/PTFE | 640 | 0.076 ± 0.02 | 437 |

| 820 | 0.135 ± 0.03 | 776.25 | |

| 970 | 0.428 ± 0.03 | 2461 | |

| 1130 | 0.67 ± 0.05 | 3852.5 | |

| 1250 | 1.317 ± 0.03 | 7572.75 | |

| Ti/PTFE | 840 | 0.094 ± 0.02 | 540.5 |

| 990 | 0.19 ± 0.02 | 1092.5 | |

| 1090 | 0.29 ± 0.03 | 1667.5 | |

| 1140 | 0.347 ± 0.03 | 1995.25 | |

| 1340 | 0.566 ± 0.05 | 3254.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Z.; He, Y.; He, Y.; Guo, L.; Ge, C.; Wang, H.; Ma, Y.; Gao, H.; Tian, W.; Wang, C. Compressive Mechanical Properties and Shock-Induced Reaction Behavior of Zr/PTFE and Ti/PTFE Reactive Materials. Materials 2022, 15, 6524. https://doi.org/10.3390/ma15196524

Zhang Z, He Y, He Y, Guo L, Ge C, Wang H, Ma Y, Gao H, Tian W, Wang C. Compressive Mechanical Properties and Shock-Induced Reaction Behavior of Zr/PTFE and Ti/PTFE Reactive Materials. Materials. 2022; 15(19):6524. https://doi.org/10.3390/ma15196524

Chicago/Turabian StyleZhang, Zhenwei, Yong He, Yuan He, Lei Guo, Chao Ge, Haifu Wang, Yue Ma, Hongyin Gao, Weixi Tian, and Chuanting Wang. 2022. "Compressive Mechanical Properties and Shock-Induced Reaction Behavior of Zr/PTFE and Ti/PTFE Reactive Materials" Materials 15, no. 19: 6524. https://doi.org/10.3390/ma15196524

APA StyleZhang, Z., He, Y., He, Y., Guo, L., Ge, C., Wang, H., Ma, Y., Gao, H., Tian, W., & Wang, C. (2022). Compressive Mechanical Properties and Shock-Induced Reaction Behavior of Zr/PTFE and Ti/PTFE Reactive Materials. Materials, 15(19), 6524. https://doi.org/10.3390/ma15196524