Interface Microstructure and Mechanical Properties of Al/Steel Bimetallic Composites Fabricated by Liquid-Solid Casting with Rare Earth Eu Additions

Abstract

:1. Introduction

2. Experimental

2.1. Materials

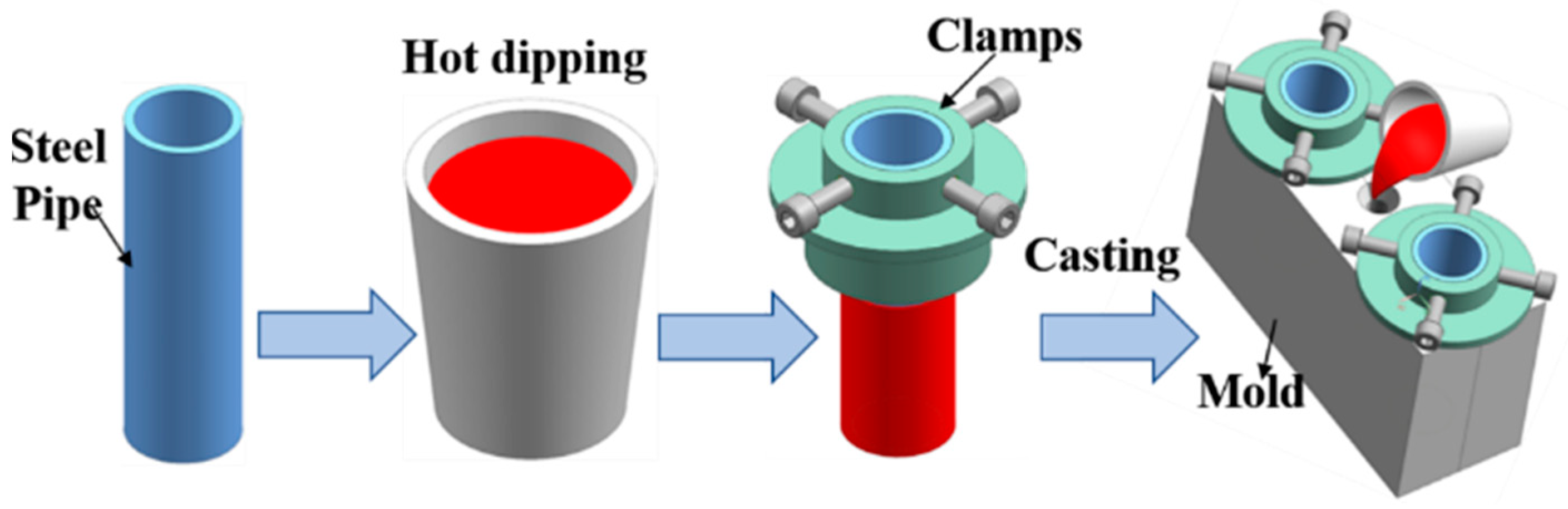

2.2. Experimental Procedure

2.3. Microstructural Characterizations

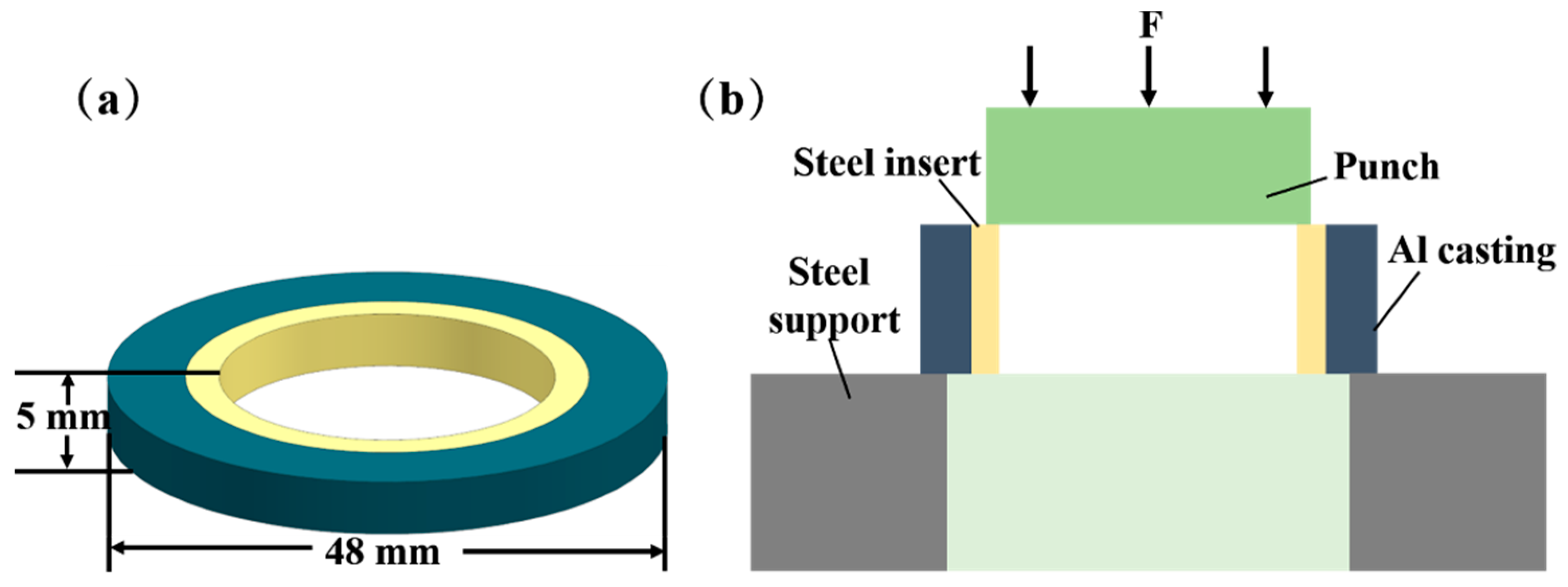

2.4. Mechanical Characterizations

3. Results

3.1. Effect of Eu on Eutectic Si of Al-Si Alloys

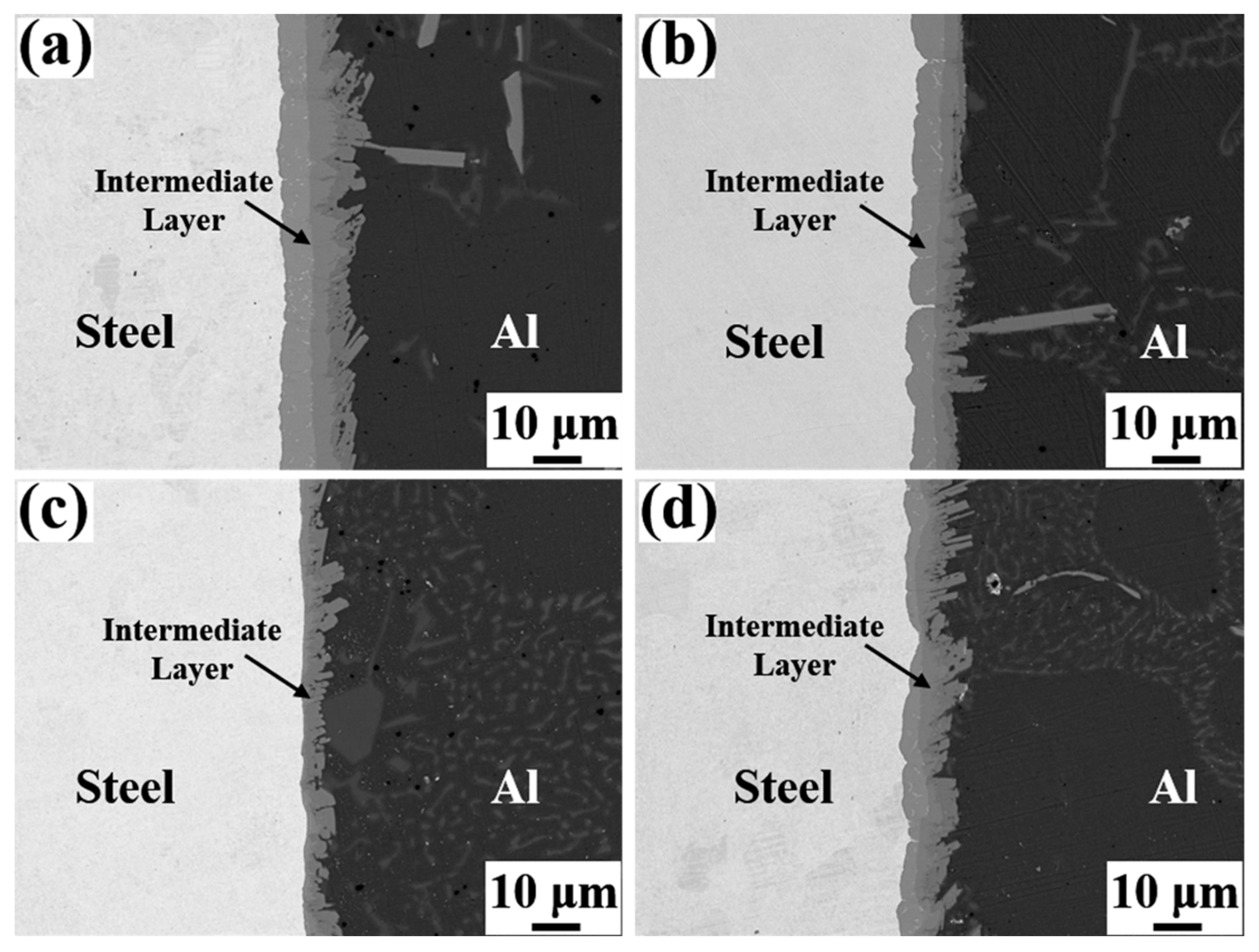

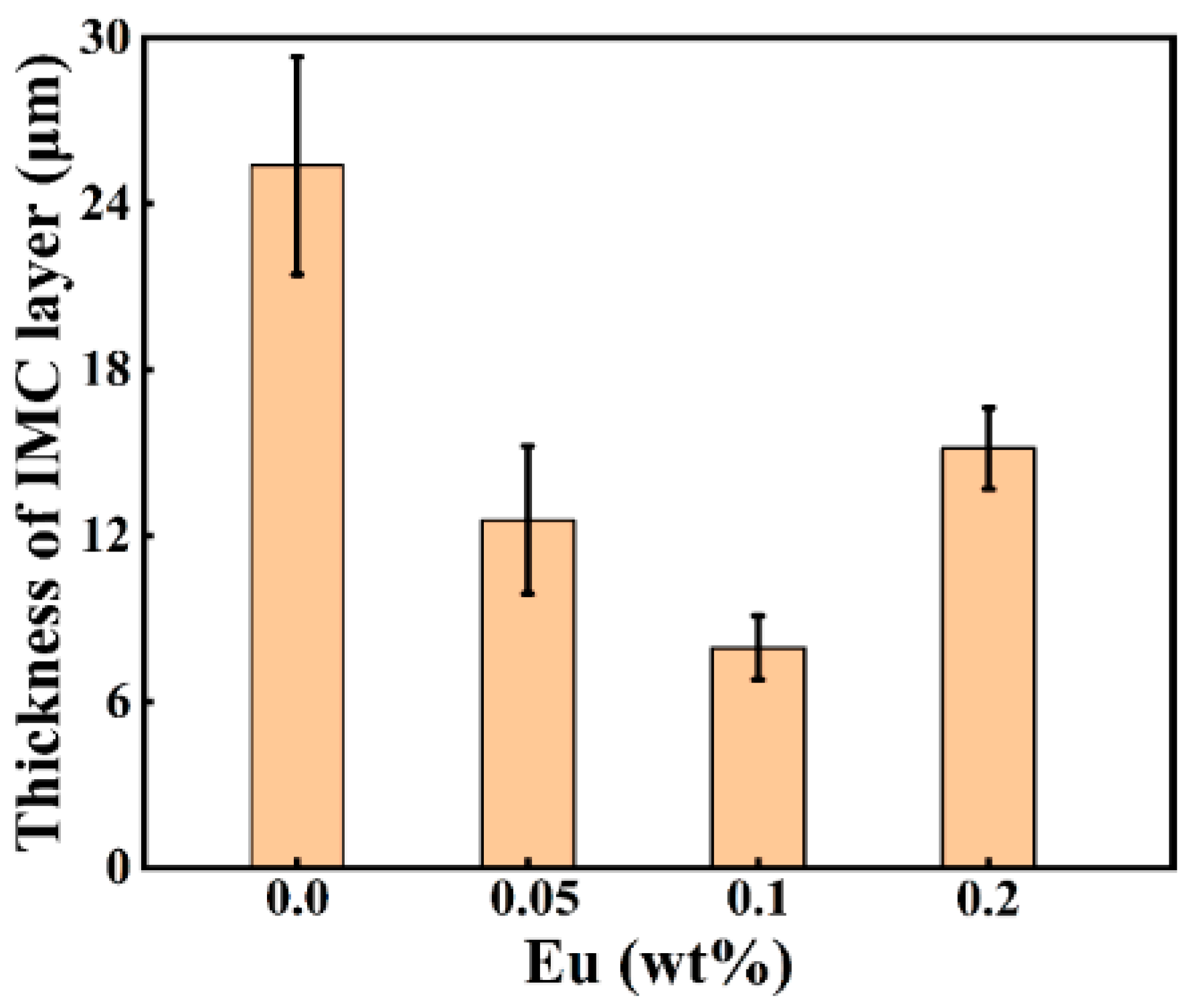

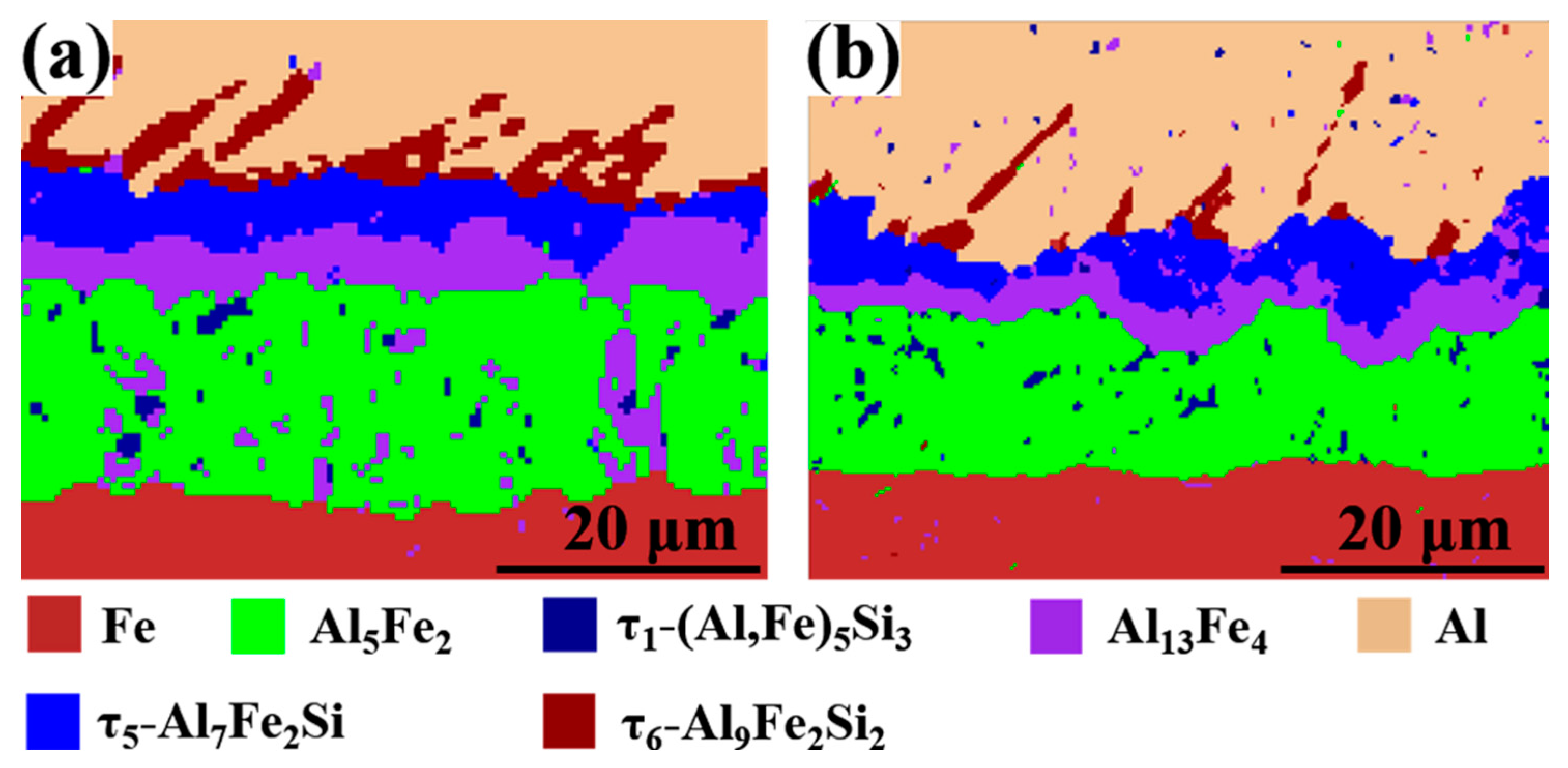

3.2. Effect of Eu Contents on Interface Microstructures of Al/Steel Bimetallic Composites

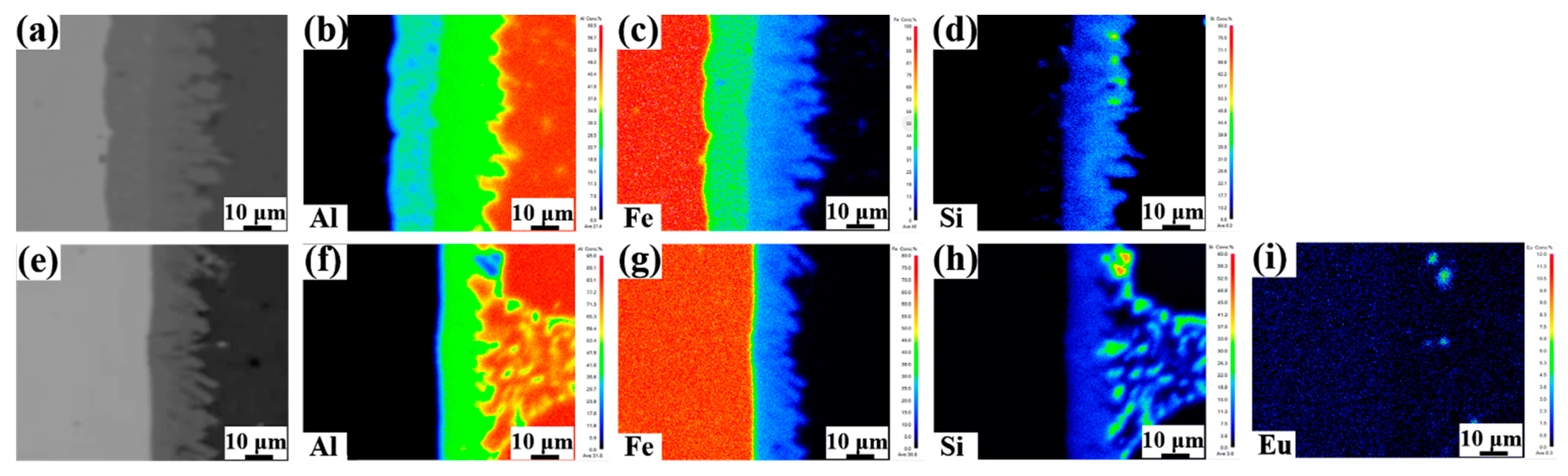

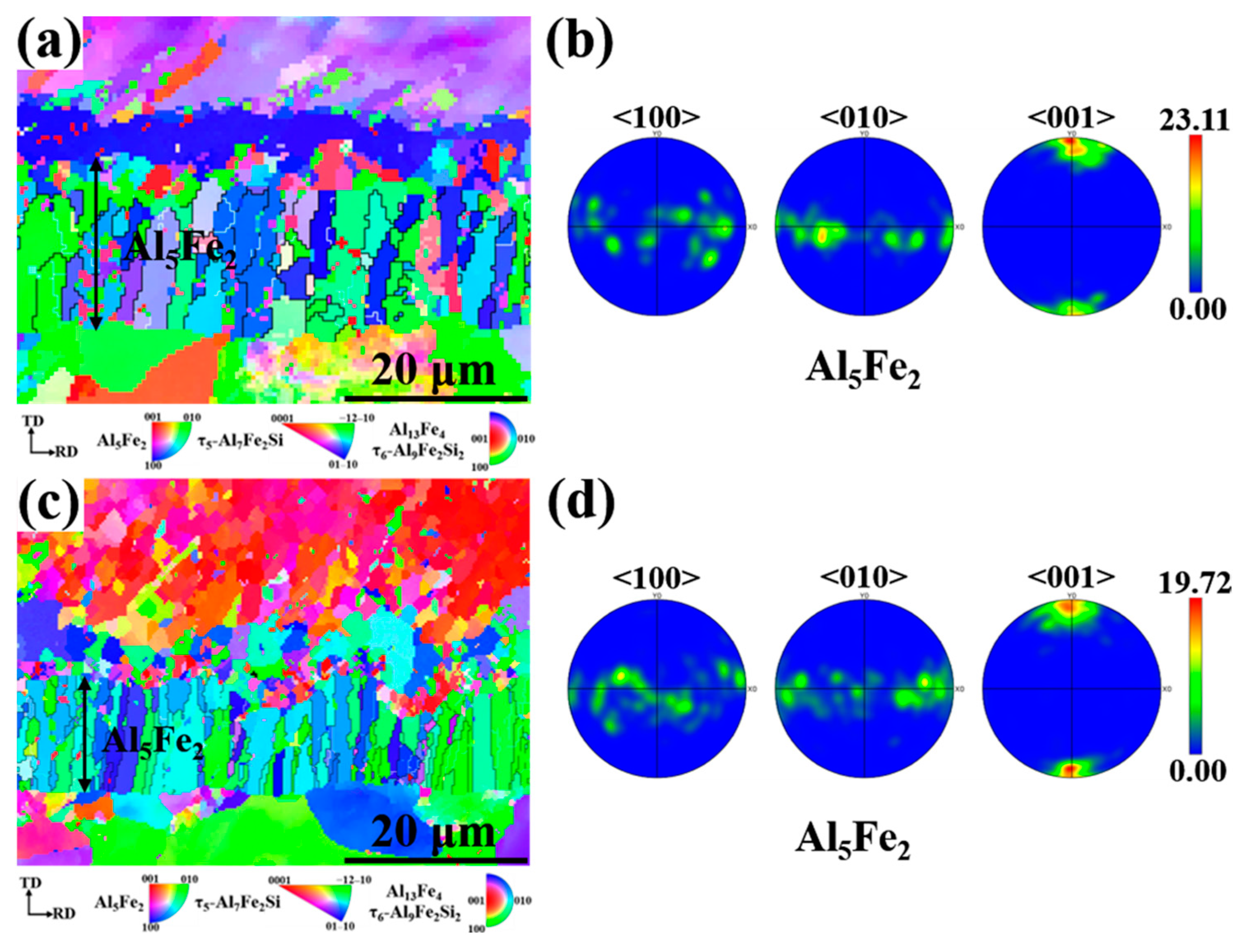

3.3. Effect Mechanism of Eu on Liquid-Solid Al/Steel Bimetallic Interface

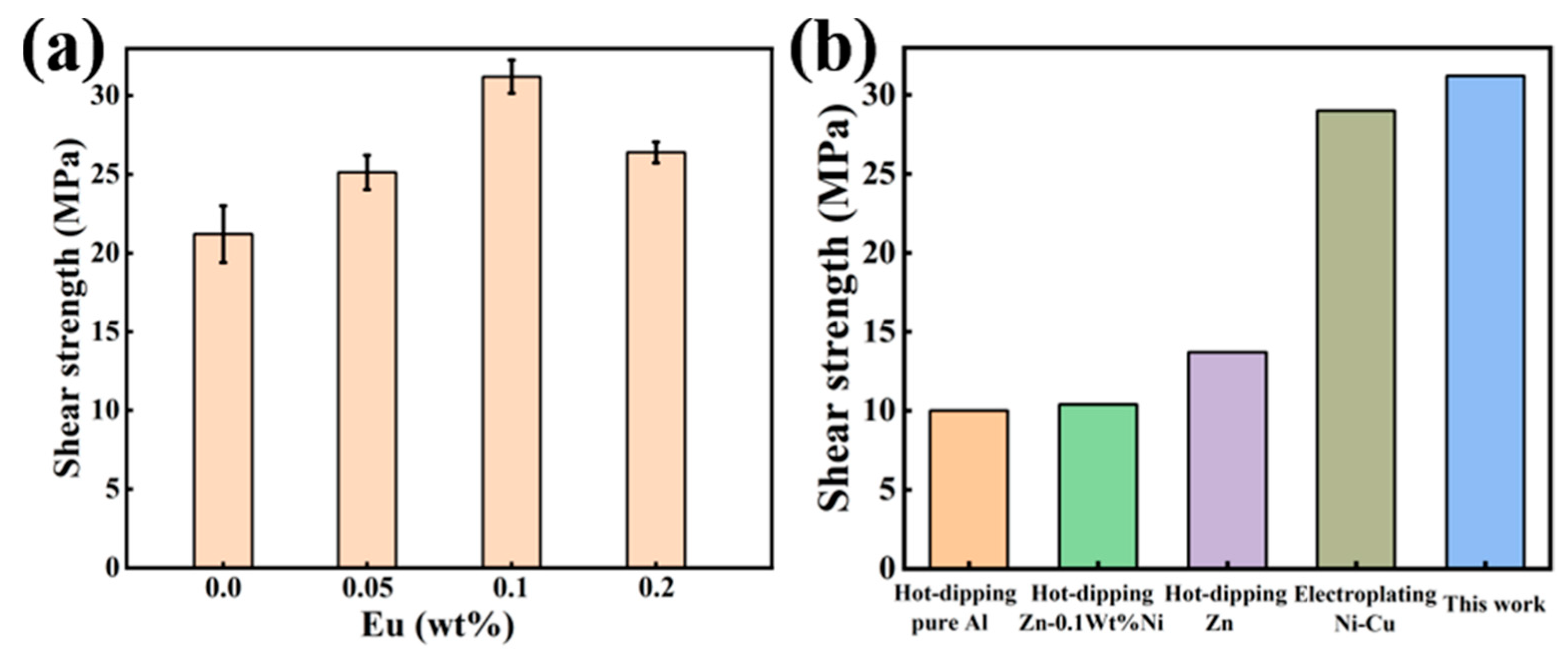

3.4. Mechanical Properties of the Al/Steel Bimetal

4. Conclusions

- (1)

- With the addition of 0.1 wt.% Eu, the morphology of eutectic silicon changed from plate-like to fine fibers with a more uniform distribution in the Al-Si alloy.

- (2)

- The Al/steel bimetallic interfacial reaction layer was composed of Al5Fe2, τ1-(Al, Si)5Fe3, Al13Fe4, τ5-Al7Fe2Si, and τ6-Al9Fe2Si2 phases. The intermetallic compound species in the reaction layer were unaffected by the addition of Eu.

- (3)

- When the Eu content is 0.1 wt.%, the average thickness of the reaction layer and the Al5Fe2 layer decreased to the minimum value. In addition, there was a more sudden drop of Fe in steel side and the Si in Al side was observed to be more than the other conditions.

- (4)

- The thickness of Al and Fe elements distribution in the reaction layer decreased as the content of Eu reached 0.1 wt.%. Eu was mainly enriched in the front of the ternary compound layer (τ6-Al9Fe2Si2) near the Al side and steel matrix.

- (5)

- The addition of the element Eu did not change the preferred orientation of the Al5Fe2, τ1-(Al, Si)5Fe3, Al13Fe4, τ5-Al7Fe2Si, and τ6-Al9Fe2Si2 phases, but refined the grain size of each phase in the interfacial reaction layer.

- (6)

- The highest shear strength of bimetallic specimens was obtained when the Eu content was 0.1 wt.%, which was 47% higher than that of bimetallic specimens without Eu addition.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ramadan, M.; Alghamdi, A.S.; Hafez, K.M.; Subhani, T.; Abdel Halim, K.S. Development and Optimization of Tin/Flux Mixture for Direct Tinning and Interfacial Bonding in Aluminum/Steel Bimetallic Compound Casting. Materials 2020, 13, 5642. [Google Scholar] [CrossRef] [PubMed]

- Chen, G.; Chang, X.S.; Liu, G.B.; Chen, Q.; Han, F.; Zhang, S.; Zhao, Z.D. Formation of metallurgical bonding interface in aluminum-steel bimetal parts by thixotropic-core compound forging. J. Mater. Process. Technol. 2020, 283, 116710. [Google Scholar] [CrossRef]

- Ramadan, M.; Alghamdi, A.S.; Subhani, T.; Halim, K.S.A. Fabrication and Characterization of Sn-Based Babbitt Alloy Nanocomposite Reinforced with Al2O3 Nanoparticles/Carbon Steel Bimetallic Material. Materials 2020, 13, 2759. [Google Scholar] [CrossRef] [PubMed]

- Fan, Z.S.; Huang, S.T.; Deng, J.H. Cladding of aluminum alloy 6061-T6 to mild steel by an electromagnetic tube bulging process: Finite element modeling. Adv. Manuf. 2019, 7, 73–83. [Google Scholar] [CrossRef]

- Guo, Z.L.; Liu, M.; Bian, X.F.; Liu, M.J.; Li, J.G. An Al–7Si alloy/cast iron bimetallic composite with super-high shear strength. J. Mater. Res. Technol. 2019, 8, 3126–3136. [Google Scholar] [CrossRef]

- Zhang, Y.; Bandyopadhyay, A. Influence of Compositionally Graded Interface on Microstructure and Compressive Deformation of 316L Stainless Steel to Al12Si Aluminum Alloy Bimetallic Structures. ACS Appl. Mater. Interfaces 2021, 13, 9174–9185. [Google Scholar] [CrossRef]

- Yu, F.; Wang, X.; Huang, T.; Chao, D. Effect of Grain Refiner on Fracture Toughness of 7050 Ingot and Plate. Materials 2021, 14, 6705. [Google Scholar] [CrossRef]

- Sui, Y.D.; Wang, Q.D.; Ye, B.; Zhang, L.; Jiang, H.Y.; Ding, W.J. Effect of solidification sequence on the microstructure and mechanical properties of die-cast Al–11Si–2Cu–Fe alloy. J. Alloys Compd. 2015, 649, 679–686. [Google Scholar] [CrossRef]

- Shaha, S.K.; Czerwinski, F.; Kasprzak, W.; Friedman, J.; Chen, D.L. Effect of Zr, V and Ti on hot compression behavior of the Al–Si cast alloy for powertrain applications. J. Alloys Compd. 2014, 615, 1019–1031. [Google Scholar] [CrossRef]

- Jiang, W.M.; Fan, Z.T.; Dai, Y.C.; Li, C. Effects of rare earth elements addition on microstructures, tensile properties and fractography of A357 alloy. Mater. Sci. Eng. A 2014, 597, 237–244. [Google Scholar] [CrossRef]

- Mao, F.; Yan, G.Y.; Xuan, Z.J.; Cao, Z.Q.; Wang, T.M. Effect of Eu addition on the microstructures and mechanical properties of A356 aluminum alloys. J. Alloys Compd. 2015, 650, 896–906. [Google Scholar] [CrossRef]

- Yao, Z.S.; Xu, G.; Jiang, Z.Y.; Tian, J.Y.; Yuan, Q.; Ma, H.W. Effects of Ni and Cr on Cryogenic Impact Toughness of Bainite/Martensite Multiphase Steels. Met. Mater. Int. 2019, 25, 1151–1160. [Google Scholar] [CrossRef]

- Yoon, J.I.; Jung, J.; Lee, H.H.; Kim, J.Y.; Kim, H.S. Relationships Between Stretch-Flangeability and Microstructure-Mechanical Properties in Ultra-High-Strength Dual-Phase Steels. Met. Mater. Int. 2019, 25, 1161–1169. [Google Scholar] [CrossRef]

- Jiang, W.M.; Li, G.Y.; Wu, Y.; Liu, X.W.; Fan, Z.T. Effect of heat treatment on bonding strength of aluminum/steel bimetal produced by a compound casting. J. Mater. Process. Technol. 2018, 258, 239–250. [Google Scholar] [CrossRef]

- Khoonsari, E.M.; Jalilian, F.; Paray, F.; Emadi, D.; Drew, R.A.L. Interaction of 308 stainless steel insert with A319 aluminium casting alloy. Mater. Sci. Technol. 2013, 26, 833–841. [Google Scholar] [CrossRef]

- Shao, L.; Shi, Y.; Huang, J.K.; Wu, S.J. Effect of joining parameters on microstructure of dissimilar metal joints between aluminum and galvanized steel. Mater. Des. 2015, 66, 453–458. [Google Scholar] [CrossRef]

- Pontevichi, S.; Bosselet, F.; Barbeau, F.; Peronnet, M.; Viala, J.C. Solid-Liquid Phase Equilibria in the Al-Fe-Si System at 727 °C. J. Phase Equilib. Diffus. 2004, 25, 528–537. [Google Scholar] [CrossRef]

- Springer, H.; Kostka, A.; Payton, E.J.; Raabe, D.; Kaysser-Pyzalla, A.; Eggeler, G. On the formation and growth of intermetallic phases during interdiffusion between low-carbon steel and aluminum alloys. Acta Mater. 2011, 59, 1586–1600. [Google Scholar] [CrossRef]

- Jiang, W.M.; Fan, Z.T.; Li, C. Improved steel/aluminum bonding in bimetallic castings by a compound casting process. J. Mater. Process. Technol. 2015, 226, 25–31. [Google Scholar] [CrossRef]

- Jiang, W.M.; Fan, Z.T.; Li, G.Y.; Liu, X.W.; Liu, F.C. Effects of hot-dip galvanizing and aluminizing on interfacial microstructures and mechanical properties of aluminum/iron bimetallic composites. J. Alloys Compd. 2016, 688, 742–751. [Google Scholar] [CrossRef]

- Jiang, W.M.; Fan, Z.T.; Li, G.Y.; Li, C. Effects of zinc coating on interfacial microstructures and mechanical properties of aluminum/steel bimetallic composites. J. Alloys Compd. 2016, 678, 249–257. [Google Scholar] [CrossRef]

- Cheng, W.J.; Wang, C.J. Effect of silicon on the formation of intermetallic phases in aluminide coating on mild steel. Intermetallics 2011, 19, 1455–1460. [Google Scholar] [CrossRef]

- Chen, X.C.; Peng, H.P.; Su, X.P.; Liu, Y.; Wu, C.J.; Chen, H.R. Effect of Nickel on the Microstructures of Coating in Hot-Dipped Aluminide Steel. Mater. Manuf. Process. 2015, 31, 1261–1268. [Google Scholar] [CrossRef]

- Mingo, B.; Arrabal, R.; Mohedano, M.; Mendis, C.L.; del Olmo, R.; Matykina, E.; Hort, N.; Merino, M.C.; Pardo, A. Corrosion of Mg-9Al alloy with minor alloying elements (Mn, Nd, Ca, Y and Sn). Mater. Des. 2017, 130, 48–58. [Google Scholar] [CrossRef]

- Liu, H.H.; Fu, P.X.; Liu, H.W.; Cao, Y.F.; Sun, C.; Du, N.Y.; Li, D.Z. Effects of Rare Earth elements on microstructure evolution and mechanical properties of 718H pre-hardened mold steel. J. Mater. Sci. Technol. 2020, 50, 245–256. [Google Scholar] [CrossRef]

- Chen, L.; Hu, M.Y.; Guo, J.; Chong, X.Y.; Feng, J. Mechanical and thermal properties of RETaO4 (RE = Yb, Lu, Sc) ceramics with monoclinic-prime phase. J. Mater. Sci. Technol. 2020, 52, 20–28. [Google Scholar] [CrossRef]

- Cai, Q.; Zhai, C.; Luo, Q.; Zhang, T.Y.; Li, Q. Effects of magnetic field on the microstructure and mechanical property of Mg-Al-Gd alloys. Mater. Charact. 2019, 154, 233–240. [Google Scholar] [CrossRef]

- Li, J.H.; Wang, X.D.; Ludwig, T.H.; Tsunekawa, Y.; Arnberg, L.; Jiang, J.Z.; Schumacher, P. Modification of eutectic Si in Al–Si alloys with Eu addition. Acta Mater. 2015, 84, 153–163. [Google Scholar] [CrossRef]

- Muhammad, A.; Xu, C.; Wang, X.J.; Hanada, S.J.; Yamagata, H.; Hao, L.R.; Ma, C.L. High strength aluminum cast alloy: A Sc modification of a standard Al–Si–Mg cast alloy. Mater. Sci. Eng. A 2014, 604, 122–126. [Google Scholar] [CrossRef]

- Shi, Z.M.; Wang, Q.; Zhao, G.; Zhang, R.Y. Effects of erbium modification on the microstructure and mechanical properties of A356 aluminum alloys. Mater. Sci. Eng. A 2015, 626, 102–107. [Google Scholar] [CrossRef]

- Li, B.; Wang, H.W.; Jie, J.C.; Wei, Z.J. Effects of yttrium and heat treatment on the microstructure and tensile properties of Al–7.5Si–0.5Mg alloy. Mater. Des. 2011, 32, 1617–1622. [Google Scholar] [CrossRef]

- Du, Y.; Schuster, J.C.; Liu, Z.K.; Hu, R.X.; Nash, P.; Sun, W.H.; Zhang, W.W.; Wang, J.; Zhang, L.J.; Tang, C.Y.; et al. A thermodynamic description of the Al–Fe–Si system over the whole composition and temperature ranges via a hybrid approach of CALPHAD and key experiments. Intermetallics 2008, 16, 554–570. [Google Scholar] [CrossRef]

- Burkhardt, U.; Grin, Y.; Ellner, M.; Peters, K. Structure Refinement of the Iron-Aluminium Phase with the Approximate Composition Fe2Al5. Acta Crystall. Sect. B Struct. Sci. 1994, 50, 313–316. [Google Scholar] [CrossRef]

- Grin, J.; Burkhardt, U.; Ellner, M.; Peters, K. Refinement of the Fe4Al13 structure and its relationship to the quasihomological homeotypical structures. Z. Kristallogr. Cryst. Mater. 1994, 209, 479–487. [Google Scholar] [CrossRef]

- Yanson, T.I.; Manyako, M.B.; Bodak, O.I.; German, N.V.; Zarechnyuk, O.S.; Cerný, R.; Pacheco, J.V.; Yvon, K. Triclinic Fe3Al2Si3 and orthorhombic Fe3Al2Si4 with new structure types. Acta Crystallogr. Sect. C Cryst. Struct. Commun. 1996, 52, 2964–2967. [Google Scholar] [CrossRef]

- Roger, J.; Bosselet, F.; Viala, J.C. X-rays structural analysis and thermal stability studies of the ternary compound α-AlFeSi. J. Solid State Chem. 2011, 184, 1120–1128. [Google Scholar] [CrossRef]

- Rømming, C.; Hansen, V.; Gjønnes, J. Crystal structure of β-Al4. 5FeSi. Acta Crystall. Sect. B Struct. Sci. 1994, 50, 307–312. [Google Scholar] [CrossRef]

- Li, Y.L.; Liu, Y.R.; Yang, J. First principle calculations and mechanical properties of the intermetallic compounds in a laser welded steel/aluminum joint. Opt. Laser Technol. 2020, 122, 105875. [Google Scholar] [CrossRef]

- Takata, N.; Nishimoto, M.; Kobayashi, S.; Takeyama, M. Crystallography of Fe2Al5 phase at the interface between solid Fe and liquid Al. Intermetallics 2015, 67, 1–11. [Google Scholar] [CrossRef]

- Takata, N.; Nishimoto, M.; Kobayashi, S.; Takeyama, M. Morphology and formation of Fe–Al intermetallic layers on iron hot-dipped in Al–Mg–Si alloy melt. Intermetallics 2014, 54, 136–142. [Google Scholar] [CrossRef]

- Richards, R.W.; Jones, R.D.; Clements, P.D.; Clarke, H. Metallurgy of continuous hot dip aluminizing. Int. Mater. Rev. 1994, 39, 191–212. [Google Scholar] [CrossRef]

- Bahadur, A.; Mohanty, O. Structural Studies of Hot Dip Aluminized Coatings on Mild Steel. Mater. Trans. JIM 1991, 32, 1053–1061. [Google Scholar] [CrossRef]

- Dezellus, O.; Digonnet, B.; Sacerdote-Peronnet, M.; Bosselet, F.; Rouby, D.; Viala, J.C. Mechanical testing of steel/aluminium–silicon interfaces by pushout. Int. J. Adhes. Adhes. 2007, 27, 417–421. [Google Scholar] [CrossRef]

- Aguado, E.; Baquedano, A.; Uribe, U.; Fernandez-Calvo, A.I.; Niklas, A. Comparative Study of Different Interfaces of Steel Inserts in Aluminium Castings. Mater. Sci. Forum 2013, 765, 711–715. [Google Scholar] [CrossRef]

| Alloys | Compositions | |||||||

|---|---|---|---|---|---|---|---|---|

| Al | Si | Eu | Fe | Cu | C | Mn | Cr | |

| 45 steel | - | 0.24 | - | Bal. | 0.21 | 0.45 | 0.57 | 0.17 |

| Al-7Si | Bal. | 6.97 | 0 | 0.07 | <0.01 | - | <0.01 | - |

| Al-7Si-0.05Eu | Bal. | 6.98 | 0.047 | 0.06 | <0.01 | - | <0.01 | - |

| Al-7Si-0.1Eu | Bal. | 7.03 | 0.09 | 0.06 | <0.01 | - | <0.01 | - |

| Al-7Si-0.2Eu | Bal. | 6.95 | 0.198 | 0.08 | <0.01 | - | <0.01 | - |

| Points | Compositions (at%) | Possible Phase | ||

|---|---|---|---|---|

| Al | Fe | Si | ||

| 1 | 68.62 | 28.74 | 2.64 | Al5Fe2 |

| 2 | 48.18 | 37.71 | 14.11 | τ1-(Al, Fe)5Si3 |

| 3 | 73.93 | 23.34 | 2.73 | Al13Fe4 |

| 4 | 68.95 | 20.86 | 10.19 | τ5-Al7Fe2Si |

| 5 | 70.69 | 16.03 | 13.28 | τ6-Al9Fe2Si2 |

| Points | Compositions (at%) | Possible Phase | |||

|---|---|---|---|---|---|

| Al | Fe | Si | Eu | ||

| 1 | 69.16 | 29.44 | 1.39 | 0.01 | Al5Fe2 |

| 2 | 46.37 | 39.03 | 14.58 | 0.02 | τ1-(Al, Fe)5Si3 |

| 3 | 71.01 | 24.34 | 3.99 | 0.06 | Al13Fe4 |

| 4 | 67.09 | 21.71 | 11.12 | 0.08 | τ5-Al7Fe2Si |

| 5 | 69.49 | 15.24 | 15.08 | 0.19 | τ6-Al9Fe2Si2 |

| Points | Compositions (at%) | Possible Phase | |||

|---|---|---|---|---|---|

| Al | Fe | Si | Eu | ||

| 1 | 67.11 | 29.75 | 3.14 | 0.00 | Al5Fe2 |

| 2 | 53.89 | 34.95 | 11.15 | 0.01 | τ1-(Al, Fe)5Si3 |

| 3 | 70.74 | 25.67 | 3.54 | 0.05 | Al13Fe4 |

| 4 | 68.37 | 20.64 | 10.89 | 0.1 | τ5-Al7Fe2Si |

| 5 | 67.48 | 15.56 | 16.32 | 0.64 | τ6-Al9Fe2Si2 |

| Points | Compositions (at%) | Possible Phase | |||

|---|---|---|---|---|---|

| Al | Fe | Si | Eu | ||

| 1 | 68.18 | 29.02 | 2.79 | 0.01 | Al5Fe2 |

| 2 | 45.51 | 15.25 | 39.18 | 0.06 | τ1-(Al, Fe)5Si3 |

| 3 | 73.95 | 23.57 | 2.41 | 0.07 | Al13Fe4 |

| 4 | 67.69 | 20.94 | 11.19 | 0.18 | τ5-Al7Fe2Si |

| 5 | 65.88 | 16.91 | 16.78 | 0.43 | τ6-Al9Fe2Si2 |

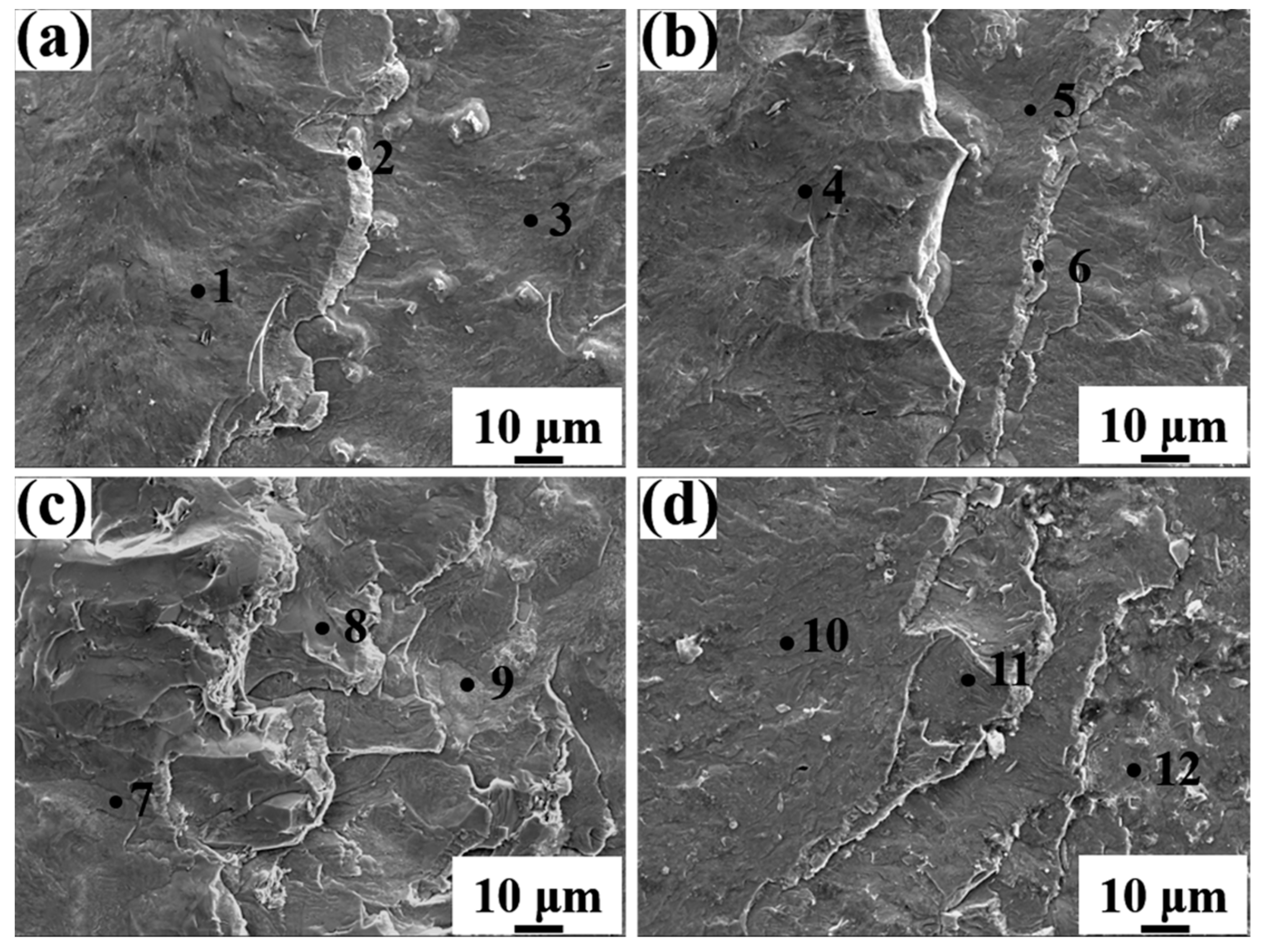

| Points | Compositions (at%) | Phase | |||

|---|---|---|---|---|---|

| Al | Fe | Si | Eu | ||

| 1 | 70.59 | 27.51 | 1.90 | 0.00 | Al5Fe2 |

| 2 | 69.09 | 28.29 | 2.62 | 0.00 | Al5Fe2 |

| 3 | 69.81 | 27.85 | 2.34 | 0.00 | Al5Fe2 |

| 4 | 69.58 | 28.07 | 2.18 | 0.17 | Al5Fe2 |

| 5 | 69.20 | 28.10 | 2.63 | 0.07 | Al5Fe2 |

| 6 | 69.64 | 28.90 | 1.31 | 0.15 | Al5Fe2 |

| 7 | 67.36 | 29.93 | 2.50 | 0.21 | Al5Fe2 |

| 8 | 68.34 | 27.34 | 3.86 | 0.46 | Al5Fe2 |

| 9 | 70.61 | 27.87 | 1.39 | 0.13 | Al5Fe2 |

| 10 | 69.76 | 28.44 | 1.75 | 0.06 | Al5Fe2 |

| 11 | 70.51 | 28.09 | 1.29 | 0.11 | Al5Fe2 |

| 12 | 67.92 | 29.14 | 2.86 | 0.08 | Al5Fe2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mao, F.; Zhang, P.; Wei, S.; Chen, C.; Zhang, G.; Xiong, M.; Wang, T.; Guo, J.; Wang, C. Interface Microstructure and Mechanical Properties of Al/Steel Bimetallic Composites Fabricated by Liquid-Solid Casting with Rare Earth Eu Additions. Materials 2022, 15, 6507. https://doi.org/10.3390/ma15196507

Mao F, Zhang P, Wei S, Chen C, Zhang G, Xiong M, Wang T, Guo J, Wang C. Interface Microstructure and Mechanical Properties of Al/Steel Bimetallic Composites Fabricated by Liquid-Solid Casting with Rare Earth Eu Additions. Materials. 2022; 15(19):6507. https://doi.org/10.3390/ma15196507

Chicago/Turabian StyleMao, Feng, Po Zhang, Shizhong Wei, Chong Chen, Guoshang Zhang, Mei Xiong, Tao Wang, Junliang Guo, and Changji Wang. 2022. "Interface Microstructure and Mechanical Properties of Al/Steel Bimetallic Composites Fabricated by Liquid-Solid Casting with Rare Earth Eu Additions" Materials 15, no. 19: 6507. https://doi.org/10.3390/ma15196507

APA StyleMao, F., Zhang, P., Wei, S., Chen, C., Zhang, G., Xiong, M., Wang, T., Guo, J., & Wang, C. (2022). Interface Microstructure and Mechanical Properties of Al/Steel Bimetallic Composites Fabricated by Liquid-Solid Casting with Rare Earth Eu Additions. Materials, 15(19), 6507. https://doi.org/10.3390/ma15196507