Controlling Welding Residual Stress and Distortion of High-Strength Aluminum Alloy Thin Plates by a Trailing Hybrid High-Speed Gas Fluid Field

Abstract

:1. Introduction

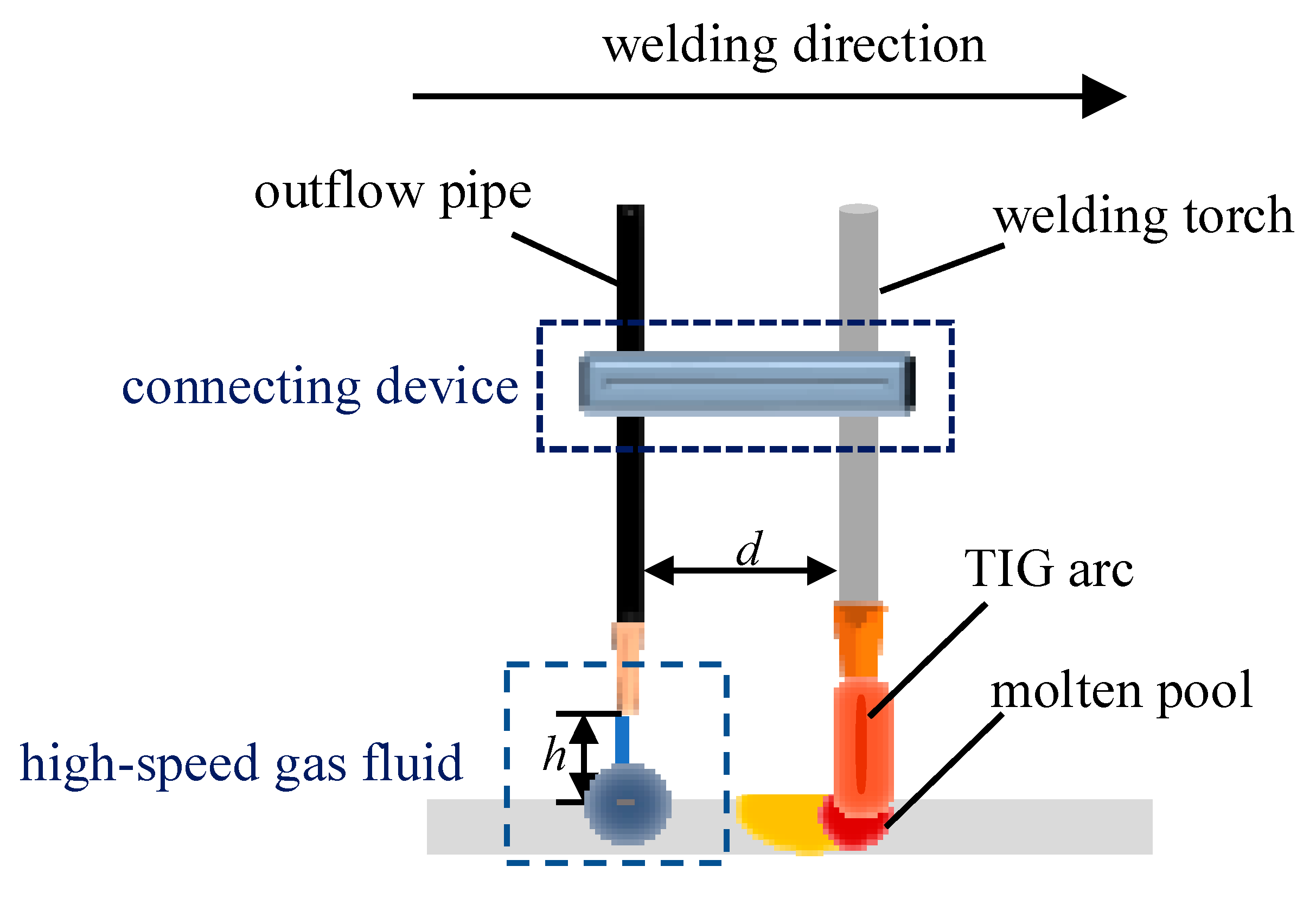

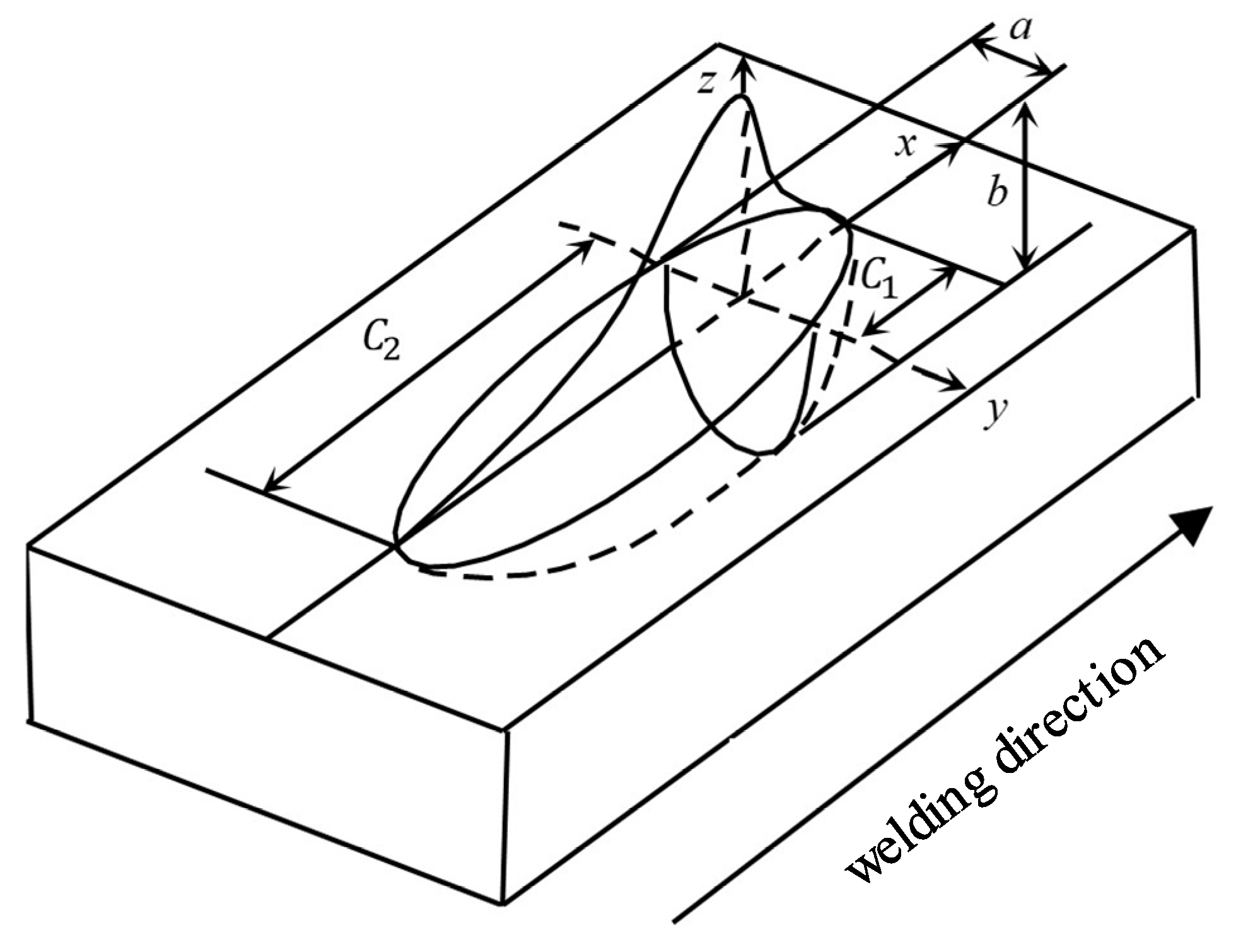

2. Modeling of the Welding of the Trailing of the Hybrid High-Speed Gas Fluid Field

2.1. Theoretical Fundamentals

2.2. The Principle of Controlling the Distortion of Thin Plate Welding with High-Speed Welding

2.3. Parametric Characterization of the Aerodynamic Load

3. Numerical Simulation of Welding with the Trailing of the Hybrid High-Speed Gas Fluid Field

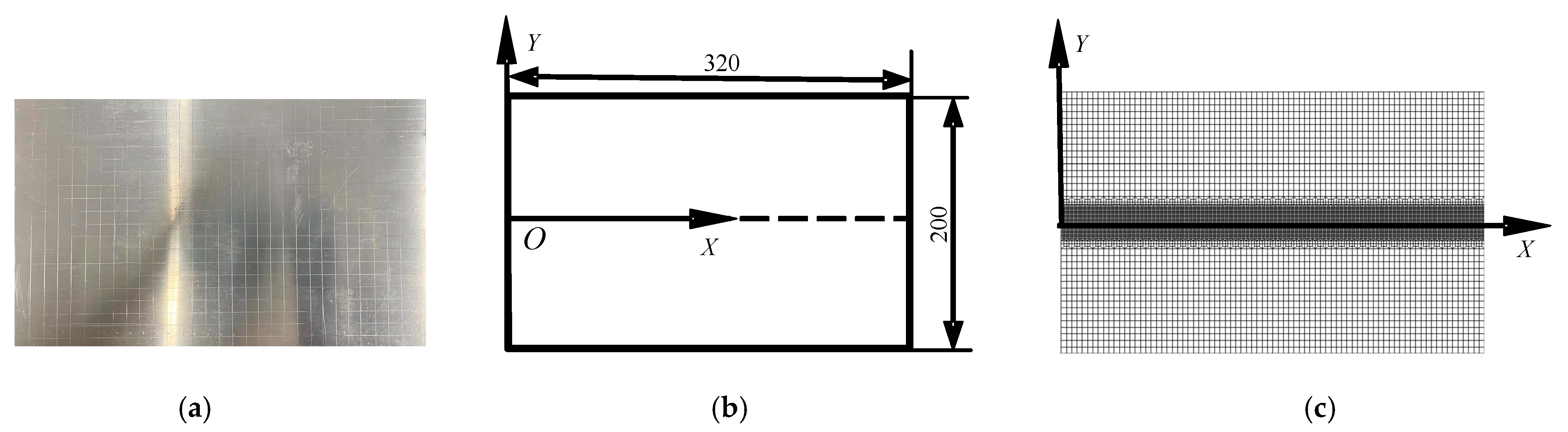

3.1. Finite Element Modeling

3.2. Development and Compilation of the Aerodynamic Load Subroutines

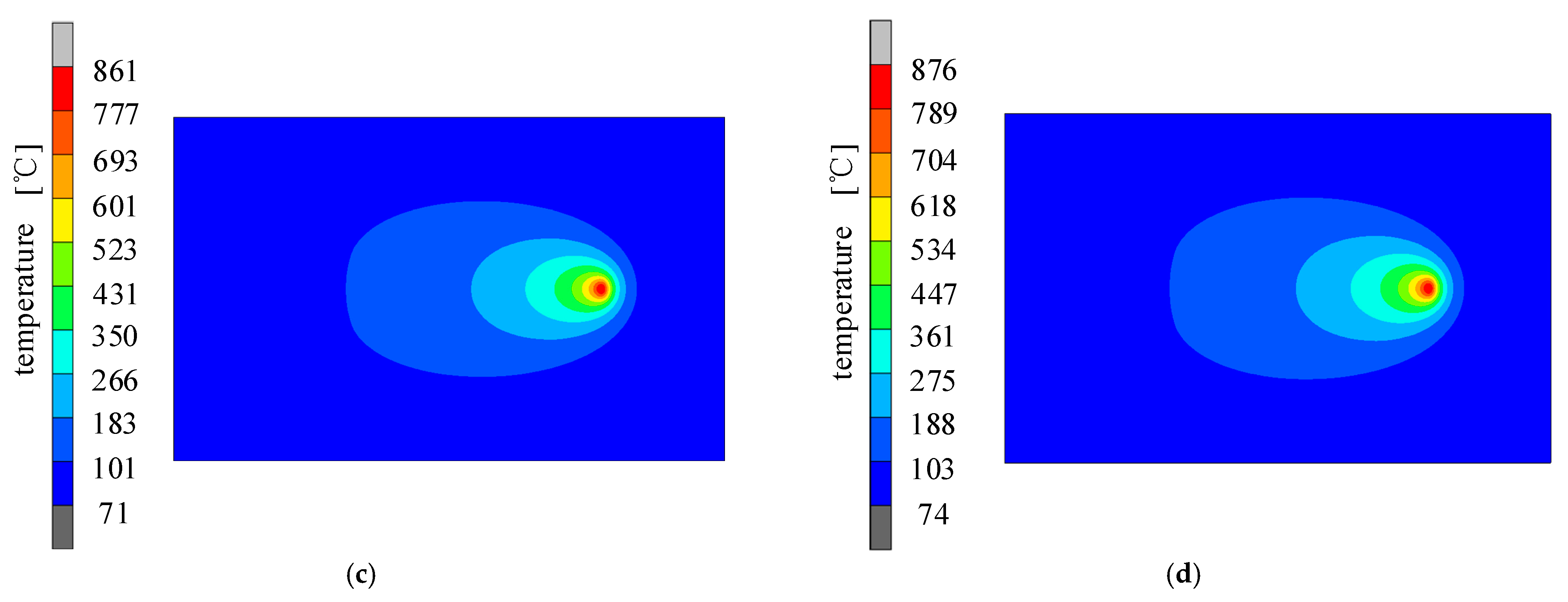

3.3. Temperature Field with the Action of Welding with the Trailing of the Hybrid High-Speed Gas Fluid Field

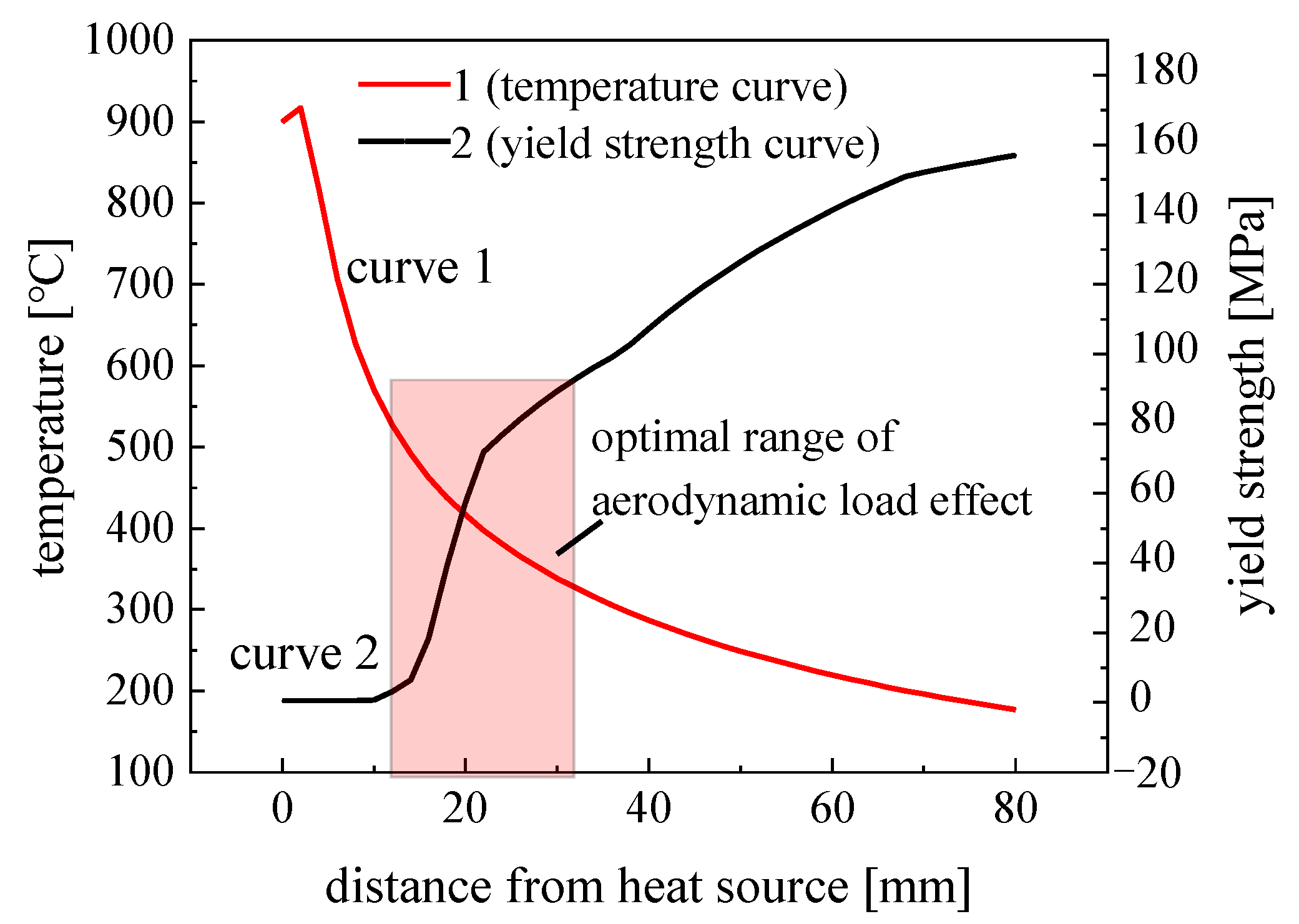

3.4. Determination of the Aerodynamic Load Action Distance Range

3.5. Variations in the Welding Residual Stress under an Aerodynamic Load

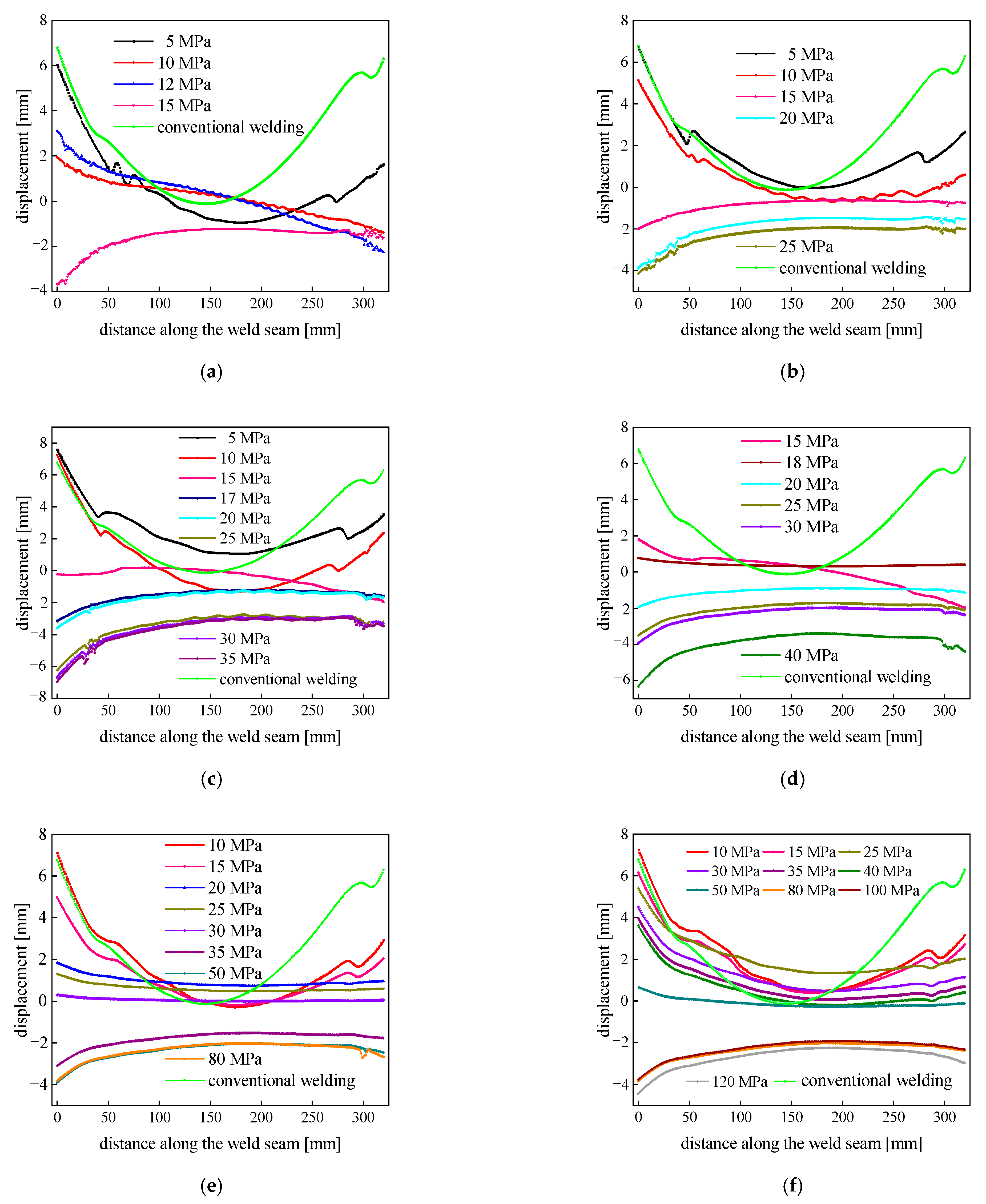

3.6. Analysis of the Welding Deflection Distortion under an Aerodynamic Load

4. Welding Test with the Trailing of the Hybrid High-Speed Gas Fluid Field

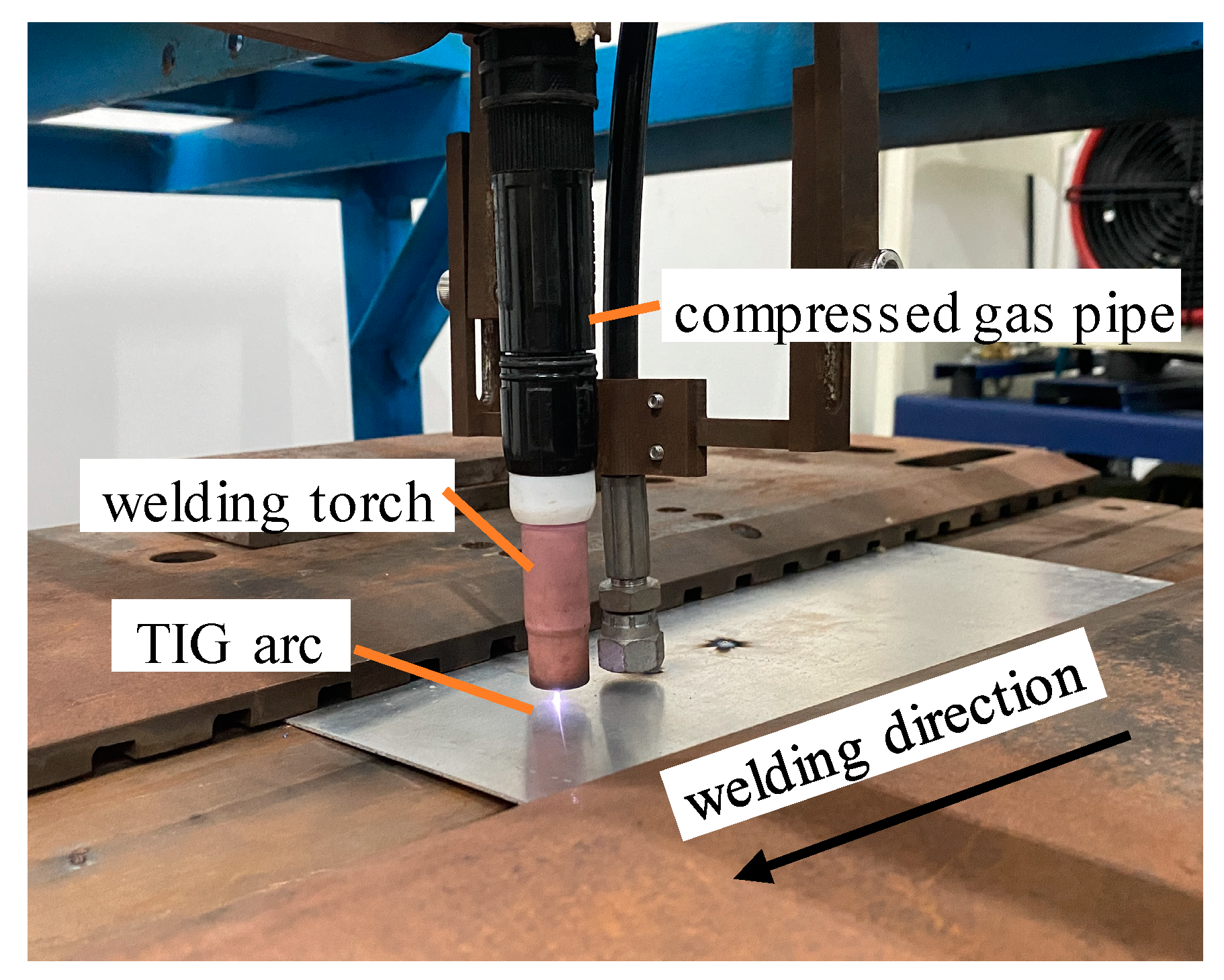

4.1. Welding Test

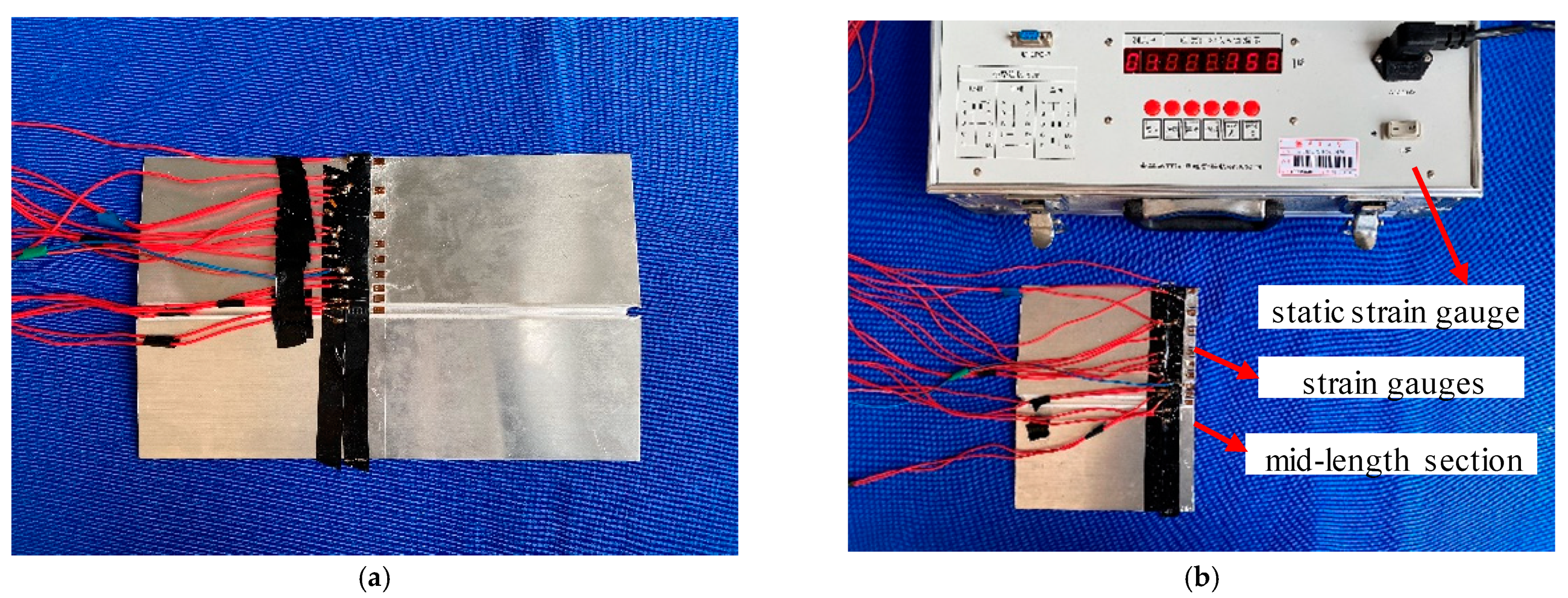

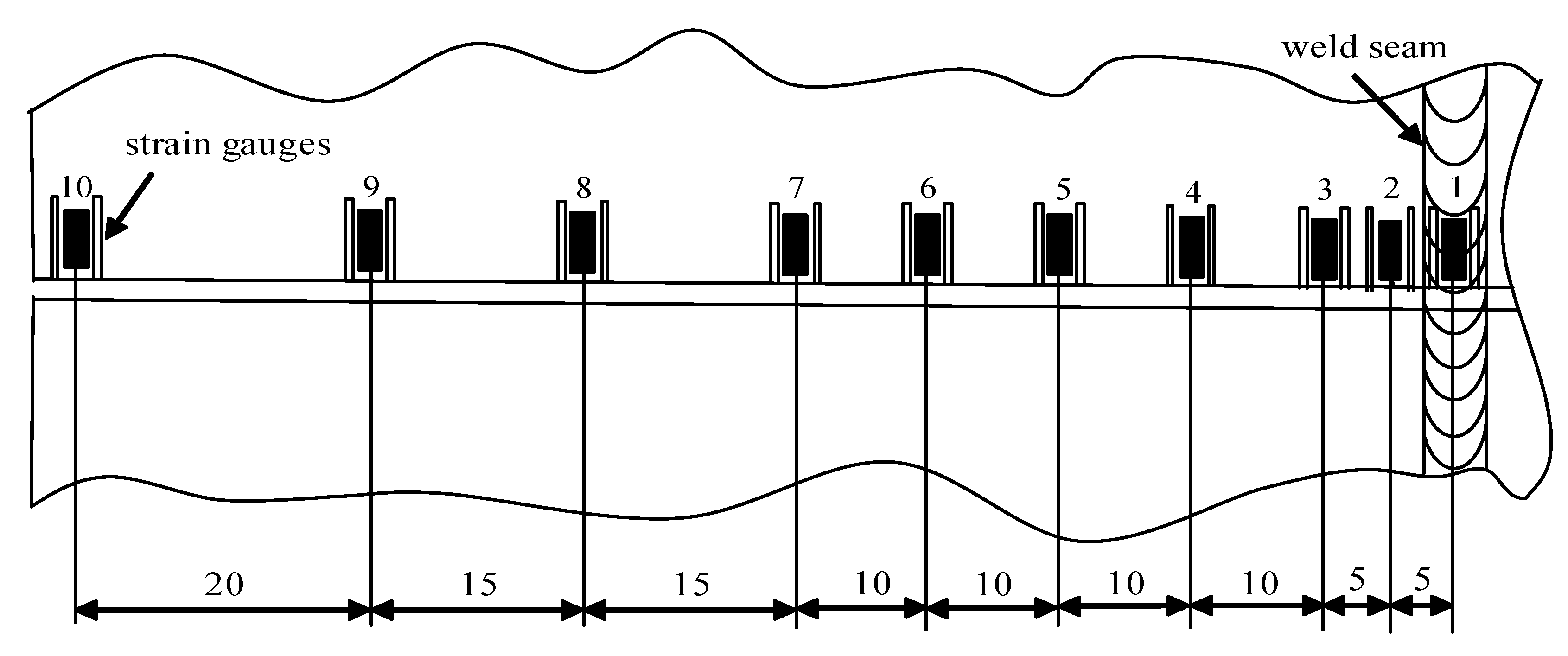

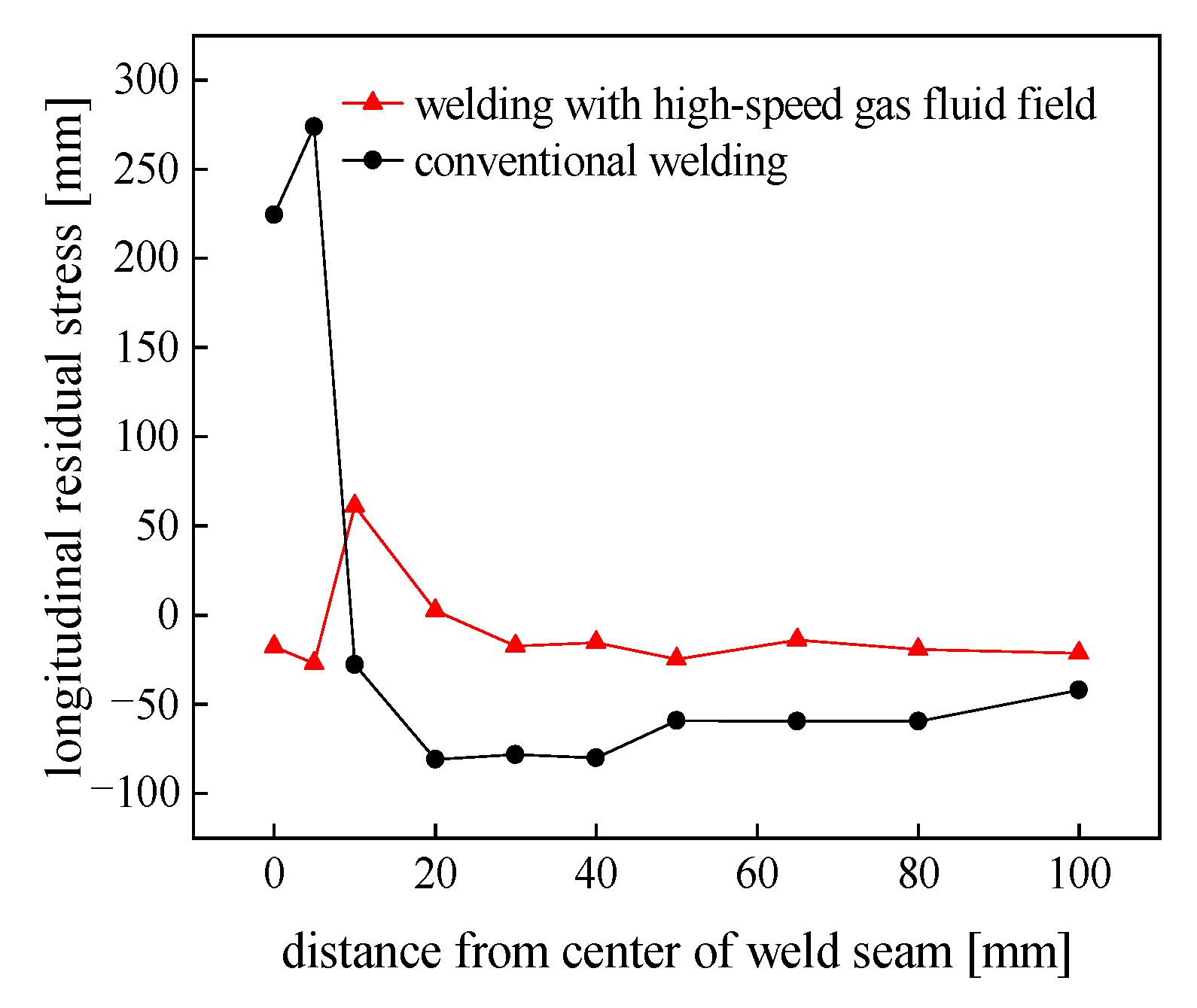

4.2. Longitudinal Residual Stress Test under a High Speed Gas Fluid Field during Welding

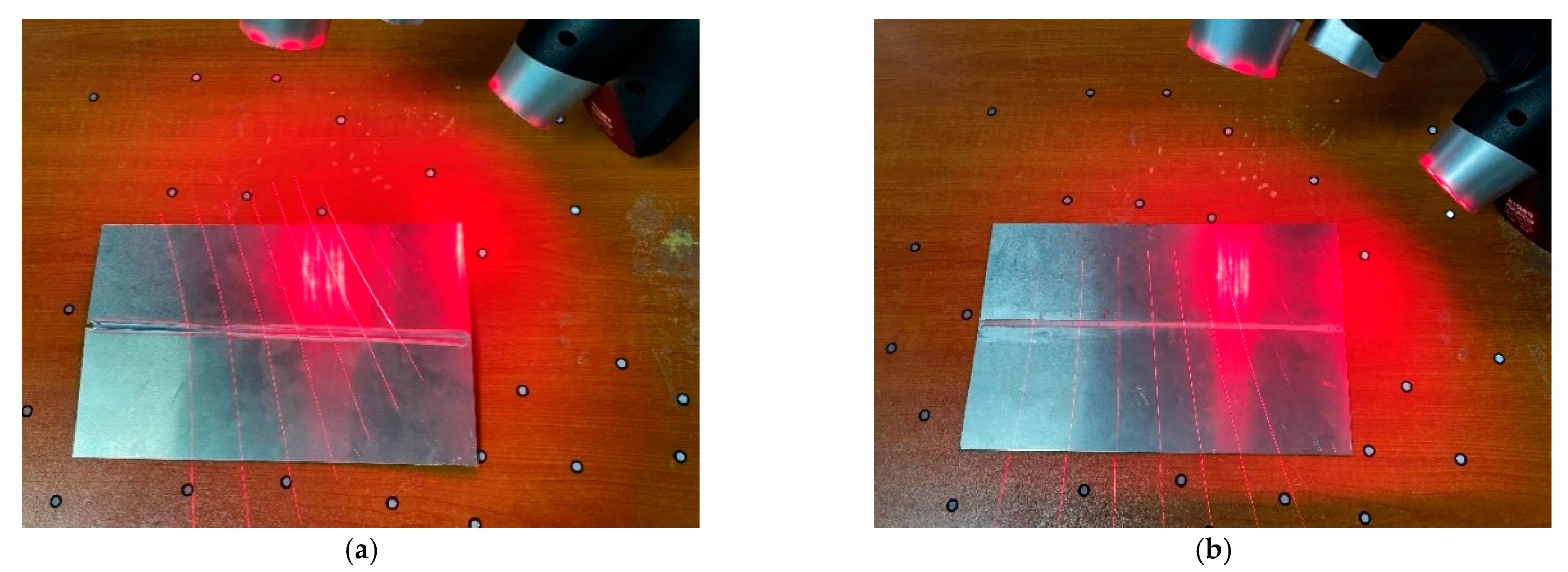

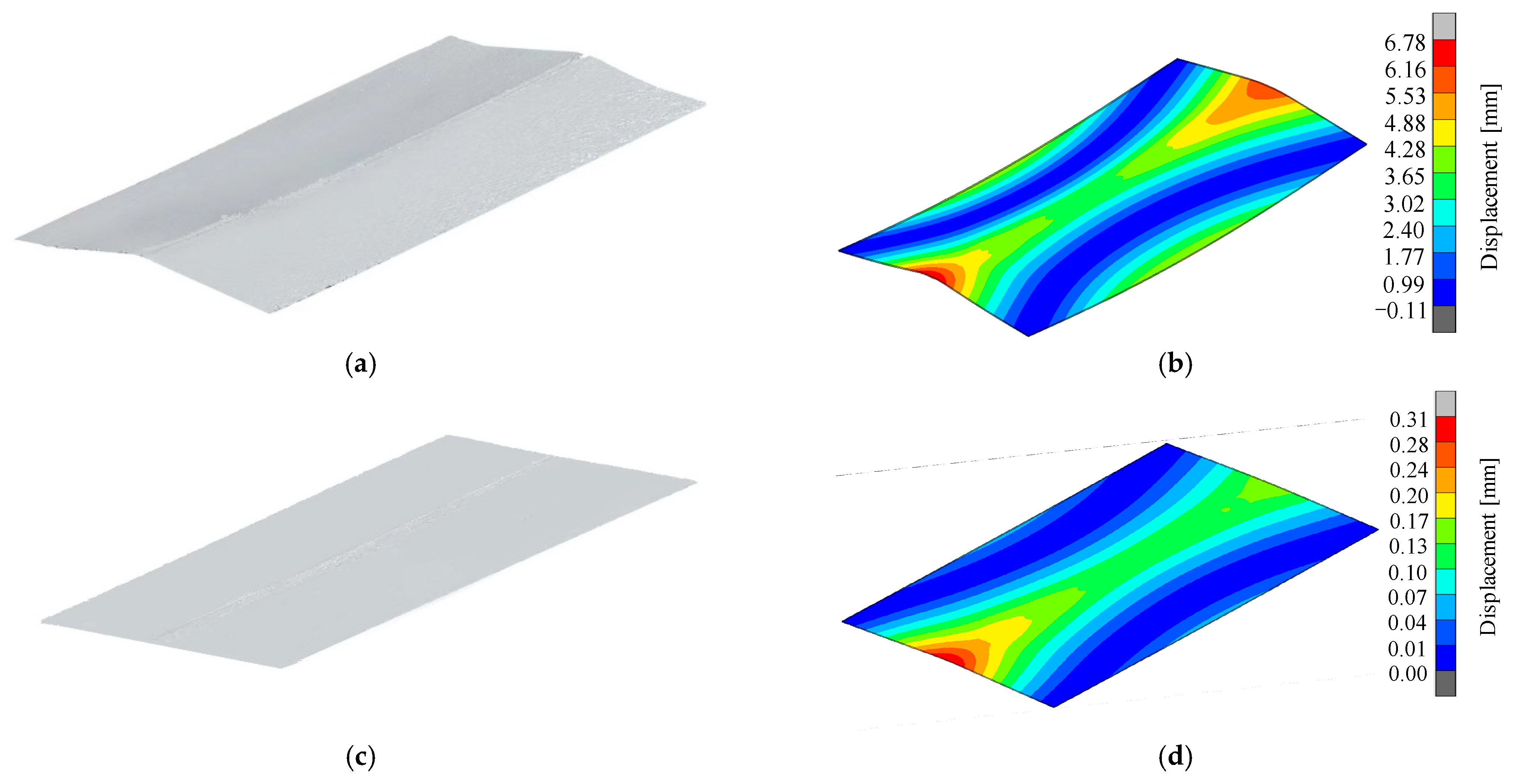

4.3. Flexural Distortion Test under a High-Speed Gas Fluid Field during Welding

5. Conclusions

- (1)

- A new method was proposed to control the welding distortion of high-strength aluminum alloy sheet by “welding with a trailing hybrid high-speed gas fluid field”. It was based on the original perspectives of mechanical mechanisms and the concept of “flexible” control. Otherwise, a welding distortion control model was established with a trailing hybrid high-speed gas fluid field, which was also parametrically characterized;

- (2)

- Through the numerical simulations of the temperature field of the welding process under conditions of welding with a trailing hybrid high-speed gas fluid field, the effective action distance (d) between the aerodynamic load and the heat source was determined to range from 12 to 32 mm. Various aerodynamic loads were set according to the corresponding loading distance (d). The longitudinal residual stresses in the mid-length section were measured at an aerodynamic load loading distance of 20 mm and a gas pressure of 30 MPa;

- (3)

- The aerodynamic load applied to the weld could effectively reduce the residual stress of the weld. The control effect was good when the loading distance was 20–28 mm and the aerodynamic load was 30 MPa. The maximum tensile residual stress under a high-speed gas flow field condition was 61.02 MPa, which decreased by 77.73% over that of conventional welding, and the peak residual compressive stress was −24.87 MPa, which decreased by 69.23%.

- (4)

- The maximum deflection of LY12 aluminum-alloy-welded parts under conditions of welding with a trailing hybrid high-speed gas fluid field was 1.79 mm, which was 83.76% lower than the 11.02 mm of conventional welding.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, Y.; Hou, J.; Zheng, W.; Wan, Z.; Tang, W. A Numerical Simulation Method Considering Solid Phase Transformation and the Experimental Verification of Ti6Al4V Titanium Alloy Sheet Welding Processes. Materials 2022, 15, 2882. [Google Scholar] [CrossRef] [PubMed]

- Sabzi, M.; Mousavi, S.H.; Chalandar, A.R.; Bali, N.; Jafarian, H.R.; Eivani, A.R. An experimental investigation on the effect of gas tungsten arc welding current modes upon the microstructure, mechanical, and fractography properties of welded joints of two grades of AISI 316L and AISI310S alloy metal sheets. Mater. Sci. Eng. A 2022, 840, 142877. [Google Scholar] [CrossRef]

- Chihoski, R.A. Expansion and Stress Around Aluminum Weld Puddles. Weld. J. 1979, 58, 263–276. [Google Scholar]

- Guo, S.; Xu, W.; Liu, X. Control of welding deformation of aluminum alloy sheet by temperature difference tension. Han Chieh Hsueh Pao Trans. China Weld. Inst. 1999, 1, 36–44. [Google Scholar]

- Hanus, F.; Hubo, R. Flame straightening of thermomechanically rolled structural steel. Steel Res. 1999, 40, 193–197. [Google Scholar] [CrossRef]

- Kondakov, T.F. High temperature rolling in welding butt joints. Weld. Inter. 1988, 2, 172–175. [Google Scholar] [CrossRef]

- Xie, P.; Zhao, H.; Wu, B.; Gong, S. Evaluation of Residual Stresses Relaxation by Post Weld Heat Treatment Using Contour Method and X-ray Diffraction Method. Exp. Mech. 2015, 55, 1329–1337. [Google Scholar] [CrossRef]

- Cho, J.R.; Lee, B.Y.; Moon, Y.H.; Van Tyne, C.J. Investigation of residual stress and post weld heat treatment of multi-pass welds by finite element method and experiments. J. Mater. Process. Technol. 2004, 155, 1690–1695. [Google Scholar] [CrossRef]

- Zhang, H.; Chen, S.; Zhang, Y.; Chen, X.; Li, Z.; Yang, Z. Effect of High Rotational-Speed Friction-Stir Welding on Microstructure and Properties of Welded Joints of 6061-T6 Al Alloy Ultrathin Plate. Materials 2021, 14, 6012. [Google Scholar] [CrossRef]

- Zhou, G.; Liu, X.; Jin, C. Welding deformation controlling of aluminum-alloy thin plate by two-direction pre-stress method. Mater. Sci. Eng. A 2009, 499, 147–152. [Google Scholar] [CrossRef]

- Zhou, G.; Huang, H.; Fang, H. Control of welding stress and distortion of aluminum alloy sheet by ultrasonic excitation method. Nonferrous Met. Soc. China Trans. 2014, 24, 919–925. [Google Scholar]

- Yan, W.; Luo, X.; Xu, G.; Wang, H.; Wang, Z.; Chen, X. Significant improvement in CGHAZ toughness of HSLA steel via welding with trailing mechanical treatment. Mater. Sci. Eng. A. 2022, 837, 142725. [Google Scholar] [CrossRef]

- Xu, D.; Liu, X.S.; Wang, P.; Yang, J.G.; Fang, H.Y. New technique to control welding buckling distortion and residual stress with non-contact electromagnetic impact. Sci. Technol. Weld. Join. 2013, 14, 753–759. [Google Scholar] [CrossRef]

- Yang, Y.P.; Dong, P.; Zhang, J.; Tian, X. A Hot-Cracking Mitigation Technique for Welding High-Strength Aluminum Alloy. Weld. J. 2000, 79, 9. [Google Scholar]

- Xu, W.; Liu, X.S.; Yang, J.Q.; Fang, H.Y.; Xu, W.L. Effect of temperature on plastic deformation of sheet by electromagnetic force. J. Mater. Process. Technol. 2009, 209, 2693–2698. [Google Scholar]

- Patil, H.S.; Patel, D.C. Al2O3 and TiO2 flux enabling activated tungsten inert gas welding of 304 austenitic stainless steel plates. Fract. Struct. Integr. 2022, 16, 59–68. [Google Scholar] [CrossRef]

- Kurtulmus, M.; Yukler, A.I.; Dogan, E. Activated flux TIG welding of non-ferrous metals. Indian J. Chem. Technol. 2021, 26, 164–169. [Google Scholar]

- Fattahi, M.; Ghaheri, A.; Arabian, N.; Amirkhanlu, F.; Moayedi, H. Applying the ultrasonic vibration during TIG welding as a promising approach for the development of nanoparticle dispersion strengthened aluminum weldments. J. Mater. Process. Technol. 2019, 282, 116672. [Google Scholar] [CrossRef]

- Xie, R.; Liang, T.; Shi, Y.; Liu, H. Revealing the bonding mechanisms between deposit and substrate of the friction rolling additive manufactured hybrid aluminum alloys. Addit. Manuf. 2022, 56, 102942. [Google Scholar] [CrossRef]

- Jata, K.V.; Semiatin, S.L. Continuous dynamic recrystallization during friction stir welding of high strength aluminum alloys. Scr. Mater. 2000, 43, 743–749. [Google Scholar] [CrossRef]

- Yu, X.; Cao, C.; Yao, Z.; Zhou, D.; Yin, Z. Study of double layer rare earth metal conversion coating on aluminum alloy LY12. Corros. Sci. 2001, 43, 1283–1294. [Google Scholar]

- Wu, J.; Qiang, B.; Liao, X.; Kang, L.; Yao, C.; Li, Y. Experimental investigation and numerical simulation of welding residual stress in orthotropic steel deck with diaphragm considering solid-state phase transformation. Eng. Struct. 2022, 250, 113415. [Google Scholar] [CrossRef]

- Liu, F.; Tao, C.; Dong, Z.; Jiang, K.; Zhou, S.; Zhang, Z.; Shen, C. Prediction of welding residual stress and deformation in electro-gas welding using artificial neural network. Mater. Today Commun. 2021, 29, 102786. [Google Scholar] [CrossRef]

- Mai, C.; Hu, X.; Zhang, L.; Song, B.; Zheng, X. Influence of Interlayer Temperature and Welding Sequence on the Temperature Distribution and Welding Residual Stress of the Saddle-Shaped Joint of Weldolet-header Butt Welding. Materials 2021, 14, 5980. [Google Scholar] [CrossRef]

- Ma, J.; Wang, P.; Fang, H. Fatigue Life of 7005 Aluminum Alloy Cruciform Joint Considering Welding Residual Stress. Materials 2021, 14, 1253. [Google Scholar] [CrossRef]

- Chen, J.; Chu, J.; Jiang, W.; Yao, B.; Zhou, F.; Wang, Z.; Zhao, P. Experimental and Numerical Simulation to Study the Reduction of Welding Residual Stress by Ultrasonic Impact Treatment. Materials 2020, 13, 837. [Google Scholar] [CrossRef]

- Kang, S.; Yun, W.; Kim, H.; Kim, J.; Ji, C.; Lee, K.; Chun, K. A Study on Minimizing Welding Deformation of Joints for the Sealing of Emission After-Treatment Structure. Materials 2021, 14, 6982. [Google Scholar] [CrossRef]

- Granell, I.; Ramos, A.; Carnicero, A. A Geometry-Based Welding Distortion Prediction Tool. Materials 2021, 14, 4789. [Google Scholar] [CrossRef]

- Urbański, T.; Taczała, M. Prediction of the welding distortions of buttwelded joints using total moments method based on equivalent loads. J. Manuf. Syst. 2022, 75, 1039–1057. [Google Scholar]

- Wang, Y.M.; Zheng, F.H.; Wang, J.; Ju, J.S.; Sang, X.X. Study on the influence of geometric imperfections and welding deformation on the global stability of orthogonal mixed with oblique single-layer reticulated shell. J. Phys. Conf. Ser. 2021, 2045, 012002. [Google Scholar] [CrossRef]

- Zhu, J.; Khurshid, M.; Barsoum, I. Computational weld-mechanics assessment of welding distortions in a large beam structure. Eng. Struct. 2021, 236, 112055. [Google Scholar] [CrossRef]

- Ueda, S.; Muragawa, E.; Ma, N. Methods and Programs for Numerical Calculation of Welding Deformation and Residual Stress; Sichuan University Press: Chengdu, China, 2008; pp. 25–39. ISBN 9787561441862. [Google Scholar]

- Shaposhnikov, D.S. Evolution of Disturbances on the Surface of an Elastic Plate in Supersonic Gas Flow. Comp. Math. Math. Phys. 2015, 55, 1201–1205. [Google Scholar] [CrossRef]

- Adib, M. Numerical and experimental study of oscillatory behavior of liquid surface agitated by high-speed gas jet. Appl. Math. Model. 2018, 6, 510–525. [Google Scholar] [CrossRef]

- Nima, J.; Hassan, B.T.; Hosseini, M. Experimental and numerical study of simultaneous cooling with CO2 gas during friction stir welding of Al-5052. J. Mater. Process. Technol. 2016, 237, 243–253. [Google Scholar]

- He, W.; Xiao, C.; Shi, F. Real-time Ultrasonic Impact Reduction of Welding Residual Stress. Han Chieh Hsueh Pao Trans. China Weld. Inst. 2015, 8, 84–87+117. [Google Scholar]

- John, G.; Aditya, C.; Malcolm, B. A new finite element model for welding heat sources. Met. Trans. B 1984, 15, 302–306. [Google Scholar]

| T/°C | E/GPa | α/(10−6 °C−1) | σs/MPa | c/(J·kg−1 °C−1) | K/(W·m−1 °C−1) |

|---|---|---|---|---|---|

| 20 | 70.0 | 22.8 | 300 | 900 | 117 |

| 100 | 60.8 | 23.1 | 280 | 921 | 121 |

| 200 | 54.4 | 24.7 | 240 | 1005 | 126 |

| 300 | 43.1 | 25.5 | 160 | 1047 | 130 |

| 400 | 32.0 | 26.5 | 113 | 1089 | 138 |

| Loading Distance (mm) | Aerodynamic Load Range (MPa) |

|---|---|

| 12 | 5–15 |

| 16 | 5–25 |

| 20 | 5–35 |

| 24 | 10–40 |

| 28 | 10–80 |

| 32 | 10–120 |

| Mg | Si | Cu | Cr | Fe | Zn | Mn | Al |

|---|---|---|---|---|---|---|---|

| 0.8 | 0.4 | 0.15 | 0.04 | 0.7 | 0.25 | 0.15 | Remaining |

| Plate Thickness (mm) | Tungsten Pole Diameter (mm) | Welding Current (A) | Arc Voltage (V) | Welding Speed (mm·s−1) | Argon Gas Flow (L/Min) |

|---|---|---|---|---|---|

| 1 | 1.6 | 70 | 12–15 | 4 | 14 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, G.; Liu, B.; Song, W.; Li, H.; Kuang, J.; Qiu, M. Controlling Welding Residual Stress and Distortion of High-Strength Aluminum Alloy Thin Plates by a Trailing Hybrid High-Speed Gas Fluid Field. Materials 2022, 15, 6451. https://doi.org/10.3390/ma15186451

Zhou G, Liu B, Song W, Li H, Kuang J, Qiu M. Controlling Welding Residual Stress and Distortion of High-Strength Aluminum Alloy Thin Plates by a Trailing Hybrid High-Speed Gas Fluid Field. Materials. 2022; 15(18):6451. https://doi.org/10.3390/ma15186451

Chicago/Turabian StyleZhou, Guangtao, Biao Liu, Wei Song, Huachen Li, Jingzhen Kuang, and Mingwang Qiu. 2022. "Controlling Welding Residual Stress and Distortion of High-Strength Aluminum Alloy Thin Plates by a Trailing Hybrid High-Speed Gas Fluid Field" Materials 15, no. 18: 6451. https://doi.org/10.3390/ma15186451

APA StyleZhou, G., Liu, B., Song, W., Li, H., Kuang, J., & Qiu, M. (2022). Controlling Welding Residual Stress and Distortion of High-Strength Aluminum Alloy Thin Plates by a Trailing Hybrid High-Speed Gas Fluid Field. Materials, 15(18), 6451. https://doi.org/10.3390/ma15186451