Influencing Mechanisms of Prior Cold Deformation on Mixed Grain Boundary Network in the Thermal Deformation of Ni80A Superalloy

Abstract

:1. Introduction

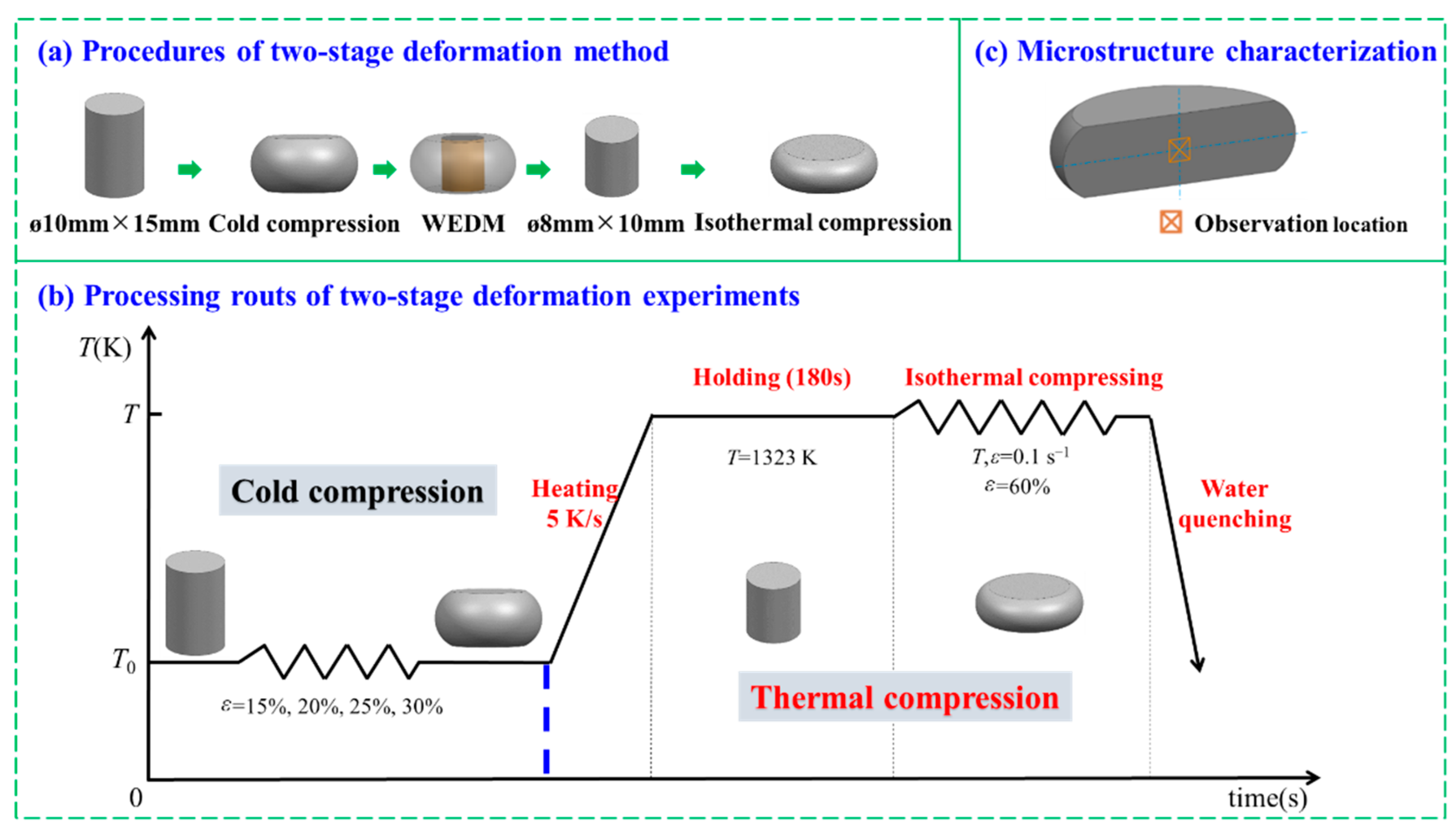

2. Material and Experimental Procedures

3. Results and Discussion

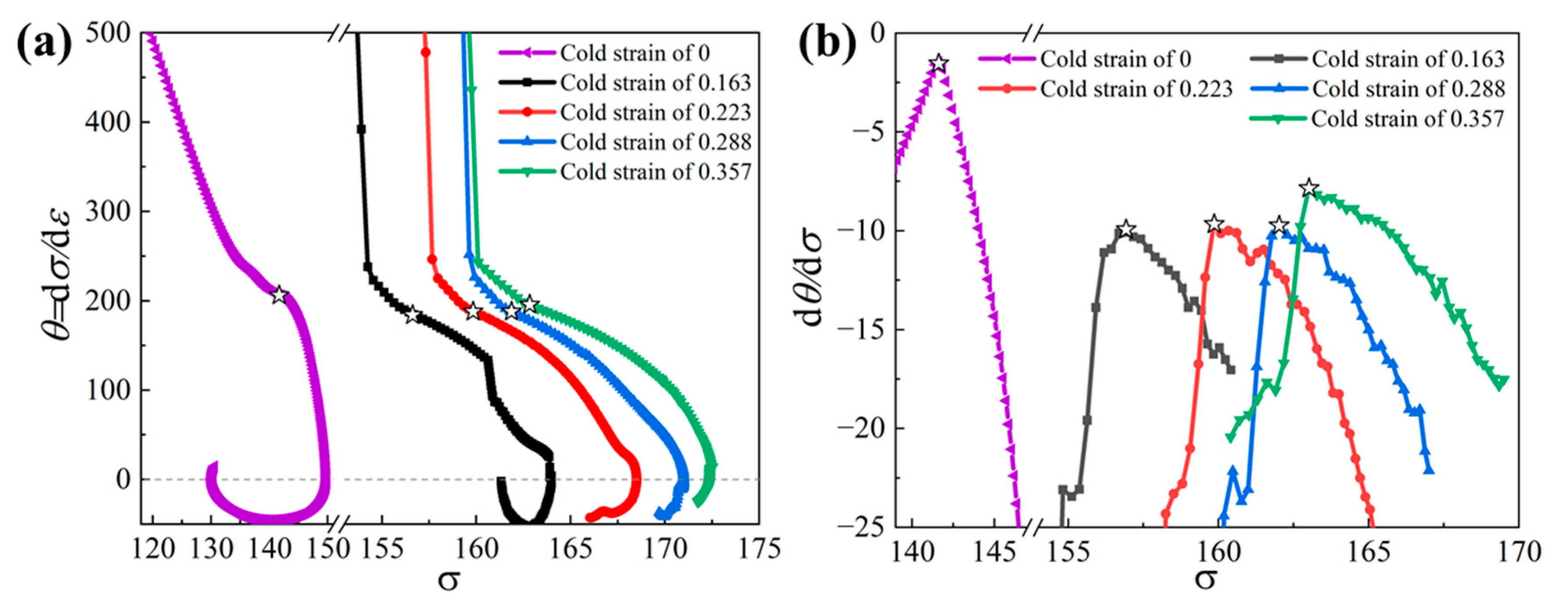

3.1. Characterization of the Flow Behaviors from the True Stress–Strain Curves

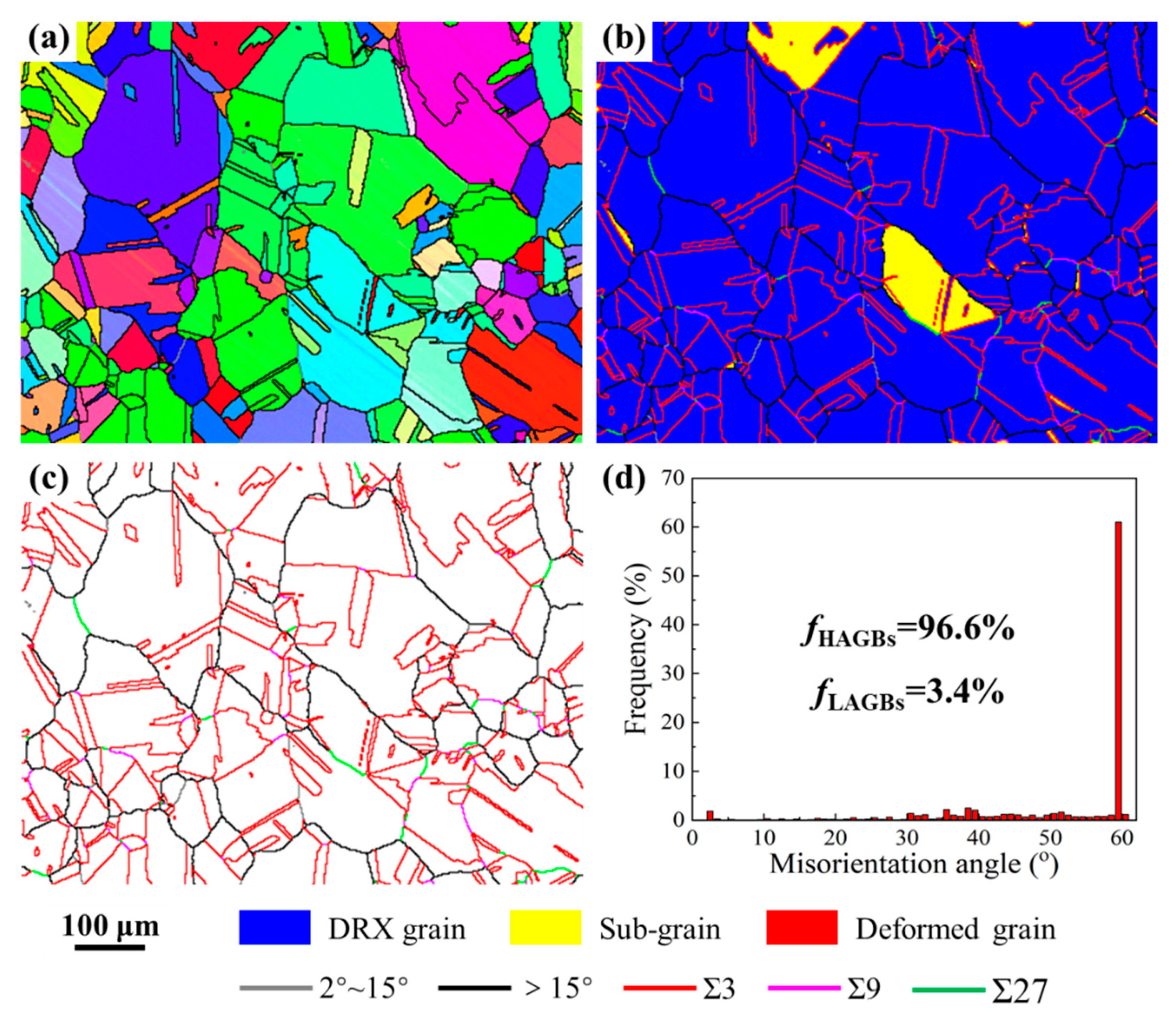

3.2. Evolution of Microstructures in Cold Deformation

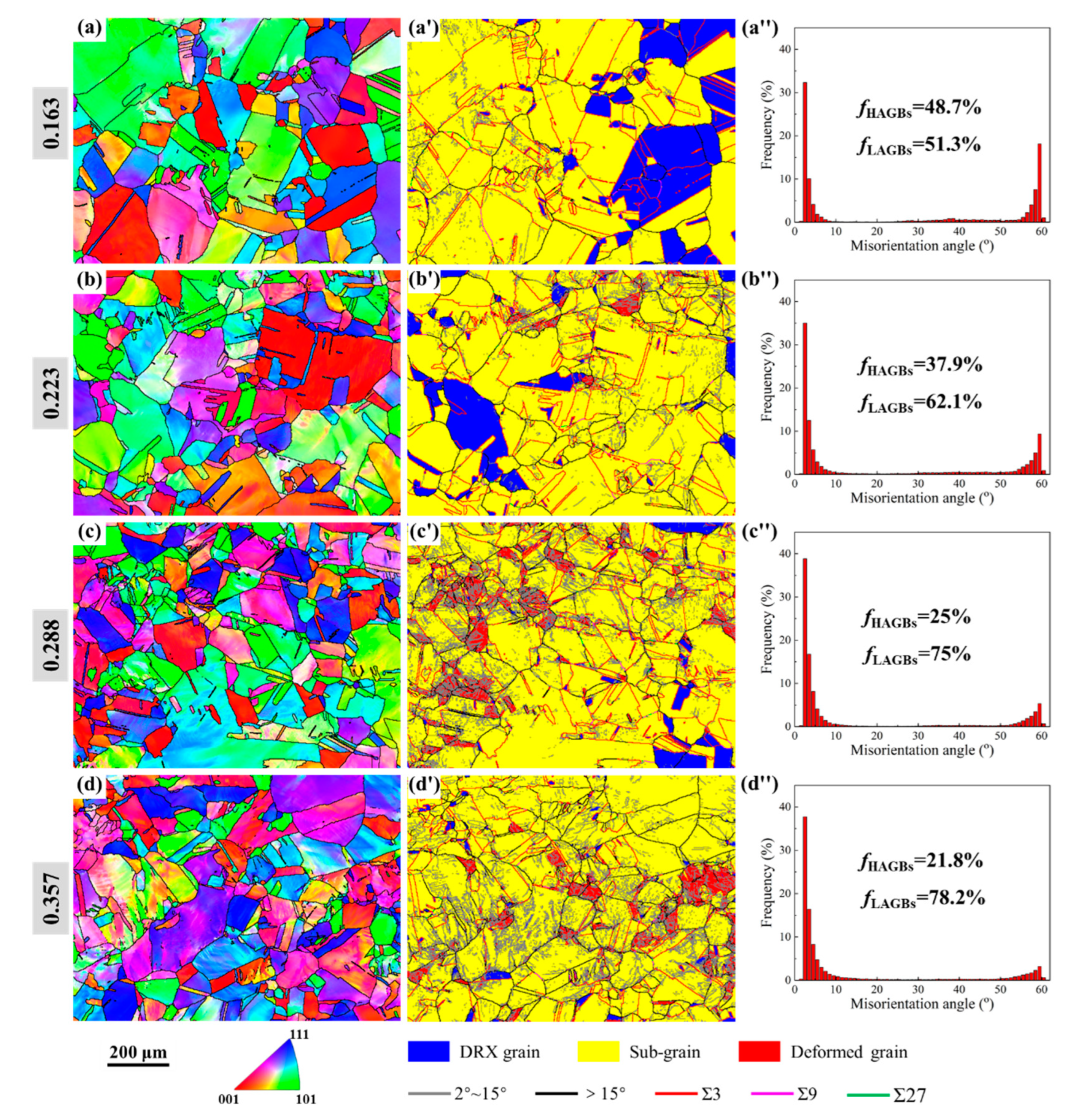

3.3. Evolution of Mixed Grain Boundary Network in Thermal Deformation

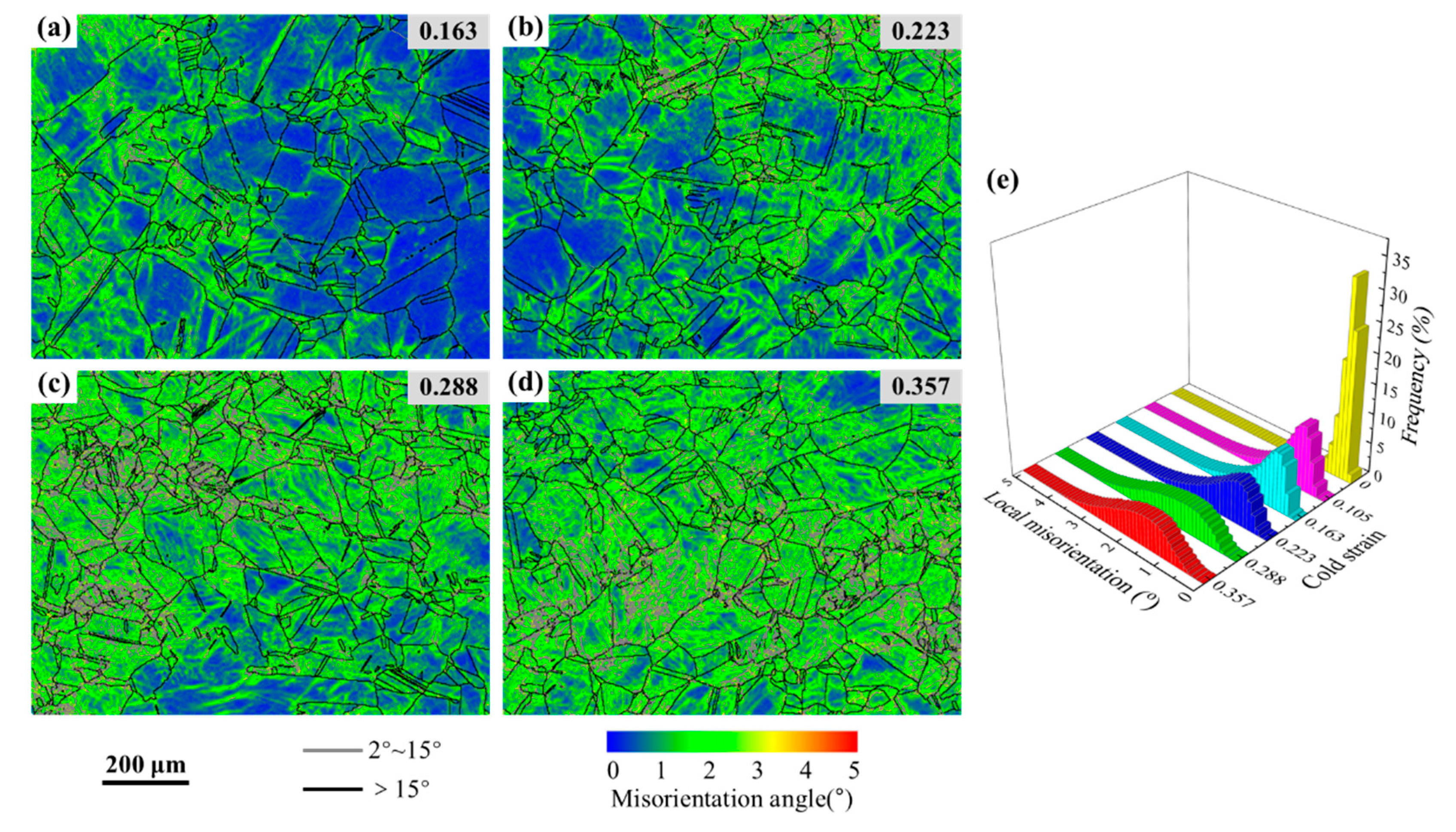

3.3.1. Development of Sub-Grain Network

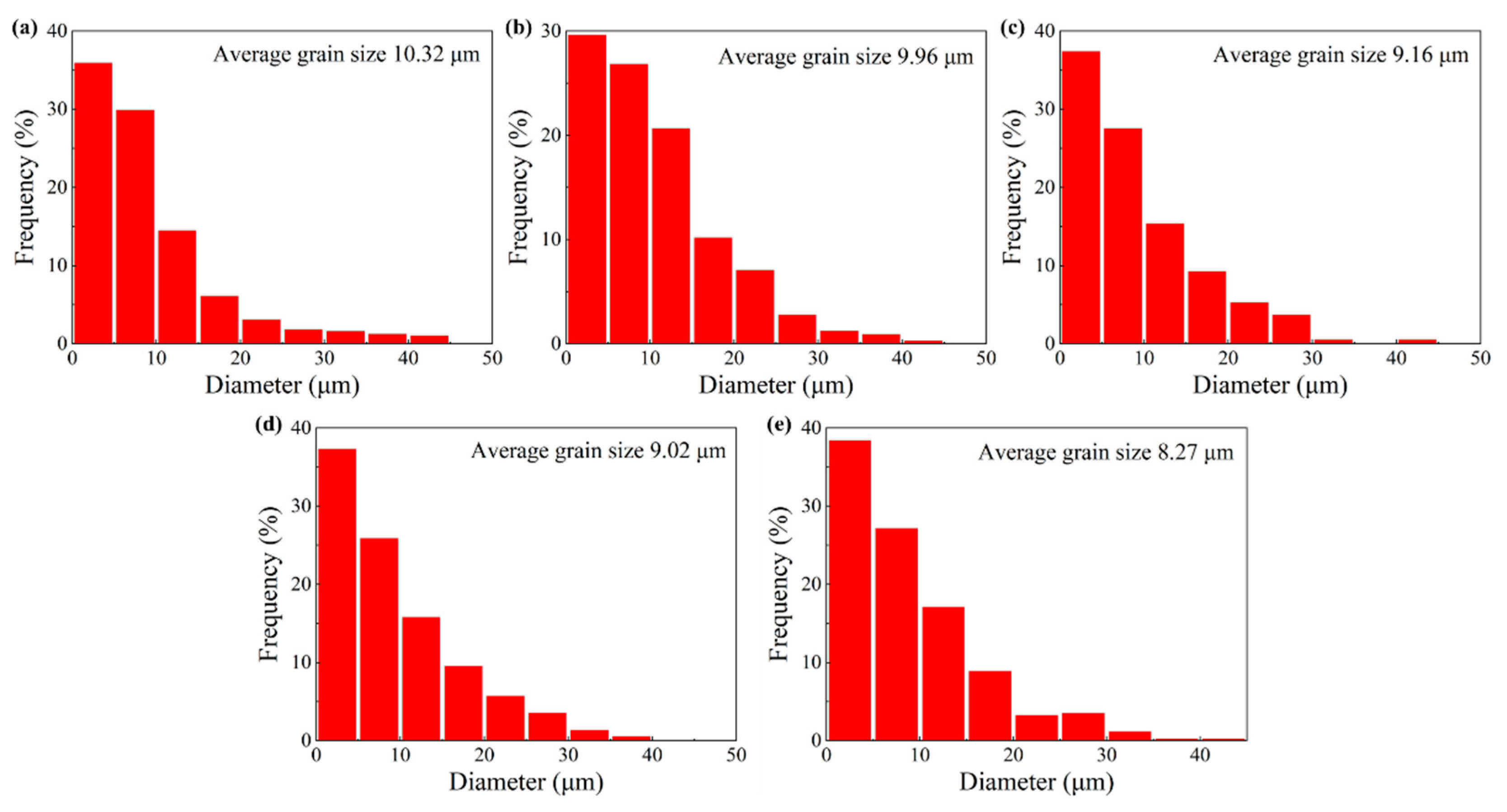

3.3.2. DRX Volume Fraction and Grain Size Evolution

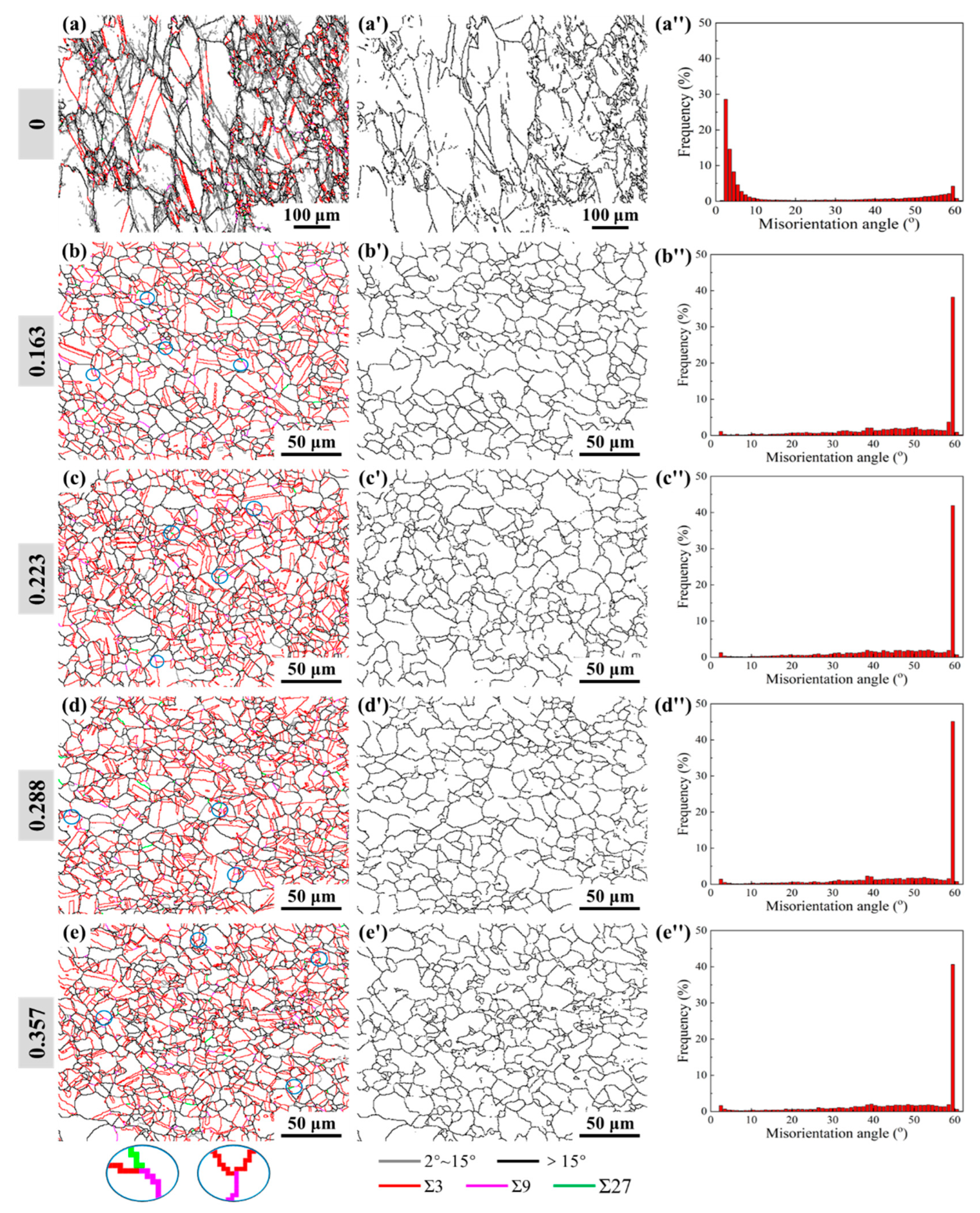

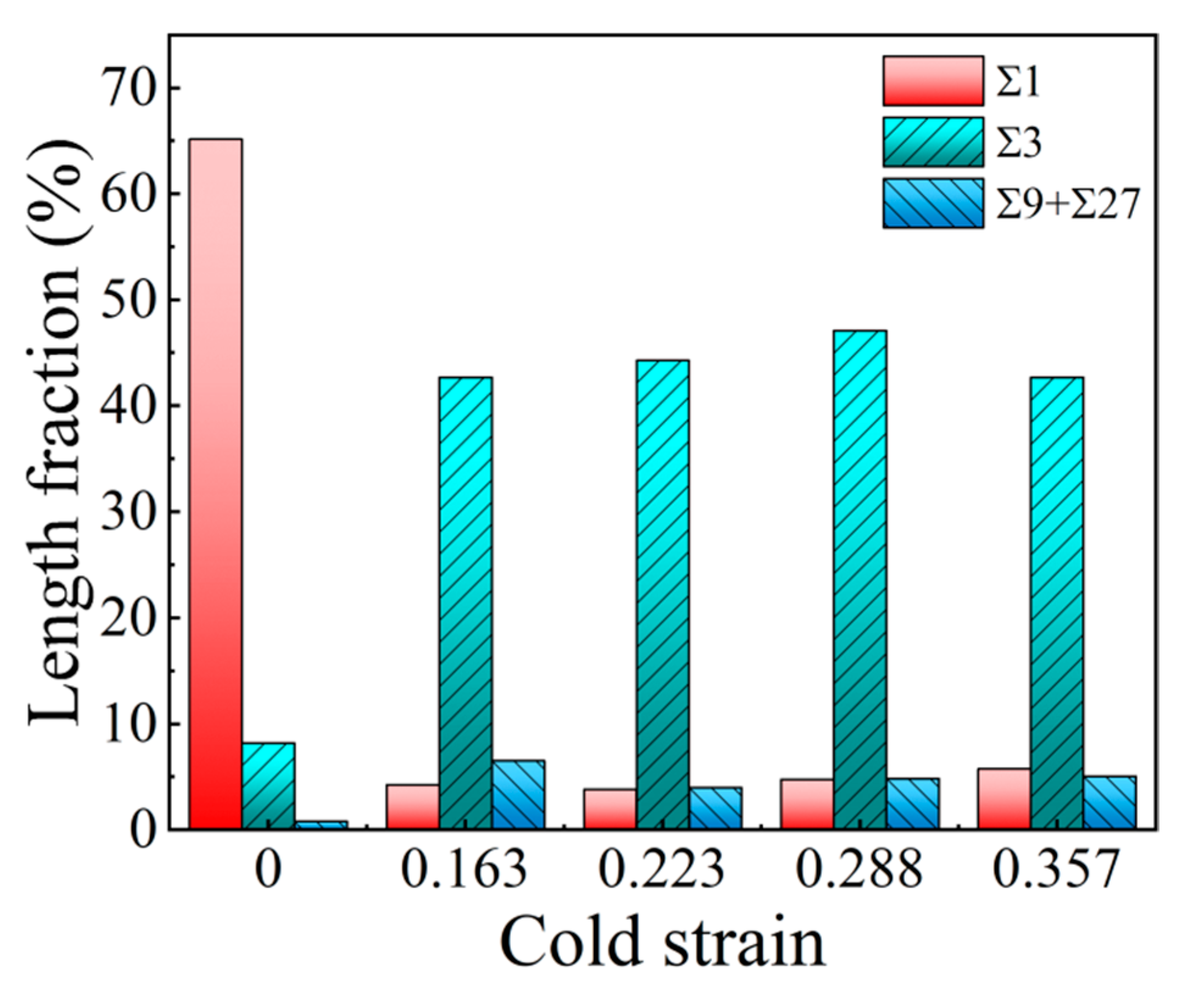

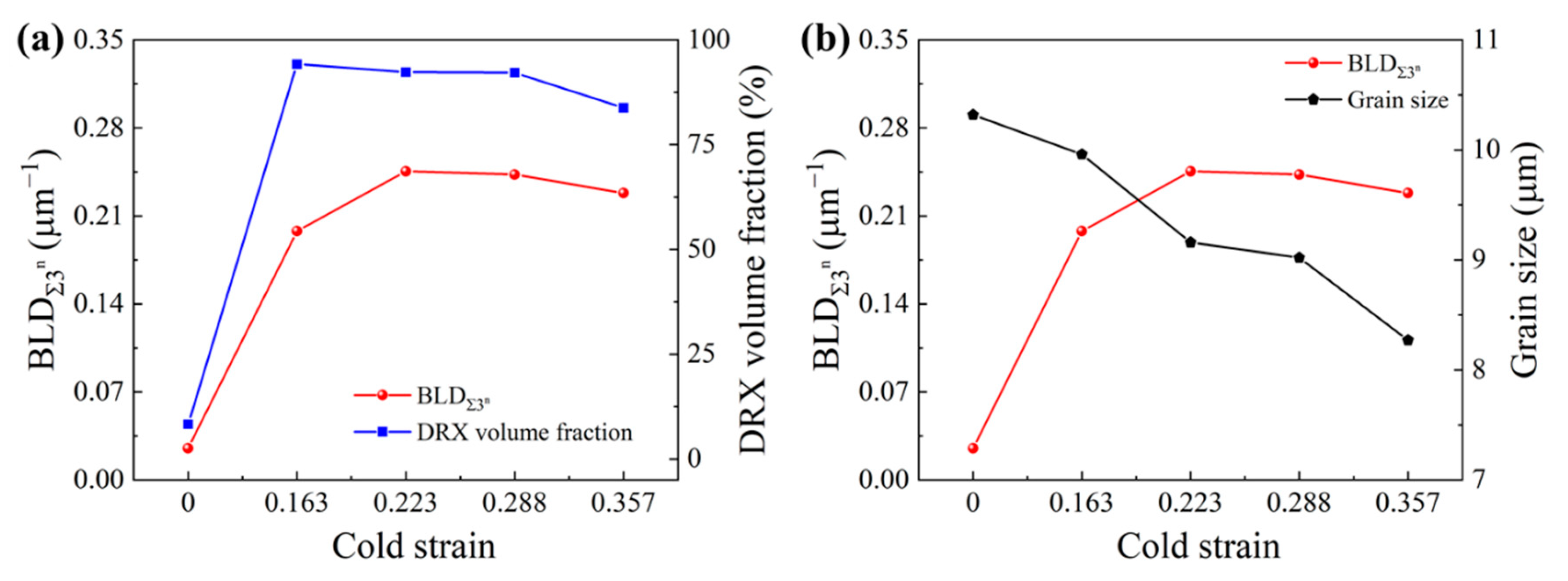

3.3.3. Twin Boundary Characteristics and Its Density Evolution

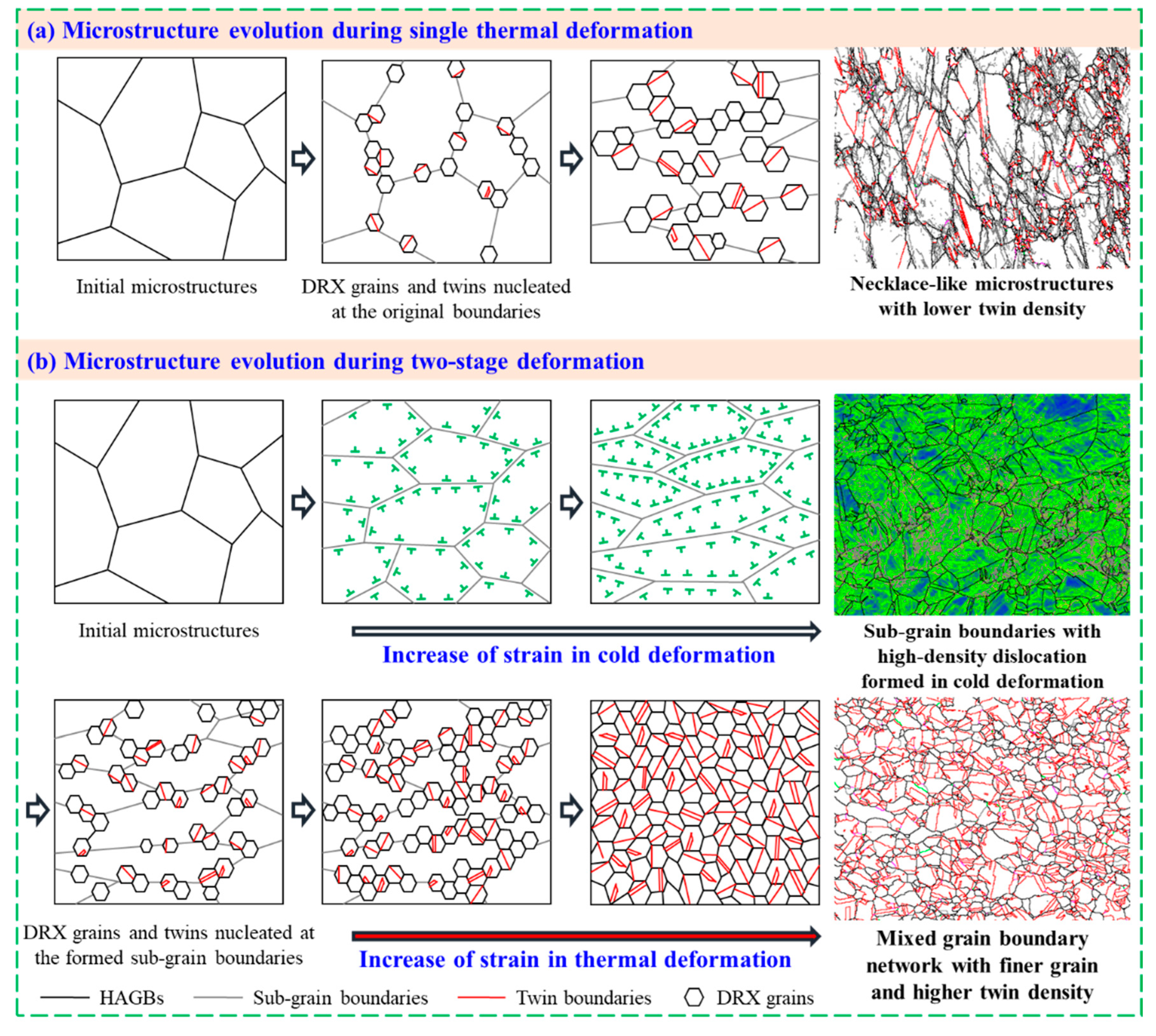

3.4. Mechanism for Improving Mixed Grain Boundary Network

4. Conclusions

- (1)

- The flow behaviors of Ni80A superalloy are significantly influenced by prior cold deformation. The critical strain for the onset of DRX and peak strain decreases remarkably under the effect of prior cold deformation, implying that DRX is activated in advance. These two indicators decrease with increasing cold strain;

- (2)

- In comparison to the necklace-like microstructures from the single thermal deformation, the microstructures of the two-stage deformation process are characterized by finer and equiaxed DRX grains accompanied by abundant Σ3n twin boundaries and a significantly improved value of BLDΣ3n of about nine times. With increasing cold strain, the grain size decreases continuously, while BLDΣ3n increases at first and then decreases gradually;

- (3)

- The variations of BLDΣ3n against prior cold strain exhibit an approximately similar tendency to that of the DRX volume fraction, with it increasing at first and then decreasing gradually with grain refinement. This indicates that the relationship between BLDΣ3n and grain size is non-liner. The mixed grain boundary network, with higher BLDΣ3n and finer grains under thermal deformation, can be obtained by adjusting the prior cold deformation;

- (4)

- The mechanisms for improving the mixed grain boundary network by a two-stage deformation method have been uncovered. The sub-grain boundaries formed in prior cold deformation stimulate the nucleation of the DRX grains and twins; meanwhile, the driving force for grain boundary migration is enhanced due to the prior stored energy. In these cases, DRX is activated in advance and occurs more completely, thereby promoting the formation of Σ3n twin boundaries.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhu, Y.-Z.; Yin, Z.-M.; Xu, J.-P. Microstructural mapping in closed die forging process of superalloy Nimonic 80a valve head. J. Alloys Compd. 2011, 509, 6106–6112. [Google Scholar] [CrossRef]

- Quan, G.-Z.; Pan, J.; Wang, X.; Zhang, Z.-H.; Zhang, L.; Wang, T. Correspondence between grain refinements and flow softening behaviors at Nimonic 80A superalloy under different strain rates, temperatures and strains. Mater. Sci. Eng. A 2017, 679, 358–371. [Google Scholar] [CrossRef]

- Zhang, Y.-Q.; Quan, G.-Z.; Zhao, J.; Xiong, W. Influence of variable loading path pattern on deformation and grain size in large-scale electric upsetting process of Nimonic superalloy. Int. J. Adv. Manuf. Technol. 2022, 120, 5933–5954. [Google Scholar] [CrossRef]

- Watanabe, T. An approach to grain boundary design for strong and ductile polycrystals. Res. Mech. 1984, 11, 47–84. [Google Scholar]

- Wang, W.; Lartigue-Korinek, S.; Brisset, F.; Helbert, A.L.; Bourgon, J.; Baudin, T. Formation of annealing twins during primary recrystallization of two low stacking fault energy Ni-based alloys. J. Mater. Sci. 2014, 50, 2167–2177. [Google Scholar] [CrossRef]

- Randle, V. Mechanism of twinning-induced grain boundary engineering in low stacking-fault energy materials. Acta Mater. 1999, 47, 4187–4196. [Google Scholar] [CrossRef]

- Palumbo, G.; Lehockey, E.M.; Lin, P. Applications for grain boundary engineered materials. JOM 1998, 50, 40–43. [Google Scholar] [CrossRef]

- Kobayashi, S.; Kobayashi, R.; Watanabe, T.W. Control of grain boundary connectivity based on fractal analysis for improvement of intergranular corrosion resistance in SUS316L austenitic stainless steel. Acta Mater. 2016, 102, 397–405. [Google Scholar] [CrossRef]

- Tsurekawa, S.; Nakamichi, S.; Watanabe, T. Correlation of grain boundary connectivity with grain boundary character distribution in austenitic stainless steel. Acta Mater. 2006, 54, 3617–3626. [Google Scholar] [CrossRef]

- Randle, V. Grain boundary engineering: An overview after 25 years. Mater. Sci. Technol. 2013, 26, 253–261. [Google Scholar] [CrossRef]

- Qian, M.; Lippold, J.C. The effect of annealing twin-generated special grain boundaries on HAZ liquation cracking of nickel-base superalloys. Acta Mater. 2003, 51, 3351–3361. [Google Scholar] [CrossRef]

- Deepak, K.; Sumantra, M.; Athreya, C.N.; Kim, D.I.; Boer, B.; Subramanya, S.V. Implication of grain boundary engineering on high temperature hot corrosion of alloy 617. Corros. Sci. 2016, 106, 293–297. [Google Scholar]

- Peng, Z.-C.; Zou, J.-W.; Wang, Y.; Zhou, L.; Tang, Y. Effects of solution temperatures on creep resistance in a powder metallurgy nickel-based superalloy. Mater. Today Commun. 2021, 28, 102573. [Google Scholar] [CrossRef]

- Shi, Z.-X.; Yan, X.-F.; Duan, C.-H.; Zhao, M.-H. Effect of strain rate on hot deformation characteristics of GH690 superalloy. Trans. Nonferrous Met. Soc. China 2017, 27, 538–550. [Google Scholar] [CrossRef]

- Azarbarmas, M.; Aghaie-Khafri, M.; Cabrera, J.M.; Calvo, J. Dynamic recrystallization mechanisms and twining evolution during hot deformation of Inconel 718. Mater. Sci. Eng. A 2016, 678, 137–152. [Google Scholar] [CrossRef]

- Ebrahimi, G.R.; Momeni, A.; Ezatpour, H.R.; Jahazi, M.; Bocher, P. Dynamic recrystallization in Monel400 Ni-Cu alloy: Mechanism and role of twinning. Mater. Sci. Eng. A 2019, 744, 376–385. [Google Scholar] [CrossRef]

- Guo, Q.-M.; Li, D.-F.; Guo, S.-L.; Peng, H.-J.; Hu, J. The effect of deformation temperature on the microstructure evolution of Inconel 625 superalloy. J. Nucl. Mater. 2011, 414, 440–450. [Google Scholar] [CrossRef]

- Jiang, H.; Dong, J.-X.; Zhang, M.-C.; Yao, Z.-H. Evolution of twins and substructures during low strain rate hot deformation and contribution to dynamic recrystallization in alloy 617B. Mater. Sci. Eng. A 2016, 649, 369–381. [Google Scholar] [CrossRef]

- Shi, H.; Chen, K.; Shen, Z.; Wu, J.-Q.; Dong, X.-P.; Zhang, L.-T.; Shan, A.-D. Twin boundary characters established during dynamic recrystallization in a nickel alloy. Mater. Charact. 2015, 110, 52–59. [Google Scholar] [CrossRef]

- Pradhan, S.K.; Mandal, S.; Athreya, C.N.; Babu, K.A.; Boer, B.; Subramanya, S.V. Influence of processing parameters on dynamic recrystallization and the associated annealing twin boundary evolution in a nickel base superalloy. Mater. Sci. Eng. A 2017, 700, 49–58. [Google Scholar] [CrossRef]

- Detrois, M.; Goetz, R.L.; Helmink, R.C.; Tin, S. Modeling the effect of thermal–mechanical processing parameters on the density and length fraction of twin boundaries in Ni-base superalloy RR1000. Mater. Sci. Eng. A 2015, 647, 157–162. [Google Scholar] [CrossRef]

- Quan, G.-Z.; Zhang, Y.-Q.; Zhang, P.; Ma, Y.-Y.; Wang, W.-Y. Correspondence between low-energy twin boundary density and thermal-plastic deformation parameters in nickel-based superalloy. Trans. Nonferrous Met. Soc. China 2021, 31, 438–455. [Google Scholar] [CrossRef]

- Dong, J.-X.; Zhang, M.-C.; Yao, Z.-H. A Study on the effect of strain rate on the dynamic recrystallization mechanism of alloy 617B. Metall. Mater. Trans. A 2016, 47, 5071. [Google Scholar]

- He, G.-A.; Liu, F.; Huang, L.; Huang, Z.-W.; Jiang, L. Microstructure evolutions and nucleation mechanisms of dynamic recrystallization of a powder metallurgy Ni-based superalloy during hot compression. Mater. Sci. Eng. A 2016, 677, 496–504. [Google Scholar] [CrossRef]

- Kumar, S.; Raghu, T.; Bhattacharjee, P.; Rao, G.; Borah, U. Evolution of microstructure and microtexture during hot deformation in an advanced P/M nickel base superalloy. Mater. Charact. 2018, 146, 217–236. [Google Scholar] [CrossRef]

- Qin, F.-M.; Zhu, H.; Wang, Z.-X.; Zhao, X.-D.; He, W.-W.; Chen, H.-Q. Dislocation and twinning mechanisms for dynamic recrystallization of as-cast Mn18Cr18N steel. Mater. Sci. Eng. A 2017, 684, 634–644. [Google Scholar] [CrossRef]

- Horton, D.; Thomson, C.B.; Randle, V. Aspects of twinning and grain growth in high purity and commercially pure nickel. Mater. Sci. Eng. A 1995, 203, 408–414. [Google Scholar] [CrossRef]

- Mandal, S.; Bhaduri, A.K.; Sarma, V.S. Studies on twinning and grain boundary character distribution during anomalous grain growth in a Ti-modified austenitic stainless steel. Mater. Sci. Eng. A 2009, 515, 134–140. [Google Scholar] [CrossRef]

- Chen, X.-M.; Lin, Y.C.; Wu, F. EBSD study of grain growth behavior and annealing twin evolution after full recrystallization in a nickel-based superalloy. J. Alloys Compd. 2017, 724, 198–207. [Google Scholar] [CrossRef]

- Souaï, N.; Bozzolo, N.; Nazé, L.; Chastel, Y.; Logé, R. About the possibility of grain boundary engineering via hot-working in a nickel-base superalloy. Scr. Mater. 2010, 62, 851–854. [Google Scholar] [CrossRef]

- Bozzolo, N.; Souaï, N.; Logé, R.E. Evolution of microstructure and twin density during thermomechanical processing in a γ-γ’ nickel-based superalloy. Acta Mater. 2012, 60, 5056–5066. [Google Scholar] [CrossRef]

- Wang, W.; Brisset, F.; Helbert, A.L.; Solas, D.; Drouelle, I.; Mathon, M.H.; Baudin, T. Influence of stored energy on twin formation during primary recrystallization. Mater. Sci. Eng. A 2014, 589, 112–118. [Google Scholar] [CrossRef]

- Li, Z.-G.; Zhang, L.-T.; Sun, N.-R.; Sun, Y.-L.; Shan, A.-D. Effects of prior deformation and annealing process on microstructure and annealing twin density in a nickel based alloy. Mater. Charact. 2014, 95, 299–306. [Google Scholar] [CrossRef]

- Xia, S.; Zhou, B.-X.; Chen, W.-J.; Wang, W.-G. Effects of strain and annealing processes on the distribution of Σ3 boundaries in a Ni-based superalloy. Scr. Mater. 2006, 54, 2019–2022. [Google Scholar] [CrossRef]

- Tan, L.; Sridharan, K.; Allen, T.R. Effect of thermomechanical processing on grain boundary character distribution of a Ni-based superalloy. J. Nucl. Mater. 2007, 371, 171–175. [Google Scholar] [CrossRef]

- Brandon, D.G. The structure of high-angle grain boundaries. Acta Mater. 1966, 14, 1479–1484. [Google Scholar] [CrossRef]

- Mccarley, J.; Tin, S. Understanding the effects of recrystallization and strain induced boundary migration on ∑3 twin boundary formation in Ni-base superalloys during iterative sub-solvus annealing. Mater. Sci. Eng. A 2019, 740–741, 427–438. [Google Scholar] [CrossRef]

- Moussa, C.; Bernacki, M.; Besnard, R.; Bozzolo, N. Statistical analysis of dislocations and dislocation boundaries from EBSD data. Ultramicroscopy 2017, 179, 63–72. [Google Scholar] [CrossRef]

- Randle, V. Twinning-related grain boundary engineering. Acta Mater. 2004, 52, 4067–4081. [Google Scholar] [CrossRef]

- Randle, V. ‘Special’ boundaries and grain boundary plane engineering. Scr. Mater. 2006, 54, 1011–1015. [Google Scholar] [CrossRef]

- Gertsman, V.Y.; Henager, C. Grain boundary junctions in microstructure generated by multiple twinning. Interface Sci. 2003, 11, 403–415. [Google Scholar] [CrossRef]

- Sakai, T.; Ohashi, M. Dislocation substructures developed during dynamic recrystallisation in polycrystalline nickel. Mater. Sci. Technol. 1990, 6, 1251–1257. [Google Scholar] [CrossRef]

| Element | Cr | Fe | Ti | Mn | Si | Al | C | Ni |

|---|---|---|---|---|---|---|---|---|

| Content | 20.87 | 1.26 | 2.07 | 0.63 | 0.55 | 0.68 | 0.069 | Balance |

| Cold Strain | ||

|---|---|---|

| 0 | 0.080 | 0.230 |

| 0.163 | 0.042 | 0.209 |

| 0.223 | 0.038 | 0.177 |

| 0.288 | 0.037 | 0.166 |

| 0.357 | 0.033 | 0.127 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.-Q.; Quan, G.-Z.; Zhao, J.; Xiong, W. Influencing Mechanisms of Prior Cold Deformation on Mixed Grain Boundary Network in the Thermal Deformation of Ni80A Superalloy. Materials 2022, 15, 6426. https://doi.org/10.3390/ma15186426

Zhang Y-Q, Quan G-Z, Zhao J, Xiong W. Influencing Mechanisms of Prior Cold Deformation on Mixed Grain Boundary Network in the Thermal Deformation of Ni80A Superalloy. Materials. 2022; 15(18):6426. https://doi.org/10.3390/ma15186426

Chicago/Turabian StyleZhang, Yu-Qing, Guo-Zheng Quan, Jiang Zhao, and Wei Xiong. 2022. "Influencing Mechanisms of Prior Cold Deformation on Mixed Grain Boundary Network in the Thermal Deformation of Ni80A Superalloy" Materials 15, no. 18: 6426. https://doi.org/10.3390/ma15186426

APA StyleZhang, Y.-Q., Quan, G.-Z., Zhao, J., & Xiong, W. (2022). Influencing Mechanisms of Prior Cold Deformation on Mixed Grain Boundary Network in the Thermal Deformation of Ni80A Superalloy. Materials, 15(18), 6426. https://doi.org/10.3390/ma15186426