Distortion of an LTCC Bilayer during Constrained Sintering: Comparison between Ombroscopic Imaging and Modeling

Abstract

:1. Introduction

2. Materials and Methods

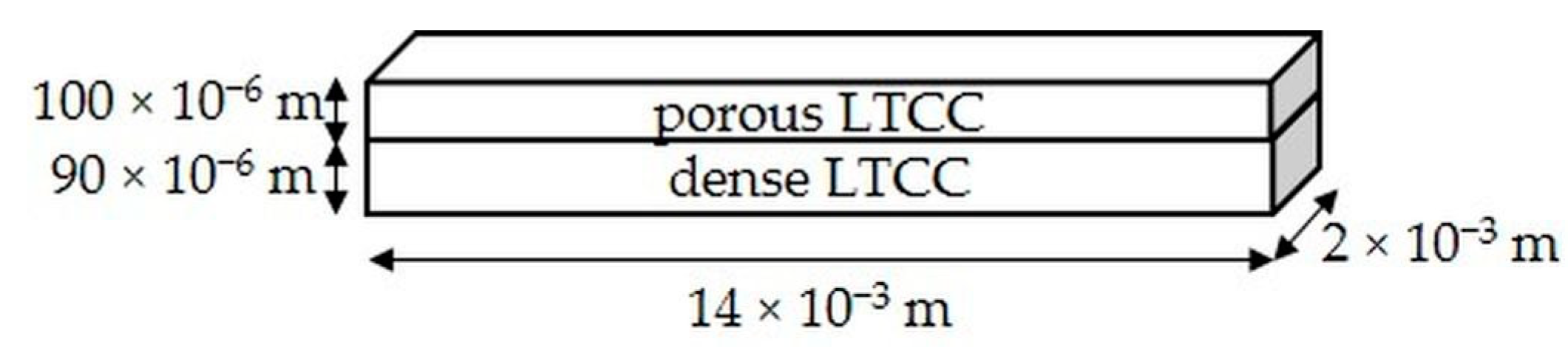

2.1. Processing of the LTCC Bilayer

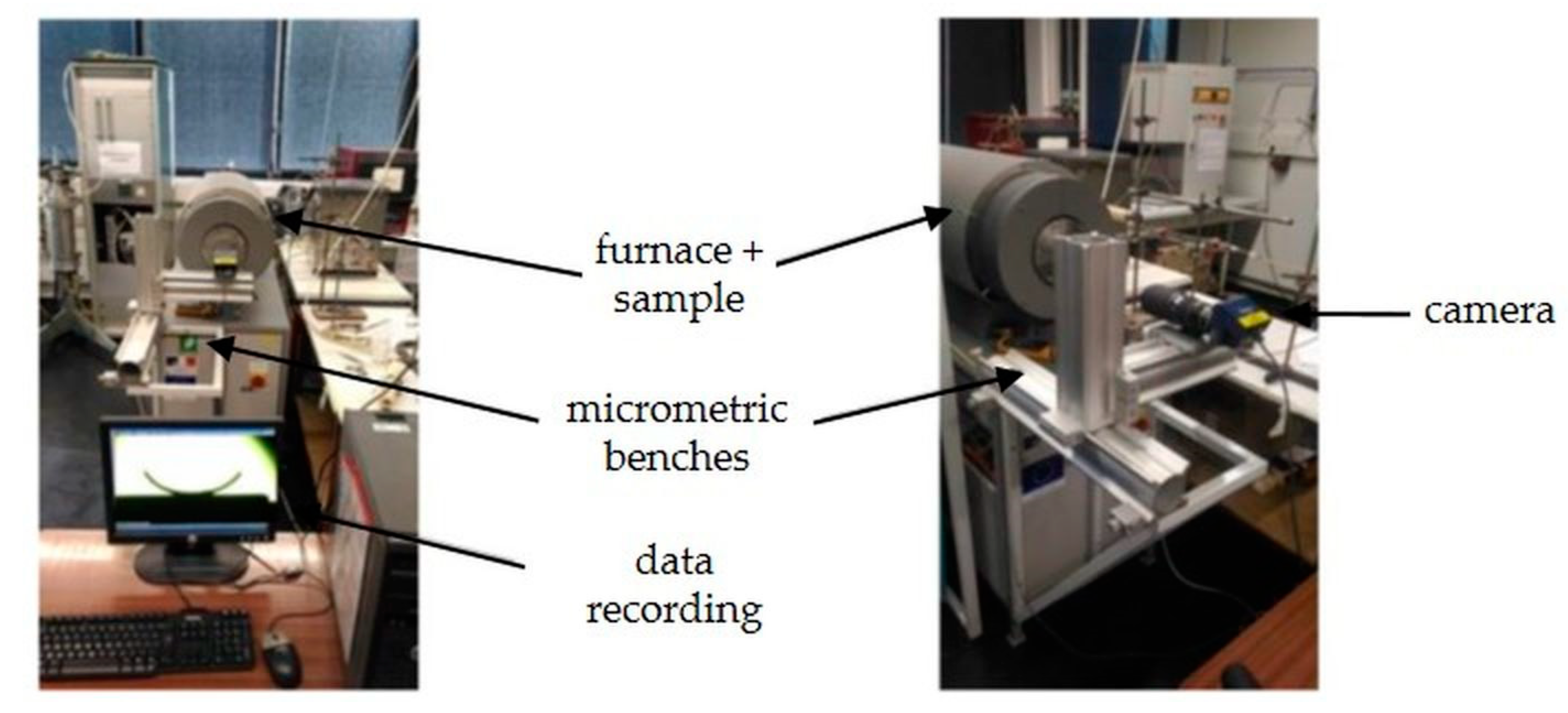

2.2. Camber Measurement by Ombroscopy

- 1.

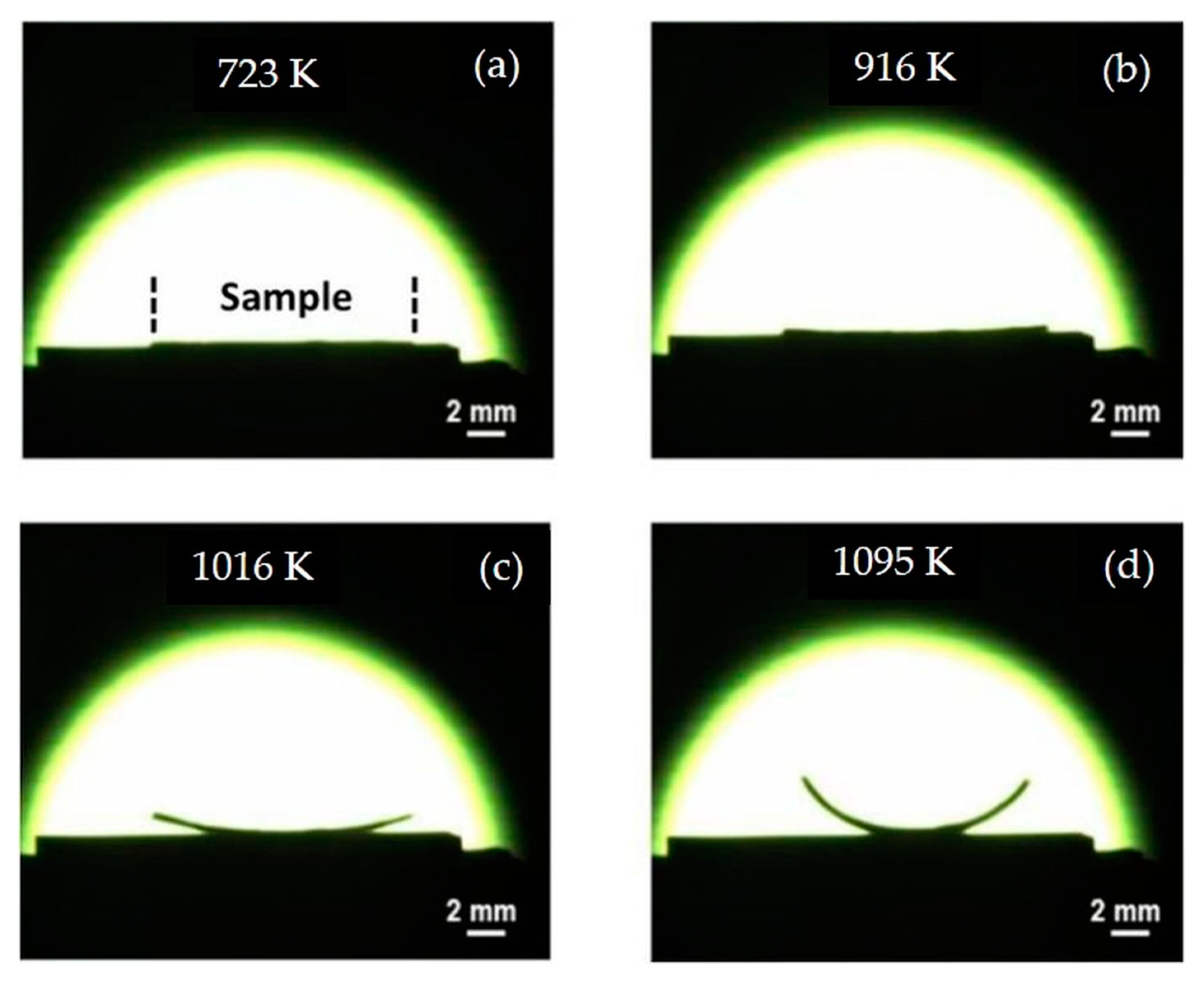

- At low temperatures, dilatation of the sample is uniform, and no camber occurs;

- 2.

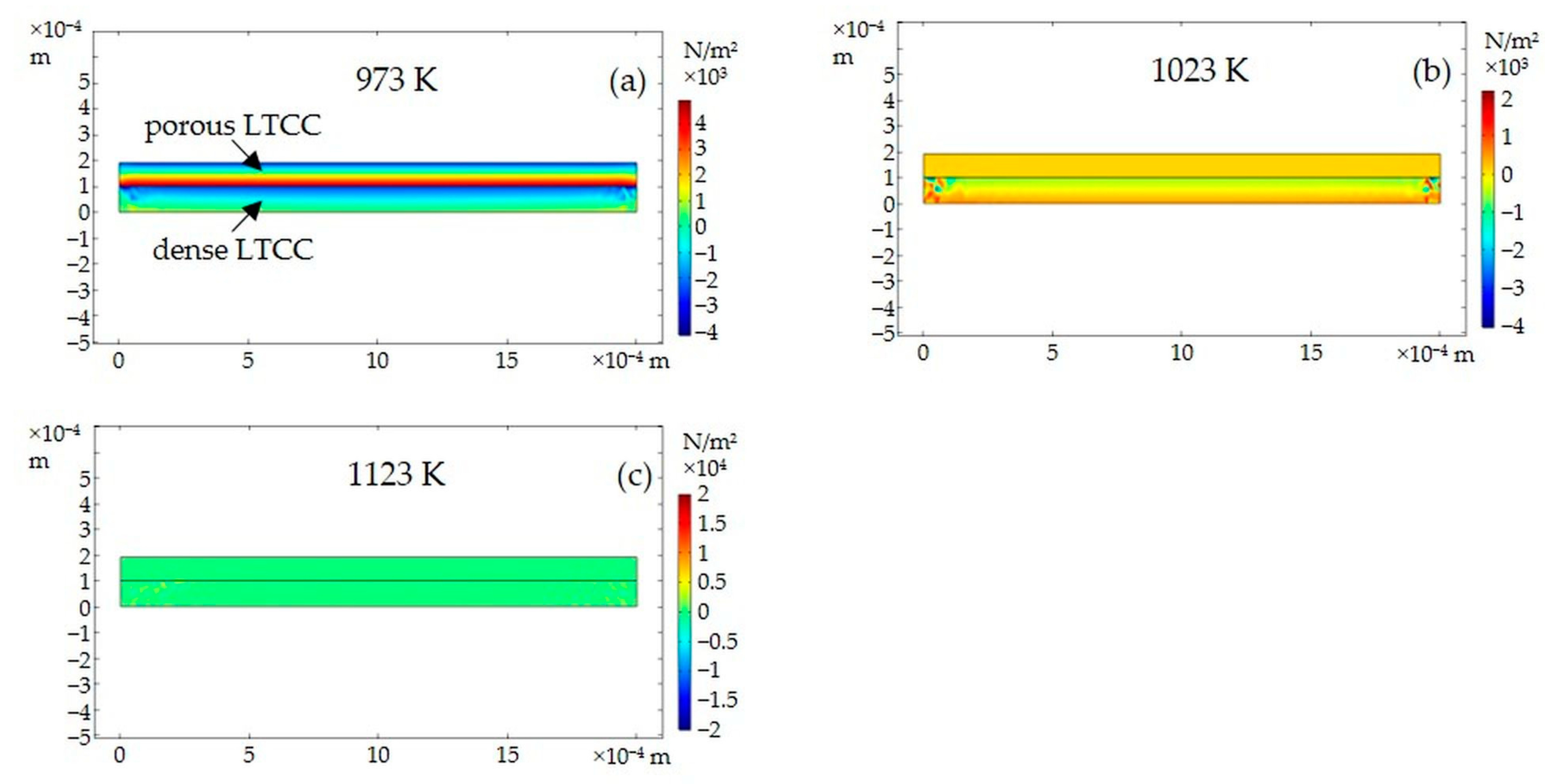

- At high temperatures (above 973 K), porous LTCC begins to densify, generating compressive stresses within the dense LTCC. Due to the low rigidity of the bilayer linked to its low thickness, a camber appears, allowing the relaxation of stresses generated by the densification of the porous LTCC.

3. Camber Modeling

- 1.

- A zero displacement is imposed in the out-of-plane direction (with respect to the bilayer joining plane) on the edge common to both LTCC layers;

- 2.

- A zero-displacement imposed in the in-plane direction (width axis) on one of the two extreme points of the former edge.

4. Results and Discussion

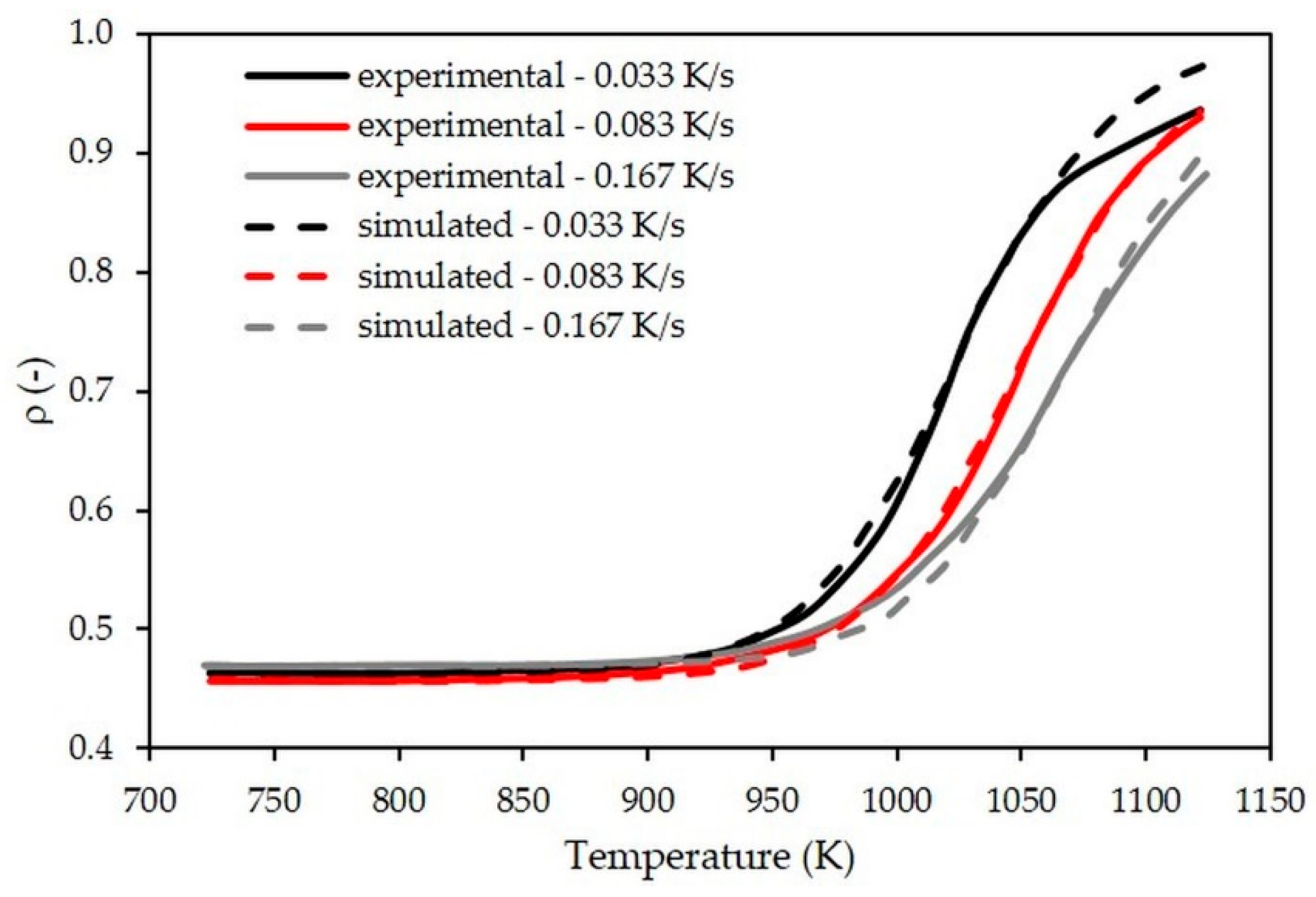

4.1. Free Sintering

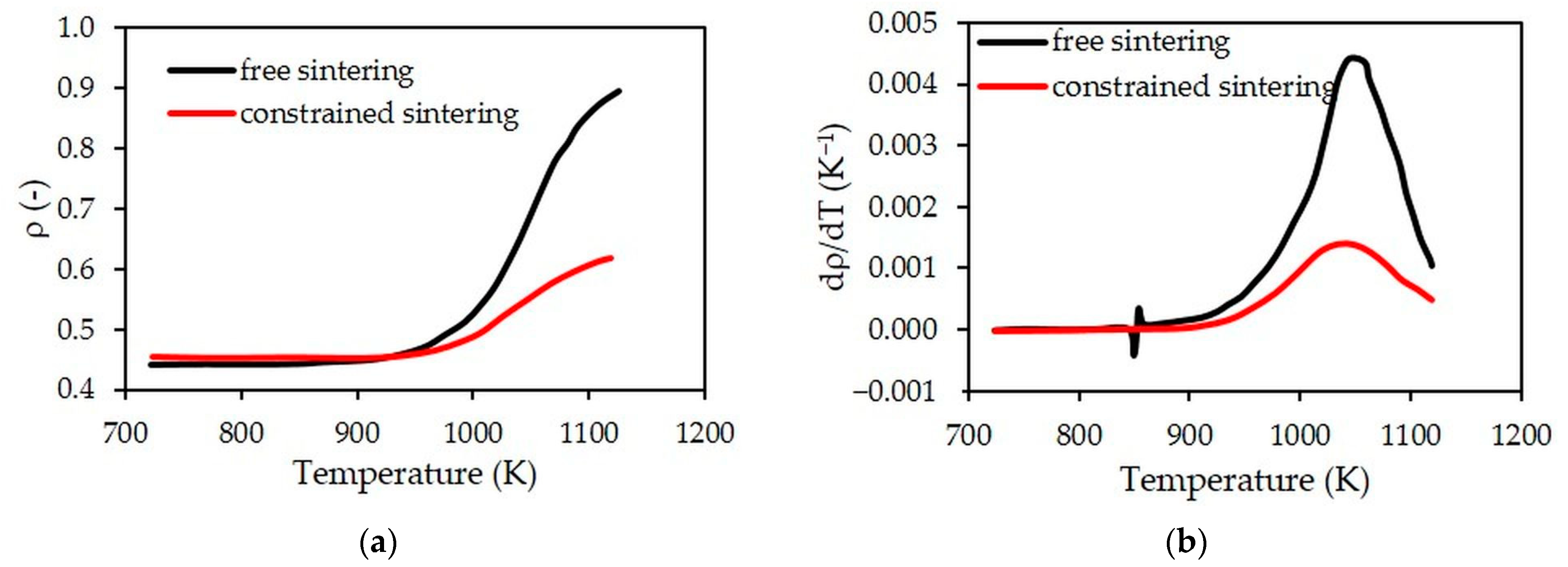

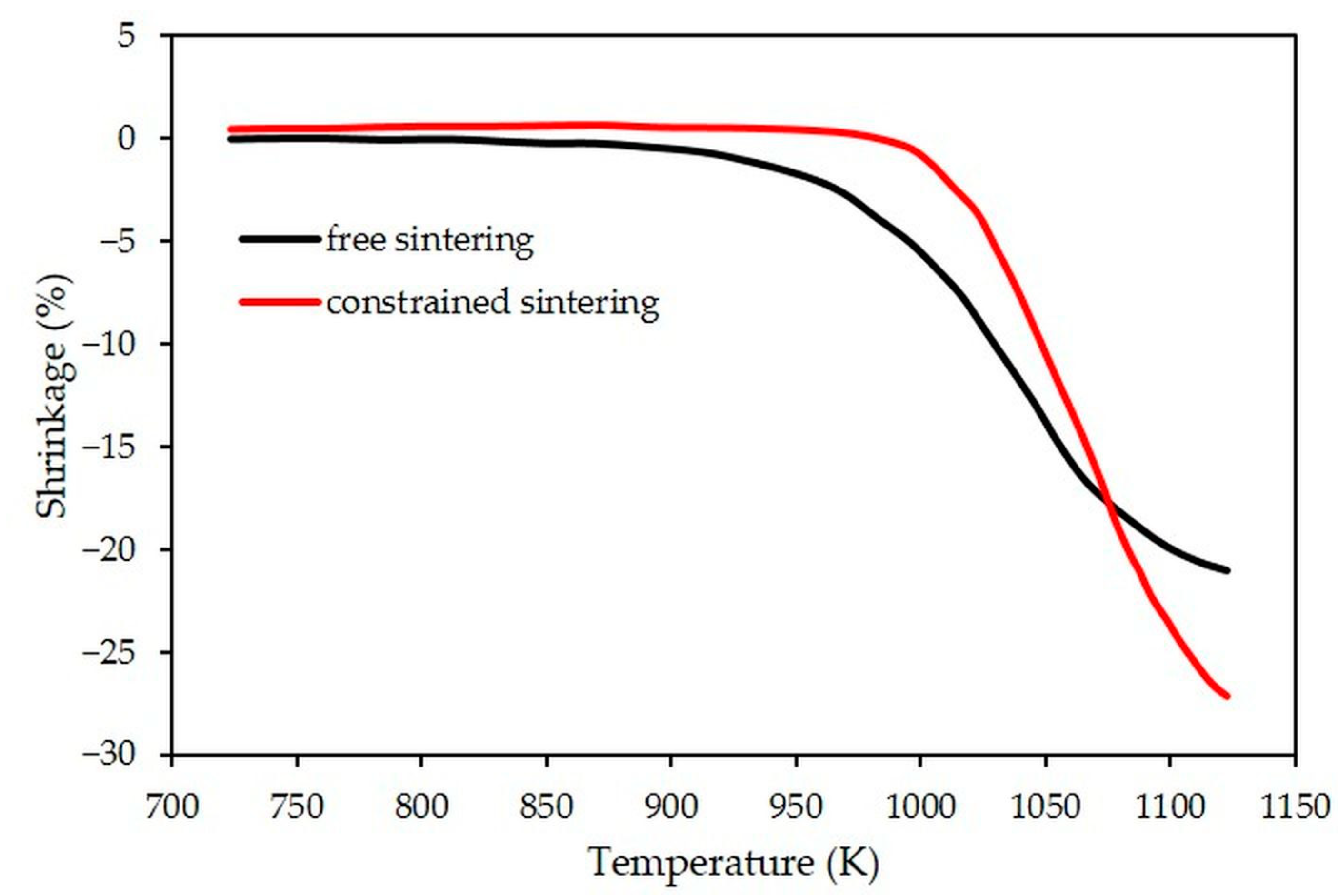

4.2. Free vs. Constrained Sintering

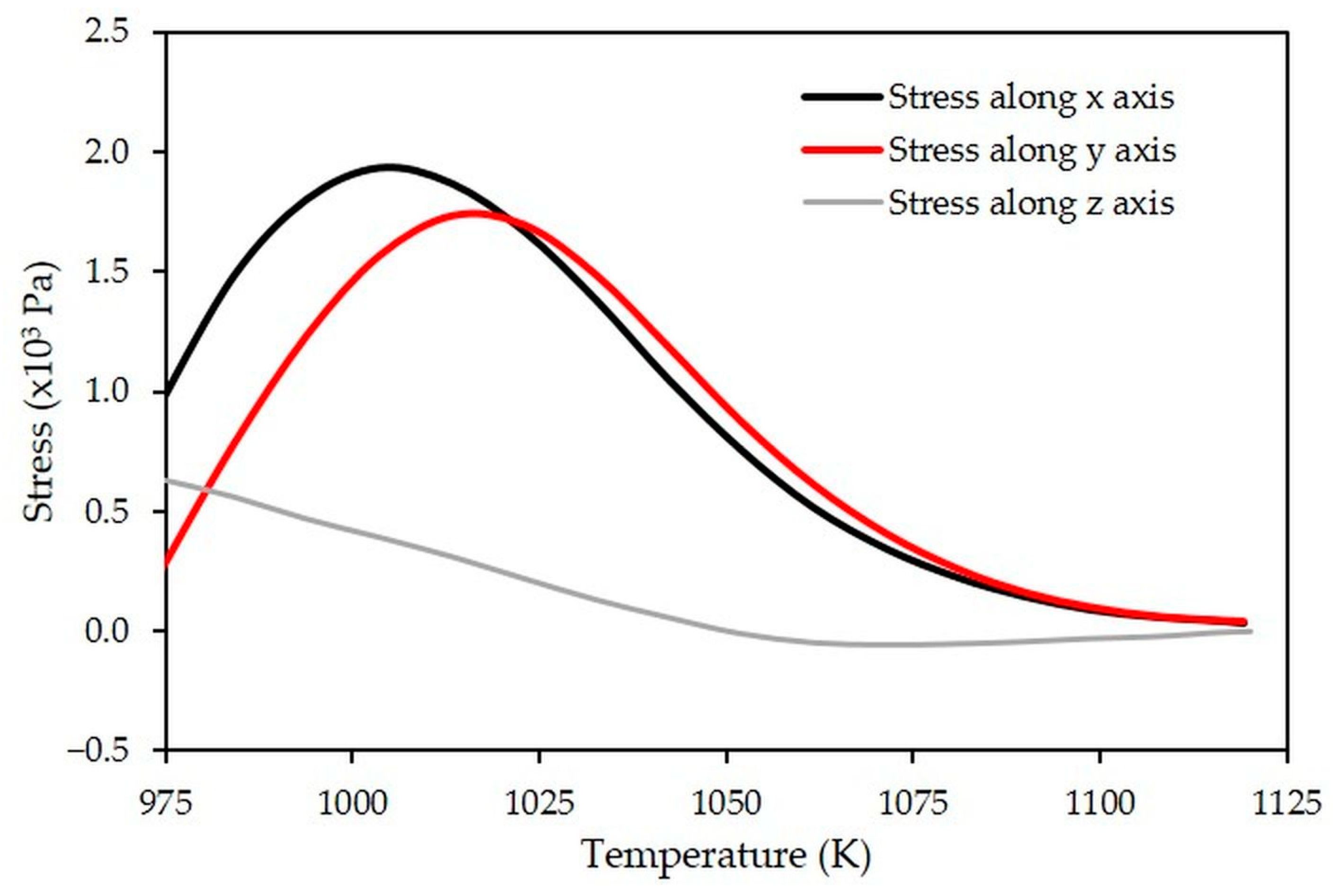

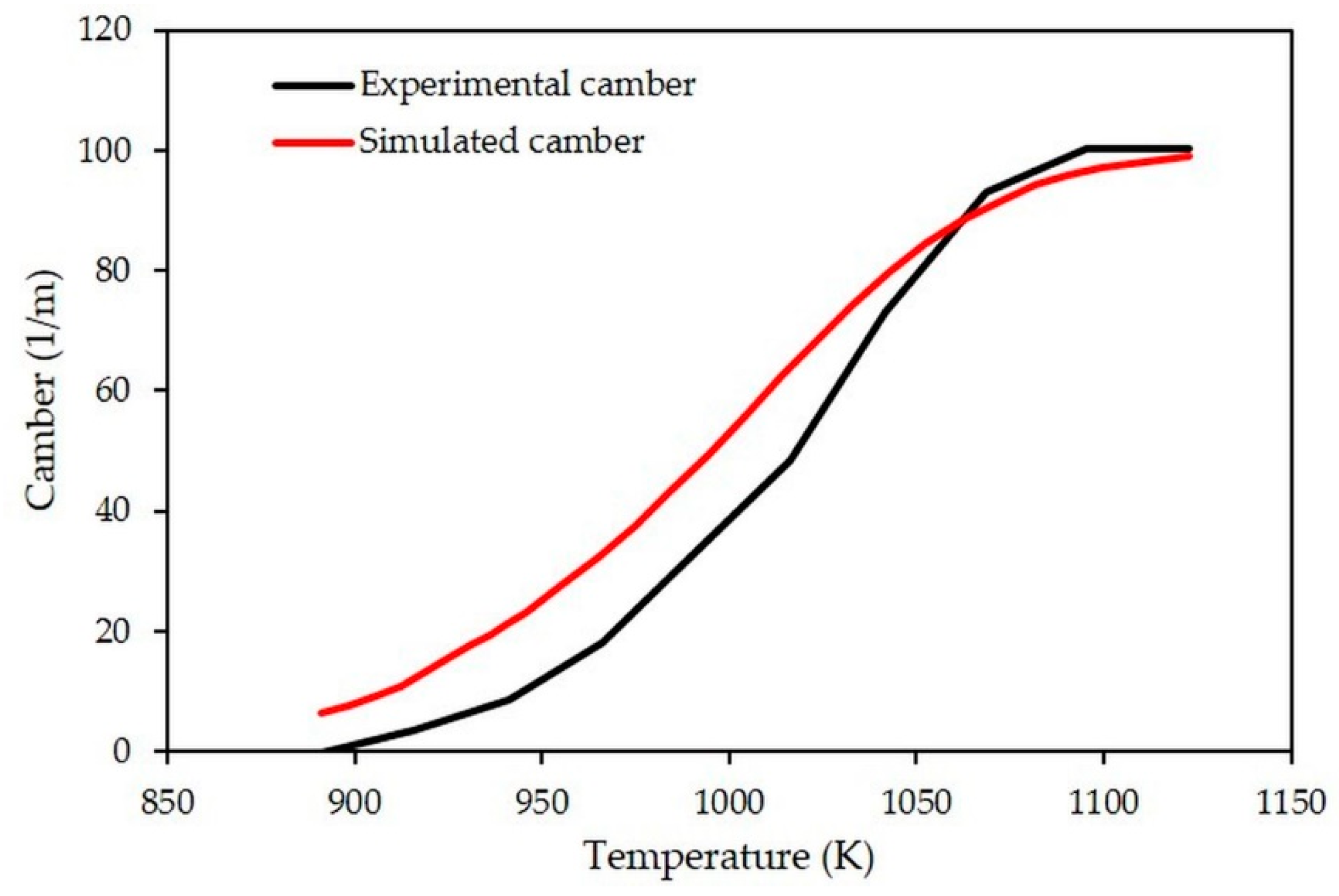

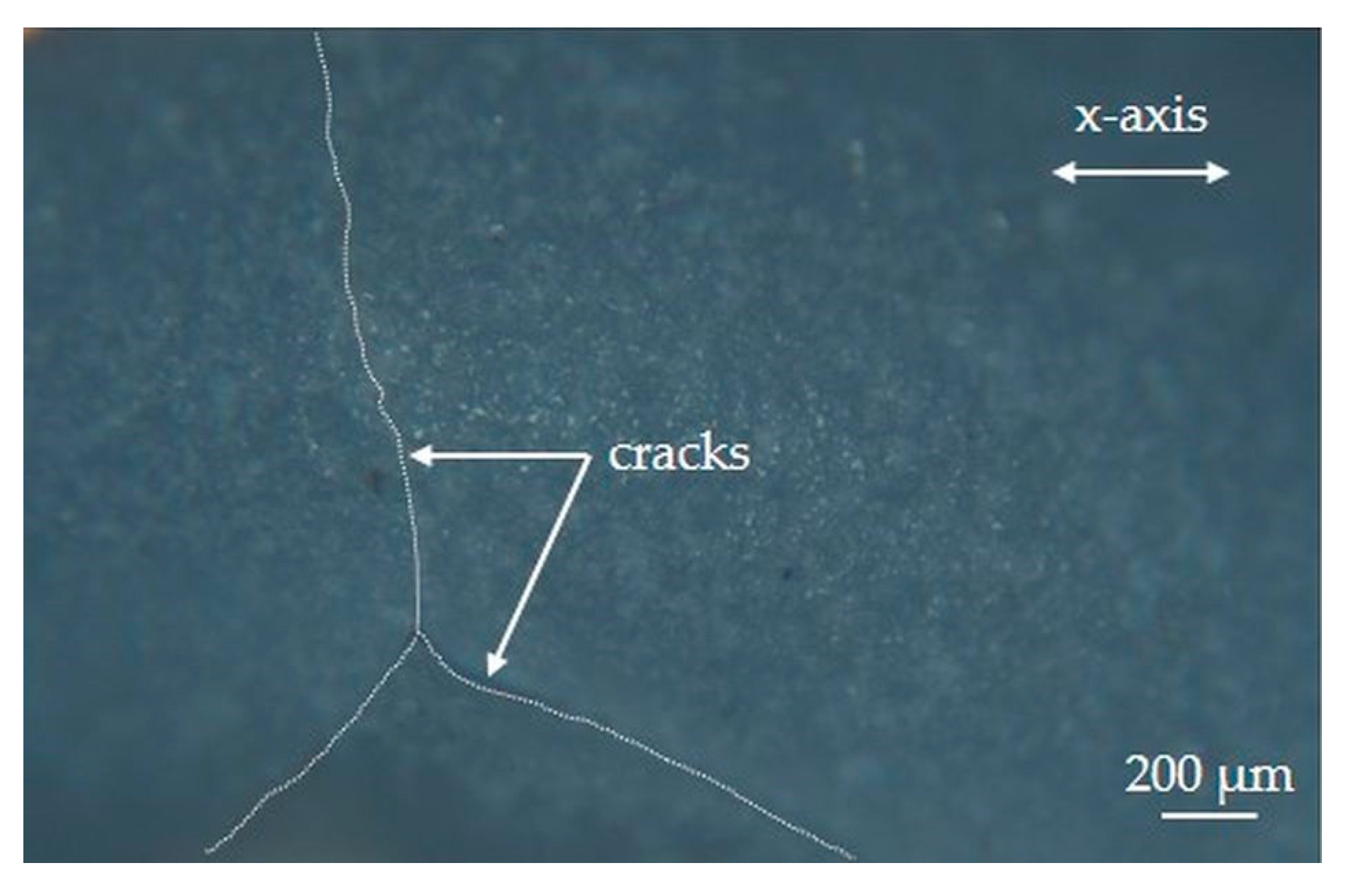

4.3. Evolution of Camber during Constrained Sintering

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ghaffarian, R. Microelectronics Packaging Technology Roadmaps, Assembly Reliability, and Prognostics. Facta Univ. Electron. Energ. 2016, 29, 543–611. [Google Scholar] [CrossRef]

- Sebastian, M.T.; Jantunen, H. Low Loss Dielectric Materials for LTCC Applications: A Review. Inter. Mater. Rev. 2008, 53, 57–90. [Google Scholar] [CrossRef]

- Choe, J.; Calat, J.N.; Lu, G.-Q. Constrained-Film Sintering of a Gold Circuit Paste. J. Mater. Res. 1995, 10, 986–994. [Google Scholar] [CrossRef]

- Holmes, P.J.; Loasby, R.G. Handbook of Thick Film Technology; Electrochemical Publications Limited.: Ayr, UK, 1976. [Google Scholar]

- Tummala, R.R. Microelectronics Packaging Handbook; Tummala, R.R., Rymaszewski, E.J., Eds.; Van Nostrand Reinhold: New York, NY, USA, 1989. [Google Scholar]

- Alias, R. Multilayer Glass–Ceramic Composites for Microelectronics: Processing and Properties. In Advances in Ceramic Matrix Composites; Elsevier: Amsterdam, The Netherlands, 2014; pp. 587–610. ISBN 978-0-85709-120-8. [Google Scholar]

- Green, D.J.; Guillon, O.; Rödel, J. Constrained Sintering: A Delicate Balance of Scales. J. Eur. Ceram. Soc. 2008, 28, 1451–1466. [Google Scholar] [CrossRef]

- Abhilash, P.; Sebastian, M.T.; Surendran, K.P. Structural, Thermal and Dielectric Properties of Rare Earth Substituted Eulytite for LTCC Applications. J. Eur. Ceram. Soc. 2016, 36, 1939–1944. [Google Scholar] [CrossRef]

- Duan, S.; Li, E.; Chen, H.; Tang, B.; Yuan, Y.; Zhang, S. Influence of Li2O–B2O3–SiO2 Glass on the Sintering Behavior and Microwave Dielectric Properties of BaO–0.15ZnO–4TiO2 Ceramics. Ceram. Int. 2016, 42, 7943–7949. [Google Scholar] [CrossRef]

- Hagymási, M.; Roosen, A.; Karmazin, R.; Dernovsek, O.; Haas, W. Constrained Sintering of Dielectric and Ferrite LTCC Tape Composites. J. Eur. Ceram. Soc. 2005, 25, 2061–2064. [Google Scholar] [CrossRef]

- Qi, S.; Zuo, R.; Ma, Z. Densification Kinetics and Anisotropic Microstructure Evolution in LTCC Films Constrained by Rigid Substrate. Ceram. Int. 2016, 42, 3388–3396. [Google Scholar] [CrossRef]

- Guillon, O. Partial Constrained Sintering of Ceramic Layers on Metallic Substrates: A Comparison Between Modeling and Experiments: Partial Constrained Sintering on Metallic Substrates. J. Am. Ceram. Soc. 2011, 94, 1040–1045. [Google Scholar] [CrossRef]

- Cai, P.Z.; Green, D.J.; Messing, G.L. Constrained Densification of Alumina/Zirconia Hybrid Laminates, II: Viscoelastic Stress Computation. J. Am. Ceram. Soc. 1997, 80, 1940–1948. [Google Scholar] [CrossRef]

- Kanters, J.; Eisele, U.; Rödel, J. Cosintering Simulation and Experimentation: Case Study of Nanocrystalline Zirconia. J. Am. Ceram. Soc. 2001, 84, 2757–2763. [Google Scholar] [CrossRef]

- Huang, R.; Pan, J. A Further Report on Finite Element Analysis of Sintering Deformation Using Densification Data—Error Estimation and Constrained Sintering. J. Eur. Ceram. Soc. 2008, 28, 1931–1939. [Google Scholar] [CrossRef]

- Ou, H.; Sahli, M.; Gelin, J.-C.; Barrière, T. Experimental Analysis and Finite Element Simulation of the Co-Sintering of Bi-Material Components. Powder Technol. 2014, 268, 269–278. [Google Scholar] [CrossRef]

- Rasp, T.; Jamin, C.; Guillon, O.; Kraft, T. Cracking and Shape Deformation of Cylindrical Cavities during Constrained Sintering. J. Eur. Ceram. Soc. 2017, 37, 2907–2917. [Google Scholar] [CrossRef]

- Du, Z.-Z.; Cocks, A.C.F. Constitutive Models for the Sintering of Ceramic Components—II. Sintering of Inhomogeneous Bodies. Acta Metall. Mater. 1992, 40, 1981–1994. [Google Scholar] [CrossRef]

- Olevsky, E.A. Theory of Sintering: From Discrete to Continuum. Mat. Sci. Eng. R Rep. 1998, 23, 41–100. [Google Scholar] [CrossRef]

- Ravi, D.; Green, D.J. Sintering Stresses and Distortion Produced by Density Differences in Bi-Layer Structures. J. Eur. Ceram. Soc. 2006, 26, 17–25. [Google Scholar] [CrossRef]

- Heux, A.; Antou, G.; Pradeilles, N.; Delhote, N.; Karnfelt, C.; Gallee, F.; Maître, A. Sintering and Thermomechanical Behavior of a Low Temperature Co-Fired Ceramic. Ceram. Int. 2018, 44, 22609–22615. [Google Scholar] [CrossRef]

- Su, H.; Johnson, D.L. Master Sintering Curve: A Practical Approach to Sintering. J. Am. Ceram. Soc. 1996, 79, 3211–3217. [Google Scholar] [CrossRef]

- Mohanram, A.; Messing, G.L.; Green, D.J. Measurement of Viscosity of Densifying Glass-Based Systems by Isothermal Cyclic Loading Dilatometry. J. Am. Ceram. Soc. 2004, 87, 192–196. [Google Scholar] [CrossRef]

- Mohanram, A.; Lee, S.; Messing, G.; Green, D. A Novel Use of Constrained Sintering to Determine the Viscous Poisson’s Ratio of Densifying Materials. Acta Mater. 2005, 53, 2413–2418. [Google Scholar] [CrossRef]

- Pagliari, L.; Dapiaggi, M.; Pavese, A.; Francescon, F. A Kinetic Study of the Quartz–Cristobalite Phase Transition. J. Eur. Ceram. Soc. 2013, 33, 3403–3410. [Google Scholar] [CrossRef]

- Ranogajec, J.; Živanović, B.; Aleksić, M. Activation of the Sintering Process of a Quartz Electrical Porcelain Body. Ceram. Inter. 1990, 16, 259–262. [Google Scholar] [CrossRef]

- Bordia, R.; Zuo, R.; Guillon, O.; Salamone, S.; Rodel, J. Anisotropic Constitutive Laws for Sintering Bodies. Acta Mater. 2006, 54, 111–118. [Google Scholar] [CrossRef]

| Parameters | Settings | Porous LTCC | Dense LTCC |

|---|---|---|---|

| Sintering parameters | Qfs (J·mol−1) | 303,000 | - |

| ρ0 (-) | 0.46 | - | |

| b (-) c (-) | −15.50 0.48 | - - | |

| Viscoplastic parameters | Qvp (J·mol−1) | 321,000 | 114,000 |

| η0 (Pa·s) β (-) νp (-) | 1.89 × 10−9 9.23 0.14 | 2.22 × 102 0 0.50 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chrétien, L.; Heux, A.; Antou, G.; Pradeilles, N.; Delhote, N.; Maître, A. Distortion of an LTCC Bilayer during Constrained Sintering: Comparison between Ombroscopic Imaging and Modeling. Materials 2022, 15, 6405. https://doi.org/10.3390/ma15186405

Chrétien L, Heux A, Antou G, Pradeilles N, Delhote N, Maître A. Distortion of an LTCC Bilayer during Constrained Sintering: Comparison between Ombroscopic Imaging and Modeling. Materials. 2022; 15(18):6405. https://doi.org/10.3390/ma15186405

Chicago/Turabian StyleChrétien, Lucie, Adrien Heux, Guy Antou, Nicolas Pradeilles, Nicolas Delhote, and Alexandre Maître. 2022. "Distortion of an LTCC Bilayer during Constrained Sintering: Comparison between Ombroscopic Imaging and Modeling" Materials 15, no. 18: 6405. https://doi.org/10.3390/ma15186405

APA StyleChrétien, L., Heux, A., Antou, G., Pradeilles, N., Delhote, N., & Maître, A. (2022). Distortion of an LTCC Bilayer during Constrained Sintering: Comparison between Ombroscopic Imaging and Modeling. Materials, 15(18), 6405. https://doi.org/10.3390/ma15186405