Lignocellulosic Biomass of C3 and C4 Perennial Grasses as a Valuable Feedstock for Particleboard Manufacture

Abstract

1. Introduction

2. Materials and Methods

2.1. Plant Establishment and Raw Material Collection

2.2. Particleboard Production

2.3. Experimental Design and Data Analysis

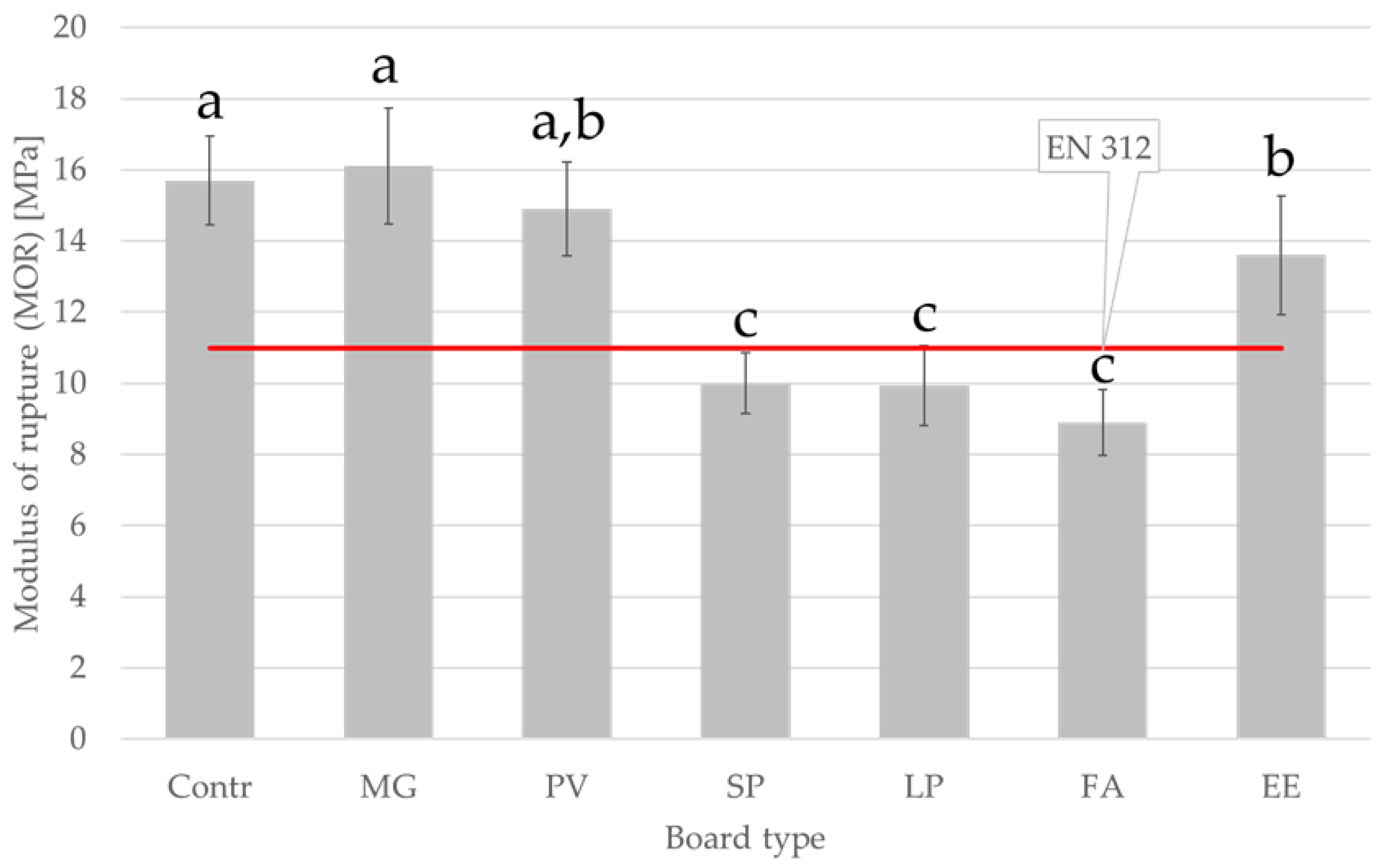

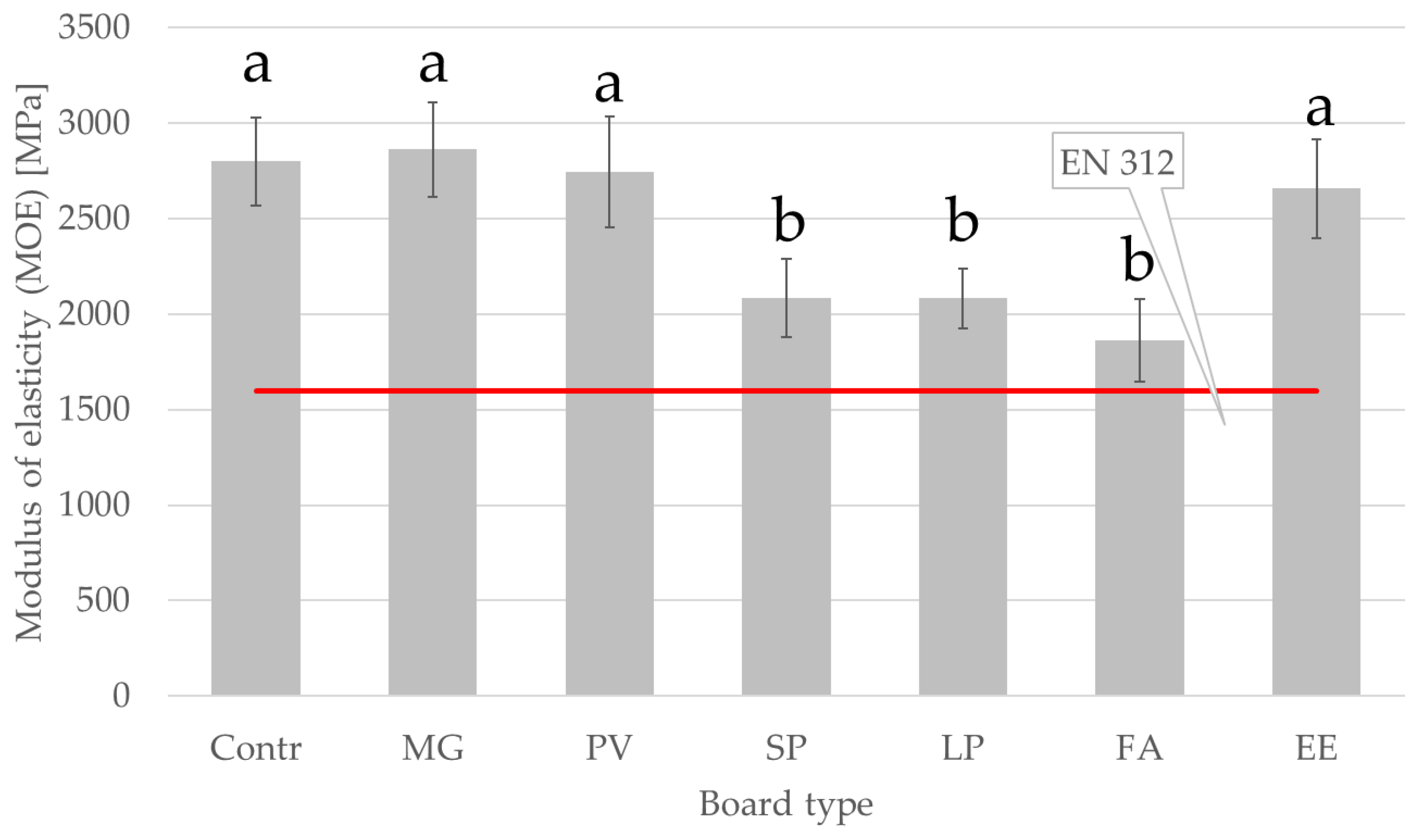

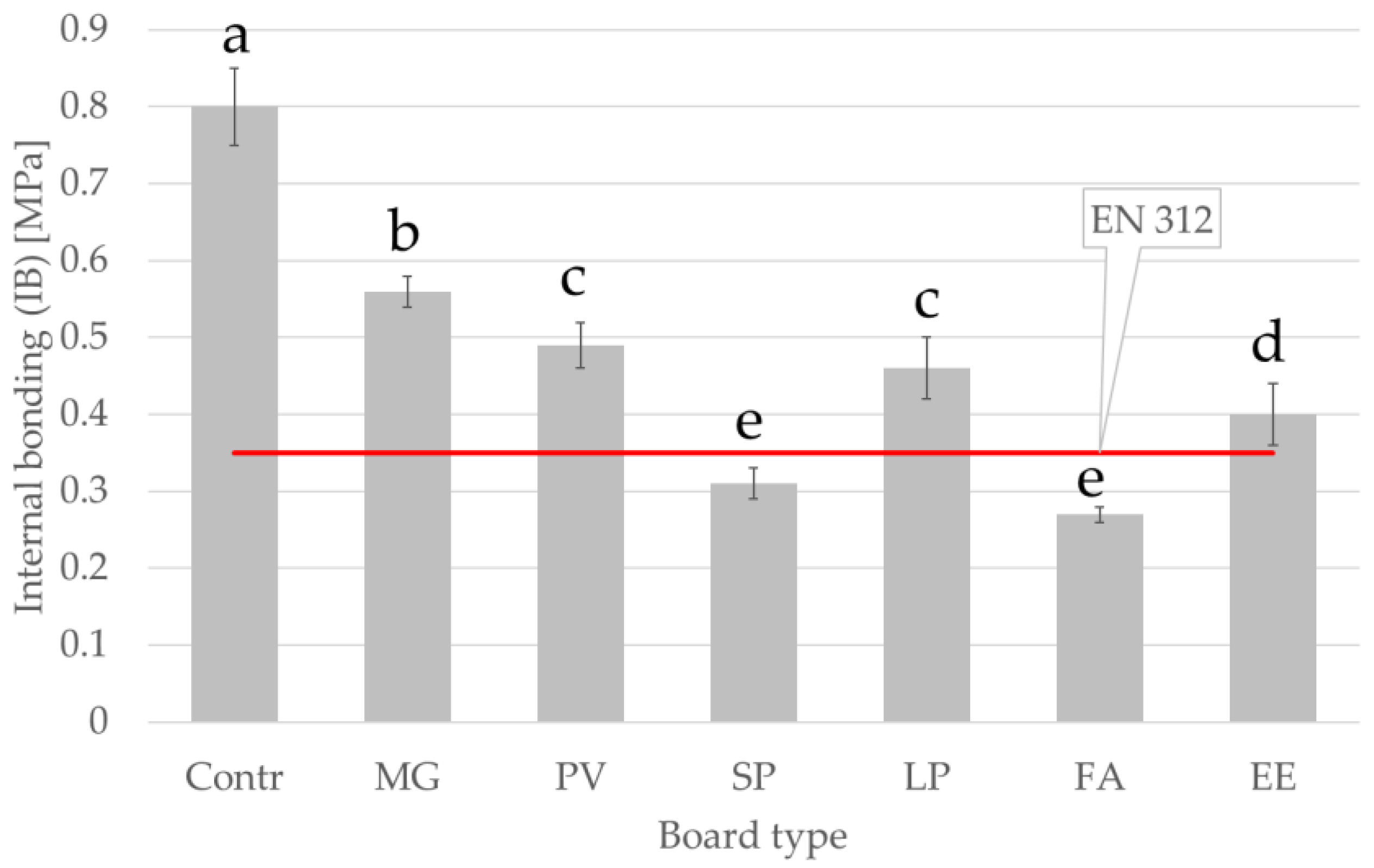

2.4. Determination of Standard Properties of Particleboards

- Modulus of rupture (MOR) and modulus of elasticity (MOE) according to EN 310:1994,

- Internal bond strength (IB) according to EN 319:1999,

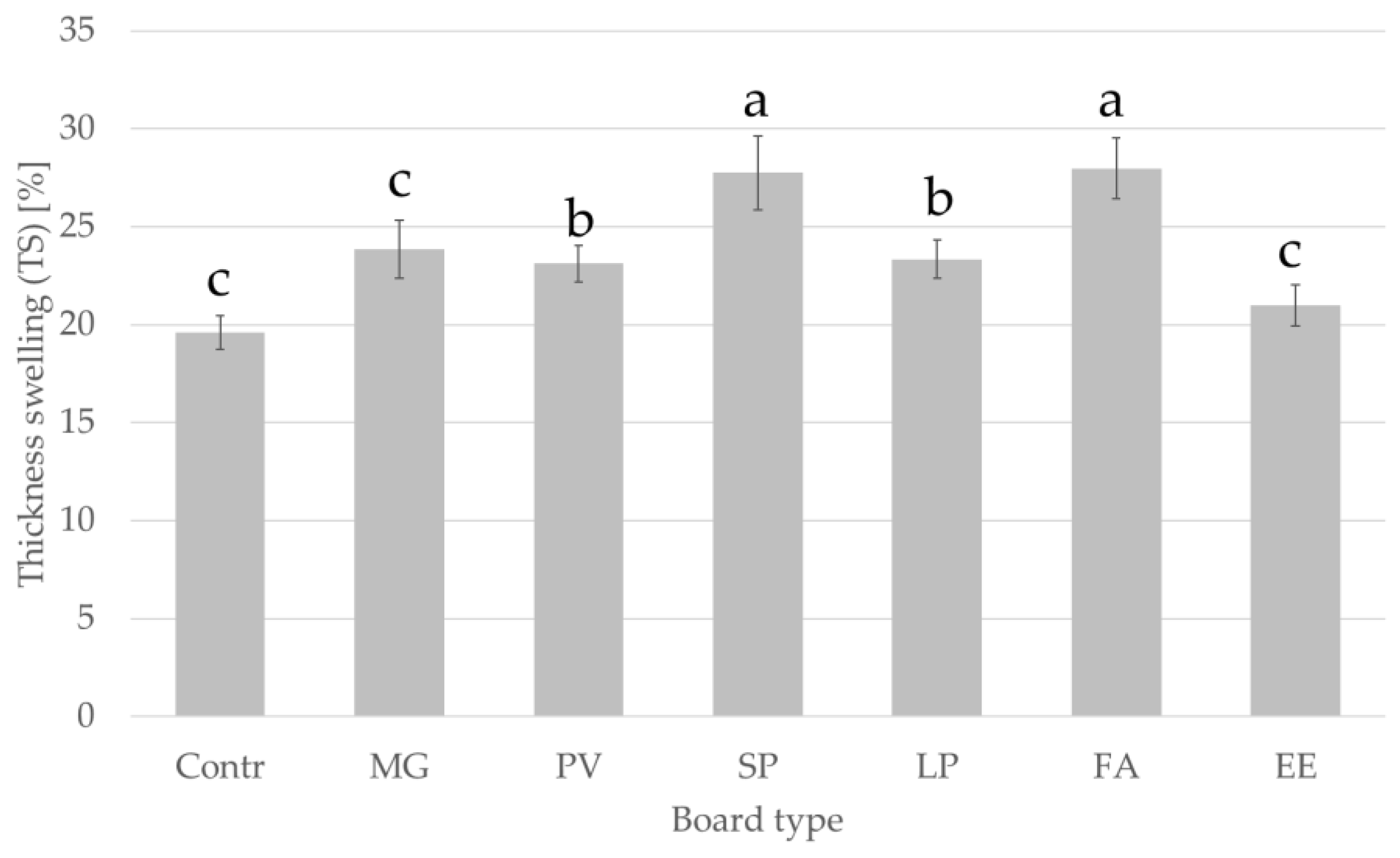

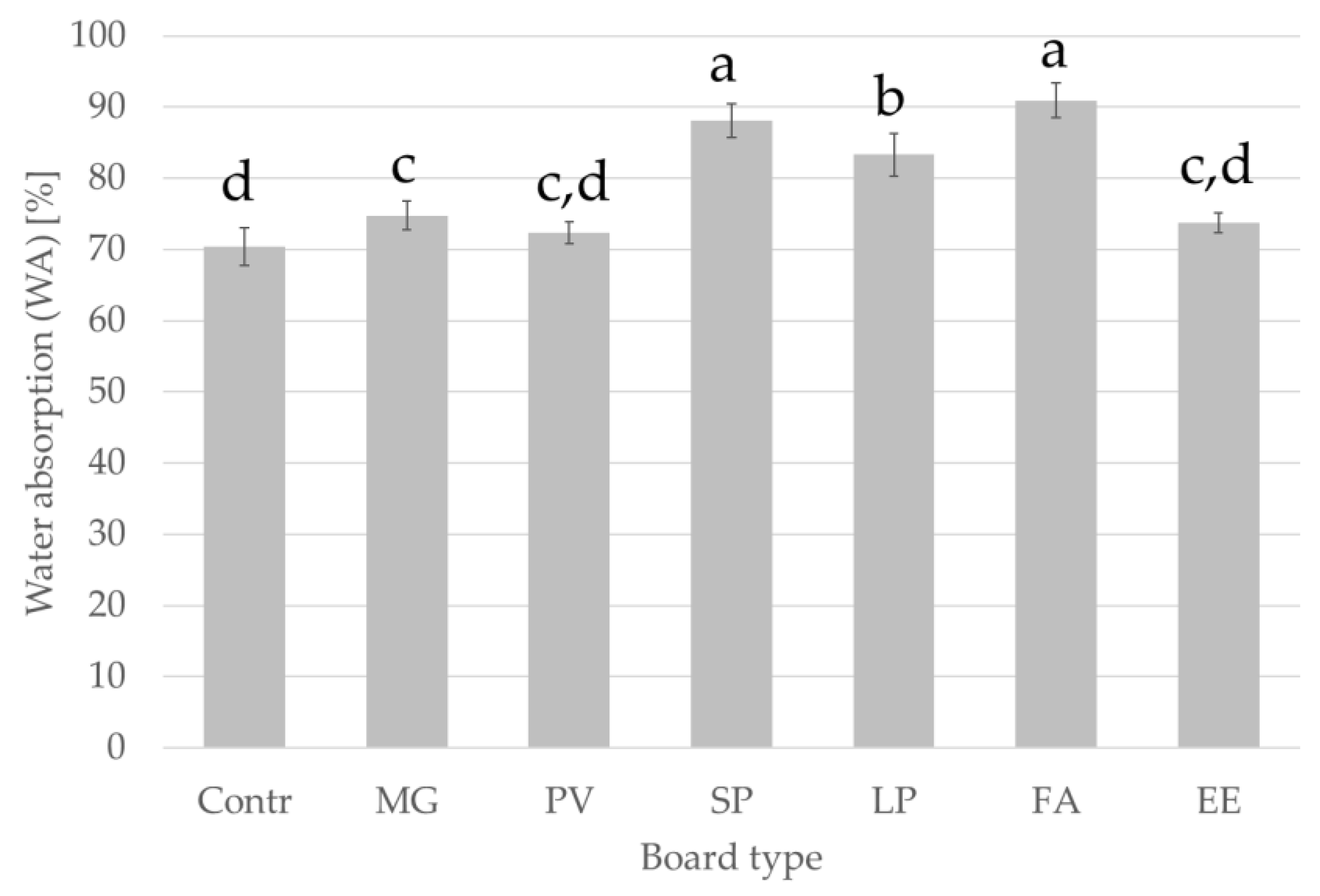

- Thickness swelling (TS) and water absorption (WA) after 24 h based on EN 317:1999,

- Formaldehyde content (FC) according to EN ISO 12460-5:2016-02, and

- Density according to EN 323:1999.

2.4.1. Mechanical Properties

2.4.2. Water Absorption and Thickness Swelling

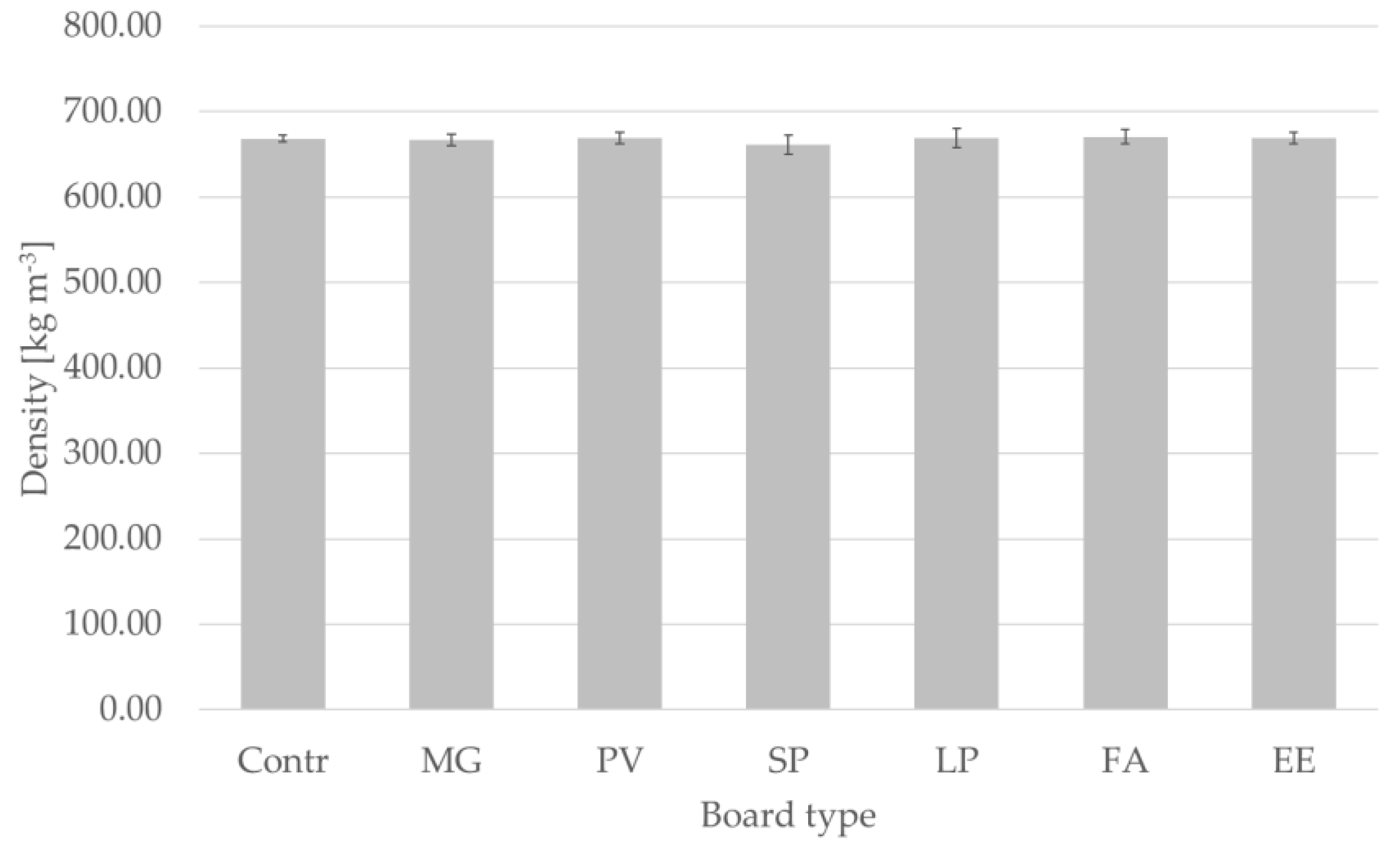

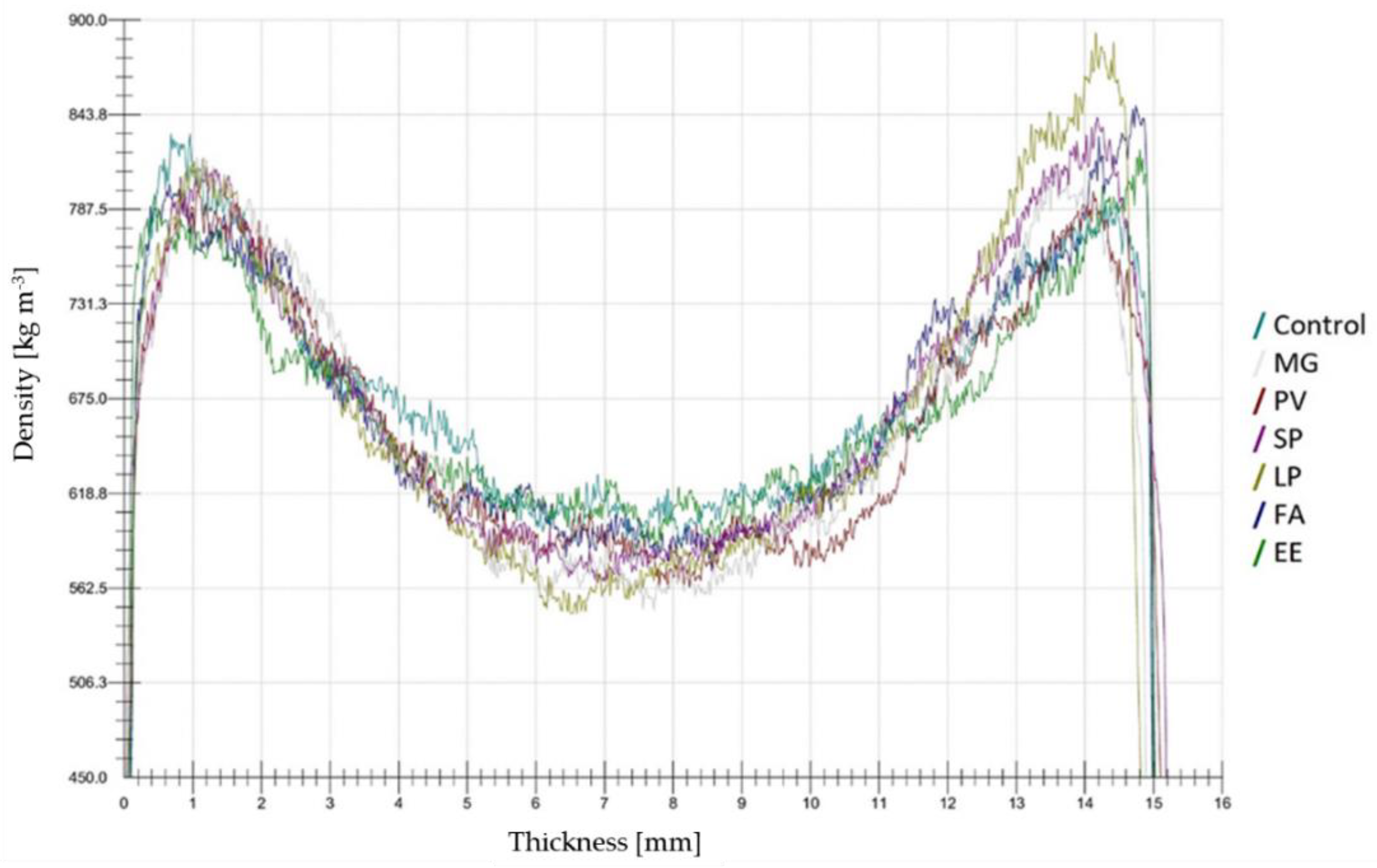

2.4.3. Density of Finished Particleboards

2.4.4. Formaldehyde Content

2.5. Statistical Analysis

3. Results and Discussion

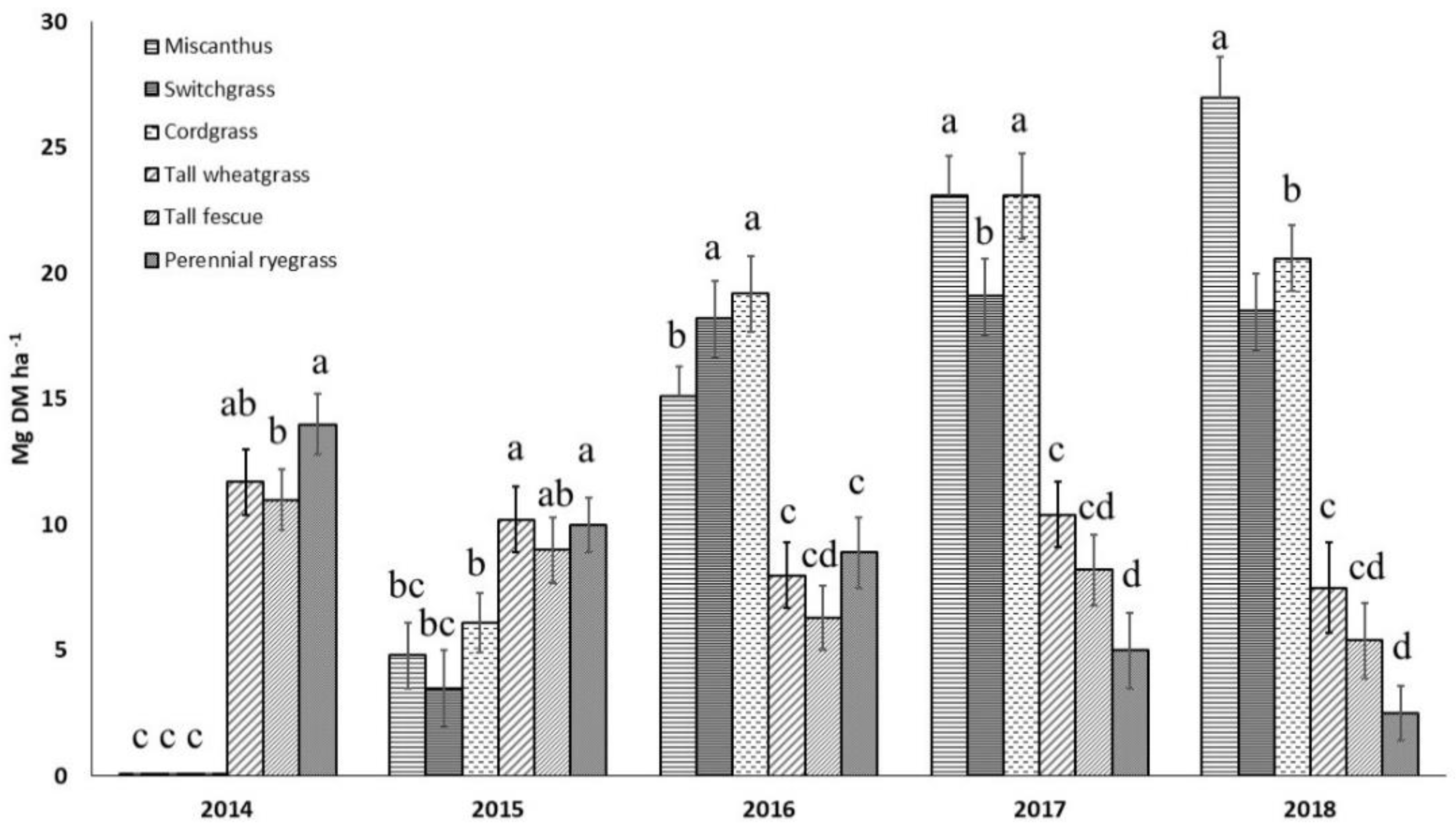

3.1. Yield Potential

3.2. Properties of Particleboards

3.3. Density of Particleboards

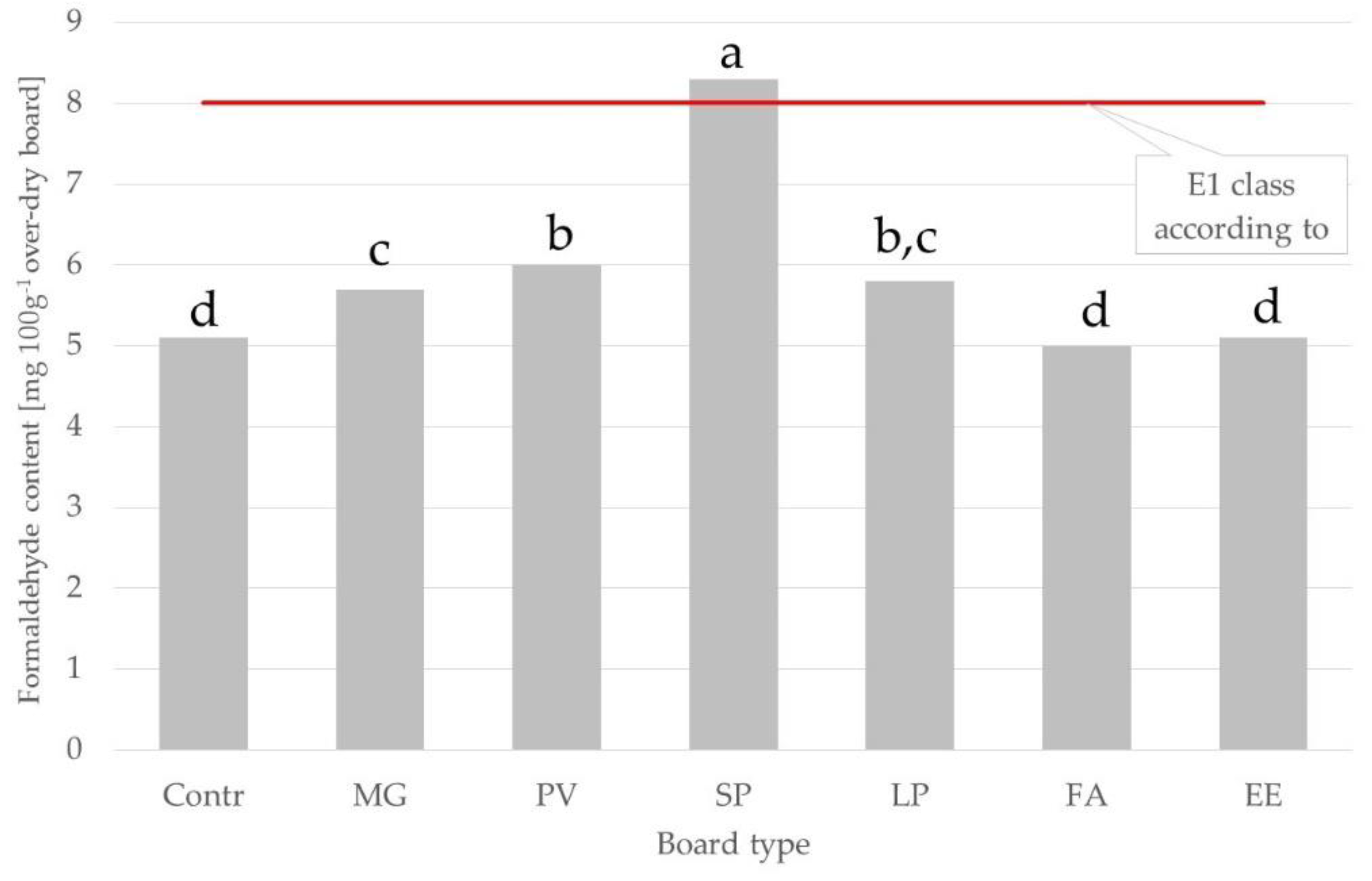

3.4. Formaldehyde Content

3.5. Future Research Directions

4. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Owodunni, A.A.; Lamaming, J.; Hashim, R.; Taiwo, O.F.A.; Hussin, M.H.; Mohamad Kassim, M.H.; Bustami, Y.; Sulaiman, O.; Amini, M.H.M.; Hiziroglu, S. Adhesive application on particleboard from natural fibers: A review. Polym. Compos. 2020, 41, 4448–4460. [Google Scholar] [CrossRef]

- Bekhta, P.; Noshchenko, G.; Réh, R.; Kristak, L.; Sedliačik, J.; Antov, P.; Mirski, R.; Savov, V. Properties of Eco-Friendly Particleboards Bonded with Lignosulfonate-Urea-Formaldehyde Adhesives and pMDI as a Crosslinker. Materials 2021, 14, 4875. [Google Scholar] [CrossRef] [PubMed]

- Oliver, C.D.; Nassar, N.T.; Lippke, B.R.; McCarter, J.B. Carbon, fossil fuel, and biodiversity mitigation with wood and forests. J. Sustain. For. 2014, 33, 248–275. [Google Scholar] [CrossRef]

- Kayo, C.; Oka, H.; Hashimoto, S.; Mizukami, M.; Takagi, S. Socioeconomic development and wood consumption. J. For. Res. 2015, 20, 309–320. [Google Scholar] [CrossRef]

- Robson, D.; Sadler, P.; Newman, G. Carbon sequestered in UK forest products and wood based panels in construction: Helping to meet UK’s greenhouse gas emission reduction targets. Int. Wood Prod. J. 2014, 5, 139–145. [Google Scholar] [CrossRef]

- Grzegorzewska, E. Assessment of the Competitiveness of the Furniture Industry—A Lesson from the Largest Exporting EU Countries. Drewno 2021, 64, 149–168. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, Y.; Ju, W.; Qiu, B.; Zhang, Z. Tracking the seasonal and inter-annual variations of global gross primary production during last four decades using satellite near-infrared reflectance data. Sci. Total Environ. 2021, 755, 142569. [Google Scholar] [CrossRef]

- Marais, B.N.; Brischke, C.; Militz, H. Wood durability in terrestrial and aquatic environments—A review of biotic and abiotic influence factors. Wood Mater. Sci. Eng. 2022, 17, 82–105. [Google Scholar] [CrossRef]

- Saez de Bikuña, K.; Garcia, R.; Dias, A.C.; Freire, F. Global warming implications from increased forest biomass utilization for bioenergy in a supply-constrained context. J. Environ. Manag. 2020, 263, 110292. [Google Scholar] [CrossRef]

- Wong, M.C.; Hendrikse, S.I.S.; Sherrell, P.C.; Ellis, A.V. Grapevine waste in sustainable hybrid particleboard production. Waste Manag. 2020, 118, 501–509. [Google Scholar] [CrossRef]

- Janiszewska, D.; Olchowski, R.; Nowicka, A.; Zborowska, M.; Marszałkiewicz, K.; Shams, M.; Giannakoudakis, D.A.; Anastopoulos, I.; Barczak, M. Activated biochars derived from wood biomass liquefaction residues for effective removal of hazardous hexavalent chromium from aquatic environments. GCB Bioenergy 2021, 13, 1247–1259. [Google Scholar] [CrossRef]

- Bonfiglio, F.; Cagno, M.; Yamakawa, C.K.; Mussatto, S.I. Production of xylitol and carotenoids from switchgrass and Eucalyptus globulus hydrolysates obtained by intensified steam explosion pretreatment. Ind. Crops Prod. 2021, 170, 113800. [Google Scholar] [CrossRef]

- Filipova, I.; Irbe, I.; Spade, M.; Skute, M.; Dāboliņa, I.; Baltiņa, I.; Vecbiskena, L. Mechanical and air permeability performance of novel biobased materials from fungal hyphae and cellulose fibers. Materials 2020, 14, 136. [Google Scholar] [CrossRef] [PubMed]

- Külçe, T.; Ateş, S.; Olgun, Ç. Evaluation of some plastic wastes as an additive to reinforcing the high density fiberboard (Hdf). Drewno 2021, 2021, 80–93. [Google Scholar] [CrossRef]

- Lesar, B.; Humar, M.; Hora, G.; Hachmeister, P.; Schmiedl, D.; Pindel, E.; Siika-Aho, M.; Liitiä, T. Utilization of recycled wood in biorefineries: Preliminary results of steam explosion and ethanol/water organosolv pulping without a catalyst. Eur. J. Wood Wood Prod. 2016, 74, 711–723. [Google Scholar] [CrossRef]

- Attribution, C.C.; License, I.; Sciences, L. A comparison of prediction efficiency for timber prices in Poland in times of economic crisis with the application of the linear approximation method and Brown’s exponential smoothing model. Drewno 2021, 64, 135–147. [Google Scholar] [CrossRef]

- Mahieu, A.; Alix, S.; Leblanc, N. Properties of particleboards made of agricultural by-products with a classical binder or self-bound. Ind. Crops Prod. 2019, 130, 371–379. [Google Scholar] [CrossRef]

- Réh, R.; Krišťák, Ľ.; Sedliačik, J.; Bekhta, P.; Božiková, M.; Kunecová, D.; Vozárová, V.; Tudor, E.M.; Antov, P.; Savov, V. Utilization of Birch Bark as an Eco-Friendly Filler in Urea-Formaldehyde Adhesives for Plywood Manufacturing. Polymers 2021, 13, 511. [Google Scholar] [CrossRef]

- Sandak, A.; Sandak, J.; Janiszewska, D.; Hiziroglu, S.; Petrillo, M.; Grossi, P. Prototype of the near-infrared spectroscopy expert system for particleboard identification. J. Spectrosc. 2018, 2018, 6025163. [Google Scholar] [CrossRef]

- Pędzik, M.; Janiszewska, D.; Rogoziński, T. Alternative lignocellulosic raw materials in particleboard production: A review. Ind. Crops Prod. 2021, 174, 114162. [Google Scholar] [CrossRef]

- Kuenzi, E.W.; Stamm, A.J.; Kollmann, F.F. Principles of Wood Science and Technology. 2. Wood Based Materials; Springer: Berlin/Heidelberg, Germany, 1975; ISBN 3540064672. [Google Scholar]

- Hýsková, P.; Hýsek, Š.; Schönfelder, O.; Šedivka, P.; Lexa, M.; Jarský, V. Utilization of agricultural rests: Straw-based composite panels made from enzymatic modified wheat and rapeseed straw. Ind. Crops Prod. 2020, 144, 112067. [Google Scholar] [CrossRef]

- Kusumah, S.S.; Umemura, K.; Yoshioka, K.; Miyafuji, H.; Kanayama, K. Utilization of sweet sorghum bagasse and citric acid for manufacturing of particleboard I: Effects of pre-drying treatment and citric acid content on the board properties. Ind. Crops Prod. 2016, 84, 34–42. [Google Scholar] [CrossRef]

- Pozzer, T.; Gauss, C.; Ament Barbirato, G.H.; Fiorelli, J. Trapezoidal core sandwich panel produced with sugarcane bagasse. Constr. Build. Mater. 2020, 264, 120718. [Google Scholar] [CrossRef]

- Komariah, R.N.; Miyamoto, T.; Tanaka, S.; Prasetiyo, K.W.; Syamani, F.A.; Subyakto; Umezawa, T.; Kanayama, K.; Umemura, K. High-performance binderless particleboard from the inner part of oil palm trunk by addition of ammonium dihydrogen phosphate. Ind. Crops Prod. 2019, 141, 111761. [Google Scholar] [CrossRef]

- Gibson, D.J. Grasses and Grassland Ecology; Oxford University Press: Oxford, UK, 2009; ISBN 019852918X. [Google Scholar]

- Reinhardt, J.; Hilgert, P.; Von Cossel, M. A review of industrial crop yield performances on unfavorable soil types. Agronomy 2021, 11, 2382. [Google Scholar] [CrossRef]

- Alpár, T.L.; Markó, G. Energy Grass as Raw Material for MDF Production. Acta Silv. Lignaria Hung. 2017, 13, 69–79. [Google Scholar] [CrossRef][Green Version]

- Eschenhagen, A.; Raj, M.; Rodrigo, N.; Zamora, A.; Labonne, L.; Evon, P.; Welemane, H. Investigation of Miscanthus and Sunflower Stalk Fiber-Reinforced Composites for Insulation Applications. Adv. Civ. Eng. 2019, 2019, 9328087. [Google Scholar] [CrossRef]

- Ajiwe, V.I.E.; Okeke, C.A.; Ekwuozor, S.C.; Uba, I.C. A pilot plant for production of ceiling boards from rice husks. Bioresour. Technol. 1998, 66, 41–43. [Google Scholar] [CrossRef]

- Yang, H.-S.; Kim, D.-J.; Kim, H.-J. Rice straw–wood particle composite for sound absorbing wooden construction materials. Bioresour. Technol. 2003, 86, 117–121. [Google Scholar] [CrossRef]

- Tröger, F.; Wegener, G.; Seemann, C. Miscanthus and flax as raw material for reinforced particleboards. Ind. Crops Prod. 1998, 8, 113–121. [Google Scholar] [CrossRef]

- Kaack, K.; Schwarz, K.-U.; Brander, P.E. Variation in morphology, anatomy and chemistry of stems of Miscanthus genotypes differing in mechanical properties. Ind. Crops Prod. 2003, 17, 131–142. [Google Scholar] [CrossRef]

- Balducci, F.; Harper, C.; Meinlschmidt, P.; Dix, B.; Sanasi, A. Development of innovative particleboard panels. Drv. Ind. Znan. Časopis Pitanja Drv. Tehnol. 2008, 59, 131–136. [Google Scholar]

- Klímek, P.; Wimmer, R.; Meinlschmidt, P.; Kúdela, J. Utilizing Miscanthus stalks as raw material for particleboards. Ind. Crops Prod. 2018, 111, 270–276. [Google Scholar] [CrossRef]

- Park, H.-J.; Oh, S.-W.; Wen, M.-Y. Manufacture and properties of Miscanthus–wood particle composite boards. J. Wood Sci. 2012, 58, 459–464. [Google Scholar] [CrossRef]

- Tajuddin, M.; Ahmad, Z.; Ismail, H. A review of natural fibers and processing operations for the production of binderless boards. BioResources 2016, 11, 5600–5617. [Google Scholar]

- Reddy, N.; Yang, Y. Innovative Bio Fibers from Renewable Resources; Springer: Berlin/Heidelberg, Germany, 2015. [Google Scholar]

- Zheng, Y.; Pan, Z.; Zhang, R.; Jenkins, B.M.; Blunk, S. Particleboard quality characteristics of saline jose tall wheatgrass and chemical treatment effect. Bioresour. Technol. 2007, 98, 1304–1310. [Google Scholar] [CrossRef]

- Danielewicz, D.; Surma-Ślusarska, B.; Żurek, G.; Martyniak, D.; Kmiotek, M.; Dybka, K. Selected grass plants as biomass fuels and raw materials for papermaking, part II. Pulp and paper properties. BioResources 2015, 10, 8552–8564. [Google Scholar] [CrossRef]

- Danielewicz, D.; Surma-Ślusarska, B.; Żurek, G.; Martyniak, D. Selected grass plants as biomass fuels and raw materials for papermaking. Part I. Calorific value and chemical composition. BioResources 2015, 10, 8539–8551. [Google Scholar] [CrossRef][Green Version]

- Nemli, G.; Demirel, S.; Gümüşkaya, E.; Aslan, M.; Acar, C. Feasibility of incorporating waste grass clippings (Lolium perenne L.) in particleboard composites. Waste Manag. 2009, 29, 1129–1131. [Google Scholar] [CrossRef]

- Lewandowski, I.; Clifton-Brown, J.C.; Scurlock, J.M.O.; Huisman, W. Miscanthus: European experience with a novel energy crop. Biomass Bioenergy 2000, 19, 209–227. [Google Scholar] [CrossRef]

- Lewandowski, I.; Scurlock, J.M.O.; Lindvall, E.; Christou, M. The development and current status of perennial rhizomatous grasses as energy crops in the US and Europe. Biomass Bioenergy 2003, 25, 335–361. [Google Scholar] [CrossRef]

- Babicka, M.; Woźniak, M.; Bartkowiak, M.; Peplińska, B.; Waliszewska, H.; Zborowska, M.; Borysiak, S.; Ratajczak, I. Miscanthus and Sorghum as sustainable biomass sources for nanocellulose production. Ind. Crops Prod. 2022, 186, 115177. [Google Scholar] [CrossRef]

- Stolarski, M.J.; Krzyżaniak, M.; Olba-Zięty, E. Biomass yield and quality of perennial herbaceous crops in a double harvest in a continental environment. Ind. Crops Prod. 2022, 180, 114752. [Google Scholar] [CrossRef]

- Abreu, M.; Silva, L.; Ribeiro, B.; Ferreira, A.; Alves, L.; Paixão, S.M.; Gouveia, L.; Moura, P.; Carvalheiro, F.; Duarte, L.C. Low Indirect Land Use Change (ILUC) Energy Crops to Bioenergy and Biofuels—A Review. Energies 2022, 15, 4348. [Google Scholar] [CrossRef]

- Dukarska, D.; Pędzik, M.; Rogozińska, W.; Rogoziński, T.; Czarnecki, R. Characteristics of straw particles of selected grain species purposed for the production of lignocellulose particleboards. Part. Sci. Technol. 2019, 39, 213–222. [Google Scholar] [CrossRef]

- Juliana, A.H.; Paridah, M.T.; Rahim, S.; Nor Azowa, I.; Anwar, U.M.K. Properties of particleboard made from kenaf (Hibiscus cannabinus L.) as function of particle geometry. Mater. Des. 2012, 34, 406–411. [Google Scholar] [CrossRef]

- Kord, B.; Zare, H.; Hosseinzadeh, A. Evaluation of the mechanical and physical properties of particleboard manufactured from canola (Brassica napus) straws. Maderas Cienc. Tecnol. 2016, 18, 9–18. [Google Scholar] [CrossRef]

- Neitzel, N.; Hosseinpourpia, R.; Walther, T.; Adamopoulos, S. Alternative Materials from Agro-Industry for Wood Panel Manufacturing—A Review. Materials 2022, 15, 4542. [Google Scholar] [CrossRef]

- Iswanto, A.H.; Aritonang, W.; Azhar, I.; Supriyanto; Fatriasari, W. The physical, mechanical and durability properties of sorghum bagasse particleboard by layering surface treatment. J. Indian Acad. Wood Sci. 2017, 14, 1–8. [Google Scholar] [CrossRef]

- Si, S.; Zheng, X.; Li, X. Effect of carbonization treatment on the physicochemical properties of bamboo particleboard. Constr. Build. Mater. 2022, 344, 128204. [Google Scholar] [CrossRef]

- Ren, H.; Richard, T.L.; Chen, Z.; Kuo, M.; Bian, Y.; Moore, K.J.; Patrick, P. Ensiling corn stover: Effect of feedstock preservation on particleboard performance. Biotechnol. Prog. 2006, 22, 78–85. [Google Scholar] [CrossRef] [PubMed]

- Ferrández-García, A.; Ferrández-Villena, M.; Ferrández-García, C.E.; García-Ortuño, T.; Ferrández-García, M.T. Potential use of Phoenix canariensis biomass in binderless particleboards at low temperature and pressure. BioResources 2017, 12, 6698–6712. [Google Scholar] [CrossRef]

- Wong, E.D. Effects of density profile on the mechanical properties of particleboard and fiberboard. Wood Res. Bull. Wood Res. Inst. Kyoto Univ. 1999, 86, 19–33. [Google Scholar]

- Nirdosha, G.; Setunge, S.; Jollands, M.; Hague, J. Properties of hardwood saw mill residue-based particleboards as affected by processing parameters. Ind. Crops Prod. 2009, 29, 248–254. [Google Scholar] [CrossRef]

- Nelis, P.A.; Michaelis, F.; Krause, K.C.; Mai, C. Kiri wood (Paulownia tomentosa): Can it improve the performance of particleboards? Eur. J. Wood Wood Prod. 2018, 76, 445–453. [Google Scholar] [CrossRef]

- Trischler, J.; Sandberg, D. Monocotyledons in particleboard production: Adhesives, additives and surface modification of Reed canary grass. BioResources 2014, 9, 3919–3938. [Google Scholar] [CrossRef][Green Version]

- Sultana, A.; Kumar, A. Optimal configuration and combination of multiple lignocellulosic biomass feedstocks delivery to a biorefinery. Bioresour. Technol. 2011, 102, 9947–9956. [Google Scholar] [CrossRef]

- Cai, J.; He, Y.; Yu, X.; Banks, S.W.; Yang, Y.; Zhang, X.; Yu, Y.; Liu, R.; Bridgwater, A.V. Review of physicochemical properties and analytical characterization of lignocellulosic biomass. Renew. Sustain. Energy Rev. 2017, 76, 309–322. [Google Scholar] [CrossRef]

| Species Name | Cultivar Name/Breeder | Plots Established from: | Plants or Seed per m2 | Distance in Rows/between Rows (m) |

|---|---|---|---|---|

| C4 species: | ||||

| Miscanthus (MG) | unknown | rhizomes | 1 | 1/1 |

| Switchgrass (SG) | MARDAN/PBAI *, POL | seedlings | 2 | |

| Cordgrass (SP) | unknown | rhizomes | 2 | |

| C3 species: | ||||

| Tall wheatgrass (EE) | BAMAR/BS ** Bartążek, POL | seed | 10 g | 0.5/0.3 |

| Tall fescue (FA) | BAROLEX/BERENBRUG, NLD | 10 g | 0.5/0.3 | |

| Perennial ryegrass (LP) | BARONKA/BS Bartążek, POL | 20 g | 0.3/0.3 |

| Parameter | Value/Units |

|---|---|

| Board density | 670 kg·m−3 |

| Board thickness | 16 mm |

| Resination ratio | 10% |

| Paraffin emulsion content | 0.3% |

| Press temperature | 200 °C |

| Pressing pressure | 20.5 MPa |

| Pressing time | 8 s·mm−1 |

| Hardener ratio | 3% |

| Hardener | 40% solution of NH4NO3 |

| Properties | MUF |

|---|---|

| Solid | 68.3% |

| Viscosity | 257 mPa·s |

| pH | 8.6 |

| Gel point (100 °C) * | 95 s |

| Board Type | Lignocellulosic Raw Material (Percentage Share) |

|---|---|

| Control | Wood particles (100%) |

| C4 group | |

| MG | Wood particles (70%), miscanthus particles (30%) |

| PV | Wood particles (70%), switchgrass particles (30%) |

| SP | Wood particles (70%), cordgrass particles (30%) |

| C3 group | |

| LP | Wood particles (70%), perennial ryegrass particles (30%) |

| FA | Wood particles (70%), tall fescue particles (30%) |

| EE | Wood particles (70%), tall wheatgrass particles (30%) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Janiszewska, D.; Żurek, G.; Martyniak, D.; Bałęczny, W. Lignocellulosic Biomass of C3 and C4 Perennial Grasses as a Valuable Feedstock for Particleboard Manufacture. Materials 2022, 15, 6384. https://doi.org/10.3390/ma15186384

Janiszewska D, Żurek G, Martyniak D, Bałęczny W. Lignocellulosic Biomass of C3 and C4 Perennial Grasses as a Valuable Feedstock for Particleboard Manufacture. Materials. 2022; 15(18):6384. https://doi.org/10.3390/ma15186384

Chicago/Turabian StyleJaniszewska, Dominika, Grzegorz Żurek, Danuta Martyniak, and Wojciech Bałęczny. 2022. "Lignocellulosic Biomass of C3 and C4 Perennial Grasses as a Valuable Feedstock for Particleboard Manufacture" Materials 15, no. 18: 6384. https://doi.org/10.3390/ma15186384

APA StyleJaniszewska, D., Żurek, G., Martyniak, D., & Bałęczny, W. (2022). Lignocellulosic Biomass of C3 and C4 Perennial Grasses as a Valuable Feedstock for Particleboard Manufacture. Materials, 15(18), 6384. https://doi.org/10.3390/ma15186384