Seismic Performance Evaluation of Corrosion-Damaged Reinforced Concrete Columns Controlled by Shear Based on Experiment and FEA

Abstract

:1. Introduction

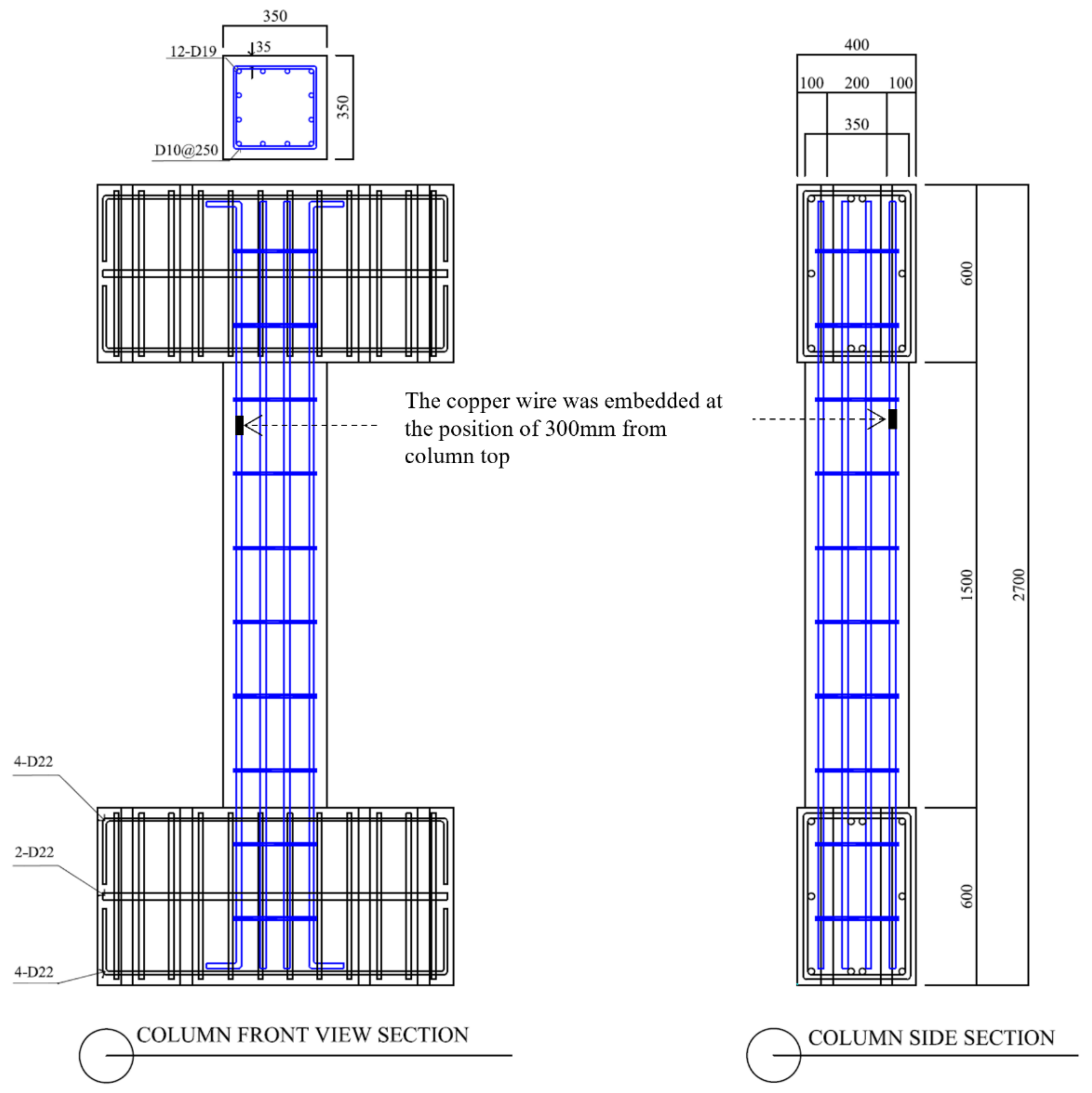

- (1)

- Formation of a white patch: Calcium carbonate is generated by the reaction of carbon dioxide in the atmosphere in cement paste with calcium hydroxide. Calcium carbonate is precipitated on the concrete surface by moisture to form white spots;

- (2)

- Brown pieces of steel: When corrosion starts, an iron oxide layer is formed on the upper part of the reinforcement, which is transported to the concrete surface by moisture;

- (3)

- Crack formation: The corrosion product takes up more space than the original material, and the pressure applied to the concrete causes the crack. The larger the corrosion, the wider the crack;

- (4)

- Concrete spalling: The bonding stress between concrete and reinforcement materials weakens, resulting in a decrease in rebar cross section;

- (5)

- Steel rebar snap: Rebar snap occurs when the cross section is reduced;

- (6)

- Bar buckling: The detachment or snaps of concrete on the reinforcement contributes to the buckling of the main reinforcement. Concrete bulges and affects the stability and life of RC buildings.

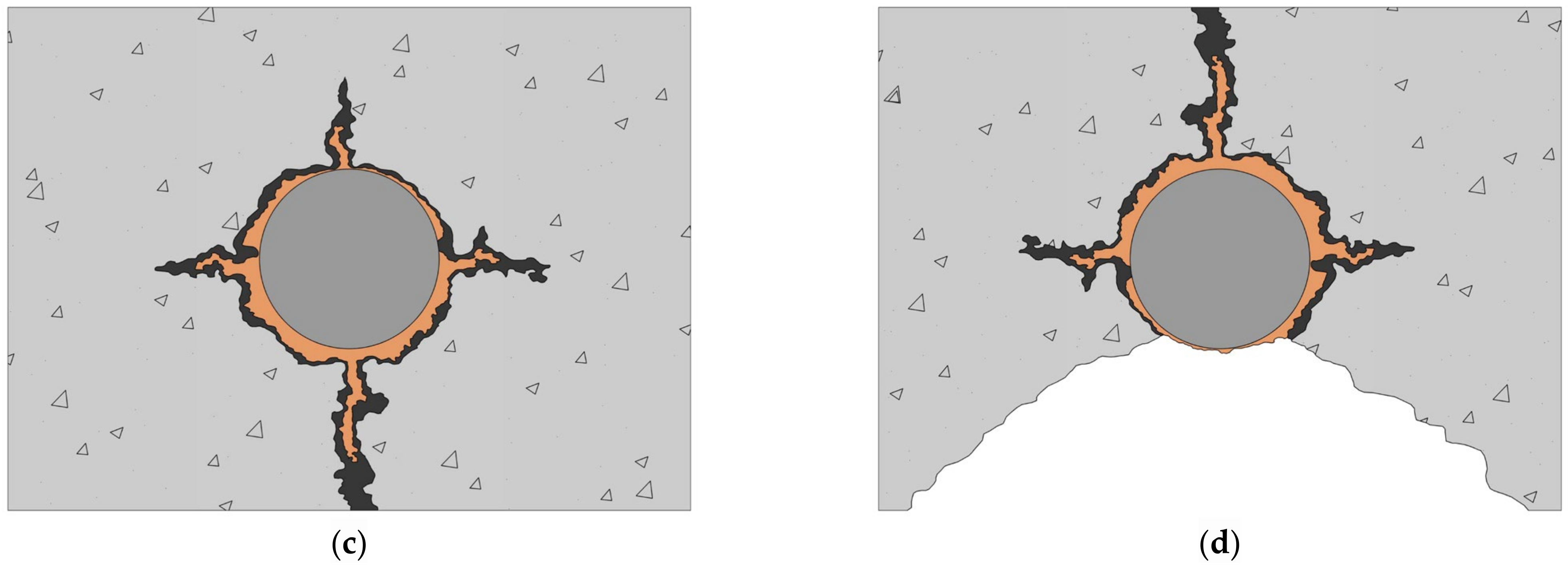

2. Experimental Program

2.1. Materials

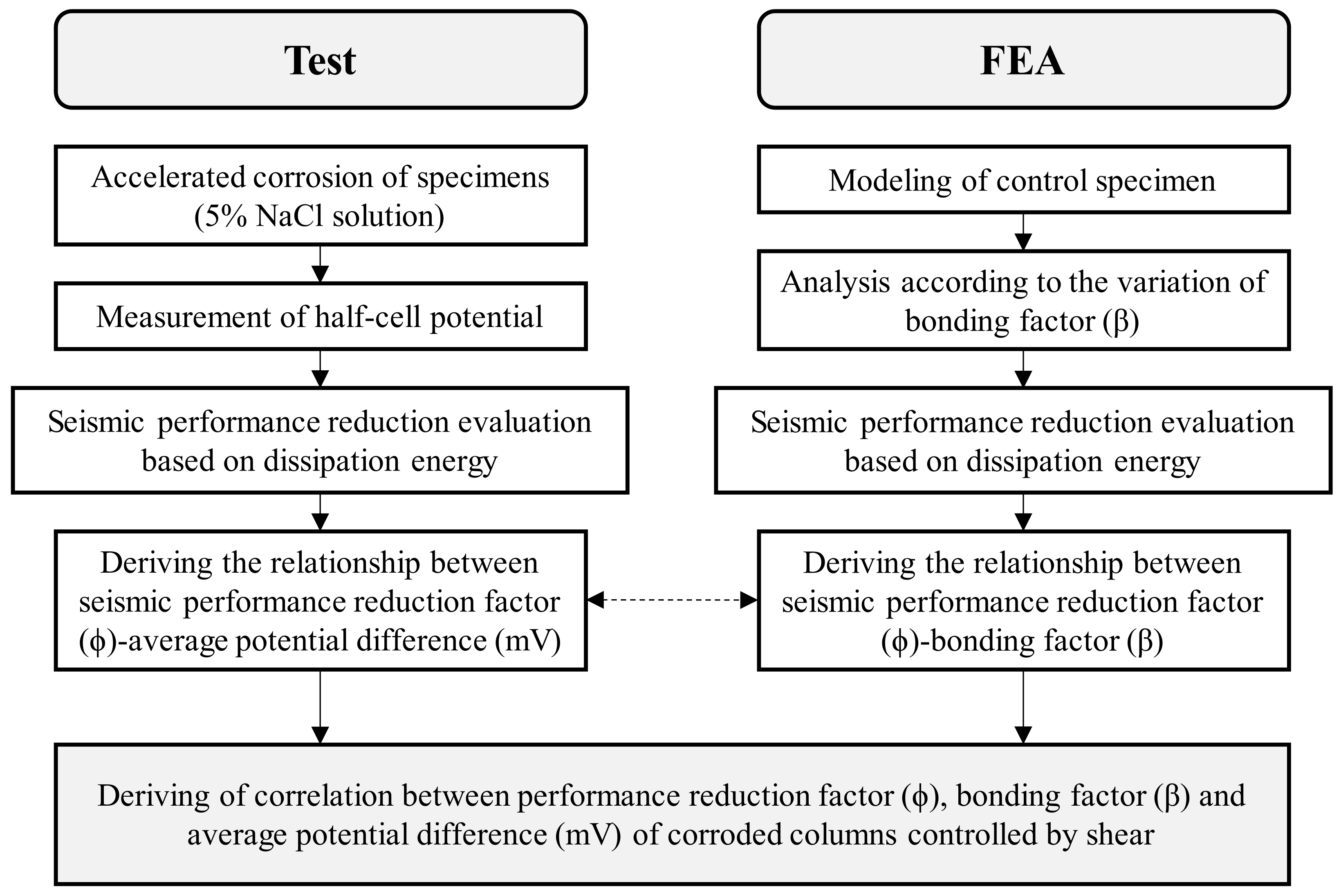

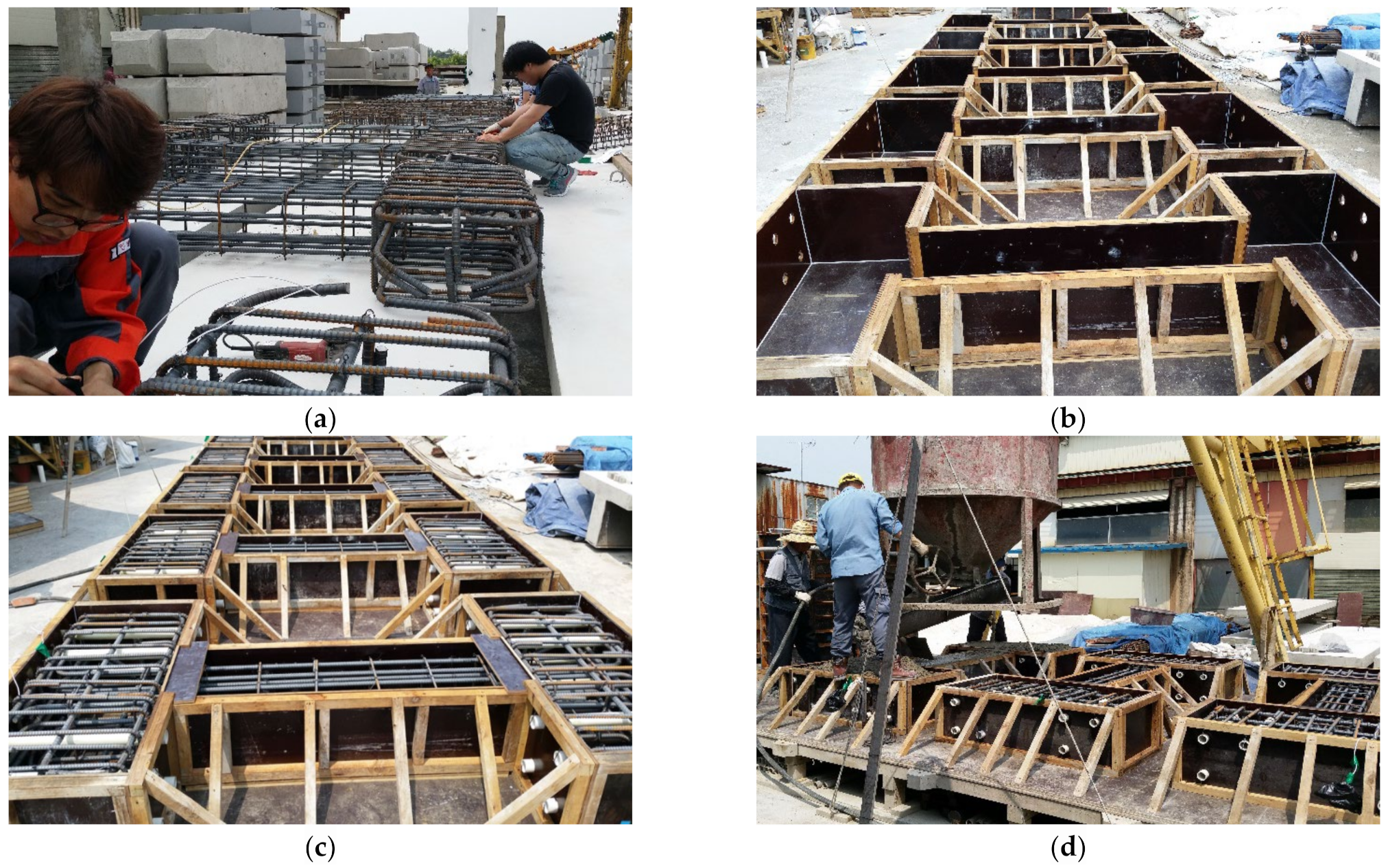

2.2. Design and Manufacture of Column Specimens

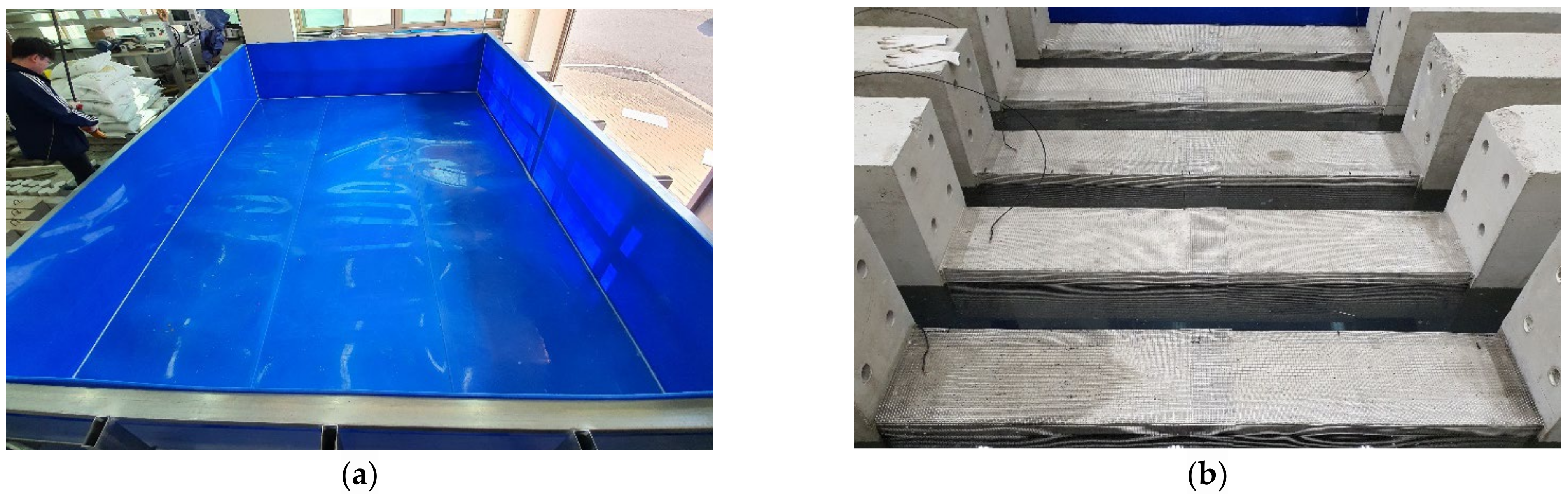

2.3. Accelerated Corrosion of Reinforcement

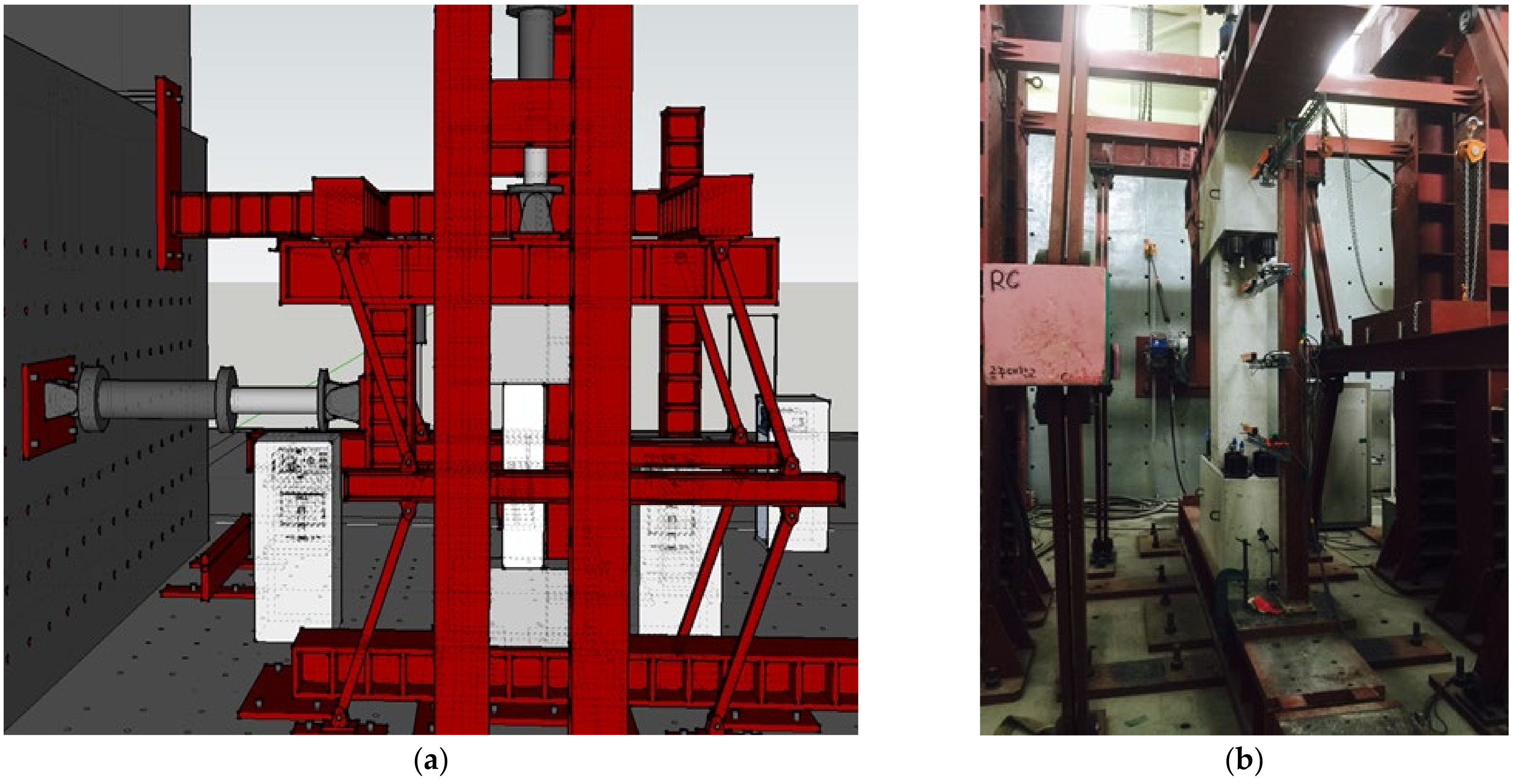

2.4. Test Program

3. Test Results and Discussion

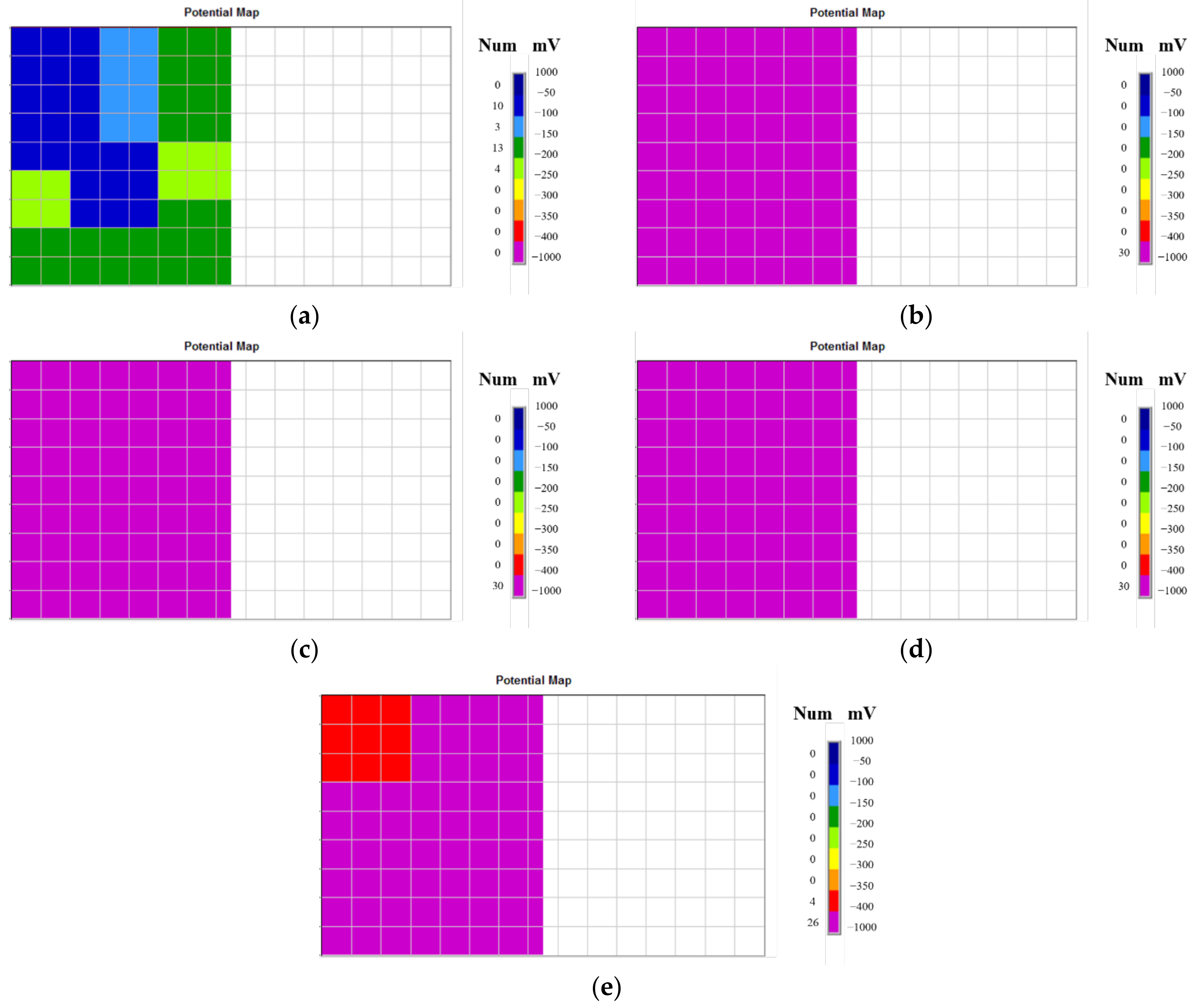

3.1. Half-Cell Potential of Reinforced Concrete Columns

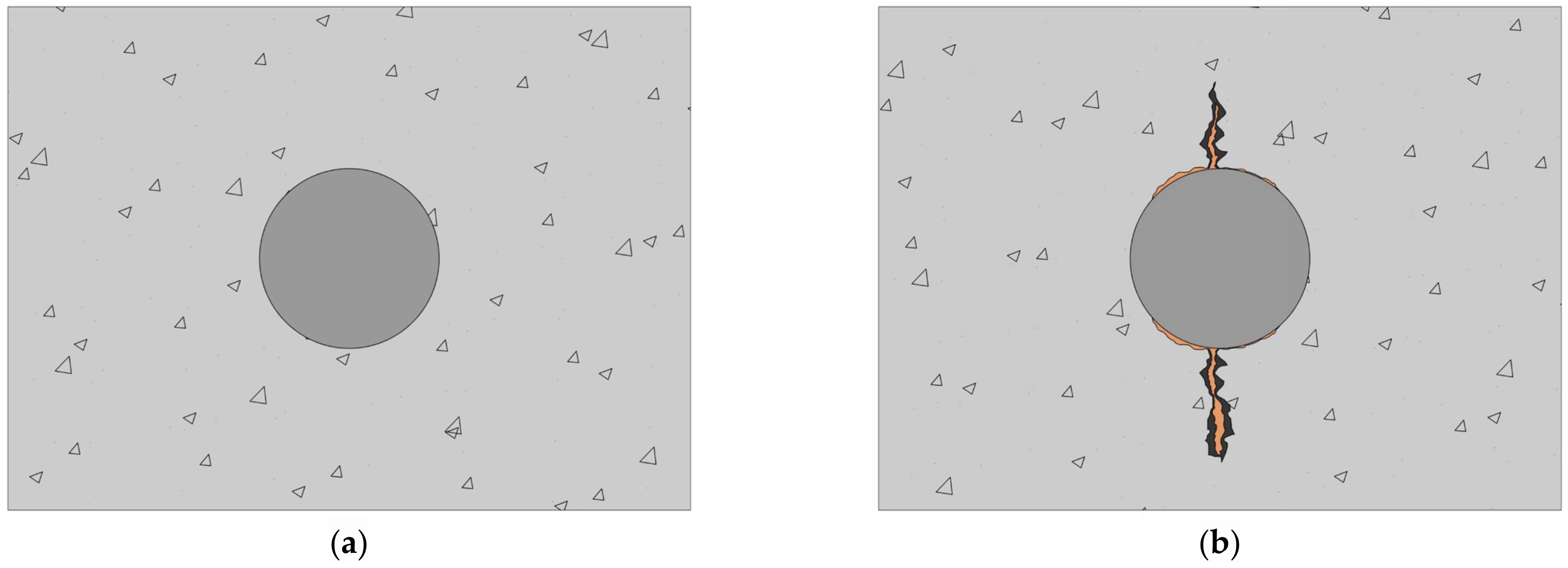

3.2. Cracking and Failure Pattern

- (1)

- SC-C0 (Control Specimen)

- (2)

- SC-C1 to SC-C4 (Corroded Specimens)

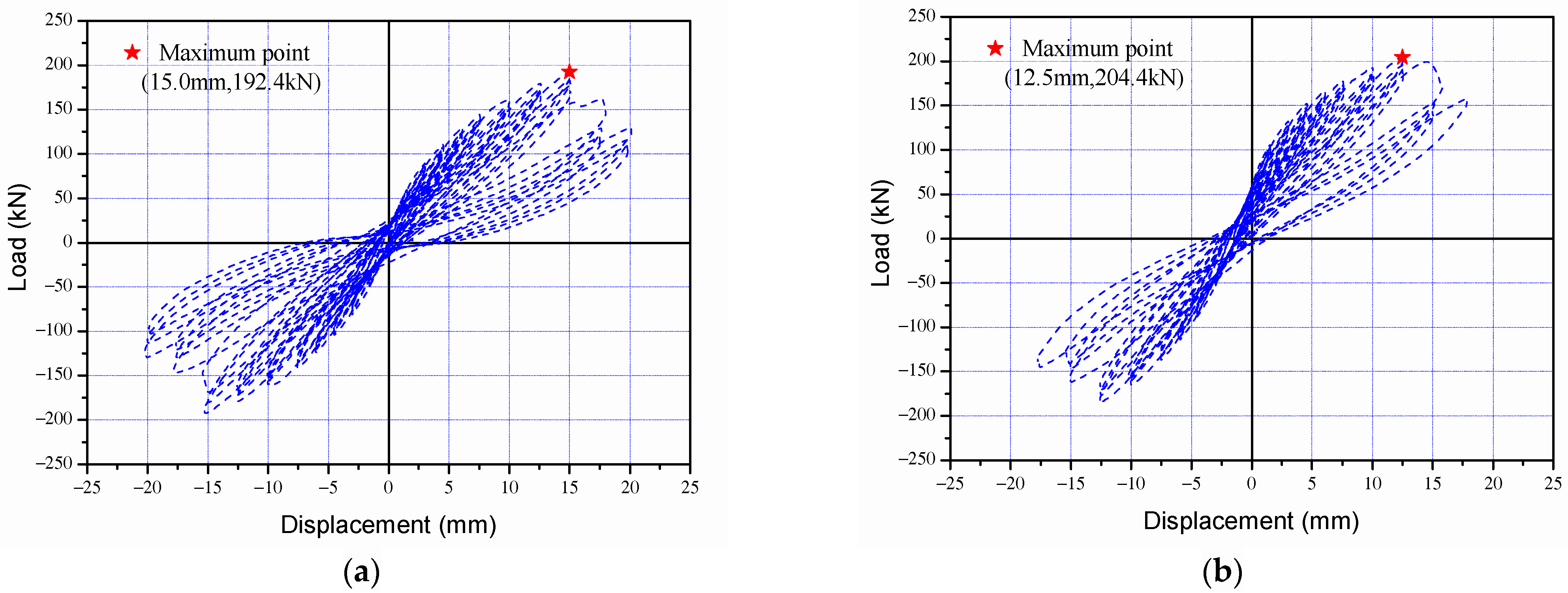

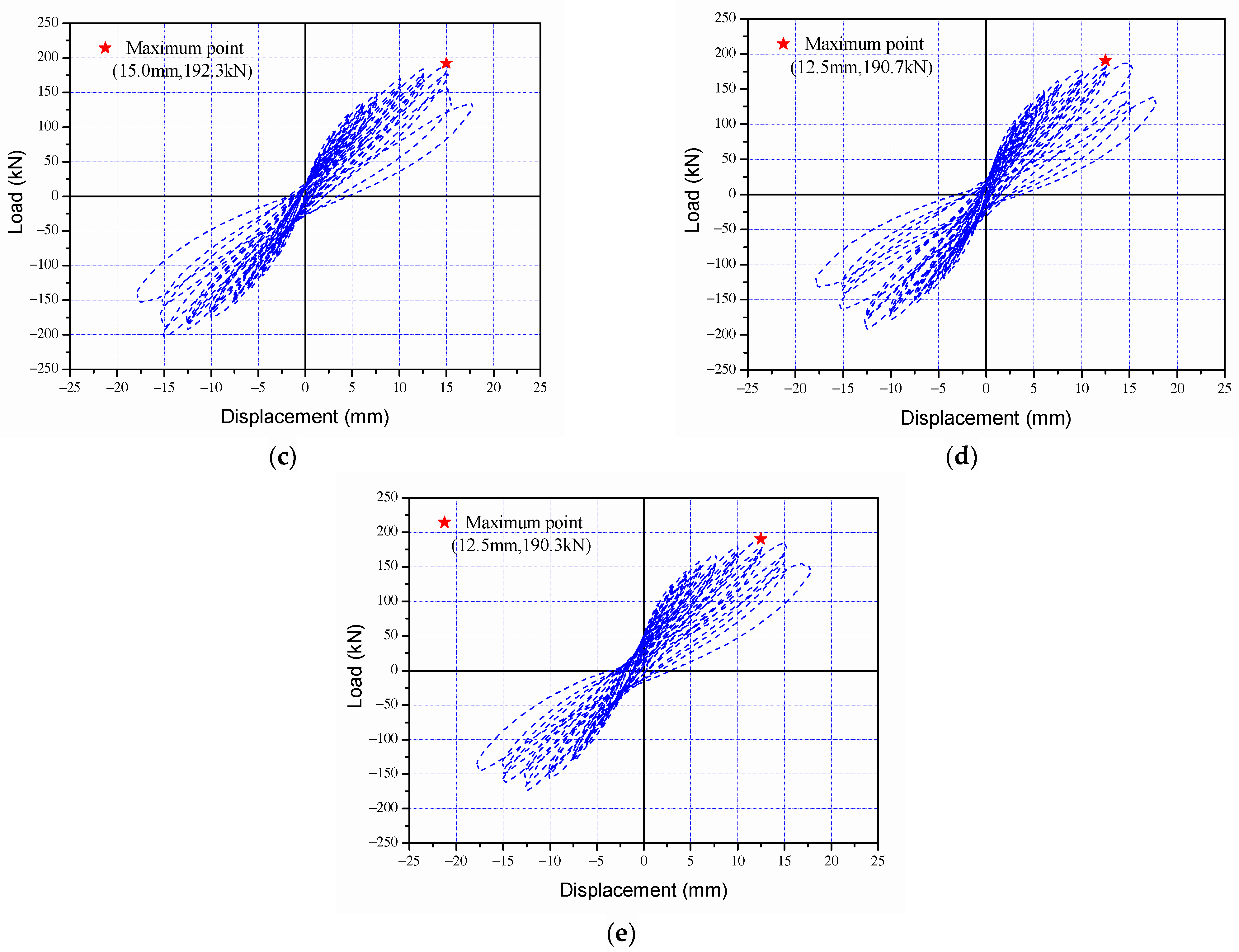

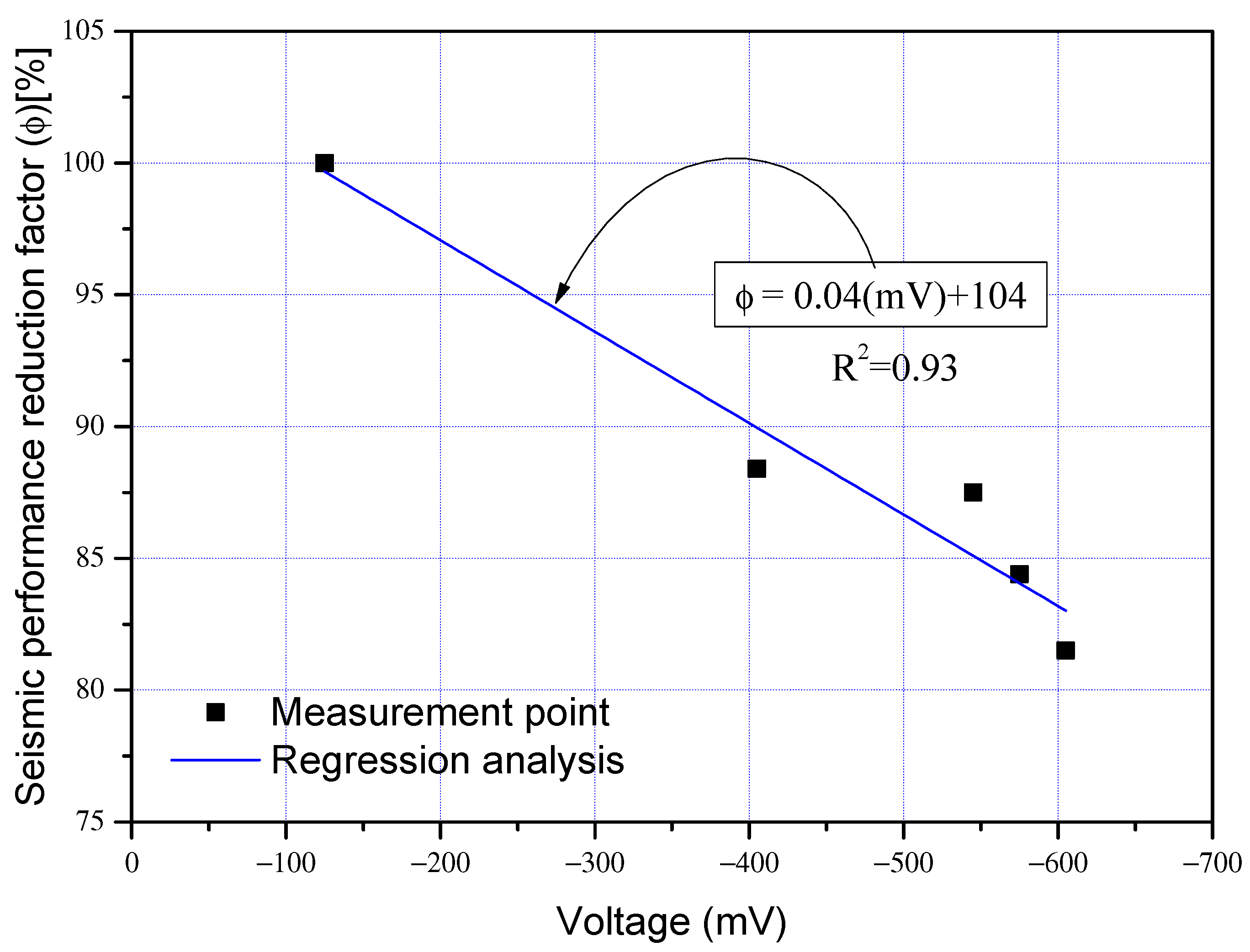

3.3. Load-Displacement and Seismic Performance Reduction Factor

4. FEA Model of Shear Failure-Type Columns and Their Results

4.1. Overview of FEA

4.1.1. Overview of Analysis Software

4.1.2. Concrete Analysis Model

- (1)

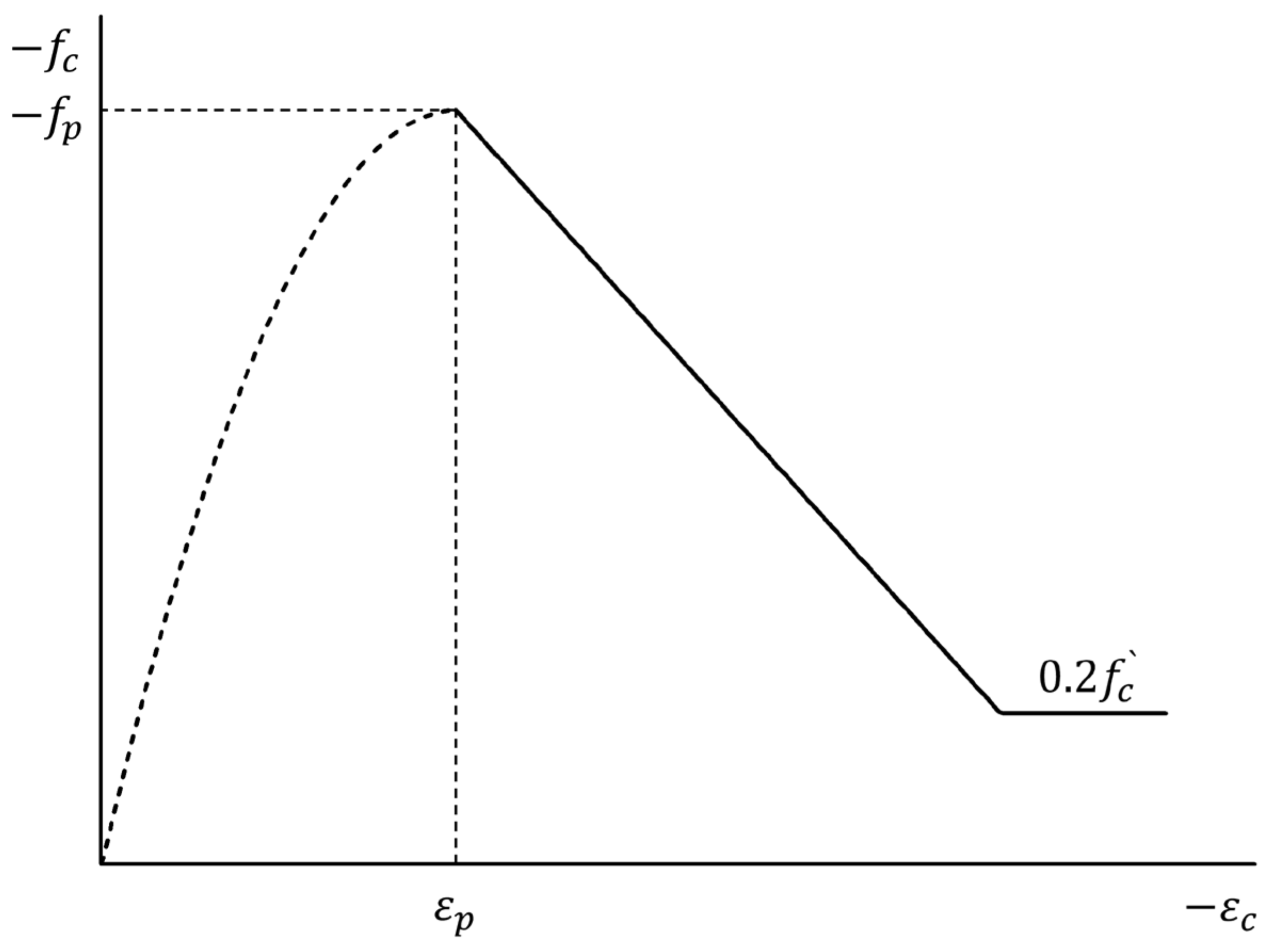

- Concrete Stress-Strain Model

- (2)

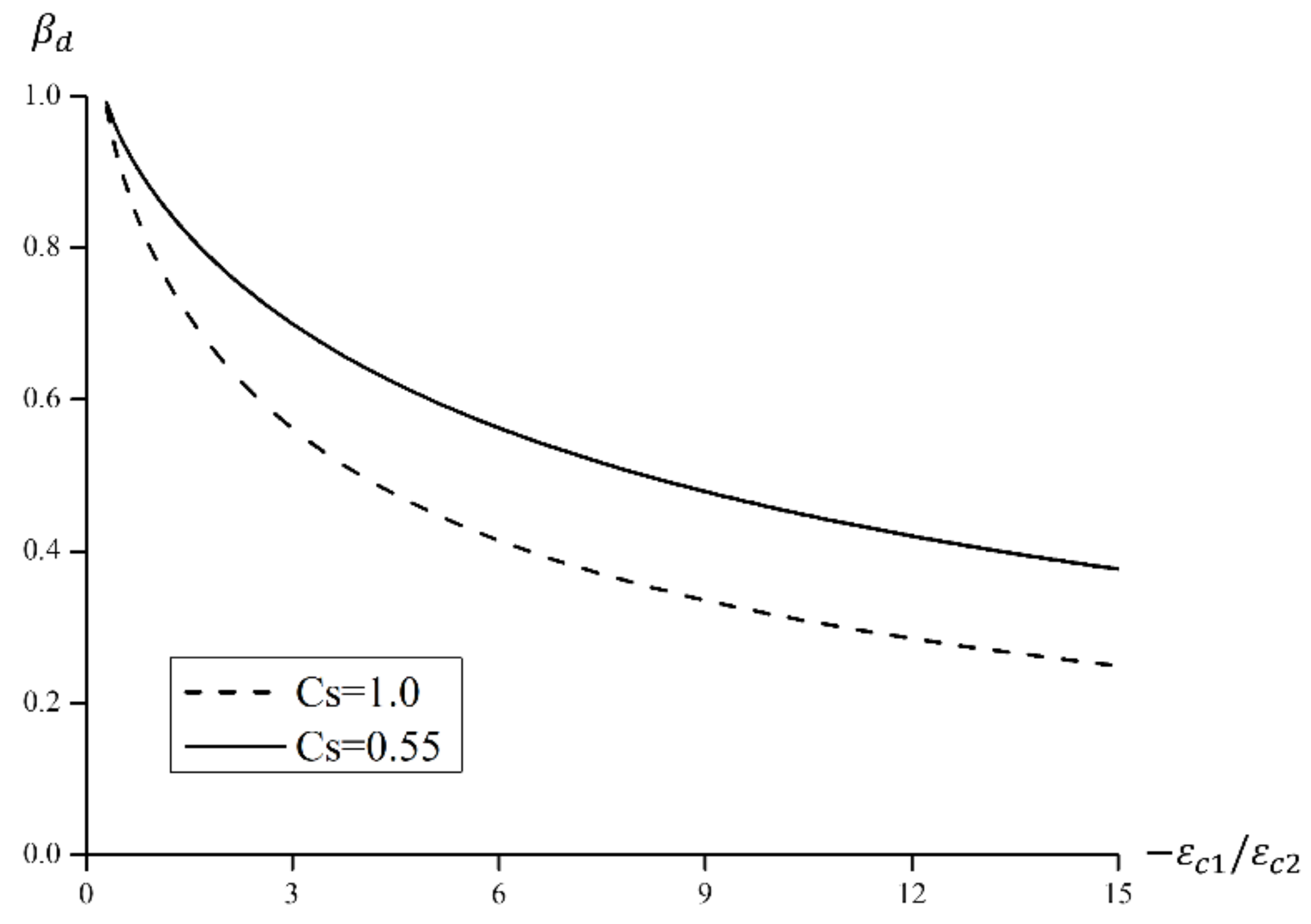

- Concrete Compression Softening Model

- (3)

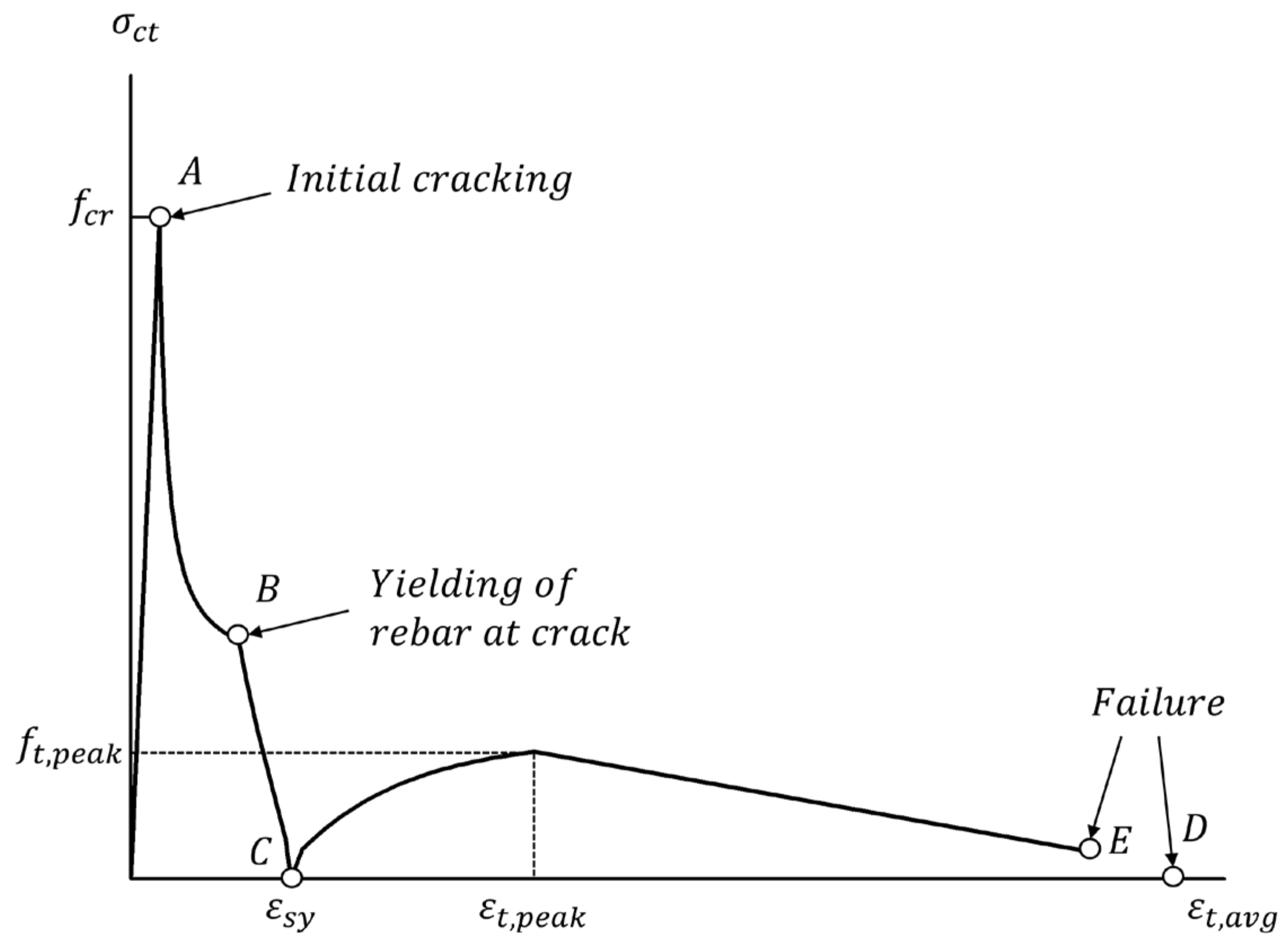

- Concrete Tension Stiffening Model

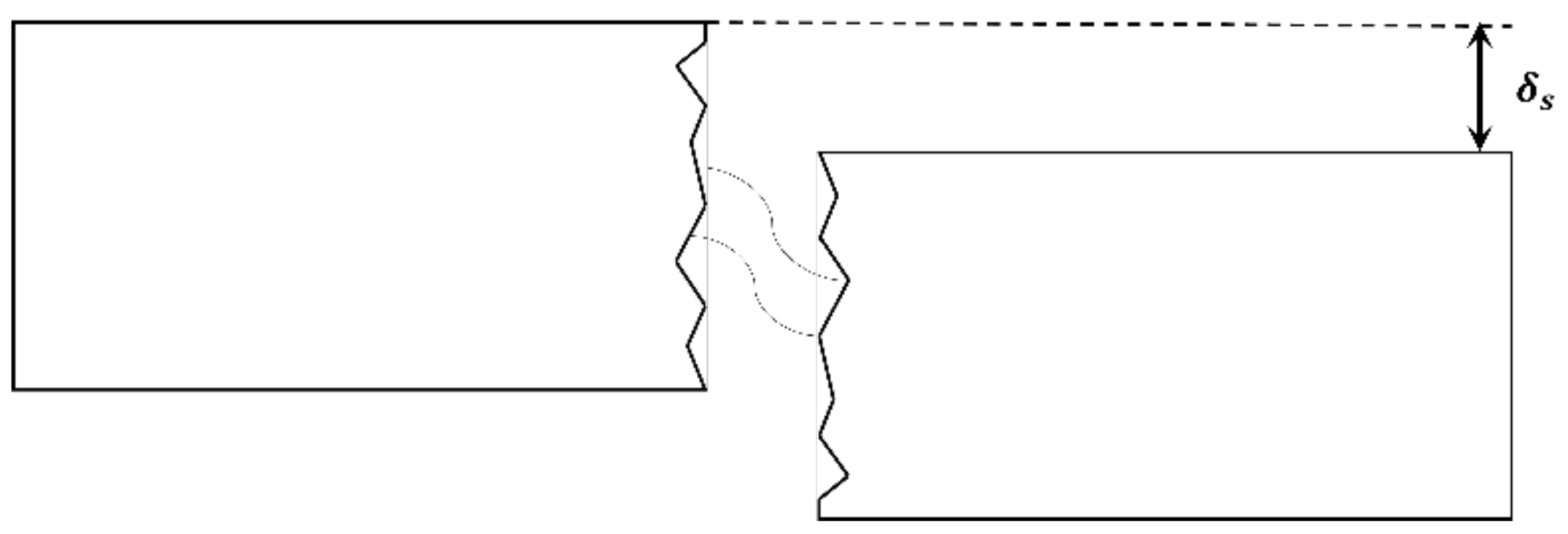

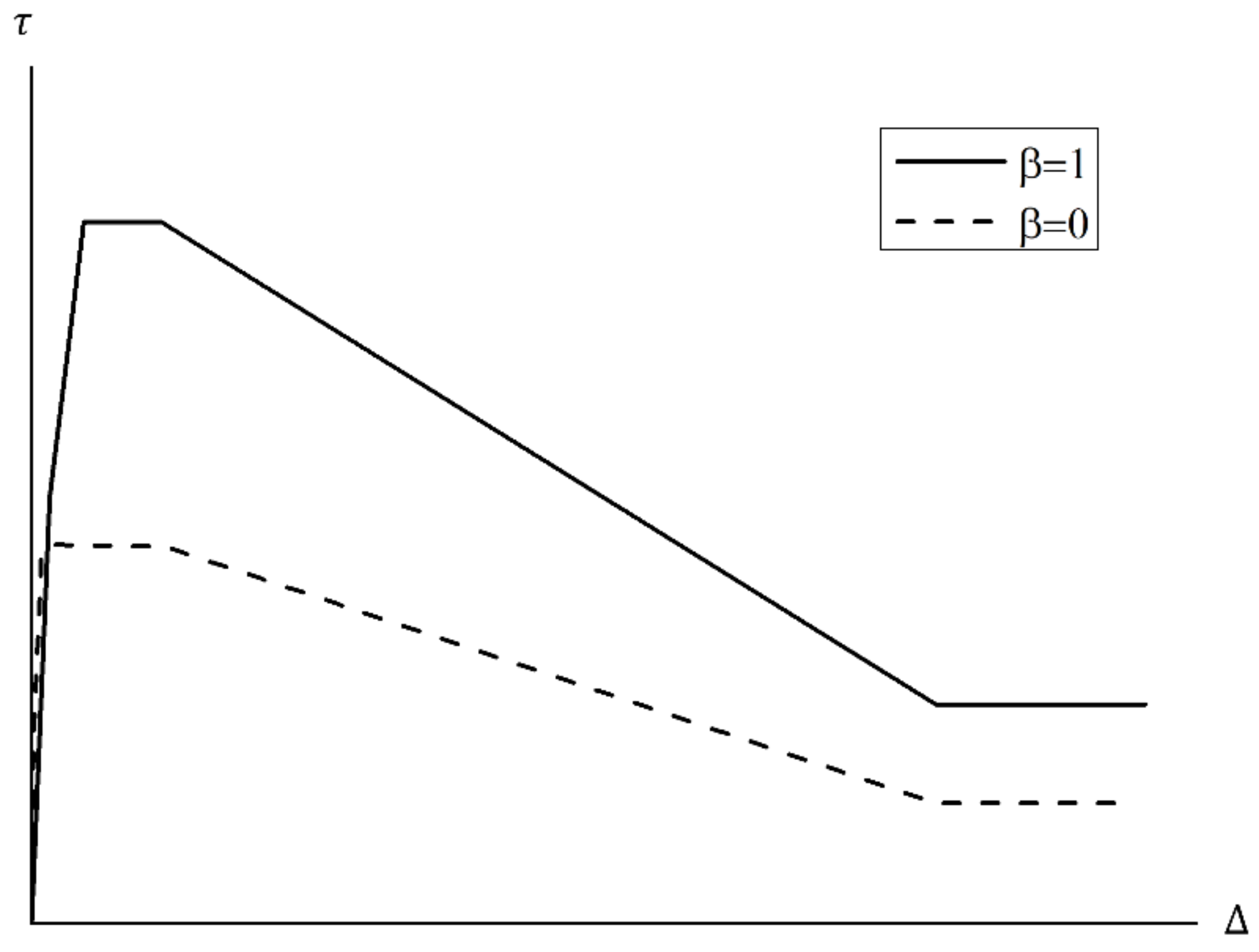

4.1.3. Steel Reinforcement Analysis Model

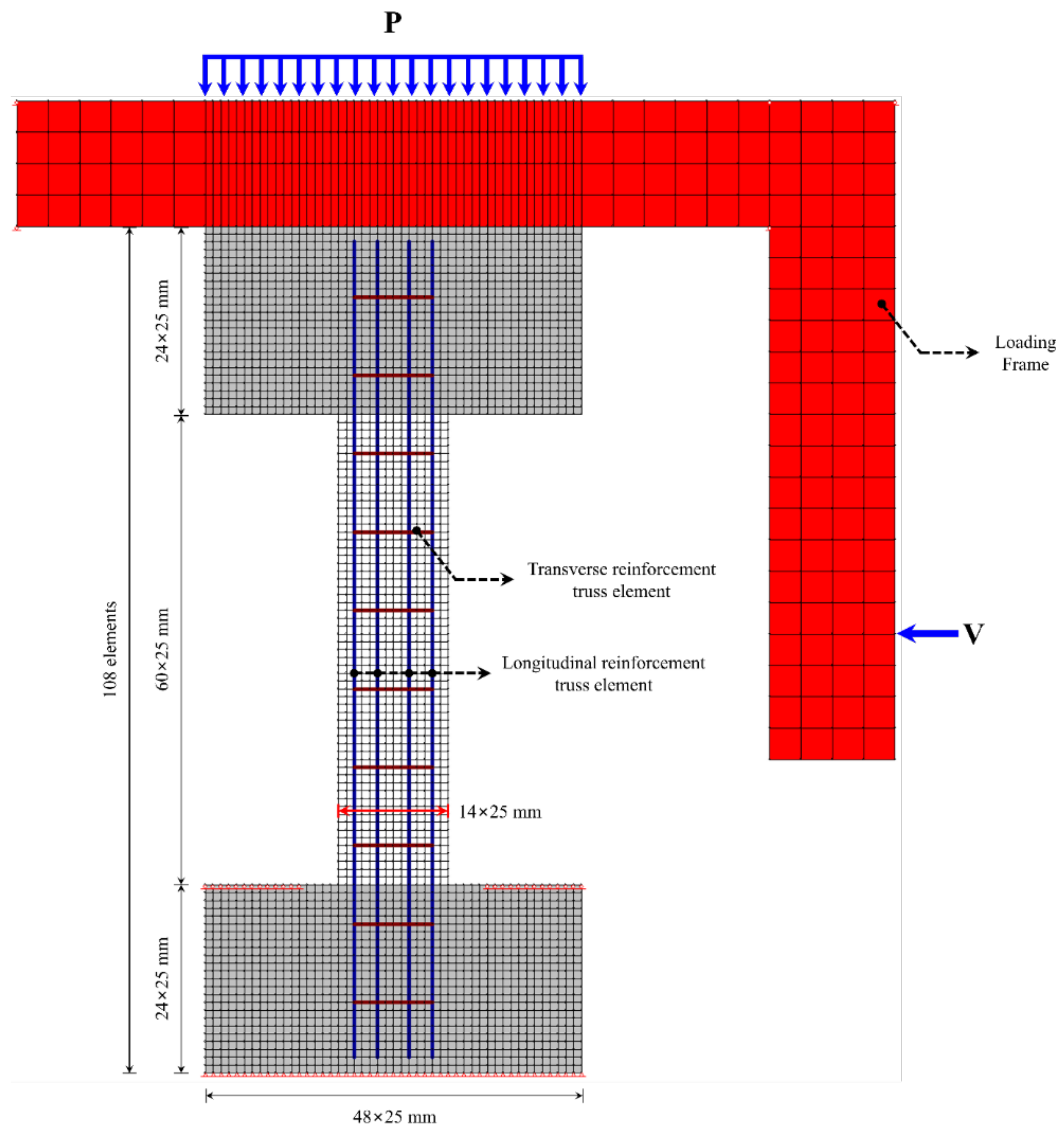

4.1.4. FEA Model

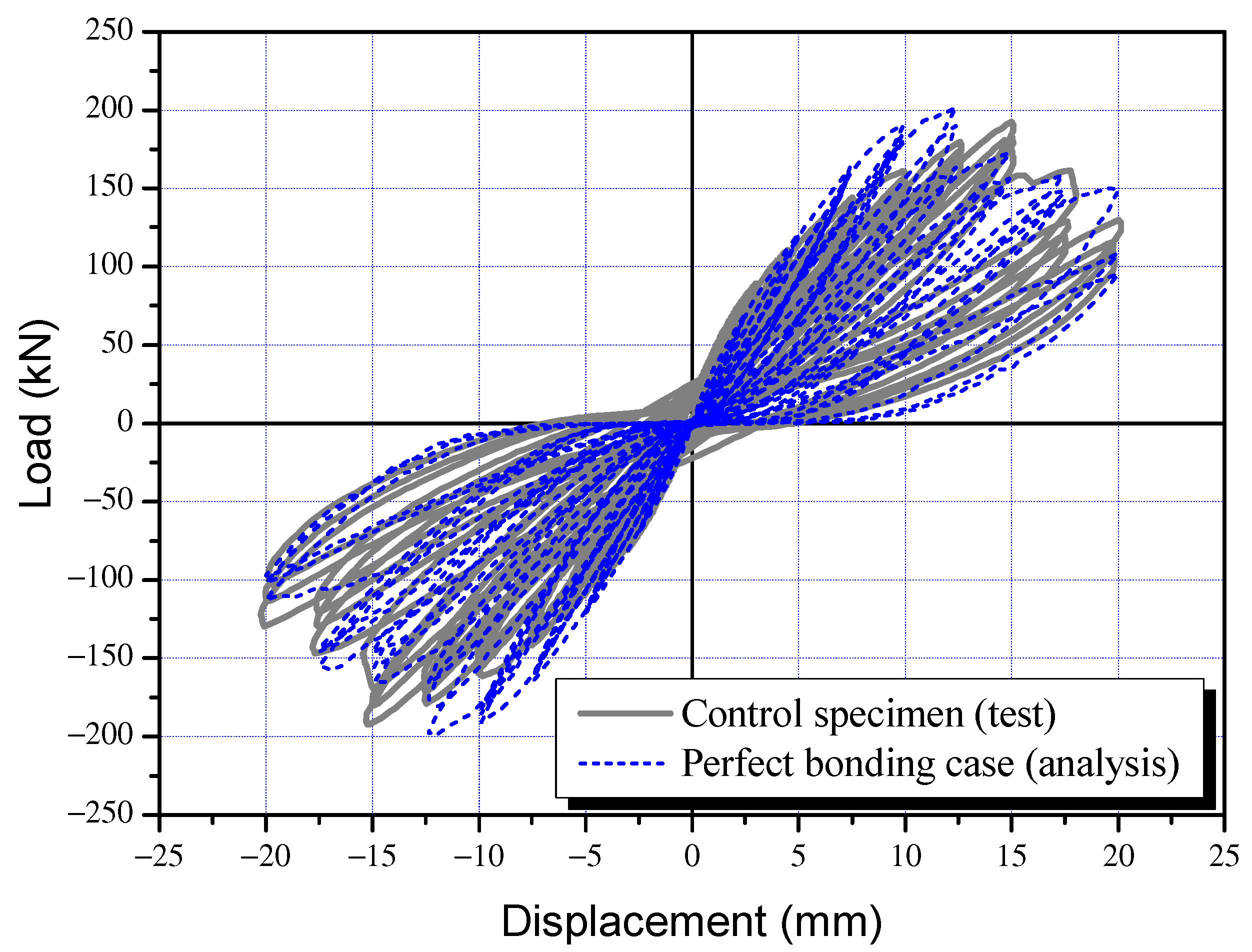

4.2. FEA Results

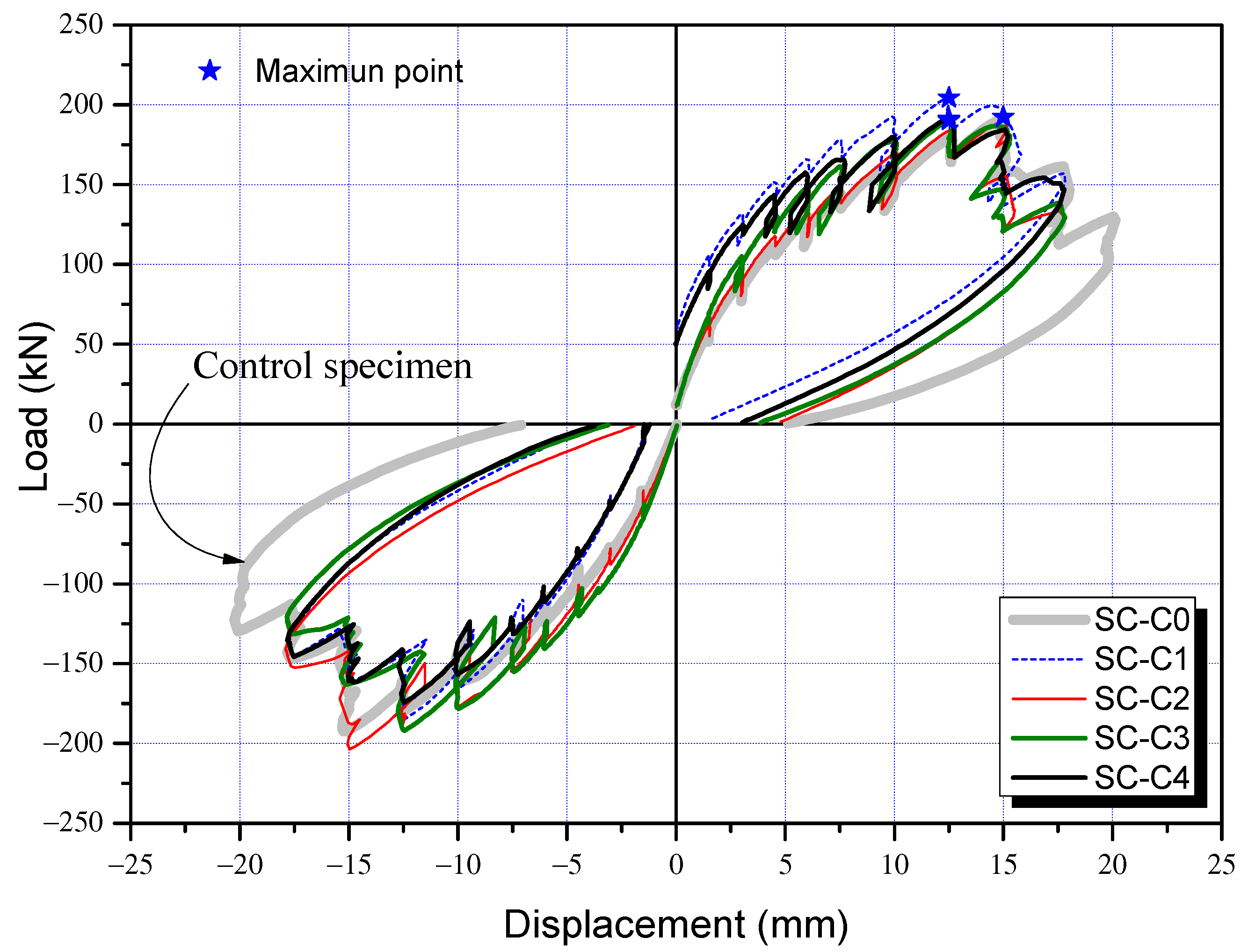

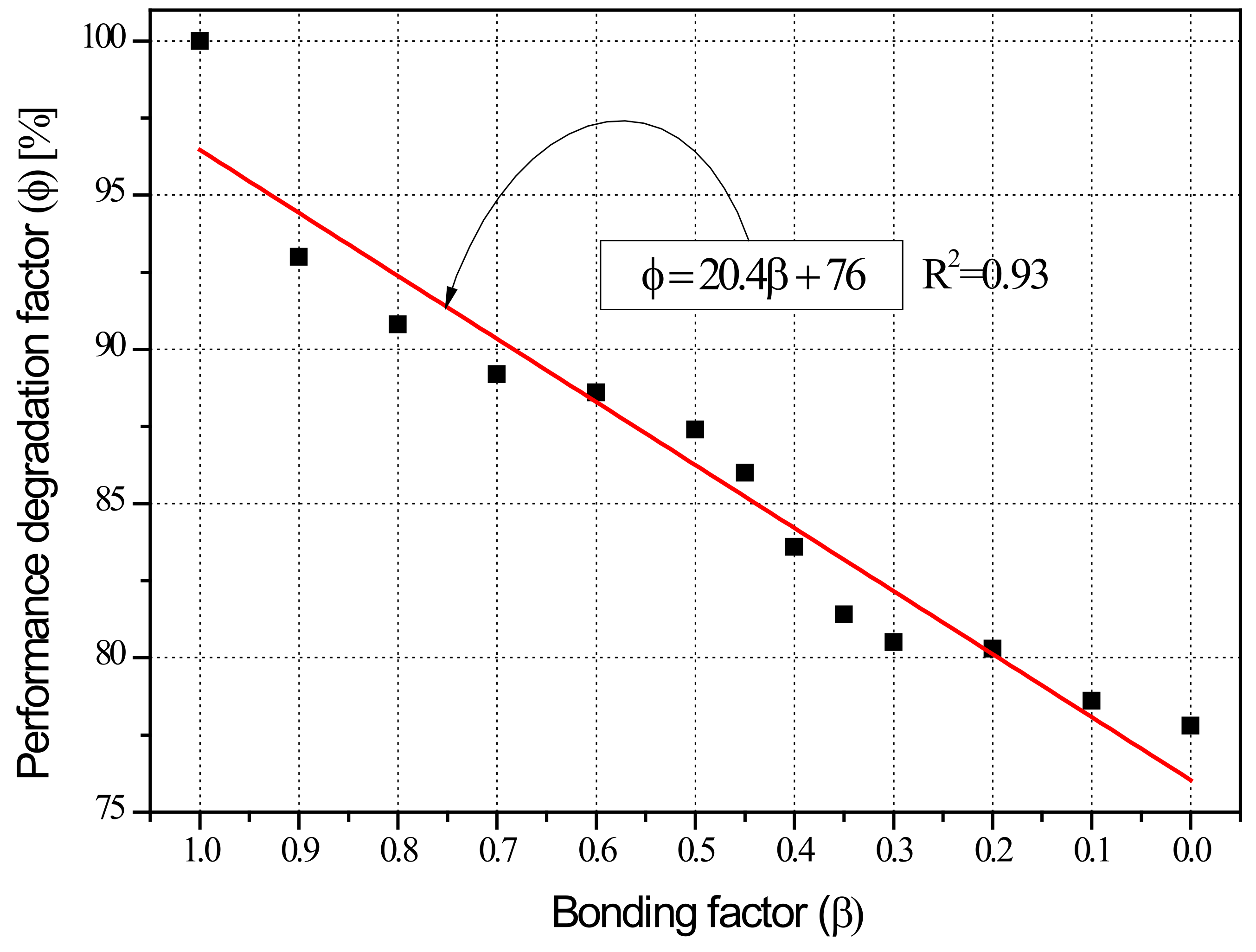

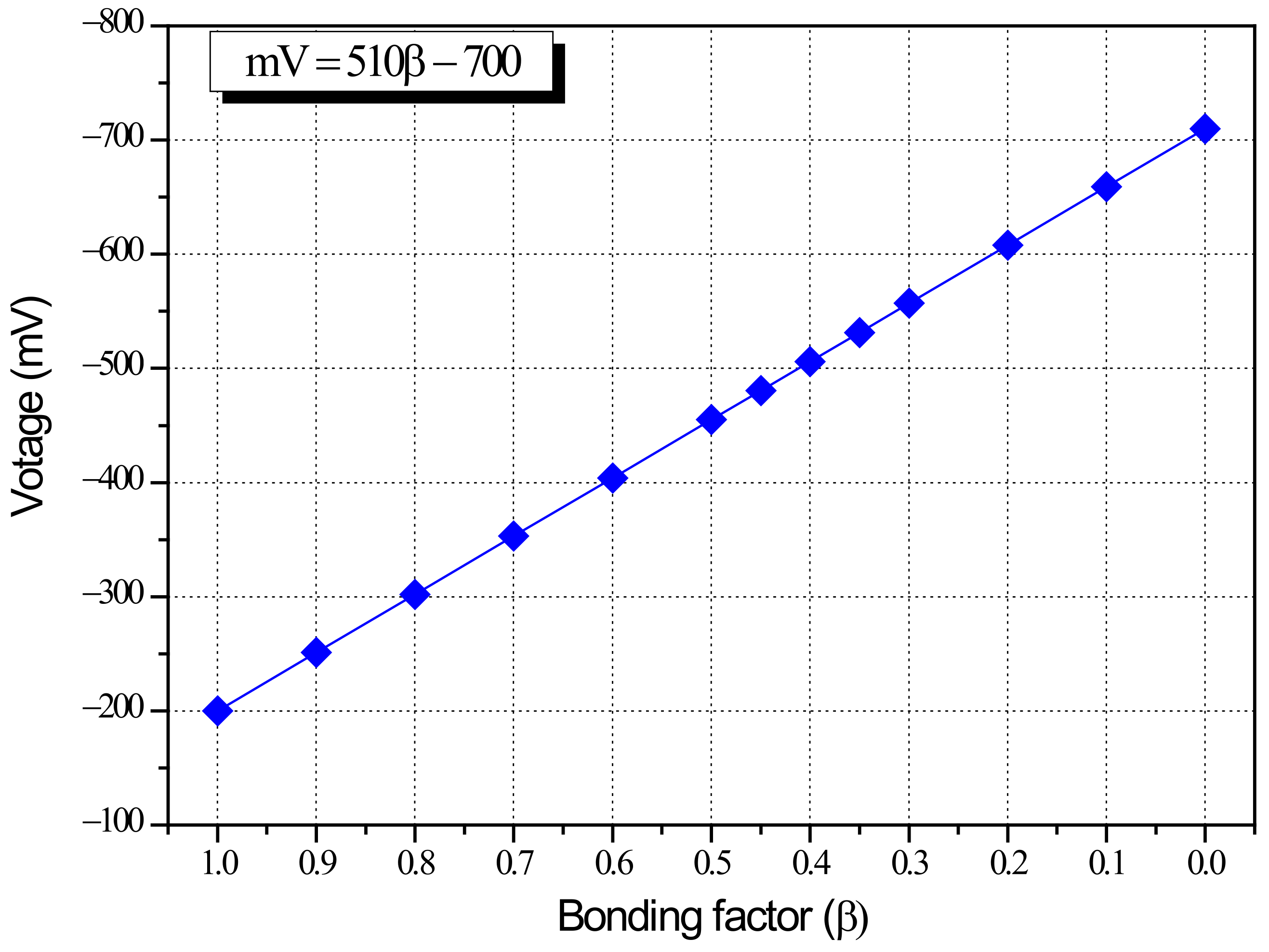

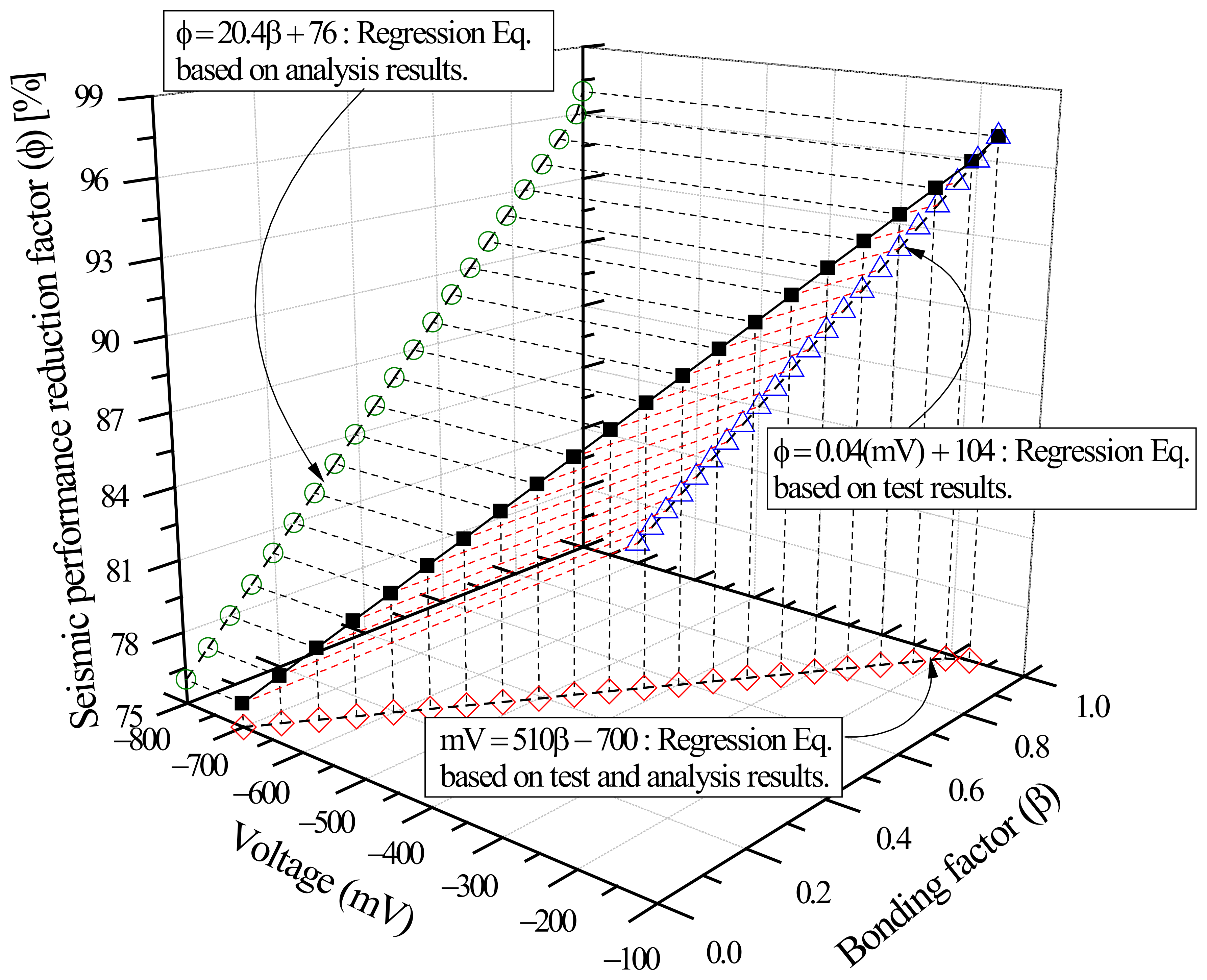

5. ϕ–β– mV Interactions Based on Structural Experiments and FEA

6. Conclusions

- (1)

- Structural experiments of shear failure-type column members in relation to reinforcement corrosion showed that the seismic performance reduction factor (ϕ) defined based on dissipation energy before and after corrosion decreases with a smaller average potential difference (mV) measured by HCP. The reduction factor can be approximated using regression analysis as , and the coefficient correlation R2 = 0.93 indicated a strong correlation;

- (2)

- The experimental results and FEA results (β = 1) were compared for the control specimen (corrosion-free, SC-C0). The ultimate load in the analysis was 202.9 kN, 105% of the experimental value of 192.4 kN. The ultimate displacement at this point was 12.5 mm in the analysis, about 83% of the experimental value of 15.0 mm. The dissipation energy was found to be 2105.9 kN-m, which is highly similar to the experimental value of 2106.7 kN. The analysis results using VecTor2 were consistent with experimental observations. The proposed FEA model can be seen as effective in examining the effects of weakened bonding on structural performance reduction based on strength-deformability, that is, the correlation between bonding factor (β) and seismic performance reduction factor (ϕ);

- (3)

- The bonding factor (β) and structural performance reduction factor (ϕ) can be approximated using , obtained by regression analysis. The correlation coefficient of β-ϕ was R2=0.93, which indicates a very strong correlation. In addition, the β–ϕ correlation and the correlation between potential difference (mV) and structural performance reduction factor (ϕ), that is, , were compared in order to express the β–mV correlation in terms of the seismic performance reduction factor (ϕ) as ;

- (4)

- The β–ϕ correlation of each column specimen based on FEA was compared to the mV–ϕ correlation, which is the relationship between average potential difference, quantitatively measured by HCP, and seismic performance reduction factor, derived from structural experiments. The mV–β–ϕ interaction diagram of shear failure-type columns was thus established. Using the mV–β–ϕ interaction diagram, it is possible to evaluate the weakened bonding (β) in relation to the extent of corrosion (mV) and seismic performance reduction factor (ϕ) based on strength-deformability. The results indicate that the proposed method can be utilized for quantitative evaluation of the seismic performance of corrosion-damaged RC members;

- (5)

- To develop practical, commercial methods for the evaluation of the seismic performance of corrosion-damaged RC structures, it is necessary to develop techniques for quantitative measurements based on HCP, estimation of seismic performance reduction factor, and nonlinear analysis of the seismic performance of the entire structure in consideration of performance deterioration. As a recommendation for future work, it is recommended to apply multiple NDE (Nondestructive Evaluation) techniques rather than HCP alone to increase the reliability of the interaction diagram proposed in this study.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jung, J.S.; Lee, B.Y.; Lee, K.S. Experimental Study on the Structural Performance Degradation of Corrosion-Damaged Reinforced Concrete Beams. Adv. Civ. Eng. 2019, 2019, 9562574. [Google Scholar] [CrossRef]

- Hansson, C.M. Comments on electrochemical measurements of the rate of corrosion of steel in concrete. Cem. Concr. Res. 1984, 14, 574–584. [Google Scholar] [CrossRef]

- Lee, H.S.; Tomosawa, F.; Noguchi, T. Effects of rebar corrosion on the structural performance of singly reinforced beams. Durab. Build. Mater. Compon. 1996, 7, 571–580. [Google Scholar]

- Frangopol, D.M.; Lin, K.-Y.; Estes, A.C. Reliability of reinforced concrete girders under corrosion attack. J. Struct. Eng. 1997, 123, 286–297. [Google Scholar] [CrossRef]

- Shamsad, A. Reinforcement corrosion in concrete structures, its monitoring and service life prediction—A review. J. Cem. Concr. Compos. 2003, 25, 459–471. [Google Scholar]

- Song, H.-W.; Shim, H.-B.; Petcherdchoo, A.; Park, S.-K. Service life prediction of repaired concrete structures under chloride environment using finite difference method. Cem. Concr. Compos. 2009, 31, 120–127. [Google Scholar] [CrossRef]

- Lee, H.-S.; Cho, Y.-S. Evaluation of the mechanical properties of steel reinforcement embedded in concrete specimen as a function of the degree of reinforcement corrosion. Int. J. Fract. 2009, 157, 81–88. [Google Scholar] [CrossRef]

- Dogan, M. Corrosion failure in concrete reinforcement to damage during seismic. Eng. Fail. Anal. 2015, 56, 275–287. [Google Scholar] [CrossRef]

- Yu, Z.; Chen, Y.; Liu, P.; Wang, W. Accelerated simulation of chloride ingress into concrete under drying-wetting alternation condition chloride environment. Constr. Build. Mater. 2015, 93, 205–213. [Google Scholar] [CrossRef]

- Kaveh, A.; Allan, S.; Alessandro, P.; Don, C. Influence of chloride corrosion on the effective mechanical properties of steel reinforcement. Struct. Infrastruct. Eng. 2019, 15, 1036–1048. [Google Scholar]

- Duvnjak, I.; Klepo, I.; Serdar, M.; Damjanovi’c, D. Damage Assessment of Reinforced Concrete Elements Due to Corrosion Effect Using Dynamic Parameters: A Review. Buildings 2021, 11, 425. [Google Scholar] [CrossRef]

- Federal Emergency Management Agency. FEMA 310 Handbook for Seismic Evaluation of Buildings—A Prestandard; Federal Emergency Management Agency: Washington, DC, USA, 1998. [Google Scholar]

- Federal Emergency Management Agency. FEMA 356 Prestandard and Commentary for Seismic Rehabilitation of Buildings; Federal Emergency Management Agency: Washington, DC, USA, 2000. [Google Scholar]

- Japan Building Disaster Prevention Association. English Version: Standard for Seismic Evaluation of Existing Reinforced Concrete Buildings; Japan Building Disaster Prevention Association: Tokyo, Japan, 2005. [Google Scholar]

- Li, Y.; Yin, S.P.; Chen, W.J. Seismic behavior of corrosion-damaged RC columns strengthened with TRC under a chloride environment. Constr. Build. Mater. 2019, 201, 736–745. [Google Scholar]

- Cabrera, J.G. Deterioration of concrete due to reinforcement steel corrosion. Cem. Concr. Compos. 1996, 18, 47–59. [Google Scholar] [CrossRef]

- Capozucca, R. Damage to reinforced concrete due to reinforcement corrosion. Constr. Build. Mater. 1995, 9, 295–303. [Google Scholar] [CrossRef]

- Jung, W.Y.; Kwon, M.H.; Ahn, M.K. Structural behavior of compressive and flexural members due to corroded reinforcing bars and different bonding interfaces. J. Disaster Manag. 2011, 11, 33–39. [Google Scholar]

- Bhargava, K.; Ghosh, A.K.; Mori, Y.; Ramanujam, S. Suggested empirical models for corrosion-induced bond degradation in reinforced concrete. J. Struct. Eng. 2008, 134, 221–230. [Google Scholar] [CrossRef]

- Park, Y.J. Experimental Research on Bond Characteristics and Tensile Strength by Corrosion of Reinforcement Steels. Master’s Thesis, Tong-Myong University, Pusan, Korea, 2004; 120p. [Google Scholar]

- Stanish, K.; Hooton, R.D.; Pantazopoulou, S.J. Corrosion effects on bond strength in reinforced concrete. ACI Struct. J. 1999, 96, 915–921. [Google Scholar]

- Yang, X.; Zhu, H. Finite element investigation on load carrying capacity of corroded RC beam based on bond-slip. Jordan J. Civ. Eng. 2012, 6, 134–146. [Google Scholar]

- Ballim, Y.; Reid, J.C. Reinforcement corrosion and the deflection of RC beams an experimental critique of current test methods. Cem. Concr. Compos. 2003, 25, 625–632. [Google Scholar] [CrossRef]

- Torres-Acostaa, A.A.; Navarro-Gutierreza, S.; Teran-Guillen, J. Residual flexure capacity of corroded reinforced concrete beams. Eng. Struct. 2007, 29, 1145–1152. [Google Scholar] [CrossRef]

- ASTM C39/C39M-15; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2015.

- ASTM E8/E8M-15; Standard Test Methods for Tension Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2015.

- ACI Committee 318. Building Code Requirements for Structural Concrete and Commentary (ACI 318-11) and Commentary; American Concrete Institute: Farmington Hills, MI, USA, 2011. [Google Scholar]

- ASTM C876-09; Standard Test Method for Corrosion Potentials of Uncoated Reinforcing Steel in Concrete. ASTM International: West Conshohocken, PA, USA, 2009.

- Japan Concrete Institute. Techniques for Structural Tests of Concrete Structures; Japan Concrete Institute: Tokyo, Japan, 2004. [Google Scholar]

- Proceq. CANIN+ Operating Instruction for Corrosion Analyzing Instrument; Proceq: Schwerzenbach, Switzerland, 2009. [Google Scholar]

- Vecchio, F.J. Disturbed Stress Field Model for Reinforced Concrete: Validation. J. Struct. Eng. ASCE 2001, 127, 350–358. [Google Scholar] [CrossRef]

- Vecchio, F.J.; Collins, M.P. The Modified Compression Field Theory for Reinforced Concrete Elements Subjected to Shear. ACI J. Proc. 2001, 83, 219–231. [Google Scholar]

- Vecchio, F.J. Available online: http://www.civ.utoronto.ca/vector/ (accessed on 1 March 2022).

- Hognestad, E. A study of Combined Bending and Axial Load in R.C. Members; Enginering Experiment Station Bulletin. No. 399; University of Illinois: Champaign, IL, USA, 1951. [Google Scholar]

- Kent, D.C.; Park, R. Flexural Members with Confined Concrete. ASCE J. Struct. Div. 1981, 97, 1341–1360. [Google Scholar] [CrossRef]

- Park, K.; Priestley, M.J.N.; Gill, W.D. Ductility of Square Confined Concrete Columns. J. Struct. Div. ASCE 1982, 108, 929–950. [Google Scholar] [CrossRef]

- Lee, S.C.; Cho, J.Y.; Vecchio, F.J. Model for post-yield tension stiffening and rebar rupture in concrete members. Eng. Struct. 2011, 33, 1723–1733. [Google Scholar] [CrossRef]

- He, X.G.; Kwan, A. Modeling dowel action of reinforcement bars for finite element analysis of concrete structures. Comput. 2001, 79, 595–604. [Google Scholar] [CrossRef]

- Eligehausen, R.; Popov, E.P.; Bertero, V.V. Local Bond Stress-Slip Relationships of Deformed Bars under Generalized Excitations; Earthquake Engineering Research Center, Report No. UCB/EERC-83/23; University of California: Berkeley, CA, USA, 1983; pp. 1–188. [Google Scholar]

| Reference | Member Type | Methodology | Corrosion Levels (%) | Residual Capacity Range (%) |

|---|---|---|---|---|

| J. S. Jung et al., (2019) [1] | Beam | Test | Not provided | 70.0–100.0 |

| D. M. Frangopol et al., (1997) [4] | Girder | Reliability-based design | Not provided | 80.0–100.0 |

| A. Shamsad (2003) [5] | - | Non-destructive test | Not provided | Not provided |

| H.S. Lee et al., (2009) [7] | Cube (Pull-out) | Test | Not provided | 85.0–100.0 |

| A. Kaveh et al., (2019) [10] | Reinforcement | Tensile test and Analysis | 0.0–24.5 | Not provided |

| J. G. Cabrera (1996) [16] | Cube (Pull-out) and Beam | Test | 0.0–12.6 and 0.0–7.8 | 23.8–100.0 and 71.8–100.0 |

| R. Capozucca (1995) [17] | Beam and Column | Analysis | - | - |

| Bhargava, K et al., (2008) [19] | Beam | Test | 1.3–10.0 | 18.9–100.0 |

| Yang, X et al., (2012) [22] | Beam | FEA | 0.0–11.0 | 30.0–100.0 |

| Ballim, Y et al., (2003) [23] | Beam | Test | 0.0–8.47 | 55.0–100.0 |

| Torres-Acostaa, A et al., (2007) [24] | Beam | Test | 0.0–16.1 | 27.2–100.0 |

| Loading Step | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|

| Loading cycles | 1~3 | 4~6 | 7~9 | 10~12 | 13~15 | 16~18 |

| Drift angle (R) (%) | 0.1 | 0.2 | 0.3 | 0.4 | 0.5 | 0.67 |

| Lateral drift (mm) | 1.5 | 3.0 | 4.5 | 6.0 | 7.5 | 10 |

| Loading step | 7 | 8 | 9 | 10 | 11 | 12 |

| Loading cycles | 19~21 | 22~24 | 25~27 | 28~30 | 31~33 | 34~36 |

| Drift angle (R) (%) | 0.83 | 1 | 1.17 | 1.33 | 1.67 | 2 |

| Lateral drift (mm) | 12.5 | 15 | 17.5 | 20 | 25 | 30 |

| Column Specimens | Average Potential Difference in Voltage mV CSE (Copper Sulfate Electrode) |

|---|---|

| SC-C0 | −125 |

| SC-C1 | −405 |

| SC-C2 | −545 |

| SC-C3 | −575 |

| SC-C4 | −605 |

| Beam | Average Potential Difference in Voltage | Ultimate | Dissipation Energy (kN-mm) | Seismic Performance Reduction Factor ϕ (%) | |

|---|---|---|---|---|---|

| mV CSE (Copper Sulfate Electrode) | Load (kN) | Displacement (mm) | |||

| SC-C0 | −125 | 192.4 | 15.0 | 2106.7 | 100.0 |

| SC-C1 | −405 | 204.4 | 12.5 | 1861.8 | 88.4 |

| SC-C2 | −545 | 192.3 | 15.0 | 1843.8 | 87.5 |

| SC-C3 | −575 | 190.7 | 12.5 | 1778.1 | 84.4 |

| SC-C4 | −605 | 190.3 | 12.5 | 1718.9 | 81.5 |

| Material | Material Property | Model |

|---|---|---|

| Concrete models | Compression pre-peak | Hognestad (parabola) |

| Compression post-peak | Kent/Park | |

| Compression softening | Vecchio 1992-A (e1/e2-form) | |

| Tension stiffening | Lee 2011 (w/post yield) | |

| Tension softening | Not considered | |

| FRC tension | Not considered | |

| Confined strength | Kupfer/Richart | |

| Dilation | Variable–isotropic | |

| Cracking criterion | Mohr–Coulomb (Stress) | |

| Crack stress calculation | Basic (DSFM/MCFT) | |

| Crack width check | Stability check omitted | |

| Crack slip calculation | Vecchio-Lai | |

| Hysteretic response | Nonlinear w/plastic offsets | |

| Reinforcement models | Hysteretic response | Elastic-hardening (curvilinear) |

| Dowel action | Tassios model (crack slip) | |

| Buckling | Buckling (Akkaya 2012 (modified Dhakal-Maekawa)) | |

| Bond models | Concrete bond | Eligehausen |

| Cases | Ultimate | Dissipation Energy (kN-mm) | Seismic Performance Reduction Factor ϕ (%) | ||

|---|---|---|---|---|---|

| Load (kN) | Deflection (mm) | ||||

| Case-1 | 1.00 | 202.9 | 12.5 | 2105.9 | 100.0 |

| Case-2 | 0.9 | 201.5 | 12.5 | 1958.5 | 93.0 |

| Case-3 | 0.8 | 199.8 | 12.5 | 1912.8 | 90.8 |

| Case-4 | 0.7 | 199.1 | 12.5 | 1879.3 | 89.2 |

| Case-5 | 0.6 | 198.5 | 12.5 | 1865.2 | 88.6 |

| Case-6 | 0.5 | 198.1 | 12.5 | 1840.4 | 87.4 |

| Case-7 | 0.45 | 201.1 | 12.5 | 1810.1 | 86.0 |

| Case-8 | 0.4 | 199.7 | 12.5 | 1760.9 | 83.6 |

| Case-9 | 0.35 | 196.7 | 12.5 | 1713.5 | 81.4 |

| Case-10 | 0.3 | 195.4 | 12.5 | 1695.1 | 80.5 |

| Case-11 | 0.2 | 195.1 | 12.5 | 1690.6 | 80.3 |

| Case-12 | 0.1 | 194.3 | 12.5 | 1654.5 | 78.6 |

| Case-13 | 0.0 | 193.4 | 12.5 | 1637.7 | 77.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, Y.-S.; Lee, B.-G.; Jung, J.-S.; Lee, K.-S. Seismic Performance Evaluation of Corrosion-Damaged Reinforced Concrete Columns Controlled by Shear Based on Experiment and FEA. Materials 2022, 15, 6361. https://doi.org/10.3390/ma15186361

Kim Y-S, Lee B-G, Jung J-S, Lee K-S. Seismic Performance Evaluation of Corrosion-Damaged Reinforced Concrete Columns Controlled by Shear Based on Experiment and FEA. Materials. 2022; 15(18):6361. https://doi.org/10.3390/ma15186361

Chicago/Turabian StyleKim, Young-Shik, Bok-Gi Lee, Ju-Seong Jung, and Kang-Seok Lee. 2022. "Seismic Performance Evaluation of Corrosion-Damaged Reinforced Concrete Columns Controlled by Shear Based on Experiment and FEA" Materials 15, no. 18: 6361. https://doi.org/10.3390/ma15186361

APA StyleKim, Y.-S., Lee, B.-G., Jung, J.-S., & Lee, K.-S. (2022). Seismic Performance Evaluation of Corrosion-Damaged Reinforced Concrete Columns Controlled by Shear Based on Experiment and FEA. Materials, 15(18), 6361. https://doi.org/10.3390/ma15186361