Axial Compressive Properties of Self-Compacting Concrete Filled Steel Tube Short Columns with Ground Desulfurization Slag

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Preparation of SCCs

2.3. Preparation of CFST Specimens

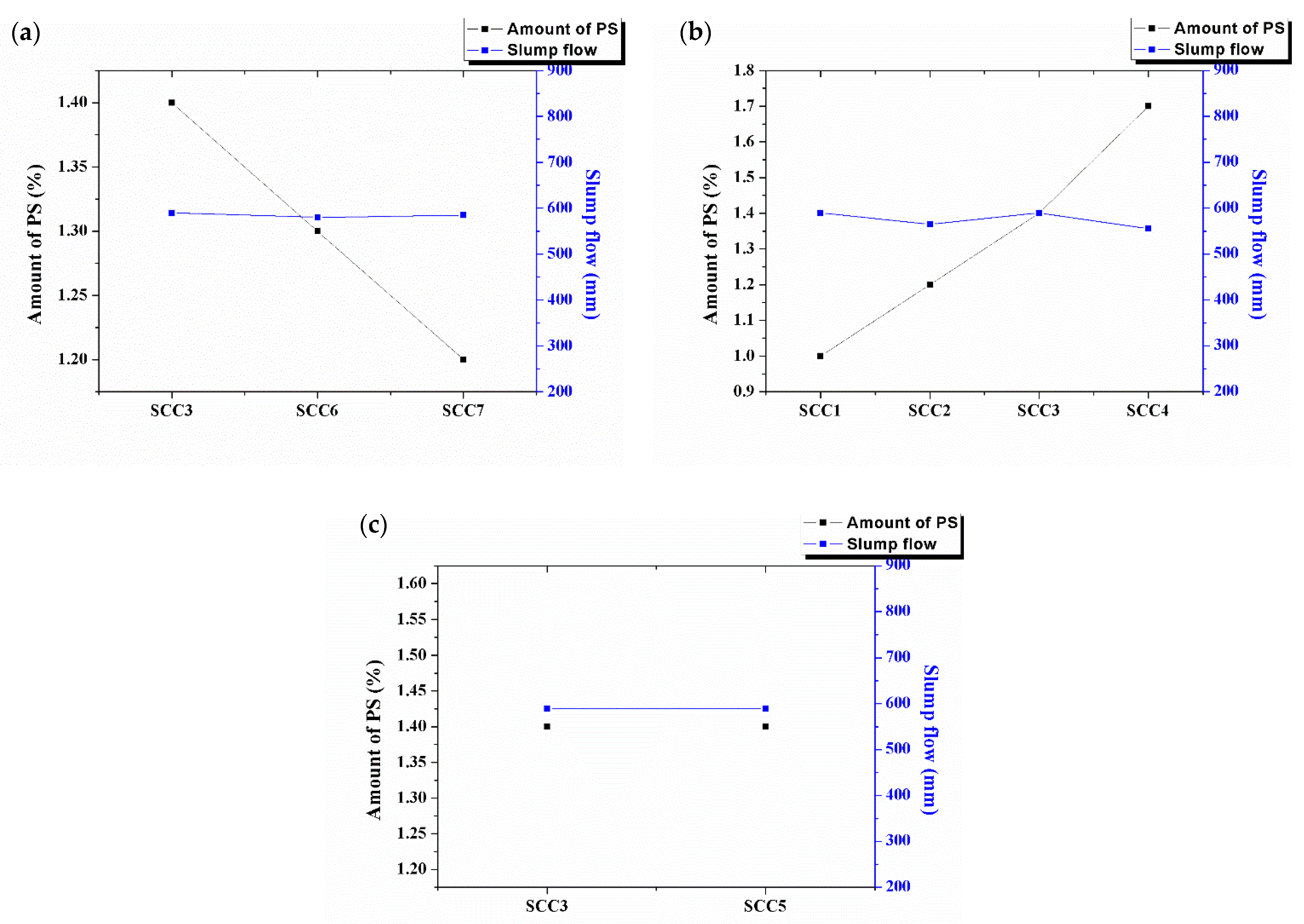

2.4. Filling Ability Test of Fresh SCCs

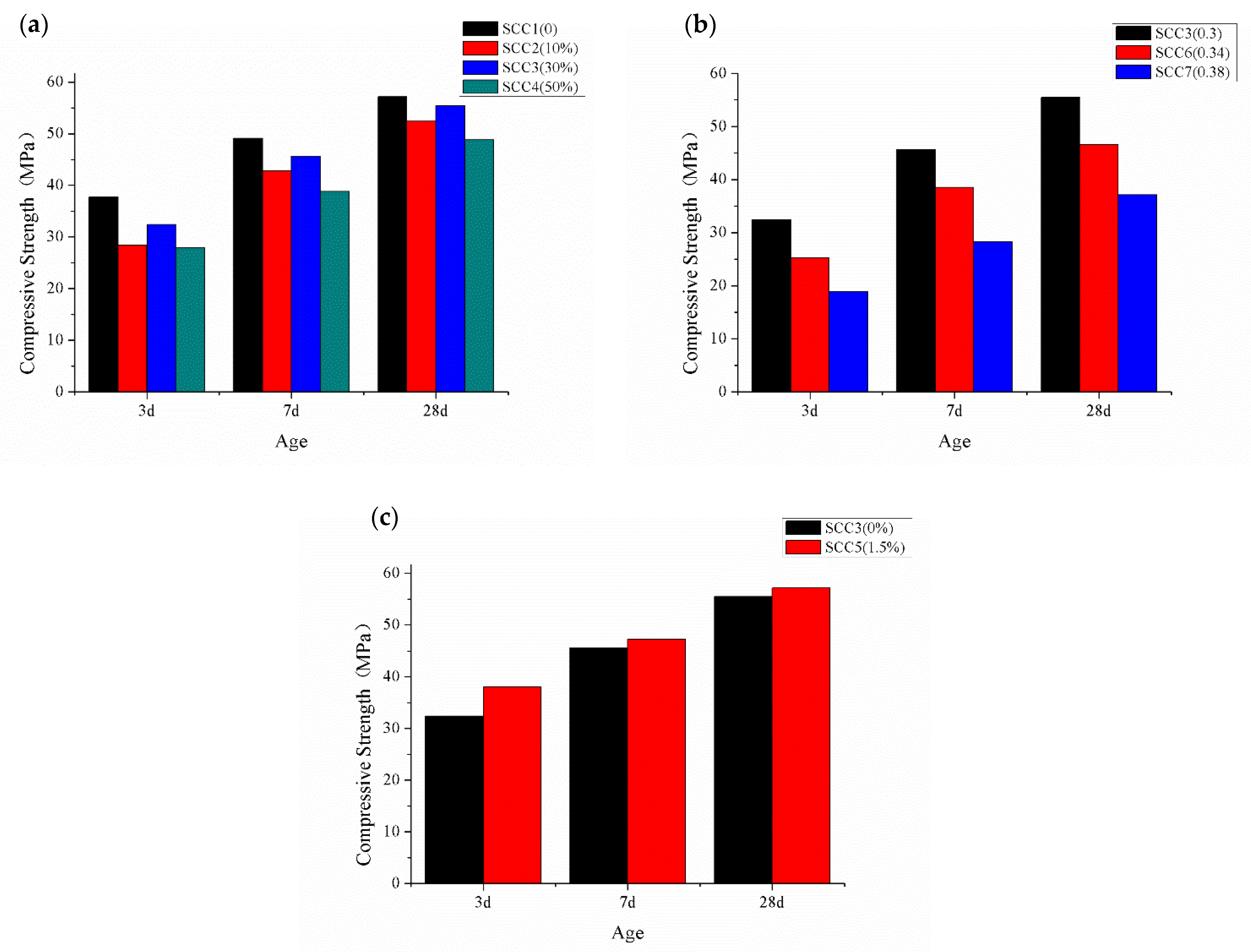

2.5. Compressive Strength Test of SCCs

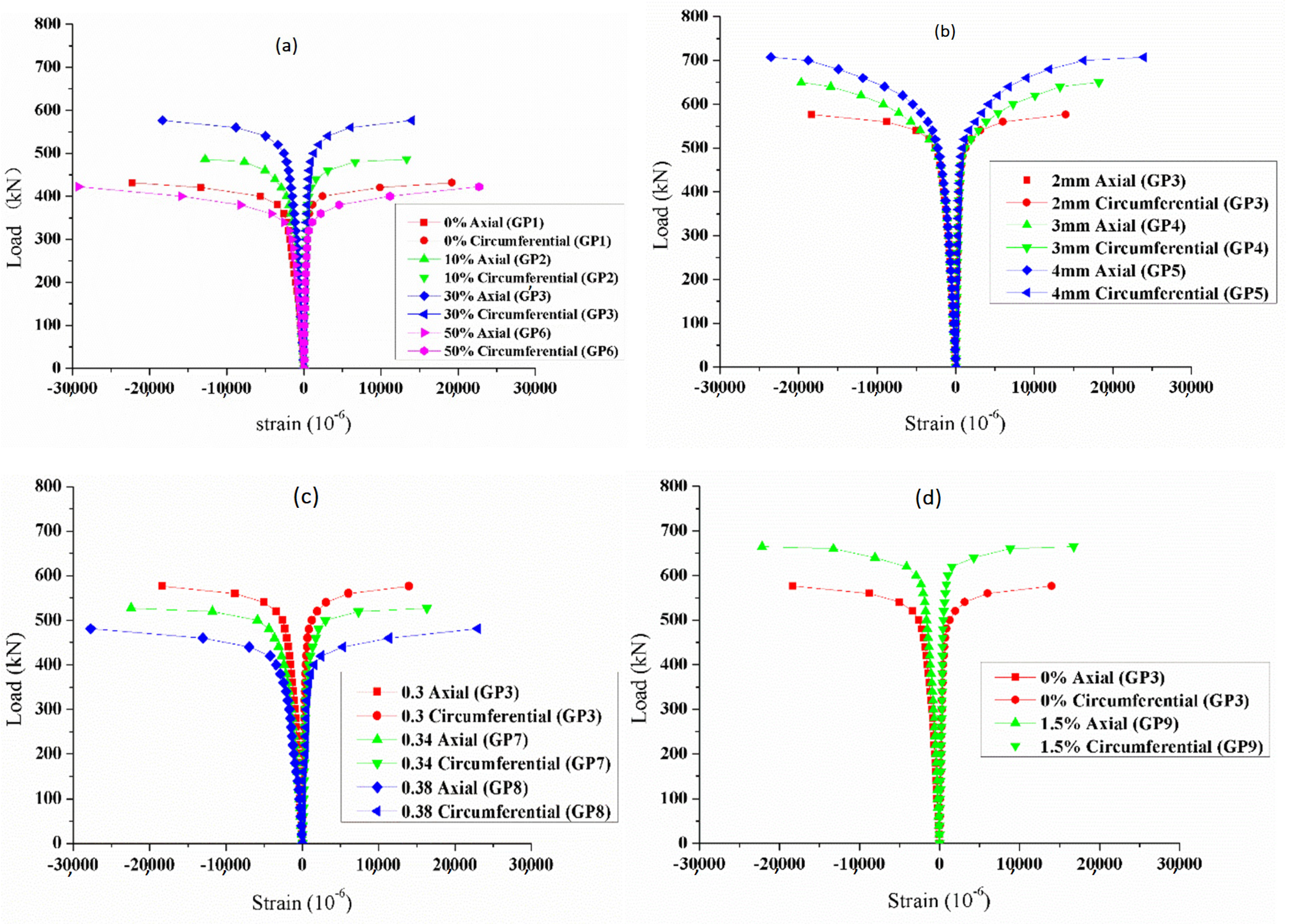

2.6. Axial Compressive Test of CFST

3. Results and Discussion

3.1. Filling Ability of the SCCs

3.2. Compressive Strength of the SCCs

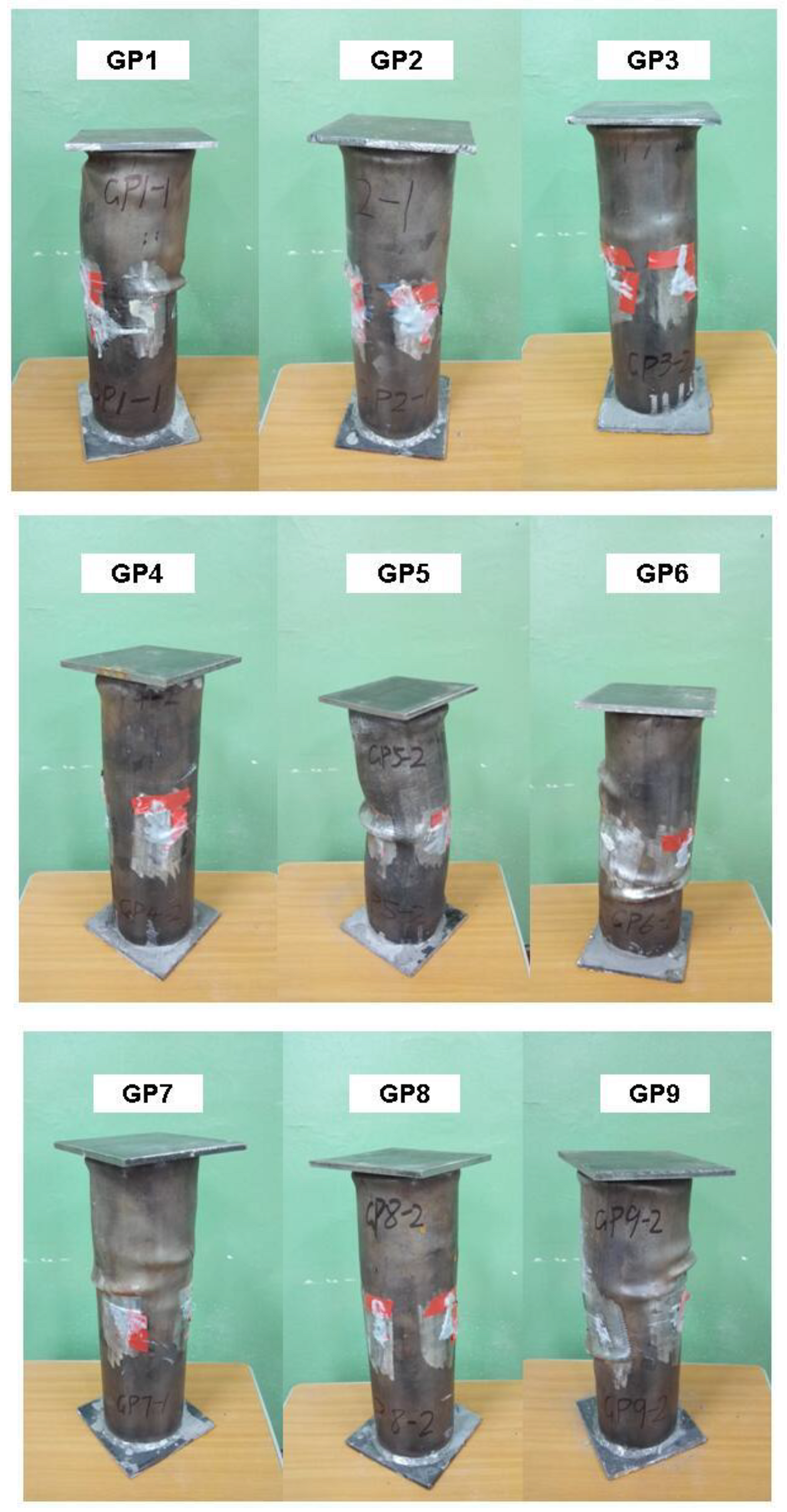

3.3. Axial Compressive Properties of the CFSTs

4. Conclusions

- While the slump flow of the SCCs is almost constant, the PS’s amount increases with the GDS’s amount but decreases with W/B. The addition of sodium sulfate has little effect on the amount of PS and the slump flow of the SCC.

- The addition of GDS decreases the 3d, 7d and 28d compressive strength of the SCCs. The decrease rate of the 28d compressive strength of SCC3 is the minimum, at only 2.8%, which means that the optimum amount of GDS for SCCs is 30%. With the increase in W/B, the compressive strength of the SCCs decreases. The addition of sodium sulfate can improve the SCC’s compressive strength. The compressive strength of 3d, 7d and 28d increase by 17.6%, 3.5% and 2.9%, respectively. Relative to the late compressive strength, sodium sulfate improved the early compressive strength of SCC to be more pronounced.

- The failure mode of the CFST short column is ductility failure. The failure form of the specimens is shear multi-fold waist drum failure. The axial load–deformation relation curve of all CFSTs can be divided into three stages, which are the elastic stage, the elastoplastic stage and the strengthening stage.

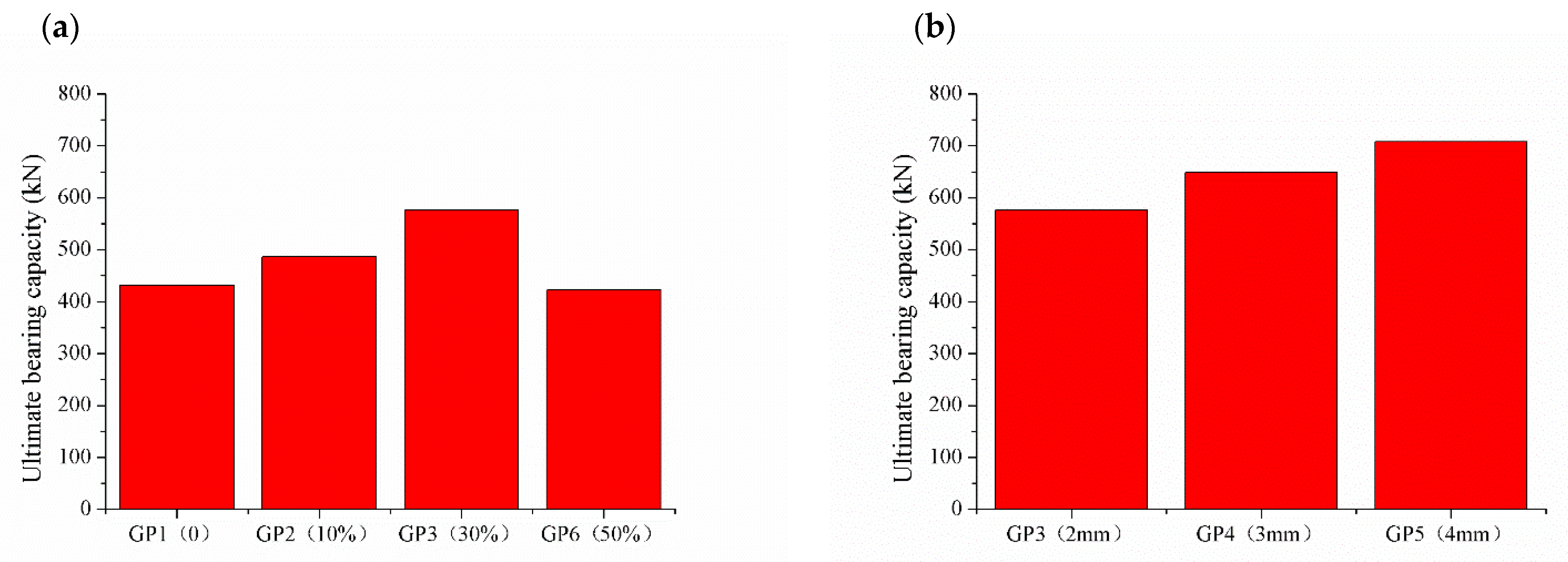

- Although the amount of GDS increases, the ultimate bearing capacity of CFSTs first increases and then decreases. When the amount of GDS is 30%, the ultimate bearing capacity of CFST short column (GP3) is the highest, which is 33.6% higher than that of GP1 without GDS. When the amount of GDS is 10%, the ultimate bearing capacity of CFST short column (GP2) is 12.8% higher than that of GP1. When the amount of GDS is 50%, the ultimate bearing capacity of CFST short column (GP4) is 2.1% lower than that of GP1. The optimum amount of GDS for CFSTs is also 30%.

- The influence law of the GDS’s amount on the CFSTs’ ultimate bearing capacity is quite different from that of the GDS’s amount on the SCCs’ compressive strength. The ultimate bearing capacity of CFSTs can be significantly improved by adding GDS. With the increase in wall thickness, the ultimate bearing capacity also increases. The ultimate bearing capacity of CFSTs decreases with the increase in W/B. Compared with GP3, the ultimate bearing capacity of GP9 increases by 15.3%, which contains 1.5% sodium sulfate. Sodium sulfate can improve the bearing capacity of the CFST.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Nagaratnam, B.H.; Rahman, M.E.; Mirasa, A.K.; Mannan, M.A.; Lame, S.O. Workability and heat of hydration of self-compacting concrete incorporating agro-industrial waste. J. Clean. Prod. 2016, 112, 882–894. [Google Scholar] [CrossRef]

- Le, H.T.; Müller, M.; Siewert, K.; Ludwig, H.-M. The mix design for self-compacting high performance concrete containing various mineral admixtures. Mater. Des. 2015, 72, 51–62. [Google Scholar] [CrossRef]

- Singh, N.; Kumar, P.; Goyal, P. Reviewing the behaviour of high volume fly ash based self compacting concrete. J. Build. Eng. 2019, 26, 100882. [Google Scholar] [CrossRef]

- Dadsetan, S.; Bai, J. Mechanical and microstructural properties of self-compacting concrete blended with metakaolin, ground granulated blast-furnace slag and fly ash. Constr. Build. Mater. 2017, 146, 658–667. [Google Scholar] [CrossRef]

- Anandaraj, S.; Karthik, S.; Elango, K.S.; Nishiketan, S.; Pandiyarajan, G.; Nithis Kumar, P.; Palanikumar, R.; Harihanandh, M. An experimental study on Fly Ash (FA) and marble powder in the properties of Self-Compacting Concrete (SCC). Mater. Today Proc. 2022, 52, 1771–1774. [Google Scholar] [CrossRef]

- Gnanaraj, S.C.; Chokkalingam, R.B.; Thankam, G.L.; Pothinathan, S.K.M. Durability properties of self-compacting concrete developed with fly ash and ultra fine natural steatite powder. J. Mater. Res. Technol. 2021, 13, 431–439. [Google Scholar] [CrossRef]

- José Oliveira, M.; Ribeiro, A.B.; Branco, F.G. Combined effect of expansive and shrinkage reducing admixtures to control autogenous shrinkage in self-compacting concrete. Constr. Build. Mater. 2014, 52, 267–275. [Google Scholar] [CrossRef]

- Niknezhad, D.; Kamali-Bernard, S.; Mesbah, H.-A. Self-Compacting Concretes with Supplementary Cementitious Materials: Shrinkage and Cracking Tendency. J. Mater. Civ. Eng. 2017, 29, 0001852. [Google Scholar] [CrossRef]

- Carballosa, P.; García Calvo, J.L.; Revuelta, D.; Sánchez, J.J.; Gutiérrez, J.P. Influence of cement and expansive additive types in the performance of self-stressing and self-compacting concretes for structural elements. Constr. Build. Mater. 2015, 93, 223–229. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, Y.; Shan, R.; Bai, Y.; Zhang, Z. Application on bending performance of annular concrete-filled steel tube stent. J. Constr. Steel Res. 2020, 168, 105984. [Google Scholar] [CrossRef]

- Yu, Z.-W.; Ding, F.-X.; Cai, C.S. Experimental behavior of circular concrete-filled steel tube stub columns. J. Constr. Steel Res. 2007, 63, 165–174. [Google Scholar] [CrossRef]

- Szadkowska, M.; Szmigiera, E. Analysis of shrinkage influence on bond in CFST elements filled with SCC. J. Con-Structional Steel Res. 2021, 184, 106824. [Google Scholar] [CrossRef]

- Huang, W.; Fan, Z.; Shen, P.; Lu, L.; Zhou, Z. Experimental and numerical study on the compressive behavior of micro-expansive ultra-high-performance concrete-filled steel tube columns. Constr. Build. Mater. 2020, 254, 119150. [Google Scholar] [CrossRef]

- Ho, J.C.M.; Ou, X.L.; Li, C.W.; Song, W.; Wang, Q.; Lai, M.H. Uni-axial behaviour of expansive CFST and DSCFST stub columns. Eng. Struct. 2021, 237, 112193. [Google Scholar] [CrossRef]

- Shen, P.; Lu, J.-X.; Zheng, H.; Lu, L.; Wang, F.; He, Y.; Hu, S. Expansive ultra-high performance concrete for concrete-filled steel tube applications. Cem. Concr. Compos. 2020, 114, 103813. [Google Scholar] [CrossRef]

- Li, H.; Wang, Y.; Wang, Y.; Liu, J.; Tian, Q. Effect of CaO and MgO based expansive agent on deformation and mechanical properties of concrete-filled steel tubes. Constr. Build. Mater. 2020, 250, 118723. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, J.; Guo, W.; Zhou, M.; Zhao, Q.; Li, B. Occurrence and migration laws of water in circulating fluidized bed bottom slag mortar and their influences on mortar properties. Constr. Build. Mater. 2022, 315, 125748. [Google Scholar] [CrossRef]

- Xun, X.; Xiaoling, F.; Chenglin, Y. Investigation on physical properties, strength and phase evolution of binary cementitious materials made of CFBC ash and lime. Constr. Build. Mater. 2020, 265, 120302. [Google Scholar] [CrossRef]

- Zhang, W.; Gu, J.; Zhou, X.; Li, Y.; Wang, Y.; Xue, Y.; Liu, X. Circulating fluidized bed fly ash based multi-solid wastes road base materials: Hydration characteristics and utilization of SO3 and f -CaO. J. Clean. Prod. 2021, 316, 128355. [Google Scholar] [CrossRef]

- Dung, N.T.; Chang, T.-P.; Chen, C.-T. Engineering and sulfate resistance properties of slag-CFBC fly ash paste and mortar. Constr. Build. Mater. 2014, 63, 40–48. [Google Scholar] [CrossRef]

- Cheng, Z.; Cheng, X.; Xie, Y.; Ma, Z.; Liu, Y. Strength Tests and Numerical Simulations of Loess Modified by Desulfurization Ash and Fly Ash. Materials 2022, 15, 512. [Google Scholar] [CrossRef]

- Zhang, W.; Wang, S.; Ran, J.; Lin, H.; Kang, W.; Zhu, J. Research progress on the performance of circulating fluidized bed combustion ash and its utilization in China. J. Build. Eng. 2022, 52, 104350. [Google Scholar] [CrossRef]

- Xia, Y.; Yan, Y.; Hu, Z. Utilization of circulating fluidized bed fly ash in preparing non-autoclaved aerated concrete production. Constr. Build. Mater. 2013, 47, 1461–1467. [Google Scholar] [CrossRef]

- Li, X.-G.; Chen, Q.-B.; Ma, B.-G.; Huang, J.; Jian, S.-W.; Wu, B. Utilization of modified CFBC desulfurization ash as an admixture in blended cements: Physico-mechanical and hydration characteristics. Fuel 2012, 102, 674–680. [Google Scholar] [CrossRef]

- Cheng, Z.; Cheng, Z.; Hou, H.; Han, T.; Liu, L. Research on the Expansion Characteristics and Compressive Strength of Mortars Containing Circulating Fluidized Bed Combustion Desulfurization Slag. Adv. Mater. Sci. Eng. 2018, 2018, 4150145. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, D.; Liao, S. Effect of mechanical grinding on physical and chemical characteristics of circulating fluidized bed fly ash from coal gangue power plant. Constr. Build. Mater. 2015, 101, 851–860. [Google Scholar] [CrossRef]

- Zhang, W.; Liu, X.; Zhang, Z.; Wang, Y.; Xue, Y.; Hao, X.; Lu, Y. Circulating Fluidized Bed Fly Ash Mixed Functional Cementitious Materials: Shrinkage Compensation of f-CaO, Autoclaved Hydration Characteristics and Environmental Performance. Materials 2021, 14, 6004. [Google Scholar] [CrossRef]

- Cheng, Z.; He, L.; Liu, L.; Cheng, Z.; Pei, X.; Ma, Z.; Václavík, V. Mechanical Properties and Durability of High-Performance Concretes Blended with Circulating Fluidized Bed Combustion Ash and Slag as Replacement for Ordinary Portland Cement. Adv. Mater. Sci. Eng. 2020, 2020, 8613106. [Google Scholar] [CrossRef]

- Li, J.; Ma, Z.; Gao, J.; Guo, Y.; Cheng, F. Synthesis and characterization of geopolymer prepared from circulating fluidized bed-derived fly ash. Ceram. Int. 2022, 48, 11820–11829. [Google Scholar] [CrossRef]

- JGJ/T 283; Technical Specification for Application of Self-Compacted Concrete. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2012.

- Li, J.; Chen, Y.; Wan, C. A mixdesign method for lightweight aggregate selfcompacting concrete based on packing and mortar film thickness theories. Constr. Build. Mater. 2017, 157, 621–634. [Google Scholar] [CrossRef]

- Chang, Y.; Chen, W.; Xiao, Q.; Rong, E.; Peng, L. Theoretical and experimental study on axial compression concrete-filled tubes with different confinements. J. Constr. Steel Res. 2021, 185, 106862. [Google Scholar] [CrossRef]

- Cheng, Z.; Pei, X.; Hou, H.; Han, T.; Liu, L.; Wang, H.; Han, Y. Expansive Behavior in Circular Steel Tube Stub Columns of SCC Blended with CFB Bottom Ashes. J. Mater. Civ. Eng. 2019, 31, 04019279. [Google Scholar] [CrossRef]

- Khairallah, F. Mechanical behavior of confined self-compacting reinforced concrete circular columns under concentric axial loading. Ain Shams Eng. J. 2013, 4, 641–649. [Google Scholar] [CrossRef]

- Liu, L.; He, L.; Cheng, Z.; Wang, X.; Ma, Z.; Cheng, X. Interface Bonding Behavior of Concrete-Filled Steel Tube Blended with Circulating Fluidized Bed Bottom Ash. Materials 2021, 14, 1529. [Google Scholar] [CrossRef]

- Rui, X.; Zhean, L.; Zhigang, R.; Chunguang, H. Experimental Research on the Performance of Micro-expansion and Self-compacting Concrete-Filled Steel Tubular Short Column under Axial Compression. Procedia Earth Planet. Sci. 2012, 5, 19–24. [Google Scholar] [CrossRef][Green Version]

- Chang, X.; Huang, C.; Zhang, P. Expansive behaviors of self-stressing concrete under different restraining conditions. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2011, 26, 780–785. [Google Scholar] [CrossRef]

| SiO2 | Al2O3 | CaO | SO3 | Fe2O3 | MgO | K2O | P205 | Na2O | Loss |

|---|---|---|---|---|---|---|---|---|---|

| 42.19 | 25.9 | 10.99 | 5.91 | 3.1 | 1.35 | 0.79 | 0.12 | 0.06 | 6.09 |

| 20.84 | 4.14 | 65.58 | 2.80 | 3.35 | 1.89 | 0.60 | 0.08 | 0.11 | 2.09 |

| No. | W/B | CLS | S | PC | GDS | Water | Sodium Sulfate | PS |

|---|---|---|---|---|---|---|---|---|

| SCC1 | 0.3 | 878 | 786 | 548 | 0.0 | 165 | 0 | 5.49 |

| SCC2 | 0.3 | 878 | 786 | 493 | 55 | 165 | 0 | 6.58 |

| SCC3 | 0.3 | 878 | 786 | 384 | 164 | 165 | 0 | 7.67 |

| SCC4 | 0.3 | 878 | 786 | 274 | 274 | 165 | 0 | 9.32 |

| SCC5 | 0.3 | 878 | 786 | 384 | 164 | 165 | 8.22 | 7.67 |

| SCC6 | 0.34 | 878 | 786 | 366 | 157 | 178 | 0 | 6.79 |

| SCC7 | 0.38 | 878 | 786 | 351 | 150 | 190 | 0 | 6.01 |

| No. | SCC | W/B | Amount of GDS (%) | Amount of Sodium Sulfate (%) | D × t × L (mm) |

|---|---|---|---|---|---|

| GP1 | SCC1 | 0.3 | 0 | 0 | 100 × 2 × 300 |

| GP2 | SCC2 | 0.3 | 10 | 0 | 100 × 2 × 300 |

| GP3 | SCC3 | 0.3 | 30 | 0 | 100 × 2 × 300 |

| GP4 | SCC4 | 0.3 | 30 | 0 | 100 × 3 × 300 |

| GP5 | SCC5 | 0.3 | 30 | 0 | 100 × 4 × 300 |

| GP6 | SCC3 | 0.3 | 50 | 0 | 100 × 2 × 300 |

| GP7 | SCC3 | 0.34 | 30 | 0 | 100 × 2 × 300 |

| GP8 | SCC6 | 0.38 | 30 | 0 | 100 × 2 × 300 |

| GP9 | SCC7 | 0.3 | 30 | 1.5 | 100 × 2 × 300 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, L.; Liu, Y.; Cheng, Z.; Cheng, X.; Zhang, H. Axial Compressive Properties of Self-Compacting Concrete Filled Steel Tube Short Columns with Ground Desulfurization Slag. Materials 2022, 15, 6306. https://doi.org/10.3390/ma15186306

Liu L, Liu Y, Cheng Z, Cheng X, Zhang H. Axial Compressive Properties of Self-Compacting Concrete Filled Steel Tube Short Columns with Ground Desulfurization Slag. Materials. 2022; 15(18):6306. https://doi.org/10.3390/ma15186306

Chicago/Turabian StyleLiu, Lan, Yuhao Liu, Zhi Cheng, Xinrong Cheng, and Hongping Zhang. 2022. "Axial Compressive Properties of Self-Compacting Concrete Filled Steel Tube Short Columns with Ground Desulfurization Slag" Materials 15, no. 18: 6306. https://doi.org/10.3390/ma15186306

APA StyleLiu, L., Liu, Y., Cheng, Z., Cheng, X., & Zhang, H. (2022). Axial Compressive Properties of Self-Compacting Concrete Filled Steel Tube Short Columns with Ground Desulfurization Slag. Materials, 15(18), 6306. https://doi.org/10.3390/ma15186306