Effect of the Moisture Content of Recycled Aggregate on the Mechanical Performance and Durability of Concrete

Abstract

:1. Introduction

2. Materials and Methods

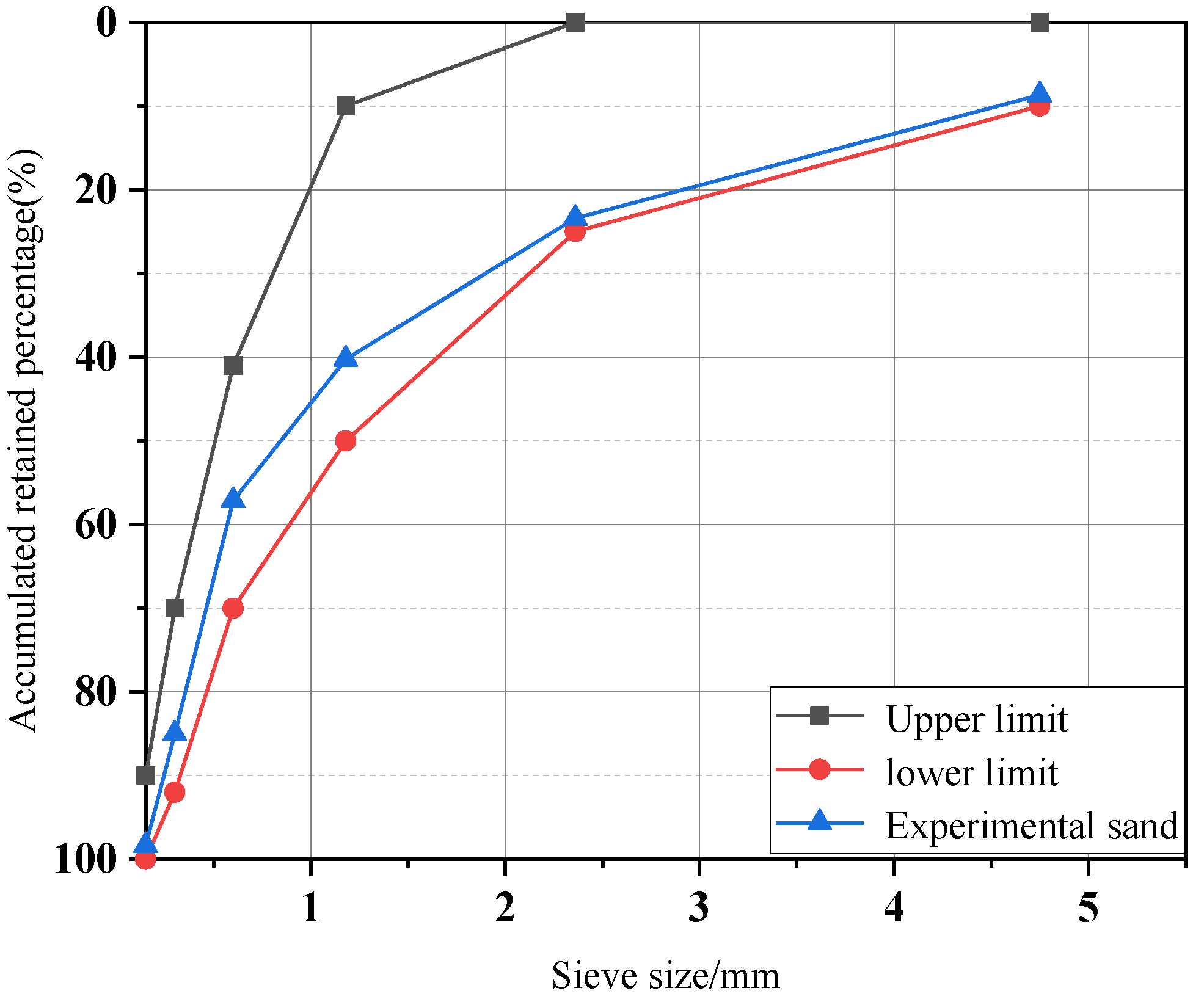

2.1. Raw Materials

2.2. Methods and Procedure

2.3. Mix Proportion

3. Results and Discussion

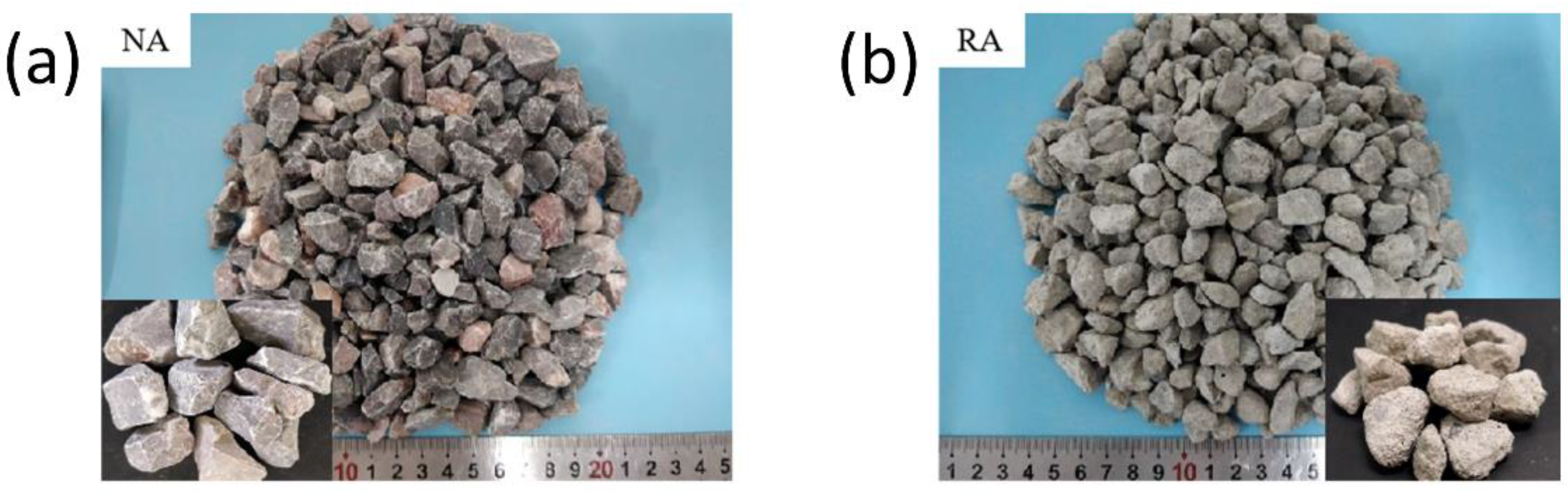

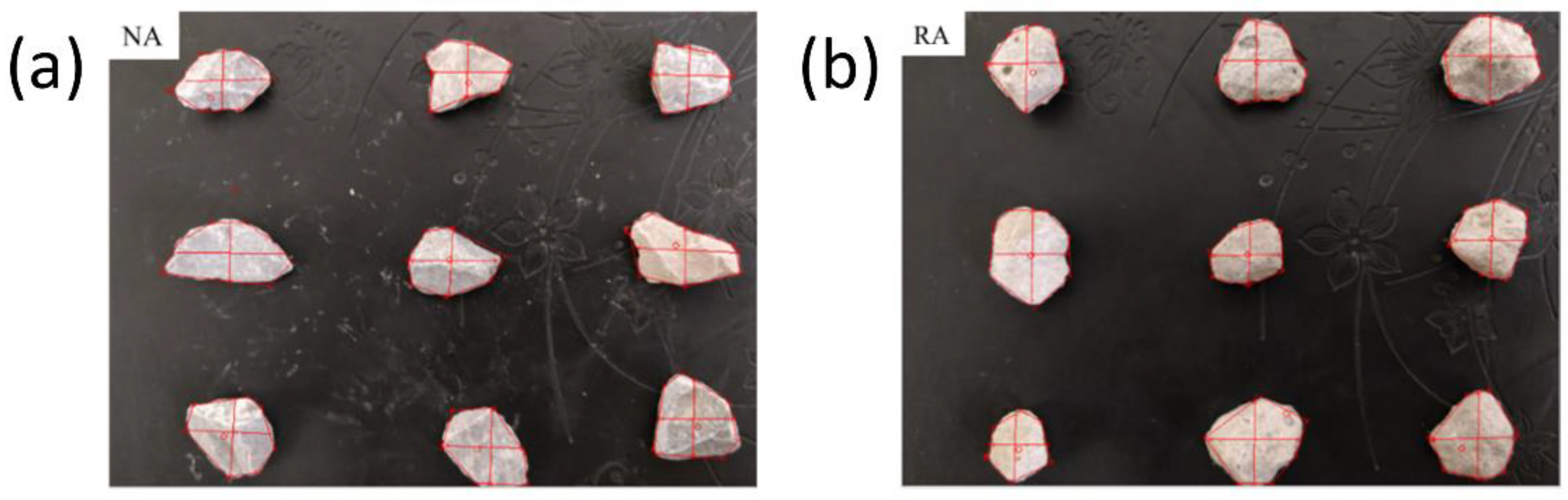

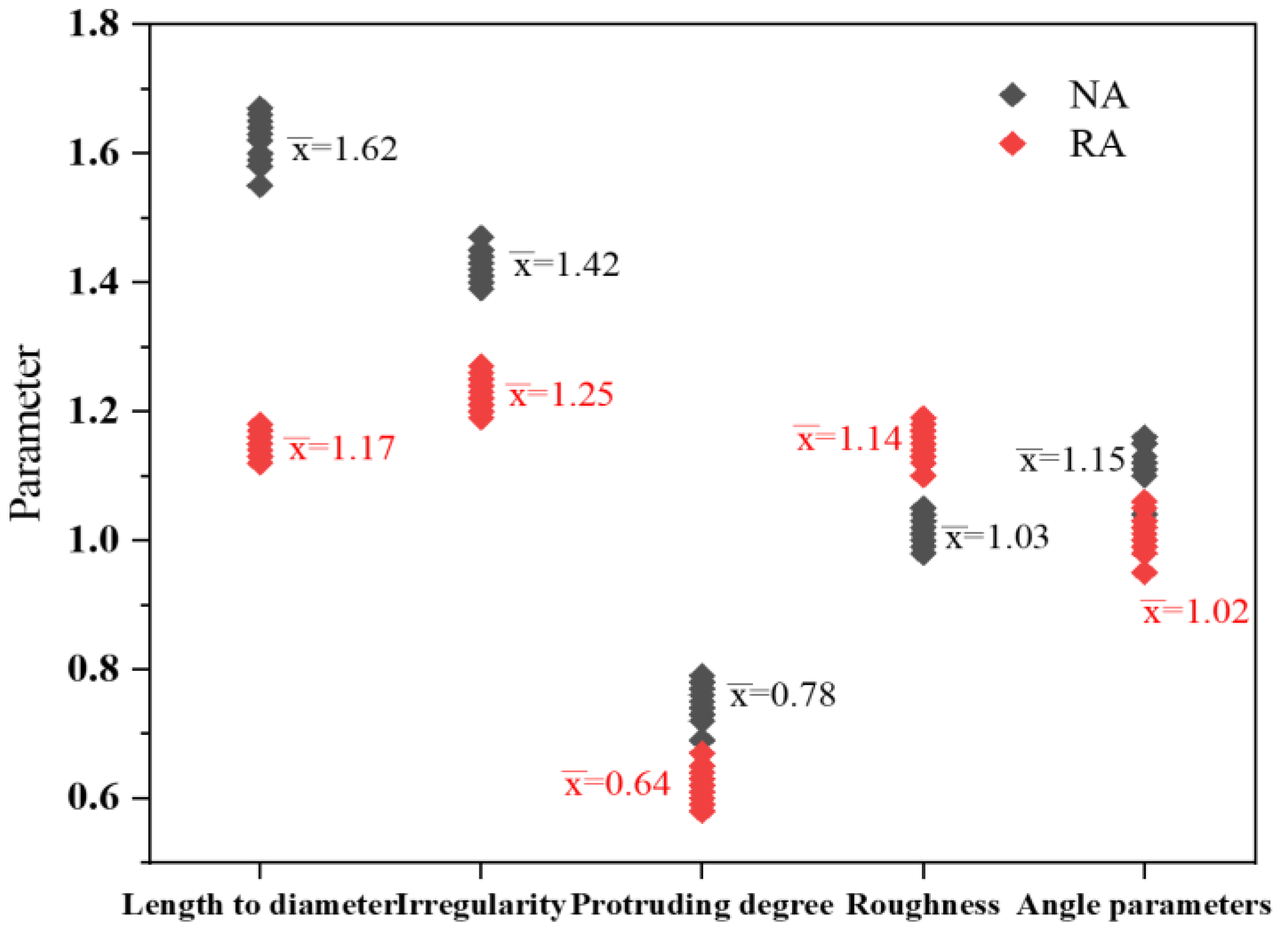

3.1. Aggregate Morphology Analysis

3.2. Aggregate Pore Structure

3.3. Properties of Recycled Concrete

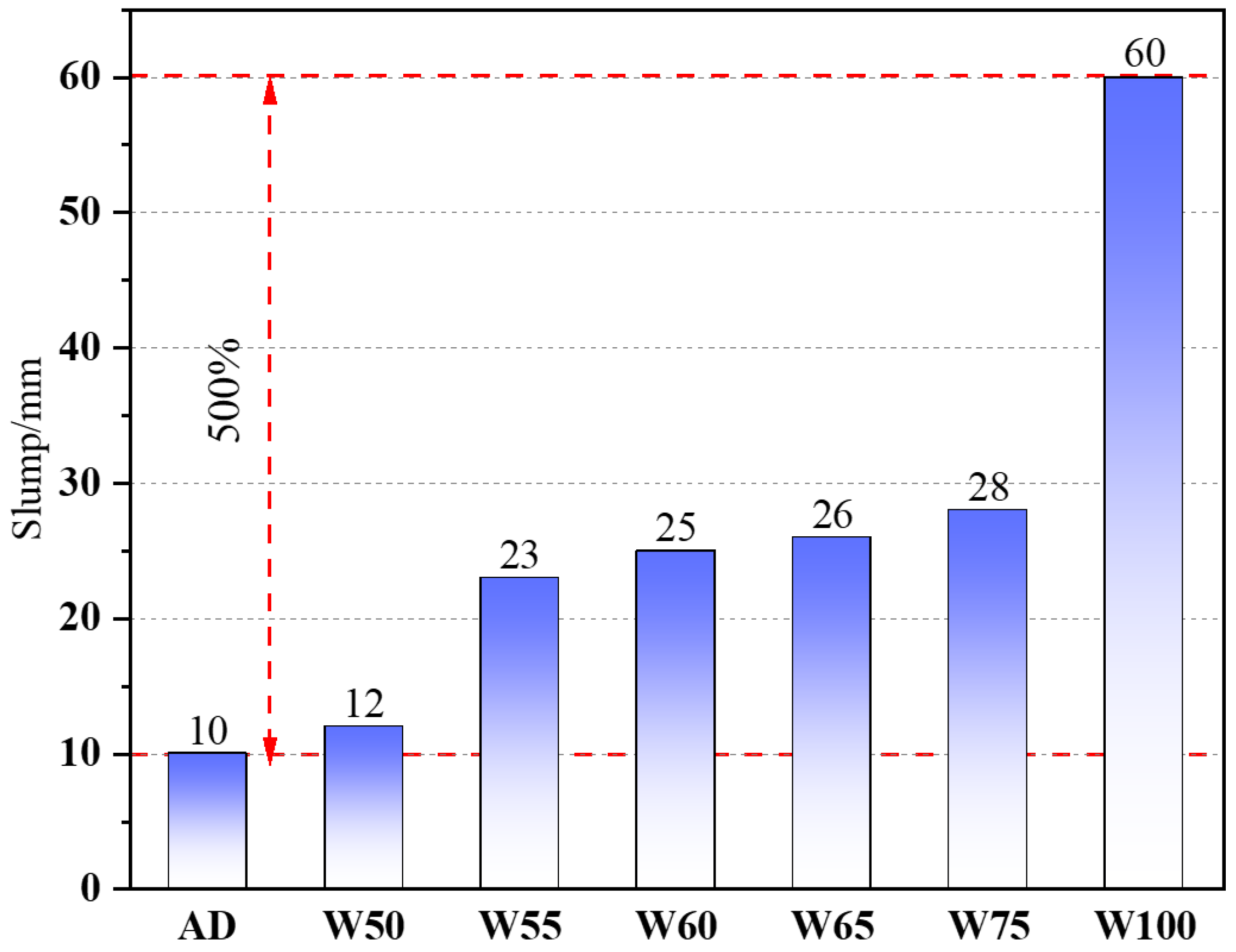

3.3.1. Slump

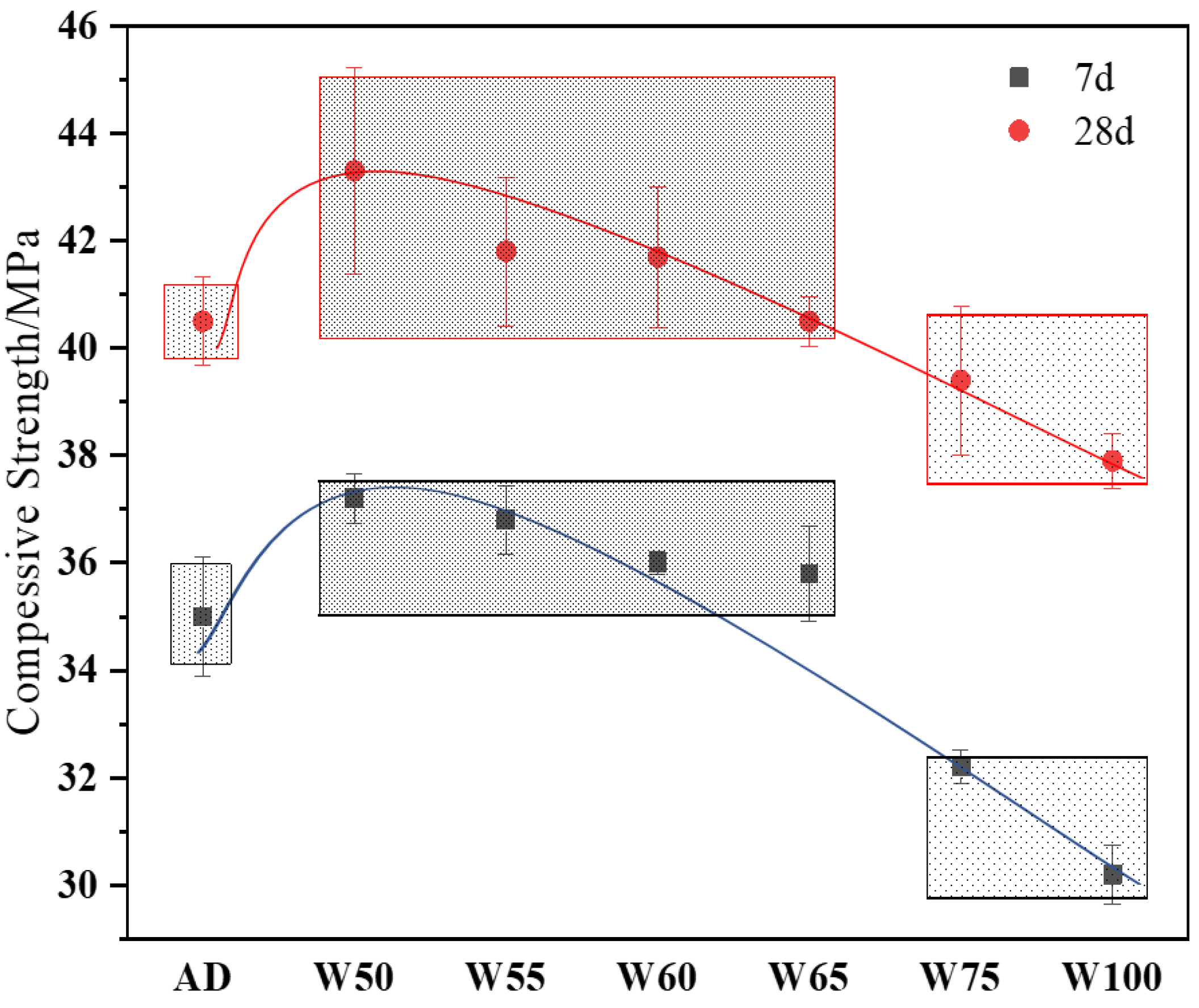

3.3.2. Compressive Strength

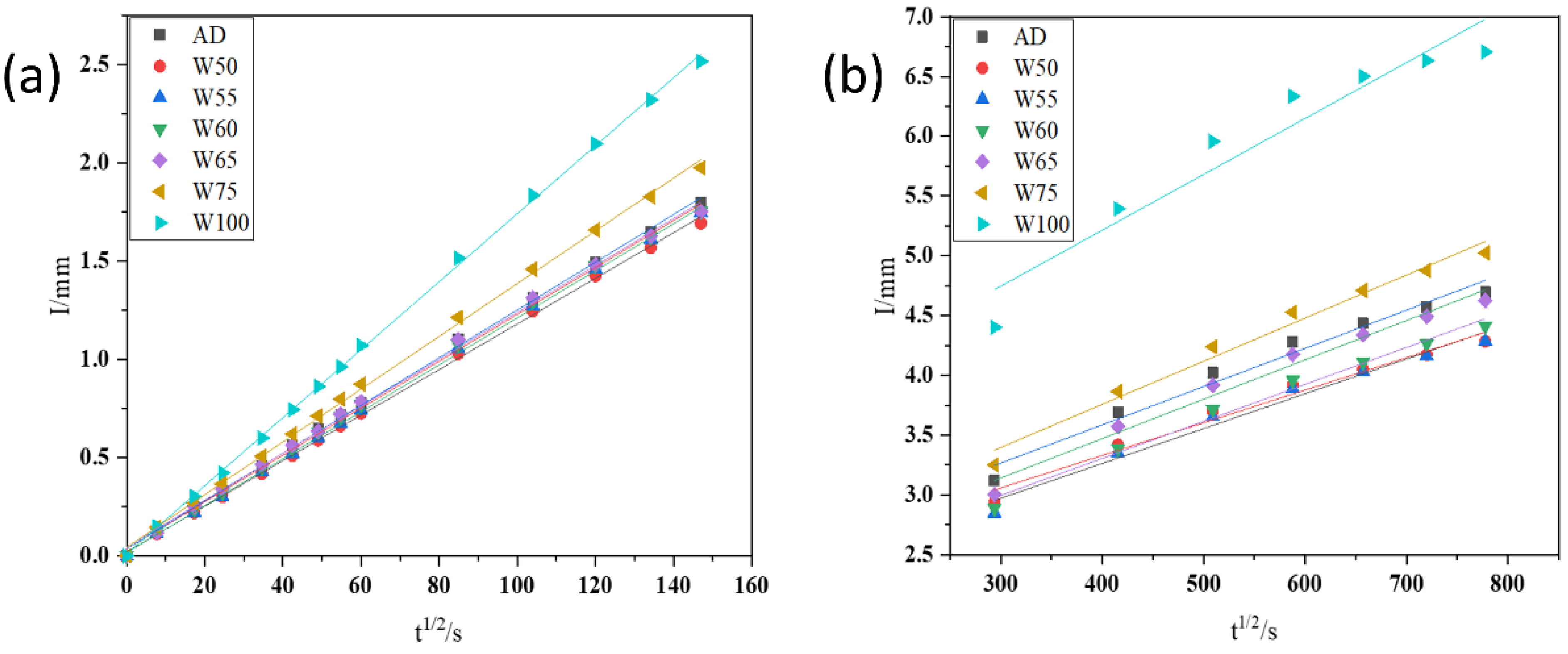

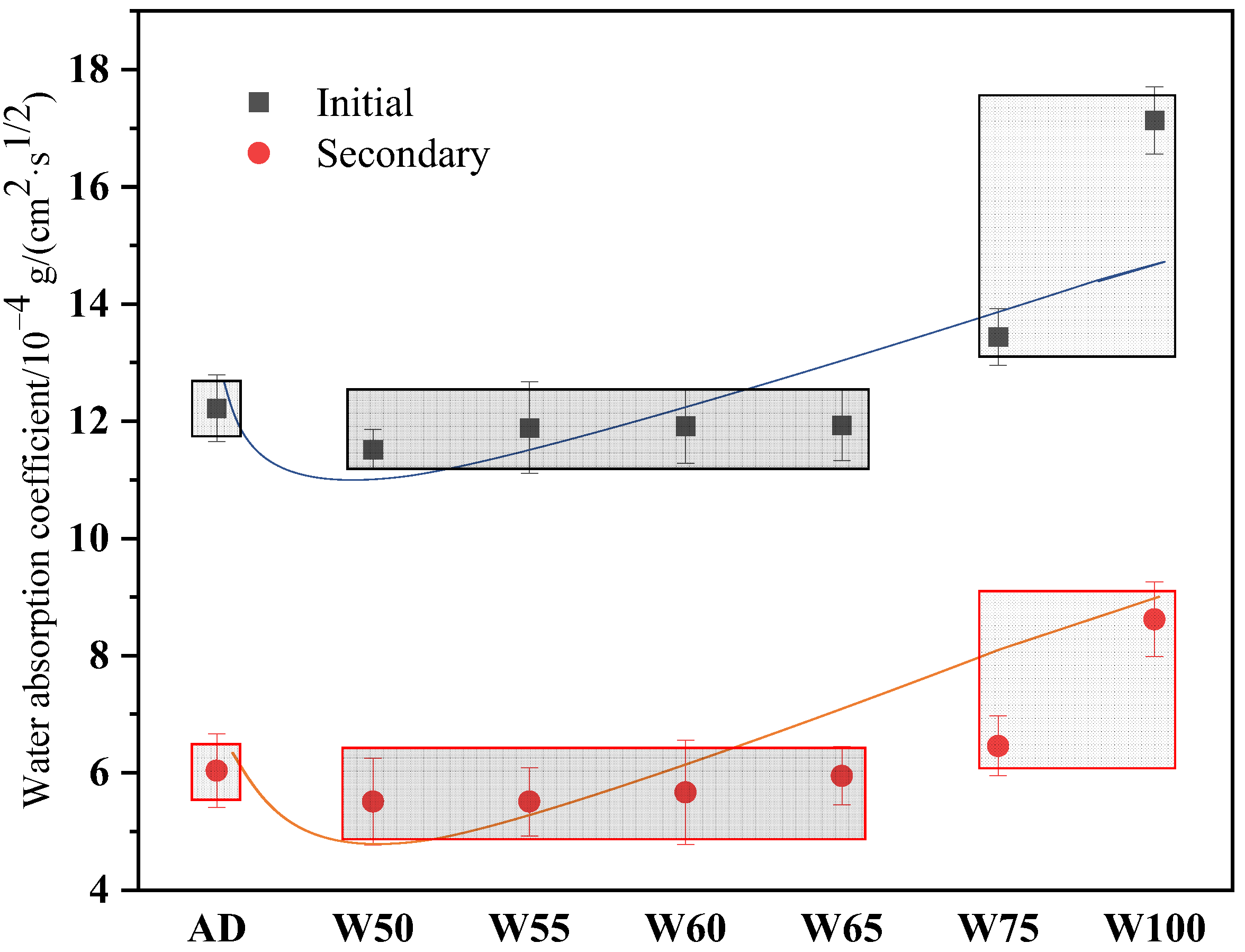

3.3.3. Capillary Water Adsorption

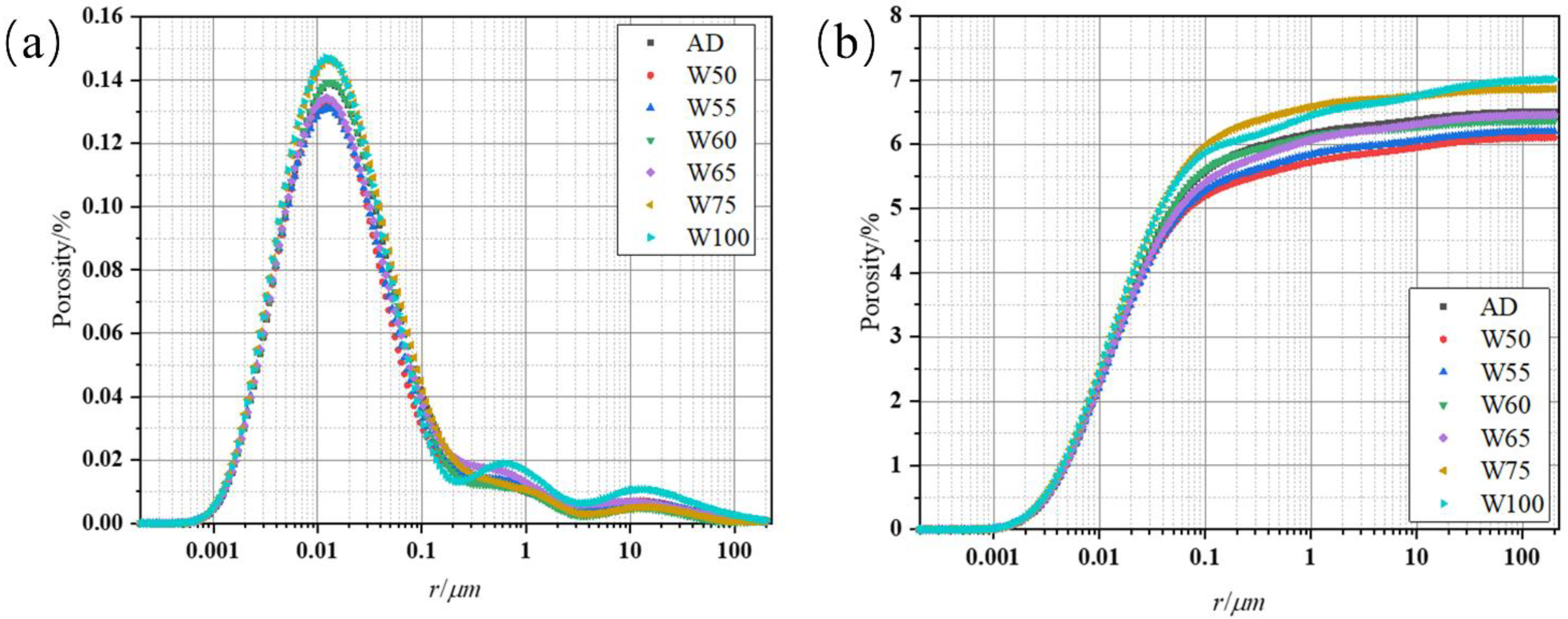

3.3.4. Pore Structure

3.4. Durability of Recycled Concrete

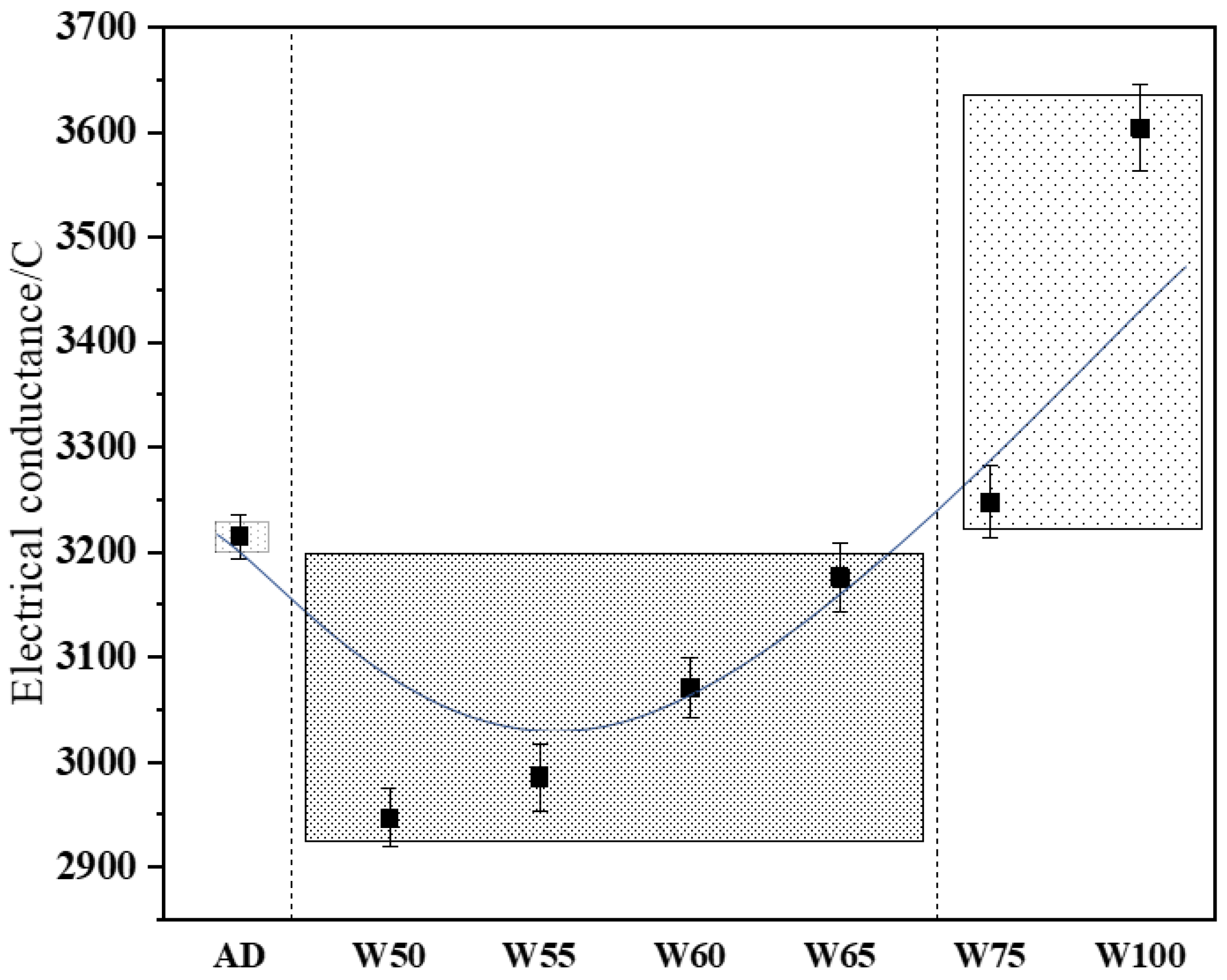

3.4.1. Electric Flux

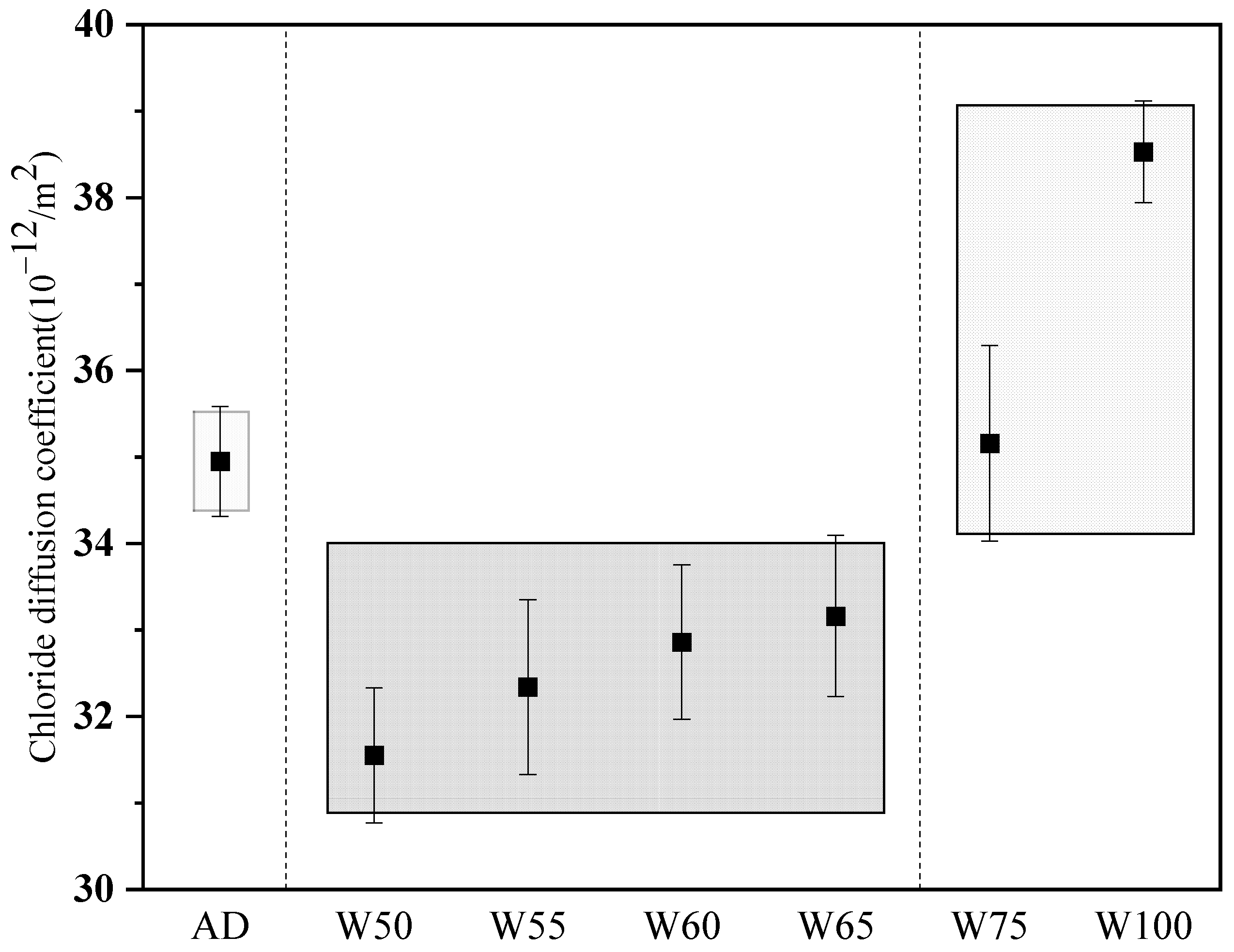

3.4.2. Chloride Ion Permeability Coefficient

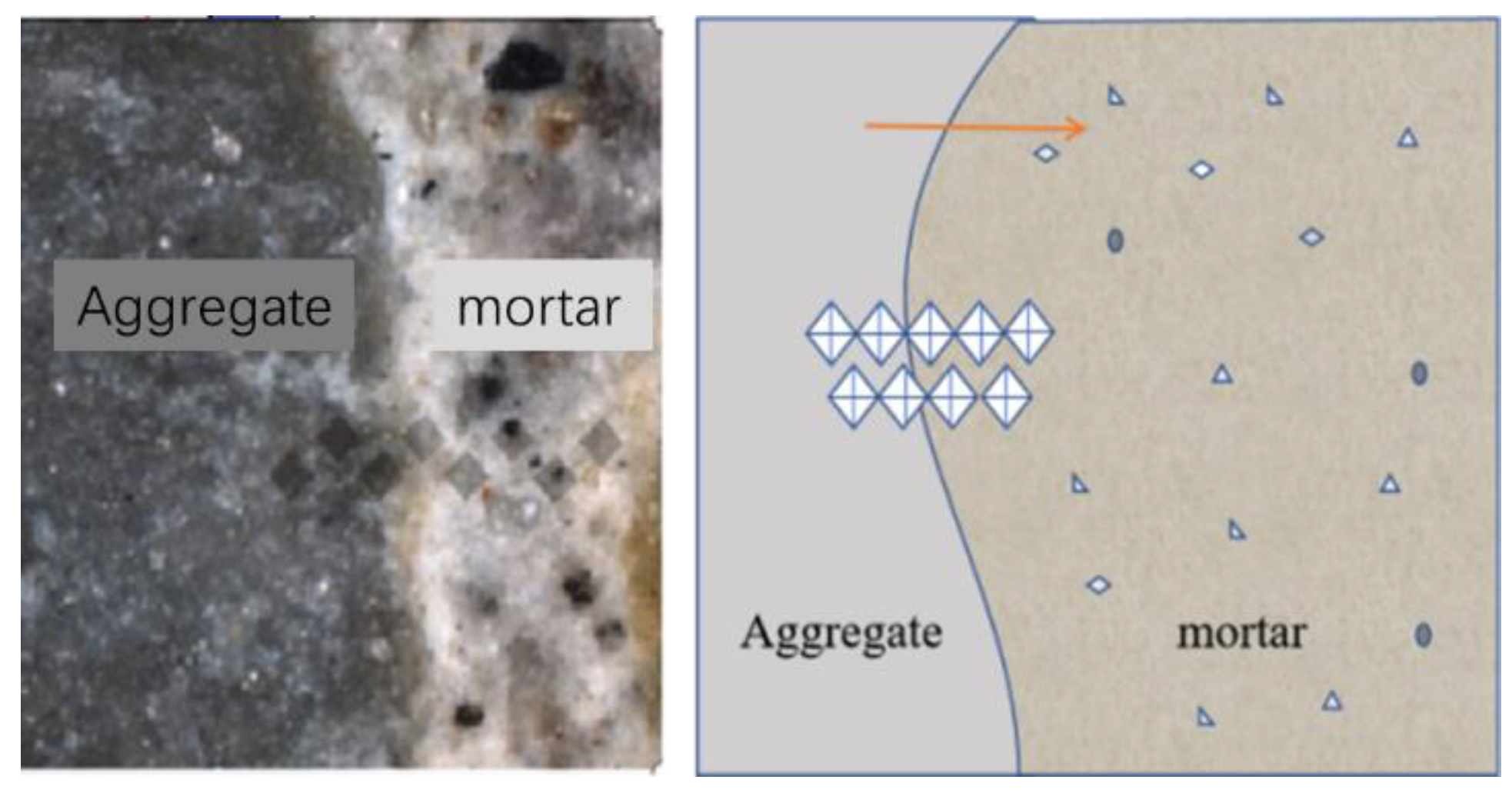

3.5. The Performance of ITZ

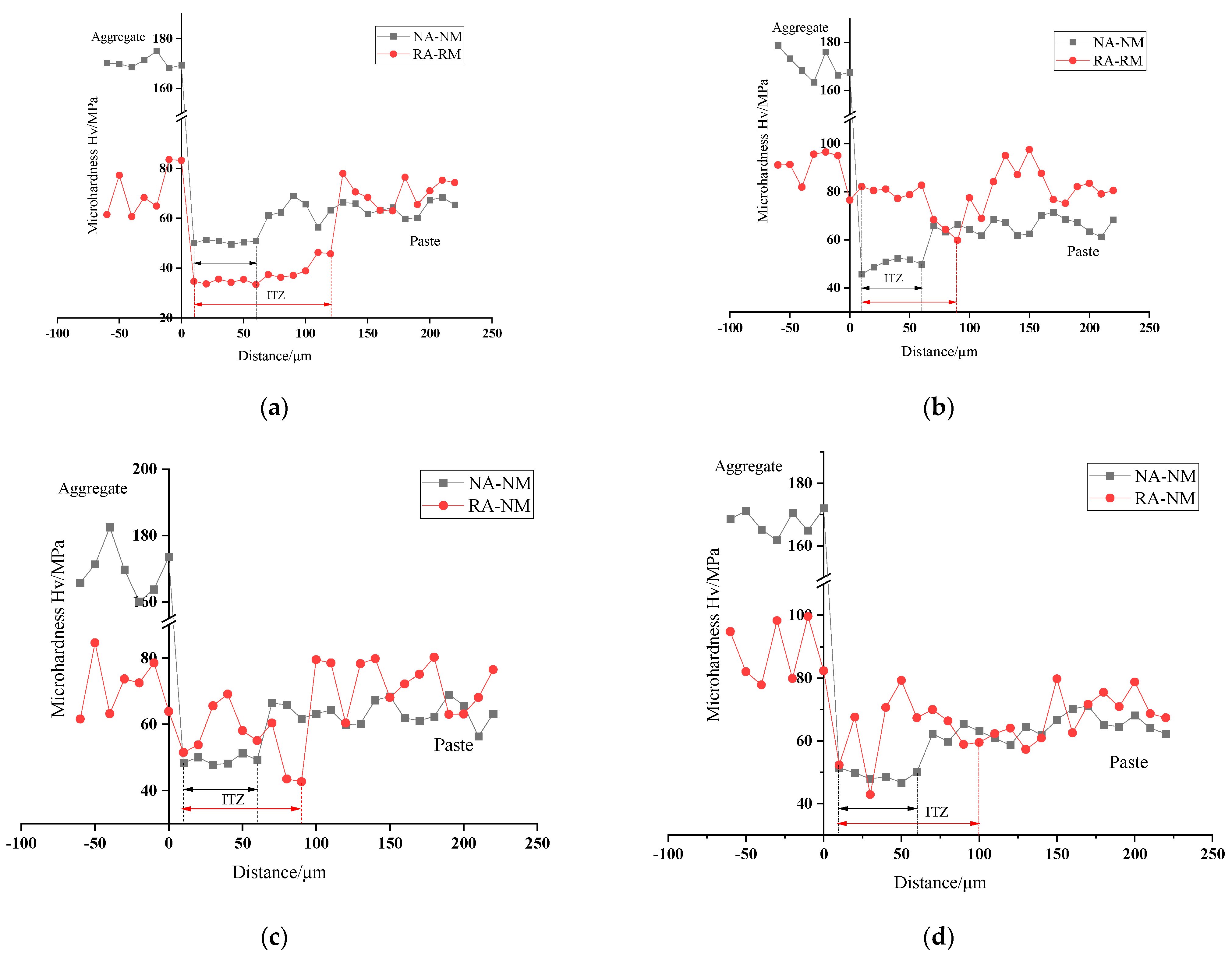

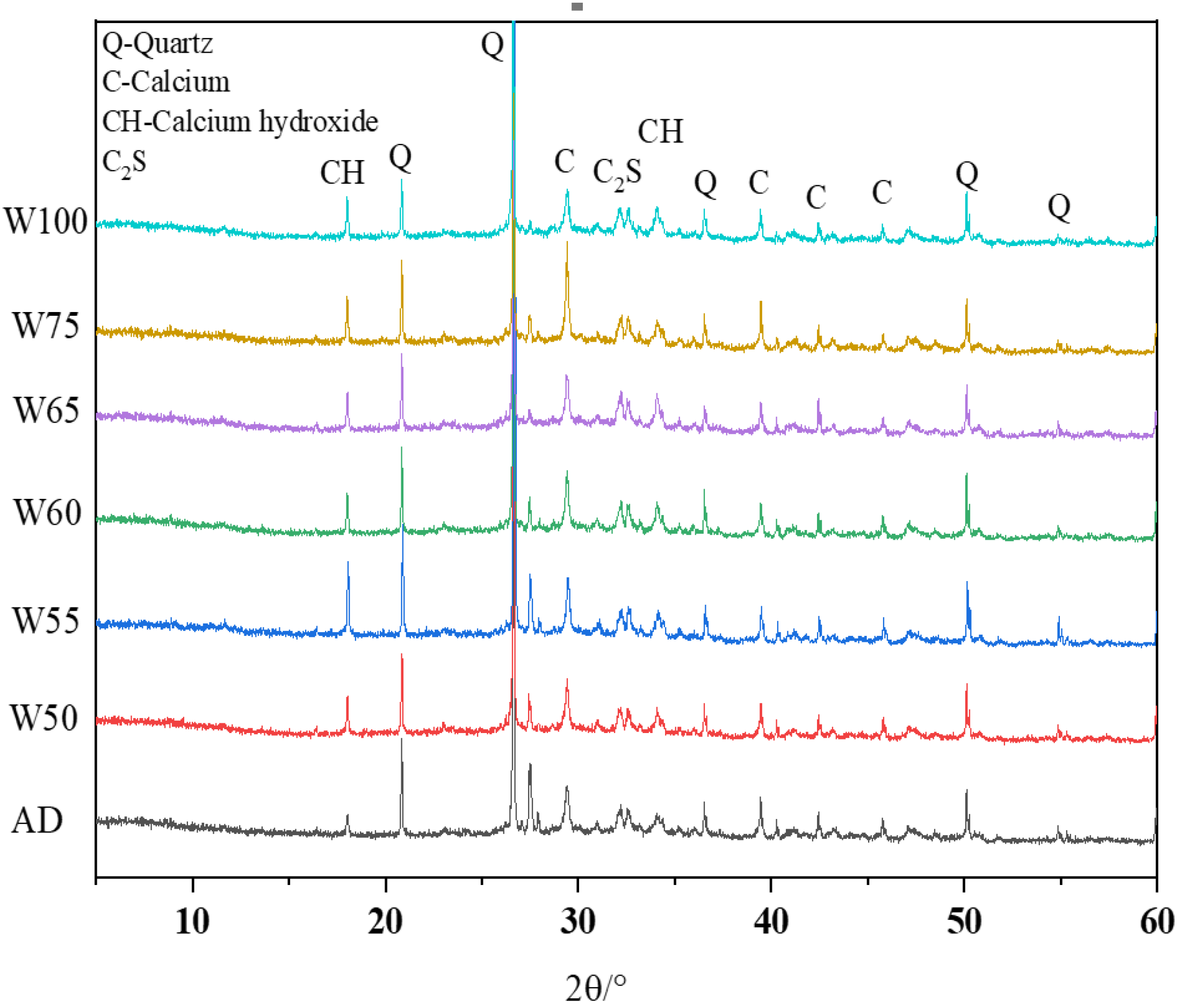

3.5.1. Microhardness

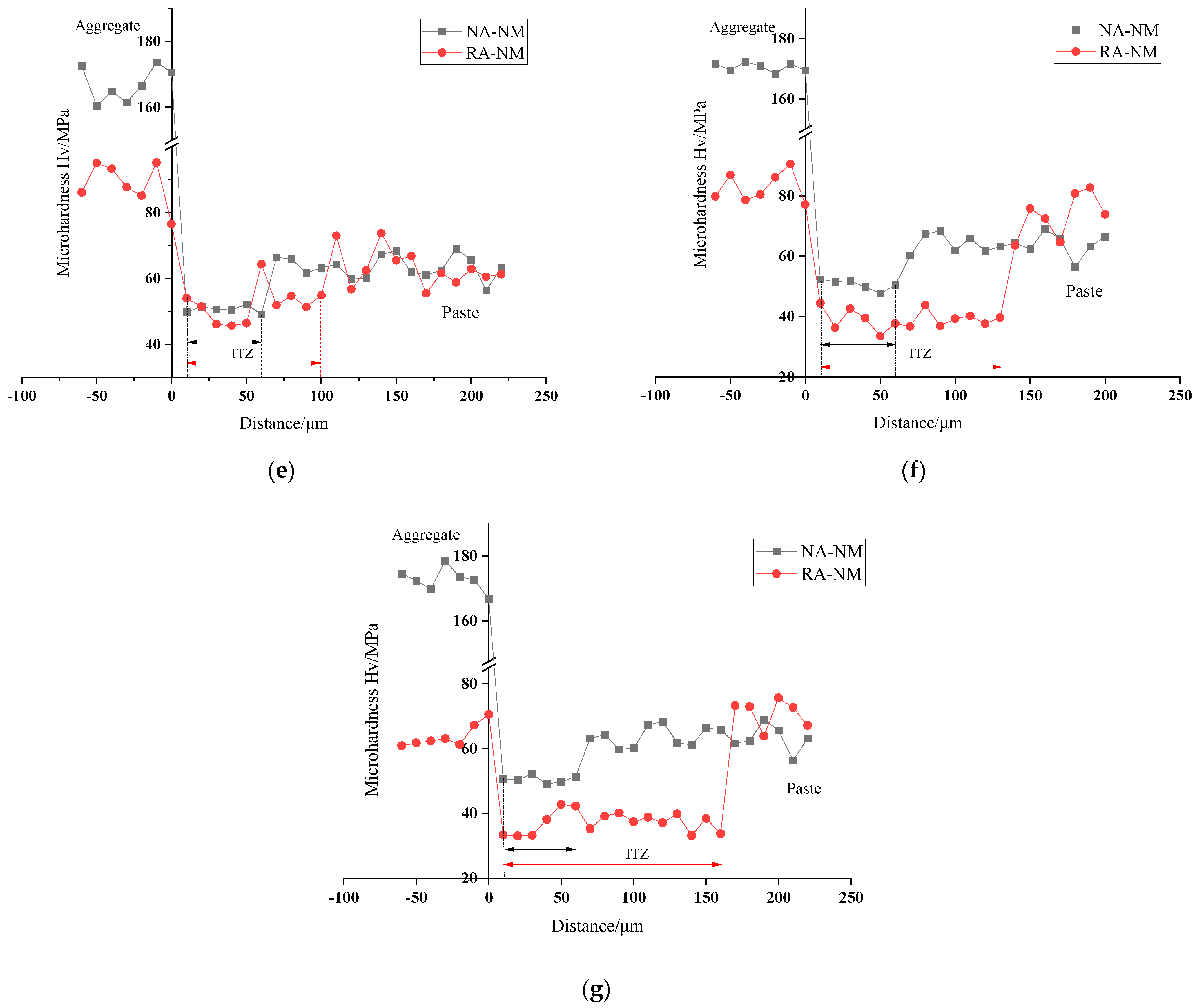

3.5.2. XRD

3.5.3. SEM

4. Conclusions

- (1)

- Recycled aggregate made from crushed concrete had a rough surface, round particle shape, and higher porosity than natural aggregate. The water absorption and crushing index were 25 times and 2.5 times higher than those of natural aggregate;

- (2)

- With the prewetted degree continuously increasing from 0% to 100%, the slump of concrete was enlarged by 500%, while the strength was higher than the plain group at 50–65% and reached the maximum of 40.5 MPa. The appropriate moisture content of recycled aggregate would balance the water absorption in concrete at an early age, and more water would be released into the matrix to increase the real W/B ratio if the prewetted degree was too high;

- (3)

- The permeability of recycled concrete was also first decreased and then highly increased with the prewetted degree of aggregate increasing from 0% to 100%, and was optimal when aggregate was prewetted to 50–55%. The internal curing effect of wet aggregate declined the porosity by 0.77–6.30% and reduced the fraction of pores larger than 50 nm. When the moisture increased further, the porosity increased significantly;

- (4)

- The microhardness demonstrated that the width of the ITZ of recycled aggregate was larger than natural aggregate. However, with the prewetted degree of 50–60%, the width decreased to 90–100 μm, and the microhardness in ITZ ranged at 42.7–82.7, which was even higher than that of natural aggregate. The morphology also proved that with the prewetted degree of 50–60%, the ITZ was more compact with fewer cracks than another status;

- (5)

- Prewetted degree influenced the driving force of water absorption at an early age and the internal curing efficiency. At an appropriate prewetted degree, the water absorption was mitigated, thinner water film formed at the aggregate surface, which caused a compact microstructure formation, and the water in the aggregate migrated gently to promote the hydration by internal curing effect. Exceeded water might rapidly release into the matrix, increasing the porosity and causing a loose ITZ, which was weak for strength and impermeability.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| Abbreviations | Symbols | ||

| C-S-H | Calcium silicate hydrate | I | Water adsorption capacity |

| XRF | X-ray fluorescence | mt | Mass at time t |

| NA | Natural aggregate | A | Contact area |

| RA | Recycled aggregate | d | Density of water |

| ITZ | Interfacial transition zone | ||

| XRD | X-ray diffraction | ||

| SSD | Saturated surface dry | ||

| AD | Air-dried | ||

| W/B | Water to binder ratio | ||

| RH | Relative humidity | ||

References

- Prakash, R.; Thenmozhi, R.; Raman, S.N.; Subramanian, C. Characterization of eco-friendly steel fiber-reinforced concrete containing waste coconut shell as coarse aggregate and fly ash as partial cement replacement. Struct. Concr. 2020, 21, 437–447. [Google Scholar] [CrossRef]

- Parkash, R.; Raman, S.N.; Subramanian, C.; Divyah, N. Eco-friendly fiber-reinforced concret. In Handbook of Sustainable Concrete and Industrial Waste Management; Elsevier: Amsterdam, The Netherlands, 2022; pp. 109–145. [Google Scholar] [CrossRef]

- Pradhan, S.; Tiwari, B.R.; Kumar, S.; Barai, S.V. Comparative LCA of recycled and natural aggregate concrete using Particle Packing Method and conventional method of design mix. J. Clean. Prod. 2019, 228, 679–691. [Google Scholar] [CrossRef]

- Tam, V.W. Economic comparison of concrete recycling: A case study approach. Resour. Conserv. Recycl. 2008, 52, 821–828. [Google Scholar] [CrossRef]

- Khan, K.; Amin, M.N.; Saleem, M.U.; Qureshi, H.J.; Al-Faiad, M.A.; Qadir, M.G. Effect of fineness of basaltic volcanic ash on pozzolanic reactivity, ASR expansion and drying shrinkage of blended cement mortars. Materials 2019, 12, 2603. [Google Scholar] [CrossRef] [PubMed]

- Shalabi, F.I.; Mazher, J.; Khan, K.; Alsuliman, M.; Almustafa, I.; Mahmoud, W.; Alomran, N. Cement-stabilized waste sand as sustainable construction materials for foundations and highway roads. Materials 2019, 12, 600. [Google Scholar] [CrossRef]

- Sabău, M.; Bompa, D.V.; Silva, L.F. Comparative carbon emission assessments of recycled and natural aggregate concrete: Environmental influence of cement content. Geosci. Front. 2021, 12, 101235. [Google Scholar] [CrossRef]

- Fraj, A.B.; Idir, R. Concrete based on recycled aggregates—Recycling and environmental analysis: A case study of paris’ region. Constr. Build. Mater. 2017, 157, 952–964. [Google Scholar] [CrossRef]

- Bao, Z.K.; Lu, W.S. A decision-support framework for planning construction waste recycling: A case study of Shenzhen, China. J. Clean. Prod. 2021, 309, 127499. [Google Scholar] [CrossRef]

- Wang, J.G.; Zhang, J.X.; Cao, D.; Ding, H.X. Comparison of recycled aggregate treatment methods on the performance for recycled concrete. Constr. Build. Mater. 2020, 234, 117366. [Google Scholar] [CrossRef]

- Kou, S.C.; Poon, C.S.; Agrela, F. Comparisons of natural and recycled aggregate concretes prepared with the addition of different mineral admixtures. Cem. Concr. Compos. 2011, 33, 788–795. [Google Scholar] [CrossRef]

- Silva, S.; Evangelista, L.; Brito, J.D. Durability and shrinkage performance of concrete made with coarse multi-recycled concrete aggregates. Constr. Build. Mater. 2020, 272, 121645. [Google Scholar] [CrossRef]

- Zhu, P.H.; Hao, Y.L.; Hui, L.; Wang, X.J.; Gu, L. Durability evaluation of recycled aggregate concrete in a complex environment. J. Clean. Prod. 2020, 273, 122569. [Google Scholar] [CrossRef]

- Xuan, D.X.; Zhan, B.J.; Poon, C.S. Durability of recycled aggregate concrete prepared with carbonated recycled concrete aggregates. Cem. Concr. Compos. 2017, 84, 214–221. [Google Scholar] [CrossRef]

- Bravo, M.; Brito, J.D.; Pontes, J.; Evangelista, L. Durability performance of concrete with recycled aggregates from construction and demolition waste plants. Constr. Build. Mater. 2015, 77, 357–369. [Google Scholar] [CrossRef]

- Poon, C.S.; Shui, Z.H.; Lam, L. Effect of microstructure of ITZ on compressive strength of concrete prepared with recycled aggregates. Constr. Build. Mater. 2004, 18, 461–468. [Google Scholar] [CrossRef]

- Kazmi, S.M.; Munir, M.J.; Wu, Y.F.; Patnaikuni, I.; Zhou, Y.W.; Xing, F. Effect of recycled aggregate treatment techniques on the durability of concrete: A comparative evaluation. Constr. Build. Mater. 2020, 264, 120284. [Google Scholar] [CrossRef]

- Djerbi, A. Effect of recycled coarse aggregate on the new interfacial transition zone concrete. Constr. Build. Mater. 2018, 190, 1023–1033. [Google Scholar] [CrossRef]

- Cuesta, V.R.; Evangelista, L.; Brito, J.D.; López, V.O.; Manso, J.M. Effect of the maturity of recycled aggregates on the mechanical properties and autogenous and drying shrinkage of high-performance concrete. Constr. Build. Mater. 2021, 299, 124001. [Google Scholar] [CrossRef]

- Duan, Z.H.; Poon, C.S. Properties recycled aggregate concrete made with recycled aggregates with different amounts of old adhered mortars. Mater. Des. 2014, 58, 19–29. [Google Scholar] [CrossRef]

- Xiao, J.Z.; Li, W.G.; Sun, Z.H.; Lange, D.A.; Shah, S.P. Properties of interfacial transition zones in recycled aggregate concrete tested by nanoindentation. Cem. Concr. Compos. 2013, 37, 276–292. [Google Scholar] [CrossRef]

- Xiao, Q.H.; Zhi, Y.C.; Guan, X.; Li, Q.; Liu, X.L. Damage to recycled concrete with different aggregate substitution rates from the coupled action of freeze-thaw cycles and sulfate attack. Constr. Build. Mater. 2019, 221, 74–83. [Google Scholar] [CrossRef]

- Bhat, J.A. Effect of strength of parent concrete on the mechanical properties of recycled aggregate concrete. Mater. Today Proc. 2021, 42, 1462–1469. [Google Scholar] [CrossRef]

- Shi, C.J.; Chao, Z.J.; Xie, Z.B. Research progress in the mechanical properties of recycled aggregate concrete. Mater. Rep. 2016, 30, 96–126. (In Chinese) [Google Scholar]

- Akbarnezhad, A.; Ong, K.C.; Tam, C.T.; Zhang, M.H. Effects of the Parent Concrete Properties and Crushing Procedure on the Properties of Coarse Recycled Concrete Aggregates. J. Mater. Civ. Eng. 2013, 25, 1795–1802. [Google Scholar] [CrossRef]

- Abbas, A.; Fathifazl, G.; Fournier, B.; Isgor, B.O.; Zavadil, R.; Razaqpur, A.G.; Foo, S. Quantification of the residual mortar content in recycled concrete aggregates by image analysis. Mater. Charact. 2009, 60, 716–728. [Google Scholar] [CrossRef]

- Juan, M.S.; Gutiérrez, P.A. Study on the influence of attached mortar content on the properties of recycled concrete aggregate. Constr. Build. Mater. 2008, 23, 872–877. [Google Scholar] [CrossRef]

- Gokce, A.; Nagataki, S.; Saeki, T.; Hisada, M. Identification of frost-susceptible recycled concrete aggregates for durability of concrete. Constr. Build. Mater. 2011, 25, 2426–2431. [Google Scholar] [CrossRef]

- Otsuki, N.; Miyazato, S.I.; Yodsudjai, W.C. Influence of Recycled Aggregate on Interfacial Transition Zone, Strength, Chloride Penetration and Carbonation of Concrete. J. Mater. Civ. Eng. 2003, 15, 443–451. [Google Scholar] [CrossRef]

- Afshar, T.; Disfani, M.; Arulrajah, A.; Narsilio, G.A.; Emam, S. Impact of particle shape on breakage of recycled construction and demolition aggregates. Powder Technol. 2017, 308, 1–12. [Google Scholar] [CrossRef]

- Yang, J.H.; Fang, B.; Gao, T.F.; Yu, J.Y. Influence of ceramsite pore on performance of concrete strength and chloride ion permeability resistance. Nat. Sci. 2022, 41, 149–155. (In Chinese) [Google Scholar]

- Zhang, G.Z.; Wei, Q.; Ding, Q.J.; Zhang, X.J. Influence of water absorption ratio of lightweight aggregate on characteristics of interfacial transition zone between lightweight aggregate and cement. J. Build. Mater. 2018, 21, 720–724. (In Chinese) [Google Scholar]

- Poon, C.S.; Shui, Z.H.; Lam, L.; Fok, H.; Kou, S.C. Influence of moisture states of natural and recycled aggregates on the slump and compressive strength of concrete. Cem. Concr. Res. 2004, 34, 31–36. [Google Scholar] [CrossRef]

- Brand, A.S.; Roesler, J.R.; Salas, A. Initial moisture and mixing effects on higher quality recycled coarse aggregate concrete. Constr. Build. Mater. 2015, 79, 83–89. [Google Scholar] [CrossRef]

- Cheng, Z.Y.; Li, J.F.; Chen, X.Y.; Xu, X.; Tian, Y.; Tu, Y.P. Influence of water content of aggregate on properties of fly ash recycled concrete. J. Wuhan Inst. Technol. 2021, 43, 534–556. (In Chinese) [Google Scholar]

- Mefteh, H.; Kebaïli, O.; Oucief, H.; Berredjem, L.; Arabi, N. Influence of moisture conditioning of recycled aggregates on the properties of fresh and hardened concrete. J. Clean. Prod. 2013, 54, 282–288. [Google Scholar] [CrossRef]

- Tran, D.L.; Mouret, M.; Cassagnabère, F. Impact of the porosity and moisture state of coarse aggregates, and binder nature on the structure of the paste-aggregate interface: Elementary model study. Constr. Build. Mater. 2022, 319, 126112. [Google Scholar] [CrossRef]

- Xu, F.M.; Lin, X.S.; Zhou, A.; Liu, Q.F. Effects of recycled ceramic aggregates on internal curing of high performance concrete. Constr. Build. Mater. 2022, 322, 126484. [Google Scholar] [CrossRef]

- Ge, Z.; Feng, Y.J.; Zhang, H.Z.; Xiao, J.Z.; Sun, R.J.; Liu, X.Y. Use of recycled fine clay brick aggregate as internal curing agent for low water to cement ratio mortar. Constr. Build. Mater. 2020, 264, 120280. [Google Scholar] [CrossRef]

- GB/T 50080; Standard for Test Method of Performance on Ordinary Fresh Concrete. National Standards of the People’s Republic of China: Beijing, China, 2016. (In Chinese)

- GB/T 50081; Standard for Test Method of Concrete Physical and Mechanical Properties. National Standards of the People’s Republic of China: Beijing, China, 2019. (In Chinese)

- ASTM C1585; Standard Test Method for Measurement of Rate of Absorption of Water by Hydraulic-Cement Concretes. ASTM International: West Conshohocken, PA, USA, 2013. (In Chinese)

- GB/T 50082; Standard for Test Methods of Long-Term Performance and Durability of Ordinary Concrete. National Standards of the People’s Republic of China: Beijing, China, 2009. (In Chinese)

- Andreu, G.; Miren, E. Experimental analysis of properties of high performance recycled aggregate concrete. Constr. Build. Mater. 2014, 52, 227–235. [Google Scholar] [CrossRef]

- Sajan, K.C.; Adhikari, R.; Mandal, B.; Gautam, D. Mechanical characterization of recycled concrete under various aggregate replacement scenarios. Clean. Eng. Technol. 2022, 7, 100428. [Google Scholar] [CrossRef]

- Etxeberria, M.; Vázquez, E.; Marí, A.; Barra, M. Influence of amount of recycled coarse aggregates and production process on properties of recycled aggregate concrete. Cem. Concr. Res. 2007, 37, 735–742. [Google Scholar] [CrossRef]

- Ma, K.; Huang, X.Y.; Shen, J.T.; Hu, M.W.; Long, G.C.; Xie, Y.J.; Zeng, X.H.; Xu, Z.J.; Zhang, W.Z. The morphological characteristics of brick-concrete recycled coarse aggregate based on the digital image processing technique. J. Build. Eng. 2021, 44, 103292. [Google Scholar] [CrossRef]

- Montero, J.; Laserna, S. Influence of effective mixing water in recycled concrete. Constr. Build. Mater. 2017, 132, 343–352. [Google Scholar] [CrossRef]

- Beushausen, H.; Höhlig, B.; Talotti, M. The influence of substrate moisture preparation on bond strength of concrete over lays and the microstructure of the OTZ. Cem. Concr. Res. 2017, 92, 84–91. [Google Scholar] [CrossRef]

- Nagataki, S.; Gokce, A.; Saeki, T. Assessment of recycling process induced damage sensitivity of recycled concrete aggregates. Cem. Concr. Res. 2004, 34, 965–971. [Google Scholar] [CrossRef]

- Le, T.; Saout, G.L.; Diaz, E.G.; Betrancourt, D.; Rémond, S. Hardened behavior of mortar based on recycled aggregate: Influence of saturation state at macro- and microscopic scales. Constr. Build. Mater. 2017, 141, 479–490. [Google Scholar] [CrossRef] [Green Version]

| Material | CaO | SiO2 | Al2O3 | Fe2O3 | MgO | Na2O | SO3 |

|---|---|---|---|---|---|---|---|

| Cement | 69.00 | 17.90 | 3.92 | 3.42 | 0.79 | 0.12 | 3.43 |

| Fly ash | 4.28 | 51.17 | 32.12 | 5.25 | 0.95 | 0.50 | 0.91 |

| Bulk Density (kg/m3) | Apparent Density (kg/m3) | Void Absorption% | Water Absorption% | Crush Index % | |

|---|---|---|---|---|---|

| NA | 1580 | 2740 | 42.3 | 0.38 | 6.13 |

| RA | 1210 | 2570 | 52.9 | 9.75 | 15.27 |

| Water | Cement | Fly Ash | Natural Aggregate | Fine Aggregate | Recycled Aggregate | Prewetting Water | SP | |

|---|---|---|---|---|---|---|---|---|

| AD | 198 | 352 | 88 | 532 | 820 | 468 | 0(AD) | 0.44 |

| W50 | 198 | 352 | 88 | 532 | 820 | 468 | 3.60 | 0 |

| W55 | 198 | 352 | 88 | 532 | 820 | 468 | 5.09 | 0 |

| W60 | 198 | 352 | 88 | 532 | 820 | 468 | 6.58 | 0 |

| W65 | 198 | 352 | 88 | 532 | 820 | 468 | 8.07 | 0 |

| W75 | 198 | 352 | 88 | 532 | 820 | 468 | 11.04 | 0 |

| W100 | 198 | 352 | 88 | 532 | 820 | 468 | 29.76(SSD) | 0 |

| AD | W50 | W55 | W60 | W65 | W75 | W100 | |

|---|---|---|---|---|---|---|---|

| NA-NM | 49.6–51.4 | 45.7–52.3 | 47.8–51.3 | 46.7–52.3 | 49.8–52.2 | 47.6–52.3 | 49.1–52.2 |

| RA-NM | 33.4–45.8 | 59.8–82.7 | 42.7–69.1 | 42.9–72.3 | 45.7–64.3 | 33.5–44.4 | 33.3–42.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, D.; Huang, W.; Liu, K.; Ma, R.; Wang, A.; Guan, Y.; Shen, S. Effect of the Moisture Content of Recycled Aggregate on the Mechanical Performance and Durability of Concrete. Materials 2022, 15, 6299. https://doi.org/10.3390/ma15186299

Sun D, Huang W, Liu K, Ma R, Wang A, Guan Y, Shen S. Effect of the Moisture Content of Recycled Aggregate on the Mechanical Performance and Durability of Concrete. Materials. 2022; 15(18):6299. https://doi.org/10.3390/ma15186299

Chicago/Turabian StyleSun, Daosheng, Wei Huang, Kaiwei Liu, Rui Ma, Aiguo Wang, Yanmei Guan, and Shansan Shen. 2022. "Effect of the Moisture Content of Recycled Aggregate on the Mechanical Performance and Durability of Concrete" Materials 15, no. 18: 6299. https://doi.org/10.3390/ma15186299

APA StyleSun, D., Huang, W., Liu, K., Ma, R., Wang, A., Guan, Y., & Shen, S. (2022). Effect of the Moisture Content of Recycled Aggregate on the Mechanical Performance and Durability of Concrete. Materials, 15(18), 6299. https://doi.org/10.3390/ma15186299