Dynamic Compressive Mechanical Properties of UR50 Ultra-Early-Strength Cement-Based Concrete Material under High Strain Rate on SHPB Test

Abstract

:1. Introduction

2. UR50 Ultra-Early-Strength Concrete Material

3. Dynamic Test with SHPB

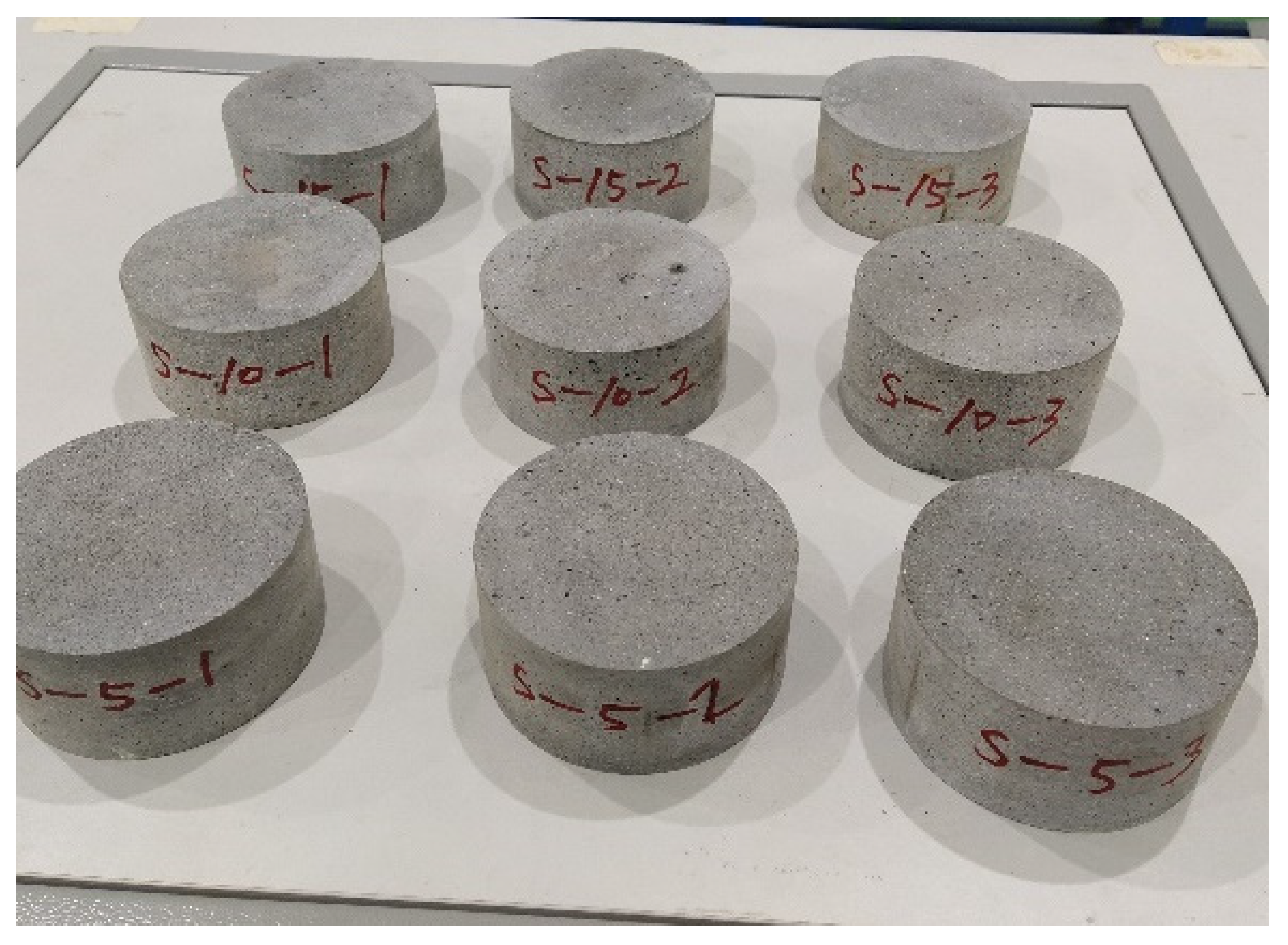

3.1. Experimental Specimen

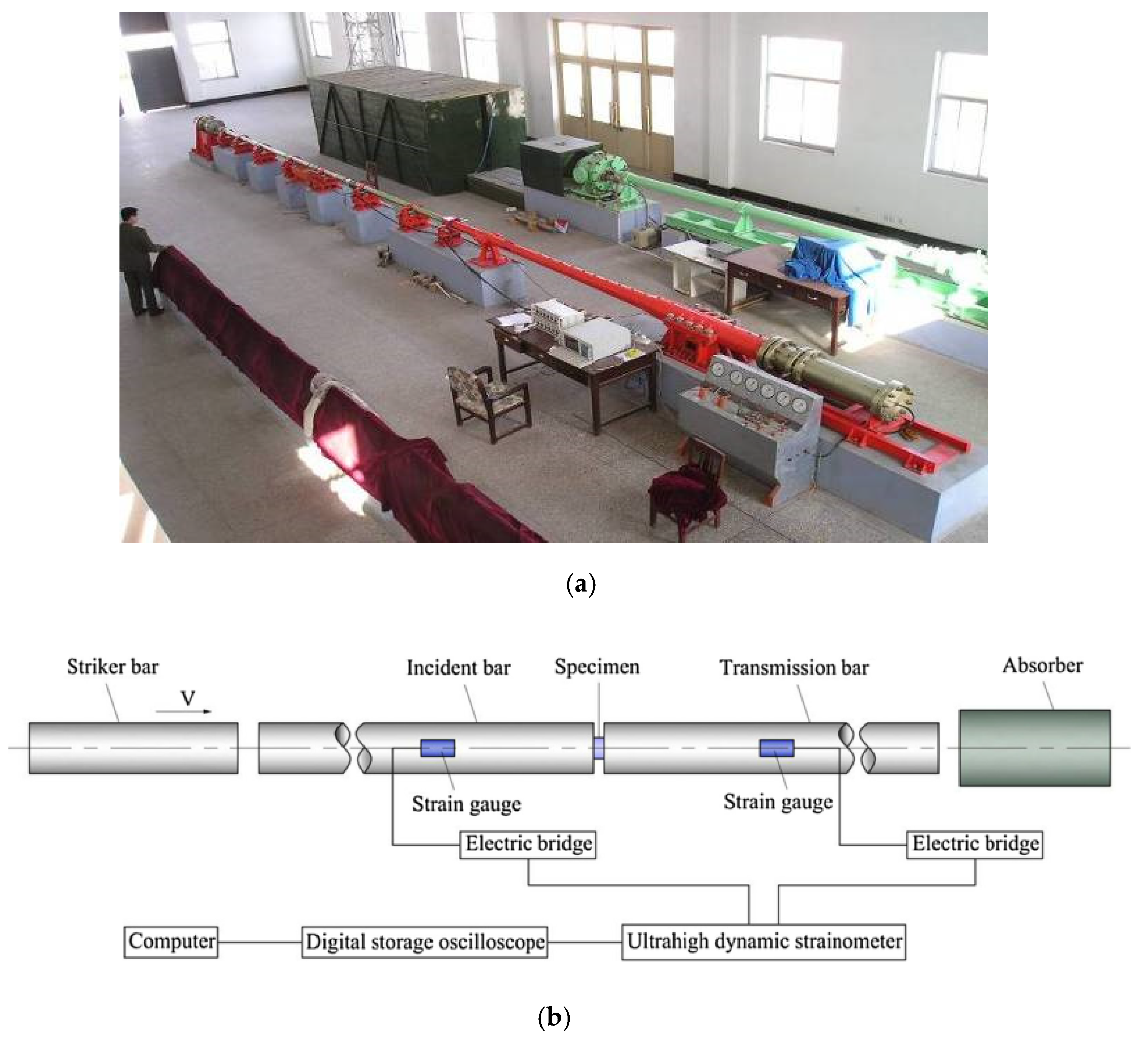

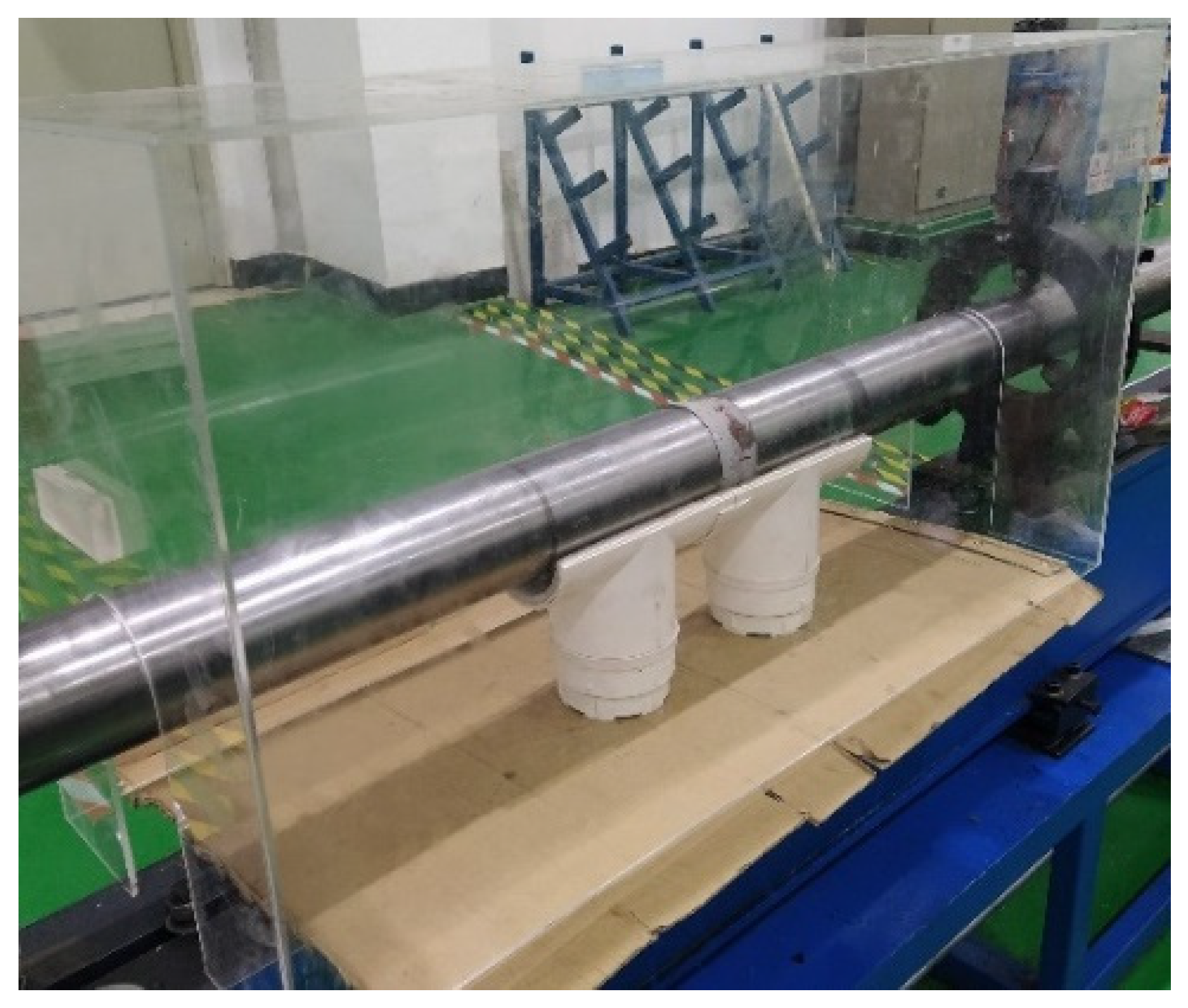

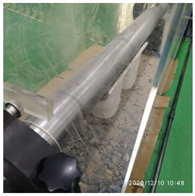

3.2. Experimental Device

3.3. Experimental Design

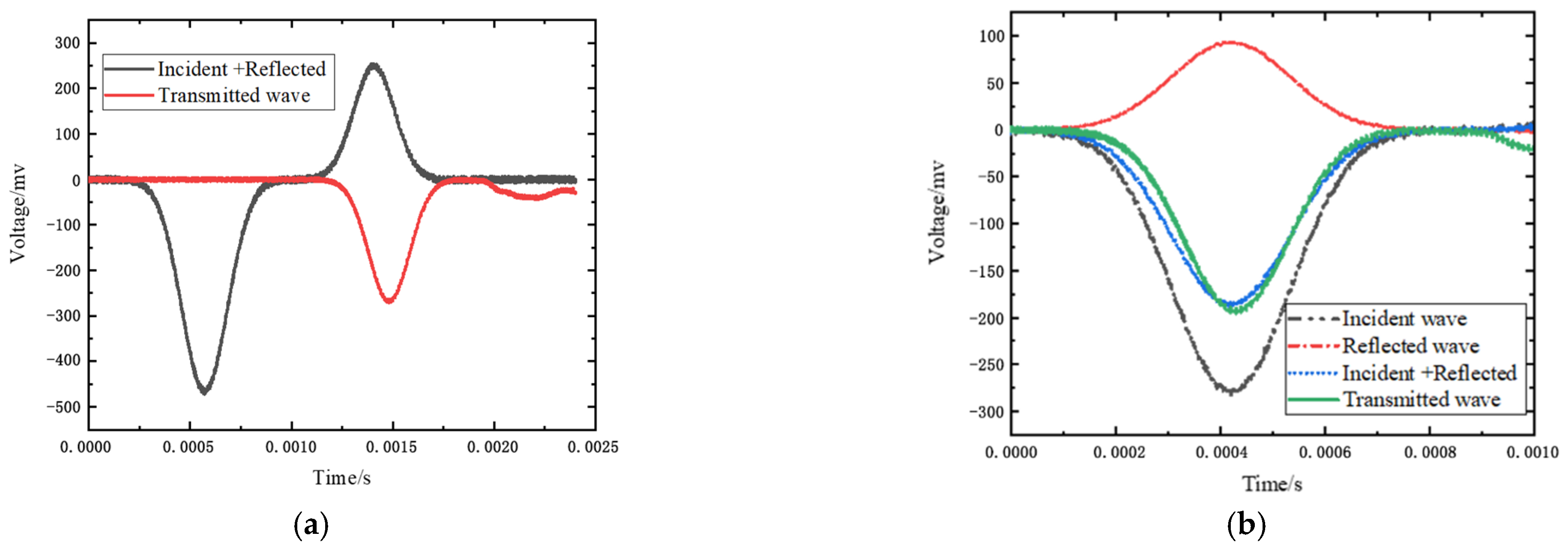

3.4. Calibration of SHPB

4. Test Results

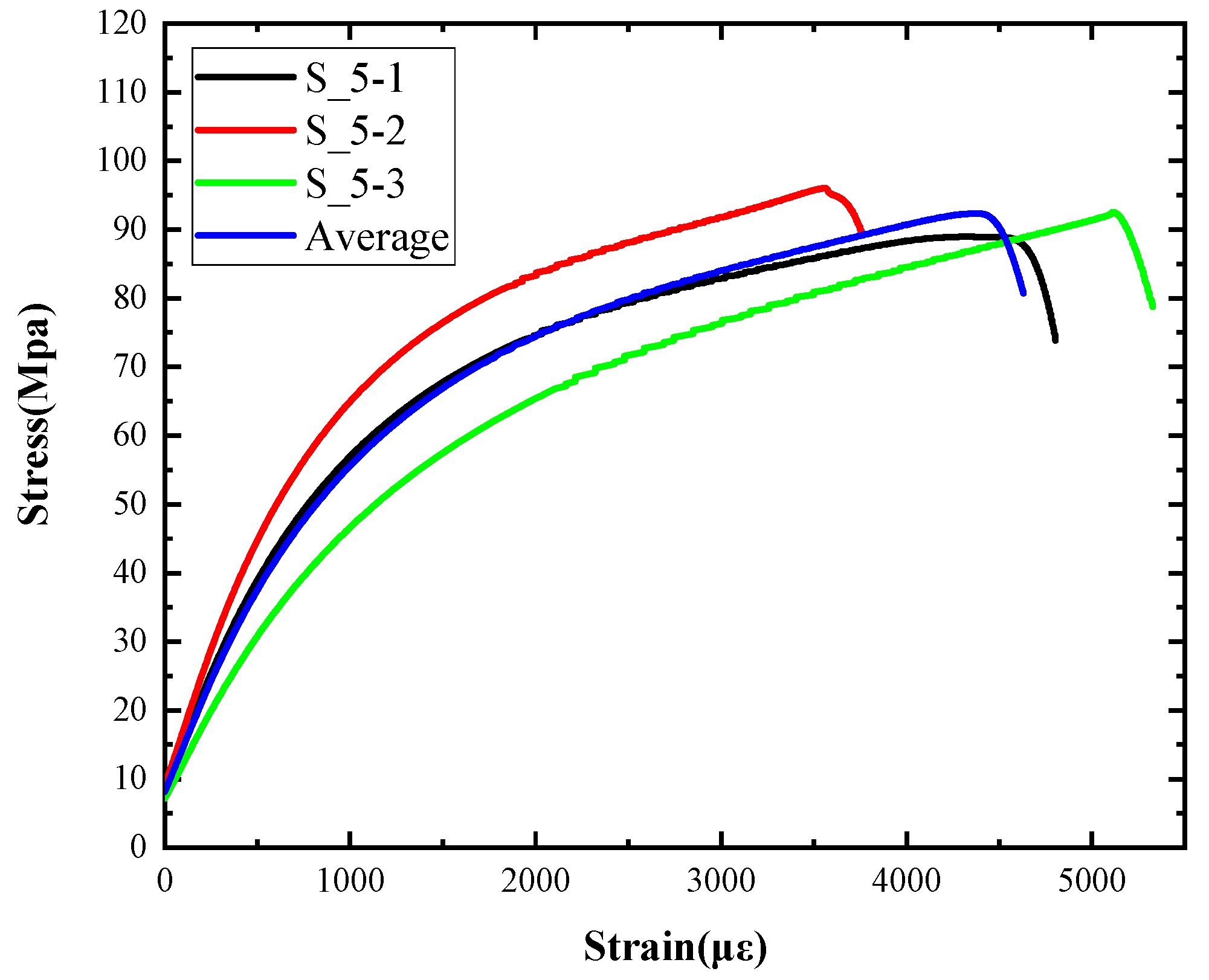

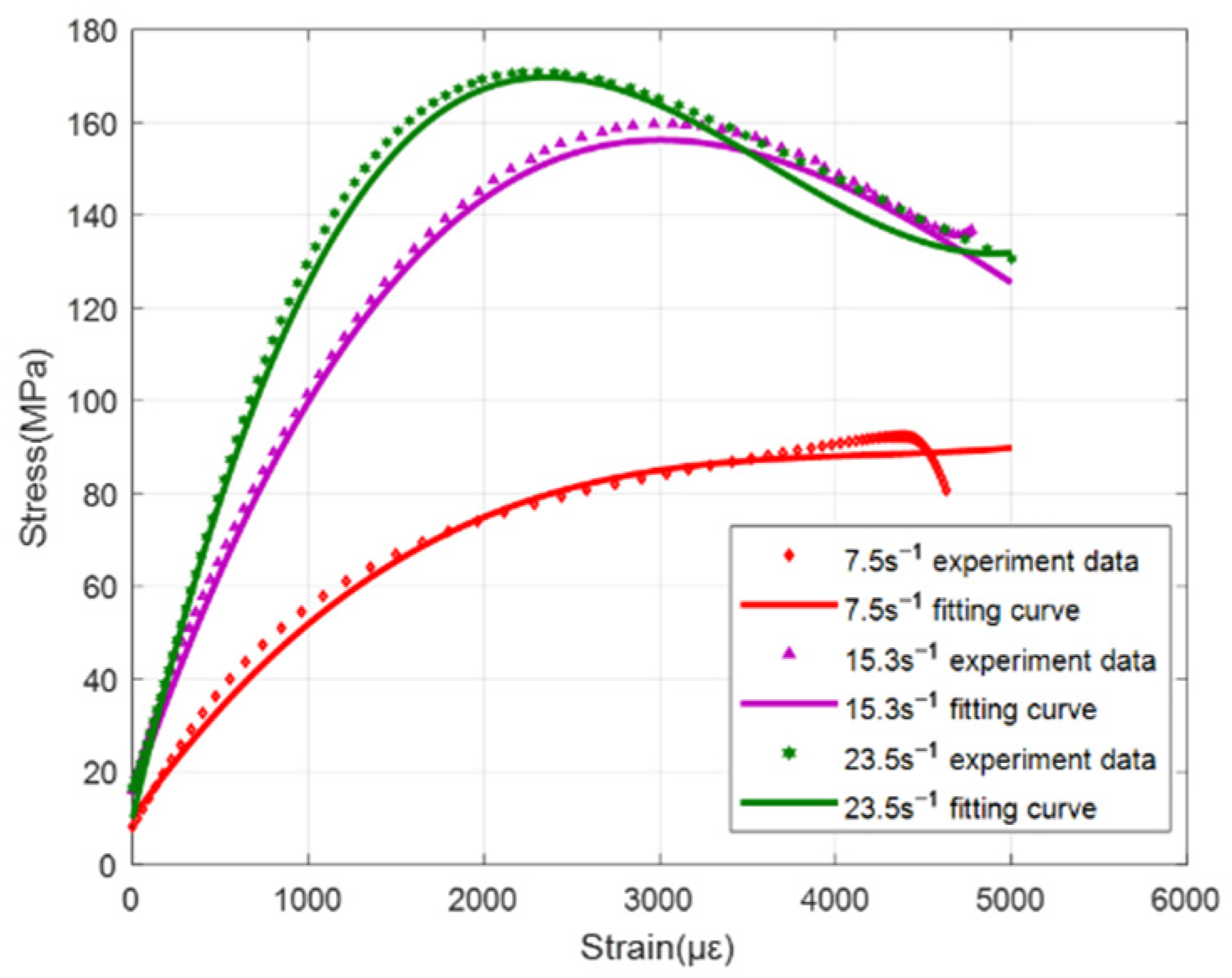

4.1. Average Strain Rate of 7.5 s−1

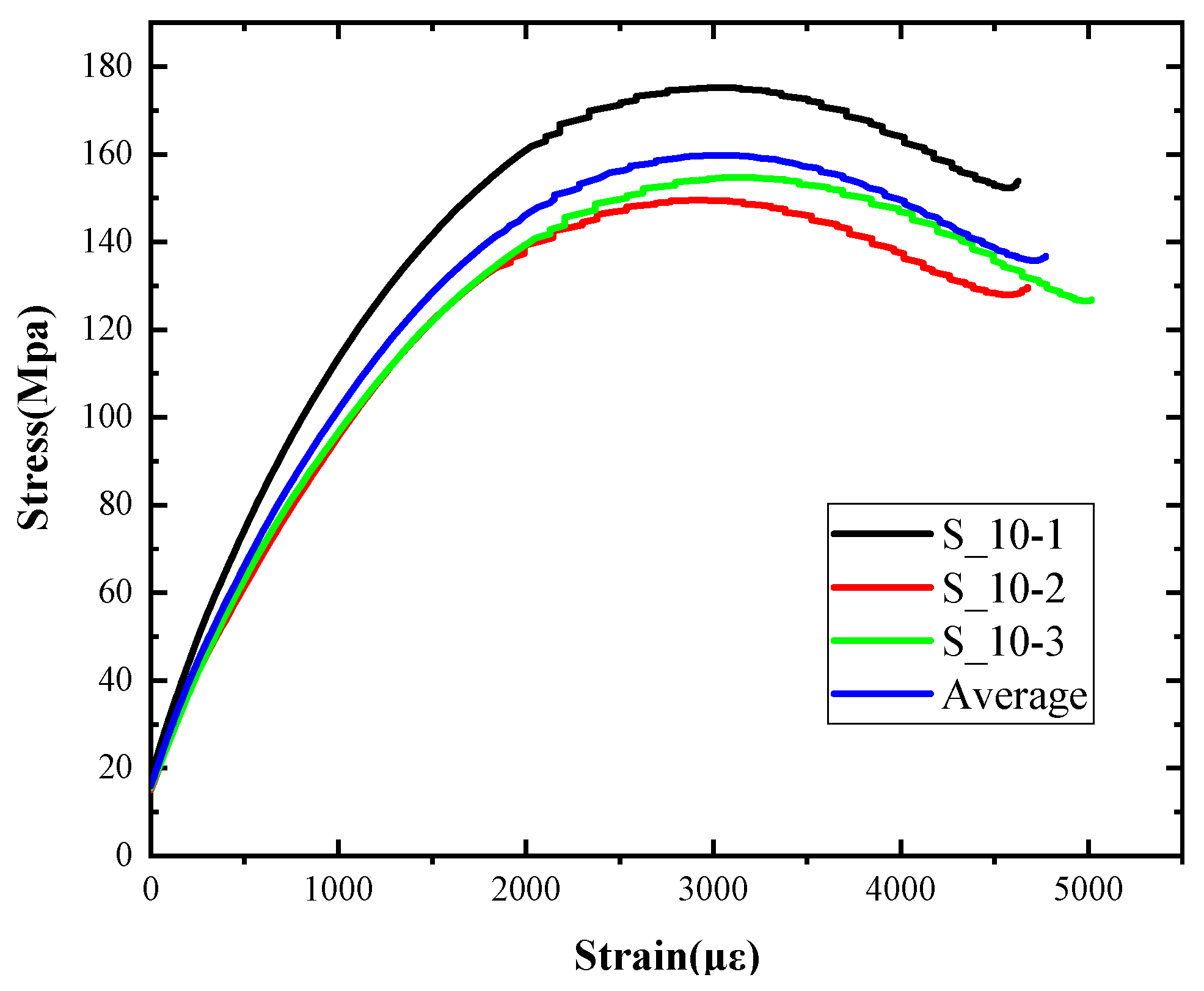

4.2. Average Strain Rate of 15.3 s−1

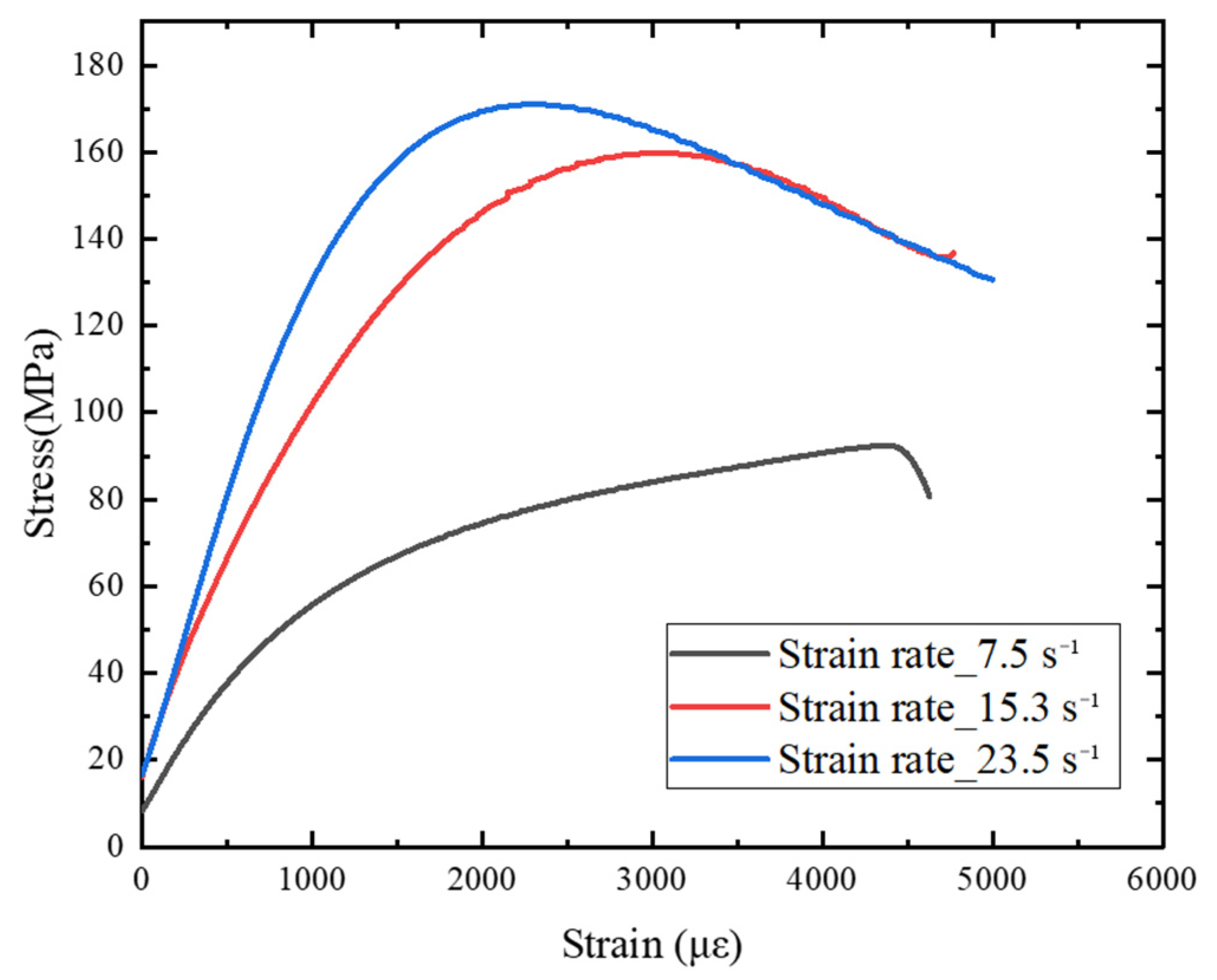

4.3. Average Strain Rate of 23.5 s−1

5. Discussion

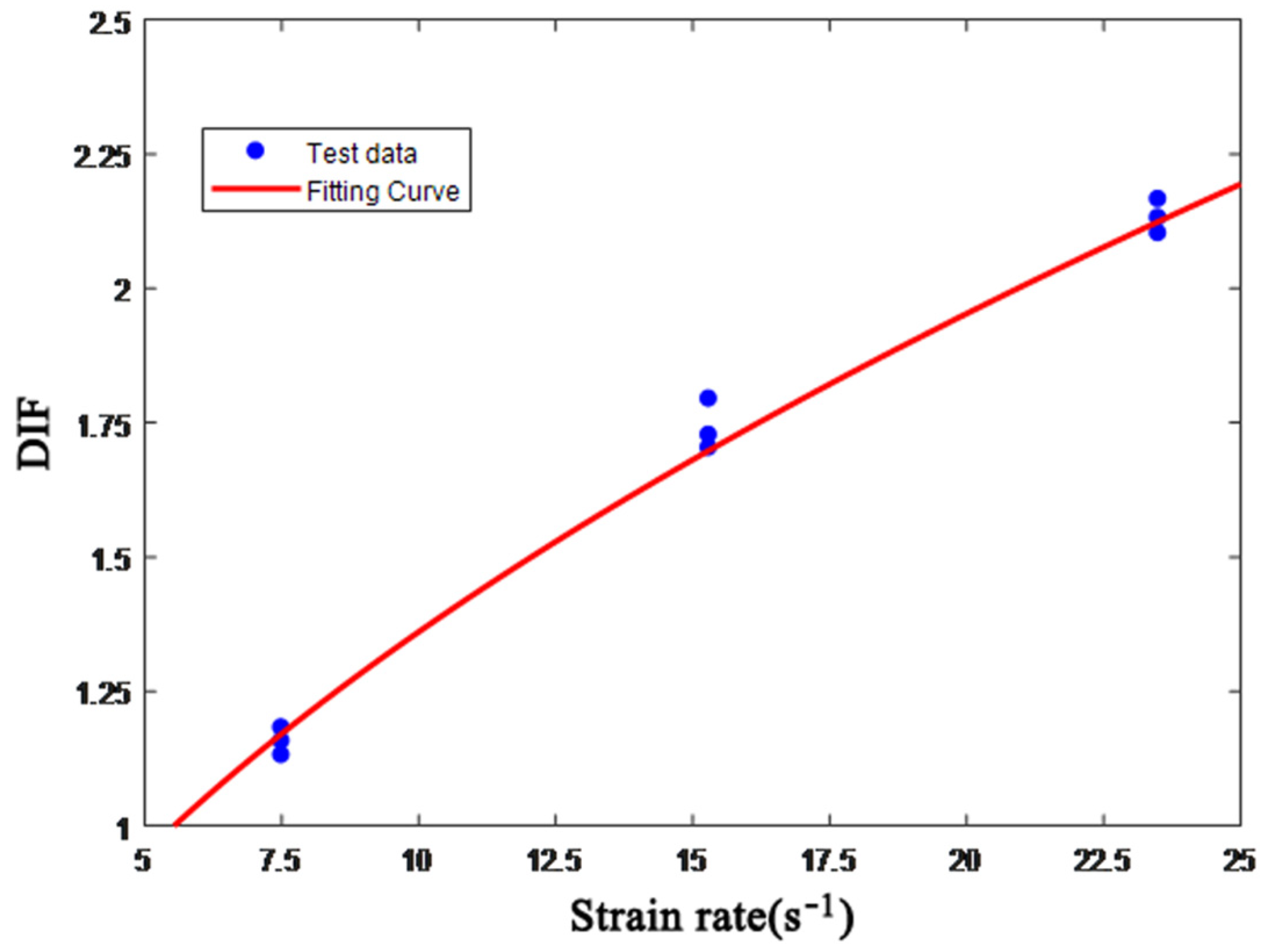

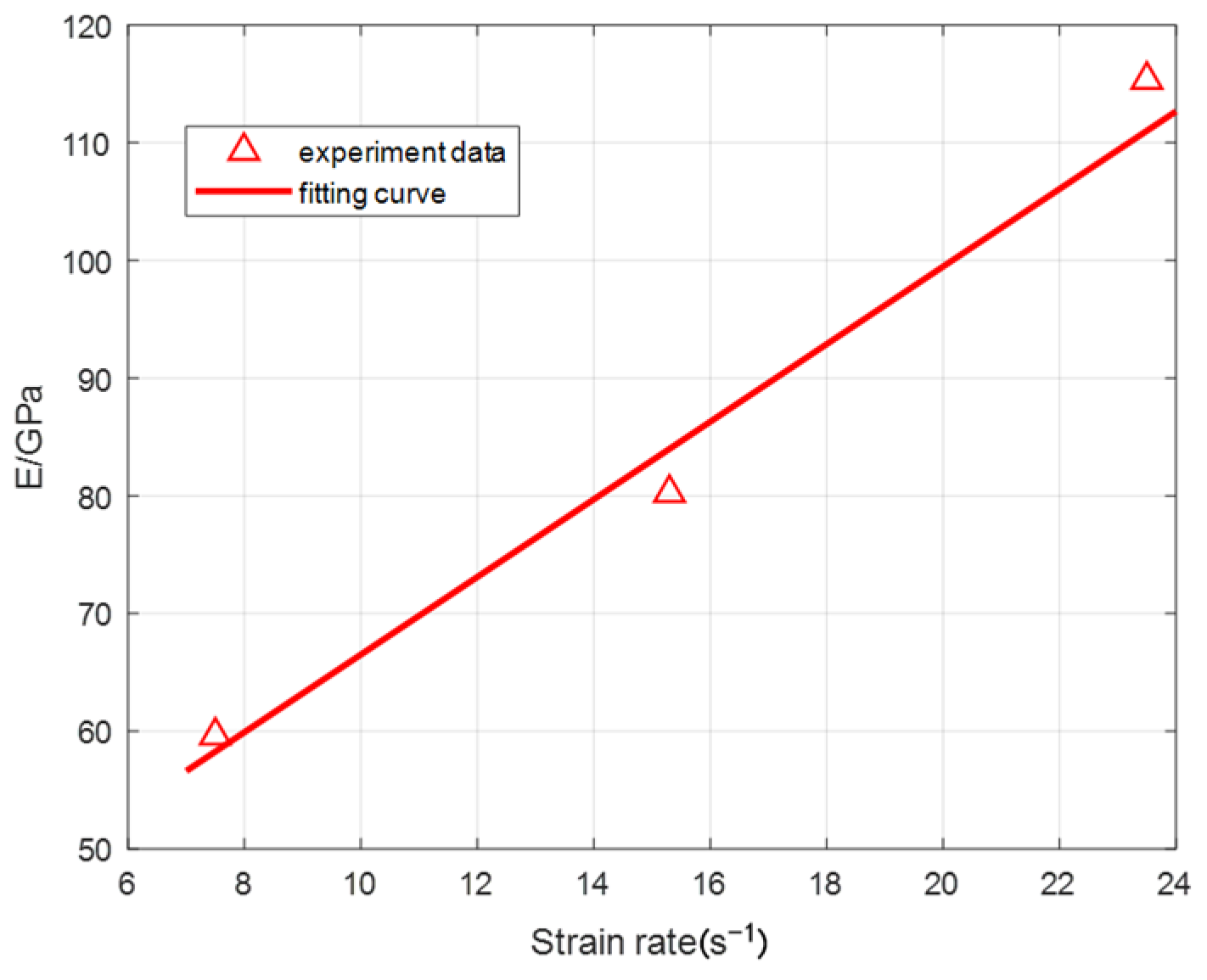

5.1. Strain Rate Effect and Analysis of Compressive Strength

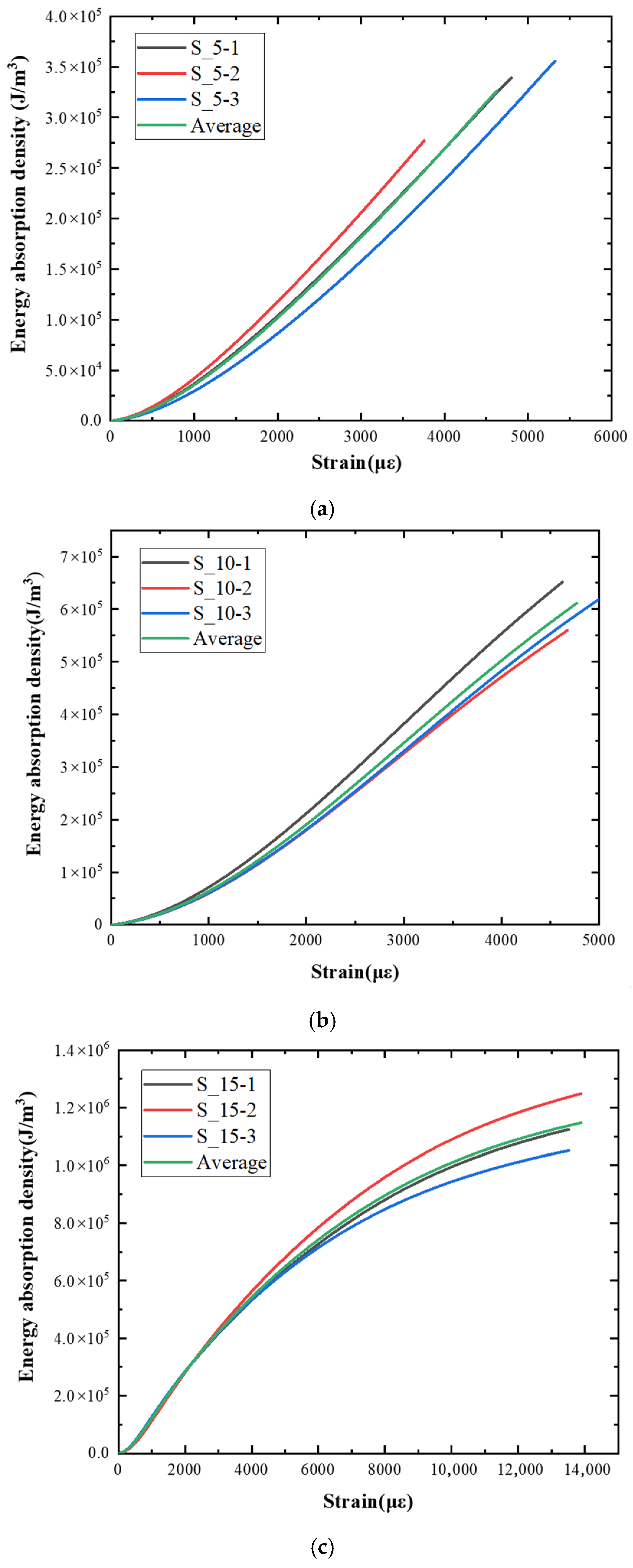

5.2. Energy Absorption Density Analysis

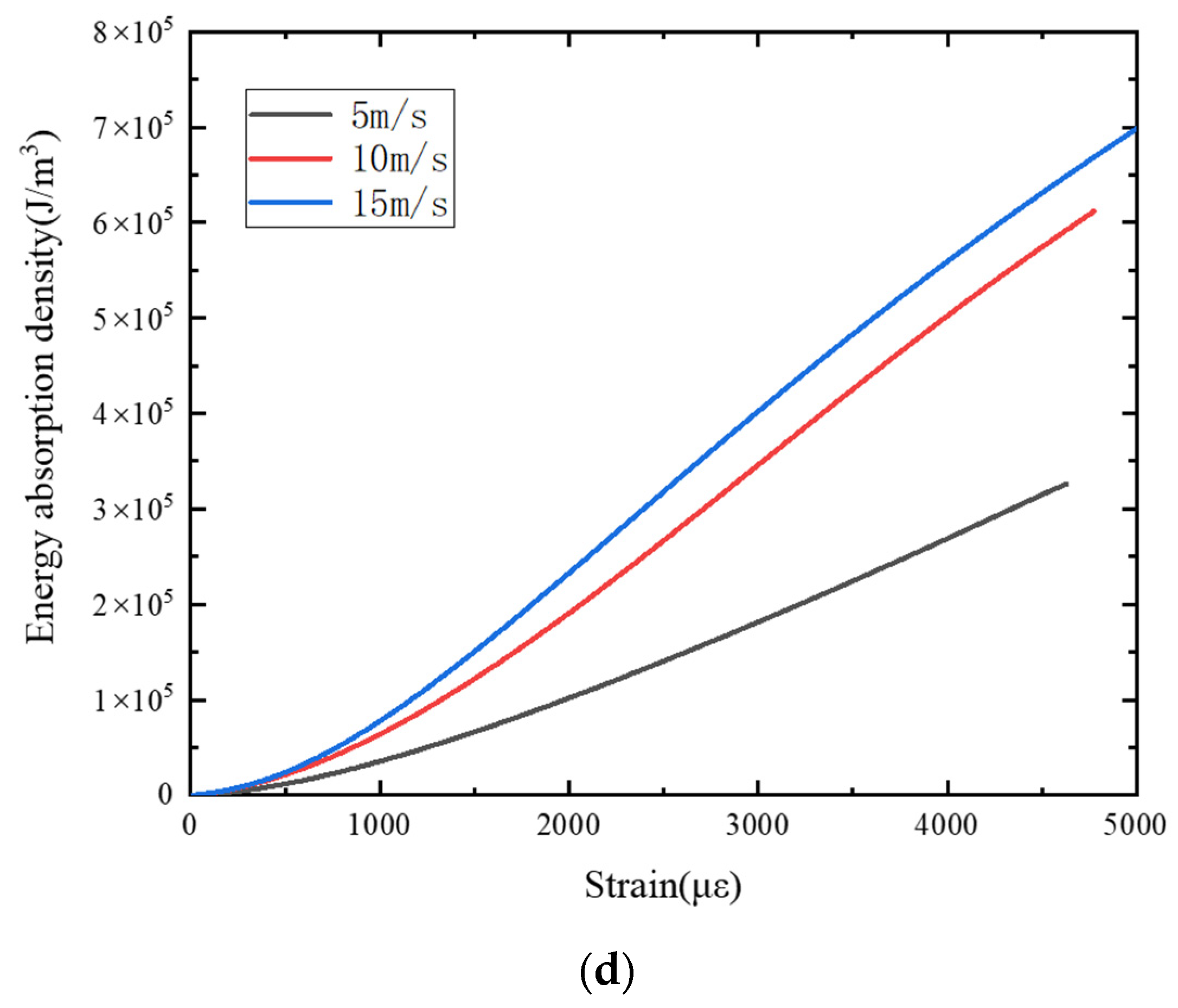

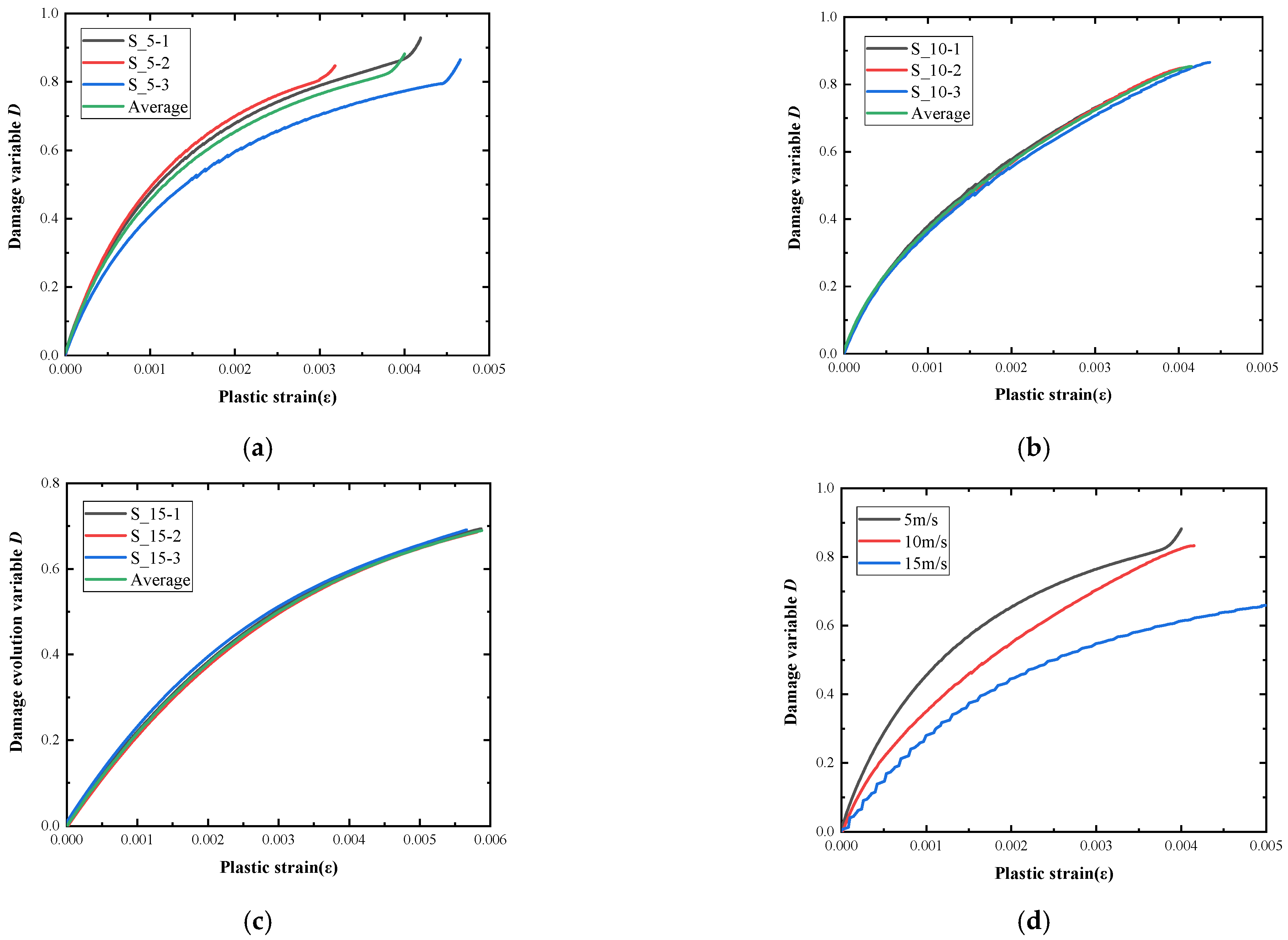

5.3. Damage Evolution Process Analysis

6. Conclusions

- (1)

- Under different loading conditions, different types of copper sheets were selected as the shaper to eliminate the dispersion effect. Under the same impact velocity, the stress–strain curves of the three specimens are in good agreement, which ensures the validity and reliability of the experimental results;

- (2)

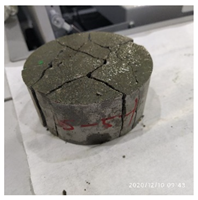

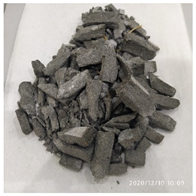

- The compression brittleness of ultra-early-strength cement-based specimens is relatively large, and the failure mode is a mainly brittle fracture, and with the increase of loading speed, the failure mode of the specimens gradually transited from larger fragments to small fragments, with an eventual large amount of powder;

- (3)

- The dynamic compressive strength of ultra-early-strength cement-based materials increases with the increase of the strain rate, which has an obvious strain rate strengthening effect. Fitting determines the relationship curve between the dynamic increase factor, DIF, and the strain rate. It has a linear relationship with the logarithm of the strain rate. The higher the strain rate, the larger the DIF, indicating that it has the advantage of impact-resistant mechanical properties;

- (4)

- The concept of absorption density is introduced to facilitate a better understanding of the toughness of ultra-early-strength cement-based materials. As the impact velocity increases, the peak stress rises, the energy absorption density value increases, and its growth rate accelerates. The peak strain at an impact velocity of 15 m/s is lower than that of low-speed impact (5 m/s and 10 m/s);

- (5)

- Based on the theory and method of continuum mechanics, the evolution process of the damage variables of ultra-early-strength cement-based materials was analyzed from a macro perspective. The damage variable equations at different strain rates were fitted according to the test results and based on the stress–strain curve, and the rationality of the damage evolution process was proved. With the increase in strain rate, the internal crack propagation of the specimen is hindered, and the increase rate of the damage variable decreases. Under the same plastic strain, the damage variable of the specimen under the high strain rate is relatively small.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hong, J.; Fang, Q.; Chen, L.; Kong, X. Numerical predictions of concrete slabs under contact explosion by modified K&C material model. Constr. Build. Mater. 2017, 155, 1013–1024. [Google Scholar]

- Tai, Y.; Chu, T.; Hu, H.; Wu, J. Dynamic response of a reinforced concrete slab subjected to air blast load. Theor. Appl. Fract. Mech. 2011, 56, 140–147. [Google Scholar] [CrossRef]

- Zhou, X.; Kuznetsov, V.; Hao, H.; Waschl, J. Numerical prediction of concrete slab response to blast loading. Int. J. Impact Eng. 2008, 35, 1186–1200. [Google Scholar] [CrossRef]

- Pang, B.J.; Wang, L.W.; Yang, Z.Q. The effect on dynamic properties of reactive powder concrete under high temperature burnt and its micro-structure analysis. Key Eng. Mater. 2010, 452, 109–112. [Google Scholar] [CrossRef]

- Hu, S.S.; Zhang, L.; Wu, H.J.; Wu, X.T. Experimental Study on Spalling Strength of Concrete Materials. Eng. Mech. 2004, 21, 128–132. [Google Scholar]

- Zhu, J.; Hu, S.; Wang, L. An analysis of stress uniformity for concrete-like specimens during SHPB tests. Int. J. Impact Eng. 2009, 36, 61–72. [Google Scholar] [CrossRef]

- Bragov, A.M.; Konstantinov, A.Y.; Lamzin, D.A.; Lomunov, A.K.; Gonov, M.E. Determination of the mechanical properties of concrete using the split Hopkinson pressure bar method. Procedia Struct. Integr. 2020, 28, 2174–2180. [Google Scholar] [CrossRef]

- Levi-Hevroni, D.; Kochavi, E.; Kofman, B.; Gruntman, S.; Sadot, O. Experimental and numerical investigation on the dynamic increase factor of tensile strength in concrete. Int. J. Impact Eng. 2018, 114, 93–104. [Google Scholar] [CrossRef]

- Zhang, M.; Wu, H.J.; Li, Q.M.; Huang, F.L. Further investigation on the dynamic compressive strength enhancement of concrete-like materials based on split Hopkinson pressure bar tests. Part I: Experiments. Int. J. Impact Eng. 2009, 36, 1327–1334. [Google Scholar] [CrossRef]

- Wang, G.; Lu, D.; Li, M.; Zhou, X.; Wang, J.; Du, X. Static–Dynamic Combined Multiaxial Strength Criterion for Concrete. J. Eng. Mech. 2021, 147, 04021017. [Google Scholar] [CrossRef]

- Gu, X.; Zhang, Q.; Huang, D.; Yv, Y. Wave dispersion analysis and simulation method for concrete SHPB test in peridynamics. Eng. Fract. Mech. 2016, 160, 124–137. [Google Scholar] [CrossRef]

- Hassan, M.; Wille, K. Experimental impact analysis on ultra-high performance concrete (UHPC) for achieving stress equilibrium (SE) and constant strain rate (CSR) in Split Hopkinson pressure bar (SHPB) using pulse shaping technique. Constr. Build. Mater. 2017, 144, 747–757. [Google Scholar] [CrossRef]

- Erzar, B.; Forquin, P. Experiments and mesoscopic modelling of dynamic testing of concrete. Mech. Mater. 2011, 43, 505–527. [Google Scholar] [CrossRef]

- Wang, B.; Chen, Y.; Fan, H.; Jin, F. Investigation of low-velocity impact behaviors of foamed concrete material. Compos. Part B Eng. 2019, 162, 491–499. [Google Scholar] [CrossRef]

- Kang, J. Composite and non-composite behaviors of foam-insulated concrete sandwich panels. Compos. Part B Eng. 2015, 68, 153–161. [Google Scholar] [CrossRef]

- Wang, X.; Liu, L.; Zhou, H.; Song, T.; Qiao, Q.; Zhang, H. Improving the compressive performance of foam concrete with ceramsite: Experimental and meso-scale numerical investigation. Mater. Des. 2021, 208, 109938. [Google Scholar] [CrossRef]

- Shafigh, P.; Jumaat, M.Z.; Mahmud, H.B.; Alengaram, U.J. A new method of producing high strength oil palm shell lightweight concrete. Mater. Des. 2011, 32, 4839–4843. [Google Scholar] [CrossRef]

- Cao, S.; Hou, X.; Rong, Q.; Zheng, W.; Abid, M.; Li, G. Effect of specimen size on dynamic compressive properties of fiber-reinforced reactive powder concrete at high strain rates. Constr. Build. Mater. 2019, 194, 71–82. [Google Scholar] [CrossRef]

- Xiong, B.; Demartino, C.; Xiao, Y. High-strain rate compressive behavior of CFRP confined concrete: Large diameter SHPB tests. Constr. Build. Mater. 2019, 201, 484–501. [Google Scholar] [CrossRef]

- Liu, G.-J.; Bai, E.-L.; Xu, J.-Y.; Yang, N.; Wang, T.-J. Dynamic compressive mechanical properties of carbon fiber-reinforced polymer concrete with different polymer-cement ratios at high strain rates. Constr. Build. Mater. 2020, 261, 119995. [Google Scholar] [CrossRef]

- Wei, Y.; Lu, Z.; Hu, K.; Li, X.; Li, P. Dynamic response of ceramic shell for titanium investment casting under high strain-rate SHPB compression load. Ceram. Int. 2018, 44, 11702–11710. [Google Scholar] [CrossRef]

- Sun, X.; Zhao, K.; Li, Y.; Huang, R.; Ye, Z.; Zhang, Y.; Ma, J. A study of strain-rate effect and fiber reinforcement effect on dynamic behavior of steel fiber-reinforced concrete. Constr. Build. Mater. 2018, 158, 657–669. [Google Scholar] [CrossRef]

- Scott, B.D.; Park, R.; Priestley, M.J.N. Stress-strain behavior of concrete confined by overlapping hoops at low and high strain rates. ACI Struct. J. 1982, 79, 13–27. [Google Scholar]

- Georgin, J.F.; Reynouard, J.M. Modeling of structures subjected to impact: Concrete behaviour under high strain rate. Cem. Concr. Compos. 2003, 25, 131–143. [Google Scholar] [CrossRef]

- Xiuli, D.; Yang, W.; Dechun, L. Non-linear uniaxial dynamic strength criterion for concrete. J. Hydraul. Eng. 2010, 41, 300–309. [Google Scholar]

- Huo, J.S.; Zheng, Q.; Chen, B.S. Tests on impact behaviour of micro-concrete-filled steel tubes at elevatedtemperatures up to 400 °C. Mater. Struct. 2009, 42, 1325–1334. [Google Scholar] [CrossRef]

- Wang, W.; Huo, Q.; Yang, J.C.; Wang, J.H.; Wang, X. Experimental investigation of ultra-early-strength cement-based self-compacting high strength concrete slabs (URCS) under contact explosions. Def. Technol. 2022. [Google Scholar] [CrossRef]

- ASTM International. ASTM C39/C39M-18 Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens; ASTM International: West Conshohocken, PA, USA, 2018. [Google Scholar]

- Davies, R.M. A critical study of the Hopkinson pressure bar. Philos. Trans. R Soc. A 1948, 240, 375–457. [Google Scholar]

- Huang, B.; Xiao, Y. Compressive impact tests of lightweight concrete with 155-mm-diameter spilt hopkinson pressure bar. Cem. Concr. Compos. 2020, 114, 103816. [Google Scholar] [CrossRef]

- Wang, C.L.; Xu, B.G.; Li, S.L. Study on damage constitutive model of steel fiber reinforced concrete under uniaxial compression. Geotech. Mech. 2006, 27, 151–154. [Google Scholar]

| Times | Compressive Strength (MPa) | Flexural Strength (MPa) |

|---|---|---|

| 2 h | 54.0 | 7.2 |

| 24 h | 71.0 | 9.7 |

| 7 d | 80.0 | 9.7 |

| 28 d | 81.2 | 10.1 |

| Speeds | Specimen Number | Measured Size of Test Specimen |

|---|---|---|

| 5 m/s | S_5-1 | Φ101.50 × 48.84 mm |

| S_5-2 | Φ100.76 × 49.44 mm | |

| S_5-3 | Φ101.08 × 51.44 mm | |

| 10 m/s | S_10-1 | Φ101.40 × 49.24 mm |

| S_10-2 | Φ101.05 × 50.40 mm | |

| S_10-3 | Φ101.40 × 50.54 mm | |

| 15 m/s | S_15-1 | Φ101.32 × 50.12 mm |

| S_15-2 | Φ101.38 × 50.32 mm | |

| S_15-3 | Φ101.42 × 51.10 mm |

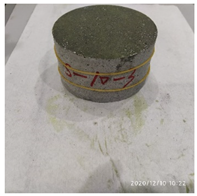

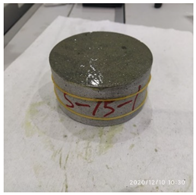

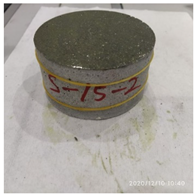

| Test No. | Before the Test | After the Test | Recycled |

|---|---|---|---|

| S_5-1 |  |  |  |

| S_5-2 |  |  |  |

| S_5-3 |  |  |  |

| Test No. | Before the Test | After the Test | Recycled |

|---|---|---|---|

| S_10-1 |  |  |  |

| S_10-2 |  |  |  |

| S_10-3 |  |  |  |

| Test No. | Before the Test | After the Test | Recycled |

|---|---|---|---|

| S_15-1 |  |  |  |

| S_15-2 |  |  |  |

| S_15-3 |  |  |  |

| Strain Rates | Dynamic Compressive Strength (Mpa) | ||

|---|---|---|---|

| 7.5 (s−1) | 93.954 | 95.982 | 91.836 |

| 15.3 (s−1) | 146.194 | 149.262 | 144.668 |

| 23.5 (s−1) | 173.013 | 175.845 | 170.697 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, W.; Zhang, Z.; Huo, Q.; Song, X.; Yang, J.; Wang, X.; Wang, J.; Wang, X. Dynamic Compressive Mechanical Properties of UR50 Ultra-Early-Strength Cement-Based Concrete Material under High Strain Rate on SHPB Test. Materials 2022, 15, 6154. https://doi.org/10.3390/ma15176154

Wang W, Zhang Z, Huo Q, Song X, Yang J, Wang X, Wang J, Wang X. Dynamic Compressive Mechanical Properties of UR50 Ultra-Early-Strength Cement-Based Concrete Material under High Strain Rate on SHPB Test. Materials. 2022; 15(17):6154. https://doi.org/10.3390/ma15176154

Chicago/Turabian StyleWang, Wei, Zhonghao Zhang, Qing Huo, Xiaodong Song, Jianchao Yang, Xiaofeng Wang, Jianhui Wang, and Xing Wang. 2022. "Dynamic Compressive Mechanical Properties of UR50 Ultra-Early-Strength Cement-Based Concrete Material under High Strain Rate on SHPB Test" Materials 15, no. 17: 6154. https://doi.org/10.3390/ma15176154

APA StyleWang, W., Zhang, Z., Huo, Q., Song, X., Yang, J., Wang, X., Wang, J., & Wang, X. (2022). Dynamic Compressive Mechanical Properties of UR50 Ultra-Early-Strength Cement-Based Concrete Material under High Strain Rate on SHPB Test. Materials, 15(17), 6154. https://doi.org/10.3390/ma15176154