Nanoscale Control of Structure and Composition for Nanocrystalline Fe Thin Films Grown by Oblique Angle RF Sputtering

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

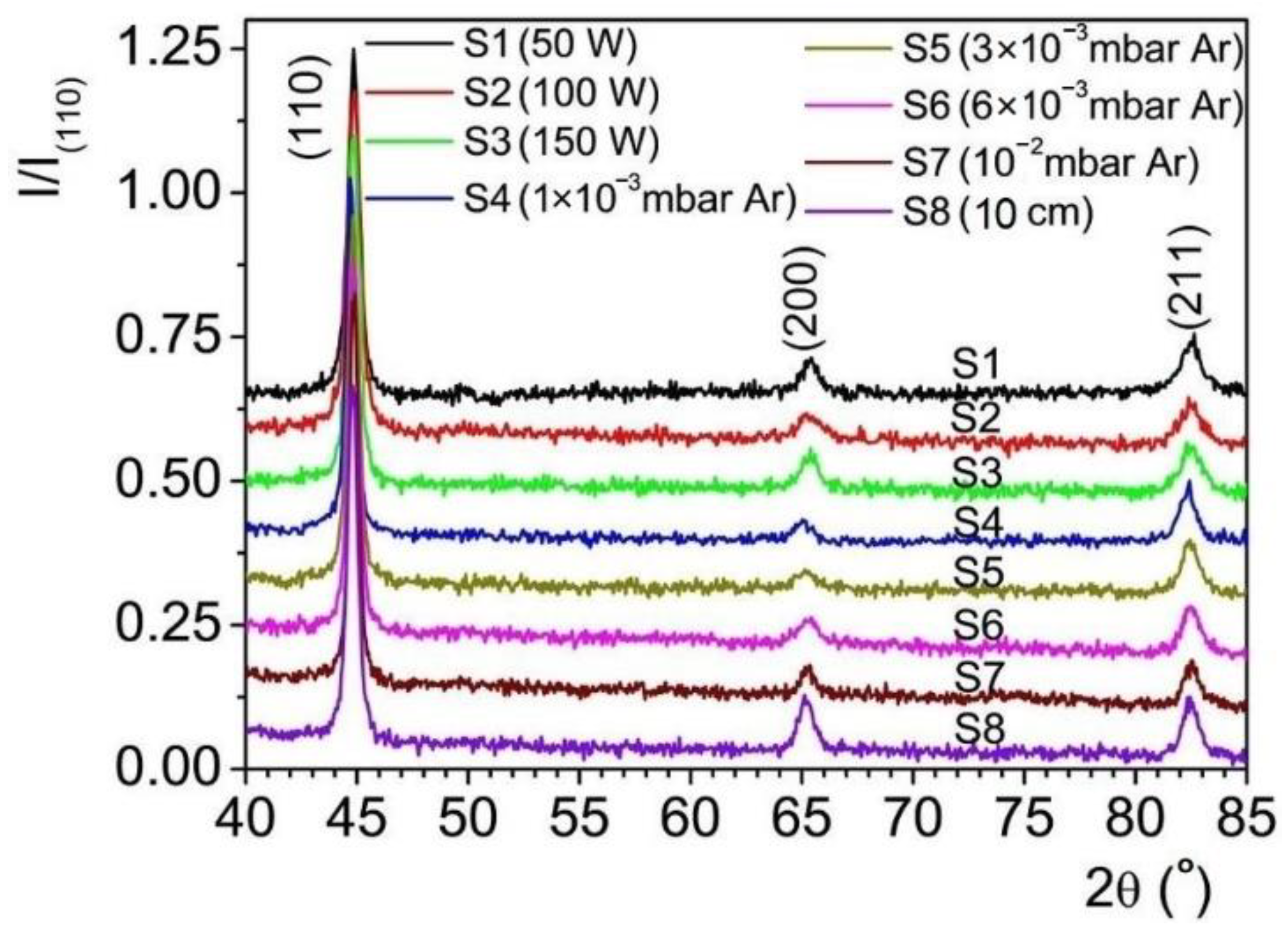

3.1. Microstructural Analysis

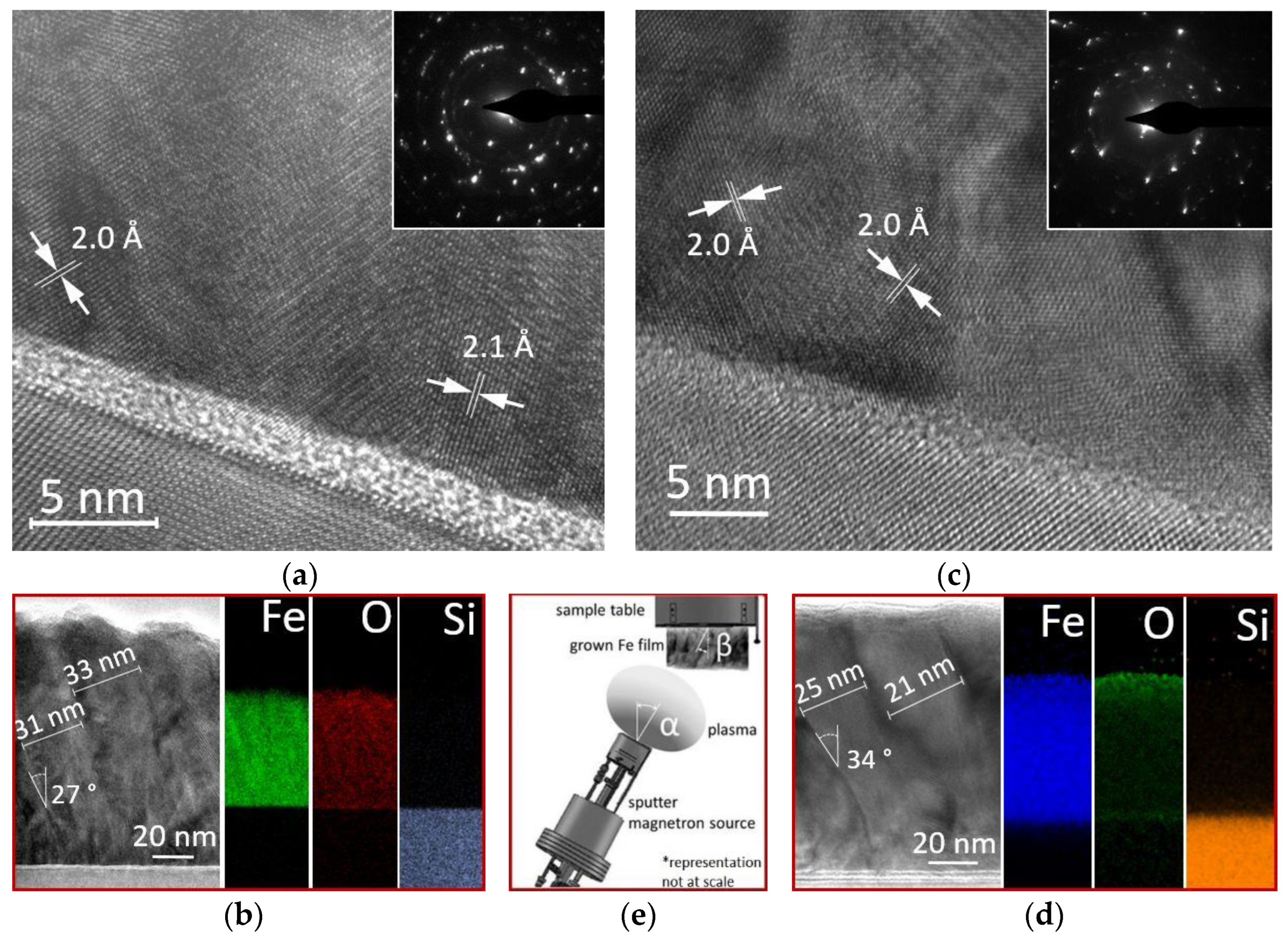

3.2. High Resolution Transmission Electron Microscopy

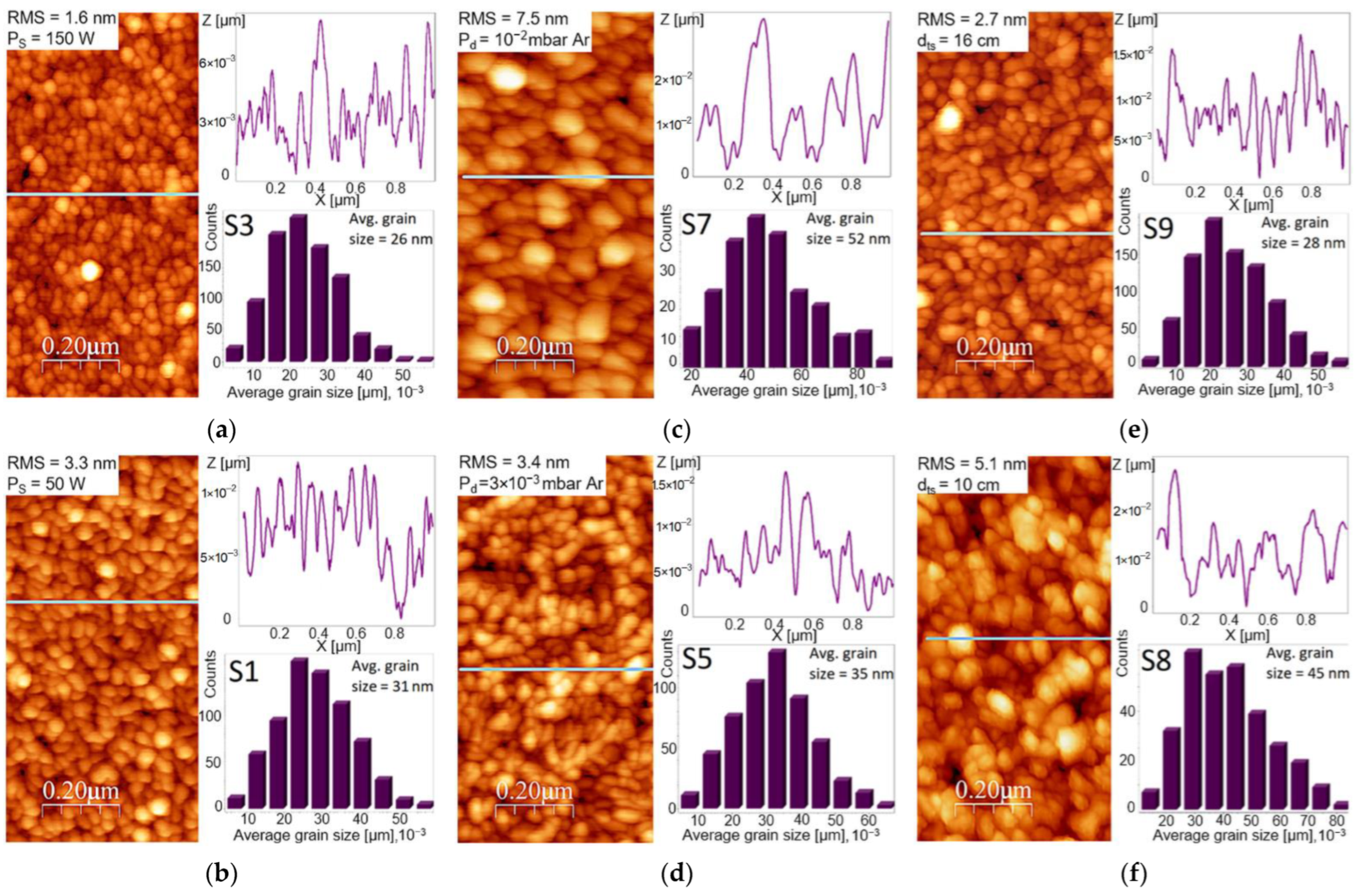

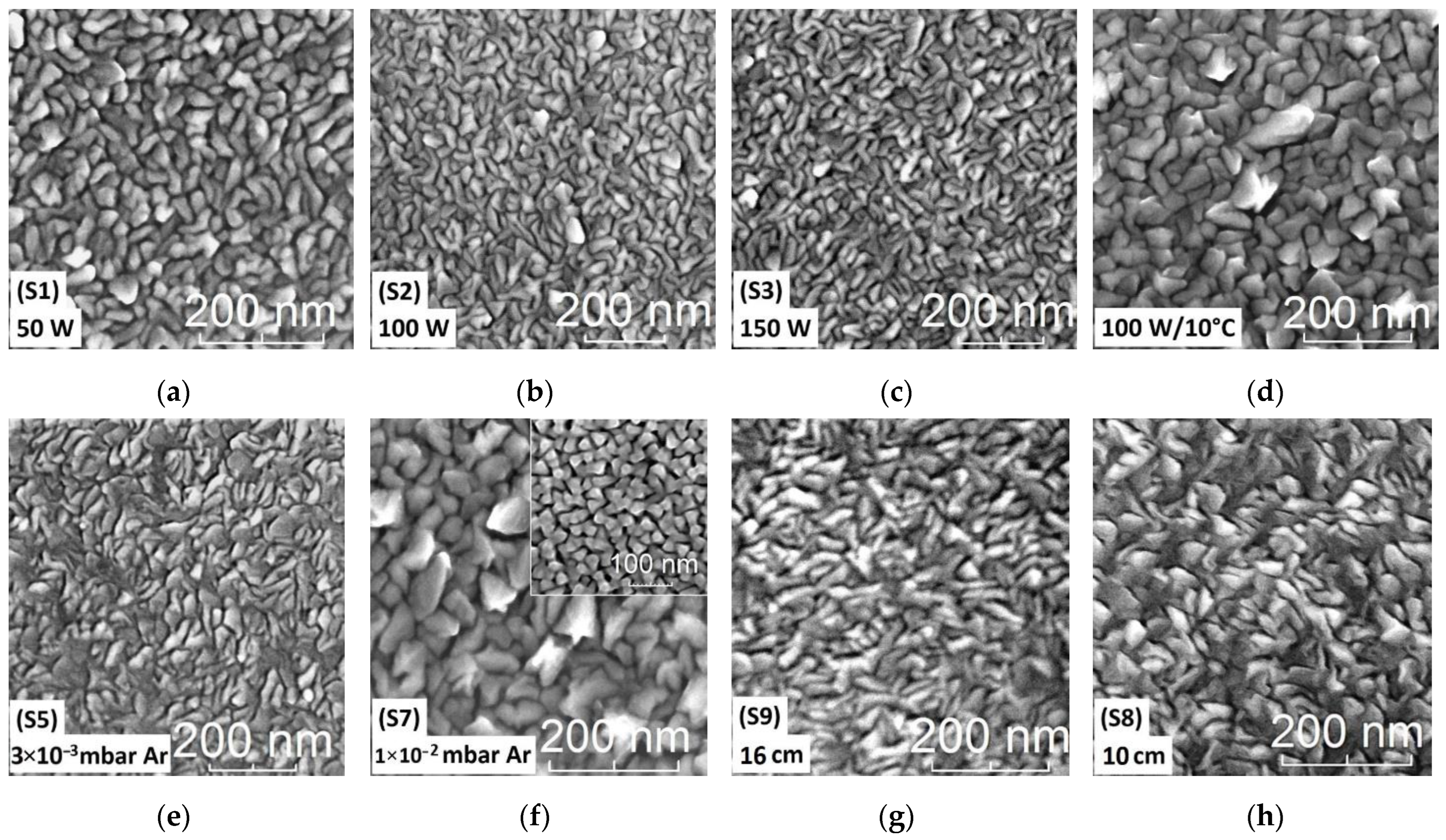

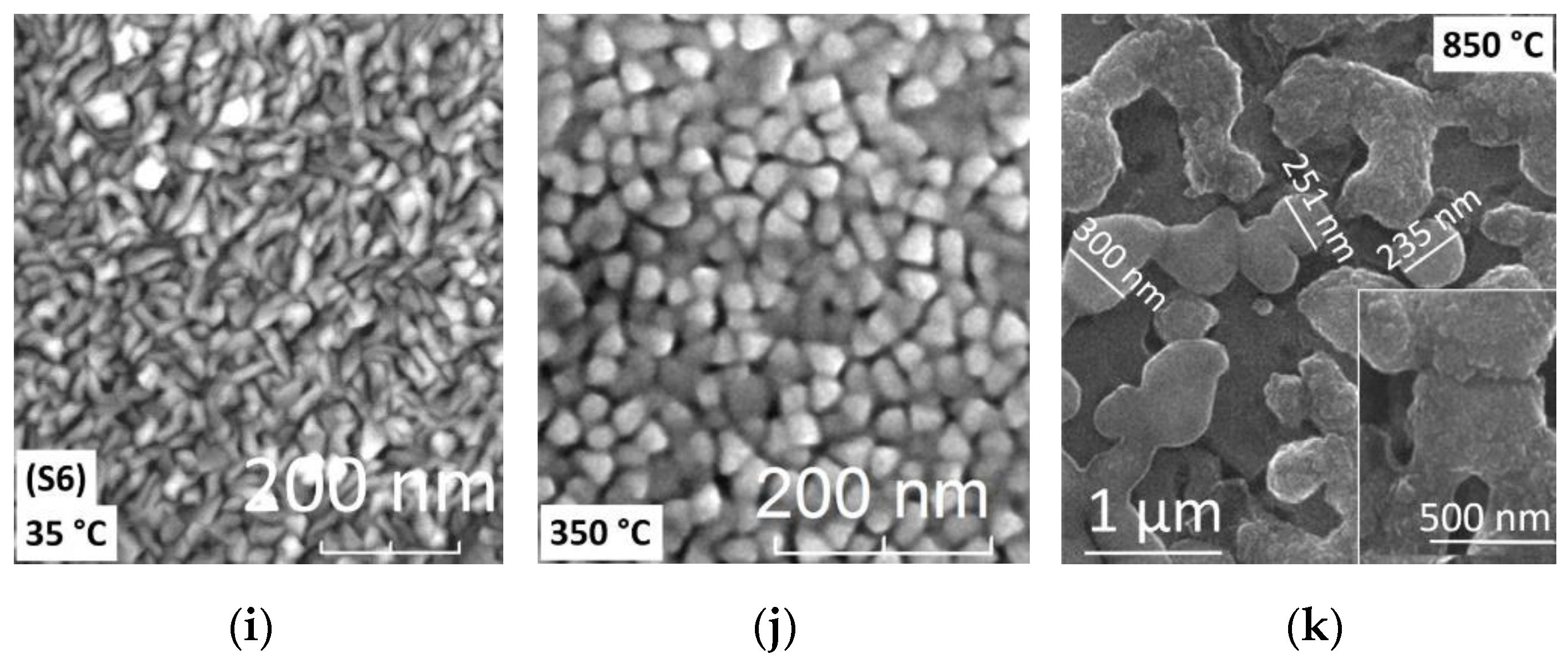

3.3. Surface Morphology and Topography Analysis

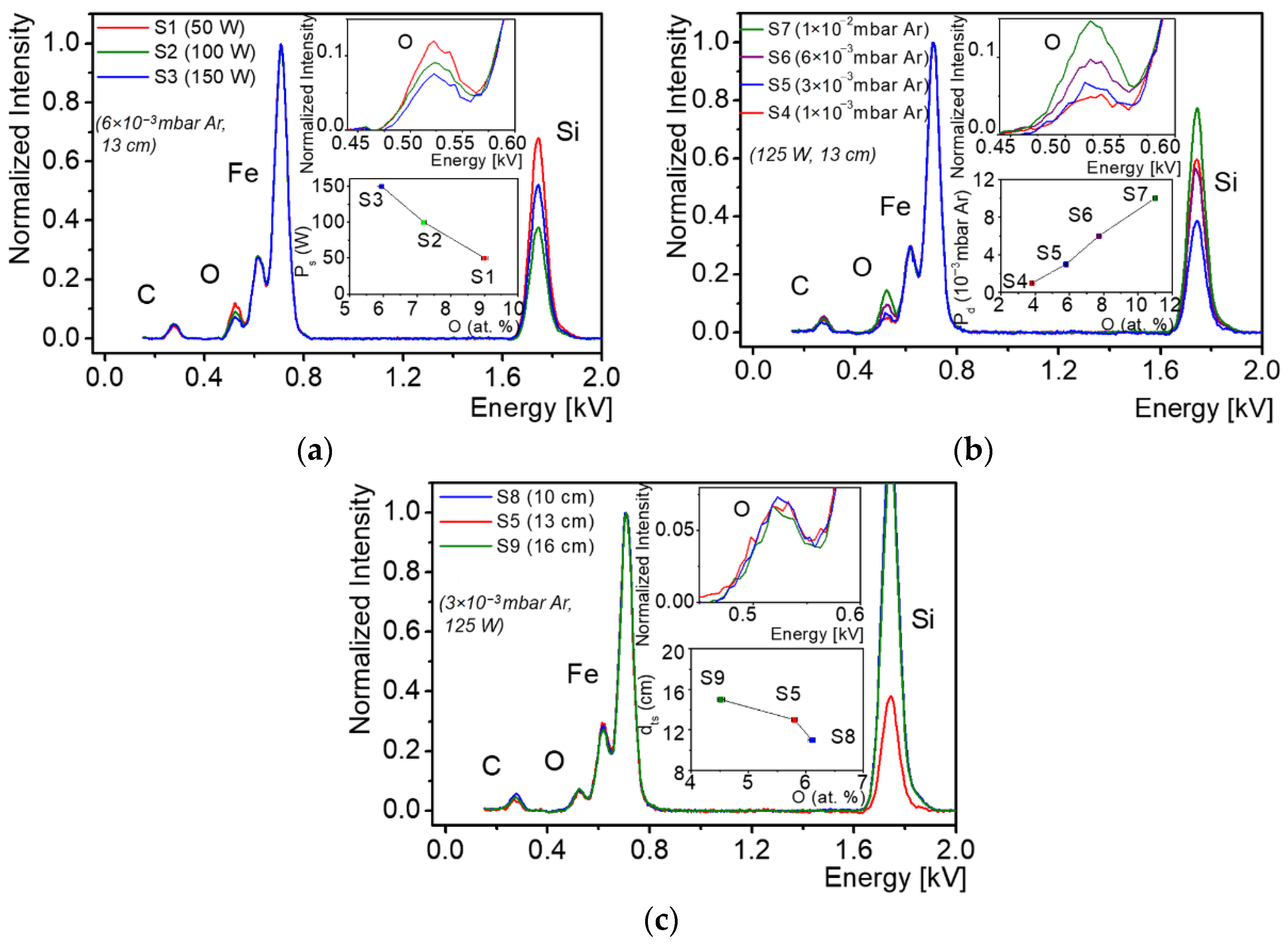

3.4. Spectroscopic Studies

4. Conclusions

- According to XRD data the films grown following a (110) preferential orientation, the degree of polycrystallinity being dependent mainly on the average angle of incidence of the adatoms arriving on the surface; average crystallite size on (110) growth direction was calculated to be in the 15–25 nm range;

- HR-TEM, SEM and AFM studies showed that, due to the oblique growth configuration and the limited adatom surface diffusion, the films presented a nanocrystalline structure featuring tilted nanocolumns, with tilt angles in the 27–34° range (for the analyzed samples);

- The average islands size was in the 20–50 nm range, the films roughness increasing mainly with deposition pressure;

- The oxygen composition and distribution within the films, studied by means of EDS and NRBS, showed a non-uniform distribution with thickness in most of the films. However, uniform distribution of oxygen could be obtained when the growth took place under a narrow window of deposition conditions, i.e., a low deposition pressure (≤3 × 10−3 mbar Ar), combined with a high RF source power (≥125 W).

- The microstructural, morphological, and spectroscopic results showed that, once the deposition parameters have been optimized, there is a real possibility for RF sputtering to allow the fabrication of polycrystalline Fe films with desirable properties, such as a preferential orientation, a controllable surface topography and/or a very low concentration in impurities (such as oxygen), uniformly distributed throughout the film.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gales, S.; Balabanski, D.L.; Negoita, F.; Tesileanu, O.; Ur, C.; Ursescu, D.; Zamfir, N. New frontiers in nuclear physics with high-power lasers and brilliant monochromatic gamma beams. Phys. Scr. 2016, 91, 93004. [Google Scholar] [CrossRef]

- Durante, M.; Golubev, A.; Park, W.-Y.; Trautmann, C. Applied nuclear physics at the new high-energy particle accelerator facilities. Phys. Rep. 2019, 800, 1–37. [Google Scholar] [CrossRef]

- Yogo, A.; Sato, K.; Nishikino, M.; Mori, M.; Teshima, T.; Numasaki, H.; Murakami, M.; Demizu, Y.; Akagi, S.; Nagayama, S.; et al. Application of laser-accelerated protons to the demonstration of DNA double-strand breaks in human cancer cells. Appl. Phys. Lett. 2009, 94, 181502. [Google Scholar] [CrossRef]

- Kraft, S.D.; Richter, C.; Zeil, K.; Baumann, M.; Beyreuther, E.; Bock, S.; Bussmann, M.; Cowan, T.E.; Dammene, Y.; Enghardt, W.; et al. Dose-dependent biological damage of tumour cells by laser-accelerated proton beams. New J. Phys. 2010, 12, 85003. [Google Scholar] [CrossRef]

- Doria, D.; Kakolee, K.F.; Kar, S.; Litt, S.K.; Fiorini, F.; Ahmed, H.; Green, S.; Jeynes, J.C.G.; Kavanagh, J.; Kirby, D.; et al. Biological effectiveness on live cells of laser driven protons at dose rates exceeding 109 Gy/s. AIP Adv. 2012, 2, 11209. [Google Scholar] [CrossRef]

- Ledingham, K.; Galster, W. Laser-driven particle and photon beams and some applications. New J. Phys. 2010, 12, 45005. [Google Scholar] [CrossRef]

- Borghesi, M.; Bigongiari, A.; Kar, S.; Macchi, A.; Romagnani, L.; Audebert, P.; Fuchs, J.; Toncian, T.; Willi, O.; Bulanov, S.; et al. Laser-driven proton acceleration: Source optimization and radiographic applications. Plasma Phys. Control. Fusion 2008, 50, 124040. [Google Scholar] [CrossRef]

- Brenner, C.; Mirfayzi, S.; Rusby, D.; Armstrong, C.; Alejo, A.; Wilson, L.; Clarke, R.; Ahmed, H.; Butler, N.; Haddock, D.; et al. Laser-driven x-ray and neutron source development for industrial applications of plasma accelerators. Plasma Phys. Control. Fusion 2016, 58, 14039. [Google Scholar] [CrossRef]

- Daido, H.; Nishiuchi, M.; Pirozhkov, A.S. Review of laser-driven ion sources and their applications. Reports Prog. Phys. 2012, 75, 56401. [Google Scholar] [CrossRef]

- Asavei, T.; Tomut, M.; Bobeica, M.; Aogaki, S.; Cernaianu, M.; Ganciu, M.; Kar, S.; Manda, G.; Mocanu, N.; Neagu, L.; et al. Materials in extreme environments for energy, accelerators and space applications at ELI-NP. Rom. Reports Phys. 2016, 68, S275–S347. [Google Scholar]

- Bobeica, M.; Aogaki, S.; Asavei, T.; Cernaianu, M.O.; Ghenuche, P.; Stutman, D. Dose calculations in a cell monolayer for high-throughput irradiation with proton beams generated by PW lasers for space applications. Life Sci. Sp. Res. 2018, 19, 68–75. [Google Scholar] [CrossRef]

- Onorato, G.; Di Schiavi, E.; Di Cunto, F. Understanding the Effects of Deep Space Radiation on Nervous System: The Role of Genetically Tractable Experimental Models. Front. Phys. 2020, 8, 362. [Google Scholar] [CrossRef]

- Norbury, J.W.; Schimmerling, W.; Slaba, T.C.; Azzam, E.I.; Badavi, F.F.; Baiocco, G.; Benton, E.; Bindi, V.; Blakely, E.A.; Blattnig, S.R.; et al. Galactic cosmic ray simulation at the NASA Space Radiation Laboratory. Life Sci. Sp. Res. 2016, 8, 38–51. [Google Scholar] [CrossRef] [PubMed]

- Chew, M.T.; Nisbet, A.; Jones, B.; Suzuki, M.; Matsufuji, N.; Murakami, T.; Bradley, D.A. Ion beams for space radiation radiobiological effect studies. Radiat. Phys. Chem. 2019, 165, 108373. [Google Scholar] [CrossRef]

- Gales, S.; Tanaka, K.A.; Balabanski, D.L.; Negoita, F.; Stutman, D.; Tesileanu, O.; Ur, C.A.; Ursescu, D.; Andrei, I.; Ataman, S.; et al. The extreme light infrastructure—nuclear physics (ELI-NP) facility: New horizons in physics with 10 PW ultra-intense lasers and 20 MeV brilliant gamma beams. Reports Prog. Phys. 2018, 81, 94301. [Google Scholar] [CrossRef]

- Cucinotta, F.A.; Alp, M.; Sulzman, F.M.; Wang, M. Space radiation risks to the central nervous system. Life Sci. Sp. Res. 2014, 2, 54–69. [Google Scholar] [CrossRef]

- Asaithamby, A.; Chen, D.J. Mechanism of cluster DNA damage repair in response to high-atomic number and energy particles radiation. Mutat. Res. Mol. Mech. Mutagen. 2011, 711, 87–99. [Google Scholar] [CrossRef]

- McKenna, P.; Ledingham, K.W.D.; Yang, J.M.; Robson, L.; McCanny, T.; Shimizu, S.; Clarke, R.J.; Neely, D.; Spohr, K.; Chapman, R.; et al. Characterization of proton and heavier ion acceleration in ultrahigh-intensity laser interactions with heated target foils. Phys. Rev. E 2004, 70, 36405. [Google Scholar] [CrossRef]

- Nishiuchi, M.; Sakaki, H.; Esirkepov, T.Z.; Nishio, K.; Pikuz, T.A.; Faenov, A.Y.; Skobelev, I.Y.; Orlandi, R.; Sako, H.; Pirozhkov, A.S.; et al. Acceleration of highly charged GeV Fe ions from a low-Z substrate by intense femtosecond laser. Phys. Plasmas 2015, 22, 33107. [Google Scholar] [CrossRef]

- Hegelich, B.M.; Albright, B.J.; Cobble, J.; Flippo, K.; Letzring, S.; Paffett, M.; Ruhl, H.; Schreiber, J.; Schulze, R.K.; Fernández, J.C. Laser acceleration of quasi-monoenergetic MeV ion beams. Nature 2006, 439, 441–444. [Google Scholar] [CrossRef]

- Prencipe, I.; Fuchs, J.; Pascarelli, S.; Schumacher, D.W.; Stephens, R.B.; Alexander, N.B.; Briggs, R.; Büscher, M.; Cernaianu, M.O.; Choukourov, A.; et al. Targets for high repetition rate laser facilities: Needs, challenges and perspectives. High Power Laser Sci. Eng. 2017, 5, e17. [Google Scholar] [CrossRef] [Green Version]

- Ceccotti, T.; Floquet, V.; Sgattoni, A.; Bigongiari, A.; Raynaud, M.; Riconda, C.; Heron, A.; Baffigi, F.; Labate, L.; Gizzi, L.; et al. Evidence of resonant surface wave excitation in the relativistic regime through measurements of proton acceleration from grating targets. Phys. Rev. Lett. 2013, 111, 185001. [Google Scholar] [CrossRef] [PubMed]

- Gheorghiu, C.C.; Cerchez, M.; Aktan, E.; Prasad, R.; Yilmaz, F.; Yilmaz, N.; Popa, D.; Willi, O.; Leca, V. Fabrication of micrometre-sized periodic gratings in free-standing metallic foils for laser–plasma experiments. High Power Laser Sci. Eng. 2022, 10, e3. [Google Scholar] [CrossRef]

- Habara, H.; Honda, S.; Katayama, M.; Sakagami, H.; Nagai, K.; Tanaka, K.A. Efficient energy absorption of intense ps-laser pulse into nanowire target. Phys. Plasmas 2016, 23, 63105. [Google Scholar] [CrossRef]

- Zhao, Z.; Cao, L.; Cao, L.; Wang, J.; Huang, W.; Jiang, W.; He, Y.; Wu, Y.; Zhu, B.; Dong, K.; et al. Acceleration and guiding of fast electrons by a nanobrush target. Phys. Plasmas 2010, 17, 123108. [Google Scholar] [CrossRef]

- Prencipe, I.; Sgattoni, A.; Dellasega, D.; Fedeli, L.; Cialfi, L.; Choi, I.W.; Kim, I.J.; Janulewicz, K.A.; Kakolee, K.F.; Lee, H.W.; et al. Development of foam-based layered targets for laser-driven ion beam production. Plasma Phys. Control. Fusion 2016, 58, 34019. [Google Scholar] [CrossRef]

- Margarone, D.; Klimo, O.; Kim, I.J.; Prokůpek, J.; Limpouch, J.; Jeong, T.M.; Mocek, T.; Pšikal, J.; Kim, H.T.; Proška, J.; et al. Laser-Driven Proton Acceleration Enhancement by Nanostructured Foils. Phys. Rev. Lett. 2012, 109, 234801. [Google Scholar] [CrossRef]

- Gheorghiu, C.C.; Ionescu, S.C.; Ghenuche, P.; Cernaianu, M.O.; Doria, D.; Popa, D.; Leca, V. Structuring Free-Standing Foils for Laser-Driven Particle Acceleration Experiments. Front. Phys. 2021, 9, 515. [Google Scholar] [CrossRef]

- Dalui, M.; Wang, W.-M.; Trivikram, T.M.; Sarkar, S.; Tata, S.; Jha, J.; Ayyub, P.; Sheng, Z.M.; Krishnamurthy, M. Preferential enhancement of laser-driven carbon ion acceleration from optimized nanostructured surfaces. Sci. Rep. 2015, 5, 11930. [Google Scholar] [CrossRef]

- Barranco, A.; Borras, A.; Gonzalez-Elipe, A.R.; Palmero, A. Perspectives on oblique angle deposition of thin films: From fundamentals to devices. Prog. Mater. Sci. 2016, 76, 59–153. [Google Scholar] [CrossRef]

- Hawkeye, M.M.; Brett, M.J. Glancing angle deposition: Fabrication, properties, and applications of micro- and nanostructured thin films. J. Vac. Sci. Technol. A 2007, 25, 1317–1335. [Google Scholar] [CrossRef]

- Bairagi, S.; Järrendahl, K.; Eriksson, F.; Hultman, L.; Birch, J.; Hsiao, C.-L. Glancing Angle Deposition and Growth Mechanism of Inclined AlN Nanostructures Using Reactive Magnetron Sputtering. Coatings 2020, 10, 768. [Google Scholar] [CrossRef]

- Zhou, C.; Li, T.; Wei, X.; Yan, B. Effect of the Sputtering Power on the Structure, Morphology and Magnetic Properties of Fe Films. Metals 2020, 10, 896. [Google Scholar] [CrossRef]

- Gheorghiu, C.C.; Leca, V.; Popa, D.; Cernaianu, M.O.; Stutman, D. Overview on the target fabrication facilities at ELI-NP and ongoing strategies. J. Instrum. 2016, 11, C10011. [Google Scholar] [CrossRef]

- Gallego, J.M.; Miranda, R. The Fe/Si(100) interface. J. Appl. Phys. 1991, 69, 1377–1383. [Google Scholar] [CrossRef]

- Horcas, I.; Fernández, R.; Gómez-Rodríguez, J.M.; Colchero, J.; Gómez-Herrero, J.; Baro, A.M. WSXM: A software for scanning probe microscopy and a tool for nanotechnology. Rev. Sci. Instrum. 2007, 78, 13705. [Google Scholar] [CrossRef]

- Ene, V.L.; Dinescu, D.; Zai, I.; Djourelov, N.; Vasile, B.S.; Serban, A.B.; Leca, V.; Andronescu, E. Study of edge and screw dislocation density in GaN/Al2O3 heterostructure. Materials 2019, 12, 4205. [Google Scholar] [CrossRef] [PubMed]

- Burducea, I.; Straticiuc, M.; Ghiță, D.G.; Moșu, D.V.; Călinescu, C.I.; Podaru, N.C.; Mous, D.J.W.; Ursu, I.; Zamfir, N.V. A new ion beam facility based on a 3MV TandetronTM at IFIN-HH, Romania. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2015, 359, 12–19. [Google Scholar] [CrossRef]

- Mayer, M. SimNRA, a simulation program for the analysis of NRA, RBS and ERDA. AIP Conf. Proc. 1999, 475, 541. [Google Scholar]

- Ion, L.; Iftimie, S.; Radu, A.; Antohe, V.A.; Toma, O.; Antohe, S. Physical properties of RF-sputtered ZnSe thin films for photovoltaic applications: Influence of film thickness. Proc. Rom. Acad. Ser. A 2021, 22, 25–34. [Google Scholar]

- Toma, O.; Ion, L.; Iftimie, S.; Antohe, V.A.; Radu, A.; Raduta, A.M.; Manica, D.; Antohe, S. Physical properties of rf-sputtered ZnS and ZnSe thin films used for double-heterojunction ZnS/ZnSe/CdTe photovoltaic structures. Appl. Surf. Sci. 2019, 478, 831–839. [Google Scholar] [CrossRef]

- Rodriguez-Carvajal, J. Study of micro-structural effects by powder diffraction using the program FULLPROF. Lab. Léon Brillouin (CEA-CNRS) CEA/Saclay 2003, 91191. [Google Scholar]

- Gheisari, K.; Ong, C.K. Magnetic properties and thermal stability of nanocrystalline Fe films prepared by oblique sputtering deposition method. Phys. B Condens. Matter 2020, 595, 412365. [Google Scholar] [CrossRef]

- Javed, A.; Morley, N.A.; Gibbs, M.R.J. Effect of growth parameters on the structure and magnetic properties of thin polycrystalline Fe films fabricated on Si〈100〉 substrates. Appl. Surf. Sci. 2011, 257, 5586–5590. [Google Scholar] [CrossRef]

- Hull, A.W. A New Method of X-Ray Crystal Analysis. Phys. Rev. 1917, 10, 661–696. [Google Scholar] [CrossRef]

- Okamoto, K.; Itoh, K. Incidence angle dependences of columnar grain structure and texture in obliquely deposited iron films. Jpn. J. Appl. Phys. 2005, 44, 1382–1388. [Google Scholar] [CrossRef]

- Okamoto, K.; Hashimoto, T.; Itoh, K.; Hara, K.; Kamiya, M.; Fujiwara, H. Crystallographic contribution to the formation of columnar grain structure in iron films deposited at oblique incidence. J. Magn. Magn. Mater. 1995, 148, 21–22. [Google Scholar] [CrossRef]

- Nieuwenhuizen, J.M.; Haanstra, H.B. Microfractography of thin films. Philips Tech. Rev. 1966, 27, 87–91. [Google Scholar]

- Lichter, S.; Chen, J. Model for Columnar Microstructure of Thin Solid Films. Phys. Rev. Lett. 1986, 56, 1396–1399. [Google Scholar] [CrossRef]

- Meakin, P. Ballistic deposition onto inclined surfaces. Phys. Rev. A 1988, 38, 994–1004. [Google Scholar] [CrossRef]

- Tait, R.N.; Smy, T.; Brett, M.J. Modelling and characterization of columnar growth in evaporated films. Thin Solid Films 1993, 226, 196–201. [Google Scholar] [CrossRef]

- Gavrilova, T.A.; Atuchin, V.V.; Kruchinin, V.N.; Lychagin, D.V. Micromorphology and spectroscopic ellipsometry of Ni(100) crystal surface. Phys. Procedia 2012, 23, 61–64. [Google Scholar] [CrossRef]

- Atuchin, V.V.; Kochubey, V.A.; Kozhukhov, A.S.; Kruchinin, V.N.; Pokrovsky, L.D.; Soldatenkov, I.S.; Troitskaia, I.B. Microstructure and dispersive optical parameters of iron films deposited by the thermal evaporation method. Optik 2019, 188, 120–125. [Google Scholar] [CrossRef]

- Nastasi, N.; Mayer, J.; Wang, Y. Ion Beam Analysis: Fundamentals and Applications, 1st ed.; Taylor & Francis: Boca Raton, FL, USA, 2015. [Google Scholar]

- Jeynes, C. Elastic Backscattering of Ions for Compositional Analysis. Charact. Mater. 2012, 1079, 1–21. [Google Scholar] [CrossRef]

- Baran, J.D.; Grönbeck, H.; Hellman, A. Mechanism for Limiting Thickness of Thin Oxide Films on Aluminum. Phys. Rev. Lett. 2014, 112, 146103. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Velişa, G.; Trocellier, P.; Thomé, L.; Vaubaillon, S.; Sattonnay, G.; Miro, S.; Serruys, Y. Patterning SiC nanoprecipitate in Si single crystals by simultaneous dual- beam ion implantation. J. Mater. Sci. 2014, 49, 4899–4904. [Google Scholar] [CrossRef]

| Sample Parameter | S1 | S2 | S3 | S4 | S5 | S6 | S7 | S8 | S9 |

|---|---|---|---|---|---|---|---|---|---|

| Ps (W) | 50 | 100 | 150 | 125 | 125 | 125 | 125 | 125 | 125 |

| Pd (mbar Ar) | 6 × 10−3 | 6 × 10−3 | 6 × 10−3 | 1 × 10−3 | 3 × 10−3 | 6 × 10−3 | 1 × 10−2 | 3 × 10−3 | 3 × 10−3 |

| dts (cm) | 13 | 13 | 13 | 13 | 13 | 13 | 13 | 10 | 16 |

| Sample Name | a (Å) | Def (nm) | A(200)/Atotal | A(211)/Atotal | eps | |εrel| |

|---|---|---|---|---|---|---|

| S1 | 2.854 | 15.2 | 0.108 | 0.178 | 3.43 × 10−3 | 1.8 × 10−3 |

| S2 | 2.855 | 17.5 | 0.099 | 0.173 | 4.16 × 10−3 | 1.65 × 10−3 |

| S3 | 2.856 | 20.6 | 0.093 | 0.166 | 4.20 × 10−3 | 1.25 × 10−3 |

| S4 | 2.863 | 16.8 | 0.099 | 0.179 | 2.96 × 10−3 | 1.0 × 10−3 |

| S5 | 2.861 | 18.2 | 0.097 | 0.176 | 3.63 × 10−3 | 5.0 × 10−4 |

| S6 | 2.855 | 21.2 | 0.095 | 0.171 | 3.68 × 10−3 | 1.4 × 10−3 |

| S7 | 2.855 | 24.7 | 0.055 | 0.139 | 3.96 × 10−3 | 1.6 × 10−3 |

| S8 | 2.859 | 23.2 | 0.138 | 0.180 | 3.79 × 10−3 | 3.5 × 10−4 |

| Sample | Variable Parameter | at. % (EDS) | at. % (NRBS) | tdNRBS (1015 atoms/cm2) | tNRBS (nm) |

|---|---|---|---|---|---|

| S1 | Ps = 50 W | Fe0.91O0.090 | (i) Fe0.938O0.062 (ii) Fe0.965O0.035 | (i) 425 (ii) 425 | 110 |

| S2 | Ps = 100 W | Fe0.928O0.072 | (i) Fe0.94O0.06 (ii) Fe0.985O0.015 | (i) 300 (ii) 710 | 129 |

| S3 | Ps = 150 W | Fe0.94O0.060 | (i) Fe0.955O0.045 (ii) Fe0.98O0.02 | (ii) 450 (iii) 450 | 116 |

| S4 | Pd = 1 × 10−3 mbar | Fe0.962O0.038 | (i) Fe0.99O0.01 (ii) Fe0.99O0.01 | (i) 450 (ii) 450 | 116 |

| S5 | Pd = 3 × 10−3 mbar | Fe0.942O0.058 | (i) Fe0.99O0.01 (ii) Fe0.99O0.01 | (i) 405 (ii) 440 | 109 |

| S6 | Pd = 6 × 10−3 mbar | Fe0.923O0.077 | (i) Fe0.95O0.05 (ii) Fe0.98O0.02 | (i) 355 (ii) 500 | 110 |

| S7 | Pd = 1 × 10−2 mbar | Fe0.89O0.11 | (i) Fe0.90O0.10 (ii) Fe0.95O0.05 | (i) 395 (ii) 395 | 102 |

| S8 | dts = 10 cm | Fe0.939O0.061 | (i) Fe0.978O0.022 (ii) Fe0.978O0.022 | (i) 315 (ii) 322 | 85 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gheorghiu, C.C.; Ionescu, A.; Zai, M.-I.; Iancu, D.; Burducea, I.; Velisa, G.; Vasile, B.S.; Ianculescu, A.C.; Bobeica, M.; Popa, D.; et al. Nanoscale Control of Structure and Composition for Nanocrystalline Fe Thin Films Grown by Oblique Angle RF Sputtering. Materials 2022, 15, 6134. https://doi.org/10.3390/ma15176134

Gheorghiu CC, Ionescu A, Zai M-I, Iancu D, Burducea I, Velisa G, Vasile BS, Ianculescu AC, Bobeica M, Popa D, et al. Nanoscale Control of Structure and Composition for Nanocrystalline Fe Thin Films Grown by Oblique Angle RF Sputtering. Materials. 2022; 15(17):6134. https://doi.org/10.3390/ma15176134

Chicago/Turabian StyleGheorghiu, Cristina C., Aurelia Ionescu, Maria-Iulia Zai, Decebal Iancu, Ion Burducea, Gihan Velisa, Bogdan S. Vasile, Adelina C. Ianculescu, Mariana Bobeica, Daniel Popa, and et al. 2022. "Nanoscale Control of Structure and Composition for Nanocrystalline Fe Thin Films Grown by Oblique Angle RF Sputtering" Materials 15, no. 17: 6134. https://doi.org/10.3390/ma15176134

APA StyleGheorghiu, C. C., Ionescu, A., Zai, M.-I., Iancu, D., Burducea, I., Velisa, G., Vasile, B. S., Ianculescu, A. C., Bobeica, M., Popa, D., & Leca, V. (2022). Nanoscale Control of Structure and Composition for Nanocrystalline Fe Thin Films Grown by Oblique Angle RF Sputtering. Materials, 15(17), 6134. https://doi.org/10.3390/ma15176134