Microstructure and Key Properties of Phosphogypsum-Red Mud-Slag Composite Cementitious Materials

Abstract

:1. Introduction

2. Materials and Methods

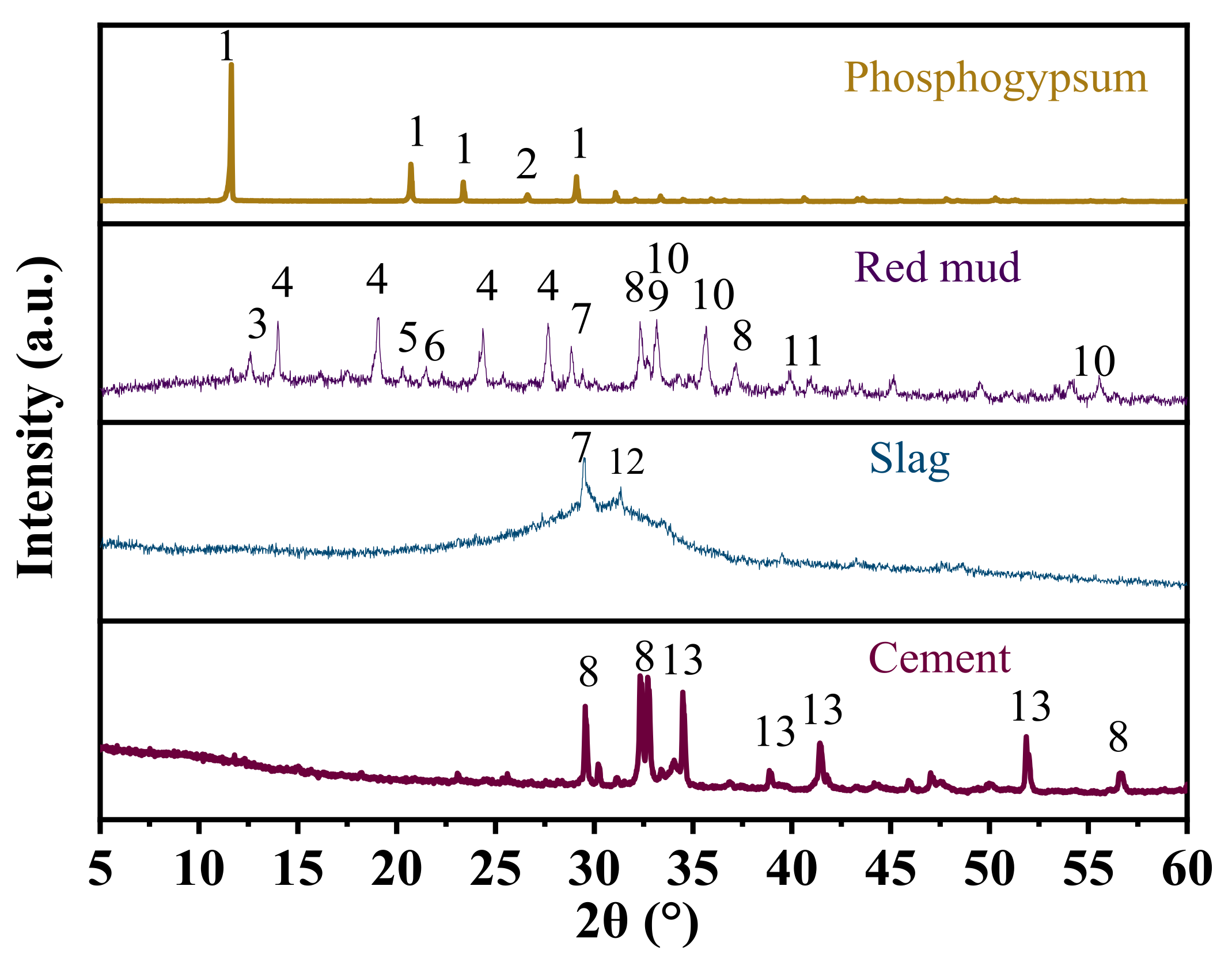

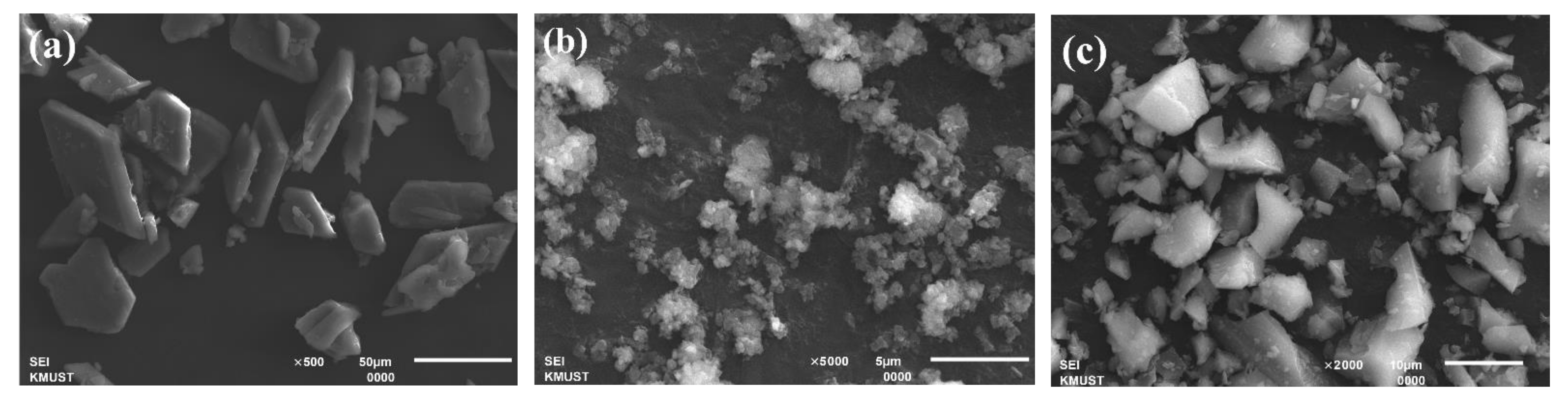

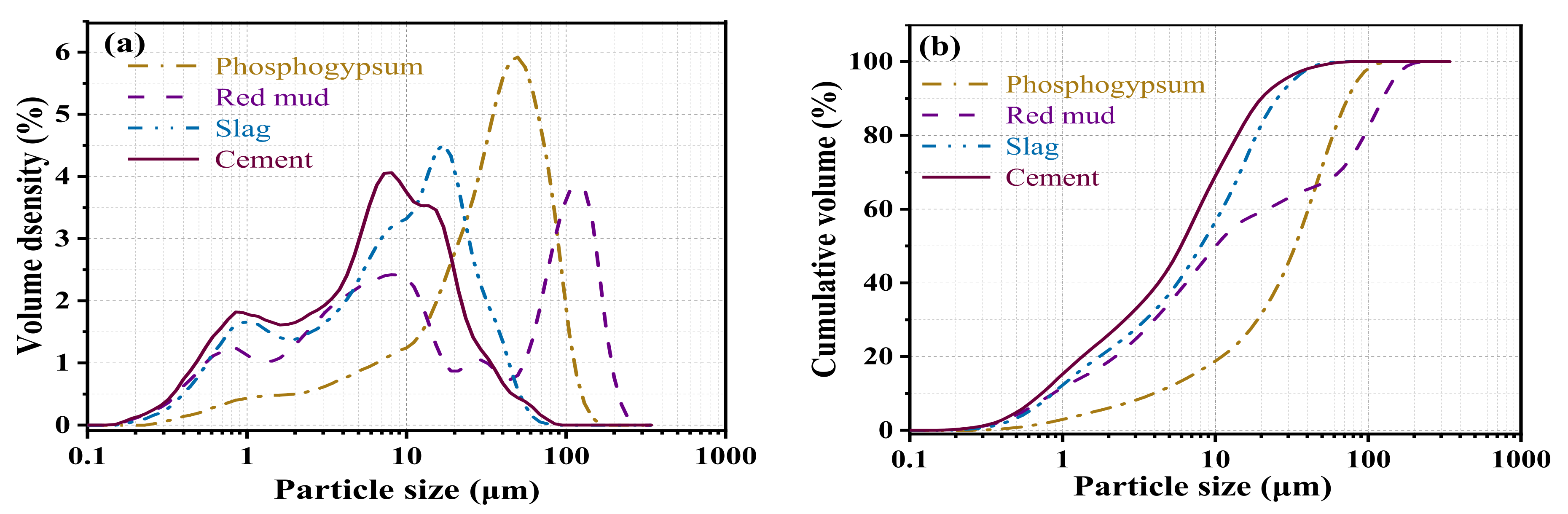

2.1. Materails

2.2. Mixture Preparation

2.3. Testing Methods

2.4. Characterization Methods

3. Results and Discussion

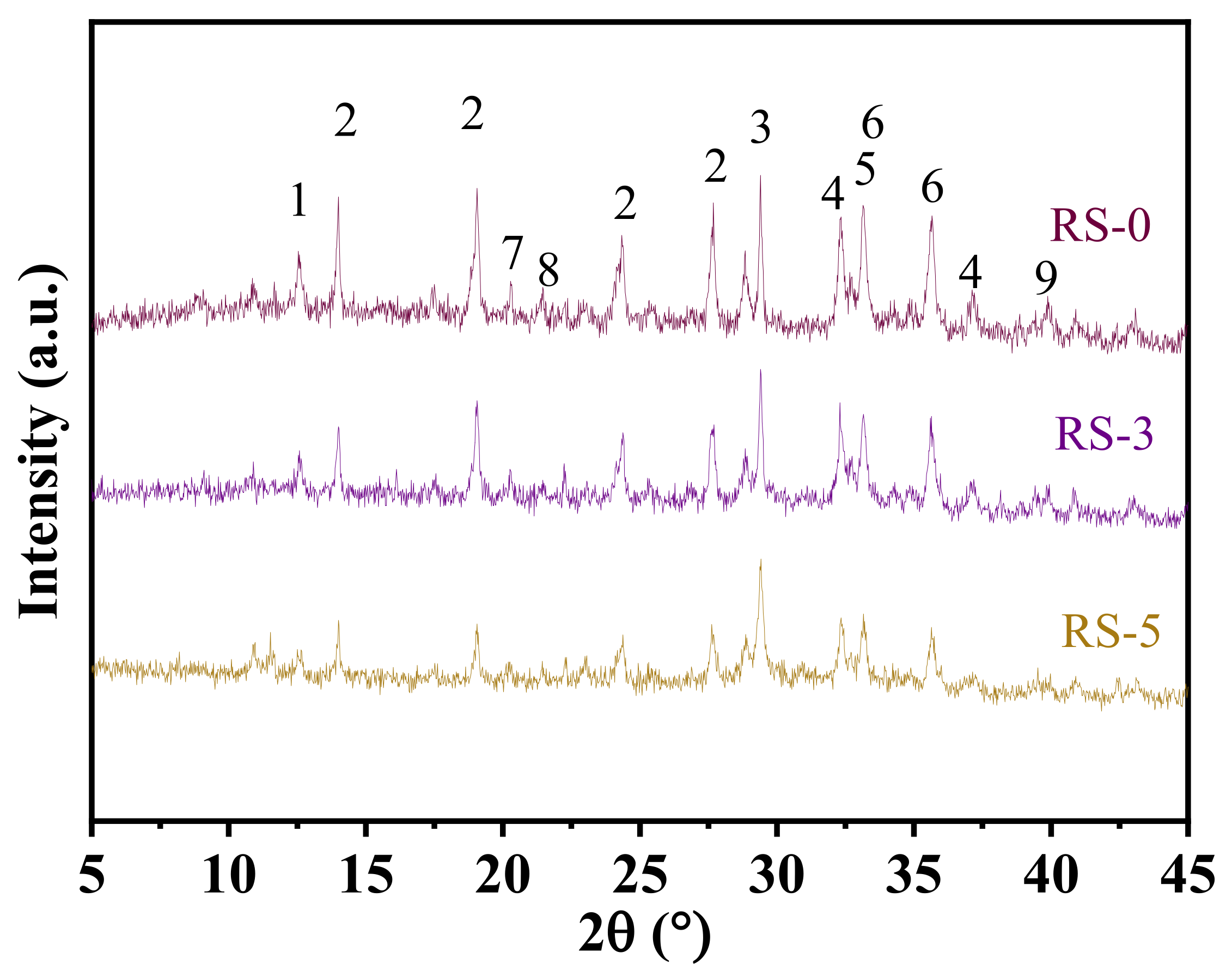

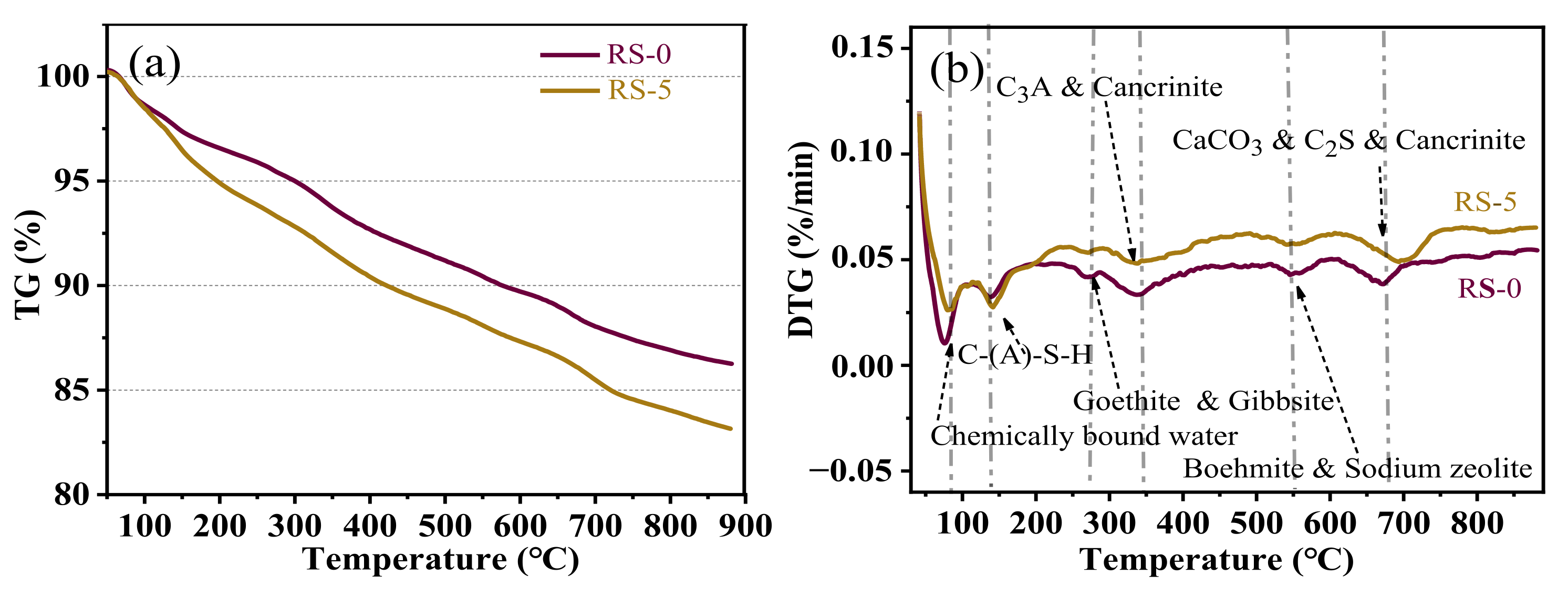

3.1. Determination of Slag Content and Mechanism Analysis

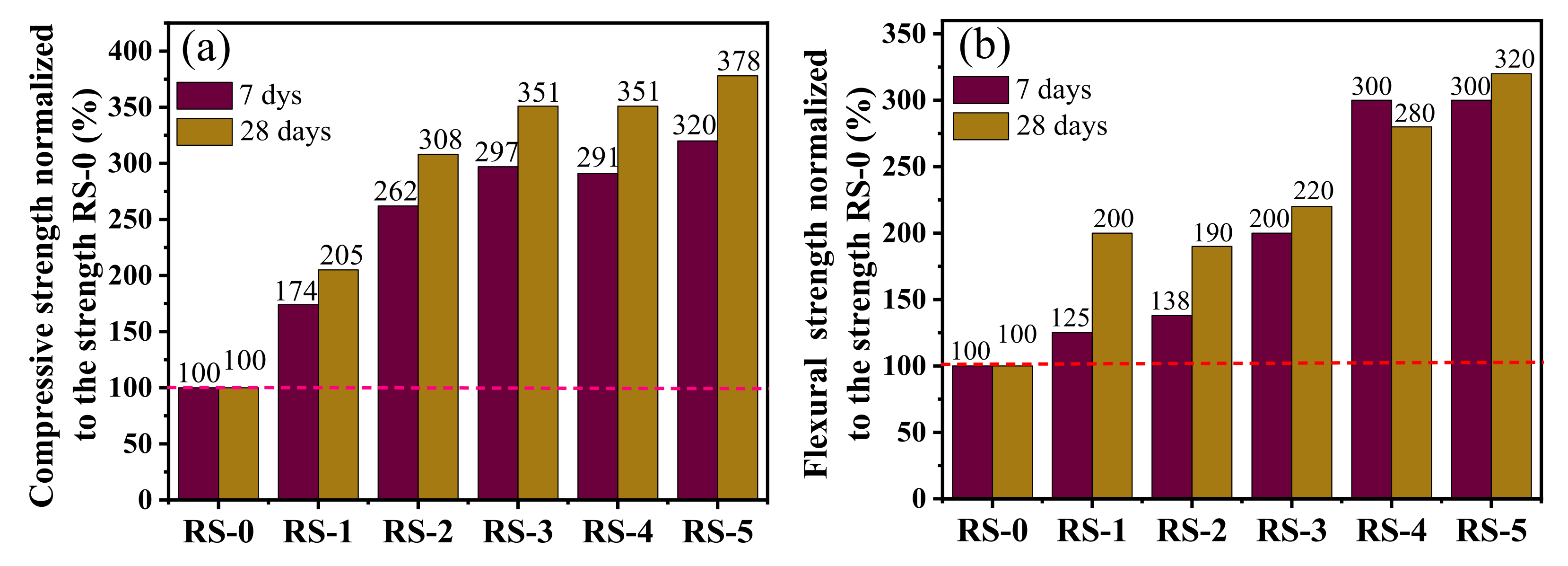

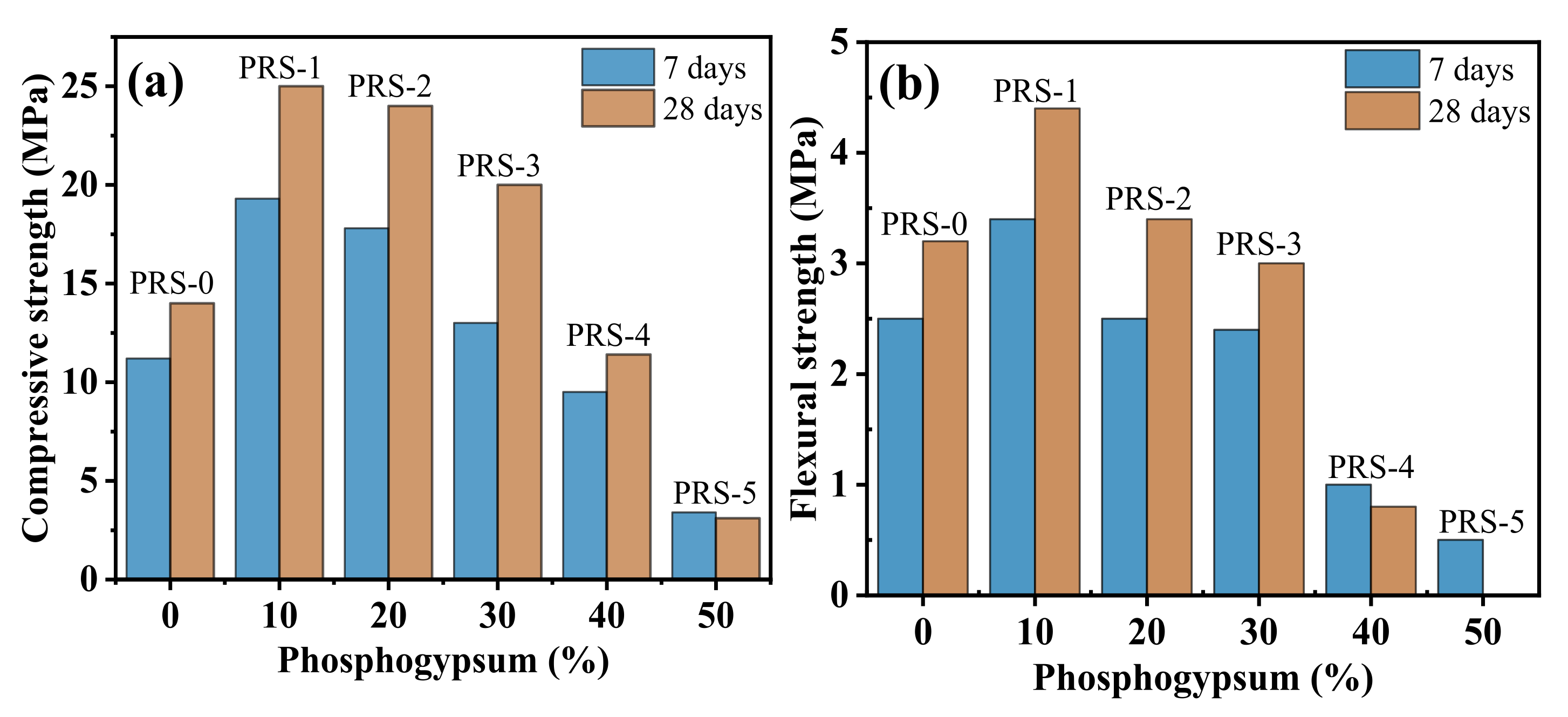

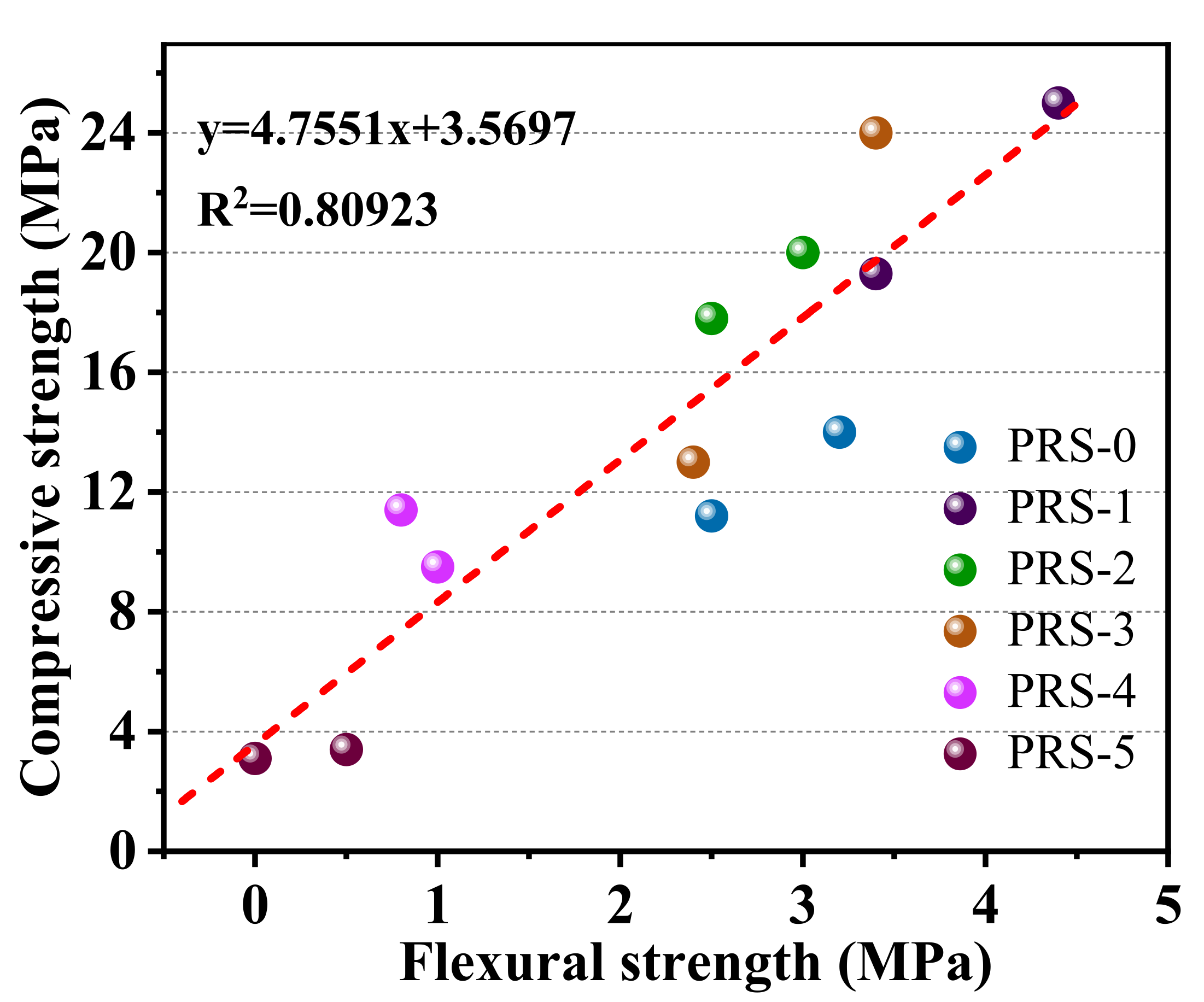

3.2. Influence of Phosphogypsum on the Strength of Composite Cementitious Materials and Mechanism Analysis

4. Conclusions

- The slag has a significant strengthening effect on the composite cementitious material. When the slag content is 0–50%, the strength of the composite cementitious material increases with the increase in the slag content. When the slag content increases to 50%, the composite cementitious material shows the highest strength, and its 28-day compressive strength can reach 14.0 MPa.

- Phosphogypsum has a significant effect on the strength development of the composite cementitious material. When the content of phosphogypsum is 0–50%, the strength of the composite cementitious material increases first and then decreases. When the content of phosphogypsum is 10%, the composite cementitious material has the highest strength, and its 28-day compressive strength reaches 25.0 MPa.

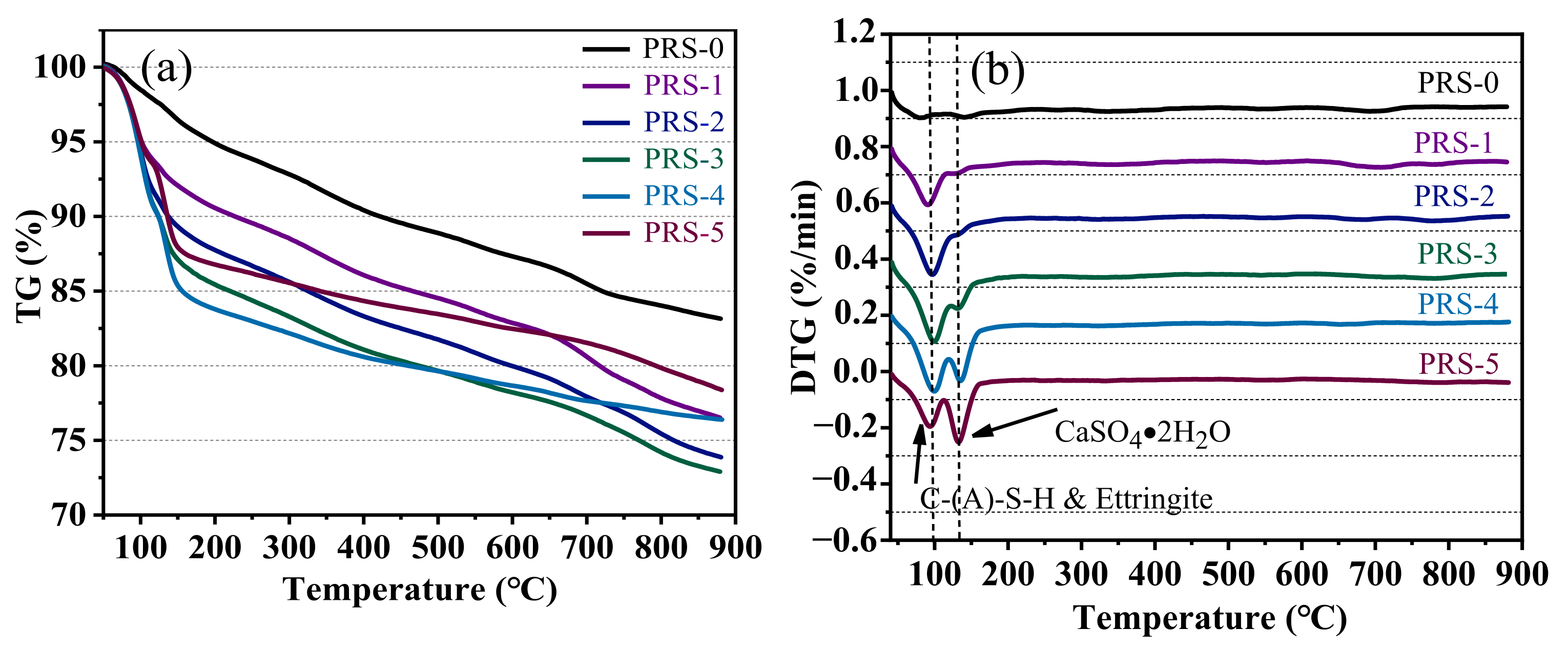

- Phosphogypsum can improve the hydration activity of slag and red mud, mainly because the SO42− released in phosphogypsum can react with the hydration product C-A-H to produce ettringite and promote the dissolution of Al3+, Ca2+, and Si4+ in slag and red mud, generating more C-(A)-S-H and ettringite, which improves the strength of the composite cementitious material.

- The hydration products of phosphogypsum-red mud-slag composite cementitious materials are mainly C-(A)-S-H and ettringite, of which C-(A)-S-H binds ettringite and unreacted particles into a dense structure, thereby improving the strength of the composite cementitious material.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, S.; Fang, P.; Ren, J.; Li, S. Application of Lime Neutralised Phosphogypsum in Supersulfated Cement. J. Clean. Prod. 2020, 272, 122660. [Google Scholar] [CrossRef]

- Rashad, A.M. Phosphogypsum as a Construction Material. J. Clean. Prod. 2017, 166, 732–743. [Google Scholar] [CrossRef]

- Zheng, T.; Lu, Y.; Luo, S.; Kong, D.; Fu, R. Effect of the Phosphogypsum Calcination Time on the Compressive Mechanical Properties of Phosphogypsum-Based Composite Cementitious Materials. Mater. Res. Express. 2022, 9, 035506. [Google Scholar] [CrossRef]

- Liu, D.Y.; Wu, C.S. Stockpiling and Comprehensive Utilization of Red Mud Research Progress. Materials 2012, 5, 1232–1246. [Google Scholar] [CrossRef]

- Wang, S.; Jin, H.; Deng, Y.; Xiao, Y. Comprehensive Utilization Status of Red Mud in China: A Critical Review. J. Clean. Prod. 2021, 289, 125136. [Google Scholar] [CrossRef]

- Ma, S.; Sun, Z.; Wei, J.; Zhang, X.; Zhang, L. Utilization of Modified Red Mud Waste from the Bayer Process as Subgrade and Its Performance Assessment in a Large-Sale Application. Coatings 2022, 12, 471. [Google Scholar] [CrossRef]

- Zeng, K.; Quan, X.; Jiang, Q.; Jiang, Z.; Qiu, F. An Efficient Dealkalization of Red Mud Through Microwave Roasting and Water Leaching. JOM 2022, 74, 3221–3231. [Google Scholar] [CrossRef]

- Li, M. Status Quo of Comprehensive Utilization of Red Mud. Int. Core J. Eng. 2022, 8, 797–801. [Google Scholar] [CrossRef]

- Huang, Y.; Lin, Z.S. Investigation on Phosphogypsum-Steel Slag-Granulated Blast-Furnace Slag-Limestone Cement. Constr. Build. Mater. 2010, 24, 1296–1301. [Google Scholar] [CrossRef]

- Huang, X.; Zhao, X.; Bie, S.; Yang, C. Hardening Performance of Phosphogypsum-Slag-Based Material. Procedia Environ. Sci. 2016, 31, 970–976. [Google Scholar] [CrossRef] [Green Version]

- Huang, Y.; Lin, Z. A Binder of Phosphogypsum-Ground Granulated Blast Furnace Slag-Ordinary Portland Cement. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2011, 26, 548–551. [Google Scholar] [CrossRef]

- Lin, C.; Dai, W.; Li, Z.; Wang, Y. Study on the Inorganic Synthesis from Recycled Cement and Solid Waste Gypsum System: Application in Grouting Materials. Constr. Build. Mater. 2020, 251, 118930. [Google Scholar] [CrossRef]

- Luukkonen, T.; Abdollahnejad, Z.; Yliniemi, J.; Kinnunen, P.; Illikainen, M. One-Part Alkali-Activated Materials: A Review. Cem. Concr. Res. 2018, 103, 21–34. [Google Scholar] [CrossRef]

- Choo, H.; Lim, S.; Lee, W.; Lee, C. Compressive Strength of One-Part Alkali Activated Fly Ash Using Red Mud as Alkali Supplier. Constr. Build. Mater. 2016, 125, 21–28. [Google Scholar] [CrossRef]

- Kumar, A.; Kumar, S. Development of Paving Blocks from Synergistic Use of Red Mud and Fly Ash Using Geopolymerization. Constr. Build. Mater. 2013, 38, 865–871. [Google Scholar] [CrossRef]

- Ye, N.; Yang, J.; Liang, S.; Hu, Y.; Hu, J.; Xiao, B.; Huang, Q. Synthesis and Strength Optimization of One-Part Geopolymer Based on Red Mud. Constr. Build. Mater. 2016, 111, 317–325. [Google Scholar] [CrossRef]

- Senff, L.; Hotza, D.; Labrincha, J.A. Effect of Red Mud Addition on the Rheological Behaviour and on Hardened State Characteristics of Cement Mortars. Constr. Build. Mater. 2011, 25, 163–170. [Google Scholar] [CrossRef]

- Joyce, P.J.; Hertel, T.; Goronovski, A.; Tkaczyk, A.H.; Pontikes, Y.; Björklund, A. Identifying Hotspots of Environmental Impact in the Development of Novel Inorganic Polymer Paving Blocks from Bauxite Residue. Resour. Conserv. Recycl. 2018, 138, 87–98. [Google Scholar] [CrossRef]

- Occhicone, A.; Vukčević, M.; Bosković, I.; Ferone, C. Red Mud-Blast Furnace Slag-Based Alkali-Activated Materials. Sustainability 2021, 13, 11298. [Google Scholar] [CrossRef]

- Occhicone, A.; Vukčević, M.; Bosković, I.; Mingione, S.; Ferone, C. Alkali-Activated Red Mud and Construction and Demolition Waste-Based Components: Characterization and Environmental Assessment. Materials 2022, 15, 1617. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, J.; Li, S.; Gao, Y.; Liu, C.; Qi, Y. Effect of Different Gypsums on the Workability and Mechanical Properties of Red Mud-Slag Based Grouting Materials. J. Clean. Prod. 2020, 245, 118759. [Google Scholar] [CrossRef]

- GB/T 8074−2008; Testing Method for Specific Surface of Cement—Blaine Method. China Standards Press: Beijing, China, 2008.

- Keliang, L.; Ziming, S. Analysis of Bayer Red Mud Activation Mechanism and Performance Based on Orthogonal Experiment. Mater. Rep. 2022, 16, 1–13. (In Chinese) [Google Scholar]

- GB/T 17671−1999; Method of Testing Cements-Determination of Strength. China Standards Press: Beijing, China, 1999.

- Hou, D.; Wu, D.; Wang, X.; Gao, S.; Yu, R.; Li, M.; Wang, P.; Wang, Y. Sustainable Use of Red Mud in Ultra-High Performance Concrete (UHPC): Design and Performance Evaluation. Cem. Concr. Compos. 2021, 115, 103862. [Google Scholar] [CrossRef]

- Liu, H.; Luo, G.; Wang, L.; Gong, Y. Strength Time-Varying and Freeze-Thaw Durability of Sustainable Pervious Concrete Pavement Material Containing Waste Fly Ash. Sustainability 2019, 11, 176. [Google Scholar] [CrossRef]

- Si, C.J. Basic Study on Solidification of Bayer Red Mud. Master’s Thesis, Kunming University of Science and Technology, Kunming, China, 2013. (In Chinese). [Google Scholar]

- Deng, Y.; Zhang, C.; Wei, X. Influence of Lithium Sulfate Addition on the Properties of Portland Cement Paste. Constr. Build. Mater. 2014, 50, 457–462. [Google Scholar] [CrossRef]

- Ustabaş, İ.; Kaya, A. Comparing the Pozzolanic Activity Properties of Obsidian to Those of Fly Ash and Blast Furnace Slag. Constr. Build. Mater. 2018, 164, 297–307. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, X.; Li, Y.; Li, D.; Zhang, W.; Xue, Y. Tailings after Iron Extraction in Bayer Red Mud by Biomass Reduction: Pozzolanic Activity and Hydration Characteristics. Materials 2021, 14, 3955. [Google Scholar] [CrossRef]

- Lam, L.; Wong, Y.L.; Poon, C.S. Degree of Hydration and Gel/Space Ratio of High-Volume Fly Ash/Cement Systems. Cem. Concr. Res. 2000, 30, 747–756. [Google Scholar] [CrossRef]

- Hill, M.R.; Bastow, T.J.; Celotto, S.; Hill, A.J. Integrated Study of the Calcination Cycle from Gibbsite to Corundum. Chem. Mater. 2007, 19, 2877–2883. [Google Scholar] [CrossRef]

- Gialanella, S.; Girardi, F.; Ischia, G.; Lonardelli, I.; Mattarelli, M.; Montagna, M. On the Goethite to Hematite Phase Transformation. J. Therm. Anal. Calorim. 2010, 102, 867–873. [Google Scholar] [CrossRef]

- Xu, F.; Wei, H.; Qian, W.; Hu, S.; Cai, Y. Compositional Minerals of Cemented Soil by Combined Thermogravimetry and Thermodynamic Modelling. Jianzhu Cailiao Xuebao/J. Build. Mater. 2022, 25, 424–433. (In Chinese) [Google Scholar] [CrossRef]

- Atasoy, A. An Investigation on Characterization and Thermal. J. Therm. Anal. Calorim. 2005, 81, 357–361. [Google Scholar] [CrossRef]

- Jeong, Y.; Yum, W.S.; Moon, J.; Oh, J.E. Utilization of Precipitated CaCO3 from Carbon Sequestration of Industrially Emitted CO2 in Cementless CaO-Activated Blast-Furnace Slag Binder System. J. Clean. Prod. 2017, 166, 649–659. [Google Scholar] [CrossRef]

- Li, X.; Ruhan, A.; Yan, P.Y. Research on Hydration Degree of Cement-Fly Ash Complex Binders. Jianzhu Cailiao Xuebao/J. Build. Mater. 2010, 13, 584–588. (In Chinese) [Google Scholar] [CrossRef]

- Shen, W.; Zhou, M.; Zhao, Q. Study on Lime-Fly Ash-Phosphogypsum Binder. Constr. Build. Mater. 2007, 21, 1480–1485. [Google Scholar] [CrossRef]

- Shen, W.; Zhou, M.; Ma, W.; Hu, J.; Cai, Z. Investigation on the Application of Steel Slag-Fly Ash-Phosphogypsum Solidified Material as Road Base Material. J. Hazard. Mater. 2009, 164, 99–104. [Google Scholar] [CrossRef]

- Li, H.; Xu, F.; Li, B.; Sun, T.; Huang, X.; Zhu, J.; Peng, C.; Lin, J.; Chen, Z. Investigation on Mechanical Properties of Excess-Sulfate Phosphogypsum Slag Cement: From Experiments to Molecular Dynamics Simulation. Constr. Build. Mater. 2022, 315, 125685. [Google Scholar] [CrossRef]

- Peng, J.H.; Wan, T.Z.; Tang, L.; Zhang, J.X. Organic Matters and P2O5 in Crystal Lattice and Their Influence on Properties of Phosphogypsum. Jianzhu Cailiao Xuebao/J. Build. Mater. 2003, 6, 221. (In Chinese) [Google Scholar]

- Daux, V.; Christophe, G.; Advocat, T.; Crovisier, J.L.; Stille, P. Kinetic Aspects of Basaltic Glass Dissolution at 90 °C: Role of Aqueous Silicon and Aluminium. Chem. Geol. 1997, 142, 109–126. [Google Scholar] [CrossRef]

- Lin, R.S.; Wang, X.Y. Effects of Cement Types and Addition of Quartz and Limestone on the Normal and Carbonation Curing of Cement Paste. Constr. Build. Mater. 2021, 305, 124799. [Google Scholar] [CrossRef]

- Lin, R.S.; Han, Y.; Wang, X.Y. Macro–Meso–Micro Experimental Studies of Calcined Clay Limestone Cement (LC3) Paste Subjected to Elevated Temperature. Cem. Concr. Compos. 2021, 116, 103871. [Google Scholar] [CrossRef]

- Lin, R.S.; Kim, T.; Wang, X.Y.; Du, W. Potential Application of MoS2 Nanoflowers as Photocatalysts in Cement: Strength, Hydration, and Dye Degradation Properties. J. Clean. Prod. 2022, 330, 129947. [Google Scholar] [CrossRef]

- Lin, R.S.; Oh, S.; Du, W.; Wang, X.Y. Strengthening the Performance of Limestone-Calcined Clay Cement (LC3) Using Nano Silica. Constr. Build. Mater. 2022, 340, 127723. [Google Scholar] [CrossRef]

- Singh, M. Treating Waste Phosphogypsum for Cement and Plaster Manufacture. Cem. Concr. Res. 2002, 32, 1033–1038. [Google Scholar] [CrossRef]

- Boonserm, K.; Sata, V.; Pimraksa, K.; Chindaprasirt, P. Improved Geopolymerization of Bottom Ash by Incorporating Fly Ash and Using Waste Gypsum as Additive. Cem. Concr. Compos. 2012, 34, 819–824. [Google Scholar] [CrossRef]

- Peng, R.; Chen, W.; Li, Q.; Yuan, B. Properties and Microstructure of Cemented Paste Tailings Activated by Sodium Sulfate. Jianzhu Cailiao Xuebao/J. Build. Mater. 2020, 23, 685–691. (In Chinese) [Google Scholar] [CrossRef]

| Raw Materials | SO3 | CaO | SiO2 | Al2O3 | Fe2O3 | Na2O | MgO | TiO2 | F | P2O5 | Other | Total |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Phosphogypsum | 47.59 | 37.93 | 11.88 | 0.62 | 0.14 | 0.31 | 0.12 | - | 0.29 | 0.67 | 0.45 | 100 |

| Red mud | 0.71 | 12.76 | 17.12 | 19.23 | 30.74 | 11.83 | 0.31 | 5.53 | - | - | 1.77 | 100 |

| Slag | 1.98 | 40.68 | 34.48 | 13.43 | 0.29 | - | 5.7 | 2.57 | - | - | 0.87 | 100 |

| Cement | 2.21 | 63.43 | 20.84 | 4.68 | 3.62 | 0.56 | 3.29 | - | - | - | 1.37 | 100 |

| No. | Red Mud | Slag | Phosphogypsum | Cement |

|---|---|---|---|---|

| R-0 | 100 | 0 | 0 | 10 |

| RS-1 | 90 | 10 | 0 | 10 |

| RS-2 | 80 | 20 | 0 | 10 |

| RS-3 | 70 | 30 | 0 | 10 |

| RS-4 | 60 | 40 | 0 | 10 |

| RS-5 | 50 | 50 | 0 | 10 |

| PRS-0 | 50 | 50 | 0 | 10 |

| PRS-1 | 50 | 40 | 10 | 10 |

| PRS-2 | 50 | 30 | 20 | 10 |

| PRS-3 | 50 | 20 | 30 | 10 |

| PRS-4 | 50 | 10 | 40 | 10 |

| PRS-5 | 50 | 0 | 50 | 10 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, F.; Chen, L.; Lin, Z.; Liu, Z.; Zhang, W.; Guo, R. Microstructure and Key Properties of Phosphogypsum-Red Mud-Slag Composite Cementitious Materials. Materials 2022, 15, 6096. https://doi.org/10.3390/ma15176096

Ma F, Chen L, Lin Z, Liu Z, Zhang W, Guo R. Microstructure and Key Properties of Phosphogypsum-Red Mud-Slag Composite Cementitious Materials. Materials. 2022; 15(17):6096. https://doi.org/10.3390/ma15176096

Chicago/Turabian StyleMa, Feiyue, Liangliang Chen, Zhiwei Lin, Zhuo Liu, Weichuan Zhang, and Rongxin Guo. 2022. "Microstructure and Key Properties of Phosphogypsum-Red Mud-Slag Composite Cementitious Materials" Materials 15, no. 17: 6096. https://doi.org/10.3390/ma15176096

APA StyleMa, F., Chen, L., Lin, Z., Liu, Z., Zhang, W., & Guo, R. (2022). Microstructure and Key Properties of Phosphogypsum-Red Mud-Slag Composite Cementitious Materials. Materials, 15(17), 6096. https://doi.org/10.3390/ma15176096