Comprehensive Understanding of Aluminosilicate Phosphate Geopolymers: A Critical Review

Abstract

:1. Introduction

2. The Preparation Process of ASP Geopolymers

2.1. Raw Materials

| Precursor Type | Main Chemical Compositions (wt.%) | Ref. | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | CaO | Fe2O3 | MgO | TiO2 | Na2O | P2O5 | LOI | |||

| Natural aluminosilicate precursors | Metakaolin | 41–75 | 22–44 | 0.01–0.91 | 0.23–7.65 | 0.06–0.65 | 0.49–4.45 | 0.03–0.62 | 0.02–0.49 | 0.1–2.43 | [26] |

| Kaolinite | 47.69 | 36.48 | 0.08 | 0.69 | 0.11 | 0.36 | 0.07 | / | 13.47 | [27] | |

| Volcanic ash | 39–45 | 16.9–17.7 | 8.1–8.7 | 11.4–14.3 | 5.41–7.65 | 2.70–3.42 | 1.7–2.9 | 0.63–1.01 | 3.35–4.81 | [28] | |

| Volcanic ash | 41.66 | 15.98 | 9.26 | 13.51 | 8.18 | 3.01 | / | 0.89 | 4.25 | [29] | |

| Raw laterite | 52.3 | 21.68 | 0.08 | 10.68 | 0.12 | 1.29 | / | 0.1 | / | [30] | |

| Raw laterite | 35.53 | 28.21 | 0.21 | 36.32 | 0.25 | 1.81 | 0.82 | / | / | [31] | |

| Halloysite | 46 | 37.8 | 0.07 | 0.72 | 0.13 | 0.07 | / | / | 14.9 | [32] | |

| Solid wastes | Fly ash | 49.07 | 32.38 | 3.43 | 7.80 | 0.55 | / | 0.06 | 1.01 | 2.30 | [33] |

| Fly ash | 53.63 | 21.71 | 10.80 | 7.96 | 1.17 | 0.86 | 1.20 | / | 0.33 | [34] | |

| LCFA * | 44.5 | 31.2 | 5.3 | 6.5 | 1.9 | 1.2 | 1.1 | / | 3.8 | [35] | |

| HCFA * | 38.1 | 26.5 | 16.5 | 8.5 | 1.2 | 1.7 | 0.6 | / | 6.5 | ||

| GGBFS * | 38.0 | 10.8 | 40.1 | 0.3 | 7.24 | 0.83 | 0.31 | 0.02 | / | [36] | |

| EMDR * | 10.36 | 4.279 | 0.064 | 8.739 | 0.09 | / | 0.052 | 0.096 | / | [37] | |

| Mine tailings | 16.2 | 2.6 | 0.4 | 38.9 | / | 0.2 | / | 0.3 | 28.1 | [38] | |

| SFCC * | 37.63 | 55.29 | 0.39 | 0.58 | / | / | 0.15 | / | / | [39] | |

2.2. Curing Conditions

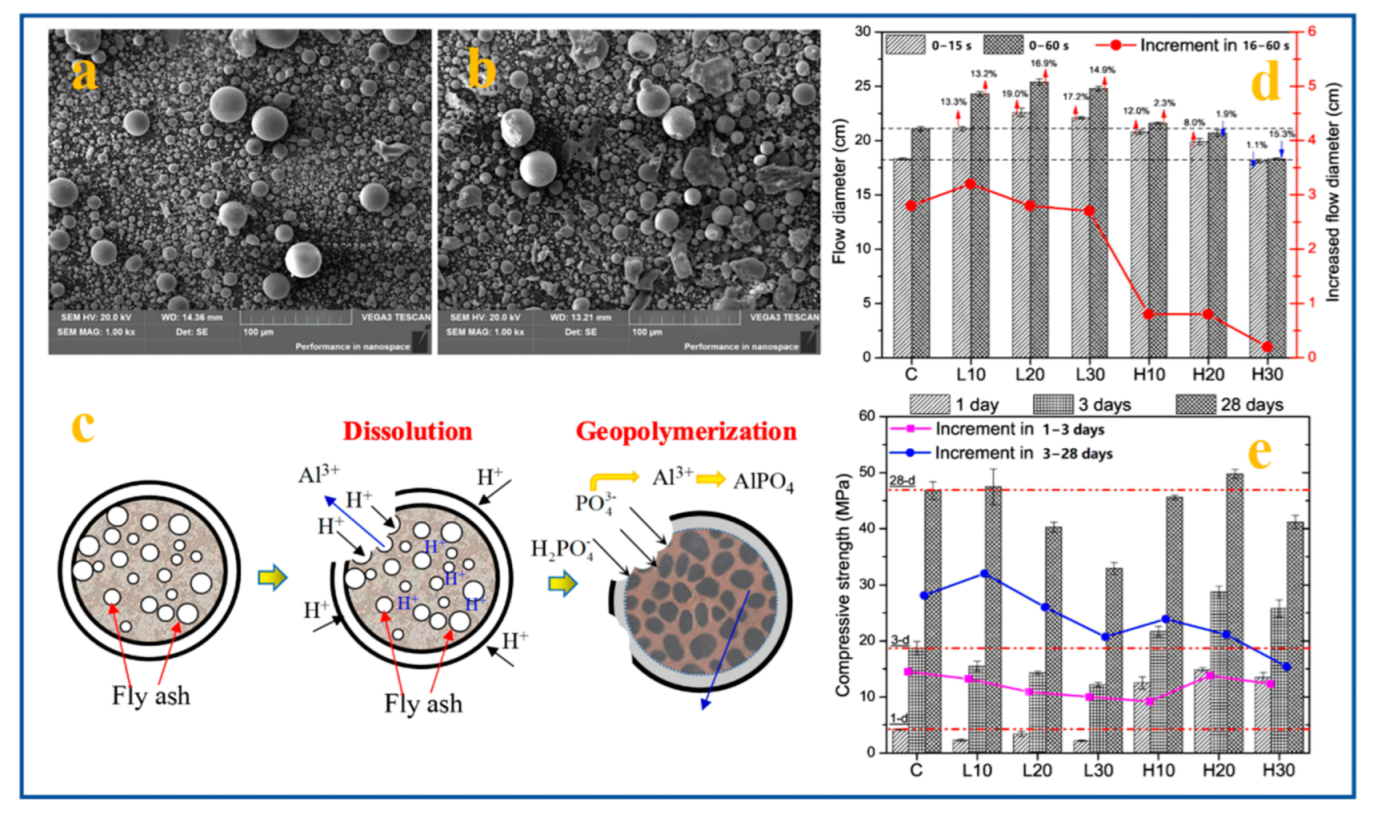

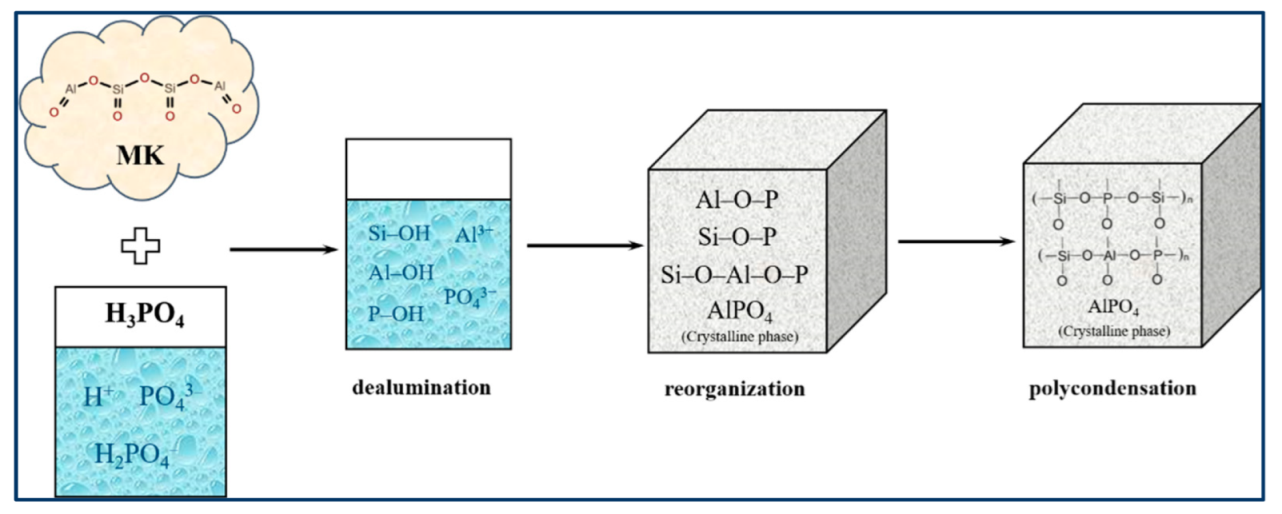

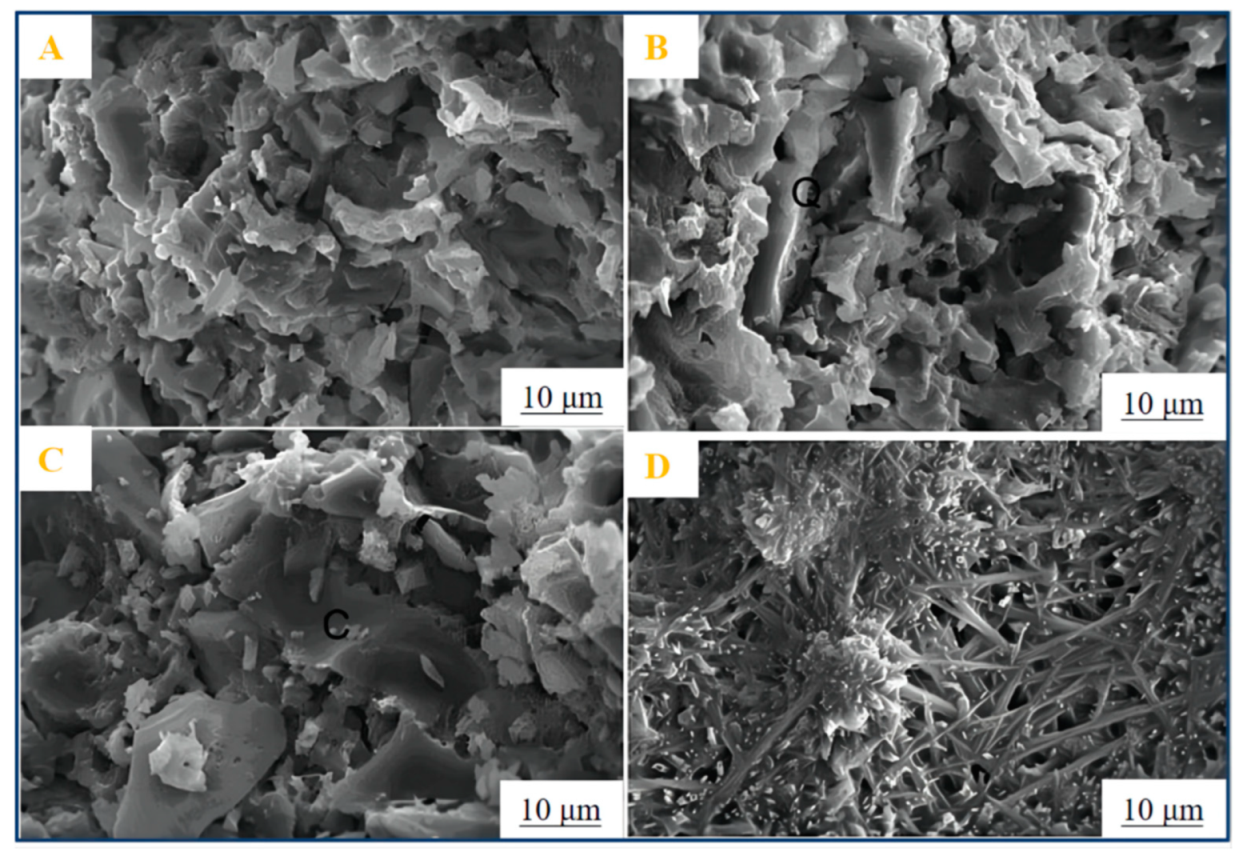

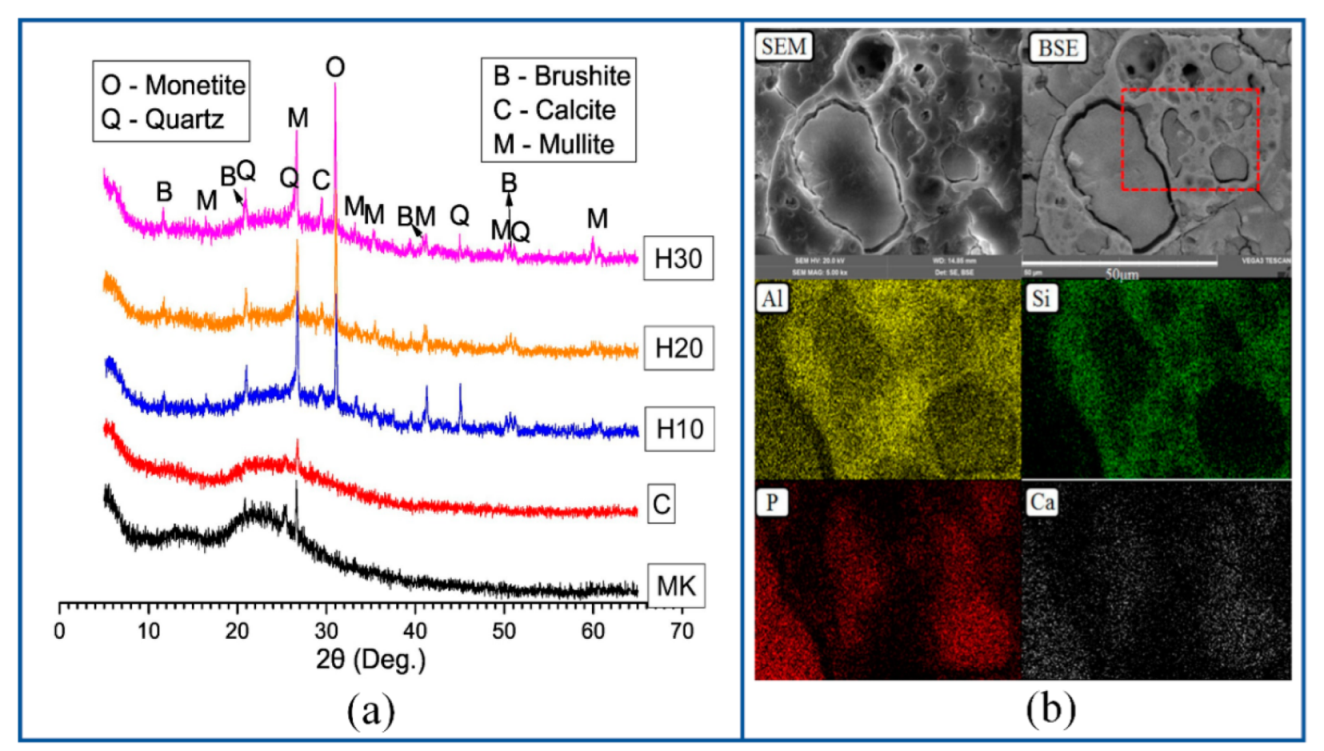

2.3. Geopolymerization Mechanism

- The first is the dealumination process of the aluminosilicate precursor. The silicon–oxygen tetrahedron and aluminum–oxygen tetrahedral structure of aluminosilicate precursors depolymerize under the action of phosphoric acid, mainly including the breaking of Al–O–Al bonds and Si–O–Al bonds and the formation of free Al3+ and –Si–O– units.

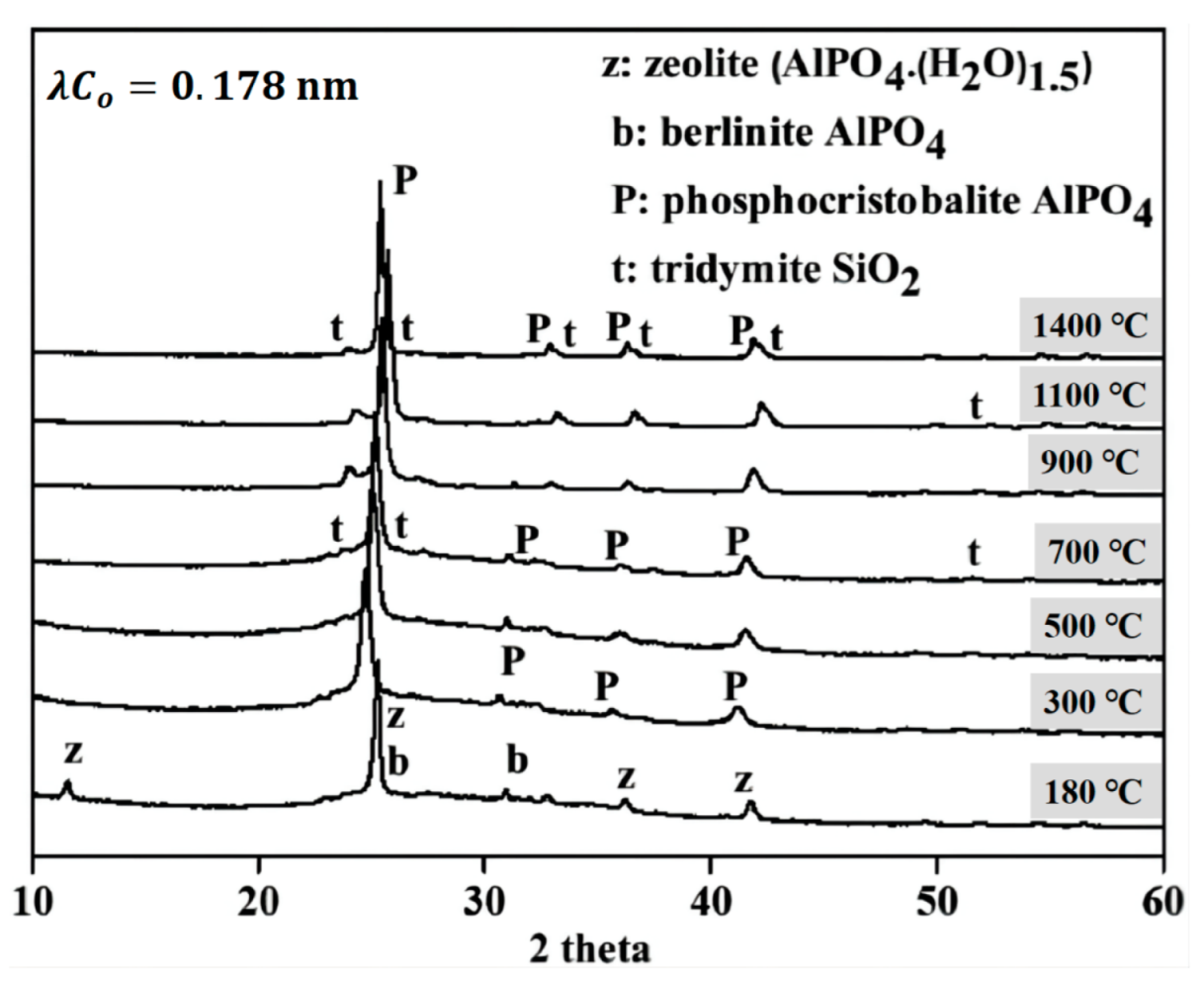

- Then, there is the polycondensation of PO43−, Al3+, and –Si–O– units and the formation of crystalline phases such as AlPO4.

- The final geopolymerization process is based on the previous polycondensation reaction, and the units are further condensed to form larger geopolymerization chains and form different three-dimensional geopolymer network structures. At the same time, the crystal phase, such as AlPO4, is dispersed in the amorphous geopolymer network structure and finally forms a kind of amorphous and crystalline composite geopolymer structure.

3. The Properties of ASP Geopolymers

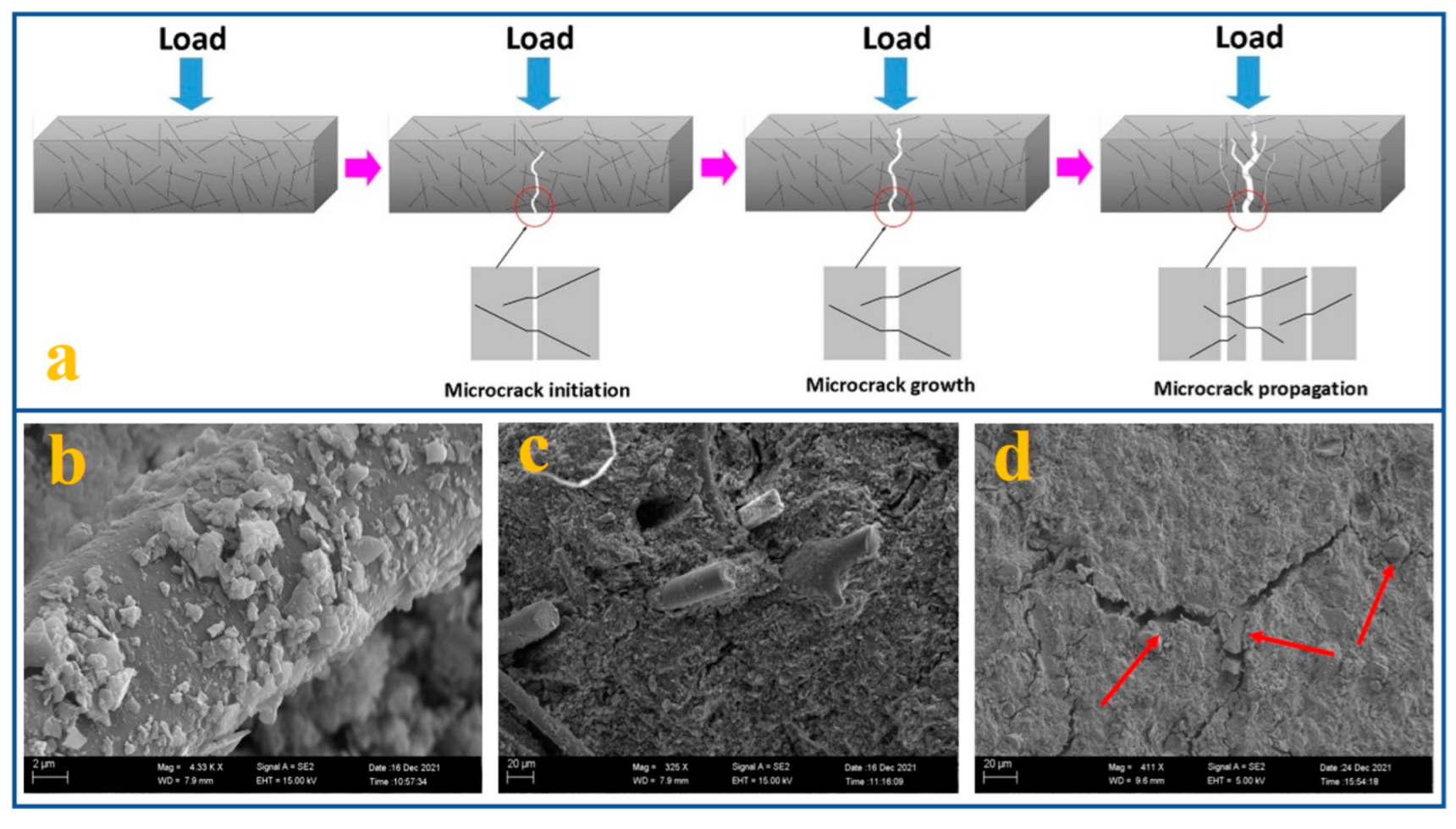

3.1. Mechanical Properties

3.2. Heat and Fire Resistance

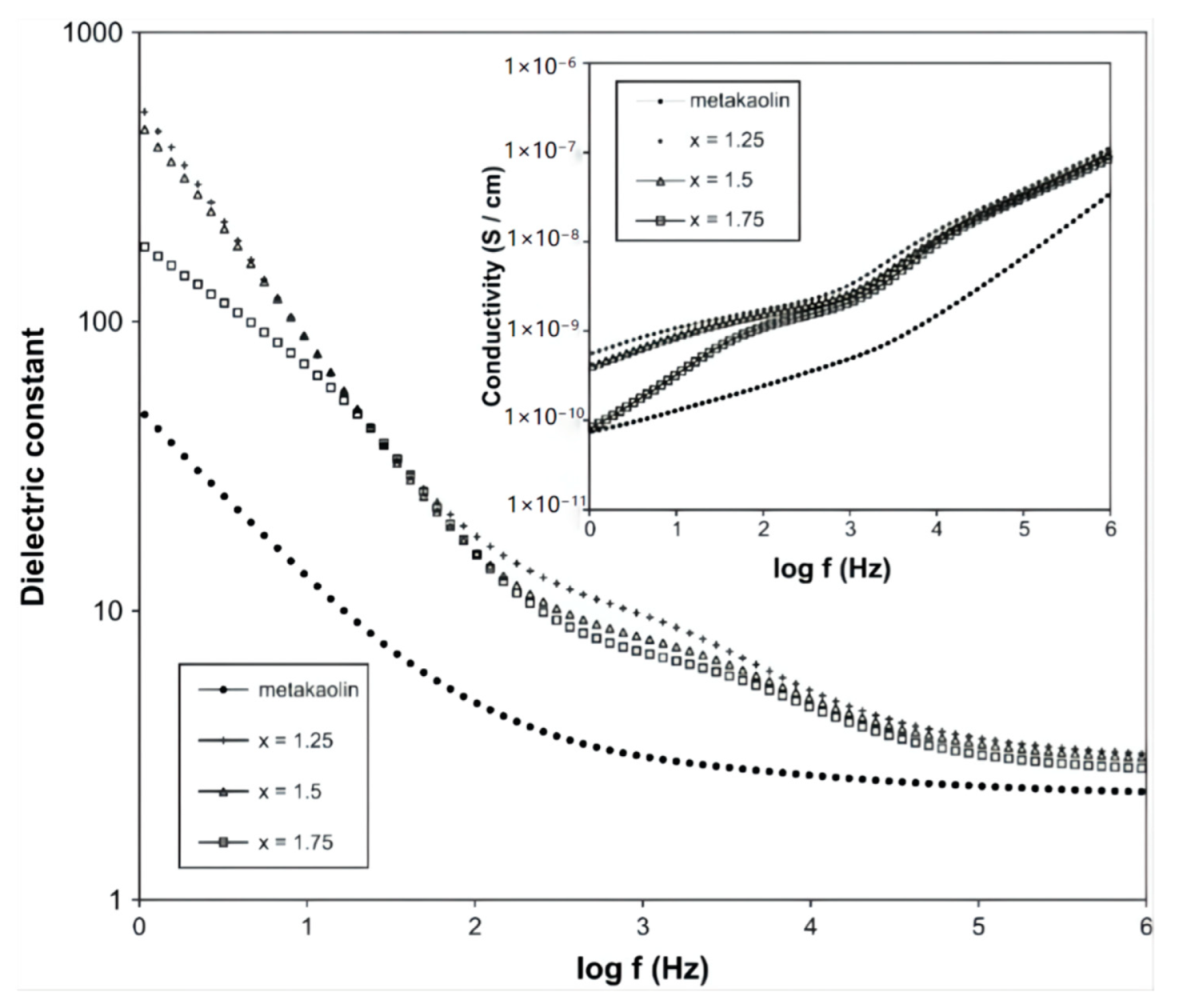

3.3. Dielectric Property

3.4. Durability

4. The Modification of ASP Geopolymers

4.1. Modified with Admixture

4.2. Modified with Fiber

5. Applied Research on ASP Geopolymers

5.1. Porous Foam Materials

5.2. Heavy Metal Solidification/Radioactive Nuclear Waste Management

5.3. Possible Applications in the Future

5.4. Discussion and Recommendations

- The use of natural raw materials is not conducive to the sustainable development of ASP geopolymers, and the exploration of solid waste utilization should be strengthened. It is necessary to focus on solving the problem of unstable performance caused by the fluctuation of solid wastes composition and paying attention to the leaching of harmful heavy metals in solid wastes.

- The gradual shortage of phosphate rock resources and the high price of phosphoric acid will be the key factors limiting the wide application of ASP geopolymers in the future. It will be of great significance to actively expand the range and types of acid activators, such as the application of waste liquid containing phosphoric acid.

- The durability enhancement and mechanism of ASP geopolymers should be further studied owing to their poor durability.

- The long-term performance of ASP geopolymers should also be evaluated, with emphasis on improving the acid and alkali resistance. In addition, the environmental impact assessment of such materials is also crucial. To date, there is a lack of relevant research, which will produce some risks in the application of this material.

- Standardizing the test methods, technical indicators, and normalizing the preparation process of ASP geopolymers will help to promote the standardized and industrialization application of ASP geopolymers.

- ASP geopolymers are better than AAS geopolymers in mechanical properties, heat resistance, and dielectric properties. However, the cost of ASP geopolymers is significantly higher than that of AAS geopolymers. Therefore, the goal of AAS geopolymers is to replace traditional Portland cement on a large scale as much as possible in the future, while ASP geopolymer materials are expected to be used in some high-valued fields, such as coatings, fire-resistance, and thermal insulation materials.

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Davidovits, J. Geopolymers: Inorganic polymeric new materials. J. Therm. Anal. Calorim. 1991, 37, 1633–1656. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymer Chemistry and Applications, 5th ed.; Geopolymer Institute: Hauts-de-France, France, 2011. [Google Scholar]

- Wang, Y.-S.; Alrefaei, Y.; Dai, J.-G. Silico-Aluminophosphate and Alkali-Aluminosilicate Geopolymers: A Comparative Review. Front. Mater. 2019, 6, 106. [Google Scholar] [CrossRef]

- Zeyad, A.M.; Magbool, H.M.; Tayeh, B.A.; de Azevedo, A.R.G.; Abutaleb, A.; Hussain, Q. Production of geopolymer concrete by utilizing volcanic pumice dust. Case Stud. Constr. Mater. 2022, 16, e00802. [Google Scholar] [CrossRef]

- Marvila, M.T.; de Azevedo, A.R.G.; de Oliveira, L.B.; Xavier, G.D.C.; Vieira, C.M.F. Mechanical, physical and durability properties of activated alkali cement based on blast furnace slag as a function of %Na2O. Case Stud. Constr. Mater. 2021, 15, e00723. [Google Scholar] [CrossRef]

- Singh, N.; Middendorf, B. Geopolymers as an alternative to Portland cement: An overview. Constr. Build. Mater. 2020, 237, 117455. [Google Scholar] [CrossRef]

- Zhao, J.; Tong, L.; Li, B.; Chen, T.; Wang, C.; Yang, G.; Zheng, Y. Eco-friendly geopolymer materials: A review of performance improvement, potential application and sustainability assessment. J. Clean. Prod. 2021, 307, 127085. [Google Scholar] [CrossRef]

- Cong, P.; Cheng, Y. Advances in geopolymer materials: A comprehensive review. J. Traffic Transp. Eng. 2021, 8, 283–314. [Google Scholar] [CrossRef]

- Metekong, J.V.S.; Kaze, C.R.; Deutou, J.G.; Venyite, P.; Nana, A.; Kamseu, E.; Melo, U.C.; Tatietse, T.T. Evaluation of performances of volcanic-ash-laterite based blended geopolymer concretes: Mechanical properties and durability. J. Build. Eng. 2021, 34, 101935. [Google Scholar] [CrossRef]

- de Azevedo, A.; Cruz, A.; Marvila, M.; de Oliveira, L.; Monteiro, S.; Vieira, C.; Fediuk, R.; Timokhin, R.; Vatin, N.; Daironas, M. Natural Fibers as an Alternative to Synthetic Fibers in Reinforcement of Geopolymer Matrices: A Comparative Review. Polymers 2021, 13, 2493. [Google Scholar] [CrossRef]

- de Oliveira, L.B.; de Azevedo, A.R.; Marvila, M.T.; Pereira, E.C.; Fediuk, R.; Vieira, C.M.F. Durability of geopolymers with industrial waste. Case Stud. Constr. Mater. 2022, 16, e00839. [Google Scholar] [CrossRef]

- Luukkonen, T.; Heponiemi, A.; Runtti, H.; Pesonen, J.; Yliniemi, J.; Lassi, U. Application of alkali-activated materials for water and wastewater treatment: A review. Rev. Environ. Sci. Bio Technol. 2019, 18, 271–297. [Google Scholar] [CrossRef]

- Jiang, C.; Wang, A.; Bao, X.; Ni, T.; Ling, J. A review on geopolymer in potential coating application: Materials, preparation and basic properties. J. Build. Eng. 2020, 32, 101734. [Google Scholar] [CrossRef]

- Barsoum, M.W.; Ganguly, A.; Hug, G. Microstructural Evidence of Reconstituted Limestone Blocks in the Great Pyramids of Egypt. J. Am. Ceram. Soc. 2006, 89, 3788–3796. [Google Scholar] [CrossRef]

- Wagh, A.S. Chemically Bonded Phosphate Ceramics: Twenty-First Century Materials with Diverse Applications; Elsevier: Amsterdam, The Netherlands, 2004; pp. 35–49. [Google Scholar] [CrossRef]

- Cao, D.; Dageng, S.U.; Bo, L.U.; Yang, Y. Synthesis and structure characterization of geopolymeric material based on metakaolinite and phosphoric acid. J. Chin. Ceram. Soc. 2005, 33, 1385–1389. [Google Scholar]

- Perera, D.S.; Hanna, J.V.; Davis, J.; Blackford, M.G.; Latella, B.A.; Sasaki, Y.; Vance, E.R. Relative strengths of phosphoric acid-reacted and alkali-reacted metakaolin materials. J. Mater. Sci. 2008, 43, 6562–6566. [Google Scholar] [CrossRef]

- Liu, L.-P.; Cui, X.-M.; He, Y.; Liu, S.-D.; Gong, S.-Y. The phase evolution of phosphoric acid-based geopolymers at elevated temperatures. Mater. Lett. 2012, 66, 10–12. [Google Scholar] [CrossRef]

- Douiri, H.; Louati, S.; Baklouti, S.; Arous, M.; Fakhfakh, Z. Structural, thermal and dielectric properties of phosphoric acid-based geopolymers with different amounts of H3PO4. Mater. Lett. 2014, 116, 9–12. [Google Scholar] [CrossRef]

- Mathivet, V.; Jouin, J.; Gharzouni, A.; Sobrados, I.; Celerier, H.; Rossignol, S.; Parlier, M. Acid-based geopolymers: Understanding of the structural evolutions during consolidation and after thermal treatments. J. Non Cryst. Solids 2019, 512, 90–97. [Google Scholar] [CrossRef]

- Tchakouté, H.K.; Rüscher, C.H. Mechanical and microstructural properties of metakaolin-based geopolymer cements from sodium waterglass and phosphoric acid solution as hardeners: A comparative study. Appl. Clay Sci. 2017, 140, 81–87. [Google Scholar] [CrossRef]

- Celerier, H.; Jouin, J.; Mathivet, V.; Tessier-Doyen, N.; Rossignol, S. Composition and properties of phosphoric acid-based geopolymers. J. Non Cryst. Solids 2018, 493, 94–98. [Google Scholar] [CrossRef]

- Celerier, H.; Jouin, J.; Tessier-Doyen, N.; Rossignol, S. Influence of various metakaolin raw materials on the water and fire resistance of geopolymers prepared in phosphoric acid. J. Non Cryst. Solids 2018, 500, 493–501. [Google Scholar] [CrossRef]

- Bewa, C.N.; Tchakouté, H.K.; Banenzoué, C.; Cakanou, L.; Mbakop, T.T.; Kamseu, E.; Rüscher, C.H. Acid-based geopolymers using waste fired brick and different metakaolins as raw materials. Appl. Clay Sci. 2020, 198, 105813. [Google Scholar] [CrossRef]

- Louati, S.; Baklouti, S.; Samet, B. Acid based geopolymerization kinetics: Effect of clay particle size. Appl. Clay Sci. 2016, 132, 571–578. [Google Scholar] [CrossRef]

- Jindal, B.B.; Alomayri, T.; Hasan, A.; Kaze, C.R. Geopolymer concrete with metakaolin for sustainability: A comprehensive review on raw material’s properties, synthesis, performance, and potential application. Environ. Sci. Pollut. Res. 2022, 75, 1–26. [Google Scholar] [CrossRef]

- Zhang, B.; Guo, H.; Deng, L.; Fan, W.; Yu, T.; Wang, Q. Undehydrated kaolinite as materials for the preparation of geopolymer through phosphoric acid-activation. Appl. Clay Sci. 2020, 199, 105887. [Google Scholar] [CrossRef]

- Pougnong, T.E.; Belibi, P.D.B.; Baenla, J.; Thamer, A.; Tiffo, E.; Elimbi, A. Effects of chemical composition of amorphous phase on the reactivity of phosphoric acid activation of volcanic ashes. J. Non Cryst. Solids 2022, 575, 121213. [Google Scholar] [CrossRef]

- Djobo, J.N.Y.; Stephan, D.; Elimbi, A. Setting and hardening behavior of volcanic ash phosphate cement. J. Build. Eng. 2020, 31, 101427. [Google Scholar] [CrossRef]

- Mimboe, A.G.; Abo, M.T.; Djobo, J.N.Y.; Tome, S.; Kaze, R.C.; Deutou, J.G.N. Lateritic soil based-compressed earth bricks stabilized with phosphate binder. J. Build. Eng. 2020, 31, 101465. [Google Scholar] [CrossRef]

- Bewa, C.N.; Tchakouté, H.K.; Rüscher, C.H.; Kamseu, E.; Leonelli, C. Influence of the curing temperature on the properties of poly(phospho-ferro-siloxo) networks from laterite. SN Appl. Sci. 2019, 1, 115568. [Google Scholar] [CrossRef]

- Zhang, B.; Guo, H.; Yuan, P.; Deng, L.; Zhong, X.; Li, Y.; Wang, Q.; Liu, D. Novel acid-based geopolymer synthesized from nanosized tubular halloysite: The role of precalcination temperature and phosphoric acid concentration. Cem. Concr. Compos. 2020, 110, 103601. [Google Scholar] [CrossRef]

- Pu, S.; Zhu, Z.; Song, W.; Huo, W.; Zhang, J. Mechanical and microscopic properties of fly ash phosphoric acid-based geopolymer paste: A comprehensive study. Constr. Build. Mater. 2021, 299, 123947. [Google Scholar] [CrossRef]

- Guo, H.; Yuan, P.; Zhang, B.; Wang, Q.; Deng, L.; Liu, D. Realization of high-percentage addition of fly ash in the materials for the preparation of geopolymer derived from acid-activated metakaolin. J. Clean. Prod. 2021, 285, 125430. [Google Scholar] [CrossRef]

- Wang, Y.-S.; Alrefaei, Y.; Dai, J.-G. Influence of coal fly ash on the early performance enhancement and formation mechanisms of silico-aluminophosphate geopolymer. Cem. Concr. Res. 2020, 127, 105932. [Google Scholar] [CrossRef]

- Djobo, J.N.Y.; Stephan, D. Control of the setting reaction and strength development of slag-blended volcanic ash-based phosphate geopolymer with the addition of boric acid. J. Aust. Ceram. Soc. 2021, 57, 1145–1154. [Google Scholar] [CrossRef]

- Han, Y.; Cui, X.; Lv, X.; Wang, K. Preparation and characterization of geopolymers based on a phosphoric-acid-activated electrolytic manganese dioxide residue. J. Clean. Prod. 2018, 205, 488–498. [Google Scholar] [CrossRef]

- Nergis, D.D.B.; Vizureanu, P.; Sandu, A.V.; Nergis, D.P.B.; Bejinariu, C. XRD and TG-DTA Study of New Phosphate-Based Geopolymers with Coal Ash or Metakaolin as Aluminosilicate Source and Mine Tailings Addition. Materials 2021, 15, 202. [Google Scholar] [CrossRef]

- Wan, Q.; Zhang, R.; Zhang, Y. Structure and Properties of Phosphate-Based Geopolymer Synthesized with the Spent Fluid Catalytic-Cracking (SFCC) Catalyst. Gels 2022, 8, 130. [Google Scholar] [CrossRef]

- Guo, H.; Zhang, B.; Deng, L.; Yuan, P.; Li, M.; Wang, Q. Preparation of high-performance silico-aluminophosphate geopolymers using fly ash and metakaolin as raw materials. Appl. Clay Sci. 2021, 204, 106019. [Google Scholar] [CrossRef]

- Guo, C.-M.; Wang, K.-T.; Liu, M.-Y.; Li, X.-H.; Cui, X. Preparation and characterization of acid-based geopolymer using metakaolin and disused polishing liquid. Ceram. Int. 2016, 42, 9287–9291. [Google Scholar] [CrossRef]

- Duxson, P.; Provis, J.L.; Lukey, G.C.; Van Deventer, J.S.J. The role of inorganic polymer technology in the development of ‘green concrete’. Cem. Concr. Res. 2007, 37, 1590–1597. [Google Scholar] [CrossRef]

- Qaidi, S.; Tayeh, B.A.; Isleem, H.F.; de Azevedo, A.R.; Ahme, H.U.; Emad, W. Sustainable utilization of red mud waste (bauxite residue) and slag for the production of geopolymer composites: A review. Case Stud. Constr. Mater. 2022, 16, e00994. [Google Scholar] [CrossRef]

- Amin, M.; Elsakhawy, Y.; Abu El-Hassan, K.; Abdelsalam, B.A. Behavior evaluation of sustainable high strength geopolymer concrete based on fly ash, metakaolin, and slag. Case Stud. Constr. Mater. 2022, 16, e00976. [Google Scholar] [CrossRef]

- Bartos, J.M.; Mullins, G.L.; Sikora, F.J.; Copeland, J.P. Availability of Phosphorus in the Water-Insoluble Fraction of Monoammonium Phosphate Fertilizers. Soil Sci. Soc. Am. J. 1991, 55, 539–543. [Google Scholar] [CrossRef]

- Raven, K.P.; Loeppert, R.H. Microwave digestion of fertilizers and soil amendments. Commun. Soil Sci. Plant Anal. 1996, 27, 2947–2971. [Google Scholar] [CrossRef]

- Feng, D.; Tan, H.; Van Deventer, J.S.J. Ultrasound enhanced geopolymerisation. J. Mater. Sci. 2004, 39, 571–580. [Google Scholar] [CrossRef]

- Cui, X.-M.; Liu, L.-P.; He, Y.; Chen, J.-Y.; Zhou, J. A novel aluminosilicate geopolymer material with low dielectric loss. Mater. Chem. Phys. 2011, 130, 1–4. [Google Scholar] [CrossRef]

- Zribi, M.; Baklouti, S. Investigation of Phosphate based geopolymers formation mechanism. J. Non Cryst. Solids 2021, 562, 120777. [Google Scholar] [CrossRef]

- Louati, S.; Baklouti, S.; Samet, B. Geopolymers Based on Phosphoric Acid and Illito-Kaolinitic Clay. Adv. Mater. Sci. Eng. 2016, 2016, 1–7. [Google Scholar] [CrossRef]

- Le-Ping, L.; Xue-Min, C.; Shu-Heng, Q.; Jun-Li, Y.; Lin, Z. Preparation of phosphoric acid-based porous geopolymers. Appl. Clay Sci. 2010, 50, 600–603. [Google Scholar] [CrossRef]

- Tome, S.; Hermann, D.T.; Shikuku, V.O.; Otieno, S. Synthesis, characterization and application of acid and alkaline activated volcanic ash-based geopolymers for adsorptive remotion of cationic and anionic dyes from water. Ceram. Int. 2021, 47, 20965–20973. [Google Scholar] [CrossRef]

- He, Y.; Liu, L.; He, L.; Cui, X. Characterization of chemosynthetic H3PO4–Al2O3–2SiO2 geopolymers. Ceram. Int. 2016, 42, 10908–10912. [Google Scholar] [CrossRef]

- Morsy, M.; Rashad, A.M.; Shoukry, H.; Mokhtar, M. Potential use of limestone in metakaolin-based geopolymer activated with H3PO4 for thermal insulation. Constr. Build. Mater. 2019, 229, 117088. [Google Scholar] [CrossRef]

- Lin, H.; Liu, H.; Li, Y.; Kong, X. Properties and reaction mechanism of phosphoric acid activated metakaolin geopolymer at varied curing temperatures. Cem. Concr. Res. 2021, 144, 106425. [Google Scholar] [CrossRef]

- Zribi, M.; Samet, B.; Baklouti, S. Effect of curing temperature on the synthesis, structure and mechanical properties of phosphate-based geopolymers. J. Non Cryst. Solids 2019, 511, 62–67. [Google Scholar] [CrossRef]

- Lin, H.; Liu, H.; Li, Y.; Kong, X. Thermal stability, pore structure and moisture adsorption property of phosphate acid-activated metakaolin geopolymer. Mater. Lett. 2021, 301, 130226. [Google Scholar] [CrossRef]

- Wang, Y.-S.; Alrefaei, Y.; Dai, J.-G. Improvement of early-age properties of silico-aluminophosphate geopolymer using dead burnt magnesia. Constr. Build. Mater. 2019, 217, 1–11. [Google Scholar] [CrossRef]

- Dong, T.; Xie, S.; Wang, J.; Chen, Z.; Liu, Q. Properties and characterization of a metakaolin phosphate acid–based geopolymer synthesized in a humid environment. J. Aust. Ceram. Soc. 2020, 56, 175–184. [Google Scholar] [CrossRef]

- Wang, Y.-S.; Dai, J.-G.; Ding, Z.; Xu, W.-T. Phosphate-based geopolymer: Formation mechanism and thermal stability. Mater. Lett. 2017, 190, 209–212. [Google Scholar] [CrossRef]

- Tchakouté, H.K.; Rüscher, C.H.; Kamseu, E.; Andreola, F.; Leonelli, C. Influence of the molar concentration of phosphoric acid solution on the properties of metakaolin-phosphate-based geopolymer cements. Appl. Clay Sci. 2017, 147, 184–194. [Google Scholar] [CrossRef]

- Zribi, M.; Samet, B.; Baklouti, S. Mechanical, microstructural and structural investigation of phosphate-based geopolymers with respect to P/Al molar ratio. J. Solid State Chem. 2020, 281, 121025. [Google Scholar] [CrossRef]

- Bai, C.; Conte, A.; Colombo, P. Open-cell phosphate-based geopolymer foams by frothing. Mater. Lett. 2017, 188, 379–382. [Google Scholar] [CrossRef]

- Derouiche, R.; Baklouti, S. Phosphoric acid based geopolymerization: Effect of the mechanochemical and the thermal activation of the kaolin. Ceram. Int. 2021, 47, 13446–13456. [Google Scholar] [CrossRef]

- Dong, T.; Zhang, Y.; Jiang, Y.; Zhao, G.; Yu, X. Workability and mechanical property of metakaolin phosphate acid based geopolymer. IOP Conf. Ser. Earth Environ. Sci. 2019, 267, 022002. [Google Scholar] [CrossRef]

- Yang, T.; Han, E.; Wang, X.; Wu, D. Surface decoration of polyimide fiber with carbon nanotubes and its application for mechanical enhancement of phosphoric acid-based geopolymers. Appl. Surf. Sci. 2017, 416, 200–212. [Google Scholar] [CrossRef]

- Ndjock, B.D.L.; Robayo-Salazar, R.; de Gutiérrez, R.M.; Baenla, J.; Mbey, J.; Cyr, M.; Elimbi, A. Phosphoric acid activation of volcanic ashes: Influence of the molar ratio R = (MgO + CaO)/P2O5 on reactivity of volcanic ash and strength of obtained cementitious material. J. Build. Eng. 2021, 33, 101879. [Google Scholar] [CrossRef]

- Gao, L.; Zheng, Y.; Tang, Y.; Yu, J.; Yu, X.; Liu, B. Effect of phosphoric acid content on the microstructure and compressive strength of phosphoric acid-based metakaolin geopolymers. Heliyon 2020, 6, e03853. [Google Scholar] [CrossRef]

- Katsiki, A.; Hertel, T.; Tysmans, T.; Pontikes, Y.; Rahier, H. Metakaolinite Phosphate Cementitious Matrix: Inorganic Polymer Obtained by Acidic Activation. Materials 2019, 12, 442. [Google Scholar] [CrossRef]

- Djobo, J.N.Y.; Nkwaju, R.Y. Preparation of acid aluminum phosphate solutions for metakaolin phosphate geopolymer binder. RSC Adv. 2021, 11, 32258–32268. [Google Scholar] [CrossRef]

- Shuai, Q.; Xu, Z.; Yao, Z.; Chen, X.; Jiang, Z.; Peng, X.; An, R.; Li, Y.; Jiang, X.; Li, H. Fire resistance of phosphoric acid-based geopolymer foams fabricated from metakaolin and hydrogen peroxide. Mater. Lett. 2019, 263, 127228. [Google Scholar] [CrossRef]

- Khabbouchi, M.; Hosni, K.; Mezni, M.; Zanelli, C.; Doggy, M.; Dondi, M.; Srasra, E. Interaction of metakaolin-phosphoric acid and their structural evolution at high temperature. Appl. Clay Sci. 2017, 146, 510–516. [Google Scholar] [CrossRef]

- Sellami, M.; Barre, M.; Toumi, M. Synthesis, thermal properties and electrical conductivity of phosphoric acid-based geopolymer with metakaolin. Appl. Clay Sci. 2019, 180, 105192. [Google Scholar] [CrossRef]

- Bewa, C.N.; Tchakouté, H.K.; Fotio, D.; Rüscher, C.H.; Kamseu, E.; Leonelli, C. Water resistance and thermal behavior of metakaolin-phosphate-based geopolymer cements. J. Asian Ceram. Soc. 2018, 6, 271–283. [Google Scholar] [CrossRef]

- Jouin, J.; Celerier, H.; Ouamara, L.; Tessier-Doyen, N.; Rossignol, S. Study of the formation of acid-based geopolymer networks and their resistance to water by time/temperature treatments. J. Am. Ceram. Soc. 2021, 104, 5445–5456. [Google Scholar] [CrossRef]

- Odeh, N.A.; Al-Rkaby, A.H. Strength, Durability, and Microstructures characterization of sustainable geopolymer improved clayey soil. Case Stud. Constr. Mater. 2022, 16, e00988. [Google Scholar] [CrossRef]

- Saif, M.S.; El-Hariri, M.O.; Sarie-Eldin, A.I.; Tayeh, B.A.; Farag, M.F. Impact of Ca+ content and curing condition on durability performance of metakaolin-based geopolymer mortars. Case Stud. Constr. Mater. 2022, 16, e00922. [Google Scholar] [CrossRef]

- Wagh, A.; Jeong, S.Y. Chemically Bonded Phosphate Ceramics: I, A Dissolution Model of Formation. J. Am. Ceram. Soc. 2010, 86, 1838–1844. [Google Scholar] [CrossRef]

- Wang, Y. Influence of Metal Ions on Formation of Silico-Aluminophosphate Geopolymer. Ph.D. Thesis, The Hong Kong Polytechnic University, Hong Kong, 2018. [Google Scholar]

- Zhang, Z.; Wang, Q.; Huang, Z. Value-added utilization of copper slag to enhance the performance of magnesium potassium phosphate cement. Resour. Conserv. Recycl. 2022, 180, 106212. [Google Scholar] [CrossRef]

- Farhan, K.Z.; Johari, M.A.M.; Demirboğa, R. Impact of fiber reinforcements on properties of geopolymer composites: A review. J. Build. Eng. 2021, 44, 102628. [Google Scholar] [CrossRef]

- Yu, C.-Q.; Yu, Y.-R.; Zhao, Y.-M.; He, P.-G.; Xu, C.-S.; Fu, S.; Yang, Z.-H. Mechanical properties and in situ fracture behavior of SiO2f/phosphate geopolymer composites. Rare Met. 2020, 39, 562–569. [Google Scholar] [CrossRef]

- Wei, Q.; Liu, Y.; Le, H. Mechanical and Thermal Properties of Phosphoric Acid Activated Geopolymer Materials Reinforced with Mullite Fibers. Materials 2022, 15, 4185. [Google Scholar] [CrossRef]

- Huang, T.; Sun, Z. Advances in multifunctional graphene-geopolymer composites. Constr. Build. Mater. 2021, 272, 121619. [Google Scholar] [CrossRef]

- Krishna, R.; Mishra, J.; Nanda, B.; Patro, S.K.; Adetayo, A.; Qureshi, T.S. The role of graphene and its derivatives in modifying different phases of geopolymer composites: A review. Constr. Build. Mater. 2021, 306, 124774. [Google Scholar] [CrossRef]

- Ndjock, B.D.L.; Baenla, J.; Yanne, E.; Mbah, J.B.; Souaïbou; Elimbi, A. Effects of Al and Fe powders on the formation of foamed cement obtained by phosphoric acid activation of volcanic ash. Mater. Lett. 2022, 308, 131147. [Google Scholar] [CrossRef]

- Gualtieri, M.L.; Romagnoli, M.; Gualtieri, A.F. Preparation of phosphoric acid-based geopolymer foams using limestone as pore forming agent—Thermal properties by in situ XRPD and Rietveld refinements. J. Eur. Ceram. Soc. 2015, 35, 3167–3178. [Google Scholar] [CrossRef]

- Tchakouté, H.K.; Fotio, D.; Rüscher, C.H.; Kamseu, E.; Djobo, J.N.; Bignozzi, M.C.; Leonelli, C. The effects of synthesized calcium phosphate compounds on the mechanical and microstructural properties of metakaolin-based geopolymer cements. Constr. Build. Mater. 2018, 163, 776–792. [Google Scholar] [CrossRef]

- Pu, S.; Zhu, Z.; Song, W.; Wang, H.; Huo, W.; Zhang, J. A novel acidic phosphoric-based geopolymer binder for lead solidification/stabilization. J. Hazard. Mater. 2017, 415, 125659. [Google Scholar] [CrossRef]

- Njimou, J.R.; Pengou, M.; Tchakoute, H.K.; Tamwa, M.S.; Tizaoui, C.; Fannang, U.; Lemougna, P.N.; Nanseu-Njiki, C.P.; Ngameni, E. Removal of lead ions from aqueous solution using phosphate-based geopolymer cement composite. J. Chem. Technol. Biotechnol. 2021, 96, 1358–1369. [Google Scholar] [CrossRef]

- Dong, T.; Xie, S.; Wang, J.; Zhao, G.; Song, Q. Solidification and Stabilization of Spent TBP/OK Organic Liquids in a Phosphate Acid-Based Geopolymer. Sci. Technol. Nucl. Install. 2020, 5, 1–7. [Google Scholar] [CrossRef]

- Zhang, X.; Bai, C.; Qiao, Y.; Wang, X.; Jia, D.; Li, H.; Colombo, P. Porous geopolymer composites: A review. Compos. Part A Appl. Sci. Manuf. 2021, 150, 106629. [Google Scholar] [CrossRef]

- Chen, G.; Wang, Y.; Qiu, J.; Cao, J.; Zou, Y.; Wang, S.; Jia, D.; Zhou, Y. Robust Inorganic Daytime Radiative Cooling Coating Based on a Phosphate Geopolymer. ACS Appl. Mater. Interfaces 2020, 12, 54963–54971. [Google Scholar] [CrossRef]

- Bhardwaj, P.; Gupta, R.; Deshmukh, K. Optimization studies and characterization of advanced geopolymer coatings for the fabrication of mild steel substrate by spin coating technique. Indian J. Chem. Technol. 2021, 28, 59–67. Available online: http://nopr.niscair.res.in/handle/123456789/56531 (accessed on 10 August 2022).

| Influence Factors | Results | Ref. |

|---|---|---|

| Impurities in aluminosilicate precursors | Impurities will weaken the compressive strength | [24] |

| Fineness of aluminosilicate precursor | The finer the particles are, the higher the compressive strength | [25] |

| Activation mode of aluminosilicate precursors | Mechanical activation is better than thermal activation | [64] |

| Phosphoric acid concentration | The compressive strength first increased and then decreased with increasing phosphoric acid concentration | [61,65] |

| Curing temperature | Properly increasing the curing temperature can improve the compressive strength | [56] |

| Curing relative humidity | The compressive strength of samples curing at 98% humidity is better than 3% humidity | [59] |

| Add fibers | Appropriate fiber content can effectively improve the compressive strength | [66] |

| Aluminosilicate Precursors | Activator | Molar Ratio/Phosphoric Acid Concentration | Liquid Solid Ratio | Curing System | Age | Compressive Strength (MPa) | Ref. |

|---|---|---|---|---|---|---|---|

| Metakaolin | H3PO4 | Si/Al = 0.96 P/Al = 0.52–0.84 | 1.0 | Precuring at 40 °C for 24 h; then curing at 60/80 °C for 24 h, respectively | 3 days | 60 °C 123.4 80 °C 96.8 | [55] |

| Metakaolin | H3PO4 | 4–14 mol/L | 0.8 | Curing at room temperature for 24 h; then curing at 60 °C for 24 h | 28 days | 93.8 | [61] |

| Kaolin | H3PO4 | 10–14 mol/L | 0.9 | Precuring at 40 °C for 48 h; then curing at 80 °C for 48 h | 7 days 28 days | 7 days 32 28 days 45 | [27] |

| Metakaolin | H3PO4 | / | 1 | Partial cured at room temperature; Partial cured at 60°C | 15 days | RT 20.7 60 °C 29.9 | [56] |

| Tunisian clay | H3PO4 | Si/P = 2.75 | / | Curing at 60 °C for 24 h | 28 days | 34 | [25] |

| Metakaolin | H3PO4 | 10 | 0.8 | Curing at 60 °C for 24 h | 28 days | 93.8 | [21] |

| Metakaolin and MgO | Al(H2PO4)3 | / | 0.5 | Curing at 25 °C and 90% relative humidity | 1 days | 8.3 | [58] |

| Electrolytic manganese slag | H3PO4 | / | 1.0 | Curing at room temperature for 24 h; Curing at 80 °C for 2 days | 28 days | RT 49.8 80 °C 70.8 | [37] |

| Volcanic ash | H3PO4 | / | 0.4–0.52 | Curing at room temperature | 28 days | 81.3 | [67] |

| Volcanic ash | H3PO4 | P2O5/H2O = 0.12 | 0.45 | Curing at room temperature | 28 days | 50.9 | [28] |

| Fly ash | H3PO4 | P/Al = 1 Si/Al = 0.91 | 1.04 | Precuring at 40 °C and 90% relative humidity for 6 days; then curing at 80 °C for 24 h | 100 days | 76 | [34] |

| Fly ash | H3PO4 | Ca/P = 2.34 | 0.35 | Curing at room temperature | 28 days | 50 | [35] |

| Laterite | H3PO4 | / | 0.8 | Precuring at 40 °C for 7 days; then curing at 65 °C for 2 days | 9 days | 38 | [30] |

| Laterite | H3PO4 | 10 mol/L | 0.8 | Curing at room temperature | 28 days | 82.6 | [31] |

| Metakaolin | Disused polishing liquid | / | 1 | Curing at 60 °C for 7 days | 7 days | 63–67 | [41] |

| Halloysite | H3PO4 | / | 1.3 | Precuring at 50 °C for 48 h; then curing at 80 °C for 48 h | 28 days | 25 | [32] |

| Metakaolin | H3PO4 | Si/Al = 1; P/Al = 1 | / | Curing at 60 °C for 24 h | / | 146 | [17] |

| Metakaolin | Al(H2PO4)3 | Al/P = 1/3 | 0.8 | Curing at room temperature | 28 days | 32 | [70] |

| Al2O3–2SiO2 powders | H3PO4 | SiO2/Al2O3 = 1 H3PO4/Al2O3 = 1 | / | Curing at 80 °C for 24 h | 33 days | 89.3 | [53] |

| Metakaolin | H3PO4 | P/Al = 0.6 | 0.3 | Curing at 60 °C and 98% relative humidity for 7 days | 77 days | 117.7 | [59] |

| Environmental Condition | Time | Phenomena | Compressive Strength (MPa) |

|---|---|---|---|

| 100% relative humidity, 20 °C | 48 h | Surface unchanged | 93.1 ± 5.8 |

| 3%NaCl solution | 48 h | Surface unchanged | 83.8 ± 5.6 |

| 1 mol/L HCl | 48 h | Sample disintegrated completely and solution changes into yellow | / |

| 1 mol/L NaOH | 48 h | Surface changed into black | 41.6 ± 4.9 |

| No. | Equations | Ref. |

|---|---|---|

| (4) | [79] | |

| (5) | [79] | |

| (6) | [79] | |

| (7) | [35] | |

| (8) | [35] | |

| (9) | [3] | |

| (10) | [58] | |

| (11) | [37] | |

| (12) | [37] |

| Foaming Agent | Content (%) | Total Porosity (%) | Thermal Conductivity (W/mK) | C S (MPa) | Ref. |

|---|---|---|---|---|---|

| Al powder | 0.04~0.22 | 40~83 | - | >6 | [51] |

| Limestone | 1~5 | 30.5~32.1 | 0.133~0.211 | >4 | [54,87] |

| Limestone | 4 | 68~70 | 0.092~0.095 | - | |

| Surfactant | 15.7 | 78.3 | - | 0.64 | [63] |

| H2O2 | 2~4 | 55~64 | - | 1.17 | [71] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, S.; Zhang, Z.; Liu, X. Comprehensive Understanding of Aluminosilicate Phosphate Geopolymers: A Critical Review. Materials 2022, 15, 5961. https://doi.org/10.3390/ma15175961

Ma S, Zhang Z, Liu X. Comprehensive Understanding of Aluminosilicate Phosphate Geopolymers: A Critical Review. Materials. 2022; 15(17):5961. https://doi.org/10.3390/ma15175961

Chicago/Turabian StyleMa, Shanliang, Zengqi Zhang, and Xiaoming Liu. 2022. "Comprehensive Understanding of Aluminosilicate Phosphate Geopolymers: A Critical Review" Materials 15, no. 17: 5961. https://doi.org/10.3390/ma15175961

APA StyleMa, S., Zhang, Z., & Liu, X. (2022). Comprehensive Understanding of Aluminosilicate Phosphate Geopolymers: A Critical Review. Materials, 15(17), 5961. https://doi.org/10.3390/ma15175961