Investigation of Radiation Effect on Structural and Optical Properties of GaAs under High-Energy Electron Irradiation

Abstract

:1. Introduction

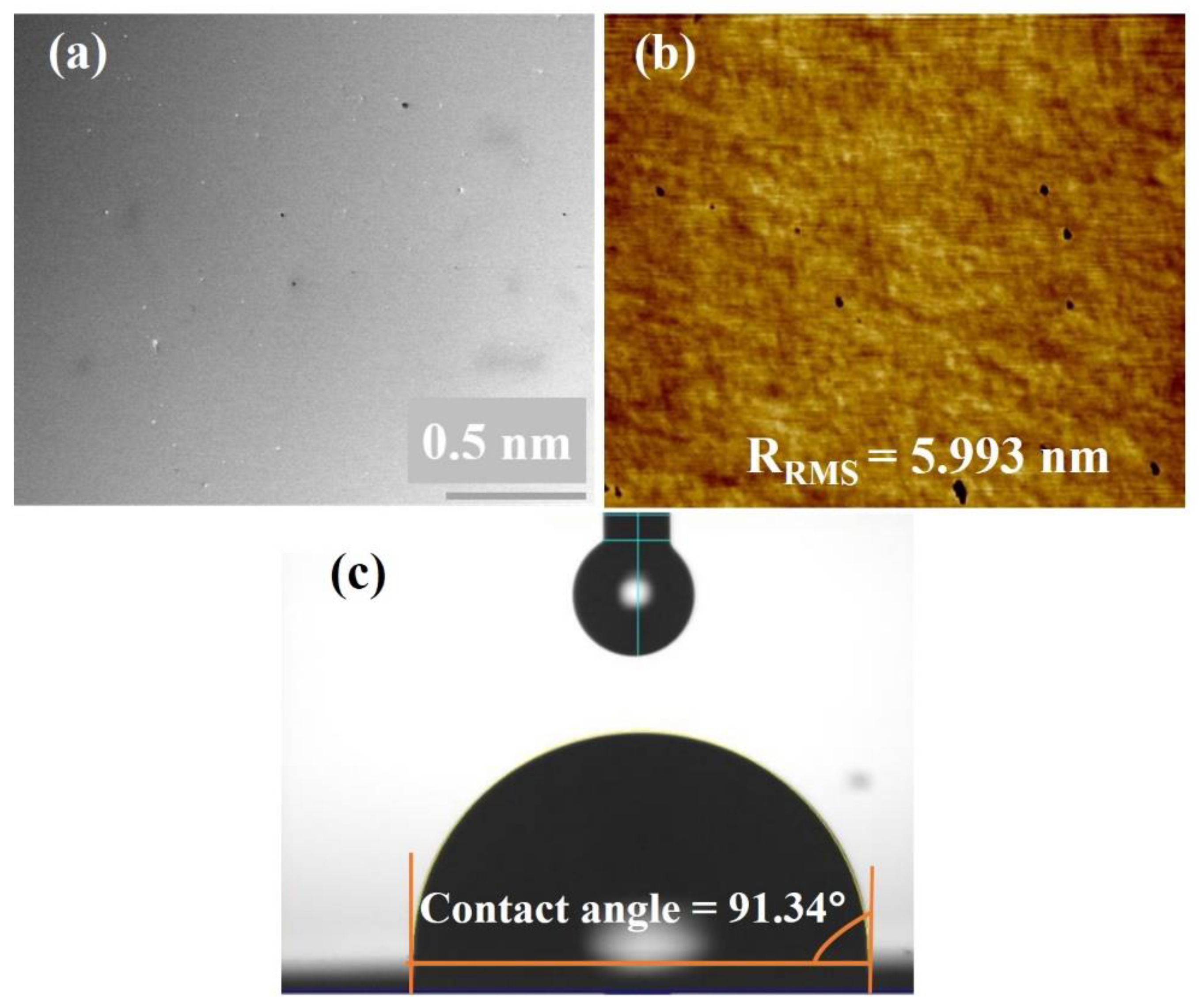

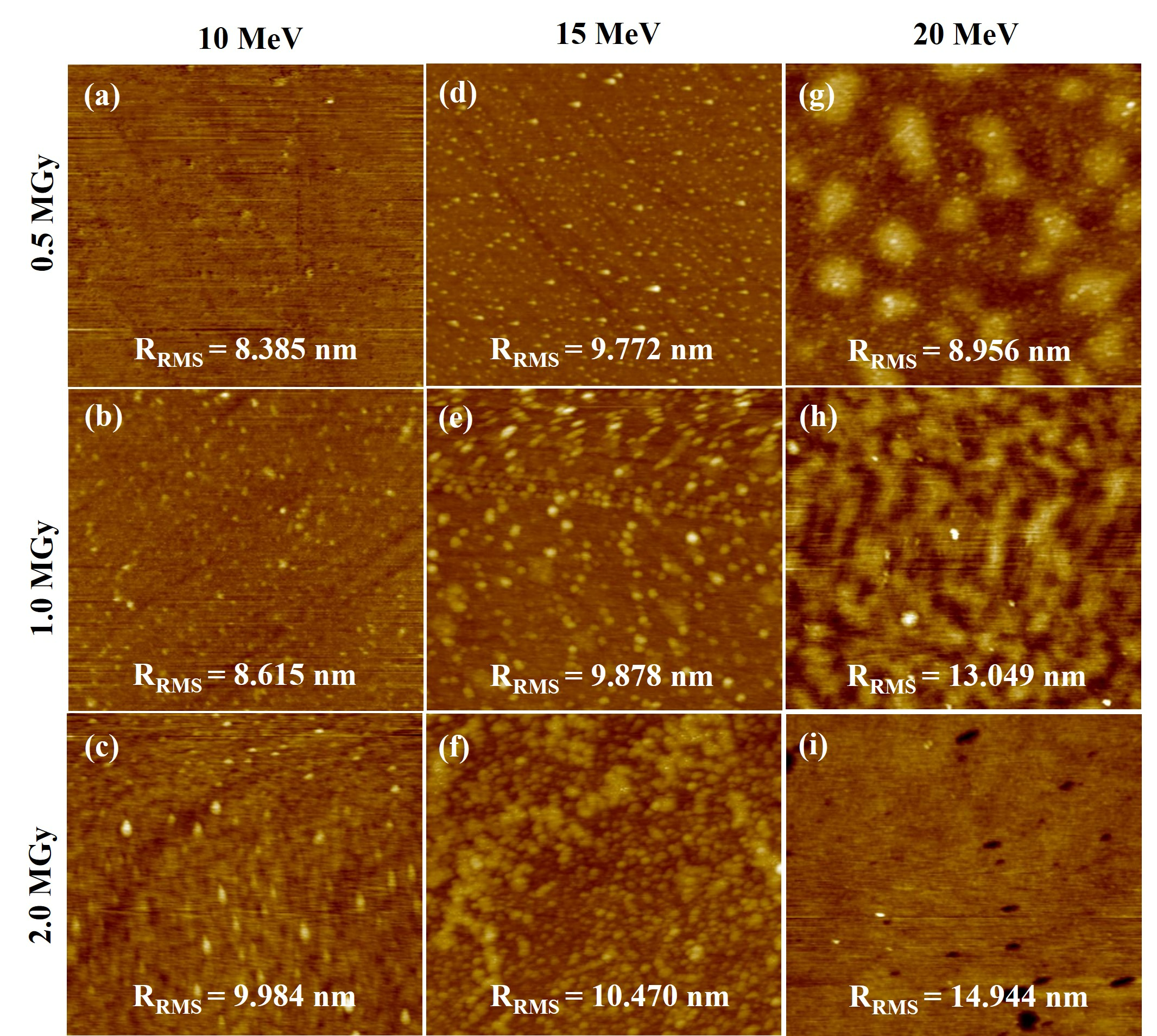

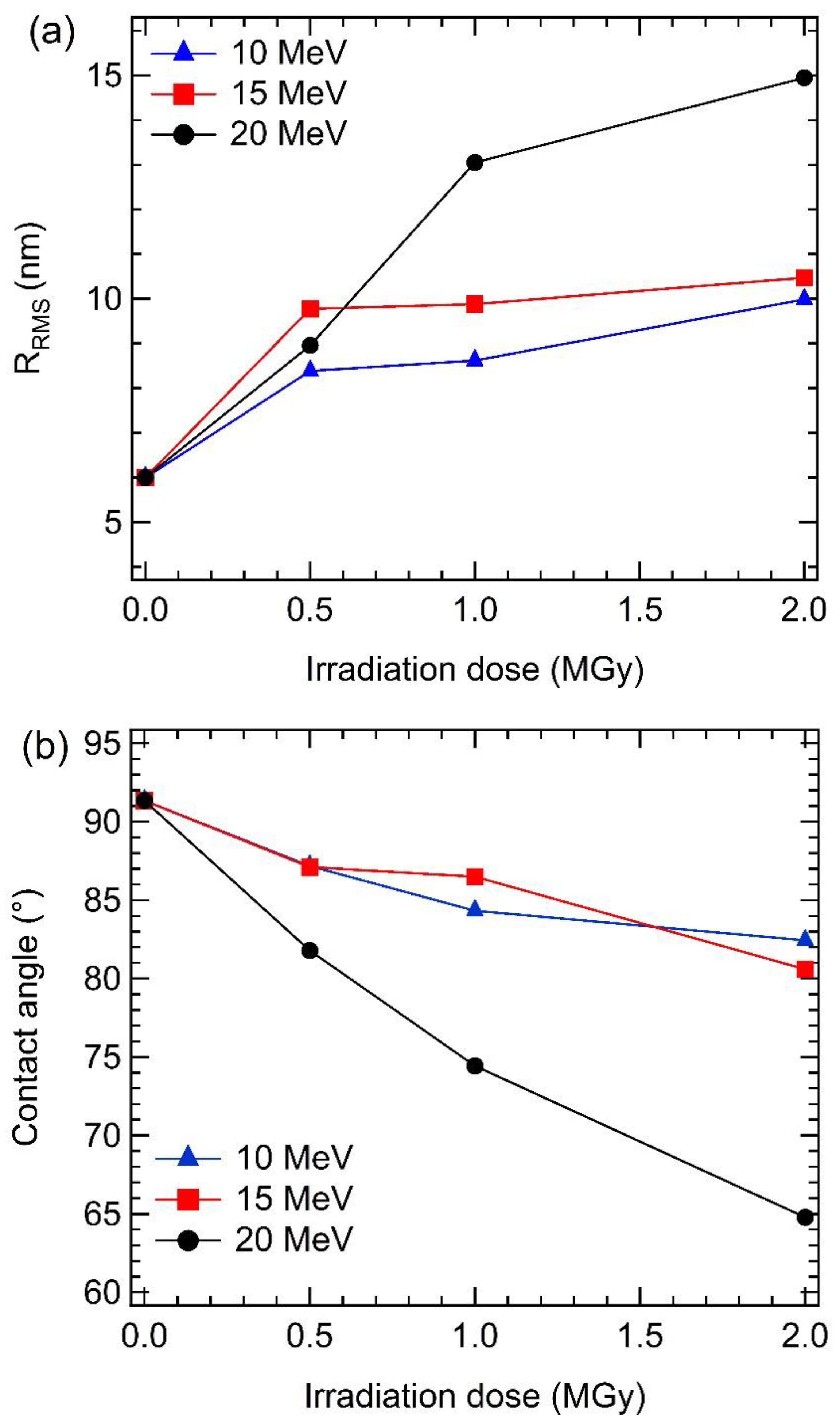

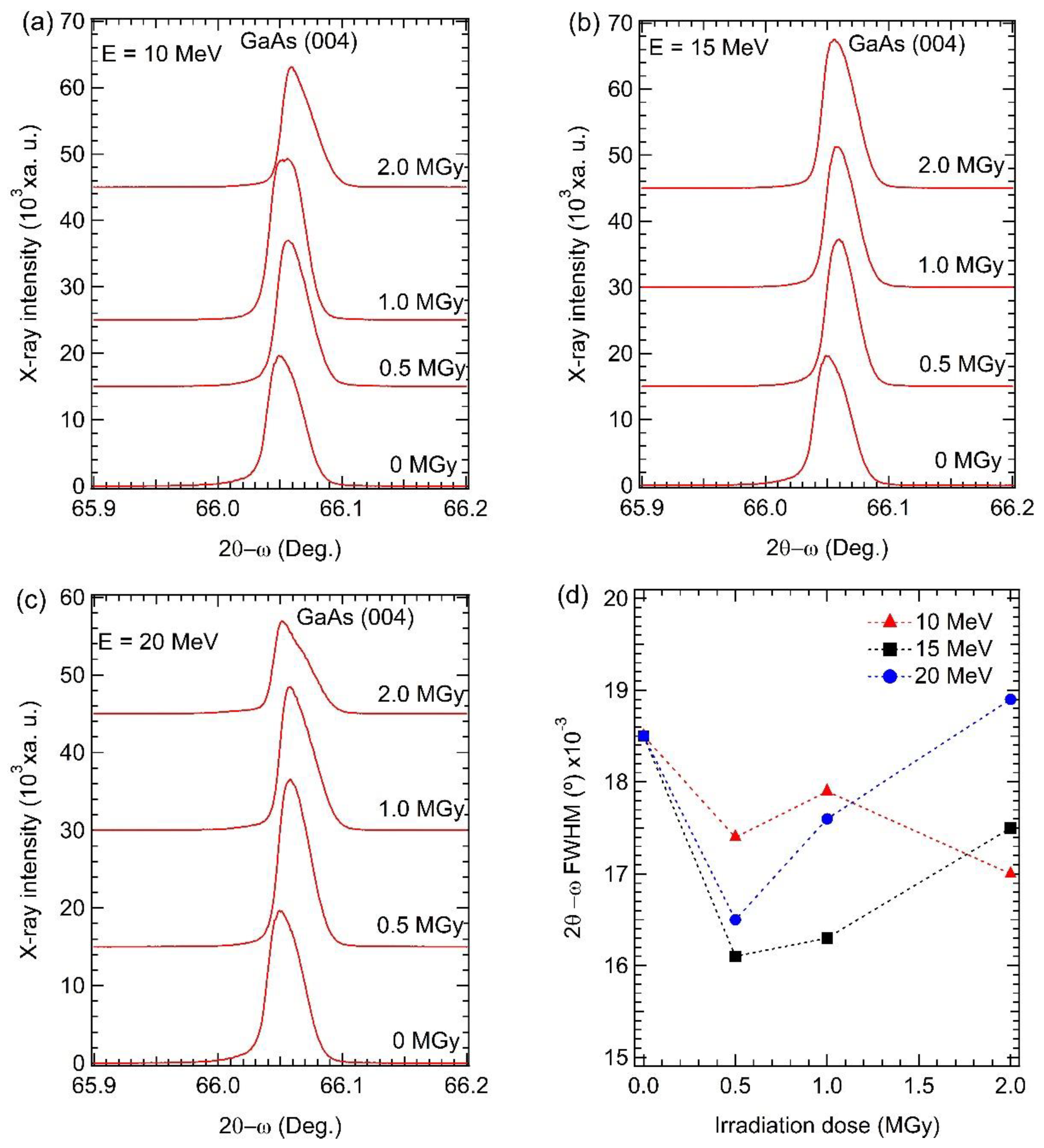

2. Materials and Methods

2.1. GaAs Wafer

2.2. Electron-Beam Irradiation Facility

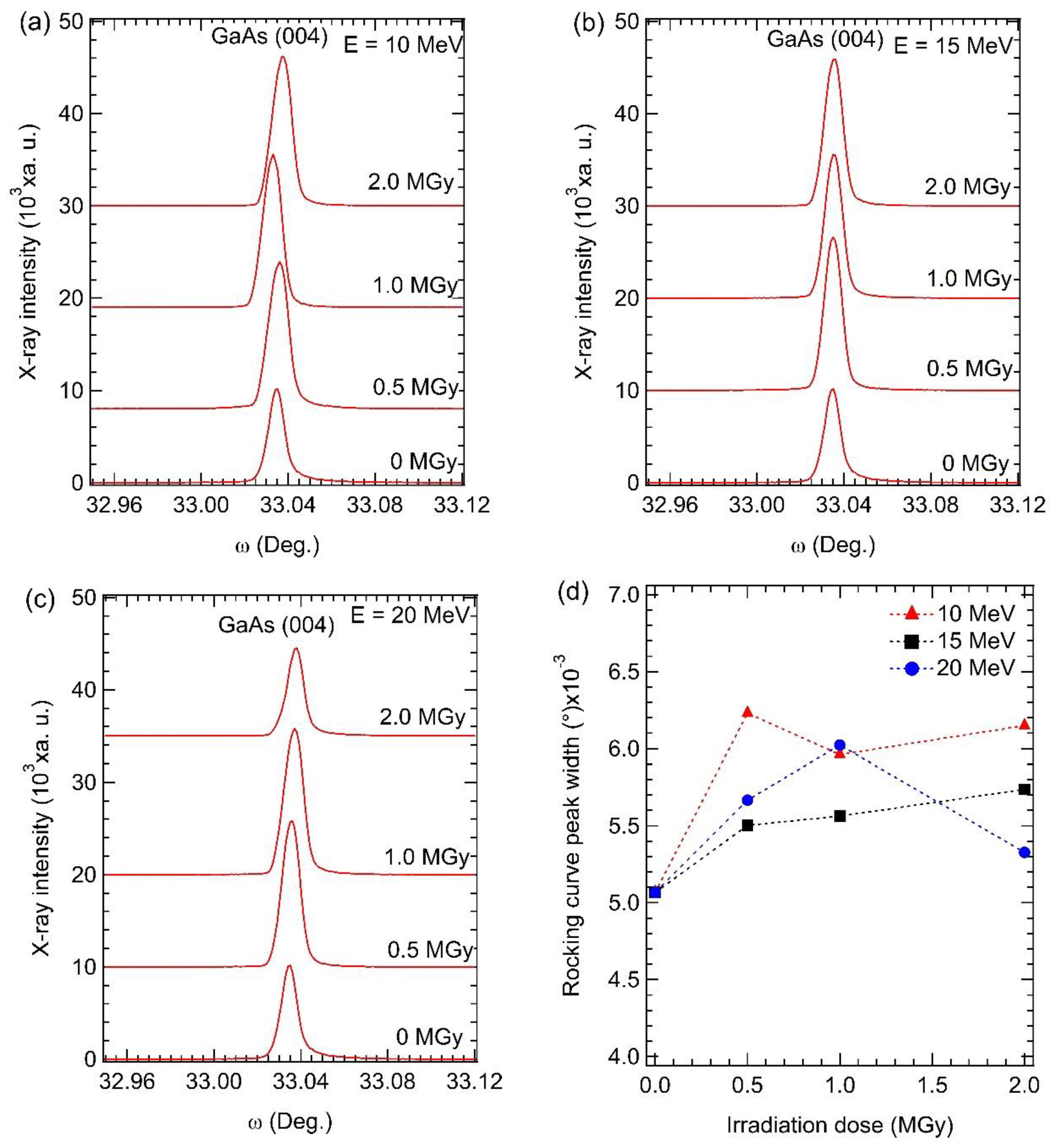

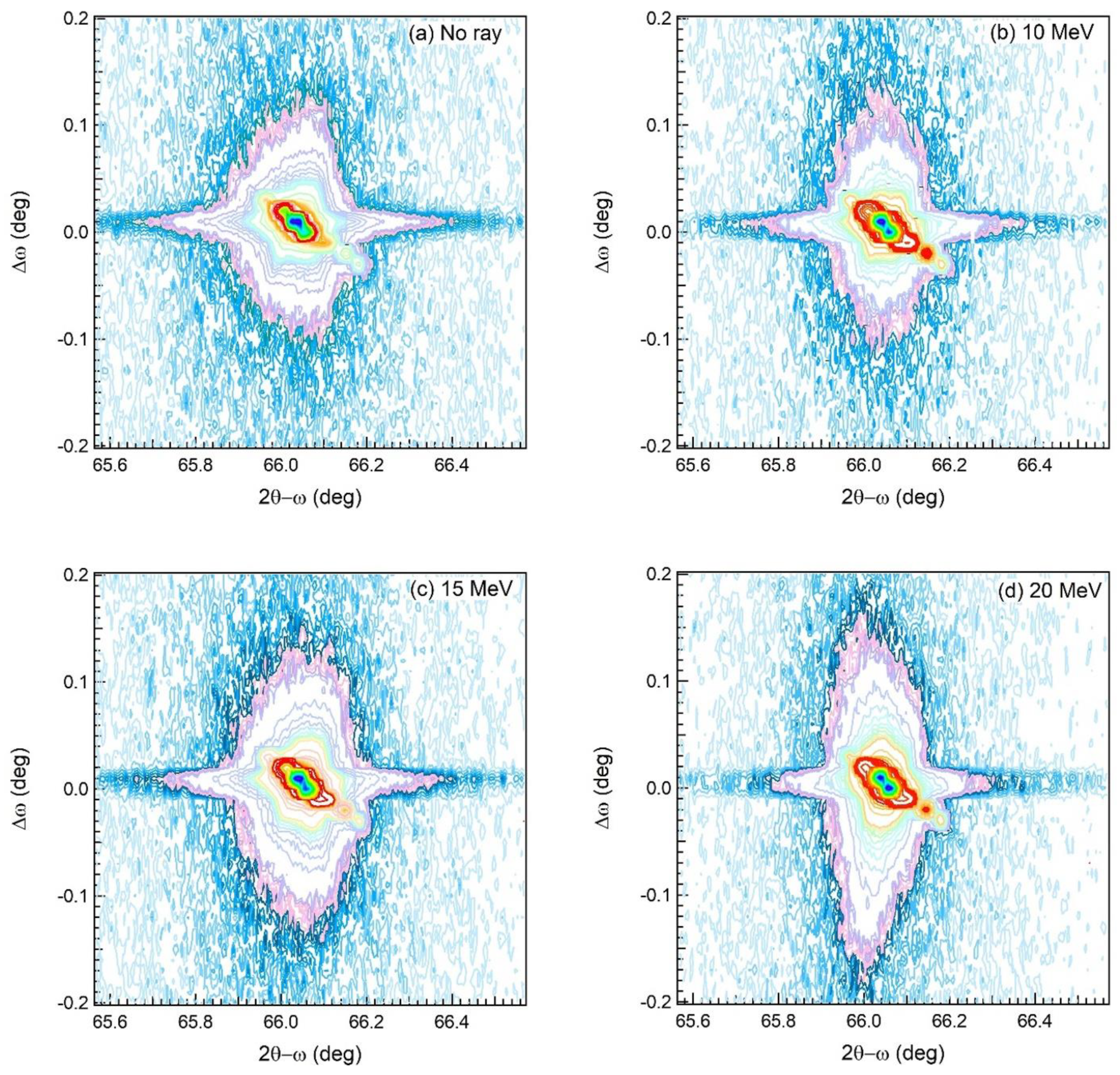

2.3. Structural Features Analysis of GaAs Wafer

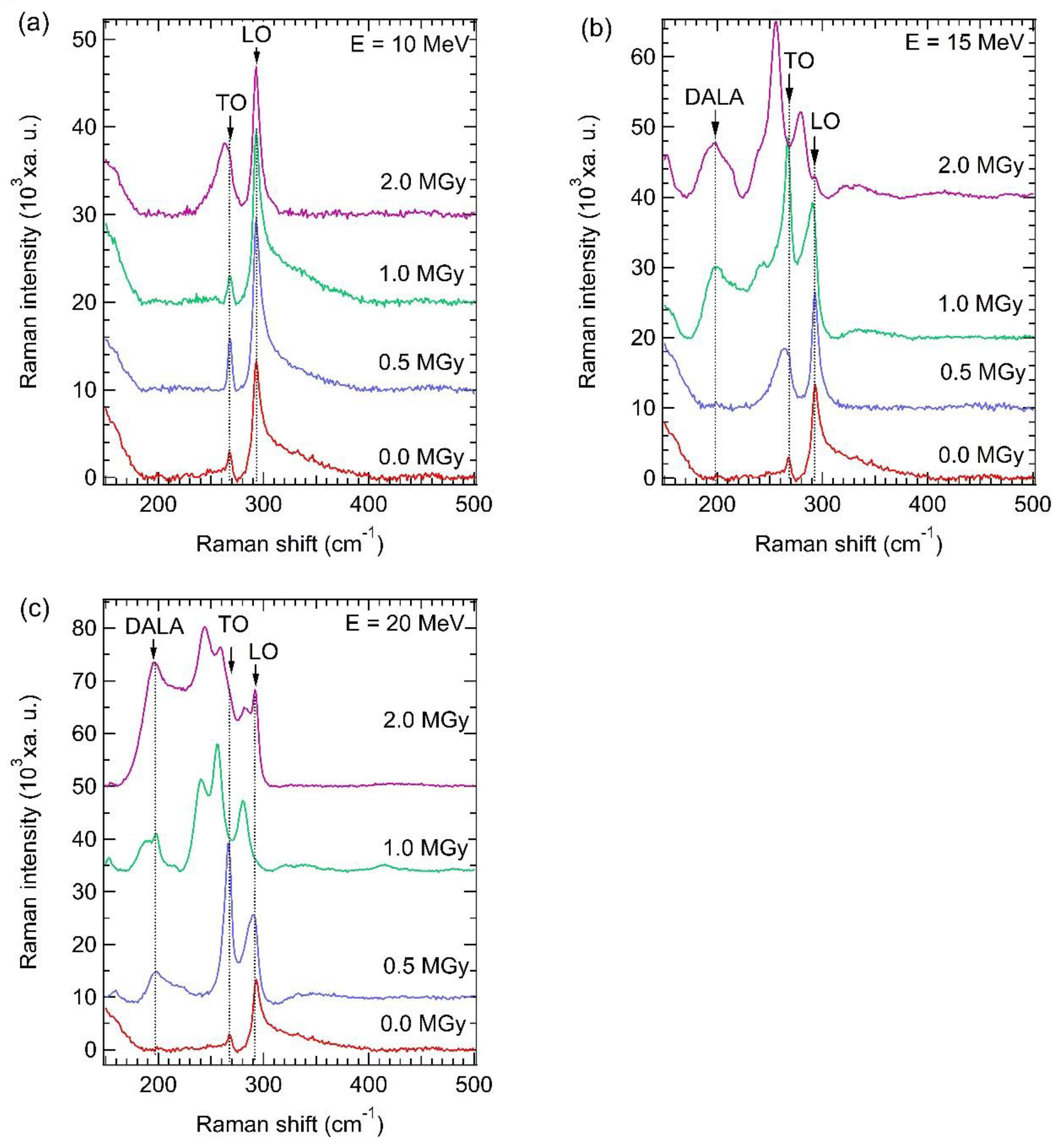

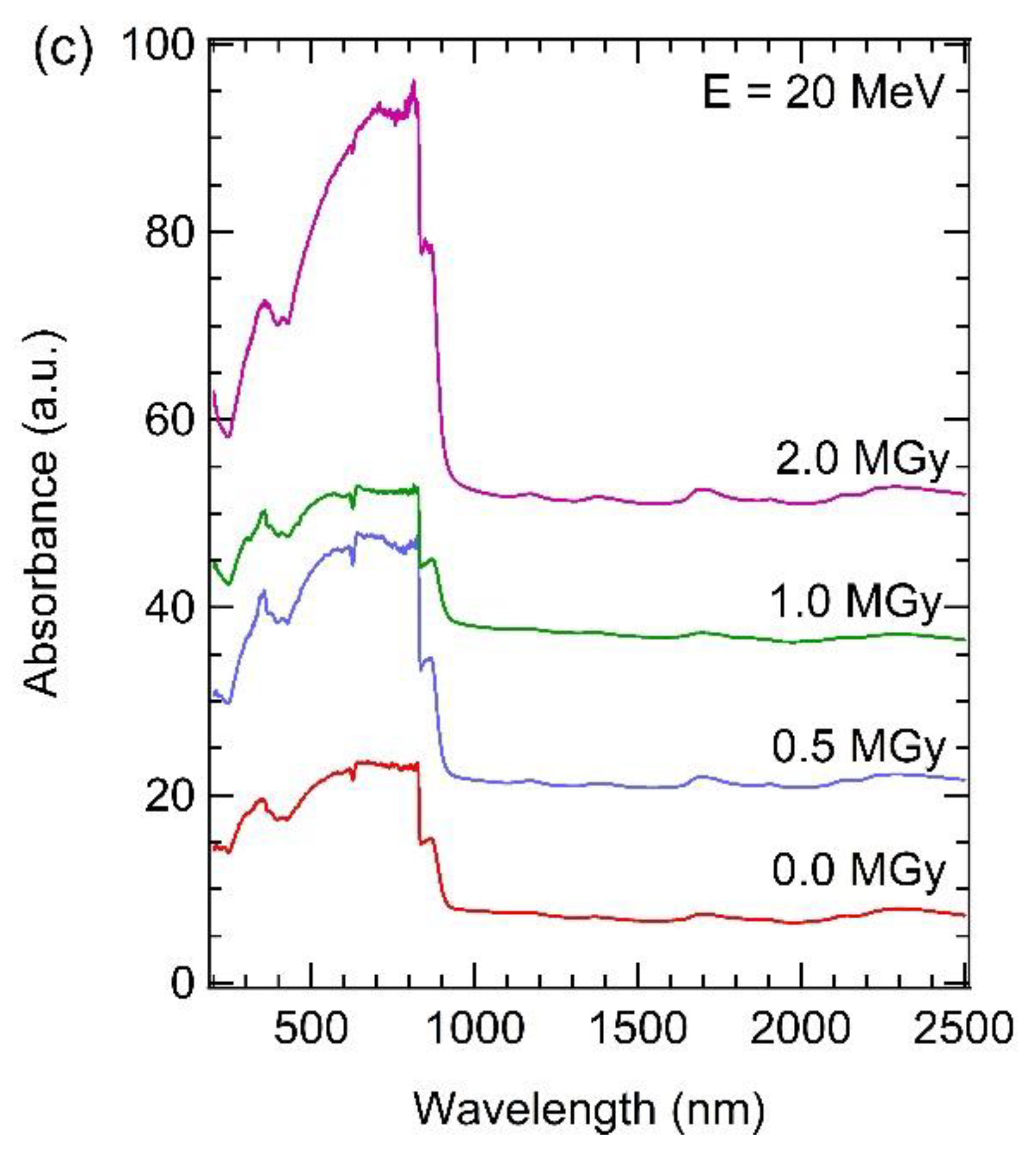

2.4. Optical Properties Analysis of GaAs Wafer

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Sze, S.M.; Ng, K.K. Physics of Semiconductor Devices, 3rd ed.; John Wiley and Sons, Inc.: New York, NY, USA, 2007; pp. 197–240. [Google Scholar] [CrossRef]

- Nelson, J. The Physics of Solar Cells; Imperial College Press: London, UK, 2003; pp. 177–210. [Google Scholar] [CrossRef]

- Nam, S.B.; Reynolds, D.C.; Litton, C.W.; Almassy, R.J.; Collin, T.C.; Wolfe, C.M. Free-exciton energy spectrum in GaAs. Phys. Rev. B 1976, 13, 761–767. [Google Scholar] [CrossRef]

- Attari, K.; Amhaimar, L.; El yaakoubi, A.; Asselman, A.; Bassou, M. The Design and Optimization of GaAs Single Solar Cells Using the Genetic Algorithm and Silvaco ATLAS. Int. J. Photoenergy 2017, 2017, 8269358. [Google Scholar] [CrossRef]

- Lin, H.; Zeng, X.; Shi, S.; Tian, H.; Yang, M.; Chu, K.; Yang, K.; Li, Q. Optimization of GaAs-based 940 nm infrared light emitting diode with dual-junction design. Optoelectron. Lett. 2019, 15, 113–116. [Google Scholar] [CrossRef]

- Akinlami, J.O.; Ashamu, A.O. Optical properties of GaAs. J. Semicond. 2013, 34, 032002. [Google Scholar] [CrossRef]

- Wang, Y.; Ren, Z.; Thway, M.; Lee, K.; Yoon, S.F.; Peters, I.M.; Buonassisi, T.; Fizgerald, E.A.; Tan, C.S.; Lee, K.H. Fabrication and characterization of single junction GaAs solar cells on Si with As-doped Ge buffer. Sol. Energy Mater. Sol. Cells 2017, 172, 140–144. [Google Scholar] [CrossRef]

- Li, S.S. High-Speed III-V Semiconductor Devices. Semiconductor Physical Electronics. In Semiconductor Physical Electronics; Springer: New York, NY, USA, 2006; pp. 613–663. [Google Scholar] [CrossRef]

- Deo, N. Microwave and millimeter wave solid-state power amplifiers for future space-based communications and radars. In Proceedings of the 2018 IEEE Aerospace Conference, Big Sky, MT, USA, 3–10 March 2018. [Google Scholar] [CrossRef]

- Mokkapati, S.; Jagadish, C. III-V compound S.C. for optoelectronic devices. Mater. Today 2009, 12, 22–32. [Google Scholar] [CrossRef]

- Ban, D.; Luo, H.; Liu, H.C.; Wasilewski, Z.R.; Spring Thorpe, A.J.; Glew, R.; Buchanan, M. Optimized GaAs∕AlGaAs light-emitting diodes and high efficiency wafer-fused optical up-conversion devices. J. Appl. Phys. 2004, 96, 5243–5248. [Google Scholar] [CrossRef]

- Jovanovic, D.; Gajic, R.; Hingerl, K. Optical properties of GaAs 2D Archimedean photonic lattice tiling with the p4g symmetry. Sci. Sinter. 2008, 40, 167–173. [Google Scholar] [CrossRef]

- Rangel-Kuoppa, V.T.; Ye, S.; Noori, Y.J.; Holmkvist, W.; Young, R.J.; Muenstermann, D. Towards GaAs thin-film tracking detectors. J. Instrum. 2021, 16, 09102. [Google Scholar] [CrossRef]

- Lezhneva, G.M.; Melkadze, R.G.; Khvedelidze, L.V. GaAs pixel-detector technology for X-ray medical imaging: A review. Russ. Microelectron. 2005, 34, 274–290. [Google Scholar] [CrossRef]

- Scholz, J.; Birnbacher, L.; Petrich, C.; Riedel, M.; Heck, L.; Gkoumass, S.; Sellerer, T.; Achterhold, K.; Herzen, J. Biomedical X-ray imaging with a GaAs photon-counting detector: A comparative study. APL Photon. 2020, 5, 106108. [Google Scholar] [CrossRef]

- Ayzenshtat, G.I.; Babichev, E.A.; Baru, S.E.; Groshev, V.R.; Savinov, G.A.; Tolbanov, O.P.; Vorobiev, A.P. GaAs detectors for medical imaging. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2003, 509, 268–273. [Google Scholar] [CrossRef]

- Hofstetter, D.; Aku-Leh, C.; Beck, H.; Bour, D.P. AlGaN-Based 1.55 µm Phototransistor as a Crucial Building Block for Optical Computers. Crystals 2021, 11, 1431. [Google Scholar] [CrossRef]

- Hopkinson, G.; Sorensen, R.H.; Leone, B.; Meynart, R.; Mohammadzadeh, A.; Rabaud, W. Radiation Effects in InGaAs and Microbolometer Infrared Sensor Arrays for Space Applications. IEEE. Trans. Nucl. Sci 2008, 55, 3483–3493. [Google Scholar] [CrossRef]

- Chen, X.; Xiao, Y.; Cheng, Y.; Zhang, Z.; Gou, Y.; Wang, J. MOCVD growth and thermal stability analysis of 1.2 µm InGaAs/GaAs multi quantum well structure. J. Alloys Compd. 2022, 922, 166173. [Google Scholar] [CrossRef]

- Kurtz, S.; Reedy, R.; Barber, G.D.; Geisz, J.F.; Friedman, D.J.; McMahon, W.E.; Olson, J.M. Incorporation of nitrogen into GaAsN grown by MOCVD using different precursors. J. Cryst. Growth 2002, 234, 318–322. [Google Scholar] [CrossRef]

- He, Z.; Wang, H.; Wang, Q.; Fan, J.; Zou, Y.; Ma, X. The effect of unintentional carbon incorporation on the electrical properties of AlGaAs grown by MOCVD. Opt. Mater. 2020, 108, 110227. [Google Scholar] [CrossRef]

- Oda, Y.; Watanabe, N.; Uchida, M.; Sato, M.; Yokoyama, H.; Kobayashi, T. Suppression of hydrogen passivation in carbon-doped GaAsSb grown by MOCVD. J. Cryst. Growth 2004, 261, 393–397. [Google Scholar] [CrossRef]

- Sadofyev, Y.G.; Samal, N. Strained GaAsSb/GaAs QW structures grown by MBE on GaAs (100) for applications near 1.3 micron. J. Cryst. Growth 2010, 312, 305–309. [Google Scholar] [CrossRef]

- Bucamp, A.; Coinon, C.; Codron, J.-L.; Troadec, D.; Wallart, X.; Desplanque, L. Buffer free InGaAs quantum well and in-plane nanostructures on InP grown by atomic hydrogen assisted MBE. J. Cryst. Growth 2019, 512, 11–15. [Google Scholar] [CrossRef]

- Deimert, C.; Wasilewski, Z.R. MBE growth of continuously-graded parabolic quantum well arrays in AlGaAs. J. Cryst. Growth 2019, 514, 103–108. [Google Scholar] [CrossRef]

- Umeno, K.; Furukawa, Y.; Urakami, N.; Mitsuyoshi, S.; Yonezu, H.; Wakahara, A. Effects of Mg doping on the electrical and luminescence characterizations of p-type GaAsN alloys grown by MBE. J. Cryst. Growth 2010, 312, 231–237. [Google Scholar] [CrossRef]

- Philipps, S.P.; Dimroth, F.; Bett, A.W. High-Efficiency III–V Multijunction Solar Cells. In McEvoy’s Handbook of Photovoltaics, 3rd ed.; Academic Press: Cambridge, MA, USA, 2018; pp. 439–472. [Google Scholar] [CrossRef]

- Campesato, R.; Tukiainen, A.; Aho, A.; Gori, G.; Isoaho, R.; Greco, E.; Guina, M. 31% European InGaP/GaAs/InGaAs Solar Cells for Space Application. In Proceedings of the 11th European Space Power Conference, Thessaloniki, Greece, 3–7 October 2016; p. 16. [Google Scholar] [CrossRef]

- Kao, Y.C.; Chou, H.M.; Hsu, S.C.; Lin, A.; Lin, C.C.; Shih, Z.H.; Chang, C.L.; Hong, H.F.; Horng, R.H. Performance comparison of III–V//Si and III–V//InGaAs multi-junction solar cells fabricated by the combination of mechanical stacking and wire bonding. Sci. Rep. 2019, 9, 4308. [Google Scholar] [CrossRef]

- Yamaguchi, M.; Nishimura, K.I.; Sasaki, T.; Suzuki, H.; Arafune, K.; Kojima, N.; Ohsita, Y.; Yamamoto, A.; Takamoto, T.; Araki, K. Novel materials for high-efficiency III–V multi-junction solar cells. Sol. Energy 2008, 82, 173–180. [Google Scholar] [CrossRef]

- Ghammraoui, B.; Gkoumas, S.; Glick, S.J. Characterization of a GaAs photon-counting detector for mammography. J. Med. Imaging 2021, 8, 033504. [Google Scholar] [CrossRef]

- Ruat, M.; Andra, M.; Bergamaschi, A.; Barten, R.; Bruckner, M.; Dinapoli, R.; Frojdh, E.; Greiffenberg, D.; Lopez-Cuenca, C.; Lozinskaya, A.D.; et al. Photon counting miscrostrip X-ray detectors with GaAs sensors. J. Instrum. 2018, 13, C01046. [Google Scholar] [CrossRef]

- Zhao, J.; Guan, R.; Zhao, H. Study of GaAs optical fiber temperature sensor. In Proceedings of the SPIE Instruments for Optics and Optoelectronic Inspection and Control, Beijing, China, 8 November 2020; Volume 4223, pp. 87–91. [Google Scholar] [CrossRef]

- Bertolucci, E.; Bisogni, M.G.; Bottigli, U.; Conti, M.; Cola, A.; Fantacci, M.E.; Maestro, P.; Mettivier, G.; Quaranta, F.; Rosso, V.; et al. Detection performance of SI GaAs detectors for nuclear medicine. Nucl. Instrum. Methods Phys. Res. A Accel. Spectrom. Detect. Assoc. Equip. 2001, 460, 123–126. [Google Scholar] [CrossRef]

- Yen, Y.; Capua, E.; Naaman, R. Application of a GaAs-based sensor for detecting hemoglobin in gastrointestinal environments. IEEE Sens. J. 2017, 17, 660–666. [Google Scholar] [CrossRef]

- Xu, J.; Guo, M.; Lu, M.; He, H.; Yang, G.; Xu, J. Effect of Alpha-Particle Irradiation on InGaP/GaAs/Ge Triple-Junction Solar Cells. Materials 2018, 11, 944. [Google Scholar] [CrossRef] [PubMed]

- Shen, Y.; Fang, X.; Ding, X.; Xiao, H.; Xiang, X.; Yang, G.; Jiang, M.; Zu, X.; Qiao, L. Structural Features and Photoelectric Properties of Si-Doped GaAs under Gamma Irradiation. Nanomaterials 2020, 10, 340. [Google Scholar] [CrossRef] [PubMed]

- Gruginskie, N.; Cappelluti, F.; Bauhuis, G.J.; Mulder, P.; Haverkamp, E.J.; Vlieg, E.; Schermer, J.J. Electron radiation–induced degradation of GaAs solar cells with different architectures. Prog. Photovolt. Res. Appl. 2020, 28, 266–278. [Google Scholar] [CrossRef]

- Li, Y.L.; Wang, X.J.; He, S.M.; Zhang, B.; Sun, L.X.; Li, Y.D.; Guo, Q.; Chen, C.Q.; Chen, Z.H.; Lu, W. Origin of the redshift of the luminescence peak in InGaN light-emitting diodes exposed to Co-60 γ-ray irradiation. J. Appl. Phys. 2012, 112, 123515. [Google Scholar] [CrossRef]

- Zhao, H.; Wu, Y.; He, S. A study of electric properties of single-junction GaAs solar cells irradiated by low-energy protons. AIP Conf. Proc. 2009, 1807, 650–656. [Google Scholar] [CrossRef]

- Hashizume, T.; Hasegawa, H. Variation of deep electron traps created by γ irradiation of GaAs. J. Appl. Phys. 1990, 68, 4598–4603. [Google Scholar] [CrossRef]

- Gao, H.; Yang, R.; Zhang, Y. Improving Radiation Resistance of GaInP/GaInAs/Ge Triple-Junction Solar Cells Using GaInP Back-Surface Field in the Middle Subcell. Materials 2020, 13, 1958. [Google Scholar] [CrossRef]

- Xu, J.; Yang, K.; Xu, Q.; Zhu, X.; Wang, X.; Lu, M. Fabrication and Irradiation Effect of Inverted Metamorphic Triple Junction GaInP/GaAs/InGaAs Solar Cells. Crystals 2022, 12, 670. [Google Scholar] [CrossRef]

- Walker, G.H.; Conway, E.J. Annealing kinetics of electron-irradiated GaAs heteroface solar cells in the range 175–200 °C. Appl. Phys. Lett. 1979, 35, 459–460. [Google Scholar] [CrossRef]

- Feteha, M.Y.; Soliman, M.; Gomaa, N.G.; Ashry, M. Metal-insulator-semiconductor solar cell under gamma irradiation. Renew. Energy 2002, 26, 113–120. [Google Scholar] [CrossRef]

- Mikoushkin, V.M.; Makarevskaya, E.A.; Brzhezinskaya, M. Effect of ion irradiation on GaAs core-level electron binding energies and band structure. Appl. Surf. Sci. 2021, 539, 148273. [Google Scholar] [CrossRef]

- He, J.; Shen, Y.; Li, B.; Xiang, X.; Li, S.; Fan, X.; Xiao, H.; Zu, X.; Qiao, L. A comparative study of the structural and optical properties of Si-doped GaAs under different ion irradiation. Opt. Mater. 2020, 111, 110611. [Google Scholar] [CrossRef]

- Jia, T.; Wang, Z.; Tang, M.; Xue, Y.; Huang, G.; Nie, X.; Lai, S.; Ma, W.; He, B.; Gou, S. Simulation Study on the Defect Generation, Accumulation Mechanism and Mechanical Response of GaAs Nanowires under Heavy-Ion Irradiation. Nanomaterials 2022, 12, 611. [Google Scholar] [CrossRef]

- Klangtakai, P.; Sanorpim, S.; Wattanawareekul, A.; Suwanyangyaun, P.; Srepusharawoot, P.; Onabe, K. Effect of gamma-ray irradiation on structural properties of GaAsN films grown by metal organic vapor phase epitaxy. J. Cryst. Growth 2018, 418, 145–152. [Google Scholar] [CrossRef]

- Lee, H.J.; Park, K. Development of Hybrid Surfaces with Tunable Wettability by Selective Surface Modifications. Materials 2016, 9, 136. [Google Scholar] [CrossRef] [Green Version]

- Jiang, D.S.; Li, X.P.; Sun, B.Q.; Han, H.X. A Raman scattering study of GaAs: As films lifted off GaAs substrate. J. Phys. D Appl. Phys. 1999, 32, 629–631. [Google Scholar] [CrossRef]

- Mlayah, A.; Carles, R.; Sayari, A.; Chtourou, R.; Charfi, F.F.; Planel, R. Resonant Raman scattering in GaAs/AlAs superlattices: The role of electron state mixing. Phys. Rev. B 1996, 53, 3960–3965. [Google Scholar] [CrossRef]

- Das, N.; Islam, S. Design and Analysis of Nano-Structured Gratings for Conversion Efficiency Improvement in GaAs Solar Cells. Energies 2016, 9, 690. [Google Scholar] [CrossRef]

- Das, N.; Chandrasekar, D.; Nur-E-Alam, M.; K Khan, M.M. Light Reflection Loss Reduction by Nano-Structured Gratings for Highly Efficient Next-Generation GaAs Solar Cells. Energies 2020, 13, 4198. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Phakkhawan, A.; Sakulkalavek, A.; Buranurak, S.; Klangtakai, P.; Pangza, K.; Jangsawang, N.; Nasompag, S.; Horprathum, M.; Kijamnajsuk, S.; Sanorpim, S. Investigation of Radiation Effect on Structural and Optical Properties of GaAs under High-Energy Electron Irradiation. Materials 2022, 15, 5897. https://doi.org/10.3390/ma15175897

Phakkhawan A, Sakulkalavek A, Buranurak S, Klangtakai P, Pangza K, Jangsawang N, Nasompag S, Horprathum M, Kijamnajsuk S, Sanorpim S. Investigation of Radiation Effect on Structural and Optical Properties of GaAs under High-Energy Electron Irradiation. Materials. 2022; 15(17):5897. https://doi.org/10.3390/ma15175897

Chicago/Turabian StylePhakkhawan, Authit, Aparporn Sakulkalavek, Siritorn Buranurak, Pawinee Klangtakai, Karnwalee Pangza, Nongnuch Jangsawang, Sawinee Nasompag, Mati Horprathum, Suphakan Kijamnajsuk, and Sakuntam Sanorpim. 2022. "Investigation of Radiation Effect on Structural and Optical Properties of GaAs under High-Energy Electron Irradiation" Materials 15, no. 17: 5897. https://doi.org/10.3390/ma15175897

APA StylePhakkhawan, A., Sakulkalavek, A., Buranurak, S., Klangtakai, P., Pangza, K., Jangsawang, N., Nasompag, S., Horprathum, M., Kijamnajsuk, S., & Sanorpim, S. (2022). Investigation of Radiation Effect on Structural and Optical Properties of GaAs under High-Energy Electron Irradiation. Materials, 15(17), 5897. https://doi.org/10.3390/ma15175897