An Analytical Solution for Stress Transfer between a Broken Prestressing Wire and Mortar Coating in PCCP

Abstract

:1. Introduction

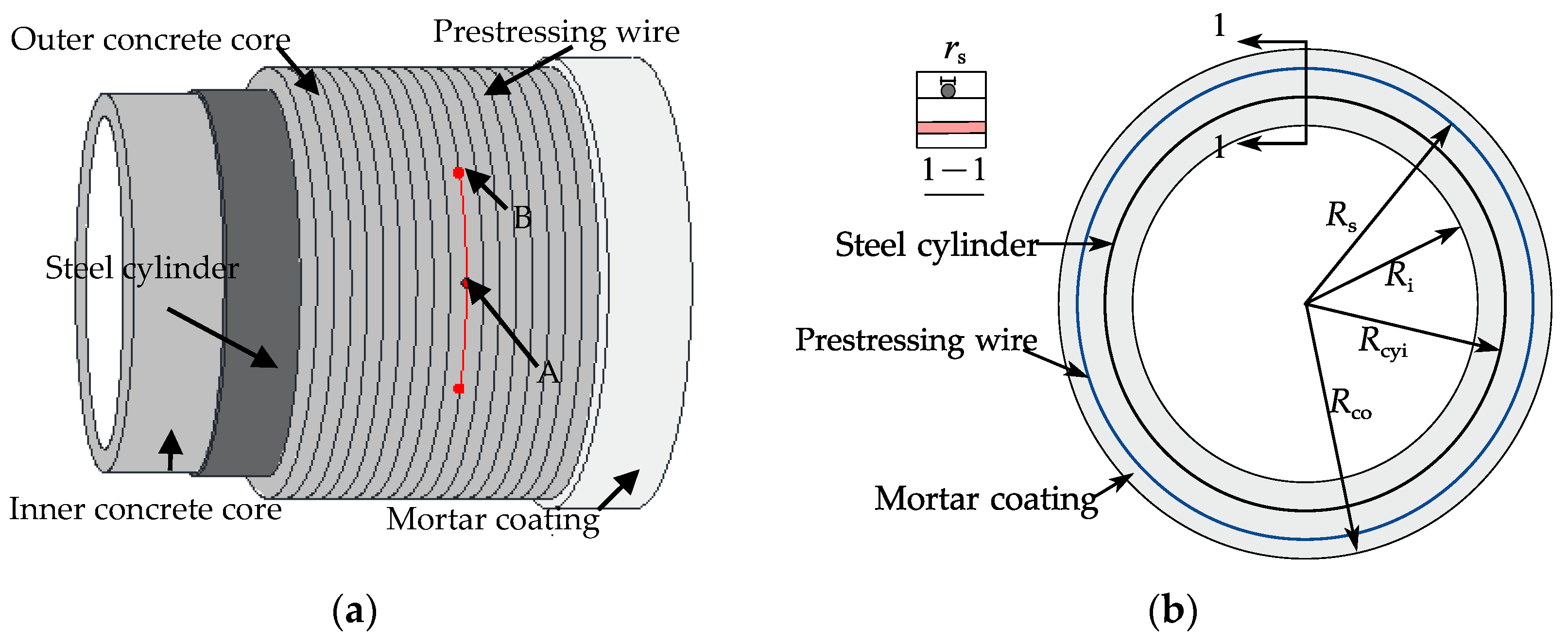

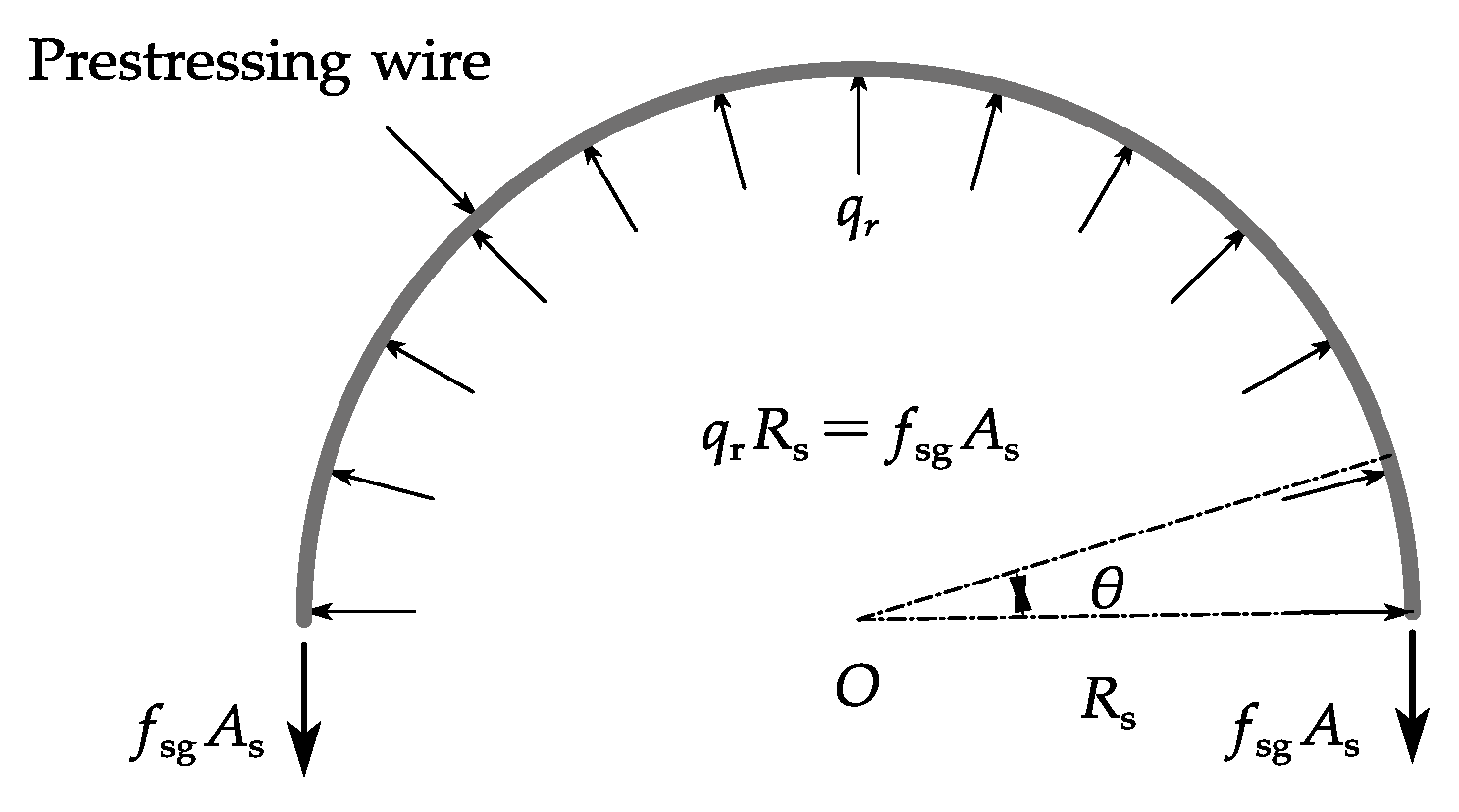

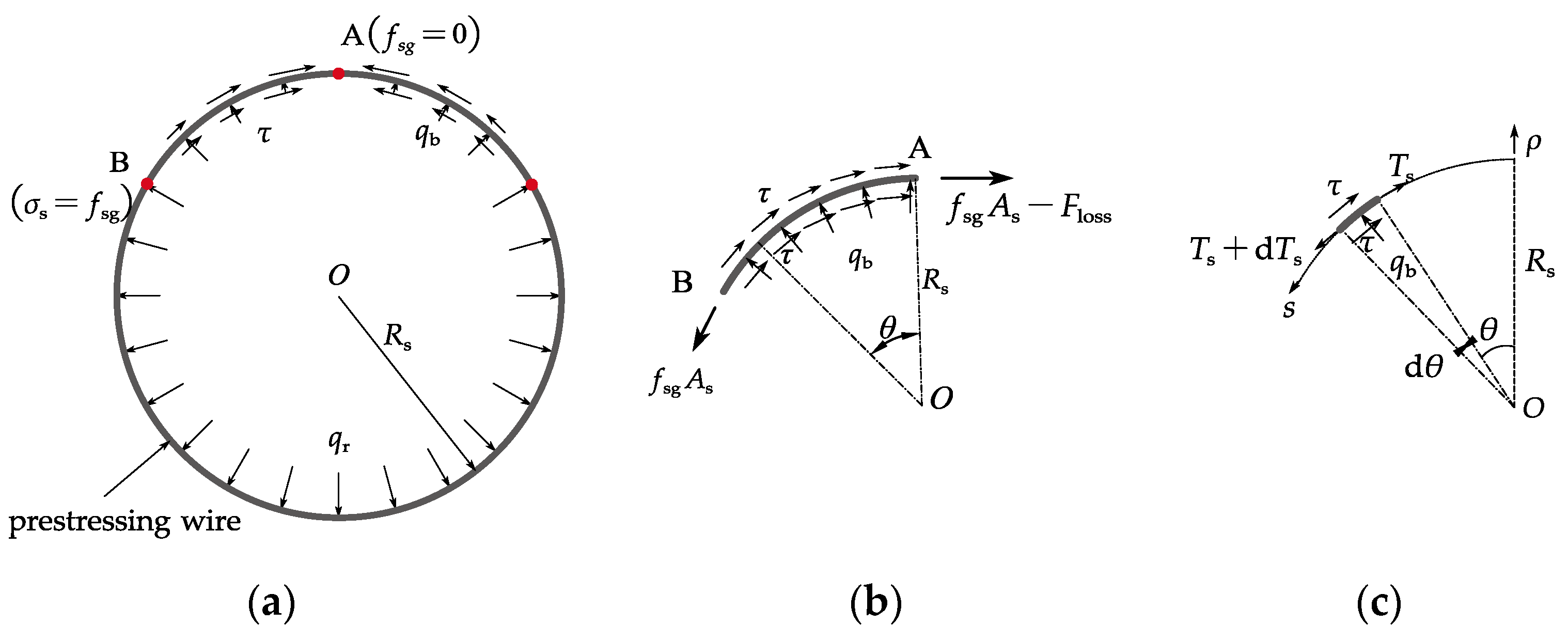

2. Assumptions and Governing Equations

- The steel cylinder, mortar coating, and concrete core are regarded as rigid bodies because the stiffness of the pipe wall is much larger than the prestressing wires;

- The prestressing wires are thin and have negligible flexural stiffness;

- The pipe is large and there is sufficient bond between the wire and the mortar so that the breakage of a wire only results in local loss of the prestress;

- The wire remains linear elastic throughout the wire breaking process. All nonlinear deformation occurs at the wire-mortar interface.

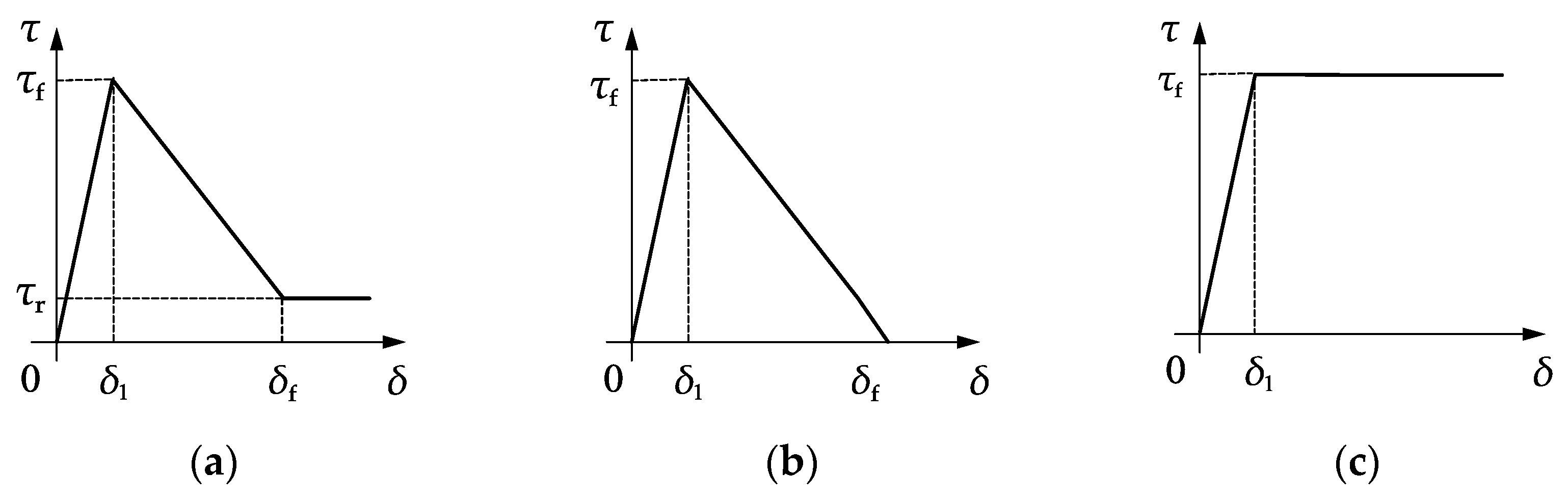

3. Bond-Slip Model

4. Analytical Solutions

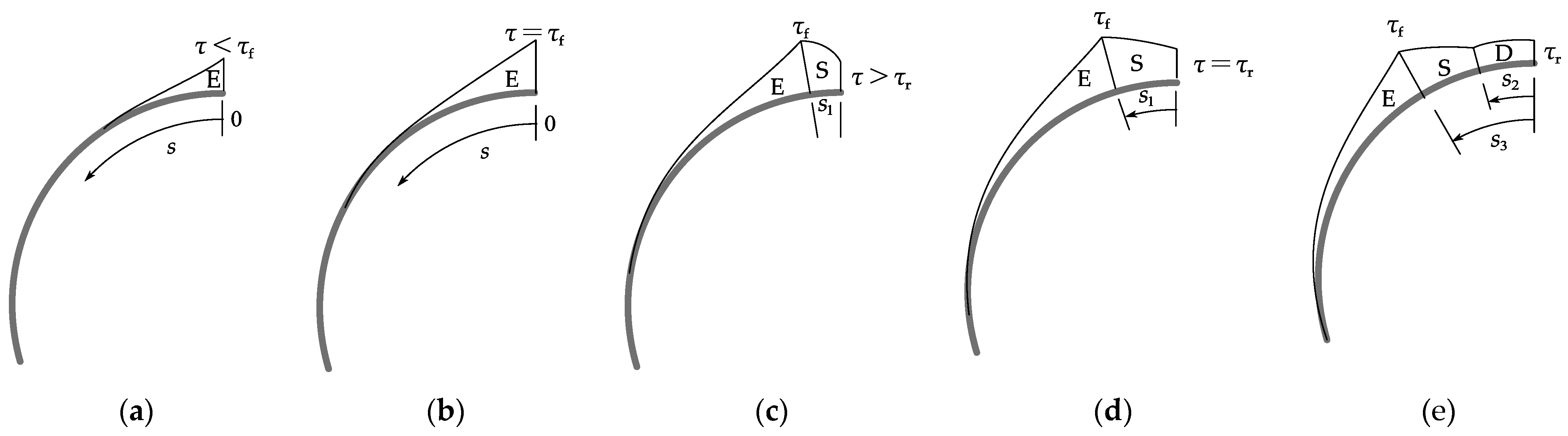

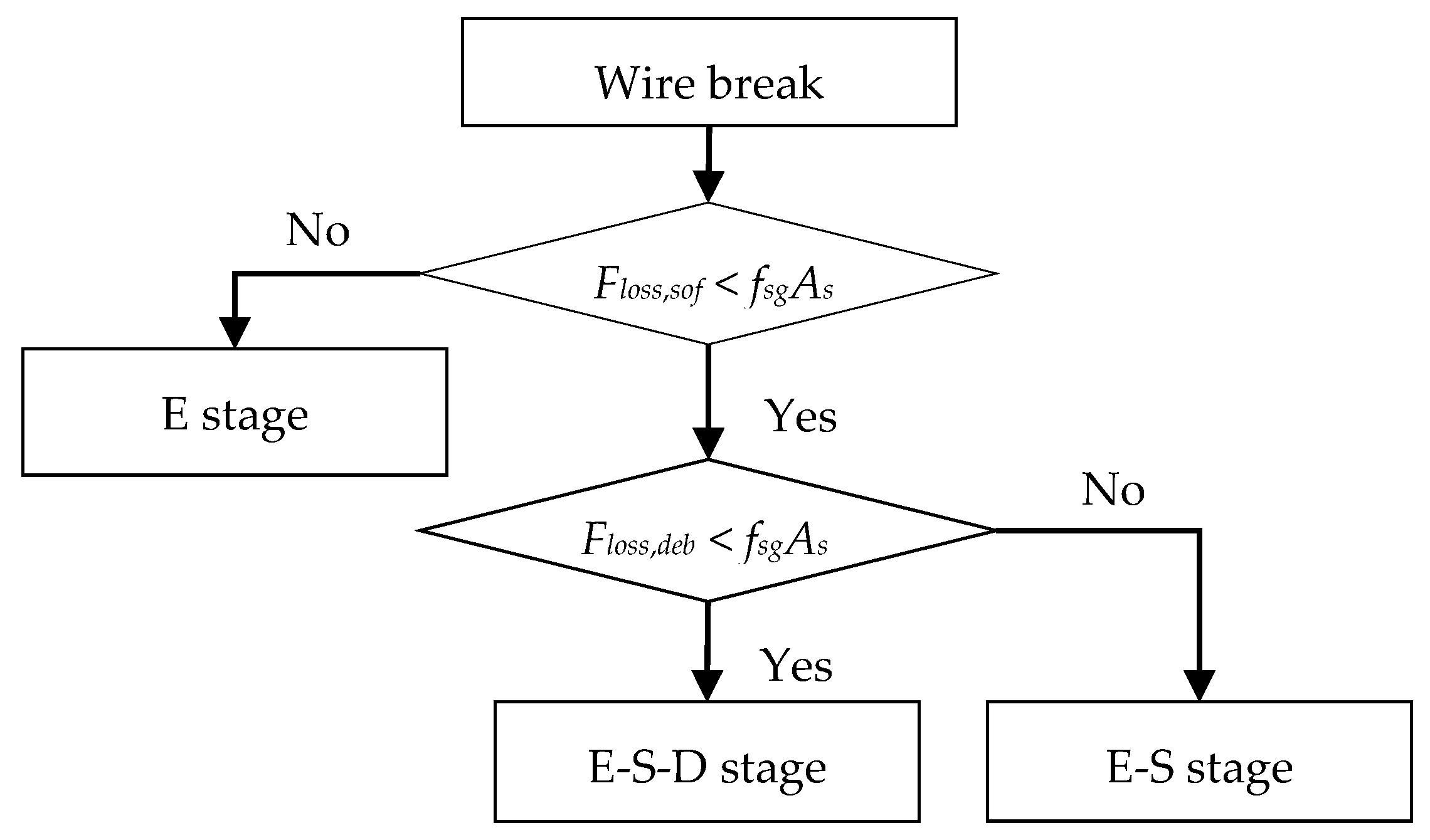

4.1. Elastic Stage

4.2. Elastic-Softening Stage

4.3. Elastic-Softening-Debonding Stage

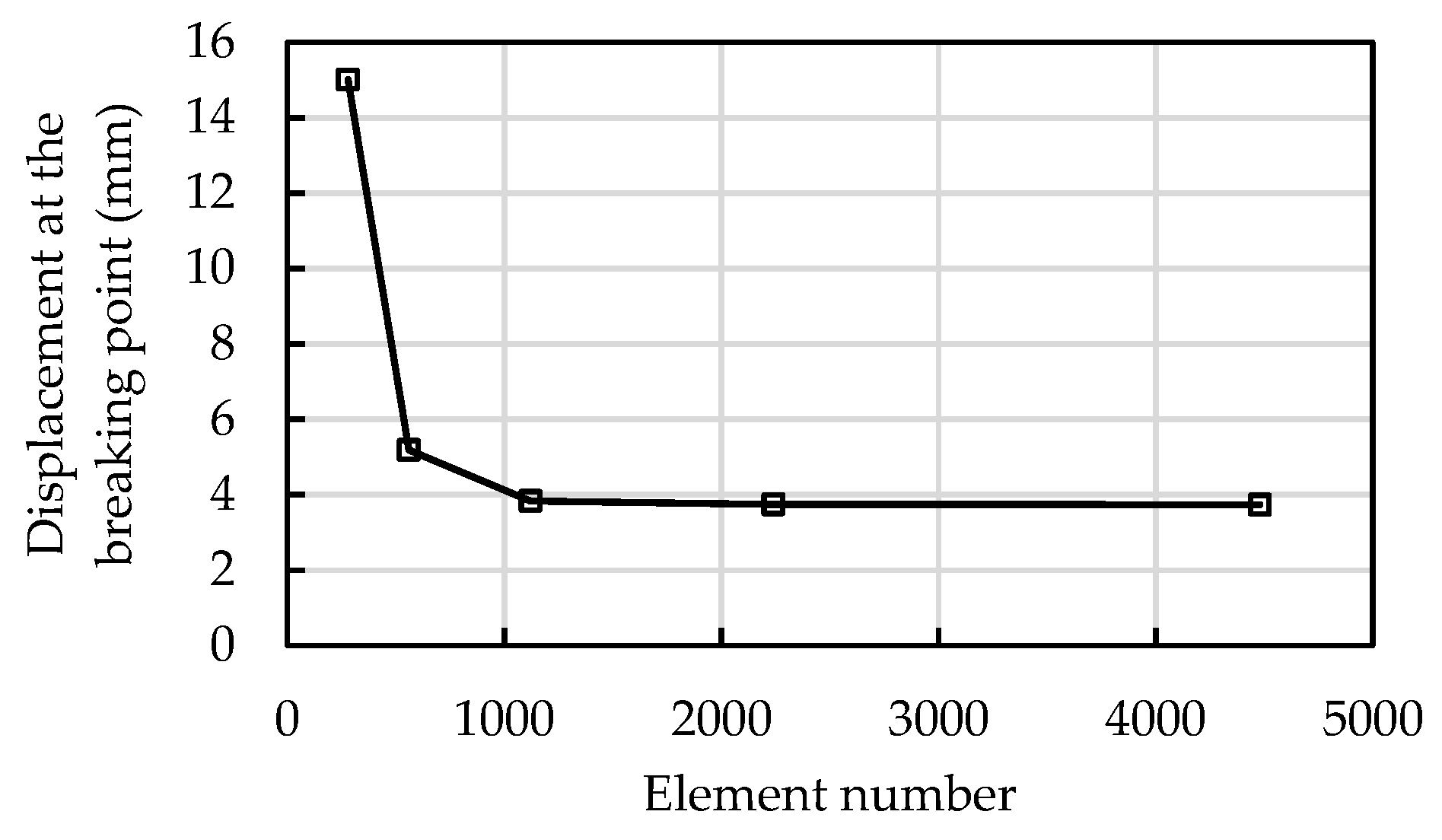

5. Finite Element Modelling

6. Parametric Study

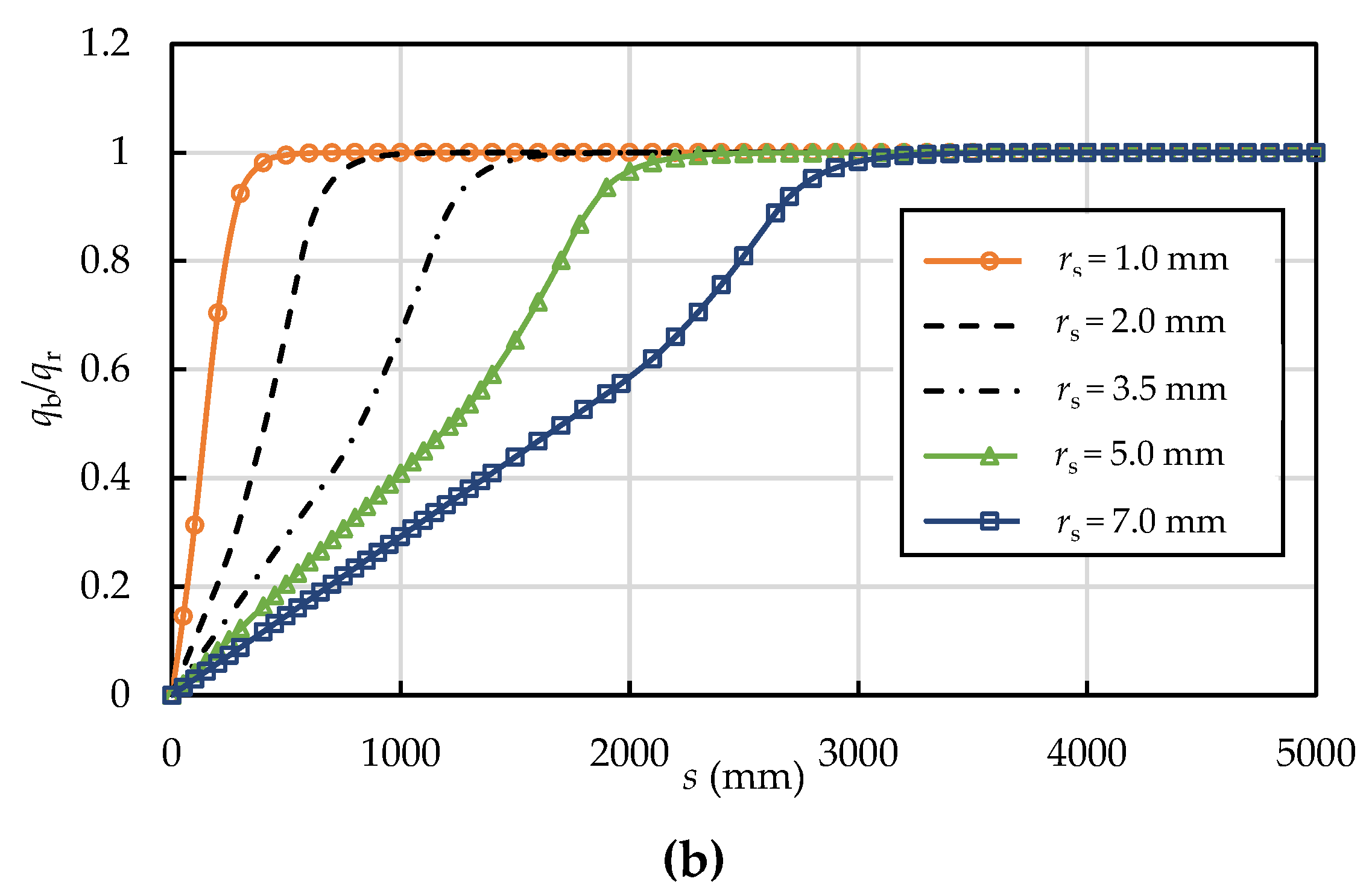

6.1. Effect of the Size of the Prestressing Wire

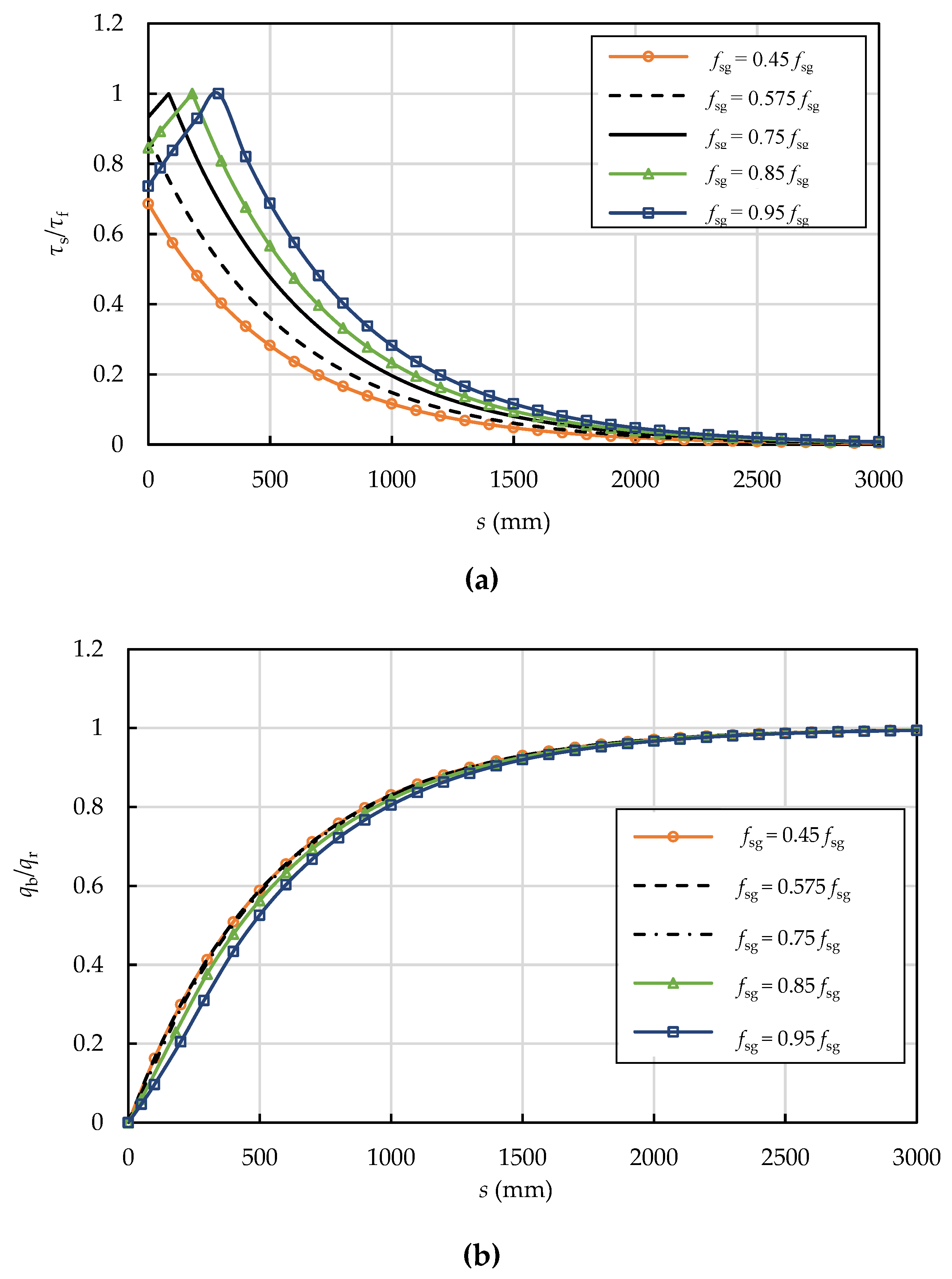

6.2. Effect of the Prestressing Level

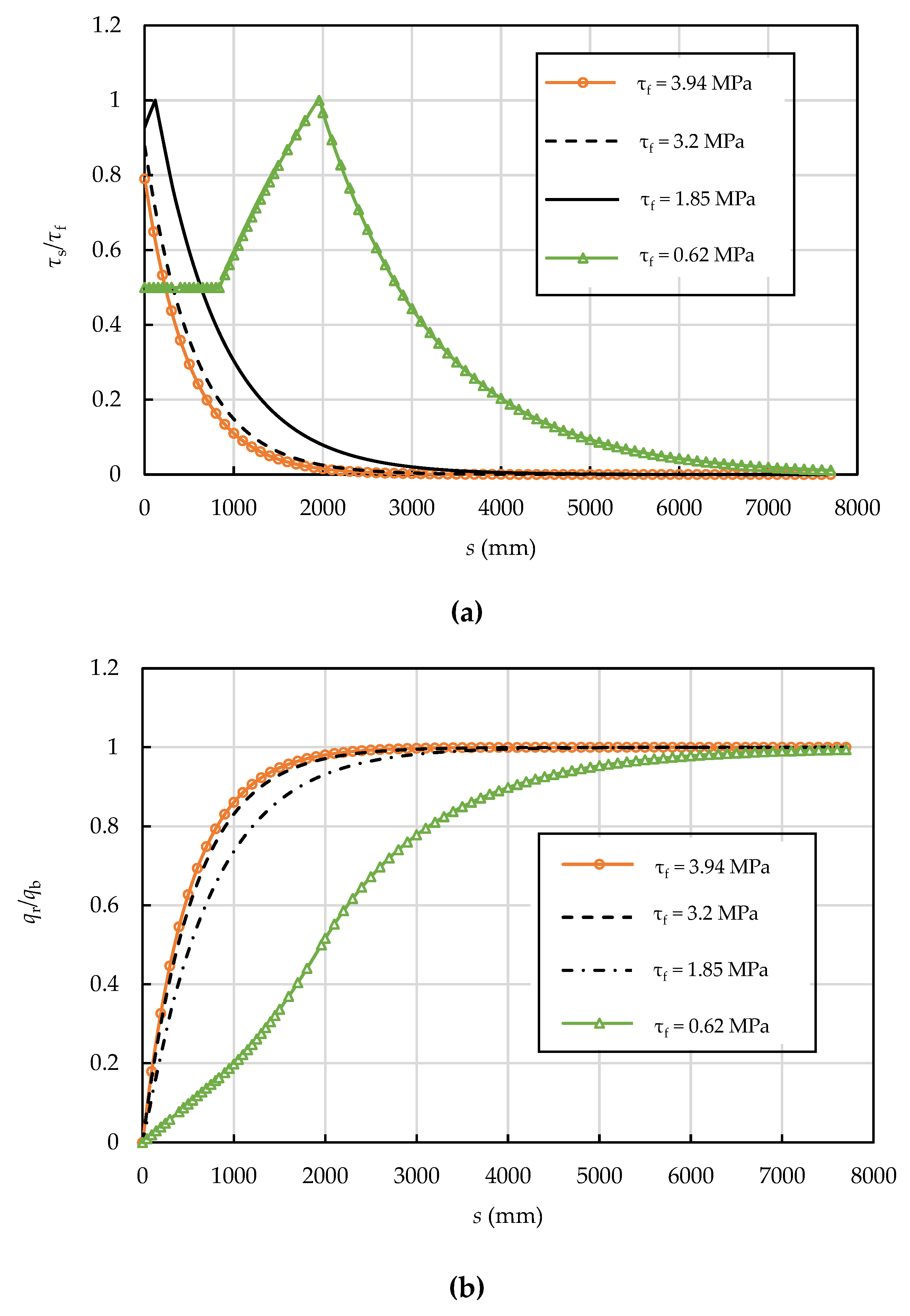

6.3. Effect of the Interfacial Shear Strength

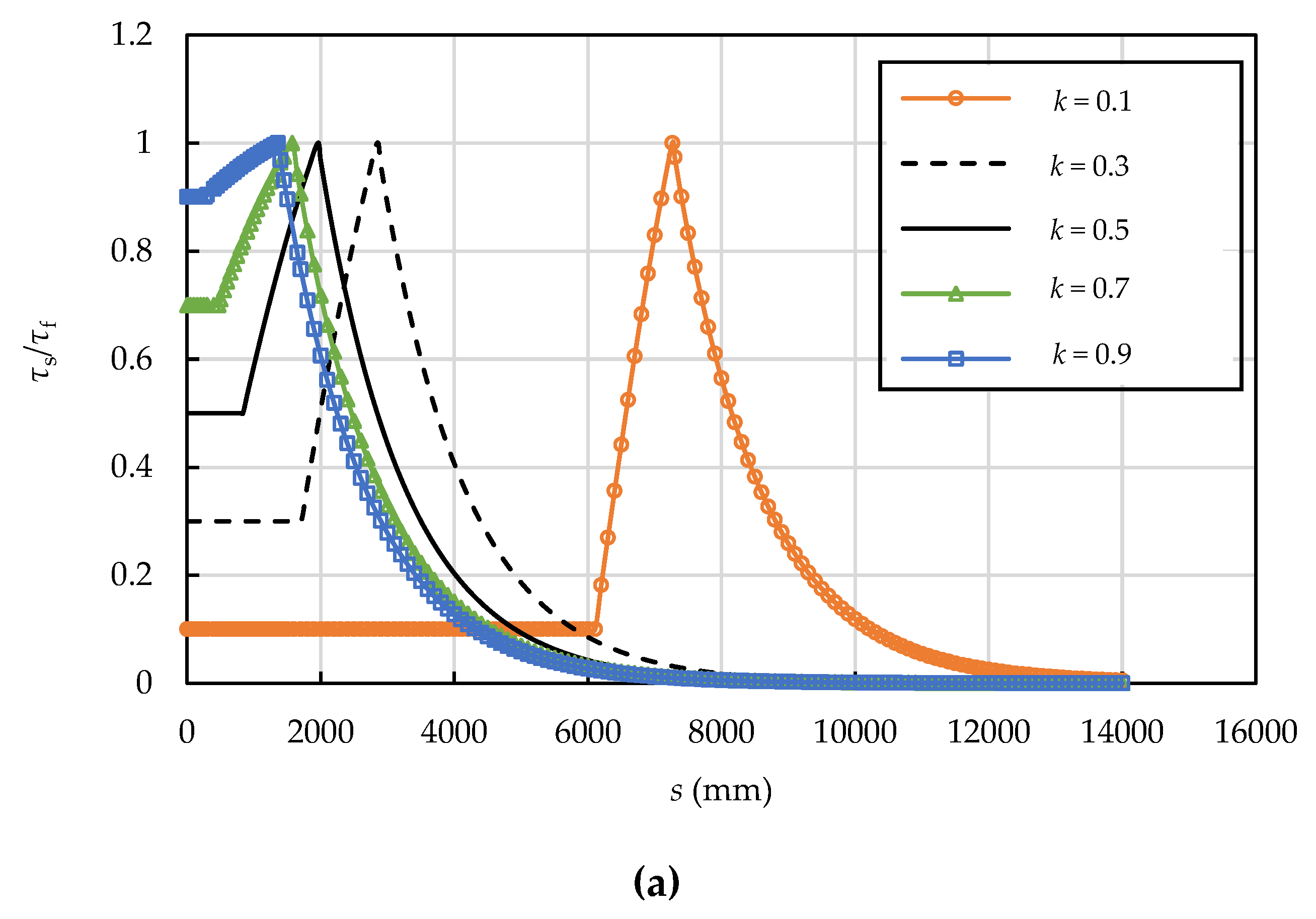

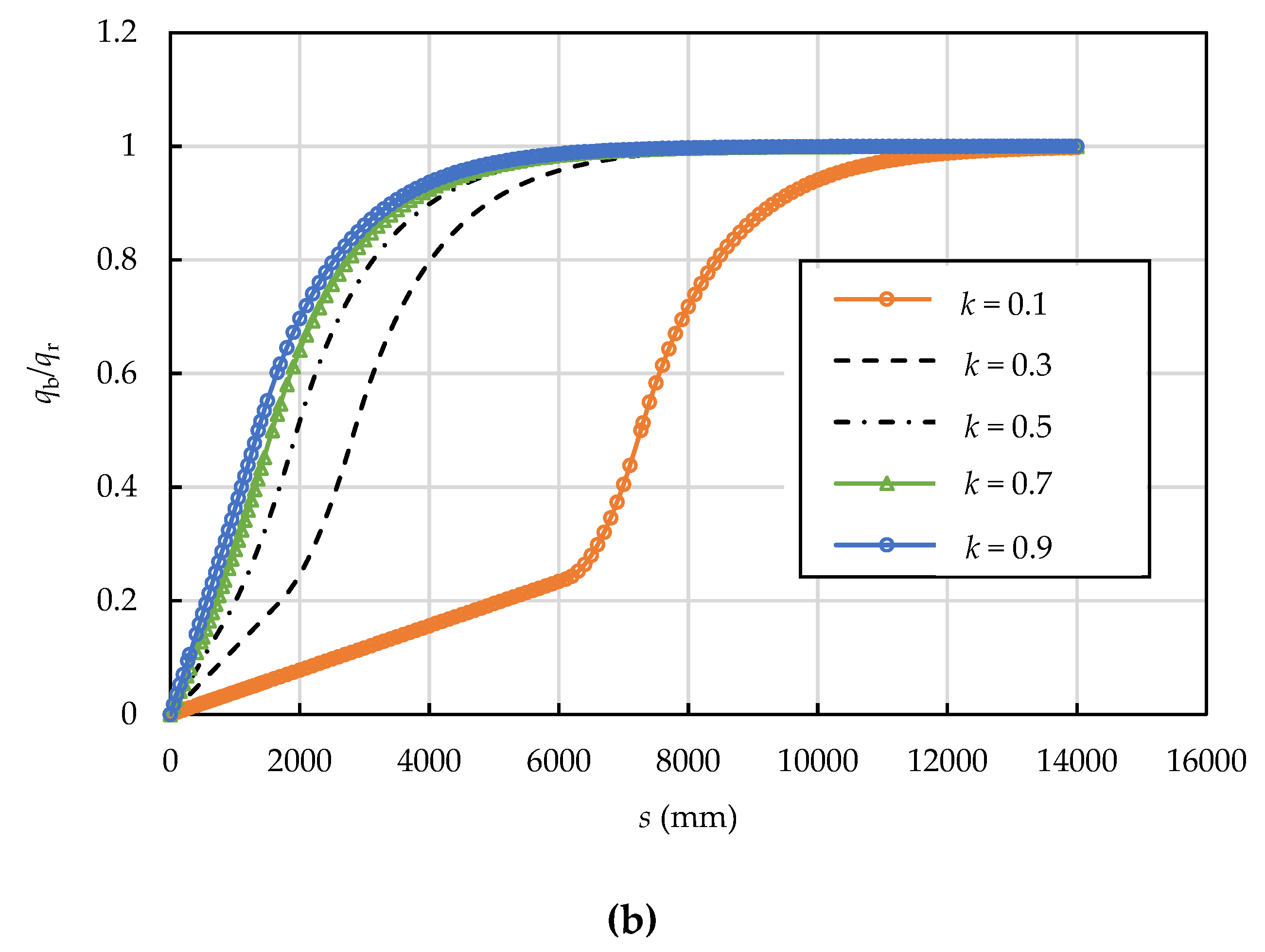

6.4. Effect of the Residual Interfacial Shear Strength Factor

7. Conclusions

- (1)

- Adapting a tri-linear bond-slip model for the prestressing wire–mortar coating bond behaviour, closed-form expressions for the axial stress in the prestressing wire, the prestress loss–displacement relation, and the interfacial shear and normal stress distributions have been derived for elastic (E), elastic-softening (E-S), and elastic-softening-debonding (E-S-D) stages of the interface. The solutions have been verified by a 2D plane strain FE model of a PCCP with a broken wire. These analytical solutions can be used to determine the mechanical state of a prestressing wire after it breaks in a PCCP.

- (2)

- Based on a parametric study, it has been found that the size of prestressing wire, the prestressing level, the interfacial shear (bond) strength, and the residual interfacial shear strength factor have significant effects on the interfacial shear and normal stress distributions.

- (3)

- The length of prestress loss zone increases as the radius of prestressing wire and residual interfacial shear strength increase, and the interfacial shear strength reduces. For an example PCCP with an inner diameter of 4 m, the length of prestress loss zone increases from 500 mm to 3300 mm as the radius of prestressing wire increases from 1 mm to 7 mm and increases from 2700 mm to 7700 mm when the interfacial shear strength reduces from 3.94 MPa to 0.62 MPa, but it reduces from 13,200 mm to 7300 mm as the residual interfacial shear stress factor increases from 0.1 to 0.9.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Es | Young’s modulus of the prestressing wire |

| Em | Young’s modulus of the mortar coating |

| Ecy | Young’s modulus of the steel cylinder |

| Ec | Young’s modulus of the concrete core |

| μs | Poisson’s ratio of the prestressing wire |

| μm | Poisson’s ratio of the mortar coating |

| μcy | Poisson’s ratio of the steel cylinder |

| μc | Poisson’s ratio of the concrete core |

| σs | Axial stress in the prestressing wire |

| τ | Interfacial shear stress |

| δ | Interfacial slip |

| us | Displacement of the broken wire |

| τf | Interfacial shear strength |

| τr | Residual interfacial shear strength |

| k | Residual interfacial shear strength factor |

| δ1 | Slip corresponding to the interfacial shear strength |

| δf | Slip corresponding to the residual interfacial shear strength |

| εsi | Initial strain of the prestressing wire |

| qr | Pressure acting on the prestressing wire |

| qb | Pressure acting on the broken wire |

| fcm | Compressive strength of the mortar coating |

| fc | Compressive strength of the concrete core |

| fsg | Wrapping stress of prestressing wire (or initial prestress) |

| fsu | Specified tensile strength of the prestressing wire |

| fsy | Yield strength of the prestressing wire |

| rs | Radius of prestressing wire |

| rm | Thickness of mortar coating |

| Rs | Distance from the axis of pipe to the prestressing wire |

| Ri | Inner radius of PCCP |

| Rcyi | Inner radius of the steel cylinder |

| Rcyo | Outer radius of the steel cylinder |

| Rco | Outer radius of PCCP |

| As | Cross-sectional area of prestressing wire |

| L | Length of prestress loss zone |

| Ts | Tensile force of the prestressing wire |

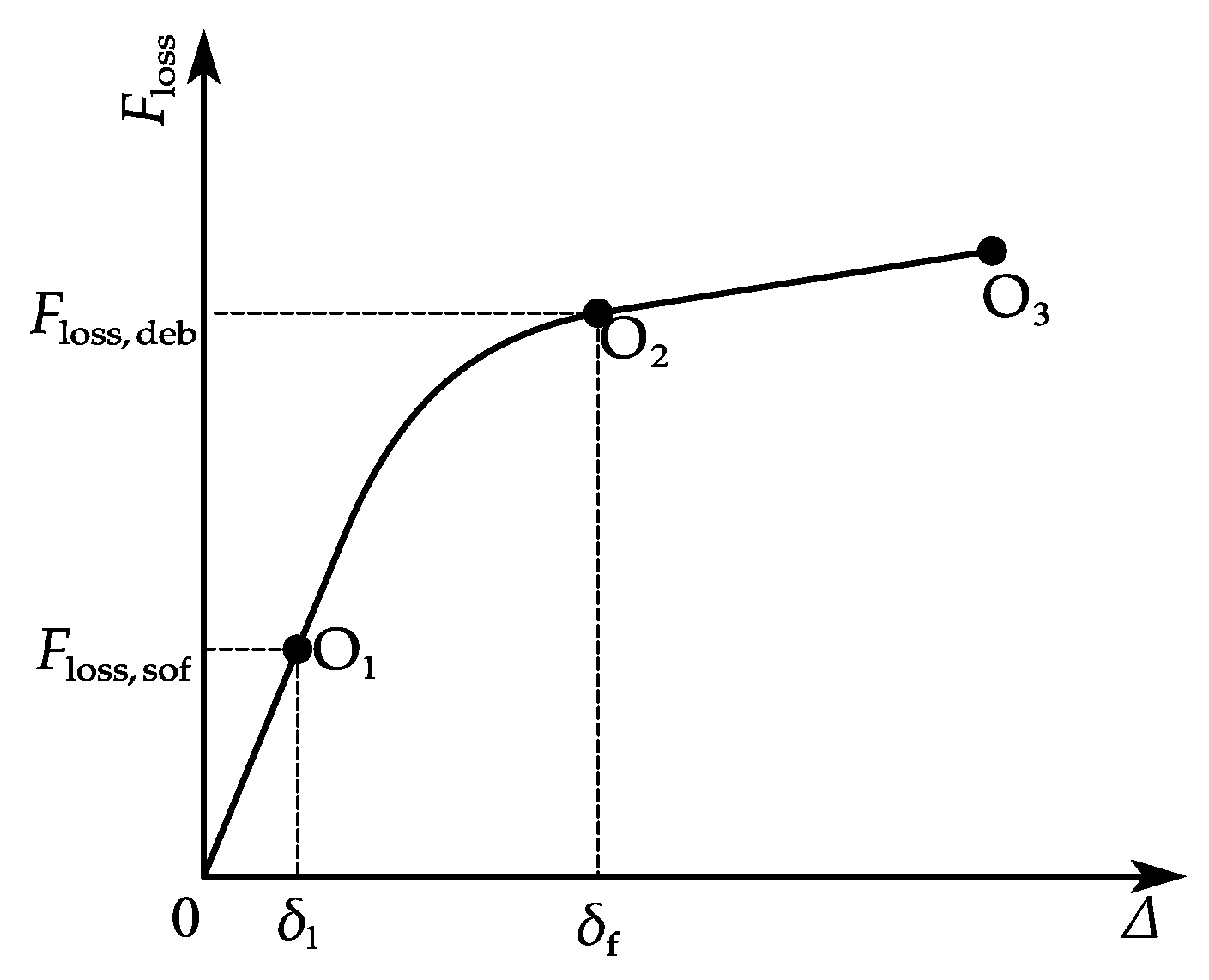

| Δ | Displacement of the broken wire at the breaking point |

| Floss | Prestress loss at the breaking point |

| Floss,sof | Prestress loss at the breaking point when the interface softening occurs |

| Floss,deb | Prestress loss at the breaking point when the interface debonding occurs |

| s1 | Length of softening zone at the elastic-softening stage |

| s2 | Length of the debonding zone at the elastic-softening-debonding stage |

| s3 | Length of the debonding zone and softening zone at the elastic-softening-debonding stage |

References

- AWWA C304-14; Design of Prestressed Concrete Cylinder Pipe. American Water Works Association: Denver, CO, USA, 2014; p. 144. [CrossRef]

- GB/T 19685—2017; Prestressed Concrete Cylinder Pipe. China National Standardization Management Committee: Beijing, China, 2017; p. 28. (In Chinese)

- Hassi, S.; Ejbouh, A.; Ebn Touhami, M.; Berrami, K.; Ech-chebab, A.; Boujad, A. Performance of prestressed concrete cylinder pipe in North Africa: Case study of the water transmission systems in the tafilalet region of Morocco. J. Pipeline Syst. Eng. Pract. 2021, 12, 05021002. [Google Scholar] [CrossRef]

- Hassi, S.; Ebn Touhami, M.; Boujad, A.; Benqlilou, H. Assessing the effect of mineral admixtures on the durability of Prestressed Concrete Cylinder Pipe (PCCP) by means of electrochemical impedance spectroscopy. Constr. Build. Mater. 2020, 262, 120925. [Google Scholar] [CrossRef]

- Berrami, K.; Ech-chebab, A.; Galai, M.; Ejbouh, A.; Hassi, S.; Benqlilou, H.; Ouaki, B.; Ebn Touhami, M. Evaluation of fly ash effect on the durability of prestressed concrete cylindrical pipe in aggressive soil by electrochemical method. Chem. Data Collect. 2021, 32, 100656. [Google Scholar] [CrossRef]

- Bavarian, B.; Reiner, L.; Santos, P.; Cervantes, O.; Herrera, G. Hydrogen embrittlement of prestressed concrete cylinder pipes. In Proceedings of the European Corrosion Conference: Long Term Prediction and Modelling of Corrosion, EUROCORR 2004, Nice, France, 12–16 September 2004; Cefracor: Nice, France, 2004. [Google Scholar]

- Zarghamee, M.S.; Moharrami, M.; Jalber, C.; Gehrig, J. A study of life extension of two prestressed concrete cylinder pipelines. In Proceedings of the Pipelines 2019, Nashville, TN, USA, 21–24 July 2019. [Google Scholar] [CrossRef]

- Washington Suburban Sanitary Commission. WSSC Pipeline Design Manual Amendment Proposed 80-Foot Setback; Washington Suburban Sanitary Commission: Laurel, MD, USA, 2012; p. 86. [Google Scholar]

- Hu, S.; Shen, j. Study on impact from wire breaking insider of super large diameter PCCP on its bearing capacity. Water Resour. Hydropower Eng. 2011, 42, 41–44. (In Chinese) [Google Scholar] [CrossRef]

- Goldaran, R.; Turer, A.; Kouhdaragh, M.; Ozlutas, K. Identification of corrosion in a prestressed concrete pipe utilizing acoustic emission technique. Constr. Build. Mater. 2020, 242, 118053. [Google Scholar] [CrossRef]

- Goldaran, R.; Turer, A. Application of acoustic emission for damage classification and assessment of corrosion in pre-stressed concrete pipes. Measurement 2020, 160, 107855. [Google Scholar] [CrossRef]

- Atherton, D.L.; Morton, K.; Mergelas, B.J. Detecting Breaks in Prestressing Pipe Wire. J. Am. Water Work. Assoc. 2000, 92, 50–56. [Google Scholar] [CrossRef]

- Ge, S.; Sinha, S. Failure analysis, condition assessment technologies, and performance prediction of prestressed-concrete cylinder pipe: State-of-the-art literature review. J. Perform. Constr. Facil. 2014, 28, 618–628. [Google Scholar] [CrossRef]

- Liu, Z.; Kleiner, Y. State of the art review of inspection technologies for condition assessment of water pipes. Measurement 2013, 46, 1–15. [Google Scholar] [CrossRef] [Green Version]

- Villalobos, S.; Stark, R.; Fisk, P. Ultrasonic measurements for condition assessment of prestressed concrete cylinder pipe. In Proceedings of the Pipelines 2019, Nashville, TN, USA, 21–24 July 2019. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, Y. Prediction of PCCP failure based on hydrophne detecting. Int. J. Smart Sens. Intell. Syst. 2013, 6, 1582–1598. [Google Scholar] [CrossRef] [Green Version]

- Huang, J.; Zhou, Z.; Zhang, D.; Yao, X.; Li, L. Online monitoring of wire breaks in prestressed concrete cylinder pipe utilising fibre Bragg grating sensors. Measurement 2016, 79, 112–118. [Google Scholar] [CrossRef]

- Wei, H.; Liao, K.; Zhao, X.; Kong, X.; Zhang, P.; Sun, C. Low-coherent fiber-optic interferometry for in situ monitoring the corrosion-induced expansion of pre-stressed concrete cylinder pipes. Struct. Health Monit. 2019, 18, 1862–1873. [Google Scholar] [CrossRef]

- Wang, X.; Hu, S.; Li, W.; Qi, H.; Xue, X. Use of numerical methods for identifying the number of wire breaks in prestressed concrete cylinder pipe by piezoelectric sensing technology. Constr. Build. Mater. 2021, 268, 121207. [Google Scholar] [CrossRef]

- Zarghamee, M.S.; Eggers, D.W.; Ojdrovic, R.P. Finite-Element Modeling of Failure of PCCP with Broken Wires Subjected to Combined Loads; American Society of Civil Engineers: Cleveland, OH, USA, 2002; p. 66. [Google Scholar] [CrossRef]

- Hajali, M.; McNealy, A.; Dettmer, A. Scattered broken wire wrap effects on structural capacity of prestressed concrete cylinder pipes. In Proceedings of the Pipelines 2020, San Antonio, TX, USA, 9–12 August 2020. [Google Scholar] [CrossRef]

- Ge, S. Development of a Numerical Model to Analyze the Condition of Prestressed Concrete Cylinder Pipe (PCCP). Ph.D. Thesis, Faculty of the Virginia Polytechnic Institute and State University, Blacksburg, VA, USA, 2016. [Google Scholar]

- Ge, S.; Sinha, S. Effect of Mortar Coating’s Bond Quality on the Structural Integrity of Prestressed Concrete Cylinder Pipe with Broken Wires. J. Mater. Sci. Res. 2015, 4, 59. [Google Scholar] [CrossRef]

- Xiong, H. Prestress Model and Prototype Test on the Ultra-diameter PCCP in Mid-route of South-to-North Water Diversion Project. Ph.D. Thesis, Tsinghua University, Beijing, China, 2010. (In Chinese). [Google Scholar]

- Zhai, K.; Fang, H.; Fu, B.; Wang, F.; Hu, B. Mechanical response of externally bonded CFRP on repair of PCCPs with broken wires under internal water pressure. Constr. Build. Mater. 2020, 239, 117878. [Google Scholar] [CrossRef]

- Hu, B.; Fang, H.; Wang, F.; Zhai, K. Full-scale test and numerical simulation study on load-carrying capacity of prestressed concrete cylinder pipe (PCCP) with broken wires under internal water pressure. Eng. Fail. Anal. 2019, 104, 513–530. [Google Scholar] [CrossRef]

- Zhai, K.; Fang, H.; Guo, C.; Ni, P.; Wu, H.; Wang, F. Full-scale experiment and numerical simulation of prestressed concrete cylinder pipe with broken wires strengthened by prestressed CFRP. Tunn. Undergr. Space Technol. 2021, 115, 104021. [Google Scholar] [CrossRef]

- Cheng, B. External Pressure Experiment and Numerical Analysis for CFRP Reinforcement of PCCP. Master’s Thesis, China Institute of Water Resources and Hydropower Research, Beijing, China, 2018. (In Chinese). [Google Scholar]

- Hu, H. Analysis of Experiment and Simulation for CFRP Renewal of Prestressed Concrete Cylinder pipe with Internal Pressure. Master’s Thesis, China Institute of Water Resources and Hydropower Research, Beijing, China, 2017. (In Chinese). [Google Scholar]

- Zhang, X.; Teng, H.; Dai, C. Analysis of the performance of PCCP with broken prestressed steel wires. Yellow River 2014, 36, 138–140. [Google Scholar] [CrossRef]

- Zhai, K.; Fang, H.; Guo, C.; Fu, B.; Ni, P.; Ma, H.; He, H.; Wang, F. Mechanical properties of CFRP-strengthened prestressed concrete cylinder pipe based on multi-field coupling. Thin-Walled Struct. 2021, 162, 107629. [Google Scholar] [CrossRef]

- Zhai, K.; Fang, H.; Guo, C.; Ni, P.; Fu, B.; Wang, F.; Zhang, C. Strengthening of PCCP with broken wires using prestressed CFRP. Constr. Build. Mater. 2021, 267, 120903. [Google Scholar] [CrossRef]

- Hu, H.; Dou, T.; Niu, F.; Zhang, H.; Su, W. Experimental and numerical study on CFRP-lined prestressed concrete cylinder pipe under internal pressure. Eng. Struct. 2019, 190, 480–492. [Google Scholar] [CrossRef]

- Hu, H.; Niu, F.; Dou, T.; Zhang, H. Rehabilitation effect evaluation of CFRP-lined prestressed concrete cylinder pipe under combined loads using numerical simulation. Math. Probl. Eng. 2018, 2018, 3268962. [Google Scholar] [CrossRef]

- Li, K.; Li, Y.; Dong, P.; Wang, Z.; Dou, T.; Ning, J.; Dong, X.; Si, Z.; Wang, J. Mechanical properties of prestressed concrete cylinder pipe with broken wires using distributed fiber optic sensors. Eng. Fail. Anal. 2022, 141, 106635. [Google Scholar] [CrossRef]

- Eligehausen, R.; Popov, E.; Bertero, V. Local Bond Stress-Slip Relationships of Deformed Bars under Generalized Excitations: Experimental Results and Analytical Model; Earthquake Engineering Research Center, College of Engineering, University of California: Berkeley, CA, USA, 1983. [Google Scholar] [CrossRef]

- CEB-FIP. FIB Model Code for Concrete Structures 2010; International Federation for Structural Concrete (FIB): Lausanne, Switzerland, 2010. [Google Scholar] [CrossRef]

- Geng, H.; Mu, Z.; Yu, X. Bond-slip constitutive model of the interface between plain bar and concrete. Bull. Chin. Ceram. Soc. 2017, 36, 3064–3069. [Google Scholar] [CrossRef]

- Ren, F.-F.; Liu, Q.; Wang, G.; Zhao, Q.-H.; Xu, C. An analytical method for predicting the pullout behavior of embedded planar reinforcements with the consideration of the residual interfacial shear strength. Int. J. Geosynth. Ground Eng. 2020, 6, 35. [Google Scholar] [CrossRef]

- Dassault Systemes Simulia Corp. ABAQUS Analysis User’s Manual, version 6.14; Dassault Systemes Simulia Corp.: Providence, RI, USA, 2014. [Google Scholar]

- Feldman, L.R.; Bartlett, F.M. Bond strength variability in pullout specimens with plain reinforcement. ACI Struct. J. 2005, 102, 860–867. [Google Scholar] [CrossRef]

| Em (GPa) | Es (GPa) | μm | fcm (MPa) | Ec (GPa) | μc | μs | Ecy (GPa) | μcy |

|---|---|---|---|---|---|---|---|---|

| 25.12 | 193.05 | 0.17 | 37.9 | 42.1 | 0.18 | 0.3 | 206.85 | 0.3 |

| fsg(MPa) | fc(MPa) | rs(mm) | rm(mm) | Rs(mm) | Ri(mm) | Rcyi(mm) | Rcyo(mm) | Rco(mm) |

| 902.39 | 72.5 | 3.5 | 25 | 2350 | 2000 | 2089 | 2091 | 2350 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Wu, J.; Hou, C.; Chen, J.-F. An Analytical Solution for Stress Transfer between a Broken Prestressing Wire and Mortar Coating in PCCP. Materials 2022, 15, 5779. https://doi.org/10.3390/ma15165779

Zhang X, Wu J, Hou C, Chen J-F. An Analytical Solution for Stress Transfer between a Broken Prestressing Wire and Mortar Coating in PCCP. Materials. 2022; 15(16):5779. https://doi.org/10.3390/ma15165779

Chicago/Turabian StyleZhang, Xiaojie, Jiayu Wu, Chao Hou, and Jian-Fei Chen. 2022. "An Analytical Solution for Stress Transfer between a Broken Prestressing Wire and Mortar Coating in PCCP" Materials 15, no. 16: 5779. https://doi.org/10.3390/ma15165779

APA StyleZhang, X., Wu, J., Hou, C., & Chen, J.-F. (2022). An Analytical Solution for Stress Transfer between a Broken Prestressing Wire and Mortar Coating in PCCP. Materials, 15(16), 5779. https://doi.org/10.3390/ma15165779