Lattice Distortion, Amorphization and Wear Resistance of Carbon-Doped SUS304 by Laser Ablation

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Choi, J.Y.; Fukuda, T.; Kakeshita, T. Effect of magnetic field on isothermal martensitic transformation in a sensitized SUS304 austenitic stainless steel. J Alloys Compd. 2019, 577, S605–S608. [Google Scholar] [CrossRef]

- Chan, J.W.; Chu, D.; Sunwoo, A.J.; Morris, J.W. Metastable austenites in cryogenic high magnetic field environments. Materials 1992, 55–59. [Google Scholar] [CrossRef][Green Version]

- Egawa, M.; Ueda, N.; Nakata, K.; Tsujikawa, M.; Tanaka, M. Effect of additive alloying element on plasma nitriding and carburizing behavior for austenitic stainless steels. Surf. Coat. Technol. 2010, 205, S246–S251. [Google Scholar] [CrossRef]

- Bell, T.; Li, C.X. Stainless steel low temperature nitriding and carburizing: Low-temperature nitriding and carburizing of austenitic stainless steels have been developed and are rapidly gaining acceptance for improving resistance to wear and corrosion. Adv. Mater. Process. 2002, 160, 49–52. [Google Scholar]

- Kochmański, P.; Baranowska, J.; Fryska, S. Microstructure of low-temperature gas-carbonitrided layers on austenitic stainless steel. Metals 2019, 9, 817. [Google Scholar] [CrossRef]

- You, Y.; Yan, J.; Yan, M. Atomistic diffusion mechanism of rare earth carburizing/nitriding on iron-based alloy. Appl. Surf. Sci. 2019, 484, 710–715. [Google Scholar] [CrossRef]

- Tsujikawa, M.; Egawa, M.; Ueda, N.; Okamoto, A.; Sone, T.; Nakata, K. Effect of molybdenum and copper on S-phase layer thickness of low-temperature carburized austenitic stainless steel. Surf. Coat. Technol. 2008, 202, 5488–5492. [Google Scholar] [CrossRef]

- Liu, B.X.; Yin, F.X.; Dai, X.L.; He, J.N.; Fang, W.; Chen, C.X.; Dong, Y.C. The tensile behaviors and fracture characteristics of stainless steel clad plates with different interfacial status. J. Mater. Sci. Eng. A 2017, 679, 172–182. [Google Scholar] [CrossRef]

- Souza, R.M.D.; Ignat, M.; Pinedo, C.E.; Tschiptschin, A.P. Structure and properties of low temperature plasma carburized austenitic stainless steels. Surf. Coat. Technol. 2009, 204, 1102–1105. [Google Scholar] [CrossRef]

- Scheuer, C.J.; Cardoso, R.P.; Pereira, R.; Mafra, M.; Brunatto, S.F. Low temperature plasma carburizing of martensitic stainless steel. J. Mater. Sci. Eng. A 2012, 539, 369–372. [Google Scholar] [CrossRef]

- Tsujikawa, M.; Noguchi, S.; Yamauchi, N.; Ueda, N.; Sone, T. Effect of molybdenum on hardness of low-temperature plasma carburized austenitic stainless steel. Surf. Coat. Technol. 2007, 201, 5102–5107. [Google Scholar] [CrossRef]

- Rovani, A.C.; Breganon, R.; de Souza, G.S.; Brunatto, S.F.; Pintaúde, G. Scratch resistance of low-temperature plasma nitrided and carburized martensitic stainless steel. Wear 2017, 376, 70–76. [Google Scholar] [CrossRef]

- Ren, Z.; Eppell, S.; Collins, S.; Ernst, F. Co–Cr–Mo alloys: Improved wear resistance through low-temperature gas-phase nitro-carburization. Surf. Coat. Technol. 2019, 378, 124943. [Google Scholar] [CrossRef]

- Courant, B.; Hantzpergue, J.J.; Avril, L.; Benayoun, S. Structure and hardness of titanium surfaces carburized by pulsed laser melting with graphite addition. J. Mater. Process. Technol. 2005, 160, 374–381. [Google Scholar] [CrossRef][Green Version]

- Kim, T.; Lee, J.; Kim, S.; Hong, E.; Lee, H. Hydrogen permeation barrier of carbon-doped TiZrN coatings by laser carburization. Corros. Sci. 2021, 190, 109700. [Google Scholar] [CrossRef]

- Valentini, L.; Di Schino, A.; Kenny, J.M.; Gerbig, Y.; Haefke, H. Influence of grain size and film composition on wear resistance of ultra fine grained AISI 304 stainless steel coated with amorphous carbon films. Wear 2002, 253, 458–464. [Google Scholar] [CrossRef]

- Alentini, L.; Di Schino, A.; Kenny, J.M.; La Rosa, S.; Lozzi, L.; Santucci, S.; Bregliozzi, G.; Gerbig, Y.; Haefke, H. Wear resistance of fine-grained high nitrogen austenitic stainless steel coated with amorphous carbon films: The soft X-ray spectroscopy approach. Tribol. Lett. 2004, 16, 51–58. [Google Scholar] [CrossRef]

- Yang, Y.; Yan, M.F.; Zhang, Y.X.; Zhang, C.S.; Wang, X.A. Self-lubricating and anti-corrosion amorphous carbon/Fe3C composite coating on M50NiL steel by low temperature plasma carburizing. Surf. Coat. Technol. 2016, 304, 142–149. [Google Scholar] [CrossRef]

- Rotundo, F.; Ceschini, L.; Martini, C.; Montanari, R.; Varone, A. High temperature tribological behavior and microstructural modifications of the low-temperature carburized AISI 316L austenitic stainless steel. Surf. Coat. Technol. 2014, 258, 772–781. [Google Scholar] [CrossRef]

- Angelini, V.; Boromei, I.; Martini, C.; Scheuer, C.J.; Cardoso, R.P.; Brunatto, S.F.; Ceschini, L. Dry sliding behavior (block-on-ring tests) of AISI 420 martensitic stainless steel, surface hardened by low temperature plasma-assisted carburizing. Tribol. Inter. 2019, 103, 555–565. [Google Scholar] [CrossRef]

- Yang, Y.; Yan, M.F.; Zhang, Y.X.; Li, D.Y.; Zhang, C.S.; Zhu, Y.D.; Wang, Y.X. Catalytic growth of diamond-like carbon on Fe3C-containing carburized layer through a single-step plasma-assisted carburizing process. Carbon 2017, 122, 1–8. [Google Scholar] [CrossRef]

- Dalibón, E.L.; Heim, D.; Forsich, C.; Rosenkranz, A.; Guitar, M.A.; Brühl, S.P. Characterization of thick and soft DLC coatings deposited on plasma nitrided austenitic stainless steel. Diam. Relat. Mater. 2015, 59, 73–79. [Google Scholar] [CrossRef]

- ISO 20808; ISO Standard, Fine Ceramics (Advanced ceramics, Advanced Technical Ceramics)—Determination of Friction and Wear Characteristics of Monolithic Ceramics by Ball-on-Disc Method. ISO: Geneva, Switzerland, 2016.

- Wu, W.; Li, X.; Chen, J.; Dong, H. Design and characterisation of an advanced duplex system based on carbon S-phase case and GiC coatings for 316LVM austenitic stainless steel. Surf. Coat. Technol. 2009, 203, 1273–1280. [Google Scholar] [CrossRef]

- Borgioli, F. From austenitic stainless steel to expanded austenite-S phase: Formation, characteristics and properties of an elusive metastable phase. Metals 2020, 10, 187. [Google Scholar] [CrossRef]

- Roy, A.; Mukhopadhyay, A.K.; Das, S.C.; Bhattacharjee, G.; Majumdar, A.; Hippler, R. Surface Stoichiometry and Optical Properties of Cu x–Ti y C z Thin Films Deposited by Magnetron Sputtering. Coatings 2019, 9, 551. [Google Scholar] [CrossRef]

- Dwivedi, N.; Yeo, R.J.; Satyanarayana, N.; Kundu, S.; Tripathy, S.; Bhatia, C.S. Understanding the role of nitrogen in plasma-assisted surface modification of magnetic recording media with and without ultrathin carbon overcoats. Sci. Rep. 2015, 5, 7772. [Google Scholar] [CrossRef]

- Li, X.; Zhang, N.; Lee, K.-R.; Wang, A. Effect of metal doping on structural characteristics of amorphous carbon system: A first-principles study. Thin Solid Films 2016, 607, 67–72. [Google Scholar] [CrossRef]

- Liu, D.; Zheng, L.; Liu, J.; Luo, L.; Wu, Y. Residual stress relief of hard a-C films though buckling. Ceram. Int. 2018, 44, 3644–3648. [Google Scholar] [CrossRef]

- Przybylska, N.; Śliwińska-Bartkowiak, M.; Kościński, M.; Rotnicki, K.; Bartkowiak, M.; Jurga, S. Confined effect of water solution of ciprofloxacin in carbon nanotubes studied by Raman and Fourier Transform Infrared Spectroscopy methods. J. Mol. Liq. 2021, 336, 115938. [Google Scholar] [CrossRef]

- Szybowicz, M.; Nowicka, A.B.; Dychalska, A. Characterization of carbon nanomaterials by Raman spectroscopy. In Characterization of Nanomaterials; Woodhead Publishing: Poznan, Poland, 2018; pp. 1–36. [Google Scholar] [CrossRef]

- Sudha, C.; Bharasi, N.S.; Anand, R.; Shaikh, H.; Dayal, R.K.; Vijayalakshmi, M. Carburization behavior of AISI 316LN austenitic stainless steel–Experimental studies and modeling. J. Nucl. Mater. 2010, 402, 186–195. [Google Scholar] [CrossRef]

- Cusenza, S.; Schaaf, P. Amorphous stainless steel coatings prepared by reactive magnetron-sputtering from austenitic stainless steel targets. Appl. Phys. A 2009, 94, 139–154. [Google Scholar] [CrossRef]

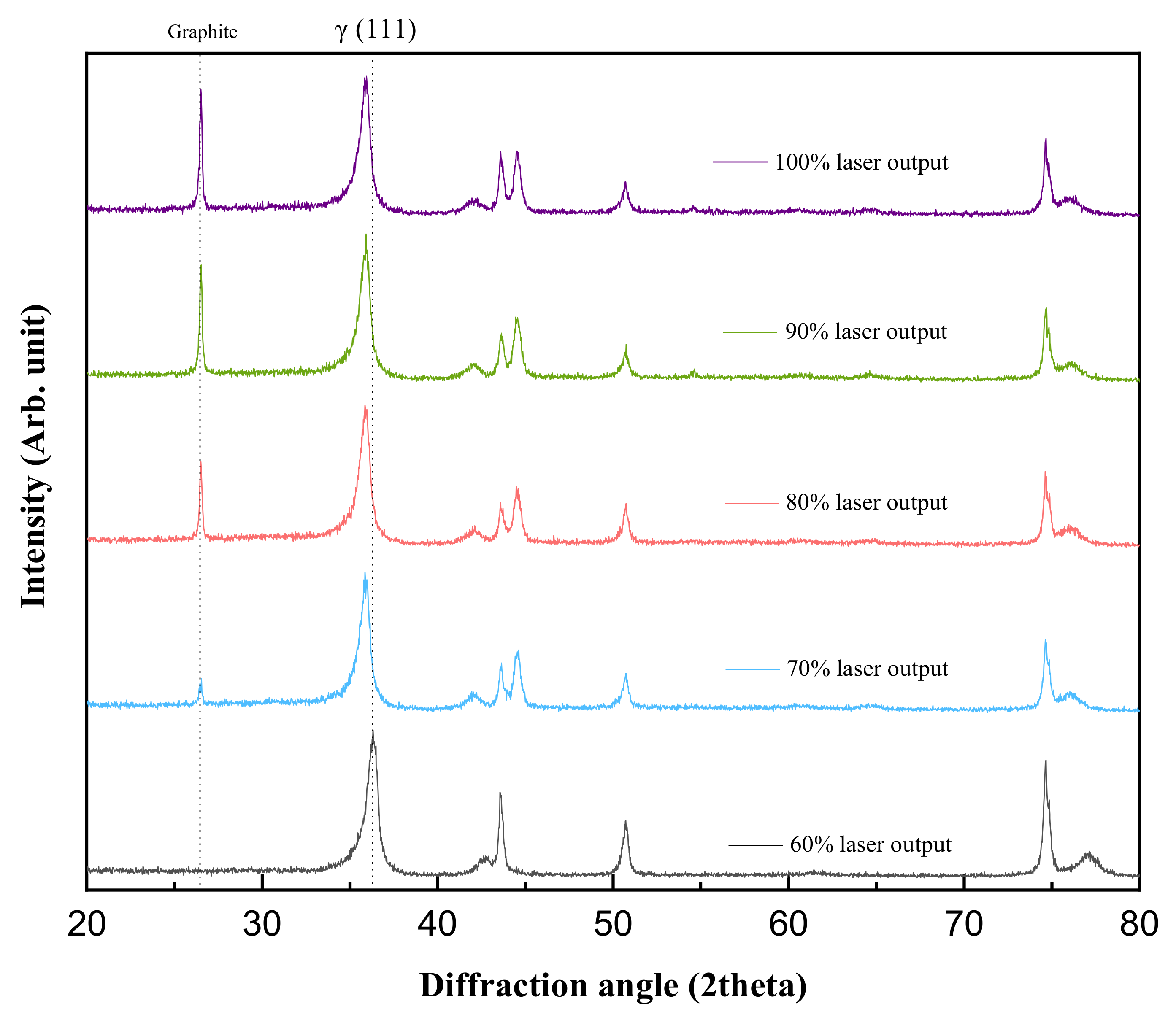

| Laser Output | Lattice Constant |

|---|---|

| As-deposited | 3.612 Å |

| 60% | 3.612 Å |

| 70% | 3.674 Å |

| 80% | 3.749 Å |

| 90% | 3.915 Å |

| 100% | 3.964 Å |

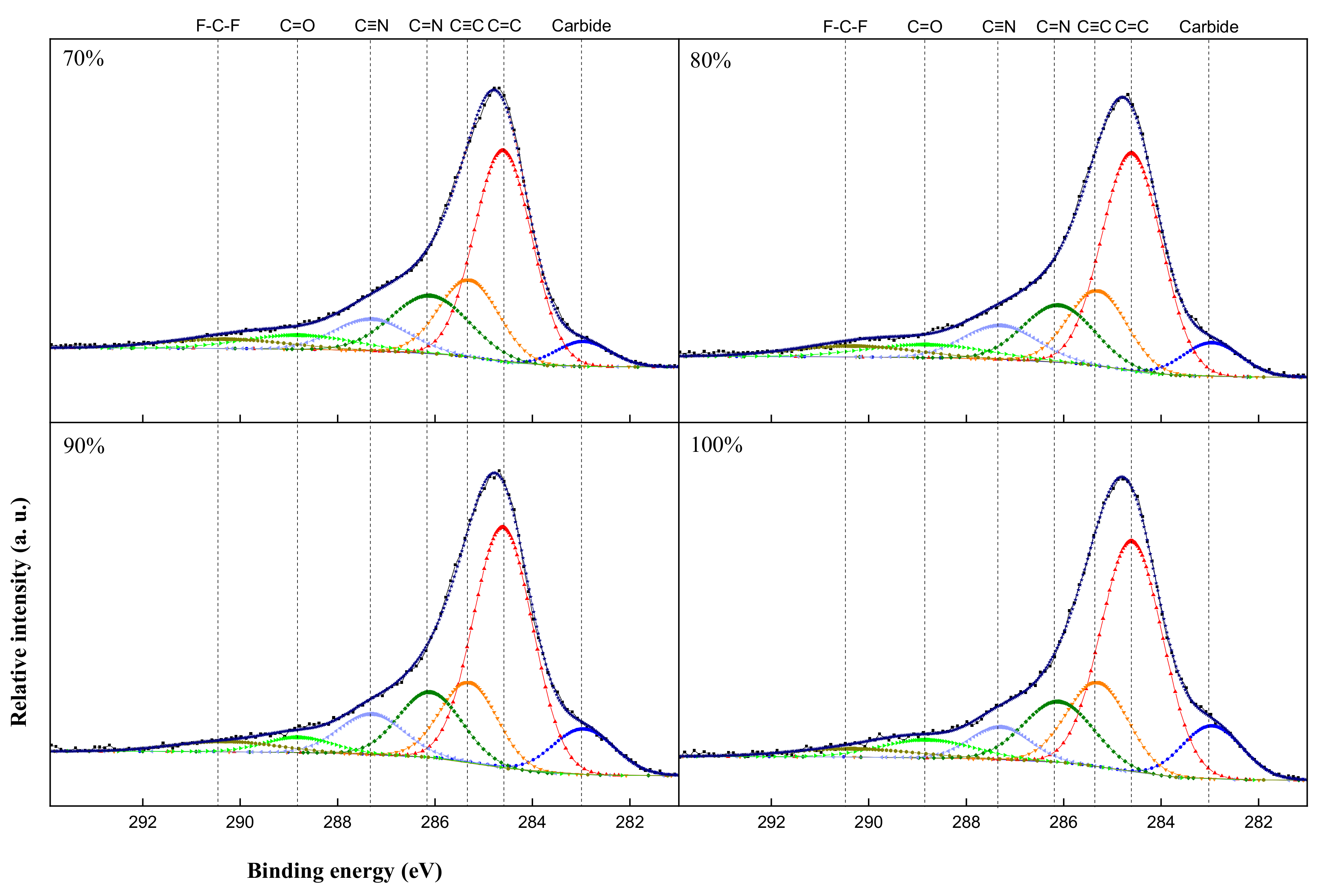

| Laser Output | sp2/sp3 Ratio |

|---|---|

| 70% | 3.21 |

| 80% | 3.14 |

| 90% | 2.67 |

| 100% | 2.52 |

| LASER Output | ID/IG |

|---|---|

| 70% | 0.68 |

| 80% | 0.85 |

| 90% | 1.24 |

| 100% | 1.68 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, S.; Kim, T.; Hong, E.; Lee, H. Lattice Distortion, Amorphization and Wear Resistance of Carbon-Doped SUS304 by Laser Ablation. Materials 2022, 15, 5764. https://doi.org/10.3390/ma15165764

Kim S, Kim T, Hong E, Lee H. Lattice Distortion, Amorphization and Wear Resistance of Carbon-Doped SUS304 by Laser Ablation. Materials. 2022; 15(16):5764. https://doi.org/10.3390/ma15165764

Chicago/Turabian StyleKim, Seonghoon, Taewoo Kim, Eunpyo Hong, and Heesoo Lee. 2022. "Lattice Distortion, Amorphization and Wear Resistance of Carbon-Doped SUS304 by Laser Ablation" Materials 15, no. 16: 5764. https://doi.org/10.3390/ma15165764

APA StyleKim, S., Kim, T., Hong, E., & Lee, H. (2022). Lattice Distortion, Amorphization and Wear Resistance of Carbon-Doped SUS304 by Laser Ablation. Materials, 15(16), 5764. https://doi.org/10.3390/ma15165764