Change of the Structural Properties of High-Performance Concretes Subjected to Thermal Effects

Abstract

:1. Introduction

2. Materials and Methods

2.1. Preparation of Samples

2.2. Heating Process

2.3. Testing of Concretes

2.4. Uniaxial Compression Test

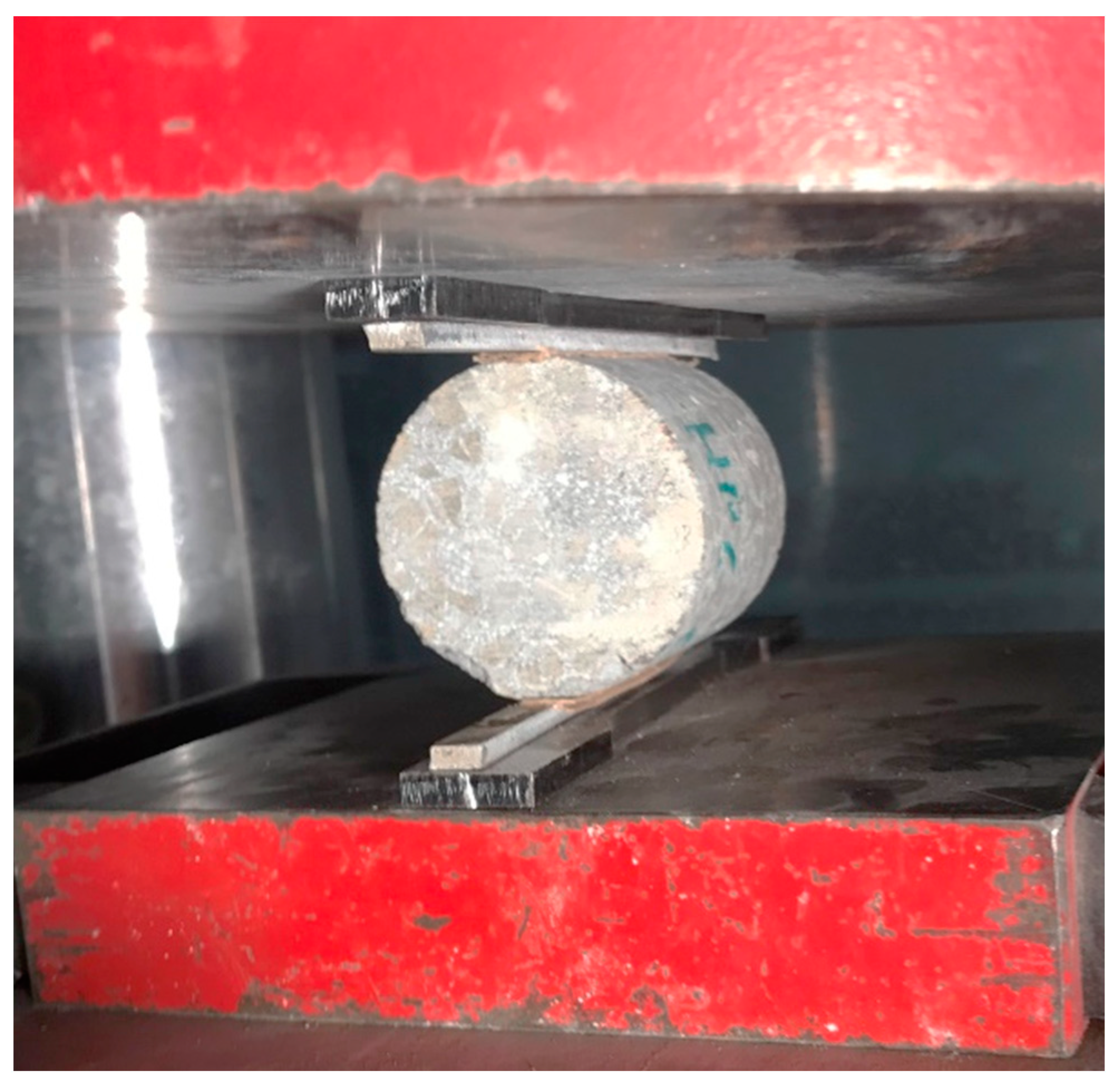

2.5. Brazilian Split Tensile Test

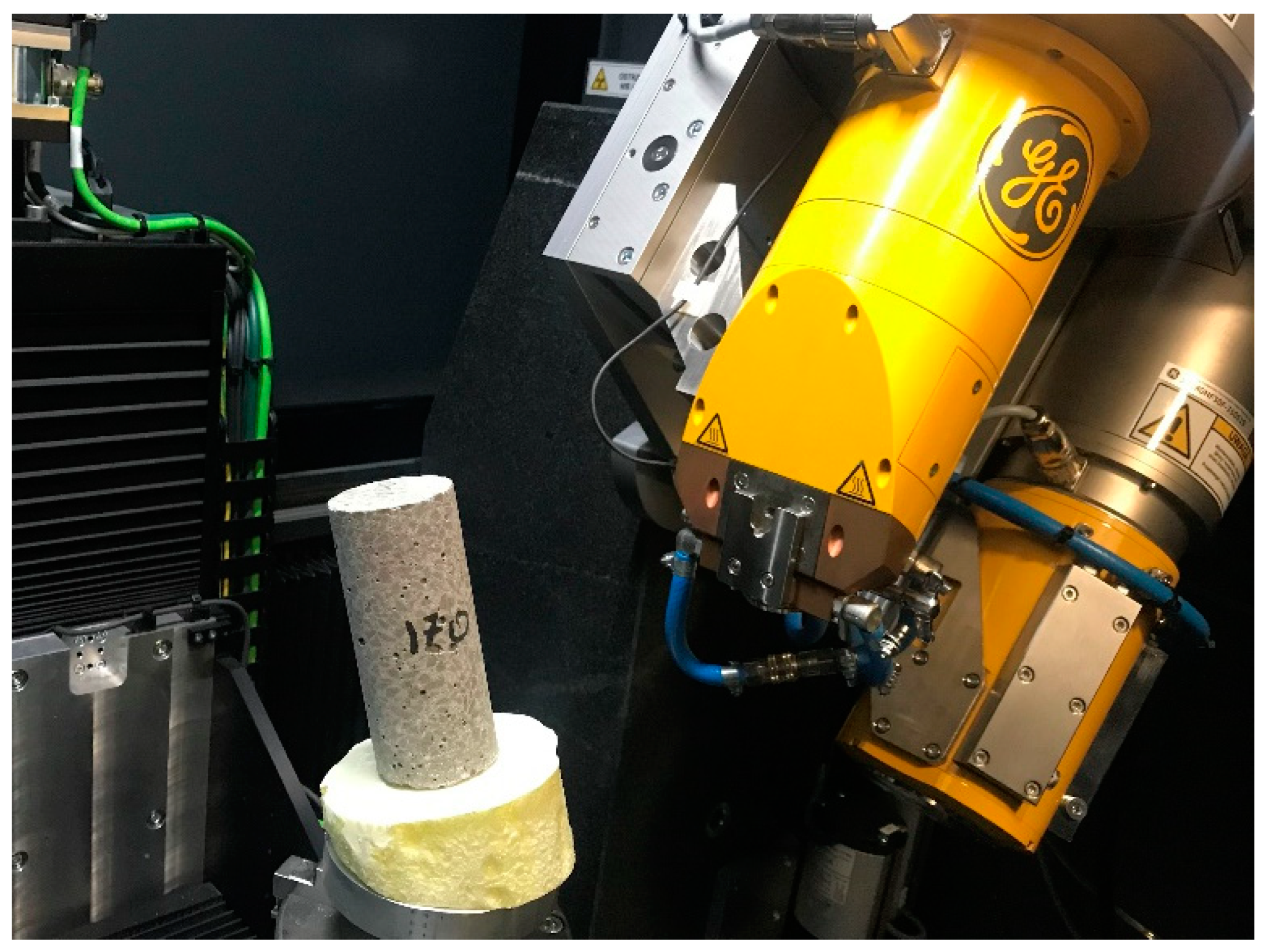

2.6. Computed Tomography

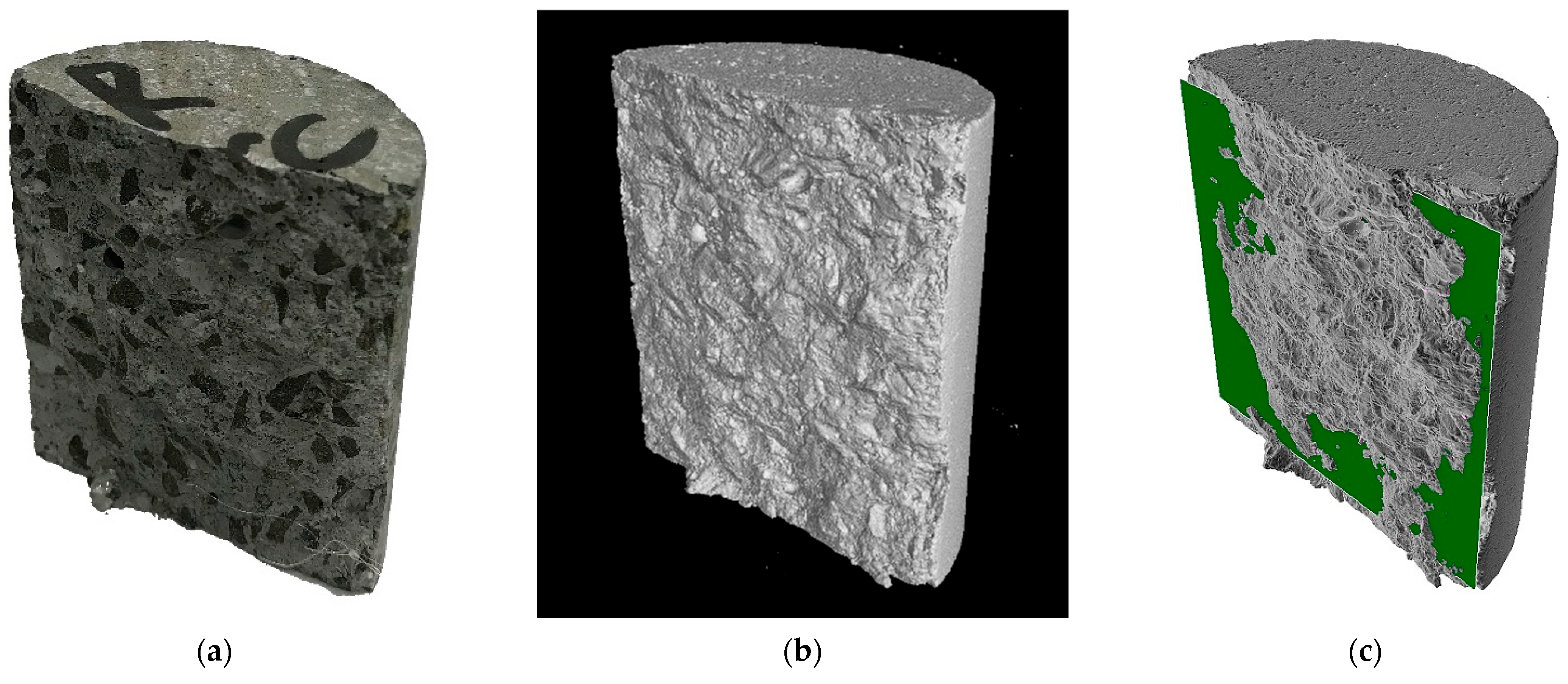

2.7. Volumetric Analysis

3. Results

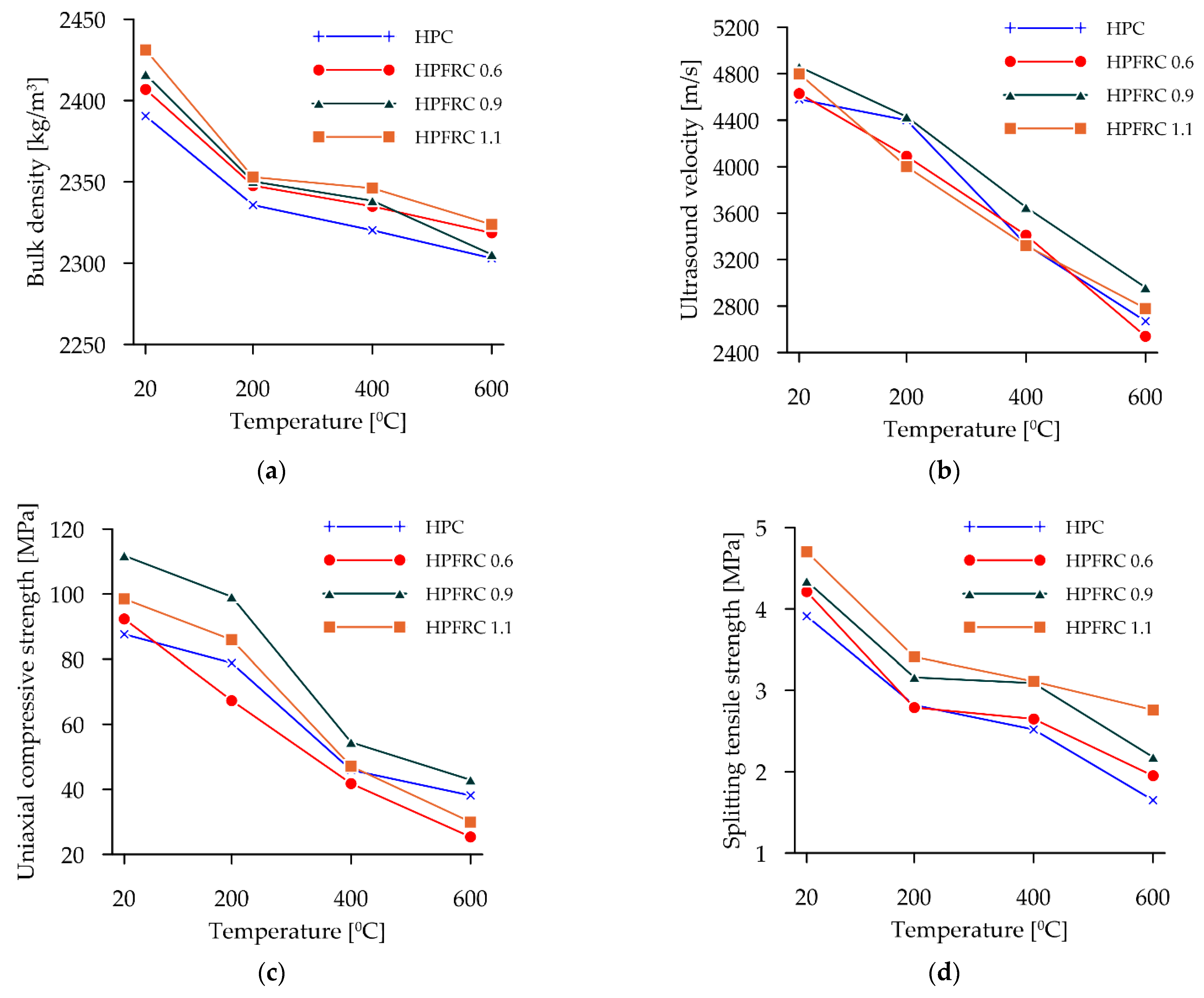

3.1. Basic Tests

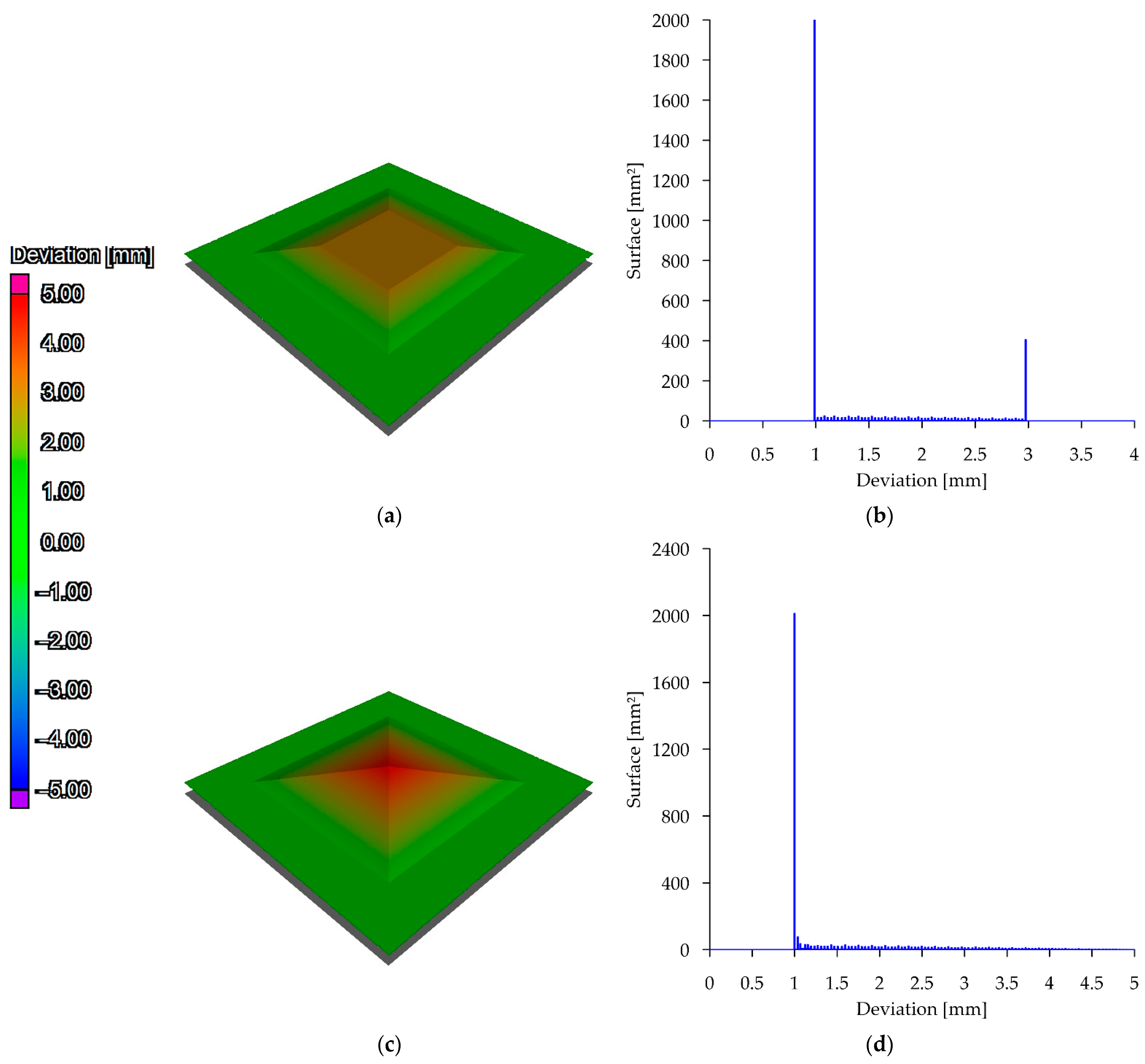

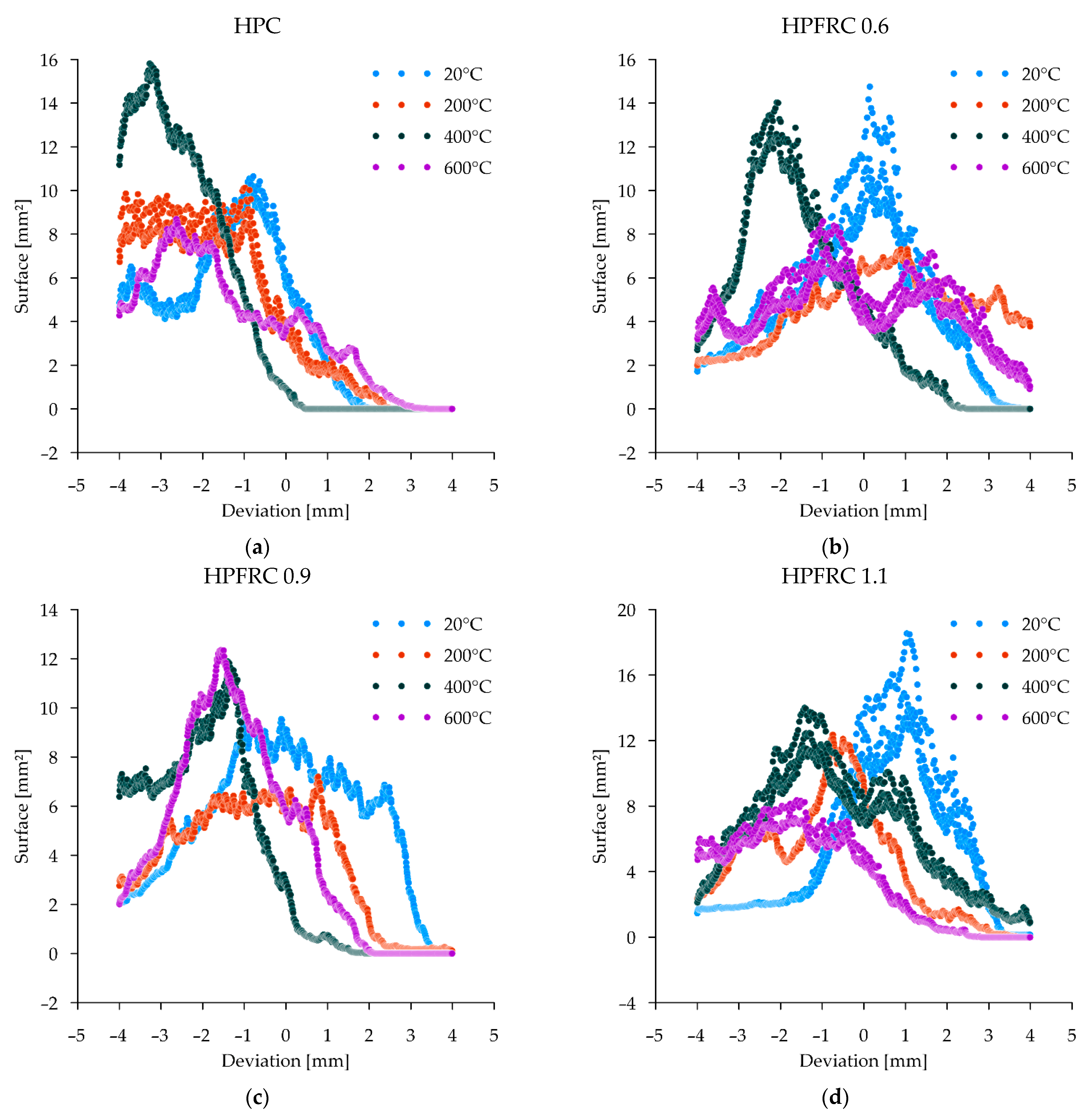

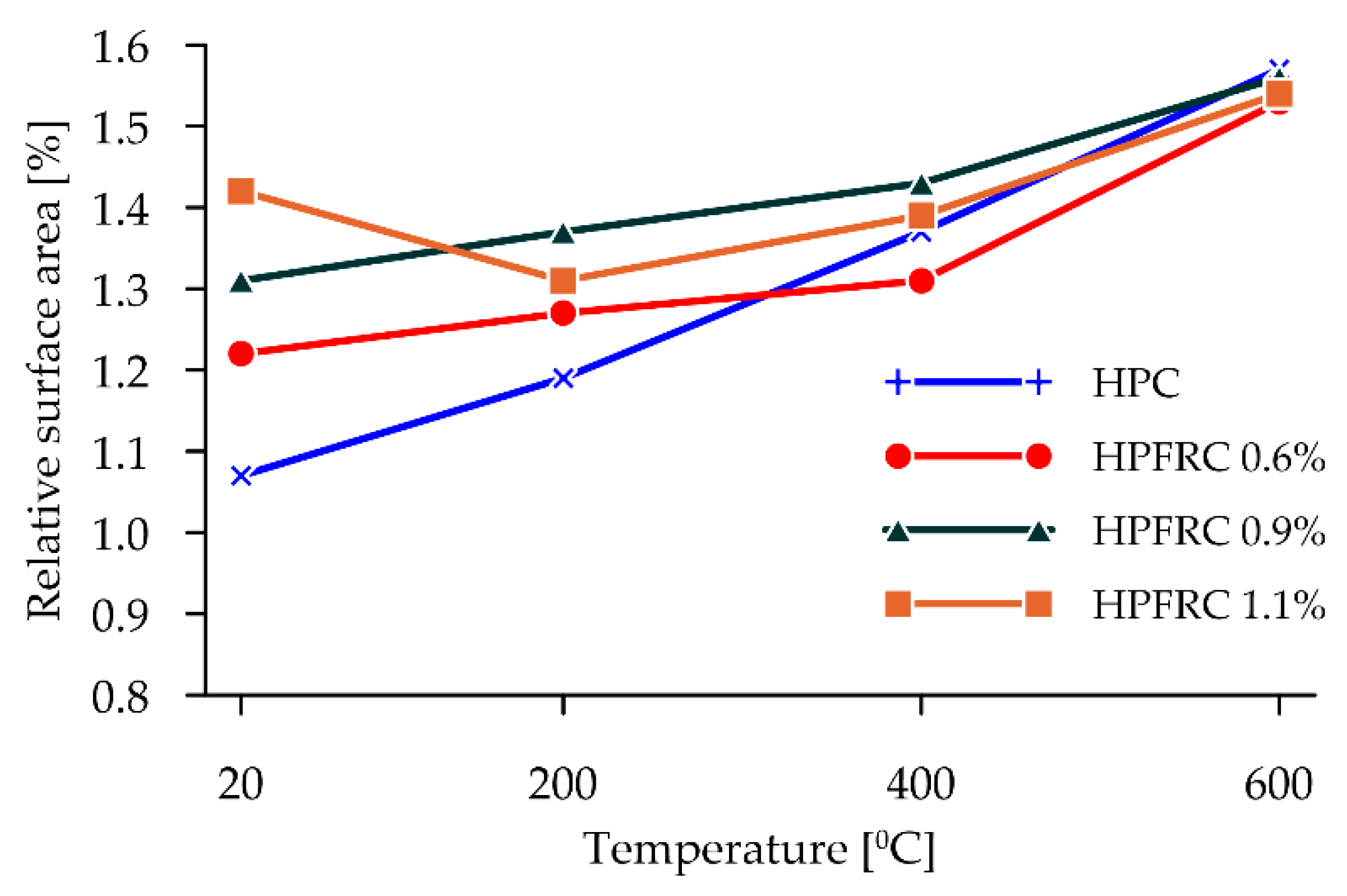

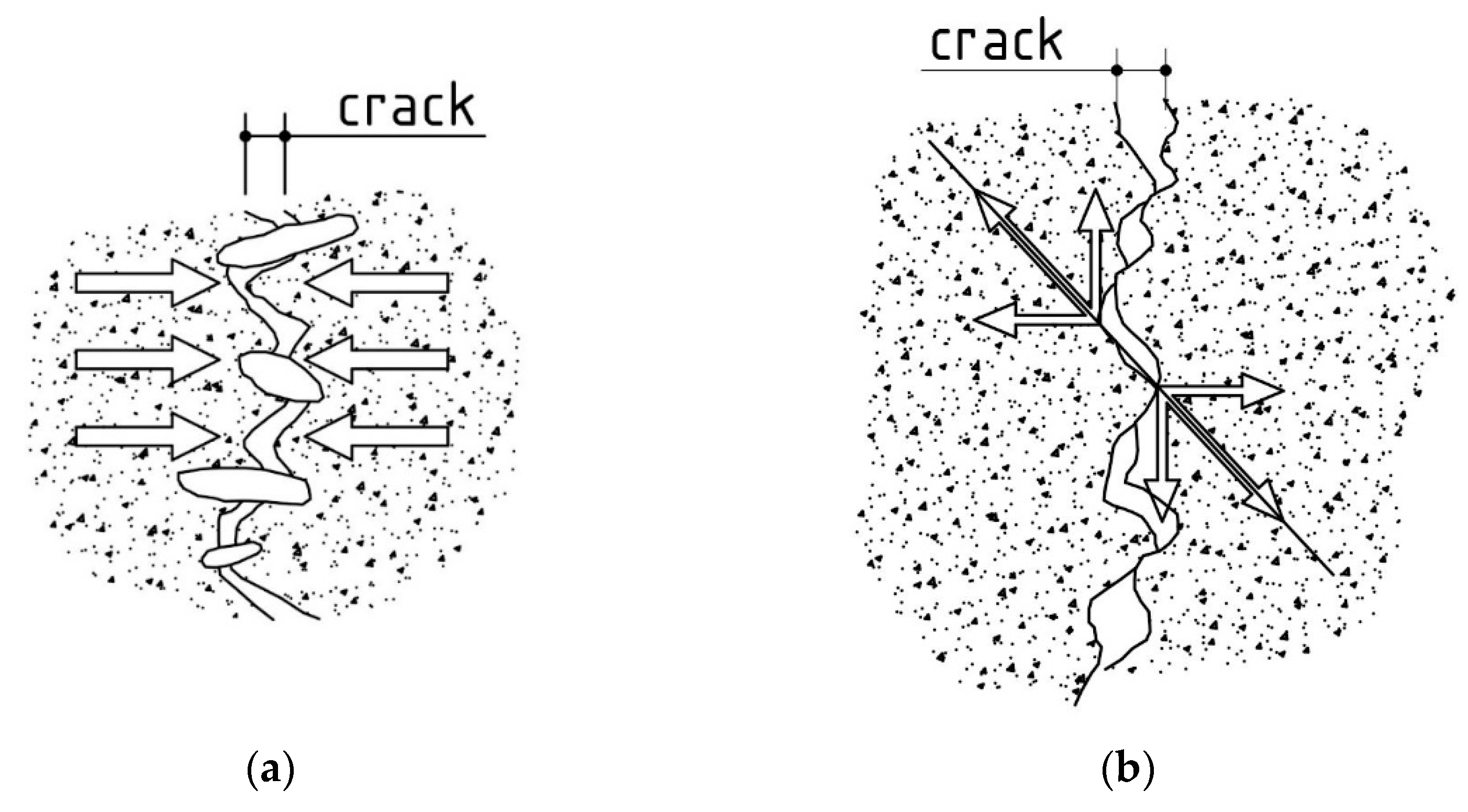

3.2. Results of the Destruction Surface from the Splitting Tensile Test

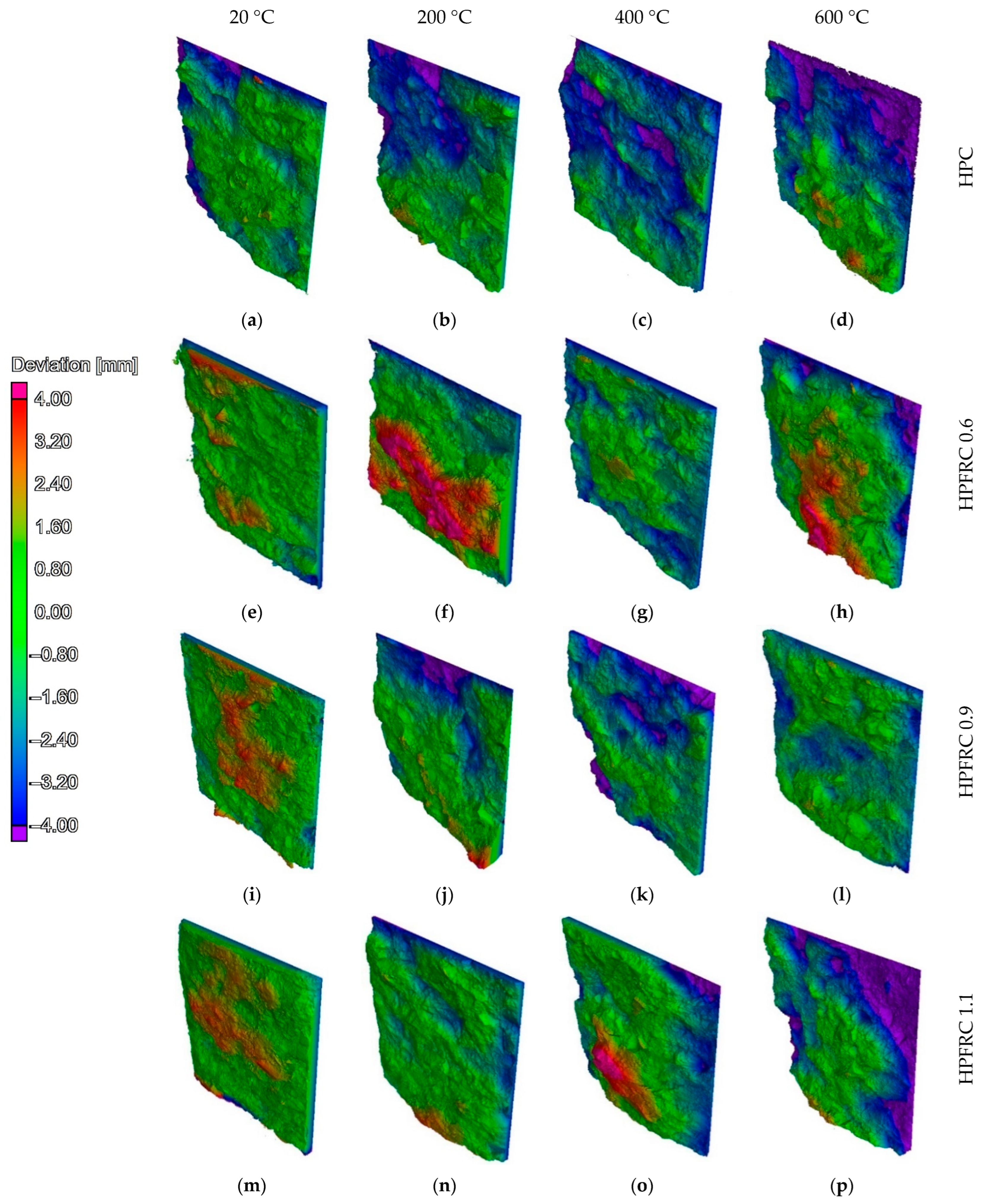

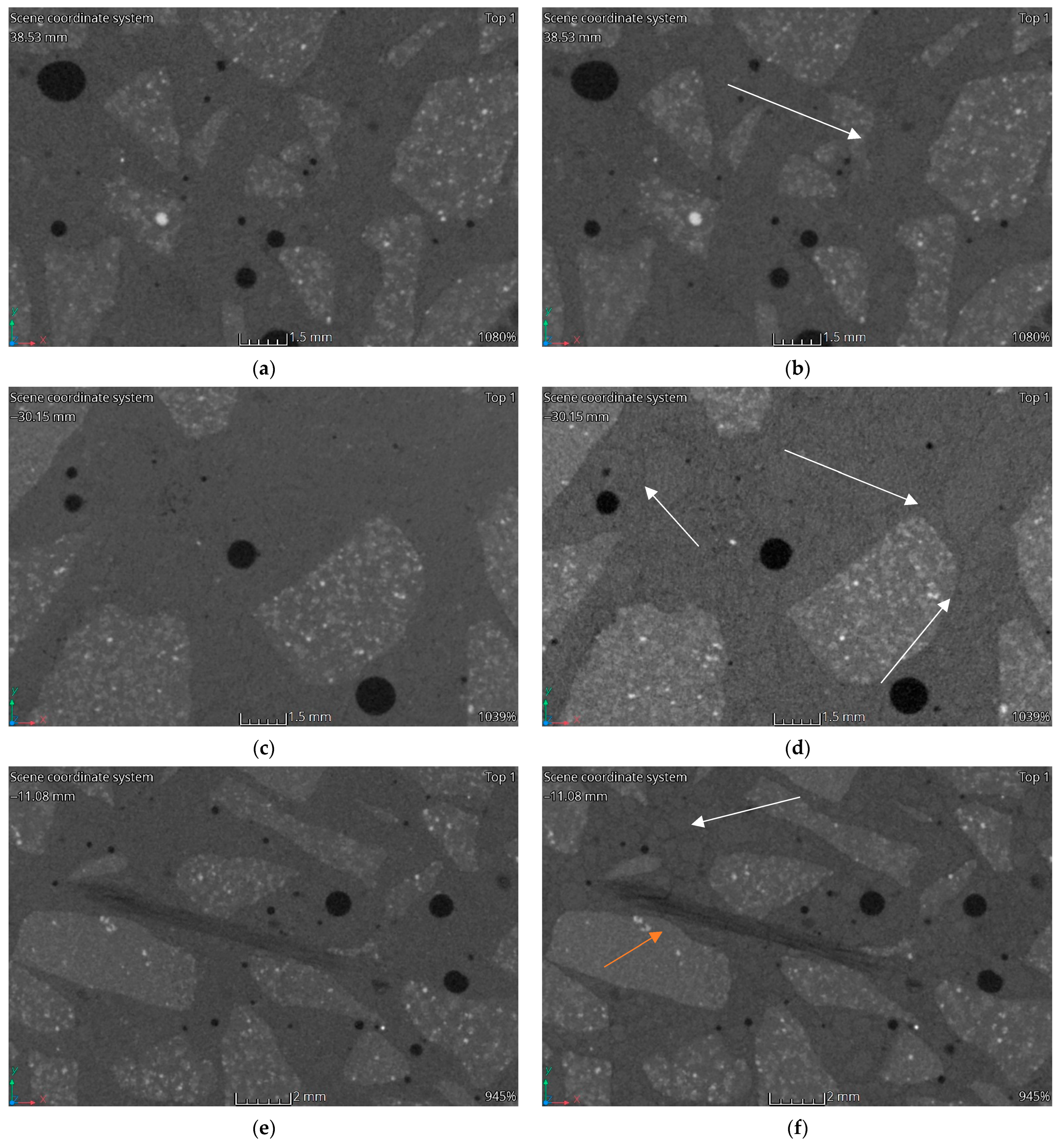

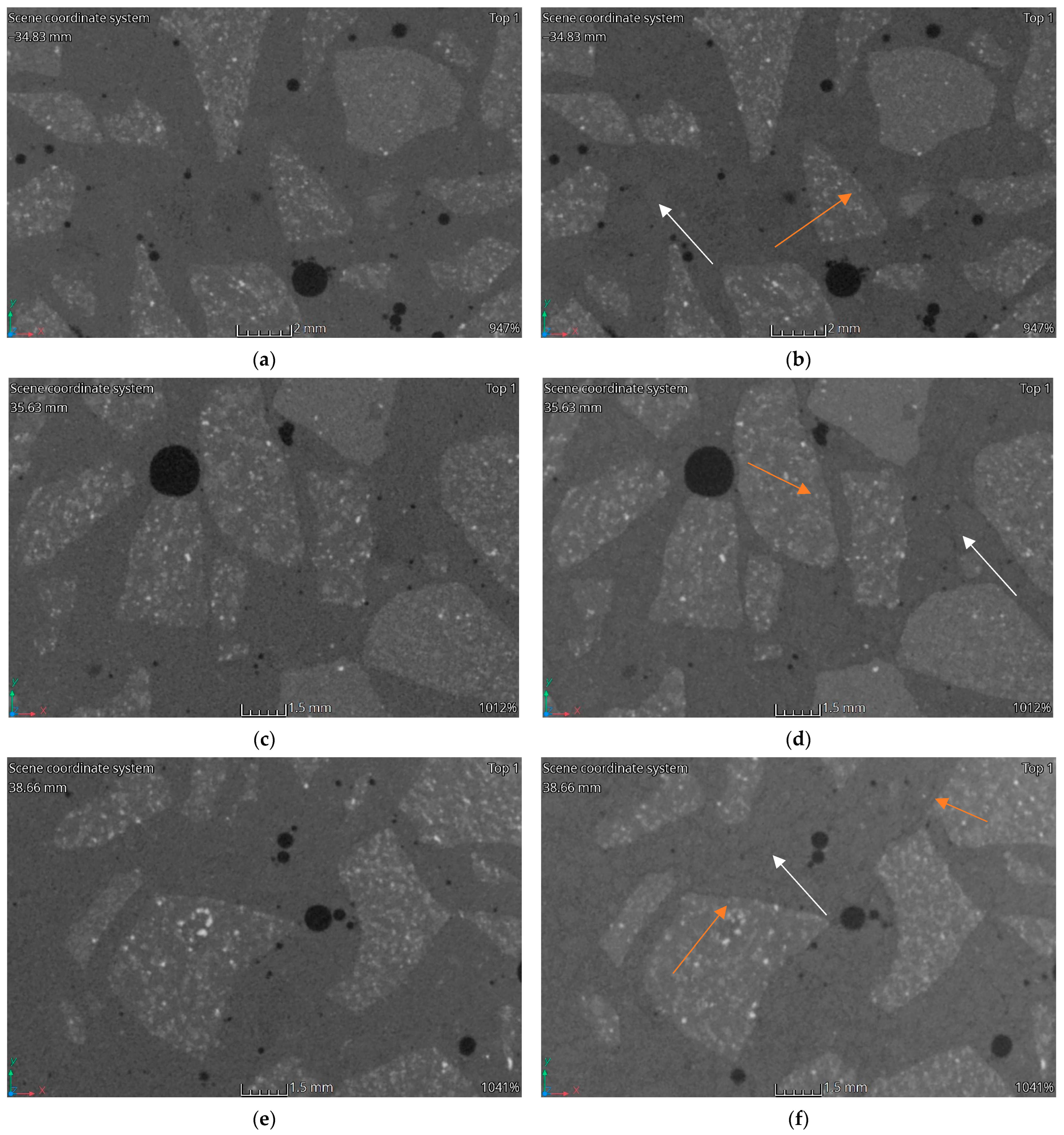

3.3. Computed Tomography

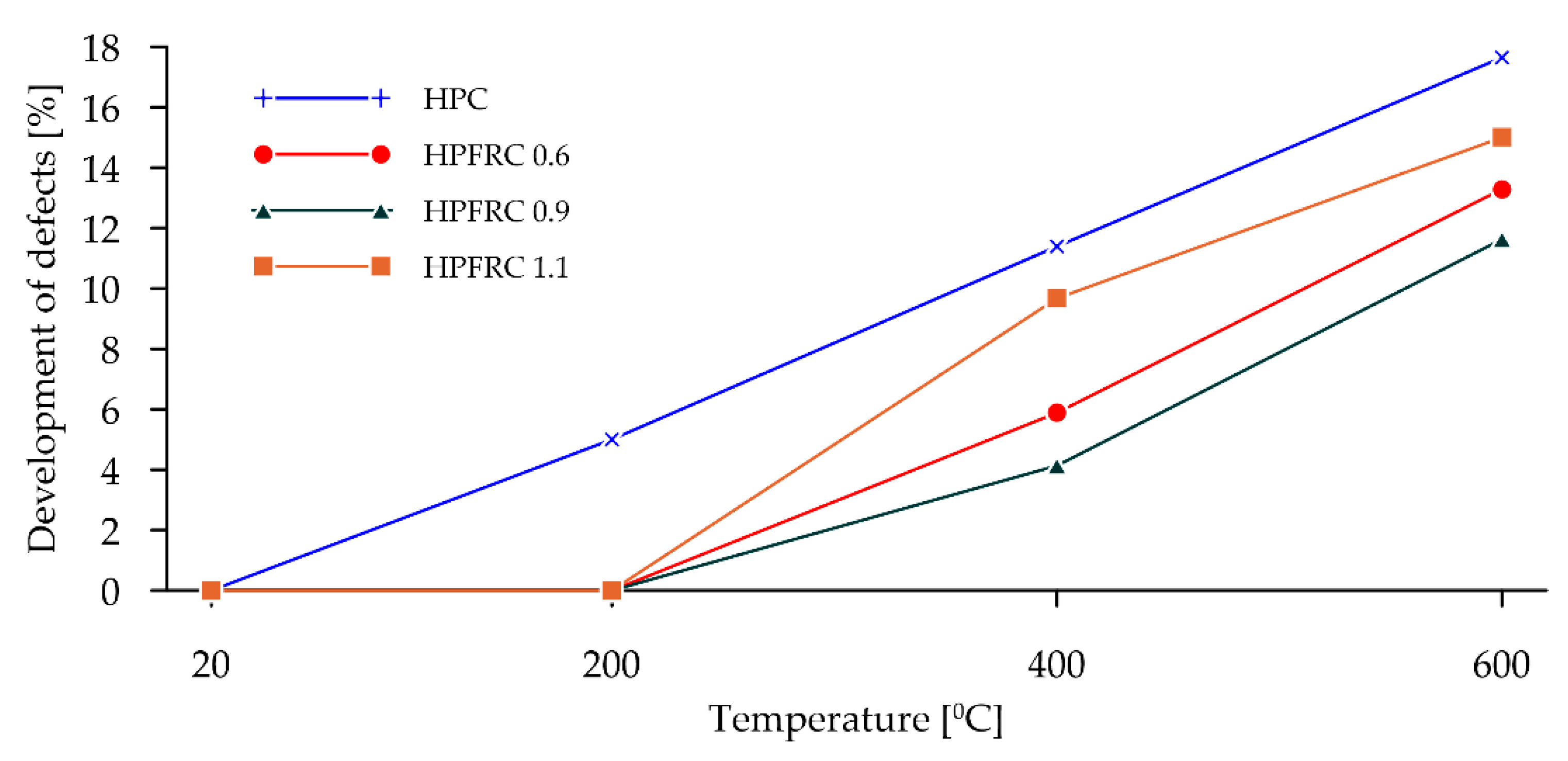

3.4. Defect Analysis

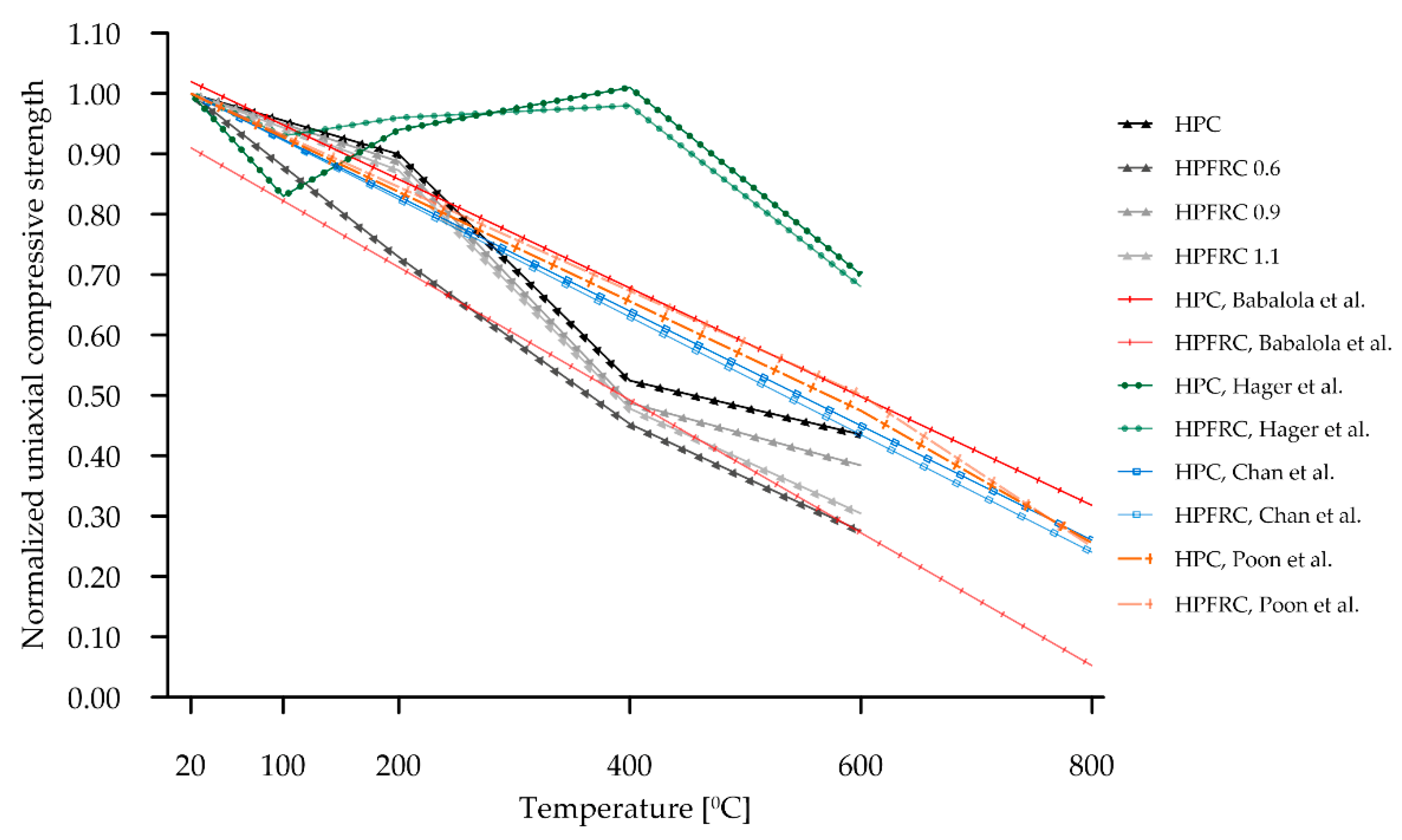

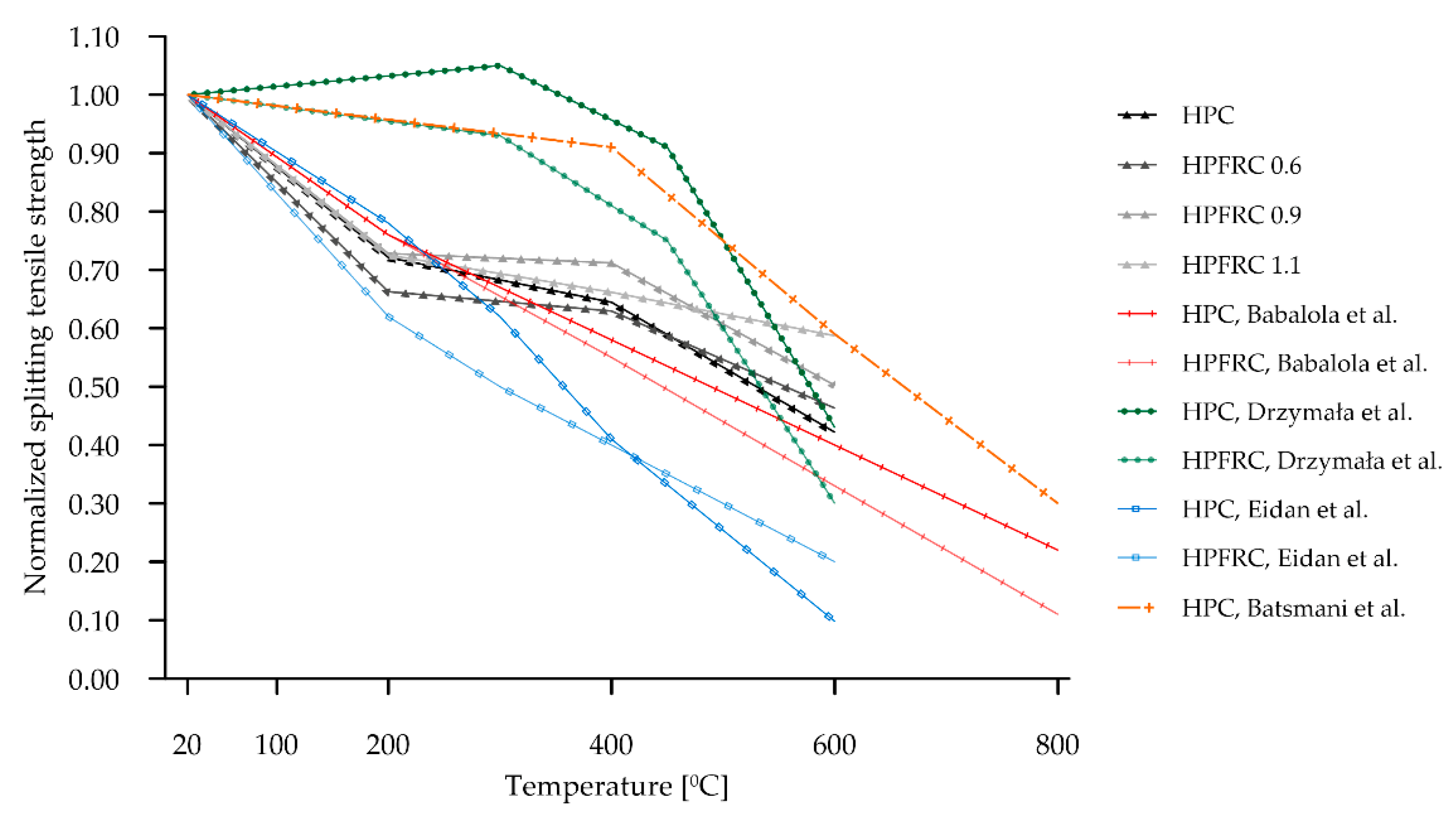

4. Discussion

5. Conclusions

- The HPFRCs tested at temperatures below the melting point of the polypropylene fibres used had higher strength parameters than the reference HPC. This is due to the contribution of the fibres used in transferring the load through the adhesive forces between their surface and the cement matrix. It should be noted, however, that the best results were obtained in specimens with 0.9 kg/m3 of polypropylene fibres.

- HPCs and HPFRCs subjected to high temperatures reduced their strength parameters. The effect of temperature on the reduction in tensile strength is greater than in compression, due to the nature of the damage that occurs in compression and tension. In addition, especially in the case of tensile strength, it should be noted that for temperatures of 200 °C, 400 °C and 600 °C, the influence of polypropylene fibres disappears due to their complete melting. Consequently, the load-bearing capacity of HPFRCs at higher temperatures is determined by the load-bearing capacity of the other concrete components analogously to HPC.

- The positive effect of polypropylene fibres is mainly observed between 20 °C and 200 °C. The melting of polypropylene fibres causes a delay in the development of micro-cracks in the structure of these concretes compared to HPC. In connection with the above, a detailed analysis of the structural changes occurring primarily between 20 °C and 200 °C is planned in the associated studies.

- Analysis of the images obtained using the CT method confirmed the assumptions made regarding changes in the structure of HPC and HPFRC under the influence of all temperatures. The analysis of defects showed that, under the influence of high temperatures, zones of a significantly lower density appear outside the pores in the cement matrix. In addition, numerous cracks appear around the grains of both the fine and coarse aggregates, which is reflected in the porosity of the concretes tested. However, it should be noted that in the case of HPFRCs, their porosity only changes from 200 °C and above, which may indicate that the heating fibres provide free space to reduce any pore pressure, ultimately resulting in little change in the concrete structure and less change in the cement matrix itself compared to HPC.

- The CT images of the structure of HPC clearly show that the first micro-cracks appear in the concrete already at 200 °C and that this phenomenon increases in proportion to the temperature increase. This confirms the positive effects of polypropylene fibres as one method of increasing the heat resistance of concretes.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bernardi, E.; Carlucci, S.; Cornaro, C.; Bohne, R.A. An analysis of the most adopted rating systems for assessing the environmental impact of buildings. Sustainability 2017, 9, 1226. [Google Scholar] [CrossRef] [Green Version]

- Yao, F.; Liu, G.; Ji, Y.; Tong, W.; Du, X.; Li, K.; Shrestha, A.; Martek, I. Evaluating the environmental impact of construction within the industrialized building process: A monetization and building information modelling approach. Int. J. Environ. Res. Public Health 2020, 17, 8396. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.; Zhang, G.; Xia, X.; Setunge, S.; Shi, L. A review of internal and external influencing factors on energy efficiency design of buildings. Energy Build. 2020, 216, 109944. [Google Scholar] [CrossRef]

- Mrówczyńska, M.; Skiba, M.; Leśniak, A.; Bazan-Krzywoszańska, A.; Janowiec, F.; Sztubecka, M.; Grech, R.; Kazak, J.K. A new fuzzy model of multi-criteria decision support based on Bayesian networks for the urban areas’ decarbonization planning. Energy Convers. Manag. 2022, 268, 116035. [Google Scholar] [CrossRef]

- Walach, D. Economic and environmental assessment of new generation concretes. IOP Conf. Ser. Mater. Sci. Eng. 2020, 960, 042013. [Google Scholar] [CrossRef]

- Shim, H.; Kim, T.; Choi, G. Technology roadmap for eco-friendly building materials industry. Energies 2019, 12, 804. [Google Scholar] [CrossRef] [Green Version]

- Petek Gursel, A.; Masanet, E.; Horvath, A.; Stadel, A. Life-cycle inventory analysis of concrete production: A critical review. Cem. Concr. Compos. 2014, 51, 38–48. [Google Scholar] [CrossRef]

- Domagała, L. Durability of structural lightweight concrete with sintered fly ash aggregate. Materials 2020, 13, 4565. [Google Scholar] [CrossRef]

- Jaskowska-Lemańska, J. Impurities of recycled concrete aggregate-types, origin and influence on the concrete strength parameters. IOP Conf. Ser. Mater. Sci. Eng. 2019, 603, 042056. [Google Scholar] [CrossRef] [Green Version]

- Skrzypczak, I.; Kokoszka, W.; Zięba, J.; Leśniak, A.; Bajno, D.; Bednarz, Ł. A Proposal of a Method for Ready-Mixed Concrete Quality Assessment Based on Statistical-Fuzzy Approach. Materials 2020, 13, 5674. [Google Scholar] [CrossRef]

- Shen, D.; Liu, X.; Zeng, X.; Zhao, X.; Jiang, G. Effect of polypropylene plastic fibers length on cracking resistance of high performance concrete at early age. Constr. Build. Mater. 2020, 244, 117874. [Google Scholar] [CrossRef]

- Kalifa, P.; Menneteau, F.D.; Quenard, D. Spalling and pore pressure in HPC at high temperatures. Cem. Concr. Res. 2000, 30, 1915–1927. [Google Scholar] [CrossRef]

- Igarashi, S.I.; Bentur, A.; Kovler, K. Autogenous shrinkage and induced restraining stresses in high-strength concretes. Cem. Concr. Res. 2000, 30, 1701–1707. [Google Scholar] [CrossRef]

- Toropovs, N.; Lo Monte, F.; Wyrzykowski, M.; Weber, B.; Sahmenko, G.; Vontobel, P.; Felicetti, R.; Lura, P. Real-time measurements of temperature, pressure and moisture profiles in High-Performance Concrete exposed to high temperatures during neutron radiography imaging. Cem. Concr. Res. 2015, 68, 166–173. [Google Scholar] [CrossRef]

- Barrett, T.J.; De La Varga, I.; Weiss, W.J. Reducing cracking in concrete structures by using internal curing with high volumes of fly ash. In Proceedings of the 2012 Structures Congress, Chicago, IL, USA, 29–31 March 2012; pp. 699–707. [Google Scholar]

- Polish Version of EN 1992-1-2:2008/NA:2010P; Eurocode 2: Design of Concrete Structures. Parts 1–2: General Rules. Structural Fire Design. PKN: Warszawa, Poland, 2005.

- Drzymała, T.; Jackiewicz-Rek, W.; Tomaszewski, M.; Kuś, A.; Gałaj, J.; Šukys, R. Effects of High Temperature on the Properties of High Performance Concrete (HPC). Procedia Eng. 2017, 172, 256–263. [Google Scholar] [CrossRef]

- Behnood, A.; Ghandehari, M. Comparison of compressive and splitting tensile strength of high-strength concrete with and without polypropylene fibers heated to high temperatures. Fire Saf. J. 2009, 44, 1015–1022. [Google Scholar] [CrossRef]

- Biolzi, L.; Cattaneo, S.; Rosati, G. Evaluating residual properties of thermally damaged concrete. Cem. Concr. Compos. 2008, 30, 907–916. [Google Scholar] [CrossRef]

- Xiao, J.; König, G. Study on concrete at high temperature in China-An overview. Fire Saf. J. 2004, 39, 89–103. [Google Scholar] [CrossRef]

- Noumowe, A. Mechanical properties and microstructure of high strength concrete containing polypropylene fibres exposed to temperatures up to 200 °C. Cem. Concr. Res. 2005, 35, 2192–2198. [Google Scholar] [CrossRef]

- Collier, N.C. Transition and decomposition temperatures of cement phases-A collection of thermal analysis data. Ceramics-Silikaty 2016, 60, 338–343. [Google Scholar] [CrossRef] [Green Version]

- Taylor, H.F.W. Cement Chemistry, 2nd ed.; Thomas Telford Publishing: London, UK, 1997; ISBN 978-0727725929. [Google Scholar]

- Hudson-Lamb, D.L.; Strydom, C.A.; Potgieter, J.H. The thermal dehydration of natural gypsum and pure calcium sulphate dihydrate (gypsum). Thermochim. Acta 1996, 282, 483–492. [Google Scholar] [CrossRef]

- Mackenzie, R.C. Differential Thermal Analysis. Mineral. Mag. 1972, 38, 774–776. [Google Scholar] [CrossRef]

- Kwan, S.; LaRosa, J.; Grutzeck, M.W. 29 Si and 27 Al MASNMR Study of Stratlingite. J. Am. Ceram. Soc. 1995, 78, 1921–1926. [Google Scholar] [CrossRef]

- Parker, L.M.; Milestone, N.B.; Newman, R.H. The Use of Hydrotalcite as an Anion Absorbent. Ind. Eng. Chem. Res. 1995, 34, 1196–1202. [Google Scholar] [CrossRef]

- Bensted, J.; Varma, S.P. Some Applications of Infrared and Raman Spectroscopy in Cement Chemistry. Part 3. Cem. Technol. 1974, 5, 440–442. [Google Scholar]

- Bushnell-Watson, S.M.; Sharp, J.H. The Application of Thermal Analysis to the Hydration and Conversion Reaction of Calcium Aluminate Cements. Mater. Construcción 1992, 42, 13–32. [Google Scholar] [CrossRef] [Green Version]

- Deutsch, Y.; Nathan, Y.; Sarig, S. Thermogravimetric evaluation of the kinetics of the gypsum-hemihydrate-soluble anhydrite transitions. J. Therm. Anal. 1994, 42, 159–174. [Google Scholar] [CrossRef]

- Hager, I. Colour Change in Heated Concrete. Fire Technol. 2014, 50, 945–958. [Google Scholar] [CrossRef] [Green Version]

- Kodur, V.K.R. Innovative strategies for enhancing fire performance of high-strength concrete structures. Adv. Struct. Eng. 2018, 21, 1723–1732. [Google Scholar] [CrossRef]

- Ni, S.; Gernay, T. Considerations on computational modeling of concrete structures in fire. Fire Saf. J. 2021, 120, 103065. [Google Scholar] [CrossRef]

- Schmidt-Polonczyk, N.; Burtan, Z.; Liszka, P. Simulation of the evacuation of people in a road tunnel in the event of fire-case study. Arch. Min. Sci. 2021, 66, 13–28. [Google Scholar] [CrossRef]

- Babalola, O.E.; Awoyera, P.O.; Le, D.H.; Bendezú Romero, L.M. A review of residual strength properties of normal and high strength concrete exposed to elevated temperatures: Impact of materials modification on behaviour of concrete composite. Constr. Build. Mater. 2021, 296, 123448. [Google Scholar] [CrossRef]

- Hager, I.; Tracz, T. The impact of the amount and length of fibrillated polypropylene fibres on the properties of HPC exposed to high temperature. Arch. Civ. Eng. 2010, 56, 57–68. [Google Scholar] [CrossRef] [Green Version]

- Chan, Y.N.; Luo, X.; Sun, W. Compressive strength and pore structure of highperformance concrete. Cem. Concr. Res. 2000, 30, 247–251. [Google Scholar] [CrossRef]

- Poon, C.S.; Shui, Z.H.; Lam, L. Compressive behavior of fiber reinforced high-performance concrete subjected to elevated temperatures. Cem. Concr. Res. 2004, 34, 2215–2222. [Google Scholar] [CrossRef]

- Eidan, J.; Rasoolan, I.; Rezaeian, A.; Poorveis, D. Residual mechanical properties of polypropylene fiber-reinforced concrete after heating. Constr. Build. Mater. 2019, 198, 195–206. [Google Scholar] [CrossRef]

- Shah, S.N.R.; Akashah, F.W.; Shafigh, P. Performance of High Strength Concrete Subjected to Elevated Temperatures: A Review. Fire Technol. 2019, 55, 1571–1597. [Google Scholar] [CrossRef]

- Borrero, E.L.S.; Farhangi, V.; Jadidi, K.; Karakouzian, M. An experimental study on concrete’s durability and mechanical characteristics subjected to different curing regimes. Civ. Eng. J. 2021, 7, 676–689. [Google Scholar] [CrossRef]

- Hager, I.; Zdeb, T.; Krzemień, K. The impact of the amount of polypropylene fibres on spalling behaviour and residual mechanical properties of Reactive Powder Concretes. In Proceedings of the MATEC Web of Conferences, Concrete Spalling due to Fire Exposure: Proceedings of the 3rd International Workshop, Paris, France, 25–27 September 2013; Volume 6. [Google Scholar]

- Luo, L.; Chen, Z.; Tao, Q.; Xie, L.; Jin, D.; Li, Z.; Deng, D. Effects of high temperatures on the splitting tensile strength and gamma ray shielding performance of radiation shielding concrete. Constr. Build. Mater. 2022, 343, 127953. [Google Scholar] [CrossRef]

- Stock, S.R. X-ray microtomography of materials. Int. Mater. Rev. 1999, 44, 141–164. [Google Scholar] [CrossRef]

- Brabant, L.; Pauwels, E.; Dierick, M.; Van Loo, D.; Boone, M.A.; Van Hoorebeke, L. A novel beam hardening correction method requiring no prior knowledge, incorporated in an iterative reconstruction algorithm. NDT E Int. 2012, 51, 68–73. [Google Scholar] [CrossRef]

- Nguyen, V.; Sanctorum, J.G.; Van Wassenbergh, S.; Dirckx, J.J.J.; Sijbers, J.; De Beenhouwer, J. Geometry Calibration of a Modular Stereo Cone-Beam X-ray CT System. J. Imaging 2021, 7, 54. [Google Scholar] [CrossRef] [PubMed]

- Sadowski, Ł.; Stefaniuk, D. The effect of surface treatment on the microstructure of the skin of concrete. Appl. Surf. Sci. 2018, 427 Pt B, 934–941. [Google Scholar] [CrossRef]

- Kong, W.; Wei, Y.; Wang, S.; Chen, J.; Wang, Y. Research progress on cement-based materials by X-ray computed tomography. Int. J. Pavement Res. Technol. 2020, 13, 366–375. [Google Scholar] [CrossRef]

- Shi, P.F.; Yang, Y.F.; Gao, Y.; Liu, J.H. Analysis of concrete meso damage based on CT. MATEC Web Conf. 2015, 31, 3–6. [Google Scholar] [CrossRef] [Green Version]

- Stefaniuk, D.; Tankiewicz, M.; Stróżyk, J. X-Ray Microtomography (μCT) as a Useful Tool for Visualization and Interpretation of Shear Strength Test Results. Stud. Geotech. Mech. 2015, 36, 47–55. [Google Scholar] [CrossRef] [Green Version]

- Tian, W.; Han, N. Pore characteristics (>0.1 mm) of non-air entrained concrete destroyed by freeze-thaw cycles based on CT scanning and 3D printing. Cold Reg. Sci. Technol. 2018, 151, 314–332. [Google Scholar] [CrossRef] [Green Version]

- Skarżyński, Ł.; Suchorzewski, J. Mechanical and fracture properties of concrete reinforced with recycled and industrial steel fibers using Digital Image Correlation technique and X-ray micro computed tomography. Constr. Build. Mater. 2018, 183, 283–299. [Google Scholar] [CrossRef]

- Jaskowska-Lemańska, J.; Kucharska, M.; Matuszak, J.; Nowak, P.; Łukaszczyk, W. Selected Properties of Self-Compacting Concrete with Recycled PET Aggregate. Materials 2022, 15, 2566. [Google Scholar] [CrossRef]

- Kaczmarczyk, G.P.; Kinasz, R.; Bilozir, V.; Bidenko, I. Application of X-ray Computed Tomography to Verify Bond Failures Mechanism of Fiber-Reinforced Fine-Grain Concrete. Materials 2022, 15, 2193. [Google Scholar] [CrossRef]

- Boshoff, W.P. A review of X-ray computed tomography of concrete and asphalt construction materials. Constr. Build. Mater. 2019, 199, 637–651. [Google Scholar] [CrossRef]

- Liu, J.; Ba, M.; Du, Y.; He, Z.; Chen, J. Effects of chloride ions on carbonation rate of hardened cement paste by X-ray CT techniques. Constr. Build. Mater. 2016, 122, 619–627. [Google Scholar] [CrossRef] [Green Version]

- Domagała, L.; Hager, I. Influence of high temperature on compressive strength of structural lightweight concrete|Wpływ wysokiej temperatury na wytrzymałość na ściskanie konstrukcyjnych betonów lekkich. Cem. Wapno Bet. 2012, 17, 138–143. [Google Scholar]

- Hager, I.; Tracz, T. Influence of elevated temperature on selected properties of high performance concrete modified with the addition of polypropylene fibres|Wpływ wysokiej temperatury na wybrane właściwości betonu wysokowartościowego z dodatkiem włókien polipropylenowych. Cem. Wapno Bet. 2009, 29, 3–10. [Google Scholar]

- Sciarretta, F.; Fava, S.; Francini, M.; Ponticelli, L.; Caciolai, M.; Briseghella, B.; Nuti, C. Ultra-High performance concrete (UHPC) with polypropylene (Pp) and steel Fibres: Investigation on the high temperature behaviour. Constr. Build. Mater. 2021, 304, 124608. [Google Scholar] [CrossRef]

- Missemer, L.; Ouedraogo, E.; Malecot, Y.; Clergue, C.; Rogat, D. Fire spalling of ultra-high performance concrete: From a global analysis to microstructure investigations. Cem. Concr. Res. 2019, 115, 207–219. [Google Scholar] [CrossRef]

- Almasaeid, H.H.; Suleiman, A.; Alawneh, R. Assessment of high-temperature damaged concrete using non-destructive tests and artificial neural network modelling. Case Stud. Constr. Mater. 2022, 16, e01080. [Google Scholar] [CrossRef]

- Ravichandran, D.; Prem, P.R.; Kaliyavaradhan, S.K.; Ambily, P.S. Influence of fibers on fresh and hardened properties of Ultra High Performance Concrete (UHPC)—A review. J. Build. Eng. 2022, 57, 104922. [Google Scholar]

- Xu, L.; Deng, F.; Chi, Y. Nano-mechanical behavior of the interfacial transition zone between steel-polypropylene fiber and cement paste. Constr. Build. Mater. 2017, 145, 619–638. [Google Scholar] [CrossRef]

- van der Merwe, J.E. Evaluation of concrete tensile strength as a function of temperature. Constr. Build. Mater. 2022, 329, 127179. [Google Scholar] [CrossRef]

- Bastami, M.; Baghbadrani, M.; Aslani, F. Performance of nano-Silica modified high strength concrete at elevated temperatures. Constr. Build. Mater. 2014, 68, 402–408. [Google Scholar] [CrossRef]

- Dybeł, P.; Wałach, D. Evaluation of the Development of Bond Strength between Two Concrete Layers. IOP Conf. Ser. Mater. Sci. Eng. 2017, 245, 032056. [Google Scholar] [CrossRef]

- Belletti, B.; Cerioni, R.; Iori, I. Nonlinear finite-element analysis of R/C deep beams. Stud. Res. Grad. Sch. Concr. Struct.–Frat. Pesenti. 2003, 24, 51–76. [Google Scholar]

| Composition | Mass [kg/m3] | |

|---|---|---|

| Cement CEM I 42.5 R | 550 | |

| Water | 176 | |

| Sand 0–2 mm | 790 | |

| Basalt aggregate 2–8 mm | 940 | |

| Superplasticiser | 5.14 (HPC)/7.56 (HPFRC) | |

| Texa-Fib 3 | HPFRC 0.6 | 0.60 |

| HPFRC 0.9 | 0.90 | |

| HPFRC 1.1 | 1.10 | |

| Water/binder ratio | 0.32 | |

| Sample | Before Heating [%] | After Heating [%] | |

|---|---|---|---|

| 200 °C | HPC | 1.40 | 1.47 |

| HPFRC 0.6 | 1.17 | 1.17 | |

| HPFRC 0.9 | 1.11 | 1.11 | |

| HPFRC 1.1 | 0.70 | 0.70 | |

| 400 °C | HPC | 1.58 | 1.76 |

| HPFRC 0.6 | 1.21 | 1.26 | |

| HPFRC 0.9 | 0.68 | 0.72 | |

| HPFRC 1.1 | 0.61 | 0.67 | |

| 600 °C | HPC | 1.70 | 2.00 |

| HPFRC 0.6 | 1.43 | 1.62 | |

| HPFRC 0.9 | 1.29 | 1.44 | |

| HPFRC 1.1 | 0.84 | 0.99 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kaczmarczyk, G.P.; Wałach, D.; Natividade-Jesus, E.; Ferreira, R. Change of the Structural Properties of High-Performance Concretes Subjected to Thermal Effects. Materials 2022, 15, 5753. https://doi.org/10.3390/ma15165753

Kaczmarczyk GP, Wałach D, Natividade-Jesus E, Ferreira R. Change of the Structural Properties of High-Performance Concretes Subjected to Thermal Effects. Materials. 2022; 15(16):5753. https://doi.org/10.3390/ma15165753

Chicago/Turabian StyleKaczmarczyk, Grzegorz Piotr, Daniel Wałach, Eduardo Natividade-Jesus, and Rui Ferreira. 2022. "Change of the Structural Properties of High-Performance Concretes Subjected to Thermal Effects" Materials 15, no. 16: 5753. https://doi.org/10.3390/ma15165753

APA StyleKaczmarczyk, G. P., Wałach, D., Natividade-Jesus, E., & Ferreira, R. (2022). Change of the Structural Properties of High-Performance Concretes Subjected to Thermal Effects. Materials, 15(16), 5753. https://doi.org/10.3390/ma15165753