A Comparative Study for Material Selection in 3D Printing of Scoliosis Back Brace

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

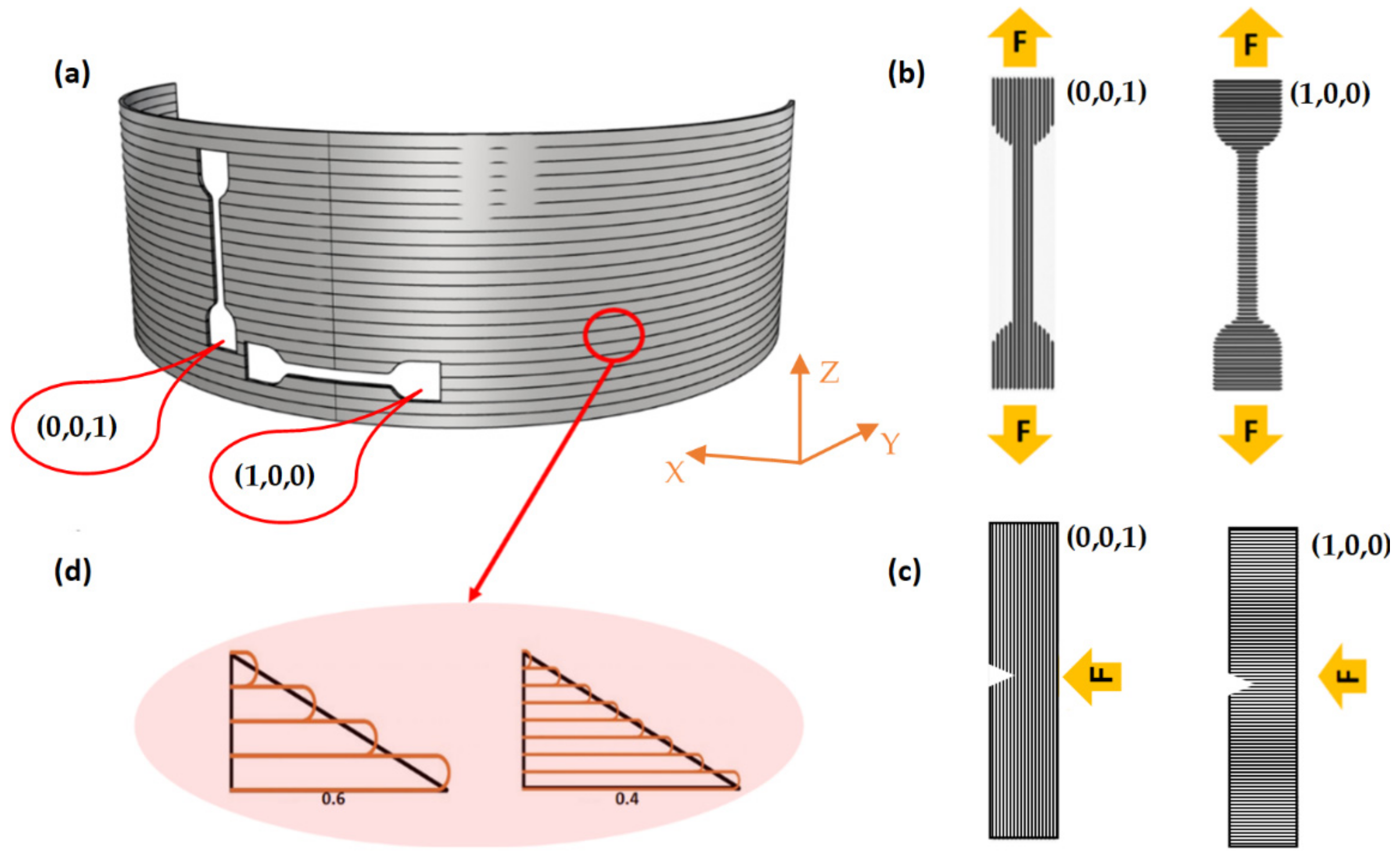

2.2. Samples Preparation

2.3. Rheological Analysis

2.4. Differential Scanning Calorimetry

2.5. Tensile Test

2.6. Charpy Impact Test

2.7. Dynamic Mechanical Thermal Analysis (DMTA)

2.8. Density Measurements

2.9. Scanning Electron Microscopy (SEM)

3. Results

3.1. Rheological Analysis

3.2. Thermal Proprieties

3.3. Mechanical Properties

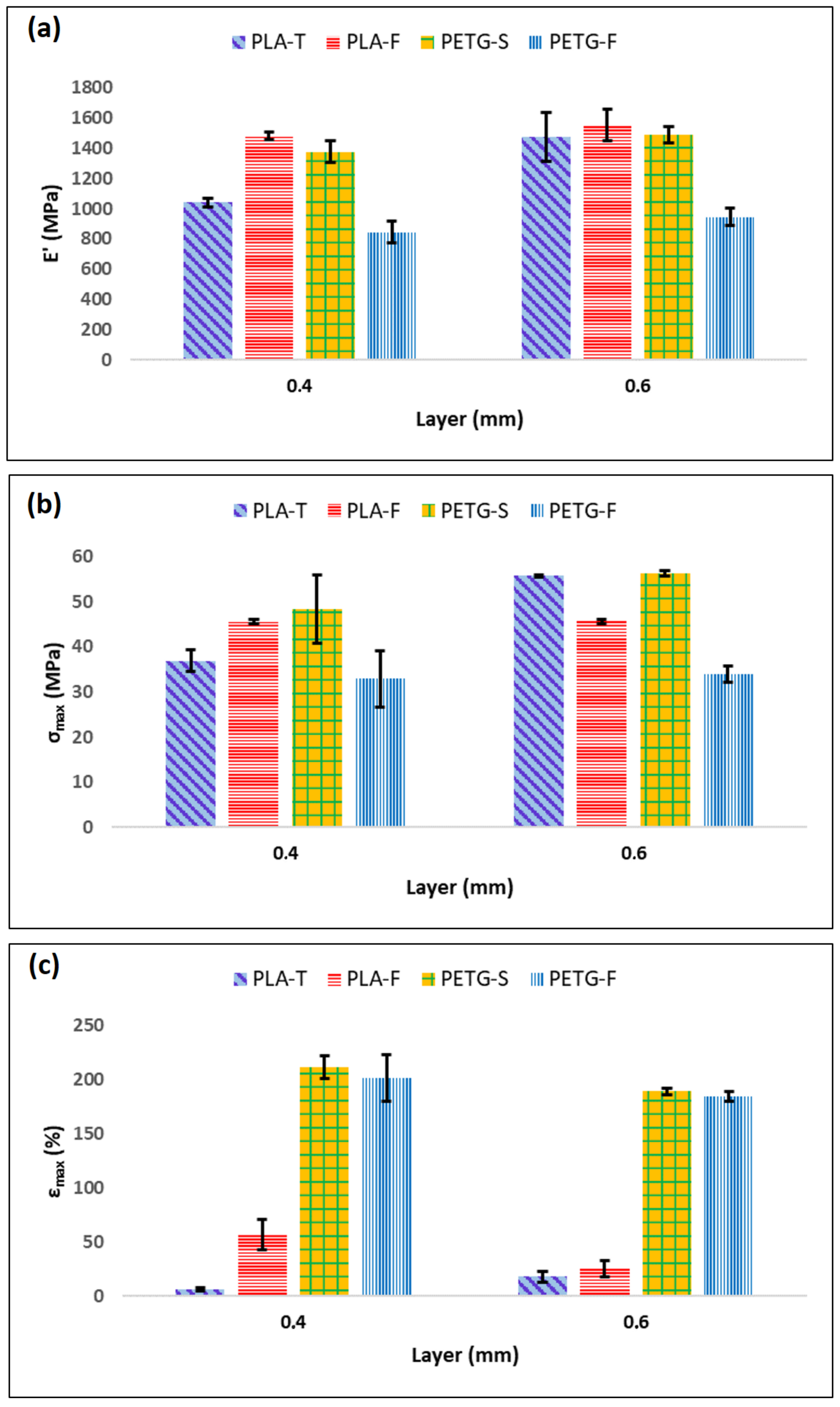

3.3.1. Tensile Test

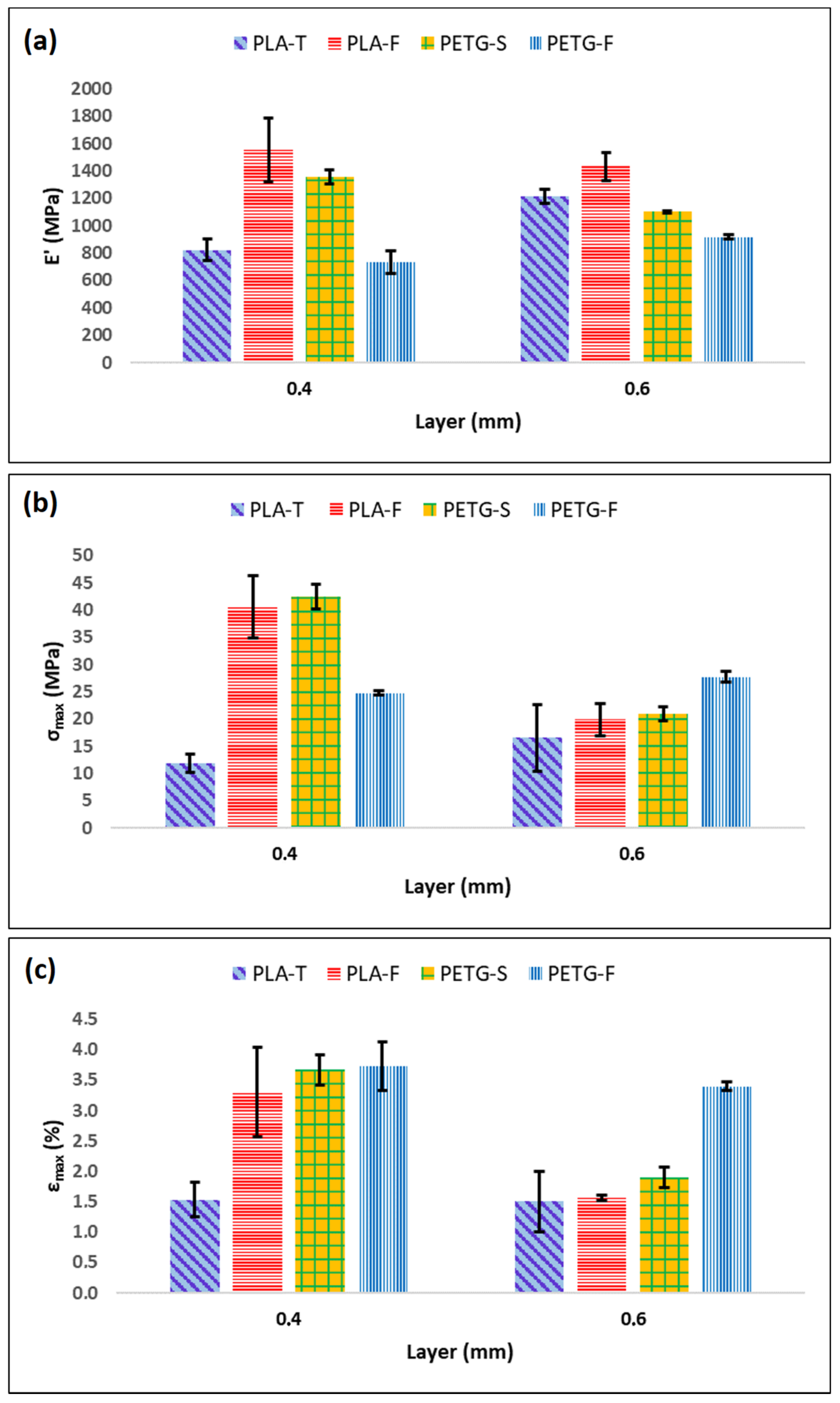

3.3.2. Charpy Impact Tests

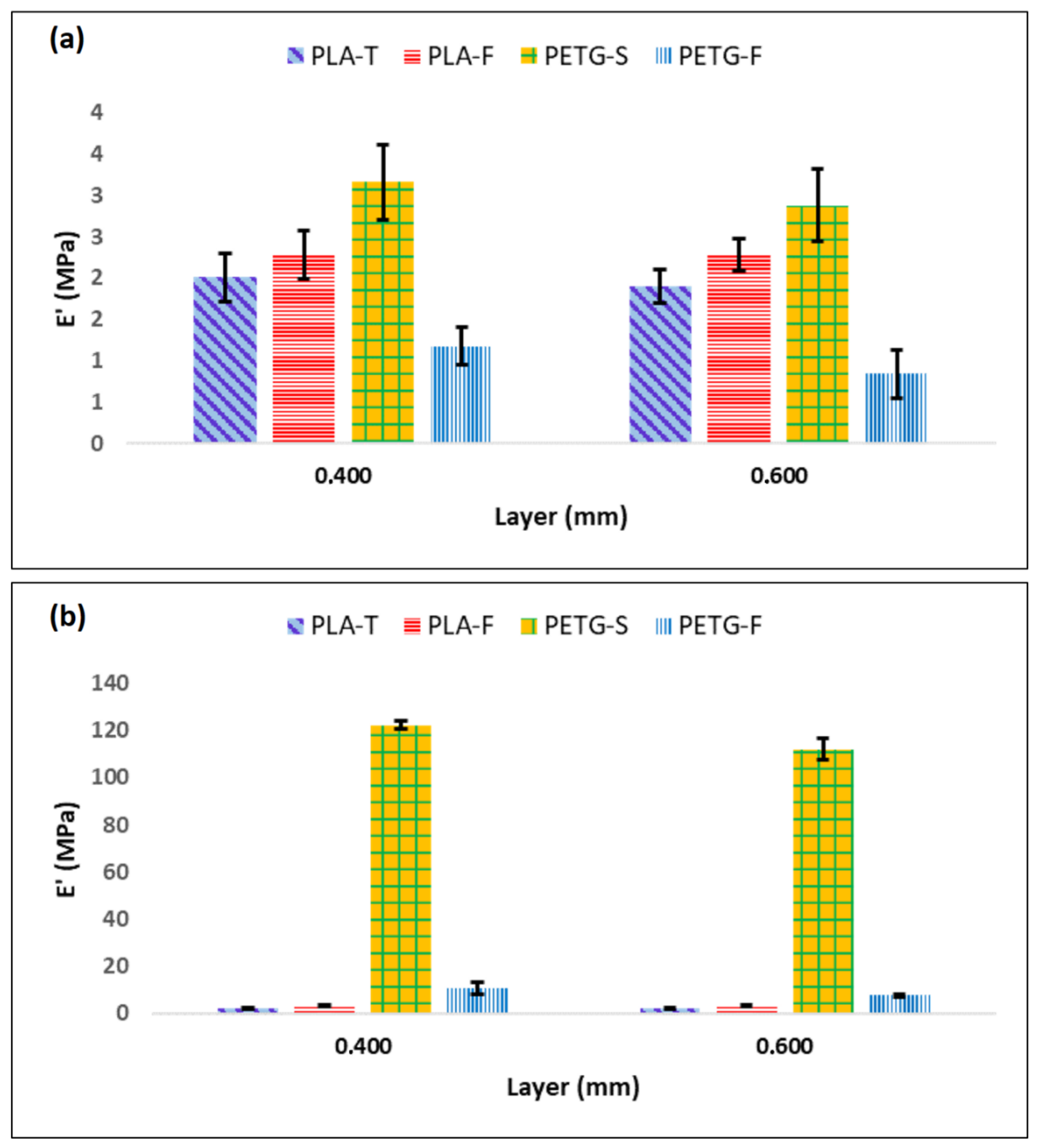

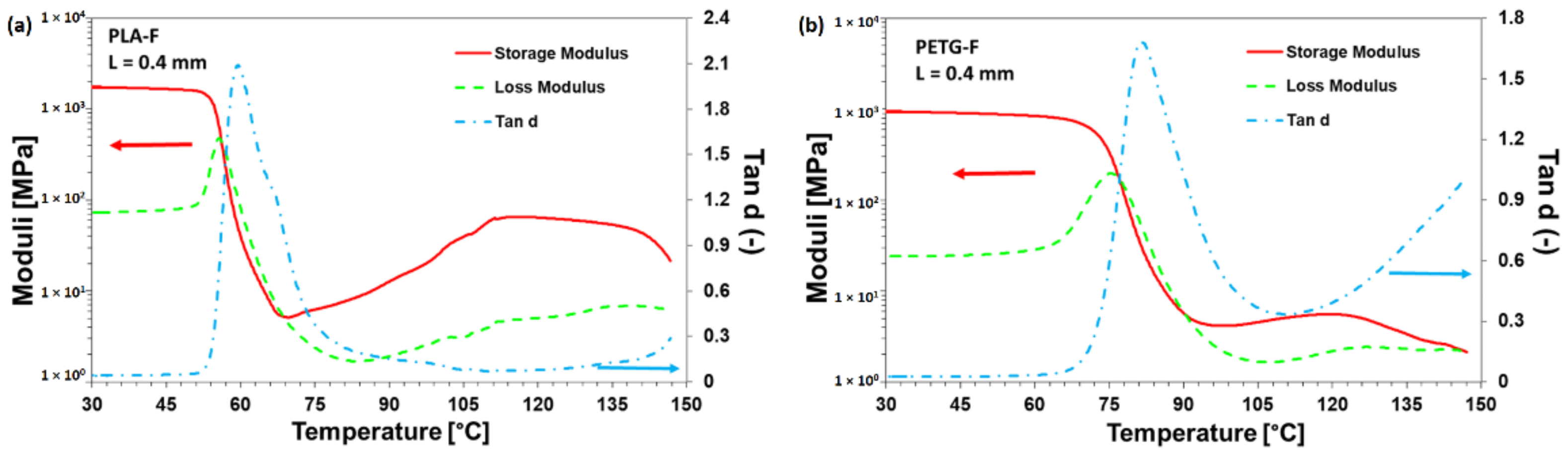

3.3.3. Dynamic Mechanical Thermal Analysis (DMTA)

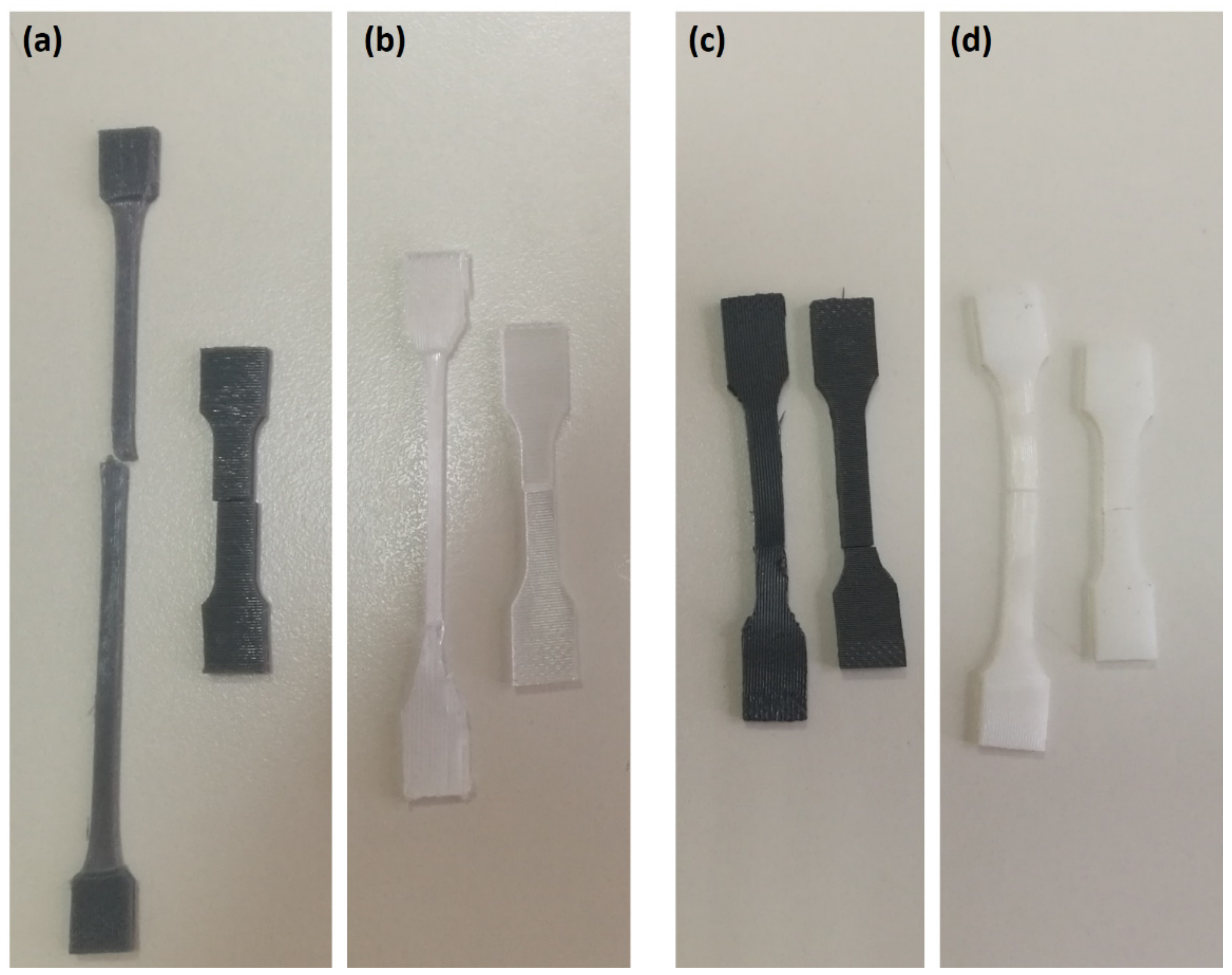

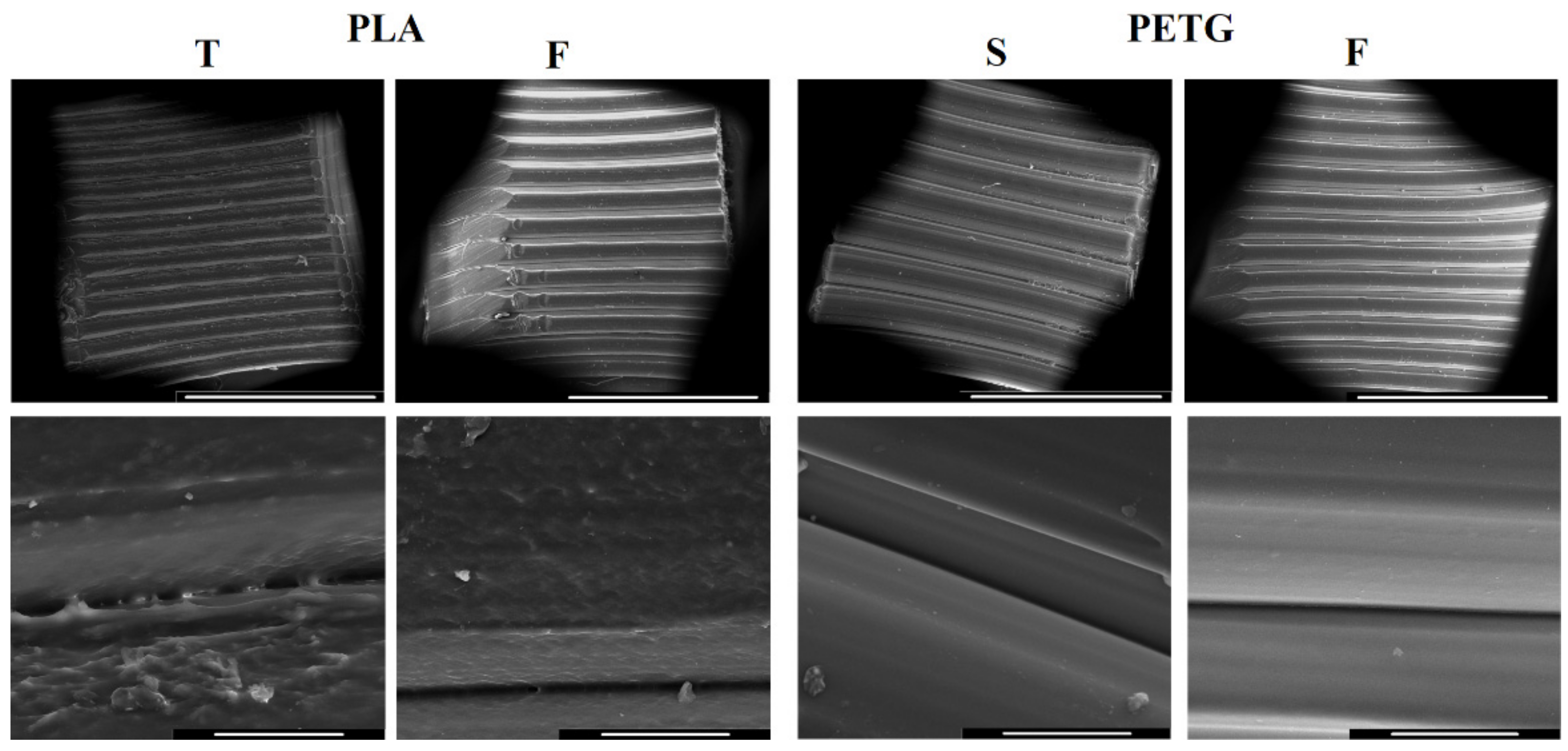

3.4. Morphological Analysis

3.5. Porosity Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Trobisch, P.; Suess, O.; Schwab, F. Idiopathic Scoliosis. Dtsch. Arztebl. Int. 2010, 107, 875–884. [Google Scholar] [CrossRef] [PubMed]

- Weinstein, S.L.; Dolan, L.A.; Spratt, K.F.; Peterson, K.K.; Spoonamore, M.J.; Ponseti, I.V. Health and function of patients with untreated idiopathic scoliosis: A 50-year natural history study. JAMA 2003, 289, 559–567. [Google Scholar] [CrossRef] [PubMed]

- Štefanovič, B.; Danko, M.; Michalíková, M.; Bednarčíková, L.; Rajťúková, V.; Tóth, T.; Trebuňová, M.; Hudák, R.; Živčák, J. Orthoses Development Using Modern Technologies. In Prosthetics and Orthotics; IntechOpen: London, UK, 2021. [Google Scholar]

- Lunsford, T.R.; Contoyannis, B. Materials Science. In Atlas of Orthoses and Assistive Devices; Elsevier: Amsterdam, The Netherlands, 2019; pp. 7–41. [Google Scholar]

- Redaelli, D.F.; Biffi, E.; Colombo, G.; Fraschini, P.; Reni, G. Current and Future Manufacturing of Chest Orthoses, Considering the Case of Osteogenesis Imperfecta. In Proceedings of the ASME 2018 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Quebec City, QC, Canada, 26–29 August 2018; pp. 1–7. [Google Scholar]

- Abtew, M.A.; Bruniaux, P.; Boussu, F. Development of adaptive bust for female soft body armour using three dimensional (3D) warp interlock fabrics: Three dimensional (3D) design process. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2017; Volume 254, p. 052001. [Google Scholar] [CrossRef]

- Wang, Y.; Tan, Q.; Pu, F.; Boone, D.; Zhang, M. A Review of the Application of Additive Manufacturing in Prosthetic and Orthotic Clinics from a Biomechanical Perspective. Engineering 2020, 6, 1258–1266. [Google Scholar] [CrossRef]

- Barrios-Muriel, J.; Romero-Sánchez, F.; Alonso-Sánchez, F.J.; Rodríguez Salgado, D. Advances in Orthotic and Prosthetic Manufacturing: A Technology Review. Materials 2020, 13, 295. [Google Scholar] [CrossRef]

- Weiss, H.; Seibel, S.; Moramarco, M.; Kleban, A. Bracing scoliosis: The evolution to CAD/CAM for improved in-brace corrections. Hard Tissue 2013, 2, 43. [Google Scholar] [CrossRef][Green Version]

- Venumbaka, S.A.; Covarubias, M.; Cesaro, G.; Ronca, A.; De Capitani, C.; Ambrosio, L.; Sorrentino, A. Application of Multi Materials Additive Manufacturing Technique in the Design and Manufacturing of Hand Orthoses. In Computers Helping People with Special Needs. ICCHP 2020. Lecture Notes in Computer Science; Miesenberger, K., Manduchi, R., Covarrubias Rodriguez, M., Peňáz, P., Eds.; Springer: Cham, Switzerland, 2020; pp. 461–468. ISBN 978-3-030-58804-5. [Google Scholar]

- Li, J.; Tanaka, H. Rapid customization system for 3D-printed splint using programmable modeling technique—A practical approach. 3D Print. Med. 2018, 4, 1–21. [Google Scholar] [CrossRef]

- Li, J.; Tanaka, H. Feasibility study applying a parametric model as the design generator for 3D–printed orthosis for fracture immobilization. 3D Print. Med. 2018, 4, 1–15. [Google Scholar] [CrossRef]

- Lou, E.; Ng, K.; Hill, D. Immediate Outcomes and Benefits of 3D Printed Braces for the Treatment of Adolescent Idiopathic Scoliosis. Front. Rehabil. Sci. 2022, 3, 17. [Google Scholar] [CrossRef]

- Mosleh, S.; Abtew, M.A.; Bruniaux, P.; Tartare, G.; Chen, Y. Developing an Adaptive 3D Vertebrae Model of Scoliosis Patients for Customize Garment Design. Appl. Sci. 2021, 11, 3171. [Google Scholar] [CrossRef]

- Singh, S.; Ramakrishna, S.; Singh, R. Material issues in additive manufacturing: A review. J. Manuf. Process. 2017, 25, 185–200. [Google Scholar] [CrossRef]

- Jin, H.; Zhang, Z.; Gao, Y.; He, H.; Feng, S.; Xu, R.; Li, Q.; Zuo, H. Case series: 3D printed orthopedic brace combined with traditional manipulative physiotherapy to treat new-onset scoliosis in adults. Medicine 2022, 101, e28429. [Google Scholar] [CrossRef] [PubMed]

- Redaelli, D.F.; Abbate, V.; Storm, F.A.; Ronca, A.; Sorrentino, A.; De Capitani, C.; Biffi, E.; Ambrosio, L.; Colombo, G.; Fraschini, P. 3D printing orthopedic scoliosis braces: A test comparing FDM with thermoforming. Int. J. Adv. Manuf. Technol. 2020, 111, 1707–1720. [Google Scholar] [CrossRef]

- Mok, S.-W.; Nizak, R.; Fu, S.-C.; Ho, K.-W.K.; Qin, L.; Saris, D.B.F.; Chan, K.-M.; Malda, J. From the printer: Potential of three-dimensional printing for orthopaedic applications. J. Orthop. Transl. 2016, 6, 42–49. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Ronca, A.; Ambrosio, L.; Grijpma, D.W. Design of porous three-dimensional PDLLA/nano-hap composite scaffolds using stereolithography. J. Appl. Biomater. Funct. Mater. 2012, 10, 249–258. [Google Scholar] [CrossRef] [PubMed]

- Tack, P.; Victor, J.; Gemmel, P.; Annemans, L. 3D-printing techniques in a medical setting: A systematic literature review. Biomed. Eng. Online 2016, 15, 115. [Google Scholar] [CrossRef] [PubMed]

- Rengier, F.; Mehndiratta, A.; Von Tengg-Kobligk, H.; Zechmann, C.M.; Unterhinninghofen, R.; Kauczor, H.-U.; Giesel, F.L. 3D printing based on imaging data: Review of medical applications. Int. J. Comput. Assist. Radiol. Surg. 2010, 5, 335–341. [Google Scholar] [CrossRef]

- Weiss, H.-R.; Tournavitis, N.; Nan, X.; Borysov, M.; Paul, L. Workflow of CAD/CAM Scoliosis Brace Adjustment in Preparation Using 3D Printing. Open Med. Inform. J. 2017, 11, 44–51. [Google Scholar] [CrossRef]

- Armillotta, A. Assessment of surface quality on textured FDM prototypes. Rapid Prototyp. J. 2006, 12, 35–41. [Google Scholar] [CrossRef]

- Dizon, J.R.C.; Espera, A.H., Jr.; Chen, Q.; Advincula, R.C. Mechanical characterization of 3D-printed polymers. Addit. Manuf. 2018, 20, 44–67. [Google Scholar] [CrossRef]

- Mohan, N.; Senthil, P.; Vinodh, S.; Jayanth, N. A review on composite materials and process parameters optimisation for the fused deposition modelling process. Virtual Phys. Prototyp. 2017, 12, 47–59. [Google Scholar] [CrossRef]

- Ronca, A.; Ambrosio, L.; Grijpma, D.W. Preparation of designed poly(d,l-lactide)/nanosized hydroxyapatite composite structures by stereolithography. Acta Biomater. 2013, 9, 5989–5996. [Google Scholar] [CrossRef] [PubMed]

- Vijay, P.; Danaiah, P.; Rajesh, K.V.D. Critical parameters effecting the rapid prototyping surface finish. J. Mech. Eng. Autom. 2011, 1, 17–20. [Google Scholar] [CrossRef]

- Somireddy, M.; Singh, C.V.; Czekanski, A. Analysis of the material behavior of 3D printed laminates via FFF. Exp. Mech. 2019, 59, 871–881. [Google Scholar] [CrossRef]

- Patterson, A.E.; Pereira, T.R.; Allison, J.T.; Messimer, S.L. IZOD impact properties of full-density fused deposition modeling polymer materials with respect to raster angle and print orientation. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2019, 235, 1891–1908. [Google Scholar] [CrossRef]

- Ahn, S.; Montero, M.; Odell, D.; Roundy, S.; Wright, P.K. Anisotropic material properties of fused deposition modeling ABS. Rapid Prototyp. J. 2002, 8, 248–257. [Google Scholar] [CrossRef]

- Kotlinski, J. Mechanical properties of commercial rapid prototyping materials. Rapid Prototyp. J. 2014, 20, 499–510. [Google Scholar] [CrossRef]

- Gibson, I.; Shi, D. Material properties and fabrication parameters in selective laser sintering process. Rapid Prototyp. J. 1997, 3, 129–136. [Google Scholar] [CrossRef]

- Es-Said, O.S.; Foyos, J.; Noorani, R.; Mendelson, M.; Marloth, R.; Pregger, B.A. Effect of layer orientation on mechanical properties of rapid prototyped samples. Mater. Manuf. Process. 2000, 15, 107–122. [Google Scholar] [CrossRef]

- Croccolo, D.; De Agostinis, M.; Olmi, G. Experimental characterization and analytical modelling of the mechanical behaviour of fused deposition processed parts made of ABS-M30. Comput. Mater. Sci. 2013, 79, 506–518. [Google Scholar] [CrossRef]

- Lee, B.H.; Abdullah, J.; Khan, Z.A. Optimization of rapid prototyping parameters for production of flexible ABS object. J. Mater. Process. Technol. 2005, 169, 54–61. [Google Scholar] [CrossRef]

- Chacón, J.M.; Caminero, M.A.; García-Plaza, E.; Núnez, P.J. Additive manufacturing of PLA structures using fused deposition modelling: Effect of process parameters on mechanical properties and their optimal selection. Mater. Des. 2017, 124, 143–157. [Google Scholar] [CrossRef]

- Forster, A. Materials Testing Standards for Additive Manufacturing of Polymer Materials: State of the Art and Standards Applicability. In Additive Manufacturing Materials; Nova Science Publishers, Inc.: New York, NY, USA, 2015. [Google Scholar]

- Oth, O.; Dauchot, C.; Orellana, M.; Glineur, R. How to sterilize 3D printed objects for surgical use? An evaluation of the volumetric deformation of 3D-printed genioplasty guide in PLA and PETG after. Open Dent. J. 2019, 13, 410–417. [Google Scholar] [CrossRef]

- Moradi, M.; Aminzadeh, A.; Rahmatabadi, D.; Hakimi, A. Experimental investigation on mechanical characterization of 3D printed PLA produced by fused deposition modeling (FDM). Mater. Res. Express 2021, 8, 035304. [Google Scholar] [CrossRef]

- Rankouhi, B.; Javadpour, S.; Delfanian, F.; Letcher, T. Failure analysis and mechanical characterization of 3D printed ABS with respect to layer thickness and orientation. J. Fail. Anal. Prev. 2016, 16, 467–481. [Google Scholar] [CrossRef]

- Rodrı’guez, J.F.; Thomas, J.P.; Renaud, J.E. Design of Fused-Deposition ABS Components for Stiffness and Strength. J. Mech. Des. 2003, 125, 545–551. [Google Scholar] [CrossRef]

- Patti, A.; Cicala, G.; Tosto, C.; Saitta, L.; Acierno, D. Characterization of 3D Printed Highly Filled Composite: Structure, Thermal Diffusivity and Dynamic-mechanical Analysis. Chem. Eng. Trans. 2021, 86, 1537–1542. [Google Scholar] [CrossRef]

- Franco-Urquiza, E.A.; Escamilla, Y.R.; Alcántara Llanas, P.I. Characterization of 3D Printing on Jute Fabrics. Polymers 2021, 13, 3202. [Google Scholar] [CrossRef]

- ASTM-D638; Standard Test Method for Tensile Properties of Plastics. Document Center, Inc.: Belmont, CA, USA, 2022.

- Saba, N.; Jawaid, M.; Sultan, M.T.H. An overview of mechanical and physical testing of composite materials. In Mechanical and Physical Testing of Biocomposites, Fibre-Reinforced Composites and Hybrid Composites; Elsevier: Amsterdam, The Netherlands, 2019; pp. 1–12. [Google Scholar]

- ASTM-D6110; Standard Test Method for Determining the Charpy Impact Resistance of Notched Specimens of Plastics. Document Center, Inc.: Belmont, CA, USA, 2018.

- ASTM D792-20; Standard Test Methods for Density and Specific Gravity (Relative Density) of Plastics by Displacement. ASTM: West Conshohocken, PA, USA, 2004.

- Mackay, M.E. The importance of rheological behavior in the additive manufacturing technique material extrusion. J. Rheol. 2018, 62, 1549–1561. [Google Scholar] [CrossRef]

- Calafel, I.; Aguirresarobe, R.H.; Peñas, M.I.; Santamaria, A.; Tierno, M.; Conde, J.I.; Pascual, B. Searching for Rheological Conditions for FFF 3D Printing with PVC Based Flexible Compounds. Materials 2020, 13, 178. [Google Scholar] [CrossRef]

- Pantani, R.; De Santis, F.; Sorrentino, A.; De Maio, F.; Titomanlio, G. Crystallization kinetics of virgin and processed poly (lactic acid). Polym. Degrad. Stab. 2010, 95, 1148–1159. [Google Scholar] [CrossRef]

- Jalali, A.; Huneault, M.A.; Elkoun, S. Effect of thermal history on nucleation and crystallization of poly (lactic acid). J. Mater. Sci. 2016, 51, 7768–7779. [Google Scholar] [CrossRef]

- Pantani, R.; Speranza, V.; Sorrentino, A.; Titomanlio, G. Molecular orientation and strain in injection moulding of thermoplastics. Macromol. Symp. 2002, 185, 293–307. [Google Scholar] [CrossRef]

- Sorrentino, A.; De Santis, F.; Titomanlio, G. Polymer crystallization under high cooling rate and pressure: A step towards polymer processing conditions. In Progress in Understanding of Polymer Crystallization; Springer: Berlin/Heidelberg, Germany, 2007; pp. 329–344. [Google Scholar]

- Kováčová, M.; Kozakovičová, J.; Procházka, M.; Janigová, I.; Vysopal, M.; Černičková, I.; Krajčovič, J.; Špitalský, Z. Novel hybrid PETG composites for 3D printing. Appl. Sci. 2020, 10, 3062. [Google Scholar] [CrossRef]

- Letcher, T.; Rankouhi, B.; Javadpour, S. Experimental study of mechanical properties of additively manufactured ABS plastic as a function of layer parameters. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, Houston, TX, USA, 13–19 November 2015; American Society of Mechanical Engineers: New York, NY, USA, 2015; Volume 57359, p. V02AT02A018. [Google Scholar]

- Caminero, M.A.; Chacón, J.M.; García-Moreno, I.; Rodríguez, G.P. Impact damage resistance of 3D printed continuous fibre reinforced thermoplastic composites using fused deposition modelling. Compos. Part B Eng. 2018, 148, 93–103. [Google Scholar] [CrossRef]

| PLA | PETG | |||

|---|---|---|---|---|

| Tradename | Filoalfa® | TreeD Filaments® | Filoalfa® | Sunlu® |

| Short-name | PLA-F | PLA-T | PETG-F | PETG-S |

| Tensile strength (ASTM D638) | 53 MPa | 53 MPa | 50 MPa | 44 MPa |

| Density (ASTM D792) | 1.24 g/cm3 | 1.24 g/cm3 | 1.27 g/cm3 | |

| Tensile modulus (ASTM D882) | 3600 MPa | 3050 MPa | 2110 MPa | |

| Flexure modulus (ASTM D790) | 3800 MPa | 2110 MPa | ||

| Flexure strength (ASTM D790) | 73 MPa | |||

| Elongation at break (ASTM D882) | 6% | 18% | ||

| IZOD impact strength (ASTM D256) | 100 J/m | |||

| Notched IZOD impact | 16 J/m | |||

| Heat deflection temperature (ASTM D648) | 55 °C | 55 °C | 70 °C | 73 °C |

| Melt flow rate | 6–11 g/10 min (220 °C, 2.16 kg) | |||

| Price(per kg) | 15–25€ | 15–25€ | 20–40€ | 20–40€ |

| SAMPLE | Tg | Tm | ΔHm | |

|---|---|---|---|---|

| (°C) | (°C) | (J/g) | ||

| PETG-S | Pre | 70.8 | - | - |

| Post | 71.6 | - | - | |

| PETG-F | Pre | 73.9 | - | - |

| Post | 77.3 | - | - | |

| PLA-F | Pre | 62.4 | 152.7 | 14.9 |

| Post | 58.5 | 150.6 | 23.9 | |

| PLA-T | Pre | 60.9 | 149.0 | 12.4 |

| Post | 59.7 | 147.3 | 17.7 |

| Sample | PLA-F | PLA-T | PETG-F | PETG-S | |||||

|---|---|---|---|---|---|---|---|---|---|

| Layer Thickness | 0.4 | 0.6 | 0.4 | 0.6 | 0.4 | 0.6 | 0.4 | 0.6 | |

| Tg (°C) | 61.1 | 59.6 | 59.0 | 56.1 | 84.5 | 81.7 | 79.3 | 79.1 | |

| E′ (MPa) | 30 °C | 1733 | 1394 | 1269 | 776 | 937 | 837 | 951 | 891 |

| 55 °C | 982 | 1050 | 53 | 227 | 868 | 772 | 879 | 812 | |

| 80 °C | 7 | 3 | 6 | 7 | 52 | 99 | 14 | 23 | |

| E″ (MPa) | 30 °C | 73 | 51 | 40 | 53 | 24 | 22 | 28 | 23 |

| 55 °C | 399 | 168 | 111 | 150 | 26 | 23 | 30 | 22 | |

| 80 °C | 2 | 1 | 1 | 2 | 82 | 117 | 25 | 36 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ronca, A.; Abbate, V.; Redaelli, D.F.; Storm, F.A.; Cesaro, G.; De Capitani, C.; Sorrentino, A.; Colombo, G.; Fraschini, P.; Ambrosio, L. A Comparative Study for Material Selection in 3D Printing of Scoliosis Back Brace. Materials 2022, 15, 5724. https://doi.org/10.3390/ma15165724

Ronca A, Abbate V, Redaelli DF, Storm FA, Cesaro G, De Capitani C, Sorrentino A, Colombo G, Fraschini P, Ambrosio L. A Comparative Study for Material Selection in 3D Printing of Scoliosis Back Brace. Materials. 2022; 15(16):5724. https://doi.org/10.3390/ma15165724

Chicago/Turabian StyleRonca, Alfredo, Valentina Abbate, Davide Felice Redaelli, Fabio Alexander Storm, Giacomo Cesaro, Cristina De Capitani, Andrea Sorrentino, Giorgio Colombo, Paolo Fraschini, and Luigi Ambrosio. 2022. "A Comparative Study for Material Selection in 3D Printing of Scoliosis Back Brace" Materials 15, no. 16: 5724. https://doi.org/10.3390/ma15165724

APA StyleRonca, A., Abbate, V., Redaelli, D. F., Storm, F. A., Cesaro, G., De Capitani, C., Sorrentino, A., Colombo, G., Fraschini, P., & Ambrosio, L. (2022). A Comparative Study for Material Selection in 3D Printing of Scoliosis Back Brace. Materials, 15(16), 5724. https://doi.org/10.3390/ma15165724