Cementitious Grouts for Semi-Flexible Pavement Surfaces—A Review

Abstract

:1. Introduction

2. Review on Modification of Asphalt Binder and Mixes for Conventional Flexible Pavements

3. History of Semi-Flexible Pavement

4. Semi-Flexible Pavement/Grouted Macadam

5. Factors Influencing the Performance of Grouts and Semi-Flexible Mixtures

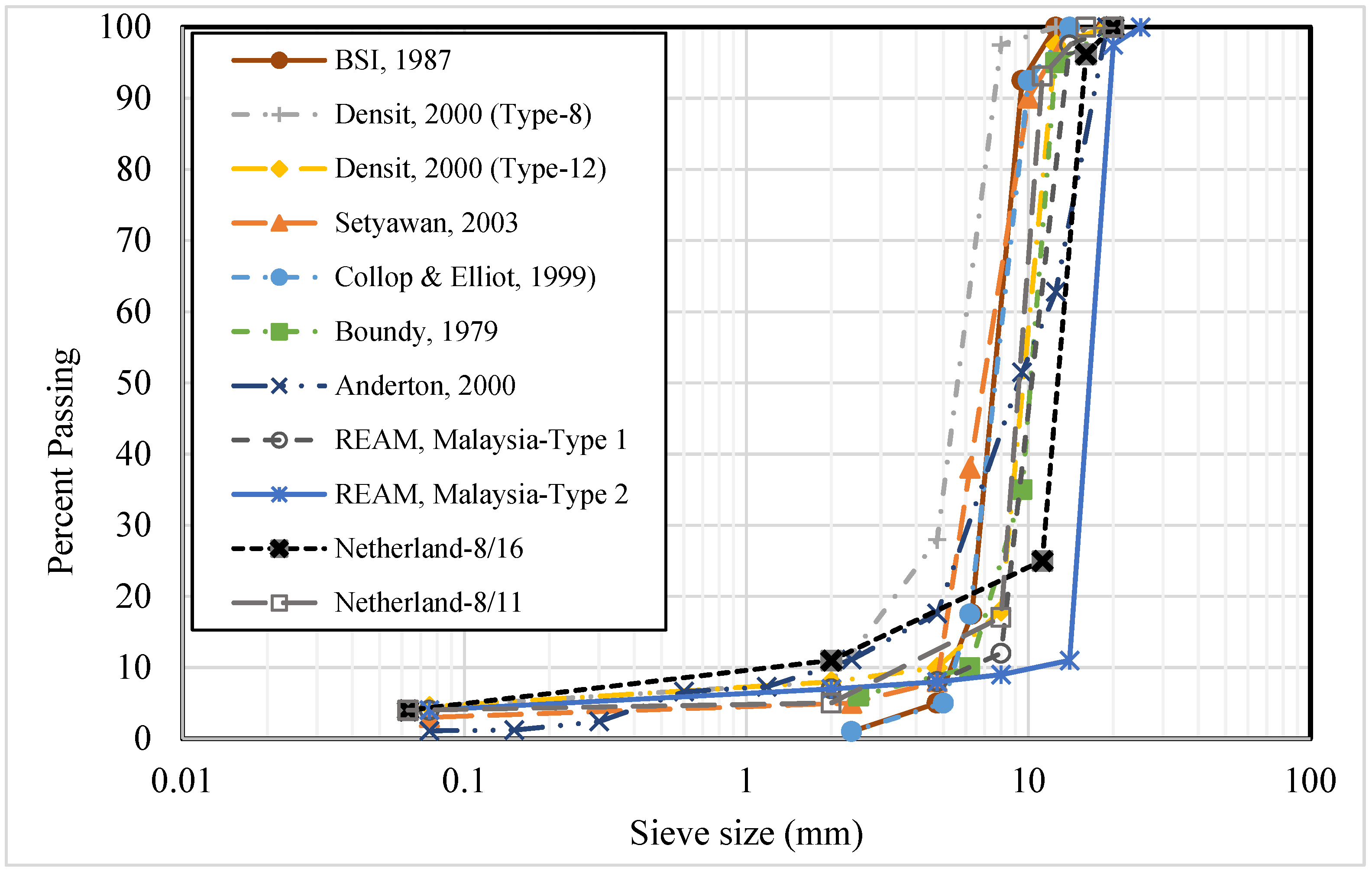

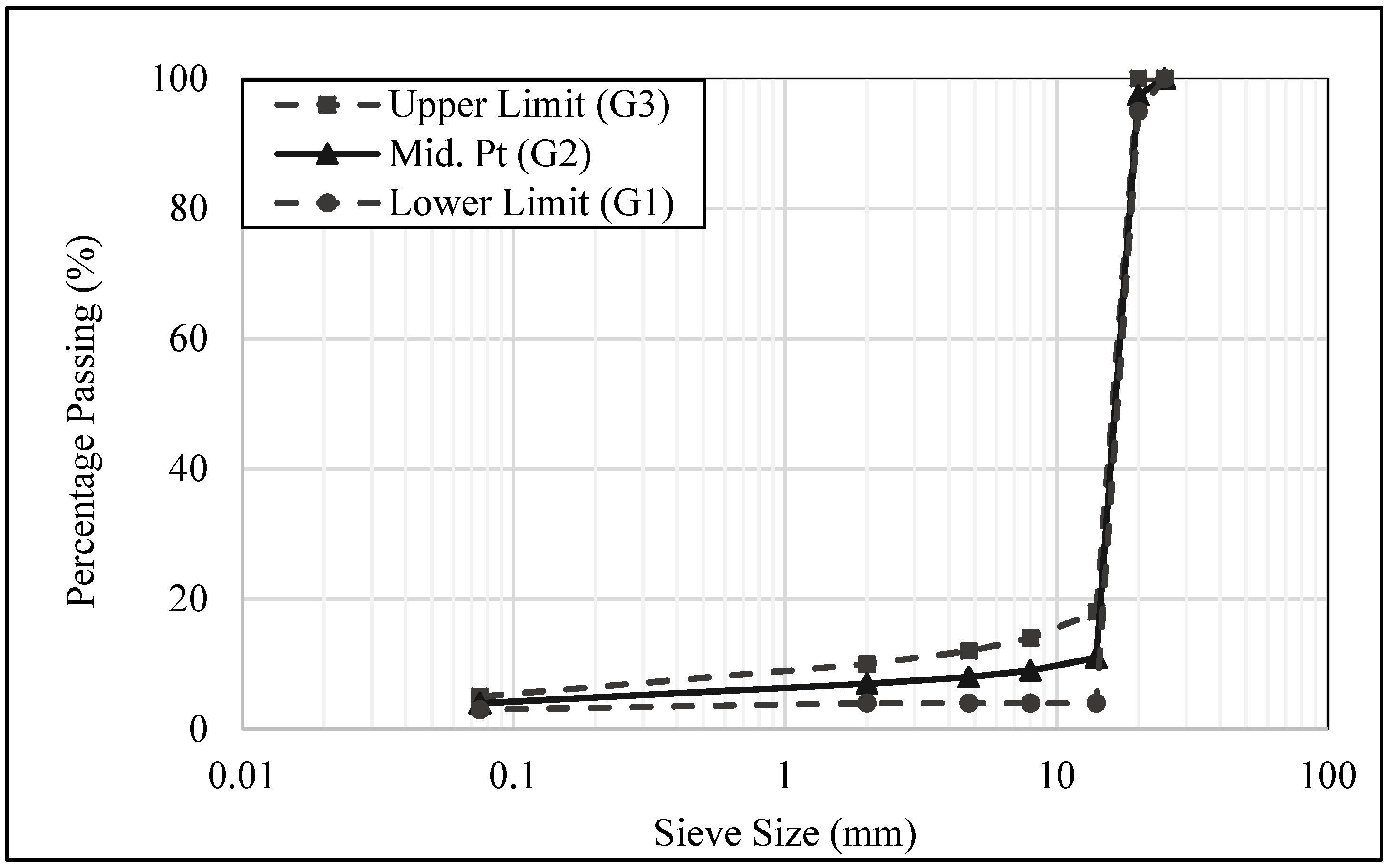

5.1. Porous Asphalt Mixture Gradation

5.2. Porosity/Voids of Asphalt Mixture

5.3. Degree of Grout Saturation

5.4. Type of Asphalt Binder

5.5. Water–Cement (w/c) Ratio of Grout

5.6. Admixtures and Other Supplementary Cementitious Materials

5.7. Industrial/Municipal Wastes and Other Polymers/Additives

| Grouts Composition | Porous Asphalt | ||

|---|---|---|---|

| Material | Weight (%) | Voids | 25 to 35% |

| Cement (Type-1) | 34 to 40 | Bitumen Content | 3.5 to 4.5% by total weight |

| Sand (silica Sand) | 16 to 20 | Penetration grade | 40 to 100 |

| Fly Ash (as Filler) | 16 to 20 | ||

| Latex Resin | 22 to 26 | ||

| Water | 2.5 to 3.5 [w/c = 0.65–0.70, Flow time: 8 to 10 s] | ||

6. Evaluation of Physical and Mechanical Properties of Cementitious Grouts

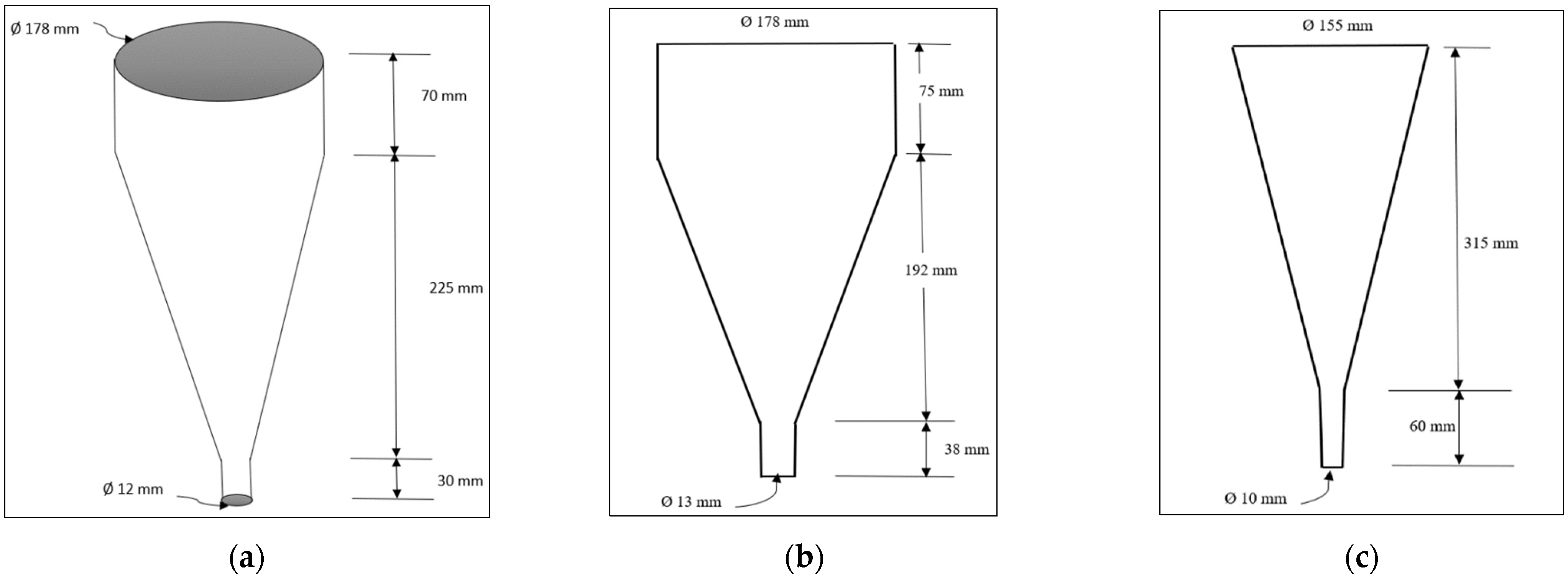

6.1. Flowability of the Cement Grouts

6.2. Strength Properties of Cement Grouts

7. Performance Evaluation of Semi-Flexible Mixtures

7.1. Grouting Ability

7.2. Indirect Tensile Strength and Moisture Resistance

7.3. Compressive and Flexural Strength

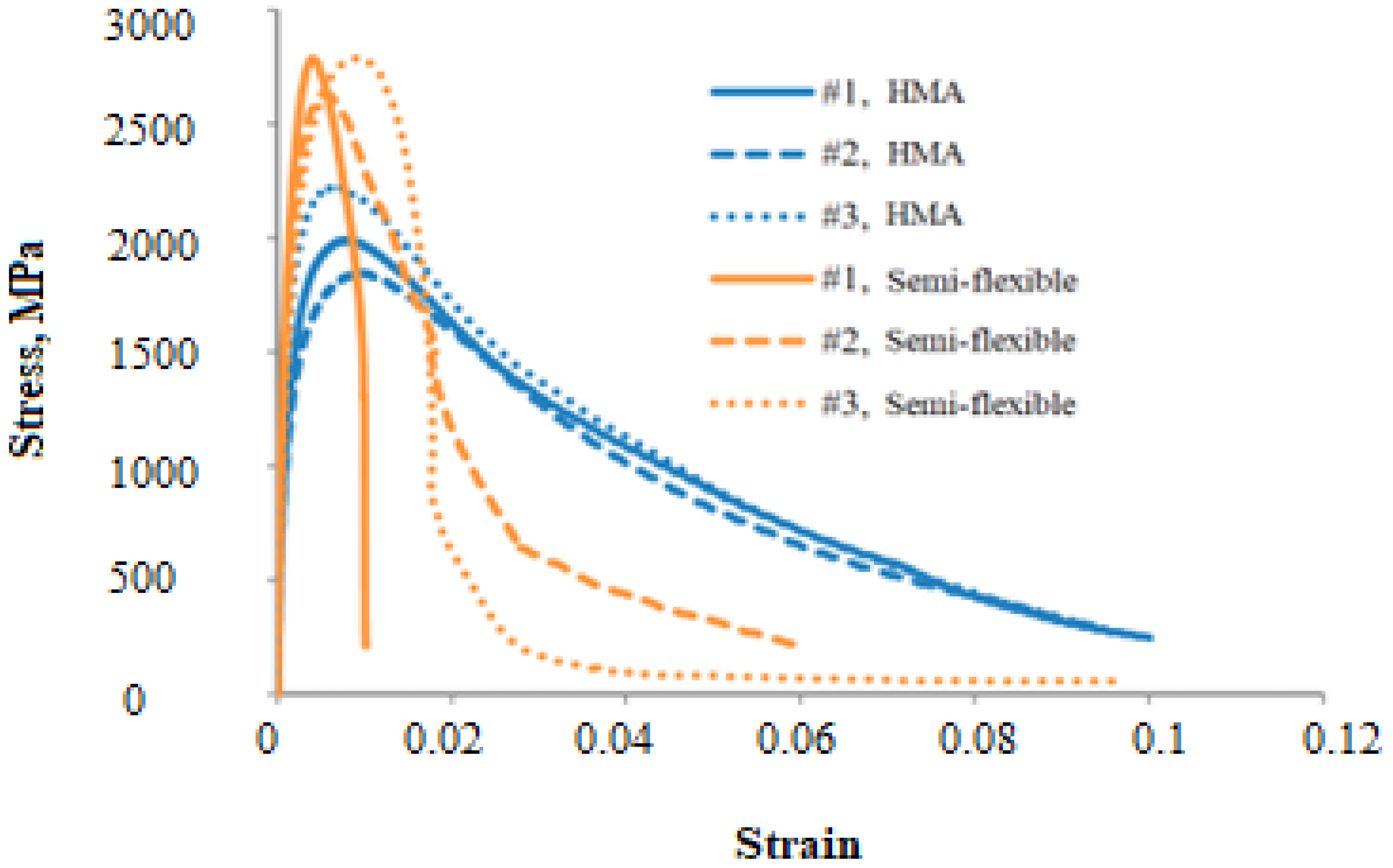

7.4. Stiffness

7.5. Fatigue Life

7.6. Rutting

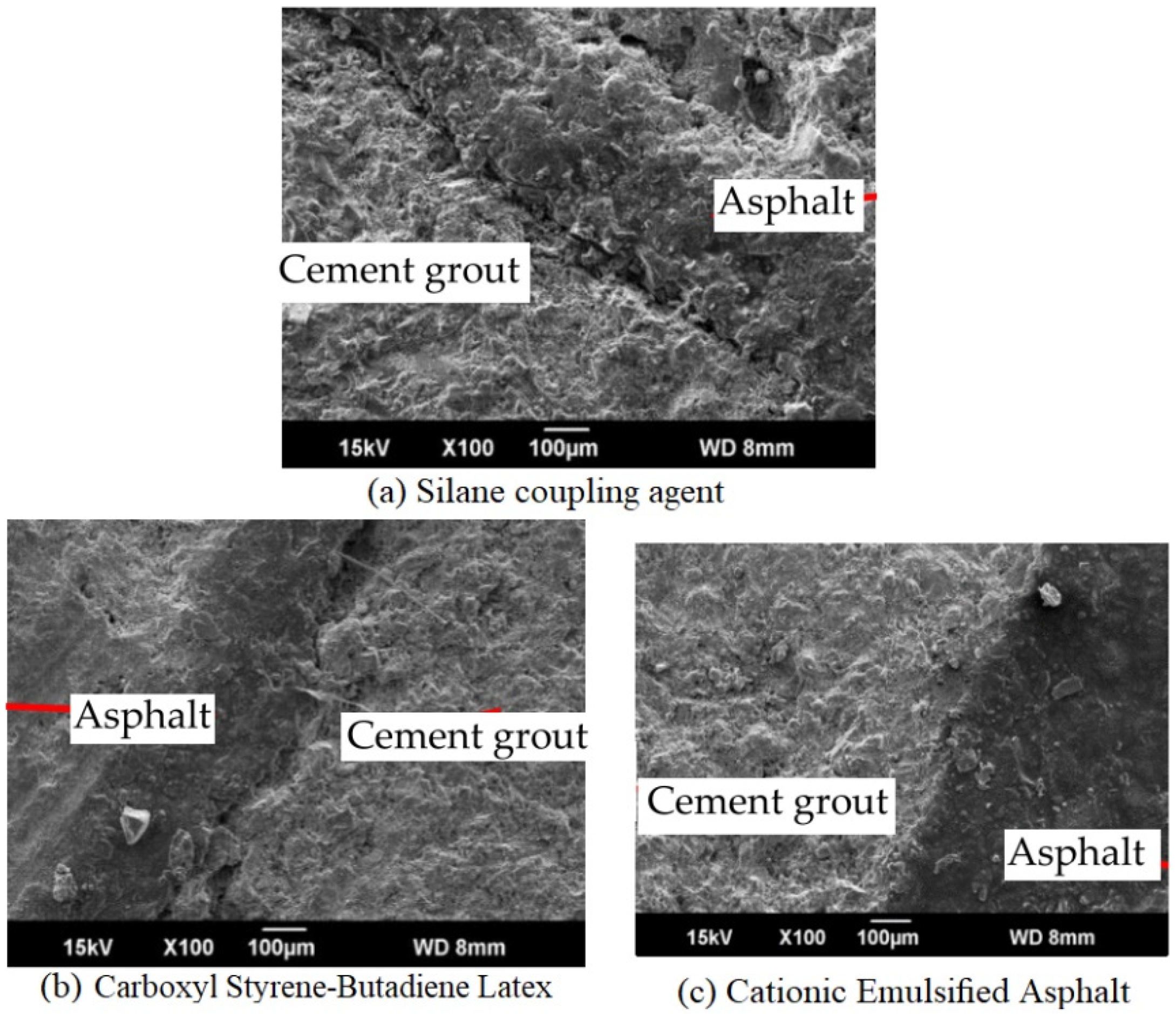

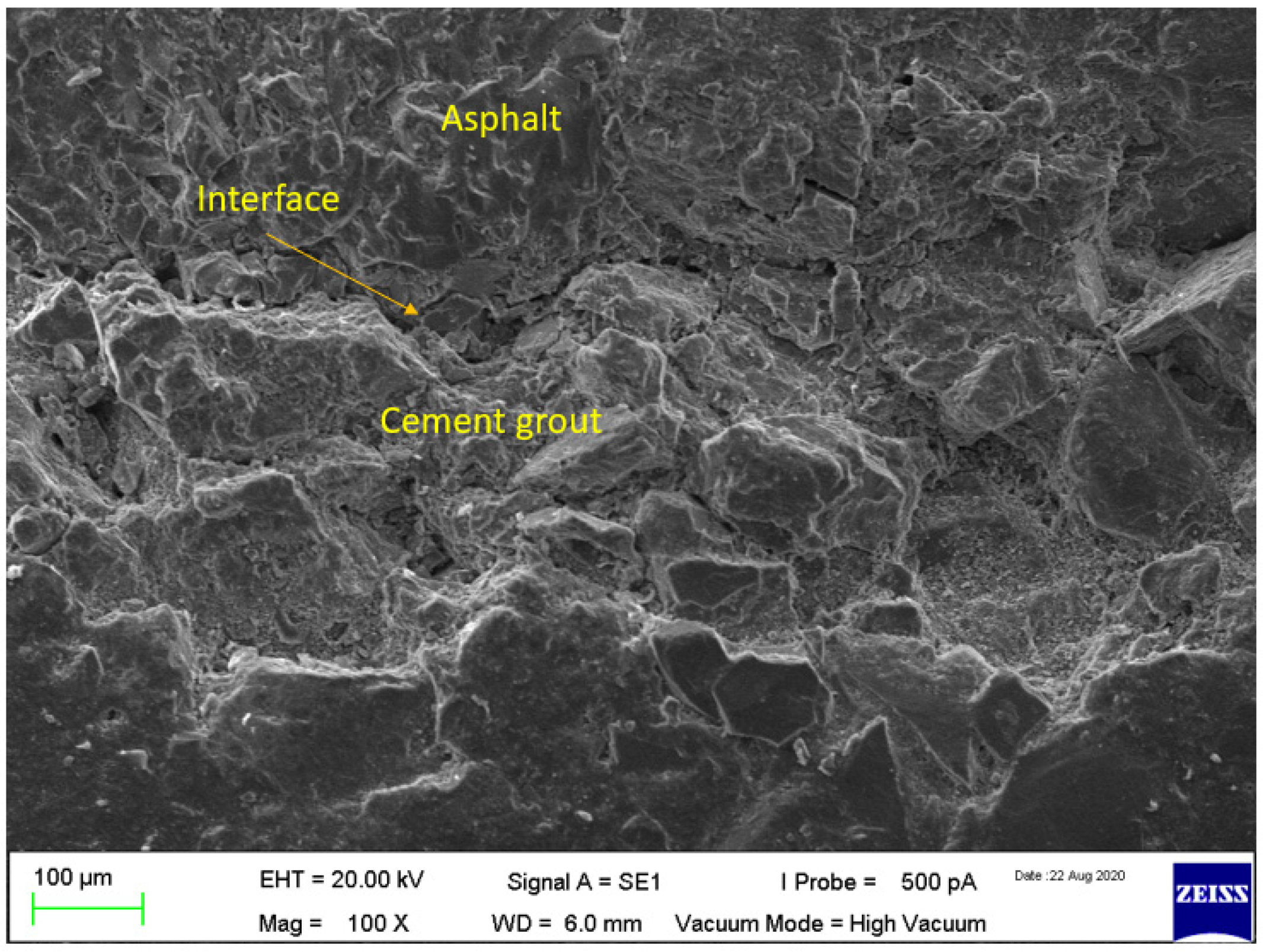

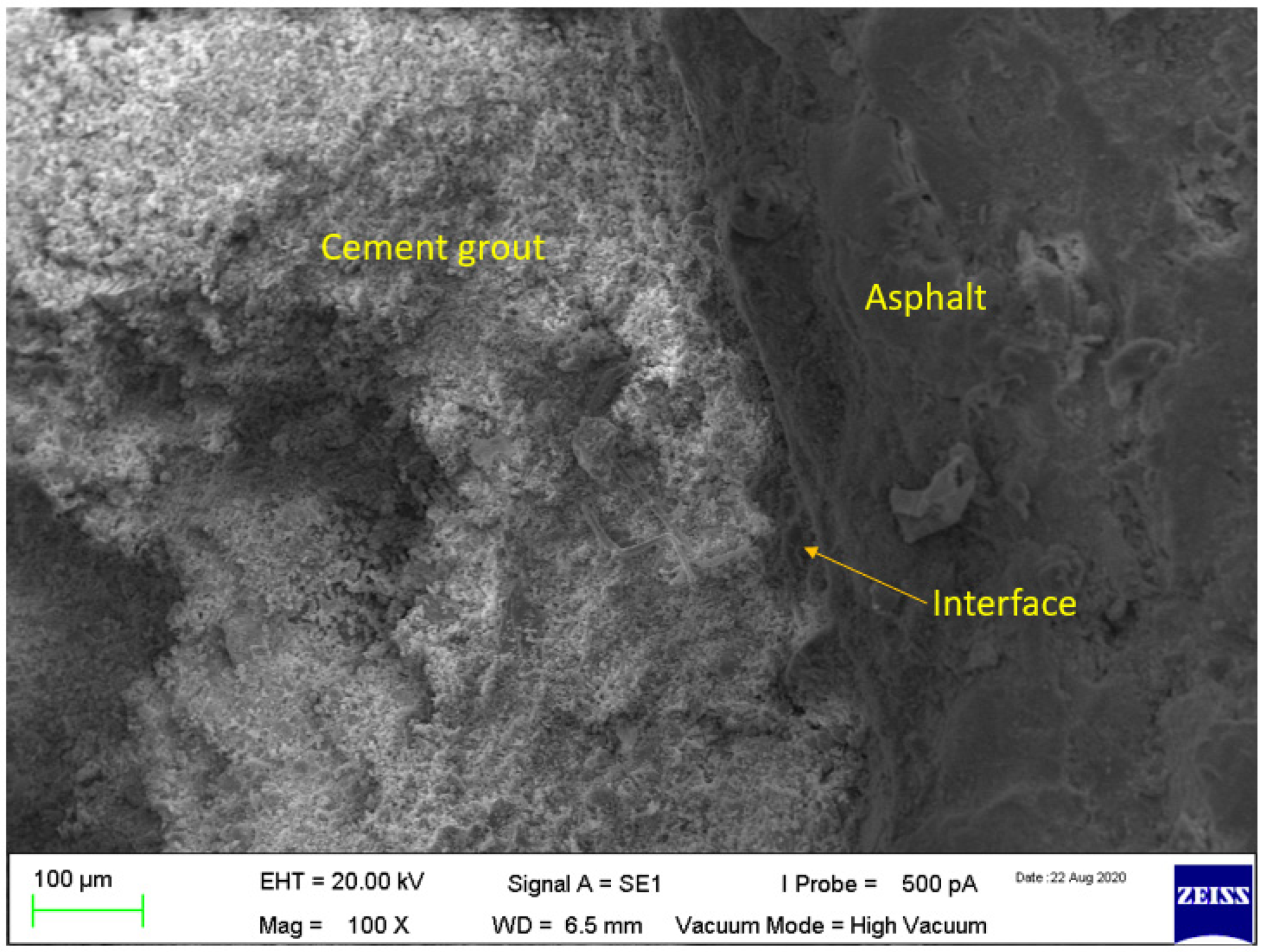

8. Compatibility of Cement Grout with Asphalt Mixture (Microstructure Characterization)

9. Conclusions

- It can be concluded that the durability and performance properties of semi-flexible pavement surfaces largely depend on the mix design of the porous asphalt skeleton and composition of cementitious grouts. The selection of aggregate gradation and type of bitumen in porous asphalt mixtures and their effect on final semi-flexible specimens have been presented. Similarly, the effect of different compositions of cementitious grout and other additives/admixtures on the performance of semi-flexible mixtures have been explained.

- Single-size aggregate is used to achieve the required porosity of porous asphalt mixtures. A single aggregate size in the range of 8–12 mm nominal size can be used in porous mixtures to achieve the void ratio of 25–35%. Furthermore, polymer-modified binder can be used in the porous asphalt skeleton to improve its resistance against high and low-temperature performance. Municipal and/or industrial wastes/byproducts could be a better choice in binder modification towards performance improvement and environmental sustainability.

- The grouts are required to be highly flowable to penetrate through the porous asphalt skeleton. The flow value of 11 to 16 s is recommended while using the flow cone of the size used in ASTM C939. Depending on the composition of grouts, a w/c ratio of 0.45–0.65 could be used to achieve the required fluidity of cementitious grouts. Moreover, superplasticizer (0 to 2%) is used to achieve high fluidity at a relatively low w/c ratio (0.30 to 0.40). Other pozzolanic and cementitious products (such as fly ash, silica fume, fine limestone, and ground granulated blast furnace slag, etc.) could be used to achieve medium-to-high-strength grouts and, hence, medium-to-high-strength semi-flexible mixtures, and achieve the sustainability goals. Fly ash, silica fume and ground granulated blast furnace slag up to 10%, 5%, and 10%, respectively, can be used to replace cement, while achieving the required strength properties.

- The performance of cementitious grout is significantly related to the performance of semi-flexible mixtures. Therefore, the grouts are carefully designed to produce high-performance semi-flexible pavement surfaces.

- The fatigue life of semi-flexible mixtures can be evaluated using two-point or four-point bending fatigue tests. However, a four-point bending fatigue test could give better and more reliable results compared to the two-point fatigue test, because the failure of beams occurs in the uniform bending moment area.

- It is recommended to use interface modifiers to enhance the bonding between the asphalt mixture and cement grouts that help in reducing cracks in the pavement.

- Further study could be conducted on utilizing industrial/municipal wastes and other byproducts as a cement replacement in cementitious grouts for semi-flexible layers. It is a known fact that the production of cement releases carbon dioxide both directly and indirectly. Hence, there is a need for the development of durable, sustainable, and cost-effective cementitious grouts for semi-flexible pavement surfaces by utilizing a large percentage of municipal and industrial wastes/byproducts.

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Amin, M.; Khan, M.; Saleem, M. Performance Evaluation of Asphalt Modified with Municipal Wastes for Sustainable Pavement Construction. Sustainability 2016, 8, 949. [Google Scholar] [CrossRef]

- Koting, S.; Karim, M.R.; Mahmud, H.B.; Hamid, A.; Anjang, N. Mechanical Properties of Cement-Bitumen Composites for Semi-Flexible Pavement Surfacing. Balt. J. Road Bridge Eng. 2014, 9, 191–199. [Google Scholar] [CrossRef] [Green Version]

- Zoorob, S.; Hassan, K.; Setyawan, A. Cold mix, cold laid semi-flexible grouted macadams, mix design and properties. In Proceedings of the 4th European Symposium on Performance of Bituminous and Hydraulic Materials in Pavements, Nottingham, UK, 11–12 April 2002; pp. 105–112. [Google Scholar]

- Oliveira, J.R.; Pais, J.C.; Thom, N.H.; Zoorob, S.E. A Study of the Fatigue Properties of Grouted Macadams. Int. J. Pavements 2007, 6, 112–123. [Google Scholar]

- Pratelli, C.; Betti, G.; Giuffrè, T.; Marradi, A. Preliminary In-Situ Evaluation of an Innovative, Semi-Flexible Pavement Wearing Course Mixture Using Fast Falling Weight Deflectometer. Materials 2018, 11, 611. [Google Scholar] [CrossRef] [Green Version]

- Muslim, N.H.; Mohamed, M.I.; Amin, Z.M.; Shafaghat, A.; Ismail, M.; Keyvanfar, A. Pavement Structural Assessment Using Automated Tools: A Comparative Study. Malays. J. Civ. Eng. 2017, 29. [Google Scholar] [CrossRef]

- Abo-Qudais, S.; Mulqi, M.W. New chemical antistripping additives for bituminous mixtures. J. ASTM Int. 2005, 2, 1–11. [Google Scholar] [CrossRef]

- Hafeez, I.; Kamal, M.; Mirza, M.; Bilal, S. Laboratory fatigue performance evaluation of different field laid asphalt mixtures. Constr. Build. Mater. 2013, 44, 792–797. [Google Scholar] [CrossRef]

- Tayfur, S.; Ozen, H.; Aksoy, A. Investigation of rutting performance of asphalt mixtures containing polymer modifiers. Constr. Build. Mater. 2007, 21, 328–337. [Google Scholar] [CrossRef]

- Al-Malack, M.H.; Abdullah, G.M.; Al-Amoudi, O.S.B.; Bukhari, A.A. Stabilization of indigenous Saudi Arabian soils using fuel oil flyash. J. King Saud Univ. Eng. Sci. 2016, 28, 165–173. [Google Scholar] [CrossRef] [Green Version]

- Asi, I.M. Stabilization of Sebkha Soil using Foamed Asphalt. J. Mater. Civ. Eng. 2001, 13, 325–331. [Google Scholar] [CrossRef]

- Wahhab, H.I.A.-A.; Baig, M.G.; Mahmoud, I.A.; Kattan, H.M. Study of road bases construction in Saudi Arabia using foam asphalt. Constr. Build. Mater. 2012, 26, 113–121. [Google Scholar] [CrossRef]

- Abdullah, G.M.; Wahhab, H.I.A.-A. Evaluation of foamed sulfur asphalt stabilized soils for road applications. Constr. Build. Mater. 2015, 88, 149–158. [Google Scholar] [CrossRef]

- Aiban, S.A.; Siddiqi, Z.U.; Al-Amoudi, B.; Al-Ahmadi, H.M.; Asi, I.M. Effect of geotextiles on the load-carrying capacity and deformation characteristics of sabkha soil. Geosynth. Int. 2006, 13, 98–110. [Google Scholar] [CrossRef]

- Aiban, S.; Al-Ahmadi, H.; Asi, I.; Siddique, Z.; Al-Amoudi, O. Effect of geotextile and cement on the performance of sabkha subgrade. Build. Environ. 2006, 41, 807–820. [Google Scholar] [CrossRef]

- Al-Amoudi; Baghabra, O.S.; Khaqan, K.; Al-Kahtani; Saban, N. Stabilization of a Saudi calcareous marl soil. Constr. Build. Mater. 2010, 24, 1848–1854. [Google Scholar] [CrossRef]

- Shawabkeh, R.; Khan, M.J.; Al-Juhani, A.A.; Wahhab, H.I.A.-A.; Hussein, I.A. Enhancement of surface properties of oil fly ash by chemical treatment. Appl. Surf. Sci. 2011, 258, 1643–1650. [Google Scholar] [CrossRef]

- Parvez, M.A.; Wahhab, H.I.A.-A.; Shawabkeh, R.A.; Hussein, I.A. Asphalt modification using acid treated waste oil fly ash. Constr. Build. Mater. 2014, 70, 201–209. [Google Scholar] [CrossRef]

- Wahhab, H.I.A.-A.; Hussein, I.A.; Parvez, M.; Shawabkeh, R.A. Use of modified oil fly ash to enhance asphalt concrete performance. Mater. Struct. 2015, 48, 3231–3240. [Google Scholar] [CrossRef]

- Bertollo, S.; Bernucci, L.B.; Fernandes, J.L.; Leite, L.M. Mechanical properties of asphalt mixtures using recycled tire rubber produced in Brazil–A laboratory evaluation. In Proceedings of the Washington: S.n. In: 83rd TRB Annual Meeting, Washington, DC, USA, 11–12 January 2004. [Google Scholar]

- Potgieter, C. Bitumen Rubber Asphalt in South Africa: Conventional Techniques. In Proceedings of the 3rd Eurasphalt and Eurobitume Congress, Vienna, Austria, 12–14 May 2004. [Google Scholar]

- Lo Presti, D. Recycled Tyre Rubber Modified Bitumens for road asphalt mixtures: A literature review. Constr. Build. Mater. 2013, 49, 863–881. [Google Scholar] [CrossRef]

- Anwar Parvez, M.; Al-Mehthel, M.; Al-Abdul Wahhab, H.I.; Hussein, I.A. Utilization of sulfur and crumb rubber in asphalt modification. J. Appl. Polym. Sci. 2014, 131, 40046. [Google Scholar] [CrossRef]

- Khan, I.M.; Kabir, S.; Alhussain, M.A.; Almansoor, F.F. Asphalt design using recycled plastic and crumb-rubber waste for sustainable pavement construction. Procedia Eng. 2016, 145, 1557–1564. [Google Scholar] [CrossRef] [Green Version]

- Sutanto, M.; Bala, N.; Al Zaro, K.; Sunarjono, S. Properties of Crumb Rubber and Latex Modified Asphalt Binders using Superpave Tests. MATEC Web Conf. 2018, 203, 05007. [Google Scholar] [CrossRef] [Green Version]

- Al-Abdul Wahhab, H.I. Effect of Modifiers and Additives on Fatigue Behavior of Asphalt Concrete Mixes in the Gulf. Int. J. Pavement Res. Technol. 2012, 5, 326–332. Available online: http://www.ijprt.org.tw/reader/pdf.php?id=255 (accessed on 10 April 2021).

- Gu, L.; Ozbakkaloglu, T. Use of recycled plastics in concrete: A critical review. Waste Manag. 2016, 51, 19–42. [Google Scholar] [CrossRef]

- Singh, N.; Hui, D.; Singh, R.; Ahuja, I.; Feo, L.; Fraternali, F. Recycling of plastic solid waste: A state of art review and future applications. Compos. Part B Eng. 2017, 115, 409–422. [Google Scholar] [CrossRef]

- Hassani, A.; Ganjidoust, H.; Maghanaki, A.A. Use of plastic waste (poly-ethylene terephthalate) in asphalt concrete mixture as aggregate replacement. Waste Manag. Res. 2005, 23, 322–327. [Google Scholar] [CrossRef] [PubMed]

- Ahmadinia, E.; Zargar, M.; Karim, M.R.; Abdelaziz, M.; Shafigh, P. Using waste plastic bottles as additive for stone mastic asphalt. Mater. Des. 2011, 32, 4844–4849. [Google Scholar] [CrossRef]

- Al-Sabaeei, A.; Yussof, N.I.M.; Napiah, M.; Sutanto, M. A Review of Using Natural Rubber in the Modification Of Bitumen and Asphalt Mixtures Used for Road Construction. J. Teknol. 2019, 81, 81–88. [Google Scholar] [CrossRef]

- Al-Sabaeei, A.; Muniandy, R.; Hassim, S.; Napiah, M. Effect of Tire Crumb Rubber (TCR) on the Gyratory Compaction of Stone Mastic Asphalt. Int. J. Civ. Eng. Technol. 2018, 9, 1138–1150. [Google Scholar]

- Roffe, J.C. Salviacim-Introducing the Pavment; Jean Lefebvre Enterprise: Paris, France, 1989. [Google Scholar]

- Ahlrich, R.C.; Anderton, G.L. Resin Modified Pavement in Airfield Applications. In Proceedings of the Airport Pavement Innovations. Theory to Practice: Proceedings of Conference, Vicksburg, MS, USA, 8–20 September 1993. [Google Scholar]

- Van de Ven, M.; Molenaar, A. Mechanical Characterization of Combi-layer. Asph. Paving Technol. 2004, 73, 1–22. [Google Scholar]

- Anderton, G.L. Engineering Properties of Resin Modified Pavement (RMP) for Mechanistic Design; Engineer Research and Development Center Vicksburg MS Geotechnical Lab: Vicksburg, MS, USA, 2000. [Google Scholar]

- British Board of Agrement (BBA). Hardicrete Heavy Duty Surfacing, Agrement Certificate No 88/1969; British Board of Agrement (BBA): Watford, UK, 1994. [Google Scholar]

- British Board of Agrement (BBA). Worthycim Heavy Duty Paving, Agrement Certificate No 87/1900; British Board of Agrement (BBA): Watford, UK, 1996. [Google Scholar]

- ApS, C. A Jointless Wearing Course with High Strength for High Loads. Available online: http://www.confalt.com/confaltr.html (accessed on 15 December 2018).

- Oliveira, J.R. Grouted Macadam: Material Characterisation for Pavement Design. Ph.D. Thesis, University of Nottingham, Nottingham, UK, 2006. [Google Scholar]

- Setyawan, A. Asessing the compressive strength properties of semi-flexible pavements. Proc. Eng. 2013, 54, 863–874. [Google Scholar] [CrossRef] [Green Version]

- Karami, M. Application of the cementitious grouts on stability and durability of semi flexible bituminous mixtures. AIP Conf. Proc. 2017, 1903, 020012. [Google Scholar] [CrossRef]

- Public Works Department of Malaysia (JKR). Bituminous Road Surfacing in High Stress Areas: Malaysian Experience; Public Works Department of Malaysia: Kuala Lumpur, Malaysia, 2002.

- ASTM-C293. Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Center-Point Loading); ASTM: Philadelphia, PA, USA, 2001. [Google Scholar]

- Du, Y.; Chen, J.; Han, Z.; Liu, W. A review on solutions for improving rutting resistance of asphalt pavement and test methods. Constr. Build. Mater. 2018, 168, 893–905. [Google Scholar] [CrossRef]

- Afonso, M.L.; Dinis-Almeida, M.; Pereira-de-Oliveira, L.A.; Castro-Gomes, J.; Zoorob, S.E. Development of a semi-flexible heavy duty pavement surfacing incorporating recycled and waste aggregates—Preliminary study. Constr. Build. Mater. 2016, 102, 155–161. [Google Scholar] [CrossRef]

- Sundahl, J.; Hede, J. Semi-flexible Materials for Heavy-Duty Pavements. In Proceedings of Proceedings of the 6th International Conference on the Bearing Capacity of Roads and Airfields, Lisbon, Portugal, 24–26 June 2002. [Google Scholar]

- Corradini, A.; Cerni, G.; D’Alessandro, A.; Ubertini, F. Improved understanding of grouted mixture fatigue behavior under indirect tensile test configuration. Constr. Build. Mater. 2017, 155, 910–918. [Google Scholar] [CrossRef]

- Zhang, J.; Cai, J.; Pei, J.; Li, R.; Chen, X. Formulation and performance comparison of grouting materials for semi-flexible pavement. Constr. Build. Mater. 2016, 115, 582–592. [Google Scholar] [CrossRef]

- Setyawan, A. Development of Semi-Flexible Heavy-Duty Pavements. Ph.D. Thesis, University of Leeds, Leeds, UK, 2003. [Google Scholar]

- Saboo, N.; Ranjeesh, R.; Gupta, A.; Suresh, M. Development of hierarchical ranking strategy for the asphalt skeleton in semi-flexible pavement. Constr. Build. Mater. 2019, 201, 149–158. [Google Scholar] [CrossRef]

- Khan, M.I.; Sutanto, M.H.; Napiah, M.B.; Zoorob, S.E.; Al-Sabaeei, A.M.; Rafiq, W.; Ali, M.; Memon, A.M. Investigating the mechanical properties and fuel spillage resistance of semi-flexible pavement surfacing containing irradiated waste PET based grouts. Constr. Build. Mater. 2021, 304, 124641. [Google Scholar] [CrossRef]

- Ricci, R. Laboratory Study of Grouted Macadams Impregnated with Mine Waste Geopolymeric Binder; University Di Bologna: Bologna, Italy, 2012. [Google Scholar]

- Hou, S.; Xu, T.; Huang, K. Aggregate Gradation Influence on Grouting Results and Mix Design of Asphalt Mixture Skeleton for Semi-Flexible Pavement. J. Test. Eval. 2017, 45, 591–600. [Google Scholar] [CrossRef]

- Setiawan, A. Design and properties of hot mixture porous asphalt for semi-flexible pavement applications. Media Tek. Sipil 2009, 5, 41–46. [Google Scholar]

- REAM. Road Engineering Association of Malaysia, "Speciication of Semi-Rigid Wearing Course"; Road Engineering Association of Malaysia (REAM): Shah Alam, Malaysia, 2007. [Google Scholar]

- Fediuk, R.S.; Smoliakov, A.K.; Timokhin, R.A.; Batarshin, V.O.; Yevdokimova, Y.G. Using thermal power plants waste for building materials. IOP Conf. Ser. Earth Environ. Sci. 2018, 87, 092010. [Google Scholar] [CrossRef] [Green Version]

- Husain, N.M.; Mahmud, H.; Karim, M.R.; Hamid, N. Effects of aggregate gradations on properties of grouted Macadam composite pavement. In Proceedings of the 2010 2nd International Conference on Chemical, Biological and Environmental Engineering, Cairo, Egypt, 2–4 November 2010; IEEE: Piscataway Township, NJ, USA; pp. 128–131. [Google Scholar]

- Husain, N.M.; Karim, M.R.; Mahmud, H.B.; Koting, S. Effects of Aggregate Gradation on the Physical Properties of Semiflexible Pavement. Adv. Mater. Sci Eng. 2014, 2014, 529305. [Google Scholar] [CrossRef] [Green Version]

- Plug, C.P.; de Bondt, A.H.; van der Woerd, B.J.; Steensma, G. Improved Performance Grouted Macadams—High Performance Applications of Grouted Macadam; Research & Development Wegbouwkundige Werkdagen: Doorwerth, The Netherlands, 2006. [Google Scholar]

- Yang, B.; Weng, X. The influence on the durability of semi-flexible airport pavement materials to cyclic wheel load test. Constr. Build. Mater. 2015, 98, 171–175. [Google Scholar] [CrossRef]

- Luo, S.; Yang, X.; Zhong, K.; Yin, J. Open-graded asphalt concrete grouted by latex modified cement mortar. Road Mater. Pavement Des. 2018, 21, 1–17. [Google Scholar] [CrossRef]

- Hassani, A.; Taghipoor, M.; Karimi, M.M. A state of the art of semi-flexible pavements: Introduction, design, and performance. Constr. Build. Mater. 2020, 253, 119196. [Google Scholar] [CrossRef]

- An, S.; Ai, C.; Ren, D.; Rahman, A.; Qiu, Y. Laboratory and Field Evaluation of a Novel Cement Grout Asphalt Composite. J. Mater. Civil. Eng. 2018, 30, 04018179. [Google Scholar] [CrossRef]

- Vavrik, W.R.; Pine, W.J.; Huber, G.; Carpenter, S.H.; Bailey, R. The bailey method of gradation evaluation: The influence of aggregate gradation and packing characteristics on voids in the mineral aggregate (with discussion). J. Assoc. Asph. Paving Technol. 2001, 70. [Google Scholar]

- Menninga, H. Grouted Macadams, Material Research (Combination Layers, An Exploratory Material Research on combination Layers), TU Delft; Traffic Engineering Section: Delft, The Netherlands, 2002.

- Densit-a/s. Densiphalt Handbook; Densit-a/s: Aalborg, Denmark, 2000. [Google Scholar]

- Makul, N.; Fediuk, R.; Amran, M.; Zeyad, A.M.; Murali, G.; Vatin, N.; Klyuev, S.; Ozbakkaloglu, T.; Vasilev, Y. Use of Recycled Concrete Aggregates in Production of Green Cement-Based Concrete Composites: A Review. Crystals 2021, 11, 232. [Google Scholar] [CrossRef]

- Ahlrich, R.C.; Anderton, G.L. Construction and Evaluation of Resin Modified Pavement; Technical Report: GL-91-13; Army Engineer Waterways Experiment Station Vicksburg MS Geotechnical Lab. 1991; Available online: https://erdc-library.erdc.dren.mil/jspui/bitstream/11681/12765/1/TR-GL-91-13.pdf (accessed on 30 December 2018).

- Pei, J.; Cai, J.; Zou, D.; Zhang, J.; Li, R.; Chen, X.; Jin, L. Design and performance validation of high-performance cement paste as a grouting material for semi-flexible pavement. Constr. Build. Mater. 2016, 126, 206–217. [Google Scholar] [CrossRef]

- Bang, J.W.; Lee, B.J.; Kim, Y.Y. Development of a Semirigid Pavement Incorporating Ultrarapid Hardening Cement and Chemical Admixtures for Cement Grouts. Adv. Mater. Sci Eng. 2017, 2017, 9. [Google Scholar] [CrossRef] [Green Version]

- Wang, D.; Liang, X.; Jiang, C.; Pan, Y. Impact analysis of Carboxyl Latex on the performance of semi-flexible pavement using warm-mix technology. Constr. Build. Mater. 2018, 179, 566–575. [Google Scholar] [CrossRef]

- Martínez-Barrera, G.; Menchaca-Campos, C.; Hernández-López, S.; Vigueras-Santiago, E.; Brostow, W. Concrete Reinforced with Irradiated Nylon Fibers. J. Mater. Res. 2006, 21, 484–491. [Google Scholar] [CrossRef]

- Ahmedzade, P.; Fainleib, A.; Günay, T.; Starostenko, O.; Kovalinska, T. Effect of gamma-irradiated recycled low-density polyethylene on the high-and low-temperature properties of Bitumen. Int. J. Polym. Sci. 2013, 2013, 9. [Google Scholar] [CrossRef]

- Huang, C.; Hong, J.X.; Lin, J.T.; Deng, C.; Li, L. Utilization of waste rubber powder in semi-flexible pavement. Key Eng. Mater. 2014, 599, 361–367. [Google Scholar] [CrossRef]

- Khan, M.I.; Huat, H.Y.; Dun, M.H.b.M.; Sutanto, M.H.; Jarghouyeh, E.N.; Zoorob, S.E. Effect of Irradiated and Non-Irradiated Waste PET Based Cementitious Grouts on Flexural Strength of Semi-Flexible Pavement. Materials 2019, 12, 4133. [Google Scholar] [CrossRef] [Green Version]

- Vijaya, S.S.A.; Karim, M.R.; Mahmud, H.; Ishak, N.F. Influence of Superplasticiser on Properties of Cementitious Grout Used in Semi-Flexible Pavement. In Proceedings of the Eastern Asia Society for Transportation Studies Volume 7, The 8th International Conference of Eastern Asia Society for Transportation Studies, Surabaya, Indonesia, 1 January 2009; p. 296. [Google Scholar]

- Hu, S.; Huang, S.; Ding, Q.; Zhang, R. Study on the Cementitious Mortar for Semi-Flexible Pavement. In Proceedings of the 1st International Conference on Microstructure Related Durability of Cementitious Composites, Nanjing, China, 13–15 October 2008. [Google Scholar]

- Fang, B.; Xu, T.; Shi, S. Laboratory study on cement slurry formulation and its strength mechanism for semi-flexible pavement. J. Test. Eval. 2016, 44, 907–913. [Google Scholar] [CrossRef]

- Ding, Q.; Zhao, M.; Shen, F.; Zhang, X. Mechanical behavior and failure mechanism of recycled semi-flexible pavement material. J. Wuhan Univ. Technol. -Mater. Sci. 2015, 30, 981–988. [Google Scholar] [CrossRef]

- Husain, N.M.; Ismail, N.N.; Ismail, K.M.; Syamsunur, D.; Taib, M.M. Development of high workability grout on semi rigid wearing course. Conf. Ser. Mater. Sci. Eng. 2019, 512, 012033. [Google Scholar] [CrossRef]

- Koting, S.; Mahmud, H.; Karim, M.R. Influence of superplasticizer type and dosage on the workability and strength of cementitious grout for semi-flexible pavement application. J. East. Asia Soc. Transp. Stud. 2007, 7, 2156–2167. [Google Scholar]

- Public Works Department. Description of Workmanship and Materials (Semi-Rigid Pavement), Section E; City Hall Kuala Lumpur: Kuala Lumpur, Malaysia, 2003. [Google Scholar]

- Wang, Y.J.; Guo, C.Y.; Tian, Y.F.; Wang, J.J. Design of Mix Proportion of Cement Mortar with High-Performance Composite Semi-Flexible Pavement. Adv. Mater. Res. 2013, 641–642, 342–345. [Google Scholar] [CrossRef]

- Cai, J.; Pei, J.; Luo, Q.; Zhang, J.; Li, R.; Chen, X. Comprehensive service properties evaluation of composite grouting materials with high-performance cement paste for semi-flexible pavement. Constr. Build. Mater. 2017, 153, 544–556. [Google Scholar] [CrossRef]

- Khan, M.I.; Sutanto, M.H.; Napiah, M.B.; Khan, K.; Rafiq, W. Design optimization and statistical modeling of cementitious grout containing irradiated plastic waste and silica fume using response surface methodology. Constr. Build. Mater. 2021, 271, 121504. [Google Scholar] [CrossRef]

- Khan, M.I.; Sutanto, M.H.; Napiah, M.B.; Zoorob, S.E.; Yusoff, N.I.M.; Usman, A.; Memon, A.M. Irradiated polyethylene terephthalate and fly ash based grouts for semi-flexible pavement: Design and optimisation using response surface methodology. Int. J. Pavement Eng. 2020, 1–16. [Google Scholar] [CrossRef]

- Khan, M.I.; Sutanto, M.H.; Napiah, M.B.; Zoorob, S.E. Cementitious Grouts Containing Irradiated Waste Polyethylene Terephthalate. In Cement Industry; Saleh, H.M., Ed.; IntechOpen: London, UK, 2020. [Google Scholar]

- Hassan, K.; Setyawan, A.; Zoorob, S. Effect of cementitious grouts on the properties of semi-flexible bituminous pavements. In Proceedings of the 4th European Symposium on Performance of Bituminous and Hydraulic Materials In Pavements, Bitmat 4, Nottingham, UK, 11–12 April 2002; pp. 113–120. [Google Scholar]

- Anderton, G.L. User’s Guide: Resin Modified Pavement; No. WES/MP/GL-96-7; Army Engineer Waterways Experiment Station Vicksburg MS Geotechnical Lab. 1996. Available online: https://apps.dtic.mil/sti/pdfs/ADA307526.pdf (accessed on 20 December 2018).

- Boundy, R. Development of a Resin/Cement grouted coated Macadam Surfacing Material. Master’s Thesis, University of Nottingham, Nottingham, UK, 1979. [Google Scholar]

- Alsadey, S. Effects of super plasticizing and retarding admixtures on properties of concrete. In Proceedings of the International Conference on Innovations in Engineering and Technology, Bangkok, Thailand, 25–26 December 2013; pp. 271–274. [Google Scholar]

- Khan, M.I.; Sutanto, M.H.; Khan, K.; Iqbal, M.; Napiah, M.B.; Zoorob, S.E.; Klemeš, J.J.; Bokhari, A.; Rafiq, W. Effective use of recycled waste PET in cementitious grouts for developing sustainable semi-flexible pavement surfacing using artificial neural network (ANN). J. Clean. Prod. 2022, 340, 130840. [Google Scholar] [CrossRef]

- Anagnostopoulos, C.A. Effect of different superplasticisers on the physical and mechanical properties of cement grouts. Constr. Build. Mater. 2014, 50, 162–168. [Google Scholar] [CrossRef]

- Imran, K.M.; Sutanto, M.H.; Napiah, M.B.; Zahid, M.; Usman, A. Optimization of Cementitious Grouts for Semi-Flexible Pavement Surfaces Using Response Surface Methodology. IOP Conf. Ser. Earth Environ. Sci. 2020, 498, 012004. [Google Scholar] [CrossRef]

- Koting, S.; Karim, M.R.; Mahmud, H.; Mashaan, N.S.; Ibrahim, M.R.; Katman, H.; Husain, N.M. Effects of using silica fume and polycarboxylate-type superplasticizer on physical properties of cementitious grout mixtures for semiflexible pavement surfacing. Sci. World J. 2014, 2014, 7. [Google Scholar] [CrossRef] [Green Version]

- Zhang, W.; Shen, S.; Goodwin, R.D.; Wang, D.; Zhong, J. Performance Characterization of Semi-Flexible Composite Mixture. Materials 2020, 13, 342. [Google Scholar] [CrossRef] [Green Version]

- Cai, X.; Yang, J.; Chen, X.; Zhang, J.; Zhang, H. Interlocking property evaluation of dual skeleton in semi-flexible pavement material by micromechanical model and X-ray computed tomography. Constr. Build. Mater. 2020, 254, 118934. [Google Scholar] [CrossRef]

- Cai, X.; Zhang, J.; Zhang, H.; Yao, Z.; Chen, X.; Yang, J. Identification of microstructural characteristics in semi-flexible pavement material using micromechanics and nano-techniques. Constr. Build. Mater. 2020, 246, 118426. [Google Scholar] [CrossRef]

- Zhong, K.; Sun, M.; Zhang, M.; Qin, Y.; Li, Y. Interfacial and mechanical performance of grouted open-graded asphalt concrete with latex modified cement mortar. Constr. Build. Mater. 2020, 234, 117394. [Google Scholar] [CrossRef]

- Xu, Y.; Jiang, Y.; Xue, J.; Tong, X.; Cheng, Y. High-Performance Semi-Flexible Pavement Coating Material with the Microscopic Interface Optimization. Coatings 2020, 10, 268. [Google Scholar] [CrossRef] [Green Version]

- Zarei, S.; Ouyang, J.; Yang, W.; Zhao, Y. Experimental analysis of semi-flexible pavement by using an appropriate cement asphalt emulsion paste. Constr. Build. Mater. 2020, 230, 116994. [Google Scholar] [CrossRef]

- Saboo, N.; Khalpada, V.; Sahu, P.K.; Radhakrishnan, R.; Gupta, A. Optimal proportioning of grout constituents using mathematical programming for semi flexible pavement. Int. J. Pavement Res. Technol. 2019, 12, 297–306. [Google Scholar] [CrossRef]

- Zhang, H.; Liang, S.; Ma, Y.; Fu, X. Study on the mechanical performance and application of the composite cement–asphalt mixture. Int. J. Pavement Eng. 2019, 20, 44–52. [Google Scholar] [CrossRef]

- Al-Qadi, I.L.; Gouru, H.; Weyers, R. Asphalt Portland cement concrete composite: Laboratory evaluation. J. Transp. Eng. 1994, 120, 94–108. [Google Scholar] [CrossRef]

- Shukla, M.; Gottumukkala, B.; Nagabhushana, M.N.; Chandra, S.; Shaw, A.; Das, S. Design and evaluation of mechanical properties of cement grouted bituminous mixes (CGBM). Constr. Build. Mater. 2021, 269, 121805. [Google Scholar] [CrossRef]

- Sunil, S.; Varuna, M.; Nagakumar, M.S. Performance evaluation of semi rigid pavement mix. Mater. Today: Proc. 2020. [Google Scholar] [CrossRef]

- Bharath, G.; Shukla, M.; Nagabushana, M.; Chandra, S.; Shaw, A. Laboratory and field evaluation of cement grouted bituminous mixes. Road Mater. Pavement Des. 2019, 1–19. [Google Scholar] [CrossRef]

- Hamzani; Munirwansyah; Hasan, M.; Sugiarto, S. Determining the properties of semi-flexible pavement using waste tire rubber powder and natural zeolite. Constr. Build. Mater. 2021, 266, 121199. [Google Scholar] [CrossRef]

- BS-EN-12697-26; Bituminous Mixtures–Test Methods for Hot Mix Asphalt–Part 26: Stiffness. The British Standards Institution: London, UK, 2004.

- Oliveira, J.; Sangiorgi, C.; Fattorini, G.; Zoorob, S. Investigating the Fatigue Performance of Grouted Macadams; Institution of Civil Engineers-Transport: London, UK; pp. 115–123.

- Di Benedetto, H.; de La Roche, C.; Baaj, H.; Pronk, A.; Lundström, R. Fatigue of bituminous mixtures. Mater. Struct. 2004, 37, 202–216. [Google Scholar] [CrossRef]

- Tayebali, A.A.; Deacon, J.A.; Coplantz, J.S.; Monismith, C.L. Modeling fatigue response of asphalt-aggregate mixtures. Asph. Paving Technol. 1993, 62, 385. [Google Scholar]

- NCHRP-REPORT-673; A Manual for Design of Hot Mix Asphalt with Commentary. Transportation Research Board: Washington, DC, USA, 2011; Volume 673.

- AASHTO. Standard Method of Test for Determining Rutting Susceptibility of Hot Mix. Asphalt (HMA) Using the Asphalt Pavement Analyzer (APA); AASHTO: Washington, DC, USA, 2006. [Google Scholar]

- A.T. 324; Standard Method of Test for Hamburg Wheel-Track Testing of Compacted Hot Mix Asphalt (HMA). Aashto: Washington, DC, USA, 2011.

- Cai, X.; Zhang, H.; Zhang, J.; Chen, X.; Yang, J.; Hong, J. Investigation on reinforcing mechanisms of semi-flexible pavement material through micromechanical model. Constr. Build. Mater. 2019, 198, 732–741. [Google Scholar] [CrossRef]

- Tan, H.; Xiong, Z.; Gong, M.; Chen, J.; Hong, J. Investigation on the Influences of Curing Time on the Cracking Resistance of Semiflexible Pavement Mixture. Adv. Mater. Sci. Eng. 2021, 2021, 8855565. [Google Scholar] [CrossRef]

| Reference | Country | Brand Name | Purpose of Construction |

|---|---|---|---|

| [33,35] | France | Salviacim | To provide resistance against waste oils, fuels, and abrasion |

| [36] | United States | Resin-Modified Pavement (RMP) | Airport taxiways, aprons, parking lots |

| [37,38,39] | Europe | Hardicrete Heavy Duty Surfacing. Worthycim Heavy Duty Paving. Confalt | Heavy-duty surface construction |

| [40] | Japan | RP-Pavement (Rut Proof Pavement) | Heavy-duty surface construction |

| [35] | France | combi-layer | Heavy-duty surface construction |

| Gradation Type | Modulus of Elasticity (MPa) | Compressive Strength (MPa) |

|---|---|---|

| G1 | 18,000 | 6.09 |

| G2 | 17,600 | 5.10 |

| G3 | 17,200 | 4.70 |

| Sieve Size (mm) | Passing Percentage | ||||||

|---|---|---|---|---|---|---|---|

| Boundy (1979) Mix 1 | BSI (1987) Mix 2 | Anderton (2000) Mix 3 | Densiphalt Type 8 Mix 4 | Densiphalt Type 12 Mix 5 | Setyawan (2003) Mix 6 | Hou (2017) Mix 7 | |

| 19 | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| 12.5 | 95 | 100 | 62.8 | 100 | 100 | 100 | |

| 9.5 | 35 | 92.5 | 51.5 | 95 | 95 | 90 | 44 |

| 6.3 | 10 | 17.5 | 35 | 30 | 12 | 38 | |

| 4.75 | 6 | 5 | 17.6 | 20 | 10 | 8 | 10 |

| 2.36 | 3 | 1 | 11.1 | 10 | 8 | 5 | |

| 1.18 | 7.3 | 5 | 5 | 3 | |||

| 0.6 | 6.6 | 2 | |||||

| 0.3 | 2.4 | ||||||

| 0.15 | 1.2 | ||||||

| 0.075 | 1.1 | ||||||

| Air Voids | 31–32% | 33–34% | 27–31% | 33–36% | 32–35% | 29–32% | 30–32% |

| Binder Content range, % (Optimum, %) | 2–3.5% (4%) | 2–4% (3.5%) | 2–4.5% (3.5%) | 2–4.5% (4%) | 2–4.5% (4%) | 2–4% (4%) | 2–3.5% (3.5%) |

| ITS (kPa) | 110.46 | 113.35 | 116.52 | 118.83 | 114.42 | 123.32 | 109.85 |

| S. No | Properties of Mix | Acceptable Criteria | Initial Selection of Mixes | Final Selection |

|---|---|---|---|---|

| 1 | Draindown test | <0.3% | Mix 1, 3.5% Mix 1, 4.0% Mix 2, 3.5% Mix 3, 4.0% Mix 3, 4.5% Mix 4, 4.0% Mix 4, 4.5% Mix 5, 4.0% | Densiphalt type 12 (Mix 5) with 4.0% bitumen Densiphalt type 12 (Mix 5) with 4.5% bitumen BSI (Mix 2) with 4.0% bitumen |

| 2 | Air Voids | 25% to 35% | ||

| 3 | Voids in coarse aggregate (VCA) ratio | <1% | ||

| 4 | Permeability | >100 m/day | ||

| 5 | Cantabro loss | <50% | ||

| 6 | Indirect Tensile Stiffness (ITS) | N/A |

| Cement Paste Compositions and Additives | Range of Variables Used | Recommended Values | Evaluated Properties of Grouts |

|---|---|---|---|

| Water–cement ratio | 0.51–0.57 | 0.55–0.57 | Fluidity Ductility Drying shrinkage Compressive and Flexural strength |

| TH-928 polycarboxylate superplasticizer | 0–1.0 (%) | 0.5–1.0 (%) | |

| UEA expansion admixture | 0–12 (%) | 10% | |

| ZY-99 Triterpenoid saponins air-entraining agent | 0–0.012 (%) | 0.008% |

| HPCP Composition/Type | H1 | H2 | H3 |

|---|---|---|---|

| w/c ratio | 0.56 | 0.56 | 0.56 |

| TH-928 polycarboxylate superplasticizer | 0.5% | 0.5% | 1.0% |

| UEA expansion admixture | 10% | 10% | 10% |

| ZY-99 Triterpenoid saponins air-entraining agent | 0.008% | 0.0% | 0.008% |

| Type of Cement Grout | Manufacturer Name/Country | Compositions | Properties | Application | Remarks |

|---|---|---|---|---|---|

| Densiphalt mortar | Densit®/UK | Composition Not Known Water = 16.2% by weight of powder | Compressive Strength 1-day = 50 MPa 7-day = 80 MPa 28-day = 110 MPa Density = 2200–2250 Kg/m3 Setting time = 7–9 h | Warehouses, distribution centers, goods terminals, production floors, Harbors, container terminals, warehouse facilities, Bus stops and terminals, roads for heavy traffic, road crossings, Aircraft aprons, taxiways, refueling pads, taxi-holding positions | These are the few commercially available cement grouts for semi-flexible pavement applications. Most of these grouts did not provide the compositions of cement grouts. Few grouts are provided with technical requirement. Among these grouts, nobody used waste PET and FA in the formulation of cement grouts. |

| DuraTough | Lafarge/Canada | Composition Not Known | Standard grout: Compressive Strength 7-day = 35 MPa 28-day = 60 MPa High-Strength grout: Compressive Strength 7-day = 60 MPa 28-day = 100 MPa Flexural Strength 28-day = 2.5–3.0 MPA | Bus stops and transit stations, turning lanes and intersections, high-volume and heavy-load roadways, tunnels and hard-to-access areas Apron areas, taxiways, fueling/deicing areas, hangar bays, loading bays | |

| Hardicrete | Miles Macadam Ltd./UK | Composition not known | No Specifications | Bus stations, waste sites and transfer stations, ports, airfields, and industrial facilities | |

| ULTICRETE | TARMAC A CRH company/UK | Composition not known | No Specifications | aircraft refueling areas, container ports, and distribution centers. | |

| CONFALT® mortar | Contec ApS/ Denmark | Portland Cement = 45–75% Silica sand = 25–45% Iron Oxide = 0–5% Amorphous Silica = 5–25% | Storage Facilities, Industrial Flooring, Cross Sections, Container Terminals, Airports, Multistorey Parking |

| Composition of Grouts | Strength Properties of Cement Grouts | Concluding Remarks | References |

|---|---|---|---|

| 0.50 w/c ratio, 23% fly ash and 2% superplasticizer | Not determined | Semi-flexible mixtures compared to HMA

| [97] |

| 0.31 w/c ratio, pre-designed grout (JGM-301) | Compressive Strength: 34.5 MPa at 3 d curing and 42.3 MPa at 28 d curing | It was recommended that semi-flexible pavement surfacings with this grout could be used for heavily loaded pavements. | [98,99] |

| 0.72 w/c ratio, 20% sand, 10% filler and 0–2.4% Latex | Compressive Strength: 21.6 MPa to 24.1 MPa compressive strength and 1.65 MPa to 3.54 MPa flexural strength at 7d curing | Latex in cement mortar has a positive effect on compressive and flexural strength, while negatively impacting fluidity. Semi-flexible mixtures compared to HMA

| [100] |

| Three interface optimizers were used: 0.25 to 0.75% Silane coupling agent, 5 to 15% Carboxyl styrene-butadiene latex, and 5 to 15% Cationic emulsified asphalt | 7-days compressive Strength: (1) 42.98 MPa for OPC (2) 34.65 MPa, 36.85 MPa, 33.61 MPa for Silane coupling agent (3) 25.70 MPa, 29.70 MPa, 26.15 MPa for Carboxyl styrene-butadiene latex (4) 37.79 MPa, 33.82 MPa, 31.53 MPa for Cationic emulsified asphalt | With interface optimizers

| [101] |

| 0.40 w/c ratio, 10% silica fume, 2% Superplasticizer, 0.04% aluminite powder (AP), 0.2% viscosity modifying agent (VMA) ≥ VMA/C, 20–60% Asphalt Emulsion (AE)/cement binder AE/C | 7-days compressive Strength: CP = 26 MPa CAEP20% = 13 MPa CAEP40% = 11.3 MPa CAEP60% = 10.5 MPa 28-days compressive Strength: CP = 28.5 MPa CAEP20% = 19 MPa CAEP40% = 17.8 MPa CAEP60% = 17 MPa |

| [102] |

| 2–4% Naphthalene-based Superplasticizer and 0.4 to 0.6 w/c ratio and 23% Sand (different size) by weight of cement | 7-days compressive Strength: For sand size < 0.6 mm gives maximum of 31.65 MPa compressive strength For sand size < 1.18 mm gives maximum compressive strength of 33.75 MPa For sand size 2.36 mm gives maximum compressive strength of 36.69 MPa | Grouts with 0.54 w/c ratio and 2% SP as optimum combination achieving the compressive strength of 24.25 MPa. | [103] |

| 0.5 to 2% Polycarboxylate Superplasticizer, 0.4 to 0.50 water-to-cement ratio and 23% sand (with different size) | 7-days compressive Strength: 13.15 MPa to 29.10 MPa (for sand size < 0.6 mm) 16.38 MPa to 30.39 MPA (for sand size < 1.18 mm) 18.45 MPa to 31.20 MPA (for sand size < 2.36 mm) | The optimal composition of grout: 0.48 w/c ratio of 0.48, and 1% SP with 23.46 MPa compressive strength of grout | [103] |

| 0.72 water-to-cement ratio, 20% sand, 10% filler, and 1.2 to 2.4% latex powder (LP) | 7-days Compressive Strength: Maximum compressive strength of 24.1 MPa at 1.2% LP and maximum flexure strength at 3.54 MPa at 2.4% LP | Fluidity decreases with increasing latex powder. 1.2% LP has highest compressive strength, whereas maximum flexural strength is achieved at 2.4% LP LP modified semi-flexible mixtures showed improved resistance to high temperature Poor resistance to fatigue and low-temperature cracks compared to HMA | [62] |

| 0.63 w/c ratio, 10% mineral filler, 20% Sand, and 2–12% Carboxyl Latex (CL) | 11.20 to 20.76 MPa of 7-days Compressive Strength and 18.56 to 31.43 MPa of 28-days Compressive Strength 4.95 to 28.74 MPa of 7-days Flexural Strength and 5.74 to 6.49 MPa of 28-days Flexural Strength | The addition of CL causes reduction in compressive strength, while improvement in flexural strength Optimum content of CL obtained was 8%. Rutting, low-temperature cracking, moisture damage and fatigue resistance of modified CL was improved compared with controlled grout | [72] |

| 0.60 water-to-cement and cement/sand ratio of 1/0.5 | 10.40 MPa of 3d compressive strength and 30.7 MPa of 28d compressive strength 3.3 MPa and 7.3 MPa of flexural strength at 3d and 28d curing | Semi-flexible specimens showed better high-temperature performance, improved low-temperature cracking, moisture resistance compared with HMA. | [104] |

| Designations | Description of Gradation | ITS @ 35 °C |

|---|---|---|

| AG1 | NMAS of 19 mm and Mid-point gradation of surface dressing | 1.41 MPa |

| AG2 | NMAS of 13.2 mm and Mid-point gradation of surface dressing | 1.71 MPa |

| AG3 | NMAS of 13.2 mm and Mid-point gradation of OGPC | 1.63 MPa |

| AG4 | NMAS of 13.2 mm and Modified Mid-point gradation of surface dressing | 1.57 MPa |

| AG5 | NMAS of 9.5 mm and Mid-point gradation used by Oliveira | 1.29 MPa |

| AG6 | NMAS of 19 mm and Mid-point gradation of Bituminous Macadam | 0.81 MPa |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khan, M.I.; Sutanto, M.H.; Yusoff, N.I.M.; Zoorob, S.E.; Rafiq, W.; Ali, M.; Fediuk, R.; Vatin, N.I. Cementitious Grouts for Semi-Flexible Pavement Surfaces—A Review. Materials 2022, 15, 5466. https://doi.org/10.3390/ma15155466

Khan MI, Sutanto MH, Yusoff NIM, Zoorob SE, Rafiq W, Ali M, Fediuk R, Vatin NI. Cementitious Grouts for Semi-Flexible Pavement Surfaces—A Review. Materials. 2022; 15(15):5466. https://doi.org/10.3390/ma15155466

Chicago/Turabian StyleKhan, Muhammad Imran, Muslich Hartadi Sutanto, Nur Izzi Md. Yusoff, Salah E. Zoorob, Waqas Rafiq, Mujahid Ali, Roman Fediuk, and Nikolai Ivanovich Vatin. 2022. "Cementitious Grouts for Semi-Flexible Pavement Surfaces—A Review" Materials 15, no. 15: 5466. https://doi.org/10.3390/ma15155466

APA StyleKhan, M. I., Sutanto, M. H., Yusoff, N. I. M., Zoorob, S. E., Rafiq, W., Ali, M., Fediuk, R., & Vatin, N. I. (2022). Cementitious Grouts for Semi-Flexible Pavement Surfaces—A Review. Materials, 15(15), 5466. https://doi.org/10.3390/ma15155466