Microwave Absorption Properties of Carbon Black-Carbonyl Iron/Polylactic Acid Composite Filament for Fused Deposition Modeling

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

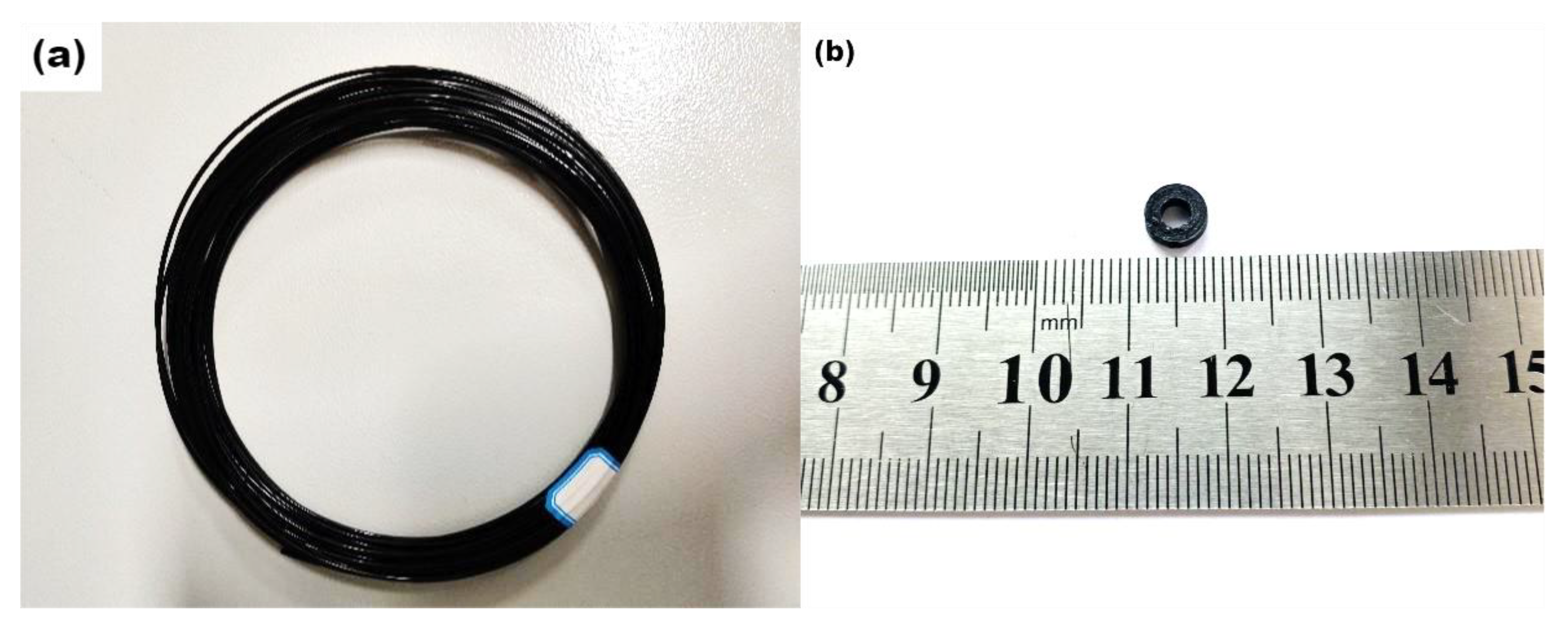

2.2. CB-CIP/PLA Composites Preparation

2.3. Experimental Design

2.4. Test and Characterization

3. Results and Discussion

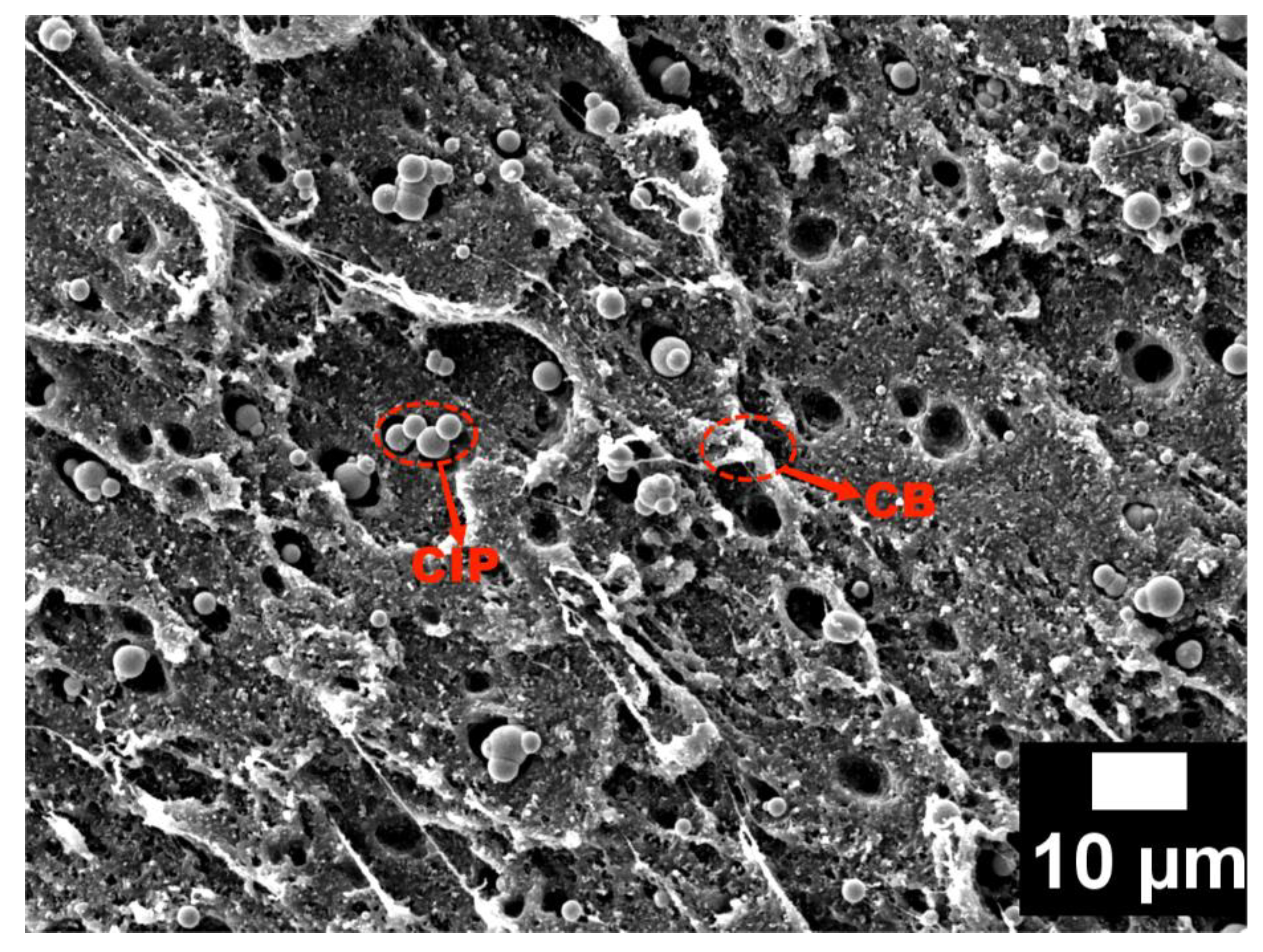

3.1. Micromorphology of Absorbent

3.2. Influence of Absorbent Content on the Electromagnetic Parameters of the Composites

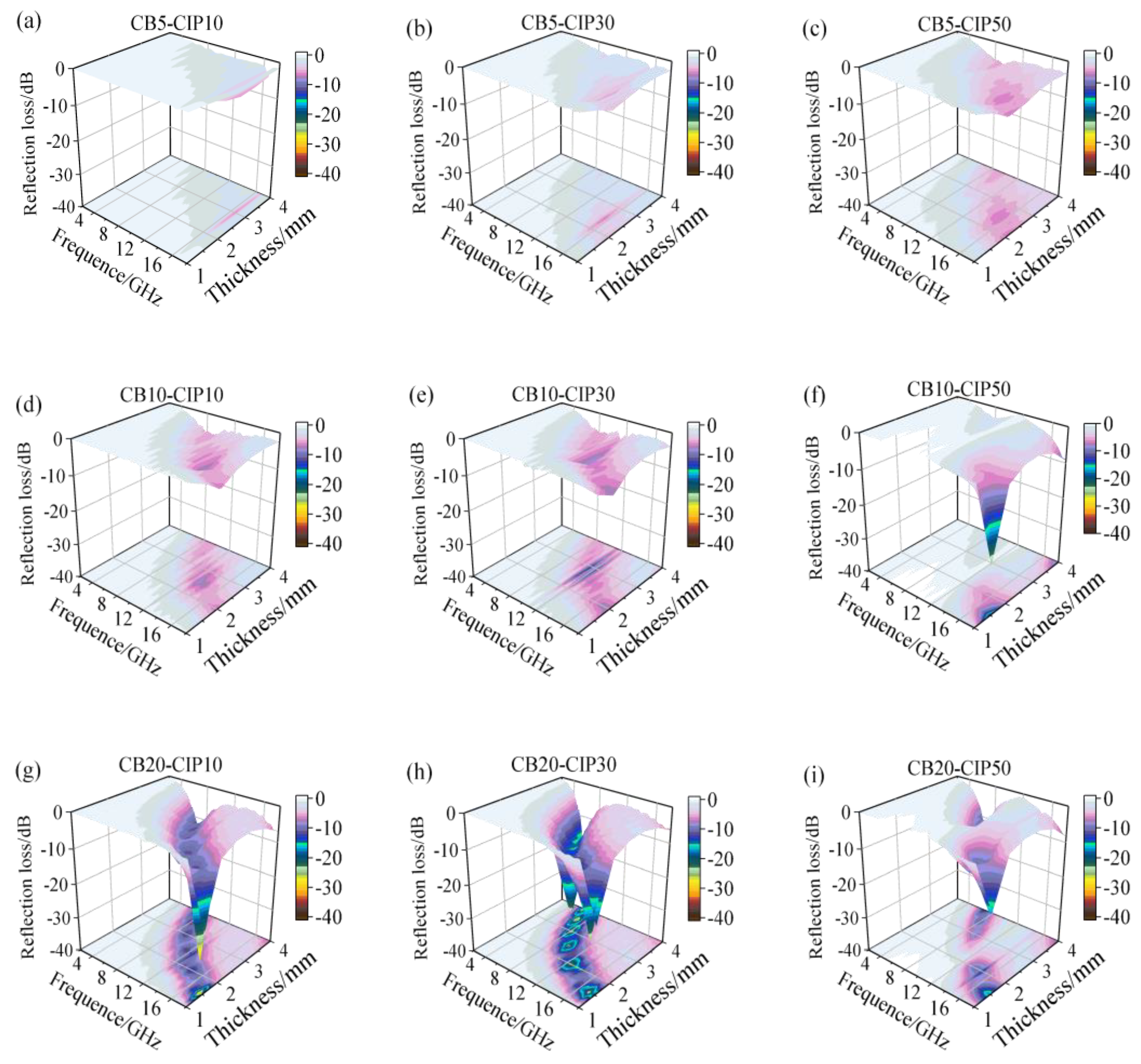

3.3. Influence of Absorbent Content on Absorbing Properties Components

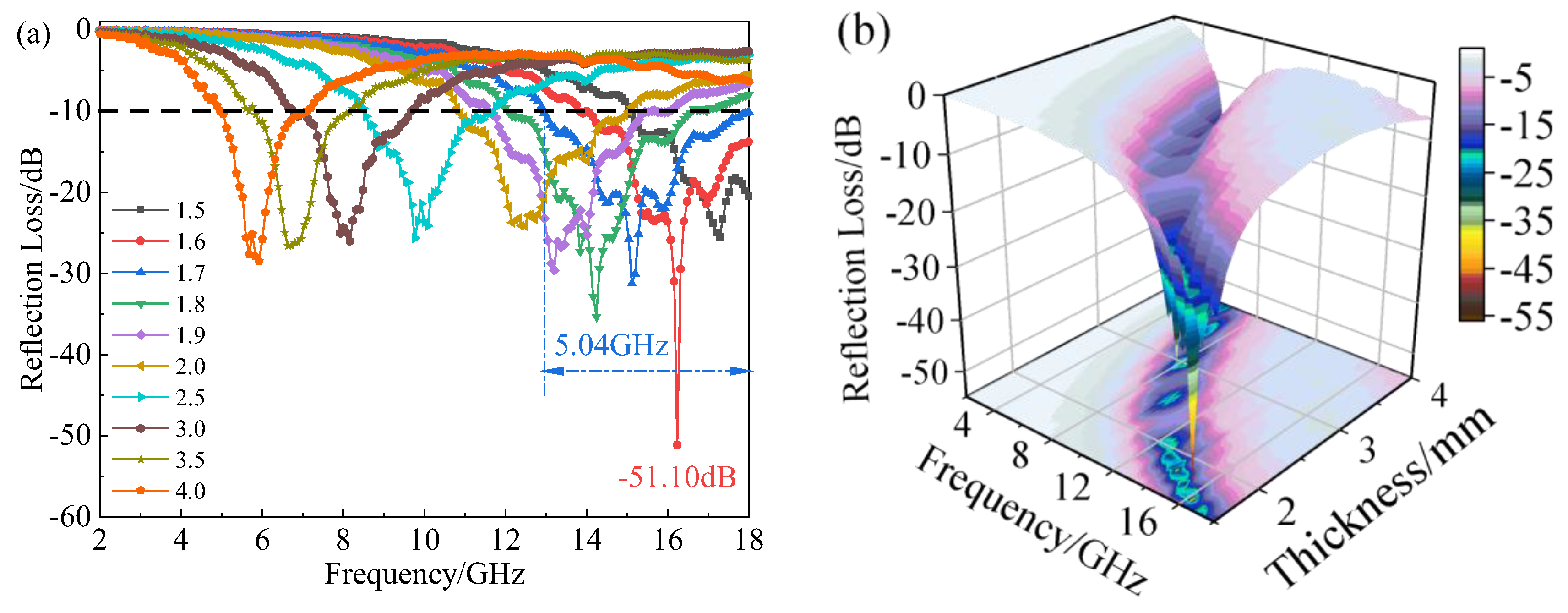

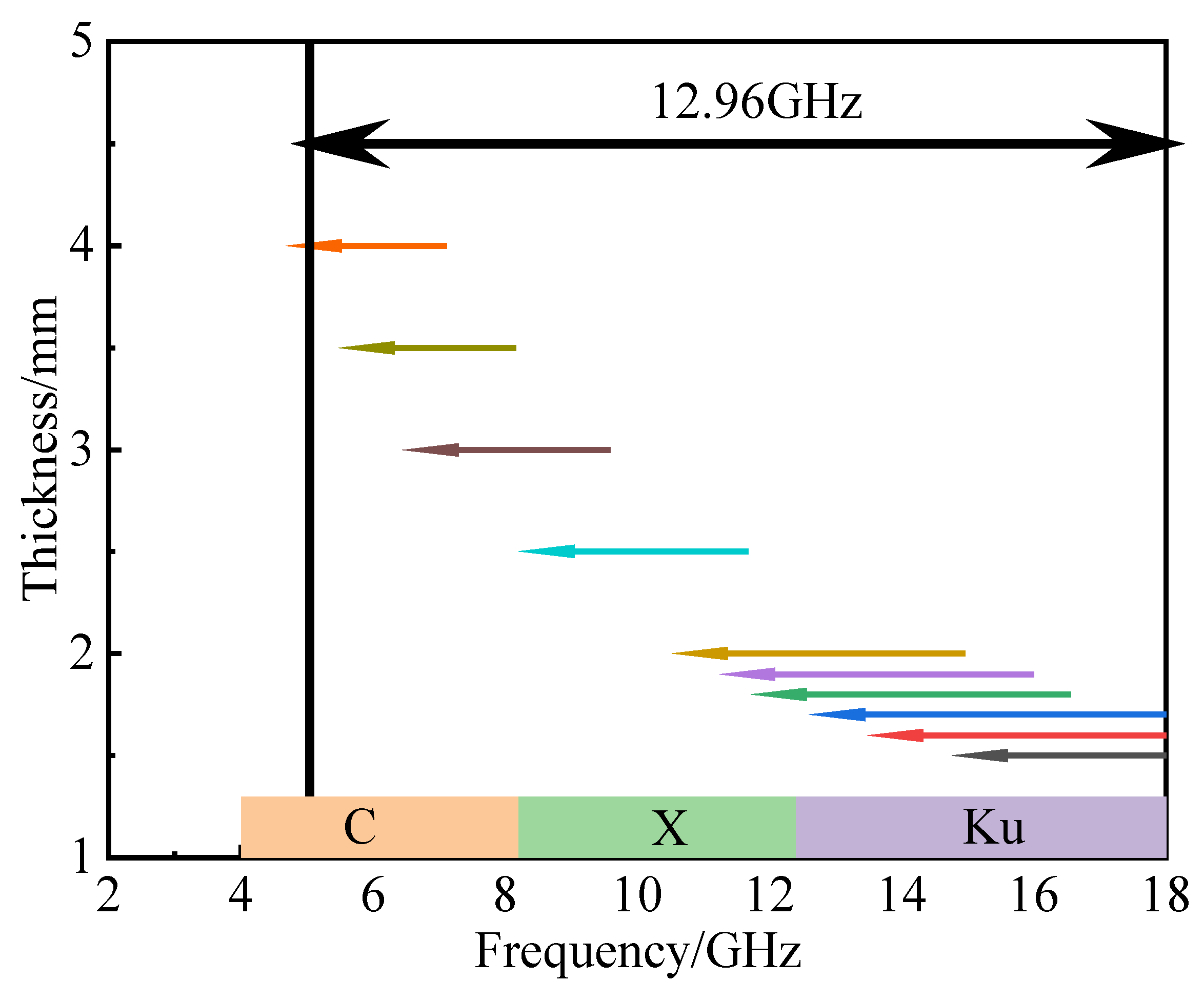

3.4. Absorbing Properties of the CB20-CIP30 Composite

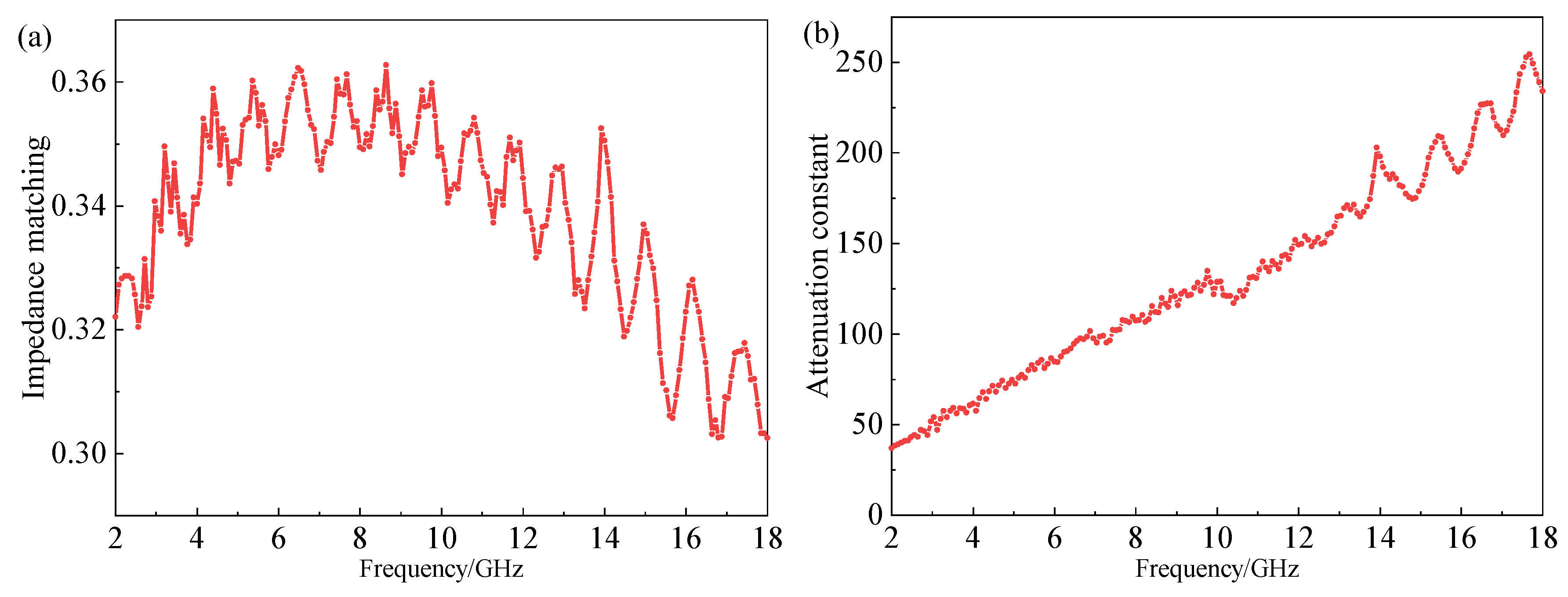

3.5. The Synergy of the Multiple Loss Mechanism of the CB20-CIP30 Composite

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Meng, X.; Zhang, J.; Xiong, L.; Zhang, T.; Zhao, H.; Zhong, B.; Xia, L.; Huang, X.; Wen, G. In-Situ Growth of Fe/Fe3O4/C Hierarchical Architectures with Wide-Band Electromagnetic Wave Absorption. Ceram. Int. 2018, 44, 21933–21941. [Google Scholar] [CrossRef] [Green Version]

- Qin, M.; Zhang, L.; Wu, H. Dielectric Loss Mechanism in Electromagnetic Wave Absorbing Materials. Adv. Sci. 2022, 9, 2105553–2105576. [Google Scholar] [CrossRef]

- Liang, X.; Liu, W.; Cheng, Y.; Lv, J.; Dai, S.; Tang, D.; Zhang, B.; Ji, G. Review: Recent Process in the Design of Carbon-Based Nanostructures with Optimized Electromagnetic Properties. J. Alloys Compd. 2018, 749, 887–899. [Google Scholar] [CrossRef]

- Min, C.; Yuxi, D.; Kang, X.; Xiaofeng, H.; Jiayu, H.; Xi, Y. Research Progress of New Carbon Based Magnetic Composite Electromagnetic Waveabsorbing Materials. Acta Mater. Compos. Sin. 2020, 37, 3004–3016. (In Chinese) [Google Scholar]

- Yang, W.; Jiang, B.; Che, S.; Yan, L.; Li, Z.; Li, Y. Research Progress on Carbon-Based Materials for Electromagnetic Wave Absorption and the Related Mechanisms. New Carbon Mater. 2021, 36, 1016–1030. [Google Scholar] [CrossRef]

- Sista, K.S.; Dwarapudi, S.; Kumar, D.; Sinha, G.R.; Moon, A.P. Carbonyl Iron Powders as Absorption Material for Microwave Interference Shielding: A Review. J. Alloys Compd. 2021, 853, 157251–157275. [Google Scholar] [CrossRef]

- Wei, H.; Zhang, Z.; Zhou, L.; Heidarshenas, B.; Zhang, C.; Xia, J.; Zhi, L.; Shen, G.; Wu, H. Influence of Heat Treatment on the Microwave Absorption Properties of Flaky Carbonyl Iron Powder. Int. J. Lightweight Mater. Manuf. 2020, 3, 258–264. [Google Scholar] [CrossRef]

- Liu, T.; Zhou, L.; Zheng, D.; Xu, Y. Absorption Property of C@Cips Composites by the Mechanical Milling Process. Appl. Phys. A 2017, 123, 565–571. [Google Scholar] [CrossRef]

- Qing, Y.C.; Zhou, W.C.; Jia, S.; Luo, F.; Zhu, D.M. Electromagnetic and Microwave Absorption Properties of Carbonyl Iron and Carbon Fiber Filled Epoxy/Silicone Resin Coatings. Appl. Phys. A 2010, 100, 1177–1181. [Google Scholar] [CrossRef]

- Xicong, Y.; Bin, O.; Chao, Y.; Zhenglang, H.; Enyi, H.; Haihua, W. Preparation of Graphene_Carbonyl Iron Powder Wire and Analysis of its Wave Absorption Performance. Acta Mater. Compos. Sin. 2022, 39, 1–12. (In Chinese) [Google Scholar]

- Chai, L.; Wang, Y.; Zhou, N.; Du, Y.; Zeng, X.; Zhou, S.; He, Q.; Wu, G. In-Situ Growth of Core-Shell Znfe2O4 @ Porous Hollow Carbon Microspheres as an Efficient Microwave Absorber. J. Colloid Interf. Sci. 2021, 581, 475–484. [Google Scholar] [CrossRef] [PubMed]

- Green, M.; Chen, X. Recent Progress of Nanomaterials for Microwave Absorption. J. Mater. 2019, 5, 503–541. [Google Scholar] [CrossRef]

- Lei, L.; Yao, Z.; Zhou, J.; Wei, B.; Fan, H. 3D Printing of Carbon Black/Polypropylene Composites with Excellent Microwave Absorption Performance. Compos. Sci. Technol. 2020, 200, 108479–108487. [Google Scholar] [CrossRef]

- Li, W.; Liu, Y.; Guo, F.; Du, Y.; Chen, Y. Self-Assembly Sandwich-Like Fe, Co, Or Ni Nanoparticles/Reduced Graphene Oxide Composites with Excellent Microwave Absorption Performance. Appl. Surf. Sci. 2021, 562, 150212–150223. [Google Scholar] [CrossRef]

- Qu, Z.; Wang, Y.; Wang, W.; Yu, D. Robust Magnetic and Electromagnetic Wave Absorption Performance of Reduced Graphene Oxide Loaded Magnetic Metal Nanoparticle Composites. Adv. Powder Technol. 2021, 32, 194–203. [Google Scholar] [CrossRef]

- Jin, C.; Wu, Z.; Zhang, R.; Qian, X.; Xu, H.; Che, R. 1D Electromagnetic-Gradient Hierarchical Carbon Microtube Via Coaxial Electrospinning Design for Enhanced Microwave Absorption. Acs Appl. Mater. Inter. 2021, 13, 15939–15949. [Google Scholar] [CrossRef]

- Tho, P.T.; Xuan, C.T.A.; Tran, N.; Tuan, N.Q.; Jeong, W.H.; Kim, S.W.; Quang, D.T.; Nguyen, V.D.; Bach, T.N.; Thanh, T.D.; et al. Ultra-Wide Effective Absorption Bandwidth of Cu, Co, and Ti Co-Doped Srfe12O19 Hexaferrite. Ceram. Int. 2022; in press. [Google Scholar]

- Yu, J.; Li, Y.; Xu, X.; Duan, G.; Li, Y.; Zhou, W. Rambutan-Like Nb2O5@Shcs Microspheres for Improved Microwave Absorption Performance. Compos. Commun. 2021, 24, 100643–100647. [Google Scholar] [CrossRef]

- Zhang, W.; Bie, S.; Chen, H.; Lu, Y.; Jiang, J. Electromagnetic and Microwave Absorption Properties of Carbonyl Iron/Mno2 Composite. J. Magn. Magn. Mater. 2014, 358–359, 1–4. [Google Scholar] [CrossRef]

- Zhao, B.; Shao, G.; Fan, B.; Zhao, W.; Zhang, R. Investigation of the Electromagnetic Absorption Properties of Ni@Tio2 and Ni@Sio2 Composite Microspheres with Core-Shell Structure. Phys. Chem. Chem. Phys. 2015, 17, 2531–2539. [Google Scholar] [CrossRef]

- Ruiz-Perez, F.; López-Estrada, S.M.; Tolentino-Hernández, R.V.; Caballero-Briones, F. Carbon-Based Radar Absorbing Materials: A Critical Review. J. Sci. Adv. Mater. Devices 2022, 7, 100454–100473. [Google Scholar] [CrossRef]

- Ning, M.; Li, J.; Kuang, B.; Wang, C.; Su, D.; Zhao, Y.; Jin, H.; Cao, M. One-Step Fabrication of N-Doped Cnts Encapsulating M Nanoparticles (M = Fe, Co, Ni) for Efficient Microwave Absorption. Appl. Surf. Sci. 2018, 447, 244–253. [Google Scholar] [CrossRef] [Green Version]

- Liu, P.; Ng, V.M.H.; Yao, Z.; Zhou, J.; Lei, Y.; Yang, Z.; Lv, H.; Kong, L.B. Facile Synthesis and Hierarchical Assembly of Flowerlike Nio Structures with Enhanced Dielectric and Microwave Absorption Properties. Acs Appl. Mater. Inter. 2017, 9, 16404–16416. [Google Scholar] [CrossRef] [PubMed]

- Zuo, Y.; Yao, Z.; Lin, H.; Zhou, J.; Lu, J.; Ding, J. Digital Light Processing 3D Printing of Graphene/Carbonyl Iron/Polymethyl Methacrylate Nanocomposites for Efficient Microwave Absorption. Compos. Part B Eng. 2019, 179, 107533–107540. [Google Scholar] [CrossRef]

- Duan, Y.; Liu, Y.; Cui, Y.; Ma, G.; Tongmin, W. Graphene to Tune Microwave Absorption Frequencies and Enhance Absorption Properties of Carbonyl Iron/Polyurethane Coating. Prog. Org. Coat. 2018, 125, 89–98. [Google Scholar] [CrossRef]

- Zheng, J.; Zhou, Z.; Zhu, L.; Chen, Q.; Hong, M.; Fu, H. Room Temperature Self-Healing Cip/Pda/Mwcnts Composites Based On Imine Reversible Covalent Bond as Microwave Absorber. React. Funct. Polym. 2022, 172, 105179–105190. [Google Scholar] [CrossRef]

- Chen, Q.; Li, L.; Wang, Z.; Ge, Y.; Zhou, C.; Yi, J. Synthesis and Enhanced Microwave Absorption Performance of Cip@ Sio2@Mn0.6Zn0.4Fe2O4 Ferrite Composites. J. Alloys Compd. 2019, 779, 720–727. [Google Scholar] [CrossRef]

- Peng, X.; Zhang, Q.; Xie, Z. Preparation and Wave Absorption of Carbon Nanotube/Polyvinyl Alcohol/Carbonyl Iron Powder Composites. Carbon Technol. 2020, 39, 39–43. (In Chinese) [Google Scholar]

- Li, X.; Zhang, Y.; Chen, J.; Duan, Y.; Wu, G.; Ma, G. Composite Coatings Reinforced with Carbonyl Iron Nanoparticles: Preparation and Microwave Absorbing Properties. Mater. Technol. 2013, 29, 57–64. [Google Scholar] [CrossRef]

- Hamed Salimkhani, P.P.A.B. Electrophoretic Deposition of Spherical Carbonyl Iron Particles on Carbon Fibers as a Microwave Absorbent Composite. Surf. Interfaces 2016, 5, 1–7. [Google Scholar] [CrossRef]

- Yin, P.; Zhang, L.; Wang, J.; Feng, X.; Wang, K.; Rao, H.; Wang, Y.; Dai, J. Low Frequency Microwave Absorption Property of Cips/Zno/Graphene Ternary Hybrid Prepared Via Facile High-Energy Ball Milling. Powder Technol. 2019, 356, 325–334. [Google Scholar] [CrossRef]

- Li, N.; Huang, G.; Li, Y.; Xiao, H.; Feng, Q.; Hu, N.; Fu, S. Enhanced Microwave Absorption Performance of Coated Carbon Nanotubes by Optimizing the Fe3O4 Nanocoating Structure. Acs Appl. Mater. Inter. 2017, 9, 2973–2983. [Google Scholar] [CrossRef] [PubMed]

- Liu, L.; He, N.; Sun, J.; Hu, P.; He, R.; Cheng, J.; Tian, W.; Tong, G. Tailoring Impedance Match and Enhancing Microwave Absorption of Fe3O4/Bi24Fe2O39/Bi Hollow Porous Microrods by Controlling their Composition. Prog. Nat. Sci. Mater. Int. 2018, 28, 575–583. [Google Scholar] [CrossRef]

- Wei, B.; Zhou, J.; Yao, Z.; Haidry, A.A.; Qian, K.; Lin, H.; Guo, X.; Chen, W. Excellent Microwave Absorption Property of Nano-Ni Coated Hollow Silicon Carbide Core-Shell Spheres. Appl. Surf. Sci. 2020, 508, 145261–1452613. [Google Scholar] [CrossRef]

- Jian, X.; Wu, B.; Wei, Y.; Dou, S.X.; Wang, X.; He, W.; Mahmood, N. Facile Synthesis of Fe3O4/Gcs Composites and their Enhanced Microwave Absorption Properties. Acs Appl. Mater. Inter. 2016, 8, 6101–6109. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Meng, F.; Mei, Y.; Wang, H.; Guo, Y.; Wang, Y.; Peng, F.; Huang, F.; Zhou, Z. Electrospun Generation of Ti3C2Tx Mxene@Graphene Oxide Hybrid Aerogel Microspheres for Tunable High-Performance Microwave Absorption. Chem. Eng. J. 2020, 391, 123512–123521. [Google Scholar] [CrossRef]

- Shi, Y.; Yu, L.; Li, K.; Li, S.; Dong, Y.; Zhu, Y.; Fu, Y.; Meng, F. Well-Matched Impedance of Polypyrrole-Loaded Cotton Non-Woven Fabric/Polydimethylsiloxane Composite for Extraordinary Microwave Absorption. Compos. Sci. Technol. 2020, 197, 108246–108255. [Google Scholar] [CrossRef]

- Hou, T.; Jia, Z.; Wang, B.; Li, H.; Liu, X.; Bi, L.; Wu, G. Mxene-Based Accordion 2D Hybrid Structure with Co9S8/C/Ti3C2Tx as Efficient Electromagnetic Wave Absorber. Chem. Eng. J. 2021, 414, 128875–128884. [Google Scholar] [CrossRef]

- Liu, D.; Du, Y.; Xu, P.; Liu, N.; Wang, Y.; Zhao, H.; Cui, L.; Han, X. Waxberry-Like Hierarchical Ni@C Microspheres with High-Performance Microwave Absorption. J. Mater. Chem. C 2019, 7, 5037–5046. [Google Scholar] [CrossRef]

- Liu, Y.; Yao, Z.; Zhou, J.; Jin, L.; Wei, B.; He, X. Facile Synthesis of Mof-Derived Concave Cube Nanocomposite by Self-Templated Toward Lightweight and Wideband Microwave Absorption. Carbon 2022, 186, 574–588. [Google Scholar] [CrossRef]

- Zhang, K.; Chen, J.; Yue, S.; Zhang, H.; Meng, C.; Wang, J. Facile Synthesis of Core-Shell Ci/Sio2 Decorated Rgo Sheets Composite for Excellent Electromagnetic Wave Absorption Performance Covering the Whole X-Band. Compos. Part A Appl. Sci. Manuf. 2020, 130, 105755–105765. [Google Scholar] [CrossRef]

- Long, Q.; Xu, Z.; Xiao, H.; Xie, K. A Facile Synthesis of a Cobalt Nanoparticle-Graphene Nanocomposite with High-Performance and Triple-Band Electromagnetic Wave Absorption Properties. RSC Adv. 2018, 8, 1210–1217. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Samples | Radio Refered to PLA | CB5-CIP10 | CB10-CIP10 | CB20-CIP10 | CB5-CIP30 | CB10-CIP30 | CB20-CIP30 | CB5-CIP50 | CB10-CIP50 | CB20-CIP50 |

|---|---|---|---|---|---|---|---|---|---|---|

| CB | wt.% (vol.%) | 5 (2.78) | 10 (5.56) | 20 (11.12) | 5 (2.78) | 10 (5.56) | 20 (11.12) | 5% | 10 (5.56) | 20 (11.12) |

| CIP | wt.% (vol.%) | 10 (1.27) | 10 (1.27) | 10 (1.27) | 30 (3.81) | 30 (3.81) | 30 (3.81) | 50 (6.35) | 50 (6.35) | 50 (6.35) |

| RL/dB | % of Electromagnetic Energy Absorbed |

|---|---|

| <−5 | >70 |

| <−10 | >90 |

| <−15 | >96.8 |

| <−20 | >99 |

| <−40 | >99.99 |

| Absorber | Matrix | EAB/GHz | Minimum RL/dB | Matching Thickness/mm | Reference |

|---|---|---|---|---|---|

| CIP/GNs | PU | 7.10 | −30.10 | 1.0 | [25] |

| CIP/PDA@MWCNTs | Paraffin | 9.68 | −30.69 | 1.5 | [26] |

| CIP@SiO2@MnZnFeO | Paraffin | 7.12 | −44.24 | 2.0 | [27] |

| CNT/PVA/CIP | Paraffin | 6.30 | −50.00 | 3.0 | [28] |

| RGO/CIP | PMMA | 3.41 | −54.40 | 2.1 | [24] |

| nmCIP/CB | PU | 3.60 | −25.80 | 2.0 | [29] |

| CIPs/CF | Epoxy | 1.50 | −13.80 | 2.0 | [30] |

| CIPs/ZnO/RGO | Paraffin | 0.41 | −45.57 | 4.0 | [31] |

| RGO/CIP | PLA | 2.92 | −27.25 | 3.0 | [10] |

| CB/CIP | PLA | 5.04 | −51.10 | 1.6 | This work |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, F.; Zhou, Q.; Zhang, Z.; Gu, Y.; Zhang, J.; Jiang, K. Microwave Absorption Properties of Carbon Black-Carbonyl Iron/Polylactic Acid Composite Filament for Fused Deposition Modeling. Materials 2022, 15, 5455. https://doi.org/10.3390/ma15155455

Wang F, Zhou Q, Zhang Z, Gu Y, Zhang J, Jiang K. Microwave Absorption Properties of Carbon Black-Carbonyl Iron/Polylactic Acid Composite Filament for Fused Deposition Modeling. Materials. 2022; 15(15):5455. https://doi.org/10.3390/ma15155455

Chicago/Turabian StyleWang, Fei, Qianfeng Zhou, Zhe Zhang, Yonghua Gu, Jiliang Zhang, and Kaiyong Jiang. 2022. "Microwave Absorption Properties of Carbon Black-Carbonyl Iron/Polylactic Acid Composite Filament for Fused Deposition Modeling" Materials 15, no. 15: 5455. https://doi.org/10.3390/ma15155455