Modeling of Heat Transfer through Firefighters Multilayer Protective Clothing Using the Computational Fluid Dynamics Assisted by X-ray Microtomography and Thermography

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. X-ray Microtomography (Micro-CT)

2.2.2. Thermal Imaging

2.2.3. Model Designing

2.2.4. Heat Transfer Simulations

Physical Basis

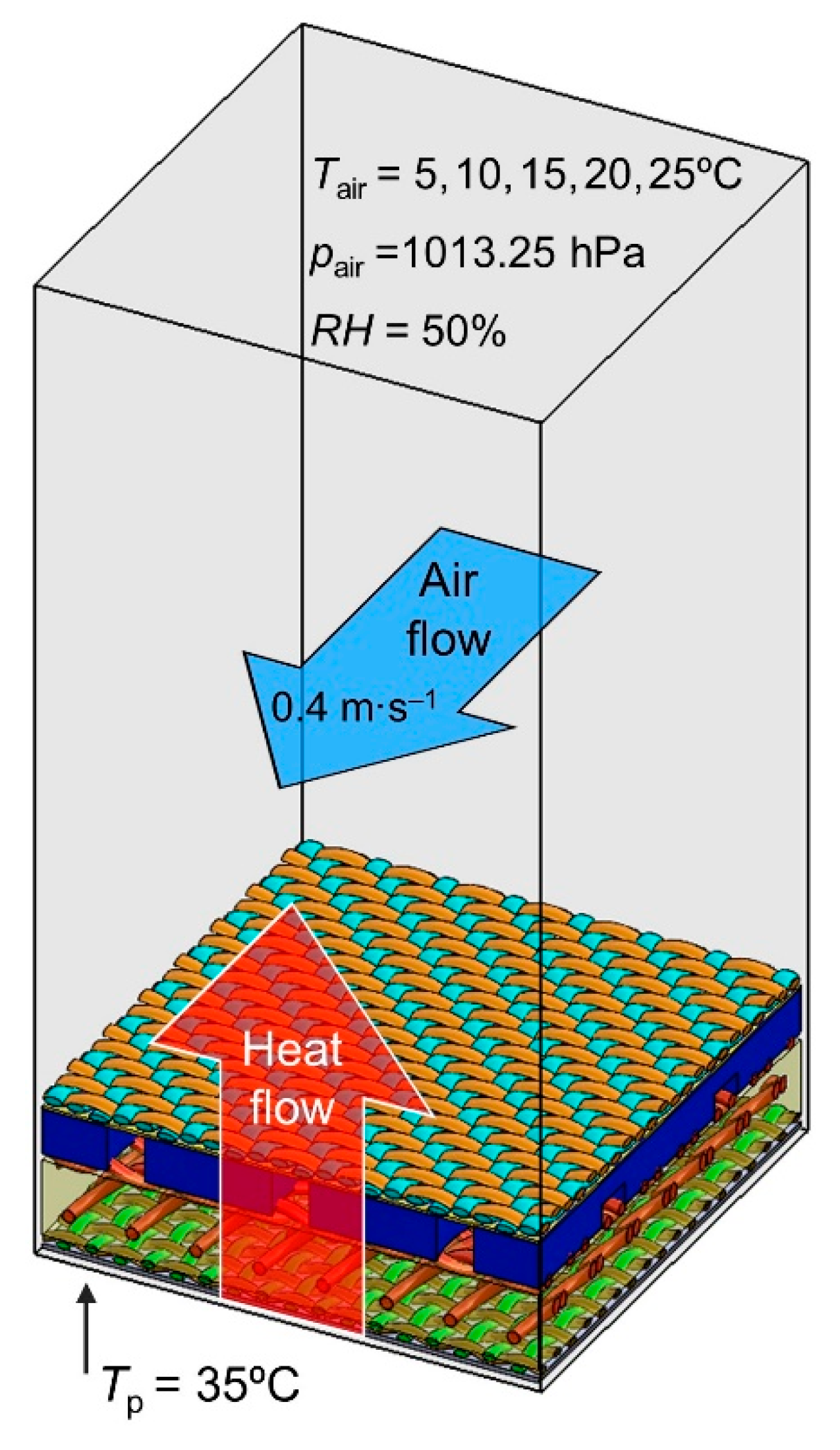

Conditions of Heat Transfer Simulations

3. Results

4. Discussion

5. Conclusions

- Mapping the subtle differences in the internal structure (spatial geometry, porosity) of the assemblies in the designed models measured using micro-CT reveals observable differences in the modeled heat transfer.

- Despite applied simplifications in geometry and the use of homogenization, the designed assembly models make it possible to predict heat transfer through real assemblies with a difference of about 2% to 5% in comparison to the experiment depending on the environmental conditions (the difference increases with the temperature difference inducing heat transfer) and the complexity of the model geometry. Generally speaking, simplifications in mapping the complex geometry of the slightly different assemblies did not affect the sensitivity for detecting differences in the modeled heat transfer that resulted from minimal differences in the morphology of the tested textiles.

- The applied design and simulation method is a useful tool for the accurate modeling and prediction of heat transfer through multilayer textiles with complex geometry before the production of clothing, which results in savings in the raw materials, energy, labor costs, and time needed to produce them.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Młynarczyk, M. The special clothing for firefighters—The normative requirements and original research results. J. Occup. Saf.–Sci. Pract. 2018, 560, 12–15. [Google Scholar] [CrossRef]

- The Firefighter Suit: Understanding the Layers of Protection. Available online: https://eu.tencatefabrics.com/blog/layers-firefighter-suit (accessed on 12 June 2022).

- Houshyar, S.; Padhye, R.; Nayak, R. Effect of moisture-wicking materials on the physical and thermo-physiological comfort properties of firefighters’ protective clothing. Fibers Polym. 2017, 18, 383–389. [Google Scholar] [CrossRef]

- Song, G.; Gholamreza, F.; Cao, W. Analyzing thermal stored energy and effect on protective performance. Text. Res. J. 2011, 81, 1124–1138. [Google Scholar] [CrossRef]

- Zhang, H.; Song, G.; Su, H.; Ren, H.; Cao, J. An exploration of enhancing thermal protective clothing performance by incorporating aerogel and phase change materials. Fire Mater. 2017, 41, 953–963. [Google Scholar] [CrossRef]

- Greszta, A.; Bartkowiak, G.; Dąbrowska, A.; Gliścińska, E.; Machnowski, W.; Kozikowski, P. Multilayer Nonwoven Inserts with Aerogel/PCMs for the Improvement of Thermophysiological Comfort in Protective Clothing against the Cold. Materials 2022, 15, 2307. [Google Scholar] [CrossRef]

- Miśkiewicz, P.; Tokarska, M.; Frydrych, I. Application of coating mixture based on silica aerogel to improve thermal protective performance of fabrics. Autex Res. J. 2022. [Google Scholar] [CrossRef]

- Tian, M.; Song, W.; Qu, L.; Chen, S.; Zhu, S.; Ning, F. Thermal Response of Skin Underneath a Thermal Protective Garment During Post-fire Exposure. Int. J. Thermophys. 2018, 39, 90–96. [Google Scholar] [CrossRef]

- Kothari, V.K.; Chakraborty, S. Protective performance of thermal protective clothing assemblies exposed to different radiant heat fluxes. Fibers Polym. 2016, 17, 809–814. [Google Scholar] [CrossRef]

- Miśkiewicz, P.; Tokarska, M.; Frydrych, I.; Makówka, M. Evaluation of thermal properties of certain flame-retardant fabrics modified with a magnetron sputtering method. Autex Res. J. 2020, 21, 428–434. [Google Scholar] [CrossRef]

- Miśkiewicz, P.; Tokarska, M.; Frydrych, I.; Makówka, M. Assessment of coating quality obtained on flame-retardant fabrics by a magnetron sputtering method. Materials 2021, 14, 1348. [Google Scholar] [CrossRef]

- Mandal, S.; Song, G.; Ackerman, M.; Paskaluk, S.; Gholamreza, F. Characterization of textile fabrics under various thermal exposures. Text. Res. J. 2013, 83, 1005–1019. [Google Scholar] [CrossRef]

- Krucińska, I.; Skrzetuska, E. Badania ergonomiczne odzieży ochronnej z zastosowaniem manekina typu Newton. In Problemy Monitoringu Eksploatacji Sprzętu i Wyposażenia w Straży Pożarnej; Wydawnictwo CNBOP-PIB: Józefów, Poland, 2015; pp. 107–117. ISBN 978-83-61520-22-1. [Google Scholar]

- Krucińska, I.; Skrzetuska, E.; Urbaniak-Domagała, W. Printed Textiles with Chemical Sensor Properties. Fibres Text. East. Eur. 2014, 22, 68–72. [Google Scholar]

- Bendkowska, W.; Kłonowska, M.; Kopias, K.; Bogdan, A. Thermal manikin evaluation of PCM cooling vests. Fibres Text. East. Eur. 2010, 18, 70–74. [Google Scholar]

- Rossi, R.; Indelicato, E.; Bolli, W. Hot steam transfer through heat protective clothing layers. Int. J. Occup. Saf. Ergon. 2004, 10, 239–245. [Google Scholar] [CrossRef] [Green Version]

- Krucińska, I.; Skrzetuska, E.; Kowalski, K. Application of a thermal mannequin to the assessment of the heat insulating power of protective garments for premature babies. Autex Res. J. 2019, 19, 134–146. [Google Scholar] [CrossRef] [Green Version]

- Korycki, R. Determination of material thicknesses in protective clothing for firefighters. Fibres Text. East. Eur. 2018, 26, 93–99. [Google Scholar] [CrossRef] [Green Version]

- Korycki, R.; Szafrańska, H. Thickness optimisation of textiles subjected to heat and mass transport during ironing. Autex Res. J. 2016, 16, 164–174. [Google Scholar] [CrossRef] [Green Version]

- Su, Y.; Li, J.; Wang, Y. Effect of air gap thickness on thermal protection of firefighter’s protective clothing against hot steam and thermal radiation. Fibers Polym. 2017, 18, 582–589. [Google Scholar] [CrossRef]

- Korycki, R. Determination of state variables in textile composite with membrane during complex heat and moisture transport. Autex Res. J. 2020. [Google Scholar] [CrossRef]

- Mikucioniene, D.; Milasiute, L.; Baltusnikaite, J.; Milasius, R. Influence of plain knits structure on flammability and air permeability. Fibres Text. East. Eur. 2012, 5, 66–69. [Google Scholar]

- Bivainytė, A.; Mikučionienė, D.; Milašienė, D. Influence of the knitting structure of double-layered fabrics on the heat transfer process. Fibres Text. East. Eur. 2012, 20, 40–43. [Google Scholar]

- Machnowski, W.; Wąs-Gubała, J. Evaluation of selected thermal changes in textile materials arising in the wake of the impact of heat radiation. Appl. Sci. 2021, 11, 6989. [Google Scholar] [CrossRef]

- Lee, Y.M.; Barker, R.L. Effect of Moisture on the Thermal Protective Performance of Heat-Resistant Fabrics. J. Fire Sci. 1986, 4, 315–331. [Google Scholar]

- Nemati, H.; Moghimi, M.A.; Naemi, R. A mathematical model to investigate heat transfer in footwear during walking and jogging. J. Therm. Biol. 2021, 97, 102778. [Google Scholar] [CrossRef]

- Nemati, H.; Naemi, R. An Analytical Model to Predict Foot Sole Temperature: Implications to Insole Design for Physical Activity in Sport and Exercise. Appl. Sci. 2022, 12, 6806. [Google Scholar] [CrossRef]

- Mohamed, R.A.; Ibrahim, A.; Abbas, A.; Abo-Dahab, S.M. Finite element analysis of hydromagnetic flow and heat transfer of a heat generation fluid over a surface embedded in a non-Darcian porous medium in the presence of chemical reaction. Commun. Nonlinear Sci. Numer. Simul. 2009, 14, 1385–1395. [Google Scholar] [CrossRef]

- Jiang, S.; Horn, T.J.; Dhir, V.K. Numerical Analysis of a Radiant Heat Flux Calibration System. Int. J. Thermophys. 2000, 21, 941–962. [Google Scholar] [CrossRef]

- Zhu, F.L.; Zhou, Y. Modelling Heat-Moisture Transport through Firefighters’ Protective Fabrics from an Impinging Flame Jet by Simulating the Drying Process. Fibres Text. East. Eur. 2013, 21, 85–90. [Google Scholar]

- Angelova, R.A.; Kyosov, M.; Stankov, P. Numerical investigation of the heat transfer through woven textiles by the jet system theory. J. Text. Inst. 2018, 110, 386–395. [Google Scholar] [CrossRef]

- Barauskas, R.; Sankauskaite, A.; Rubeziene, V.; Gadeikyte, A.; Skurkyte-Papieviene, V.; Abraitiene, A. Investigation of thermal properties of spacer fabrics with phase changing material by finite element model and experiment. Text. Res. J. 2020, 90, 1837–1850. [Google Scholar] [CrossRef]

- An, Y.Y.; Xu, G.; Shen, H. The influence of structure on the thermal properties of sleeping bags. Int. J. Cloth. Sci. Technol. 2022. [Google Scholar] [CrossRef]

- Gadeikytė, A.; Sandonavičius, D.; Rimavičius, V.; Barauskas, R. Finite element analysis of heat and mass exchange between human skin and textile structures. Balt. J. Mod. Comput. 2022, 10, 159–169. [Google Scholar] [CrossRef]

- Ielina, T.; Halavska, L.; Mikucioniene, D.; Milasius, R.; Bobrova, S.; Dmytryk, O. Development of 3D models of knits from multi-filament ultra-strong yarns for theoretical modelling of air permeability. Materials 2021, 14, 3489. [Google Scholar] [CrossRef] [PubMed]

- Gadeikytė, A.; Barauskas, R. Investigation of influence of forced ventilation through 3D textile on heat exchange properties of the textile layer. J. Meas. Eng. 2020, 8, 72–78. [Google Scholar] [CrossRef]

- Skrzetuska, E.; Agier, M.; Krucińska, I. Study of Influence of Atmospheric Conditions on the Thermal Properties of Sleeping Bags. Materials 2022, 15, 1992. [Google Scholar] [CrossRef] [PubMed]

- Chitrphiromsri, P.; Kuznetsov, A.V. Modeling heat and moisture transport in firefighter protective clothing during flash fire exposure. Heat Mass Transf. 2004, 41, 206–215. [Google Scholar] [CrossRef]

- Puszkarz, A.K.; Krucinska, I. The study of knitted fabric thermal insulation using thermography and finite volume method. Text. Res. J. 2016, 87, 643–656. [Google Scholar] [CrossRef]

- Puszkarz, A.K.; Krucińska, I. Study of multilayer clothing thermal insulation using thermography and the finite volume method. Fibres Text. East. Eur. 2016, 6, 129–137. [Google Scholar] [CrossRef]

- Puszkarz, A.K.; Krucińska, I. Modeling of air permeability of knitted fabric using the computational fluid dynamics. Autex Res. J. 2018, 18, 364–376. [Google Scholar] [CrossRef] [Green Version]

- Puszkarz, A.K.; Krucińska, I. Simulations of air permeability of multilayer textiles by the computational fluid dynamics. Int. J. Multiscale Comput. Eng. 2018, 16, 509–526. [Google Scholar] [CrossRef]

- Puszkarz, A.K.; Machnowski, M.; Błasińska, A. Modeling of thermal performance of multilayer protective clothing exposed to radiant heat. Heat Mass Transf. 2020, 56, 1767–1775. [Google Scholar] [CrossRef] [Green Version]

- Puszkarz, A.K.; Machnowski, M. Simulations of heat transfer through multilayer protective clothing exposed to flame. Autex Res. J. 2020. [Google Scholar] [CrossRef]

- Puszkarz, A.K.; Wojciechowski, J.; Krucińska, I. Analysis of the thermal insulation of textiles using thermography and CFD simulation based on micro-CT models. Autex Res. J. 2020, 20, 345–351. [Google Scholar] [CrossRef]

- Skrzetuska, E.; Puszkarz, A.K.; Pycio, Z.; Krucińska, I. Assessment of the impact of clothing structures for premature babies on biophysical properties. Materials 2021, 14, 4229. [Google Scholar] [CrossRef] [PubMed]

- PN EN 12127:2000; Textiles—Fabrics—Determination of Mass Per Unit Area Using Small Samples. ISO: Geneva, Switzerland, 2000.

- SolidWorks. Flow Simulation—Technical Reference; SolidWorks: Waltham, MA, USA, 2014. [Google Scholar]

| Assembly | Layer Type | Textile | Weave | Weft/Warp Density [cm–1] | Textile Composition | Textile/Assembly Thickness a) [mm] | Surface Mass b) [g·m–2] | Textile/Assembly Porosity a) [%] | Yarn Porosity a) [%] | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | Outer shell | Woven fabric 1 | twill | 22 | 22 | aramid | 0.37 | 4.20 | 208.27 | 49.38 | 77.51 | 26.88 |

| Moisture barrier | Membrane 1 | none | none | polyurethane | 0.15 | 182.64 | 0.43 | none | ||||

| Nonwoven fabric 1 | none | none | aramid | 1.10 | 82.20 | none | ||||||

| Thermal barrier | Nonwoven fabric 4 | none | none | aramid | 2.31 | 278.74 | 87.60 | 47.82 * | ||||

| Woven fabric 4 | plain | 18 | 18 | aramid | 0.27 | 53.52 | 24.66 | |||||

| B | Outer shell | Woven fabric 2 | twill | 29 | 29 | aramid | 0.34 | 2.61 | 202.44 | 28.70 | 66.00 | 12.44 |

| Moisture barrier | Membrane 2 | none | none | polyurethane | 0.10 | 149.02 | 0.01 | none | ||||

| Nonwoven fabric 2 | none | none | aramid | 1.00 | 78.27 | none | ||||||

| Thermal barrier | Nonwoven fabric 3 | none | none | aramid | 0.85 | 198.82 | 74.65 | none | ||||

| Woven fabric 5 | plain | 18 | 18 | aramid | 0.32 | 52.26 | 25.52 | |||||

| C | Outer shell | Woven fabric 3 | plain | 18 | 18 | aramid | 0.33 | 4.16 | 194.25 | 45.39 | 77.47 | 19.67 |

| Moisture barrier | Membrane 1 | none | none | polyurethane | 0.15 | 182.64 | 0.43 | none | ||||

| Nonwoven fabric 1 | none | none | aramid | 1.10 | 82.20 | none | ||||||

| Thermal barrier | Nonwoven fabric 4 | none | none | aramid | 2.31 | 278.74 | 87.60 | 47.82 * | ||||

| Woven fabric 4 | plain | 18 | 18 | aramid | 0.27 | 53.52 | 24.66 | |||||

| D | Outer shell | Woven fabric 2 | twill | 29 | 29 | aramid | 0.34 | 2.76 | 202.44 | 28.70 | 67.22 | 12.44 |

| Moisture barrier | Membrane 1 | none | none | polyurethane | 0.15 | 182.64 | 0.43 | none | ||||

| Nonwoven fabric 1 | none | none | aramid | 1.10 | 82.20 | none | ||||||

| Thermal barrier | Nonwoven fabric 3 | none | none | aramid | 0.85 | 198.82 | 80.61 | none | ||||

| Woven fabric 5 | plain | 18 | 18 | aramid | 0.32 | 52.26 | 25.52 | |||||

| Assembly | Solid Cells | Gas Cells | Partial Cells |

|---|---|---|---|

| A | 744,868 | 455,061 | 363,352 |

| B | 111,964 | 71,474 | 61,362 |

| C | 779,686 | 425,528 | 359,839 |

| D | 114,583 | 87,274 | 72,577 |

| Physical Parameter | Aramid | PU | Air |

|---|---|---|---|

| density [kg·m−3] | 1360 | 1260 | 1.2 |

| specific heat [J·kg−1·K−1] | 1390 | 1120 | 1005 |

| thermal conductivity [W·m−1·K−1] | 0.18 | 0.23 | 0.03 |

| Assembly | Tair [°C] | Temperature of Top Surface, Ttop [°C] | Temperature Drop, DT [°C] | ||

|---|---|---|---|---|---|

| Thermography | Simulation | Thermography | Simulation | ||

| A | 5 | 13.21 ± 1 | 13.89 ± 0.01 | 21.79 ± 1 | 21.11 ± 0.01 |

| 10 | 17.56 ± 1 | 18.39 ± 0.01 | 17.44 ± 1 | 16.61 ± 0.01 | |

| 15 | 21.91 ± 1 | 22.88 ± 0.01 | 13.09 ± 1 | 12.12 ± 0.01 | |

| 20 | 26.26 ± 1 | 27.19 ± 0.01 | 8.74 ± 1 | 7.81 ± 0.01 | |

| 25 | 30.61 ± 1 | 31.37 ± 0.01 | 4.39 ± 1 | 3.63 ± 0.01 | |

| B | 5 | 16.83 ± 1 | 17.57 ± 0.01 | 18.17 ± 1 | 17.43 ± 0.01 |

| 10 | 20.48 ± 1 | 21.24 ± 0.01 | 14.52 ± 1 | 13.76 ± 0.01 | |

| 15 | 24.13 ± 1 | 25.04 ± 0.01 | 10.87 ± 1 | 9.96 ± 0.01 | |

| 20 | 27.77 ± 1 | 28.50 ± 0.01 | 7.23 ± 1 | 6.50 ± 0.01 | |

| 25 | 31.42 ± 1 | 32.11 ± 0.01 | 3.58 ± 1 | 2.89 ± 0.01 | |

| C | 5 | 14.35 ± 1 | 15.09 ± 0.01 | 20.65 ± 1 | 19.91 ± 0.01 |

| 10 | 18.49 ± 1 | 19.36 ± 0.01 | 16.51 ± 1 | 15.64 ± 0.01 | |

| 15 | 22.63 ± 1 | 23.56 ± 0.01 | 12.37 ± 1 | 11.44 ± 0.01 | |

| 20 | 26.77 ± 1 | 27.71 ± 0.01 | 8.23 ± 1 | 7.29 ± 0.01 | |

| 25 | 30.90 ± 1 | 31.62 ± 0.01 | 4.10 ± 1 | 3.38 ± 0.01 | |

| D | 5 | 16.25 ± 1 | 17.01 ± 0.01 | 18.75 ± 1 | 17.99 ± 0.01 |

| 10 | 20.03 ± 1 | 20.80 ± 0.01 | 14.97 ± 1 | 14.20 ± 0.01 | |

| 15 | 23.80 ± 1 | 24.71 ± 0.01 | 11.20 ± 1 | 10.29 ± 0.01 | |

| 20 | 27.57 ± 1 | 28.32 ± 0.01 | 7.43 ± 1 | 6.68 ± 0.01 | |

| 25 | 31.35 ± 1 | 32.05 ± 0.01 | 3.65 ± 1 | 2.95 ± 0.01 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Renard, M.; Puszkarz, A.K. Modeling of Heat Transfer through Firefighters Multilayer Protective Clothing Using the Computational Fluid Dynamics Assisted by X-ray Microtomography and Thermography. Materials 2022, 15, 5417. https://doi.org/10.3390/ma15155417

Renard M, Puszkarz AK. Modeling of Heat Transfer through Firefighters Multilayer Protective Clothing Using the Computational Fluid Dynamics Assisted by X-ray Microtomography and Thermography. Materials. 2022; 15(15):5417. https://doi.org/10.3390/ma15155417

Chicago/Turabian StyleRenard, Morgan, and Adam K. Puszkarz. 2022. "Modeling of Heat Transfer through Firefighters Multilayer Protective Clothing Using the Computational Fluid Dynamics Assisted by X-ray Microtomography and Thermography" Materials 15, no. 15: 5417. https://doi.org/10.3390/ma15155417

APA StyleRenard, M., & Puszkarz, A. K. (2022). Modeling of Heat Transfer through Firefighters Multilayer Protective Clothing Using the Computational Fluid Dynamics Assisted by X-ray Microtomography and Thermography. Materials, 15(15), 5417. https://doi.org/10.3390/ma15155417