Properties of Rigid Polyurethane Foam Filled with Sawdust from Primary Wood Processing

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of PUR/WF Composite Foams for Testing

2.3. Characteristics of PUR/WF Composite Foams

3. Results

3.1. Characteristics of the Processing of PUR/WP Foams

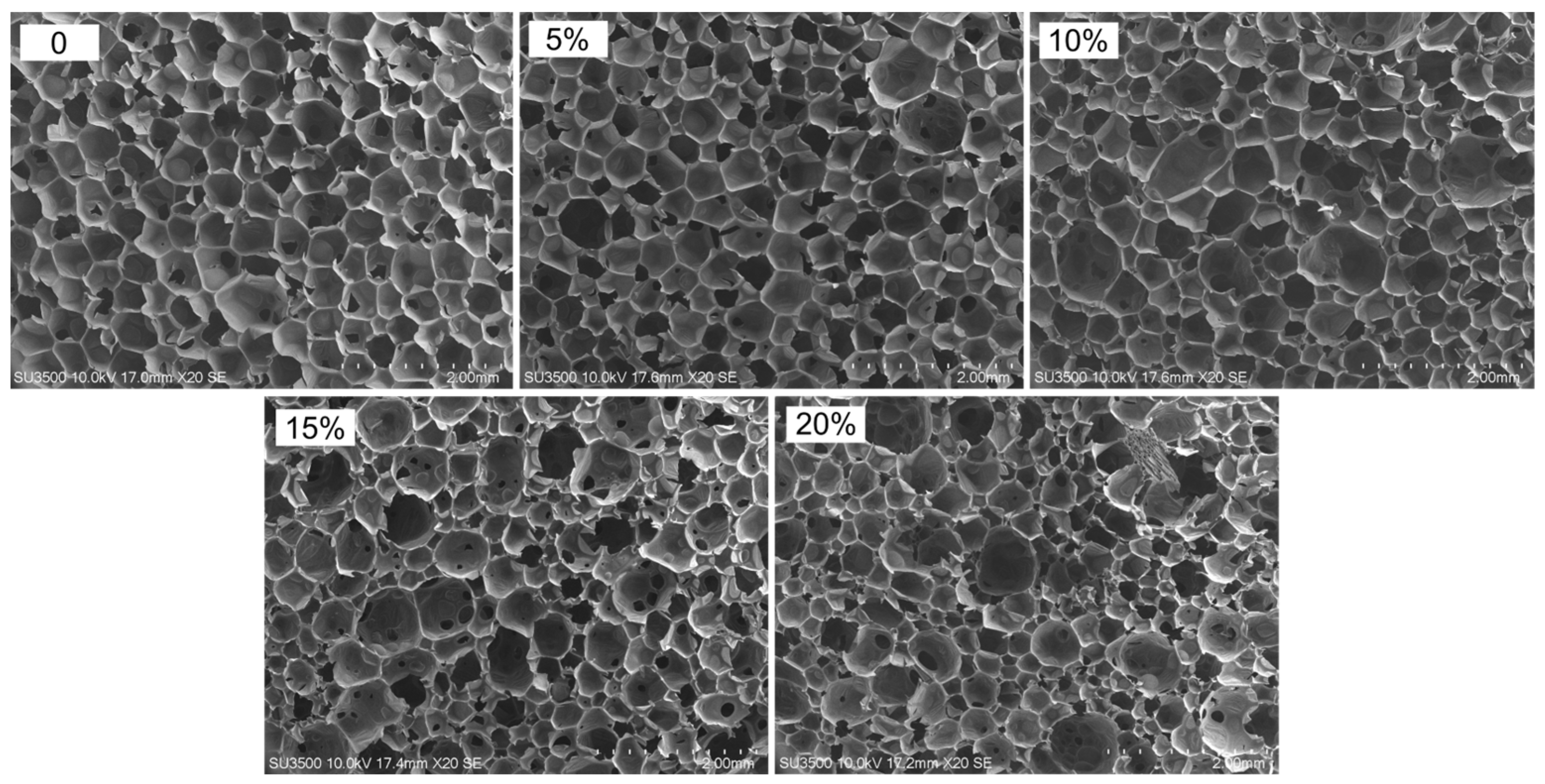

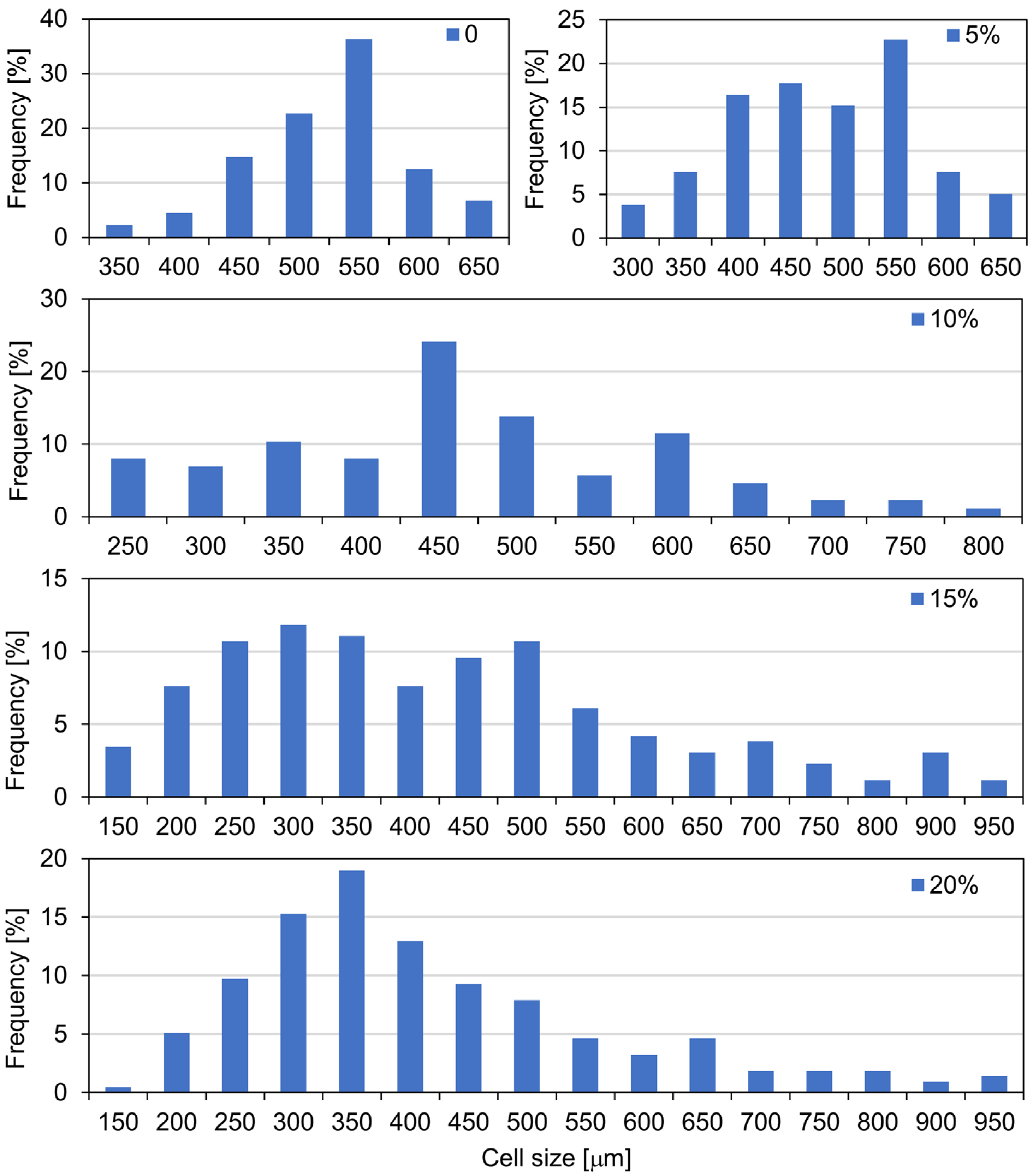

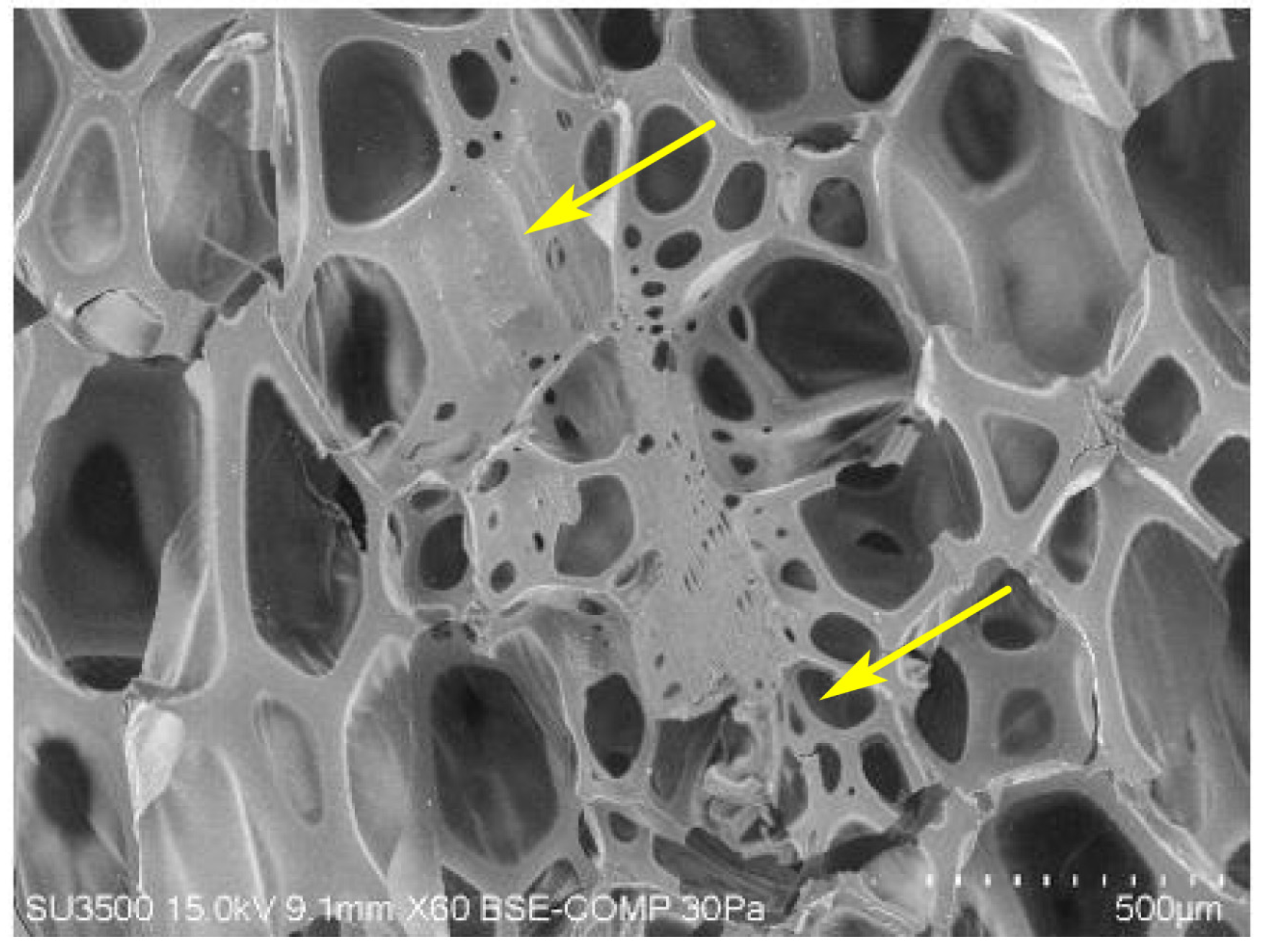

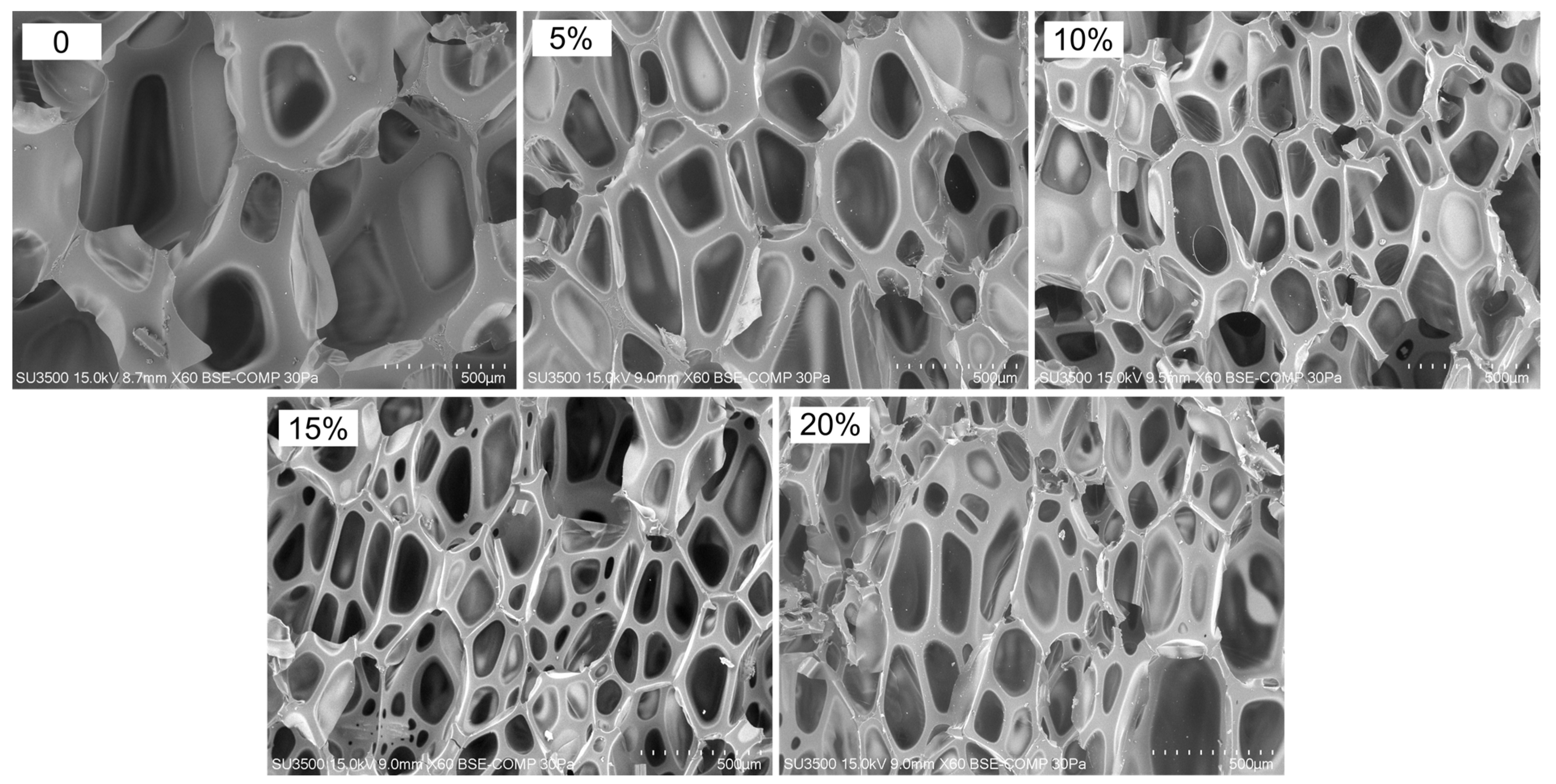

3.2. Structure of PUR/WP Foams

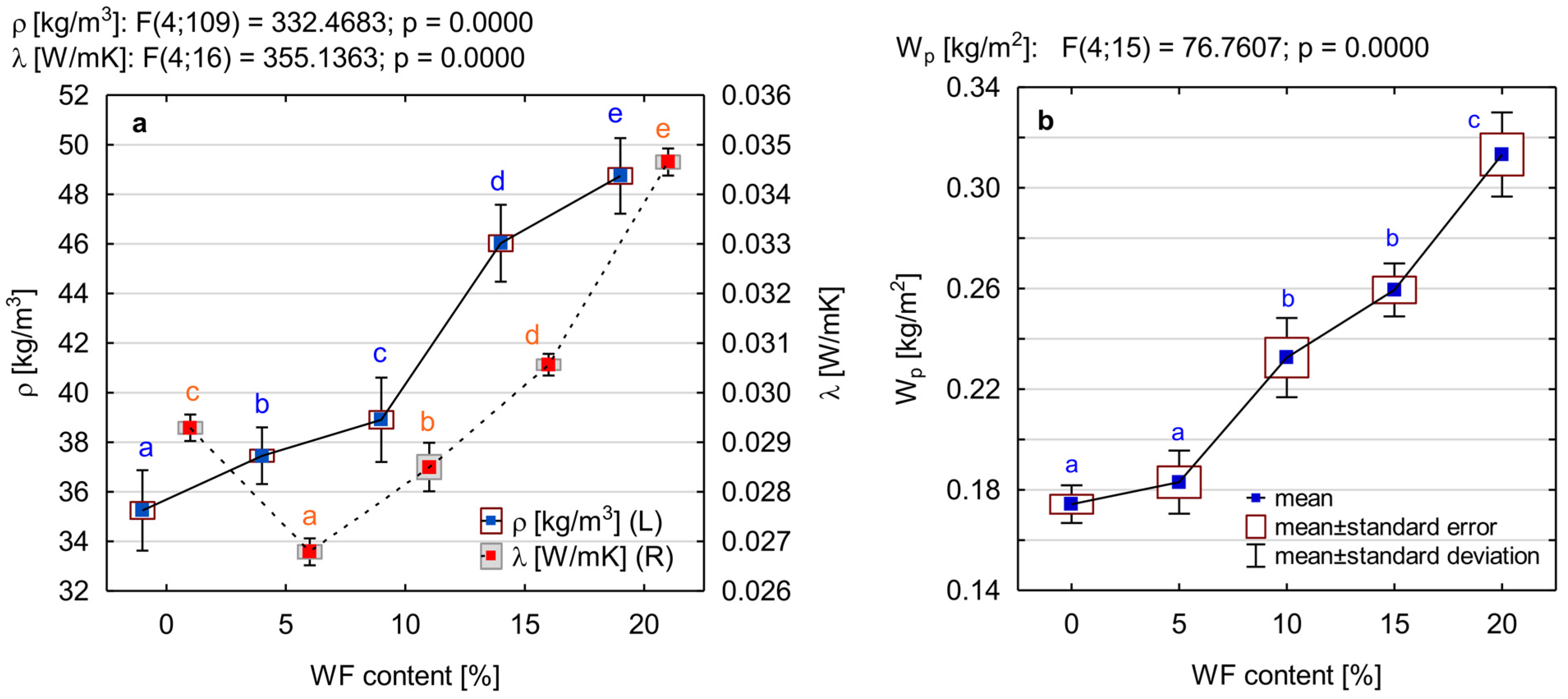

3.3. Apparent Density, Thermal Conductivity and Water Absorption of PUR/WF Foams

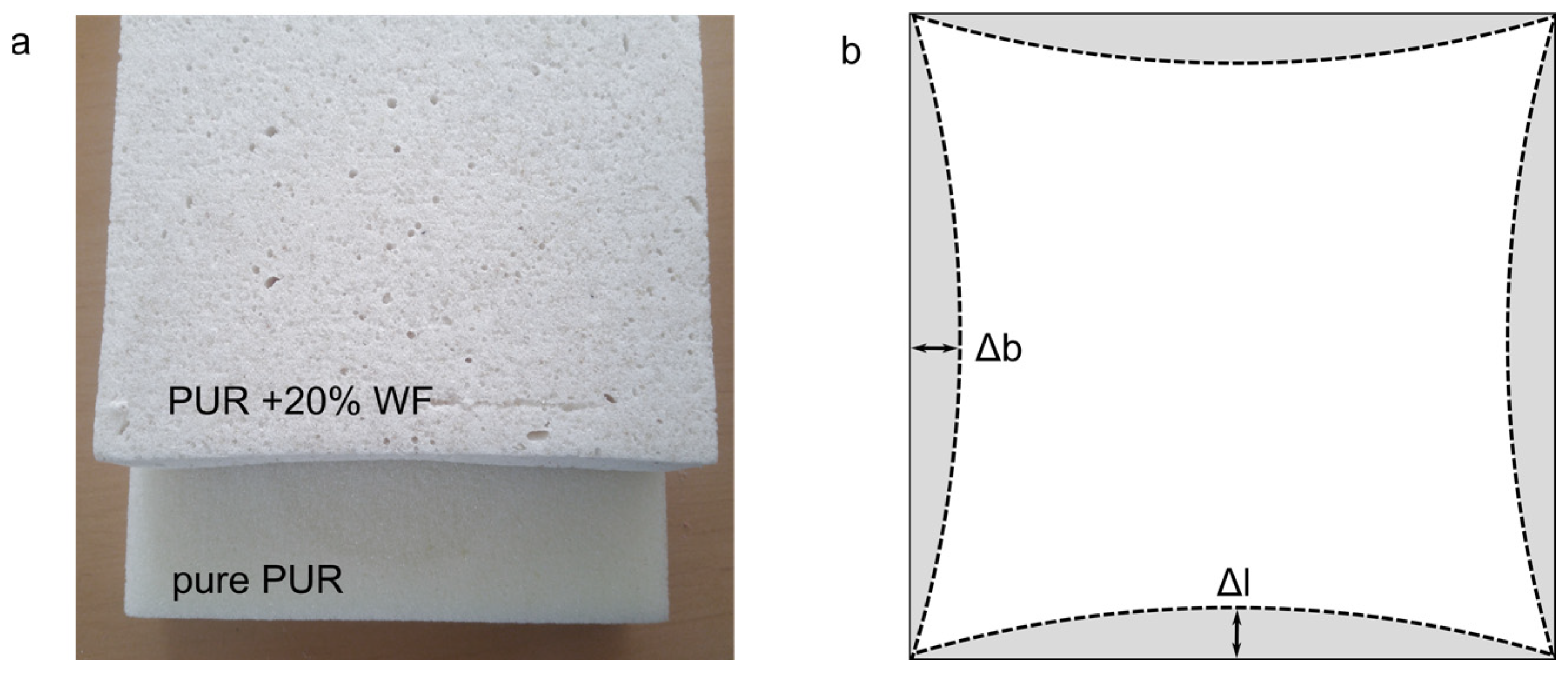

3.4. Dimensional Stability of PUR/WF Foams

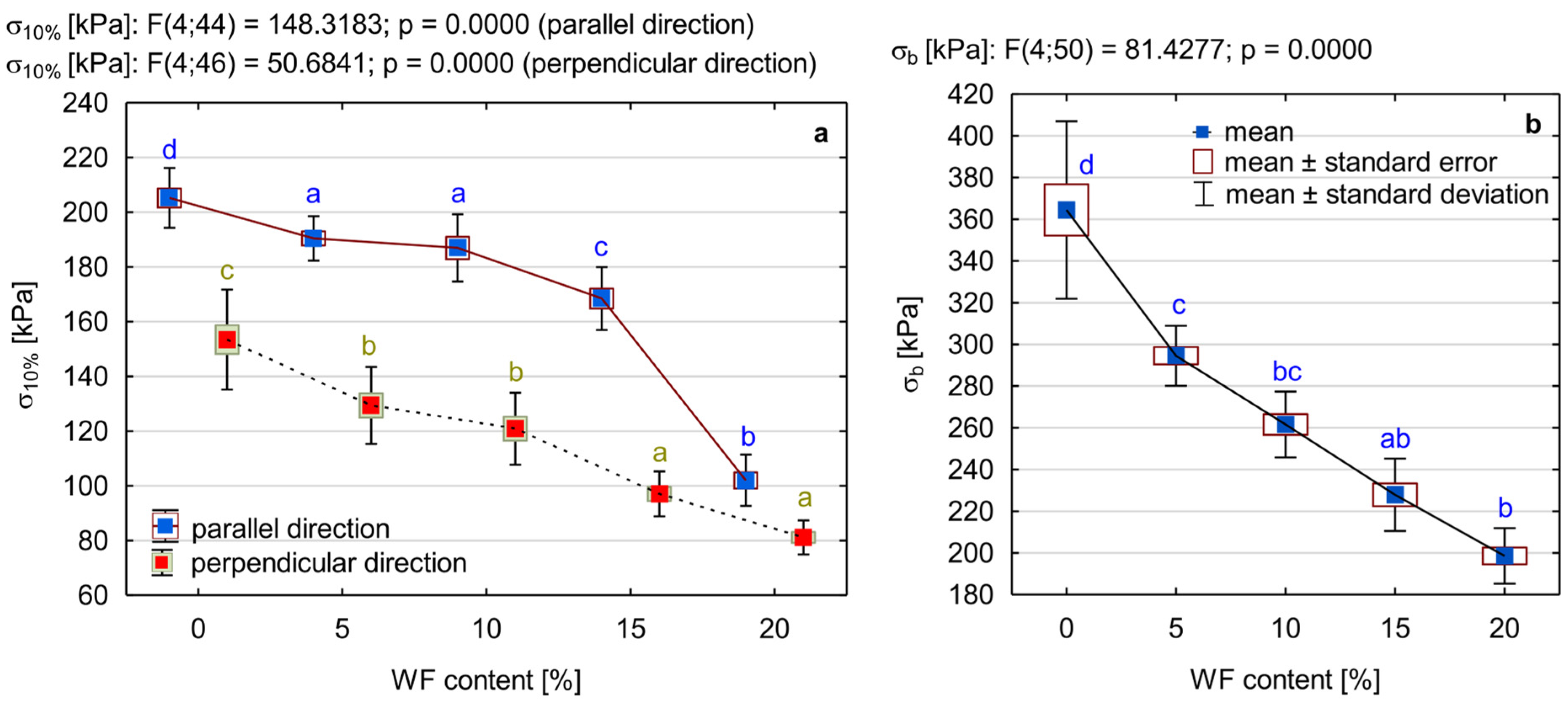

3.5. Compressive and Flexural Properties of PUR/WF Foams

3.6. Brittleness of PUR/WF Foams

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mirski, R.; Derkowski, A.; Dziurka, D.; Dukarska, D.; Czarnecki, R. Effects of a Chipboard Structure on Its Physical and Mechanical Properties. Materials 2019, 12, 3777. [Google Scholar] [CrossRef] [Green Version]

- Besserer, A.; Troilo, S.; Girods, P.; Rogaume, Y.; Brosse, N. Cascading Recycling of Wood Waste: A Review. Polymers 2021, 13, 1752. [Google Scholar] [CrossRef] [PubMed]

- Bederina, M.; Marmoret, L.; Mezreb, K.; Khenfer, M.; Bali, A.; Quéneudec, M. Effect of the addition of wood shavings on thermal conductivity of sand concretes: Experimental study and modelling. Constr. Build. Mater. 2007, 21, 662–668. [Google Scholar] [CrossRef]

- Coatanlem, P.; Jauberthie, R.; Rendell, F. Lightweight wood chipping concrete durability. Constr. Build. Mater. 2006, 20, 776–781. [Google Scholar] [CrossRef]

- Mirski, R.; Dukarska, D.; Derkowski, A.; Czarnecki, R.; Dziurka, D. By-products of sawmill industry as raw materials for manufacture of chip-sawdust boards. J. Build. Eng. 2020, 32, 101460. [Google Scholar] [CrossRef]

- Mirski, R.; Derkowski, A.; Dziurka, D.; Wieruszewski, M.; Dukarska, D. Effects of Chip Type on the Properties of Chip–Sawdust Boards Glued with Polymeric Diphenyl Methane Diisocyanate. Materials 2020, 13, 1329. [Google Scholar] [CrossRef] [Green Version]

- Włoch, M.; Landowska, P. Preparation and Properties of Thermoplastic Polyurethane Composites Filled with Powdered Buckwheat Husks. Materials 2022, 15, 356. [Google Scholar] [CrossRef] [PubMed]

- Martins, C.I.; Gil, V.; Rocha, S. Thermal, Mechanical, Morphological and Aesthetical Properties of Rotational Molding PE/Pine Wood Sawdust Composites. Polymers 2022, 14, 193. [Google Scholar] [CrossRef]

- Vitolina, S.; Shulga, G.; Neiberte, B.; Jaunslavietis, J.; Verovkins, A.; Betkers, T. Characteristics of the Waste Wood Biomass and Its Effect on the Properties of Wood Sanding Dust/Recycled PP Composite. Polymers 2022, 14, 468. [Google Scholar] [CrossRef]

- Czech-Polak, J.; Oliwa, R.; Oleksy, M.; Budzik, G. Rigid polyurethane foams with improved flame resistance. Polimery 2018, 63, 115–124. (In Polish) [Google Scholar] [CrossRef]

- Gama, N.V.; Ferreira, A.; Barros-Timmons, A. Polyurethane Foams: Past, Present, and Future. Materials 2018, 11, 1841. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Członka, S.; Strąkowska, A.; Kairytė, A. Effect of walnut shells and silanized walnut shells on the mechanical and thermal properties of rigid polyurethane foams. Polym. Test. 2020, 87, 106534. [Google Scholar] [CrossRef]

- Ciecierska, E.; Jurczyk-Kowalska, M.; Bazarnik, P.; Gloc, M.; Kulesza, M.; Kowalski, M.; Krauze, S.; Lewandowska, M. Flammability, mechanical properties and structure of rigid polyurethane foams with different types of carbon reinforcing materials. Compos. Struct. 2016, 140, 67–76. [Google Scholar] [CrossRef]

- Yuan, J.; Shi, S.Q. Effect of the addition of wood flours on the properties of rigid polyurethane foam. J. Appl. Polym. Sci. 2009, 113, 2902–2909. [Google Scholar] [CrossRef]

- Strąkowska, A.; Członka, S.; Kairytė, A. Rigid Polyurethane Foams Reinforced with POSS-Impregnated Sugar Beet Pulp Filler. Materials 2020, 13, 5493. [Google Scholar] [CrossRef] [PubMed]

- Marhoon, I. Effect of silica-fume microparticles on rigid polyurethane foam properties. Int. J. Sci. Technol. Res. 2016, 5, 96–100. [Google Scholar]

- Septevani, A.A.; Evans, D.A.C.; Annamalai, P.K.; Martin, D.J. The use of cellulose nanocrystals to enhance the thermal insulation properties and sustainability of rigid polyurethane foam. Ind. Crops Prod. 2017, 107, 114–121. [Google Scholar] [CrossRef]

- Saha, M.C.; Kabir, M.E.; Jeelani, S. Enhancement in thermal and mechanical properties of polyurethane foam infused with nanoparticles. Mater. Sci. Eng. A 2008, 479, 213–222. [Google Scholar] [CrossRef]

- Członka, S.; Kairytė, A.; Miedzińska, K.; Strąkowska, A.; Adamus-Włodarczyk, A. Mechanically Strong Polyurethane Composites Reinforced with Montmorillonite-Modified Sage Filler (Salvia officinalis L.). Int. J. Mol. Sci. 2021, 22, 3744. [Google Scholar] [CrossRef] [PubMed]

- Członka, S.; Kairytė, A.; Miedzińska, K.; Strąkowska, A. Polyurethane Composites Reinforced with Walnut Shell Filler Treated with Perlite, Montmorillonite and Halloysite. Int. J. Mol. Sci. 2021, 22, 7304. [Google Scholar] [CrossRef]

- Paciorek-Sadowska, J.; Borowicz, M.; Isbrandt, M.; Czupryński, B.; Apiecionek, Ł. The Use of Waste from the Production of Rapeseed Oil for Obtaining of New Polyurethane Composites. Polymers 2019, 11, 1431. [Google Scholar] [CrossRef] [Green Version]

- Miedzińska, K.; Członka, S.; Strąkowska, A.; Strzelec, K. Biobased Polyurethane Composite Foams Reinforced with Plum Stones and Silanized Plum Stones. Int. J. Mol. Sci. 2021, 22, 4757. [Google Scholar] [CrossRef]

- Augaitis, N.; Vaitkus, S.; Członka, S.; Kairytė, A. Research of Wood Waste as a Potential Filler for Loose-Fill Building Insulation: Appropriate Selection and Incorporation into Polyurethane Biocomposite Foams. Materials 2020, 13, 5336. [Google Scholar] [CrossRef]

- Tao, Y.; Li, P.; Cai, L. Effect of Fiber Content on Sound Absorption, Thermal Conductivity, and Compression Strength of Straw Fiber-Filled Rigid Polyurethane Foams: BioResources. Available online: https://bioresources.cnr.ncsu.edu/ (accessed on 23 May 2022).

- Sair, S.; Oushabi, A.; Kammouni, A.; Tanane, O.; Abboud, Y.; El Bouari, A. Mechanical and thermal conductivity properties of hemp fiber reinforced polyurethane composites. Case Stud. Constr. Mater. 2018, 8, 203–212. [Google Scholar] [CrossRef]

- Paciorek-Sadowska, J.; Czupryński, B.; Liszkowska, J. Application of waste products from agricultural-food industry for production of rigid polyurethane-polyisocyanurate foams. J. Porous Mater. 2011, 18, 631–638. [Google Scholar] [CrossRef] [Green Version]

- Zhang, S.; Xiang, A.; Tian, H.; Rajulu, A.V. Water-Blown Castor Oil-Based Polyurethane Foams with Soy Protein as a Reactive Reinforcing Filler. J. Polym. Environ. 2018, 26, 15–22. [Google Scholar] [CrossRef]

- Członka, S.; Bertino, M.F.; Strzelec, K. Rigid polyurethane foams reinforced with industrial potato protein. Polym. Test. 2018, 68, 135–145. [Google Scholar] [CrossRef]

- Zieleniewska, M.; Leszczyński, M.K.; Szczepkowski, L.; Bryśkiewicz, A.; Krzyżowska, M.; Bień, K.; Ryszkowska, J. Development and applicational evaluation of the rigid polyurethane foam composites with egg shell waste. Polym. Degrad. Stab. 2016, 132, 78–86. [Google Scholar] [CrossRef]

- Liszkowska, J. The effect of ground coffee on the mechanical and application properties of rigid polyurethane-polyisocyanurate foams. Polimery 2018, 63, 305–310. [Google Scholar] [CrossRef]

- Członka, S.; Sienkiewicz, N.; Strąkowska, A.; Strzelec, K. Keratin feathers as a filler for rigid polyurethane foams on the basis of soybean oil polyol. Polym. Test. 2018, 72, 32–45. [Google Scholar] [CrossRef]

- De Avila Delucis, R.; Magalhães, W.L.E.; Petzhold, C.L.; Amico, S.C. Forest-based resources as fillers in biobased polyurethane foams. J. Appl. Polym. Sci. 2018, 135, 45684. [Google Scholar] [CrossRef]

- Luo, S.; Gao, L.; Guo, W. Influence of Adding Lignin and Wood as Reactive Fillers on the Properties of Lightweight Wood–Polyurethane Composite Foams. For. Prod. J. 2021, 70, 420–427. [Google Scholar] [CrossRef]

- Mirski, R.; Dukarska, D.; Walkiewicz, J.; Derkowski, A. Waste Wood Particles from Primary Wood Processing as a Filler of Insulation PUR Foams. Materials 2021, 14, 4781. [Google Scholar] [CrossRef]

- EN ISO 845; Cellular Plastics and Rubbers-Determination of Apparent Density. European Standardization Committee: Brussels, Belgium, 2009.

- ISO 29767; Thermal Insulating Products for Building Applications–Determination of Short-Term Water Absorption by Partial Immersion. European Standardization Committee: Brussels, Belgium, 2019.

- EN 1604; Thermal Insulation Products for Buildings–Determination of Dimensional Stability under Specified Temperature and Humidity Conditions. European Standardization Committee: Brussels, Belgium, 2013.

- EN 826; Thermal Insulating Products for Building Applications–Determination of Compression Behaviour. European Standardization Committee: Brussels, Belgium, 2013.

- EN 12089; Thermal Insulating Products for Building Applications–Determination of Bending Behaviour. European Standardization Committee: Brussels, Belgium, 2013.

- Barszczewska-Rybarek, I.; Jaszcz, K.; Chladek, G.; Grabowska, P.; Okseniuk, A.; Szpot, M.; Zawadzka, M.; Sokołowska, A.; Tarkiewicz, A. Characterization of changes in structural, physicochemical and mechanical properties of rigid polyurethane building insulation after thermal aging in air and seawater. Polym. Bull. 2021, 79, 3061–3083. [Google Scholar] [CrossRef]

- ASTM C 421; Standard Test Method for Tumbling Friability of Preformed Block-Type and Preformed Pipe-Covering-Type Thermal Insulation. ASTM International: West Conshohocken, PA, USA, 1995.

- Uram, K.; Kurańska, M.; Andrzejewski, J.; Prociak, A. Rigid Polyurethane Foams Modified with Biochar. Materials 2021, 14, 5616. [Google Scholar] [CrossRef]

- Kurańska, M.; Prociak, A.; Cabulis, U.; Kirpluks, M.; Ryszkowska, J.; Auguścik, M. Innovative porous polyurethane-polyisocyanurate foams based on rapeseed oil and modified with expandable graphite. Ind. Crops Prod. 2017, 95, 316–323. [Google Scholar] [CrossRef]

- Gómez-Fernández, S.; Ugarte, L.; Calvo-Correas, T.; Peña-Rodríguez, C.; Corcuera, M.A.; Eceiza, A. Properties of flexible polyurethane foams containing isocyanate functionalized kraft lignin. Ind. Crops Prod. 2017, 100, 51–64. [Google Scholar] [CrossRef]

- Paciorek-Sadowska, J.; Borowicz, M.; Czuprynski, B.; Liszkowska, J. Composites of rigid polyurethane-polyisocyanurate foams with oak bark. Polimery 2017, 62, 666–672. (In Polish) [Google Scholar] [CrossRef]

- Beran, R.; Zarybnicka, L.; Machova, D. Recycling of rigid polyurethane foam: Micro-milled powder used as active filler in polyurethane adhesives. J. Appl. Polym. Sci. 2020, 137, 49095. [Google Scholar] [CrossRef]

- Członka, S.; Strąkowska, A.; Kairytė, A.; Kremensas, A. Nutmeg filler as a natural compound for the production of polyurethane composite foams with antibacterial and anti-aging properties. Polym. Test. 2020, 86, 106479. [Google Scholar] [CrossRef]

- Członka, S.; Strąkowska, A.; Kairytė, A. The Impact of Hemp Shives Impregnated with Selected Plant Oils on Mechanical, Thermal, and Insulating Properties of Polyurethane Composite Foams. Materials 2020, 13, 4709. [Google Scholar] [CrossRef]

- Kairytė, A.; Kremensas, A.; Balčiūnas, G.; Członka, S.; Strąkowska, A. Closed Cell Rigid Polyurethane Foams Based on Low Functionality Polyols: Research of Dimensional Stability and Standardised Performance Properties. Materials 2020, 13, 1438. [Google Scholar] [CrossRef] [Green Version]

- Członka, S.; Strąkowska, A.; Kairytė, A. Coir Fibers Treated with Henna as a Potential Reinforcing Filler in the Synthesis of Polyurethane Composites. Materials 2021, 14, 1128. [Google Scholar] [CrossRef]

- Estravís, S.; Tirado-Mediavilla, J.; Santiago-Calvo, M.; Ruiz-Herrero, J.L.; Villafañe, F.; Rodríguez-Pérez, M. Rigid polyurethane foams with infused nanoclays: Relationship between cellular structure and thermal conductivity. Eur. Polym. J. 2016, 80, 1–15. [Google Scholar] [CrossRef] [Green Version]

- Barczewski, M.; Kurańska, M.; Sałasińska, K.; Michałowski, S.; Prociak, A.; Uram, K.; Lewandowski, K. Rigid polyurethane foams modified with thermoset polyester-glass fiber composite waste. Polym. Test. 2019, 81, 106190. [Google Scholar] [CrossRef]

- Sung, G.; Kim, J.H. Influence of filler surface characteristics on morphological, physical, acoustic properties of polyurethane composite foams filled with inorganic fillers. Compos. Sci. Technol. 2017, 146, 147–154. [Google Scholar] [CrossRef]

- Grząbka-Zasadzińska, A.; Bartczak, P.; Borysiak, S. Highly Insulative PEG-Grafted Cellulose Polyurethane Foams—From Synthesis to Application Properties. Materials 2021, 14, 6363. [Google Scholar] [CrossRef] [PubMed]

- Członka, S.; Bertino, M.F.; Kośny, J.; Strąkowska, A.; Masłowski, M.; Strzelec, K. Linseed oil as a natural modifier of rigid polyurethane foams. Ind. Crop. Prod. 2018, 115, 40–51. [Google Scholar] [CrossRef]

- Silva, N.G.S.; Cortat, L.I.C.O.; Orlando, D.; Mulinari, D.R. Evaluation of rubber powder waste as reinforcement of the polyurethane derived from castor oil. Waste Manag. 2020, 116, 131–139. [Google Scholar] [CrossRef]

- Formela, K.; Hejna, A.; Zedler, Ł.; Przybysz, M.; Ryl, J.; Saeb, M.R.; Piszczyk, Ł. Structural, thermal and physico-mechanical properties of polyurethane/brewers’ spent grain composite foams modified with ground tire rubber. Ind. Crop. Prod. 2017, 108, 844–852. [Google Scholar] [CrossRef]

- Stefani, P.M.; Barchi, A.T.; Sabugal, J.; Vazquez, A. Characterization of epoxy foams. J. Appl. Polym. Sci. 2003, 90, 2992–2996. [Google Scholar] [CrossRef]

- Sture, B.; Vevere, L.; Kirpluks, M.; Godina, D.; Fridrihsone, A.; Cabulis, U. Polyurethane Foam Composites Reinforced with Renewable Fillers for Cryogenic Insulation. Polymers 2021, 13, 4089. [Google Scholar] [CrossRef]

- Kuranska, M.; Prociak, A. Porous polyurethane composites with natural fibres. Compos. Sci. Technol. 2012, 72, 299–304. [Google Scholar] [CrossRef]

- Thirumal, M.; Khastgir, D.; Singha, N.K.; Manjunath, B.S.; Naik, Y.P. Mechanical, Morphological and Thermal Properties of Rigid Polyurethane Foam: Effect of the Fillers. Cell. Polym. 2007, 26, 245–259. [Google Scholar] [CrossRef]

- Shalbafan, A.; Choupani, K.; Welling, J. Effect of blowing agent concentration on rigid polyurethane foam and the properties of foam-core particleboard. Wood Mater. Sci. Eng. 2021, 16, 85–93. [Google Scholar] [CrossRef]

- Pouzet, M.; Dubois, M.; Charlet, K.; Béakou, A. From hydrophilic to hydrophobic wood using direct fluorination: A localized treatment. Comptes Rendus. Chim. 2018, 21, 800–807. [Google Scholar] [CrossRef]

- Liszkowska, J.; Moraczewski, K.; Borowicz, M.; Paciorek-Sadowska, J.; Czupryński, B.; Isbrandt, M. The Effect of Accelerated Aging Conditions on the Properties of Rigid Polyurethane-Polyisocyanurate Foams Modified by Cinnamon Extract. Appl. Sci. 2019, 9, 2663. [Google Scholar] [CrossRef] [Green Version]

- Kairytė, A.; Ivdre, A.; Vaitkus, S. Dimensionally stable water-blown polyurethane foam extended with bio-based propylene glycol and modified with paper waste sludge. Eng. Struct. Technol. 2017, 9, 93–103. [Google Scholar] [CrossRef]

- Li, X.; Cao, H.; Zhang, Y. Properties of water blown rigid polyurethane foams with different functionality. J. Wuhan Univ. Technol. Sci. Ed. 2008, 23, 125–129. [Google Scholar] [CrossRef]

- EN 13165; Thermal Insulation Products for Buildings–Factory Made Rigid Polyurethane Foam (PU) Products–Specification. European Standardization Committee: Brussels, Belgium, 2016.

- Borkowski, R. Thermal insulation in industrial applications. Izolacje 2014, 19, 10. (In Polish) [Google Scholar]

- Kurańska, M.; Barczewski, M.; Uram, K.; Lewandowski, K.; Prociak, A.; Michałowski, S. Basalt waste management in the production of highly effective porous polyurethane composites for thermal insulating applications. Polym. Test. 2019, 76, 90–100. [Google Scholar] [CrossRef]

- Voiconi, T.; Linul, E.; Marşavina, L.; Sadowski, T.; Kneć, M. Determination of Flexural Properties of Rigid PUR Foams Using Digital Image Correlation. Solid State Phenom. 2014, 216, 116–121. [Google Scholar] [CrossRef]

- Uram, K.; Leszczyńska, M.; Prociak, A.; Czajka, A.; Gloc, M.; Leszczyński, M.K.; Michałowski, S.; Ryszkowska, J. Polyurethane Composite Foams Synthesized Using Bio-Polyols and Cellulose Filler. Materials 2021, 14, 3474. [Google Scholar] [CrossRef] [PubMed]

- Członka, S.; Strąkowska, A.; Strzelec, K.; Kairytė, A.; Kremensas, A. Melamine, silica, and ionic liquid as a novel flame retardant for rigid polyurethane foams with enhanced flame retardancy and mechanical properties. Polym. Test. 2020, 87, 106511. [Google Scholar] [CrossRef]

- Thermal Insulation Materials Made of Rigid Polyurethane Foam/Thermal-Insulation-Materials-Made-of-Rigid-Polyurethane-Foam.Pdf/PDF4PRO. Available online: https://pdf4pro.com/view/thermal-insulation-materials-made-of-rigid-polyurethane-foam-376aac.html (accessed on 19 May 2022).

- Jabber, L.J.Y.; Grumo, J.C.; Alguno, A.C.; Lubguban, A.A.; Capangpangan, R.Y. Influence of cellulose fibers extracted from pineapple (Ananas comosus) leaf to the mechanical properties of rigid polyurethane foam. Mater. Today Proc. 2021, 46, 1735–1739. [Google Scholar] [CrossRef]

- High Quality PU PUF PUR PIR Polyurethane Foam Insulation Board Cheap Price-Henan Panels Industry Co., Ltd. Available online: https://www.pnspanels.com/Polyurethane-Foam-insulation-board.html (accessed on 27 May 2022).

- Guan, J.; Hanna, M.A. Functional properties of extruded foam composites of starch acetate and corn cob fiber. Ind. Crops Prod. 2004, 19, 255–269. [Google Scholar] [CrossRef]

- Saint-Michel, F.; Chazeau, L.; Cavaillé, J.-Y. Mechanical properties of high density polyurethane foams: II Effect of the filler size. Compos. Sci. Technol. 2006, 66, 2709–2718. [Google Scholar] [CrossRef]

- Omotoyinbo, J.A.; Oladele, I.O.; Jabar, J.M.; Borode, J.O.; Alaneme, K.K.; Akinwekomi, A.D.; Oke, S.R.; Omotosho, T.F.; Saliu, L.O. Comparative investigation of the influence of kaolin and dolomite on the properties of polyurethane foam. Manuf. Rev. 2021, 8, 27. [Google Scholar] [CrossRef]

- Liszkowska, J. The use of citric acid in the production of polyols for rigid PUR-PIR foams. Polym. Bull. 2017, 74, 283–305. [Google Scholar] [CrossRef] [Green Version]

| WF Content [%] | Mean Processing Times [s] | Tmax [°C] | h [mm] | Δh [%] | ||||

|---|---|---|---|---|---|---|---|---|

| Cream | Start of Growth | Gelling | Growth | Tack-Free | ||||

| 0 | 12 ± 1 * | 38 ± 1 | 113 ± 6 | 180 ± 6 | 249 ± 11 | 114 ± 2 | 155 ± 3 | - |

| 5 | 12 ± 1 | 33 ± 1 | 122 ± 2 | 187 ± 3 | 260 ± 14 | 113 ± 1 | 150 ± 2 | 3.4 |

| 10 | 12 ± 2 | 30 ± 2 | 117 ± 4 | 201 ± 10 | 258 ± 5 | 117 ± 2 | 146 ± 1 | 5.8 |

| 15 | 11 ± 1 | 33 ± 2 | 136 ± 7 | 240 ± 3 | 276 ± 6 | 114 ± 2 | 143 ± 2 | 7.7 |

| 20 | 15 ± 2 | 30 ± 2 | 157 ± 4 | 254 ± 6 | 288 ± 6 | 90 ± 3 | 132 ± 9 | 15.0 |

| WF Content [%] | T = 60 °C, RH = 80% | T= −20 °C | ||||

|---|---|---|---|---|---|---|

| Δεl [%] | Δεb [%] | Δεd [%] | Δεl [%] | Δεb [%] | Δεd [%] | |

| 0 | 0.32 ± 0.09 * | 0.37 ± 0.10 | 0.29 ± 0.11 | 0.03 ± 0.03 | 0.05 ± 0.06 | 0.05 ± 0.08 |

| 5 | 0.32 ± 0.07 | 0.42 ± 0.14 | 0.35 ± 0.14 | 0.03 ± 0.04 | 0.03 ± 0.04 | 0.03 ± 0.05 |

| 10 | 1.31 ± 0.28 | 1.44 ± 0.47 | 0.24 ± 0.08 | 0.14 ± 0.07 | 0.16 ± 0.05 | 0.01 ± 0.06 |

| 15 | 3.94 ± 0.55 | 4.05 ± 0.31 | 0.20 ± 0.10 | 0.21 ± 0.08 | 0.23 ± 0.09 | 0.05 ± 0.05 |

| 20 | 7.53 ± 1.29 | 6.92 ± 1.40 | −0.57 ± 0.26 | 0.39 ± 0.15 | 0.42 ± 0.13 | 0.05 ± 0.08 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dukarska, D.; Walkiewicz, J.; Derkowski, A.; Mirski, R. Properties of Rigid Polyurethane Foam Filled with Sawdust from Primary Wood Processing. Materials 2022, 15, 5361. https://doi.org/10.3390/ma15155361

Dukarska D, Walkiewicz J, Derkowski A, Mirski R. Properties of Rigid Polyurethane Foam Filled with Sawdust from Primary Wood Processing. Materials. 2022; 15(15):5361. https://doi.org/10.3390/ma15155361

Chicago/Turabian StyleDukarska, Dorota, Joanna Walkiewicz, Adam Derkowski, and Radosław Mirski. 2022. "Properties of Rigid Polyurethane Foam Filled with Sawdust from Primary Wood Processing" Materials 15, no. 15: 5361. https://doi.org/10.3390/ma15155361

APA StyleDukarska, D., Walkiewicz, J., Derkowski, A., & Mirski, R. (2022). Properties of Rigid Polyurethane Foam Filled with Sawdust from Primary Wood Processing. Materials, 15(15), 5361. https://doi.org/10.3390/ma15155361