The Effect of ECAP Processing Conditions on Microstructural Evolution and Mechanical Properties of Pure Magnesium—Experimental, Mathematical Empirical and Response Surface Approach

Abstract

:1. Introduction

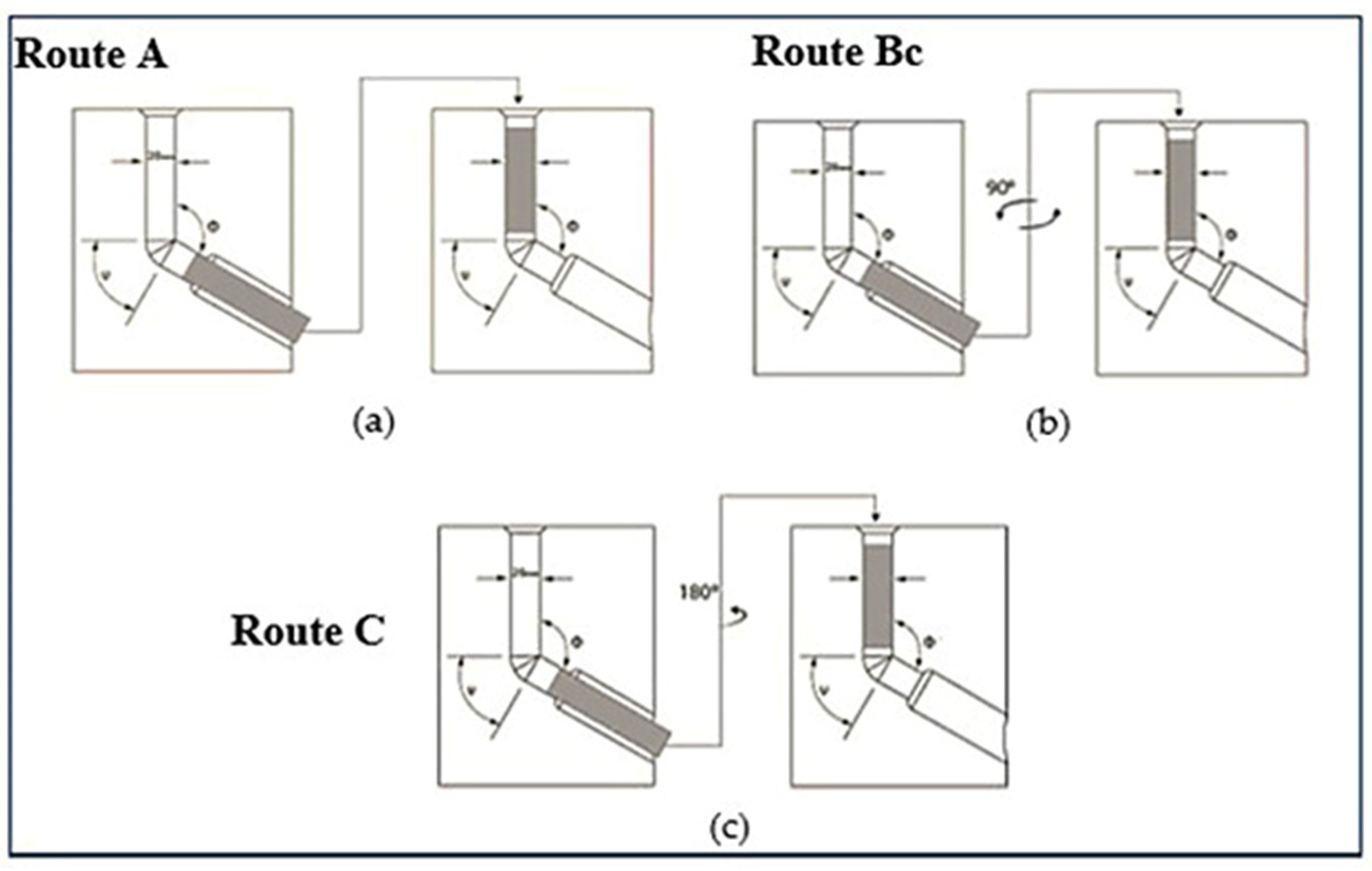

2. Materials and Methods

2.1. Experimental Design

2.2. Material and Methodology

2.3. Regression Model

2.4. Genetic Algorithm (GA)

3. Results and Discussion

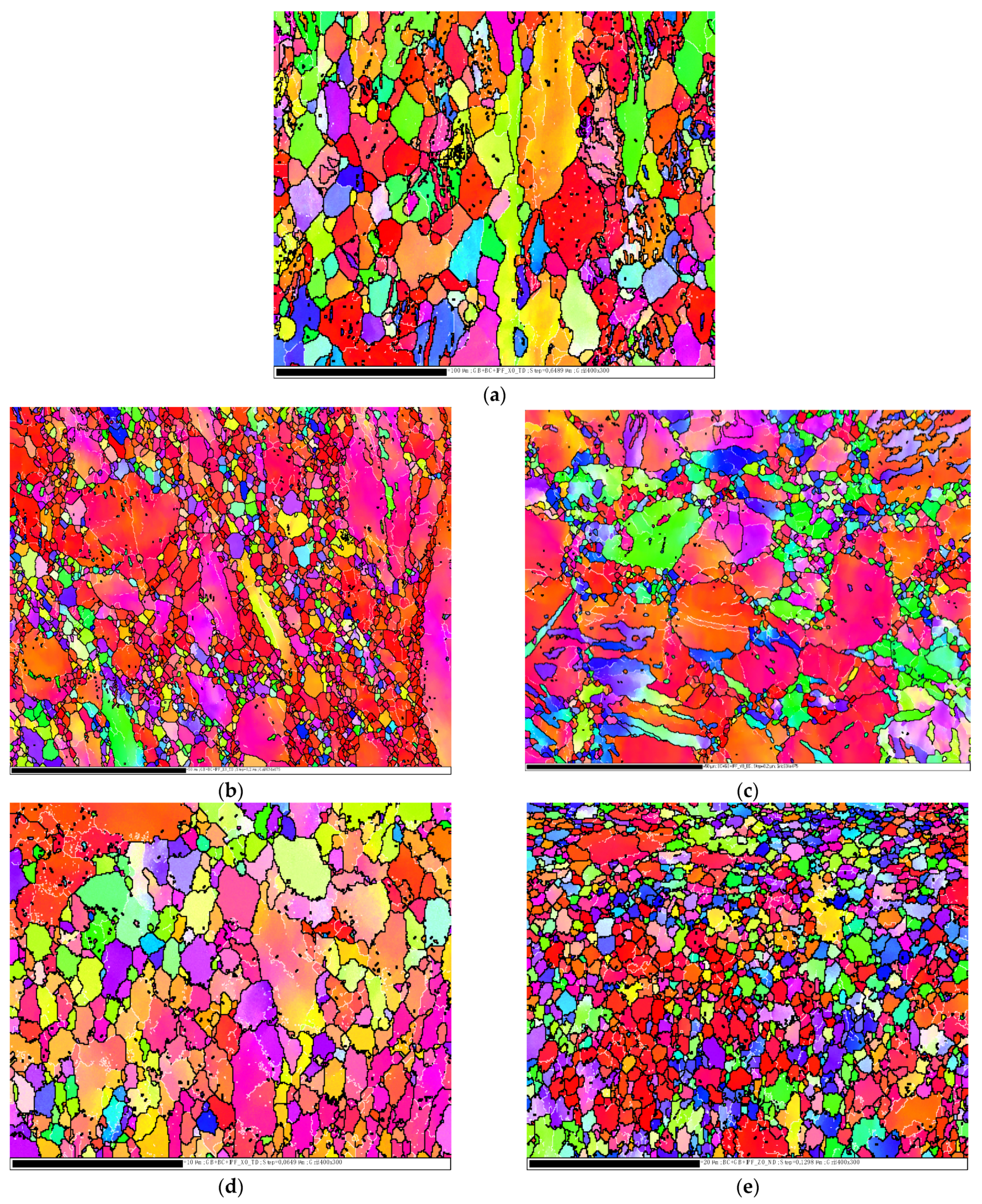

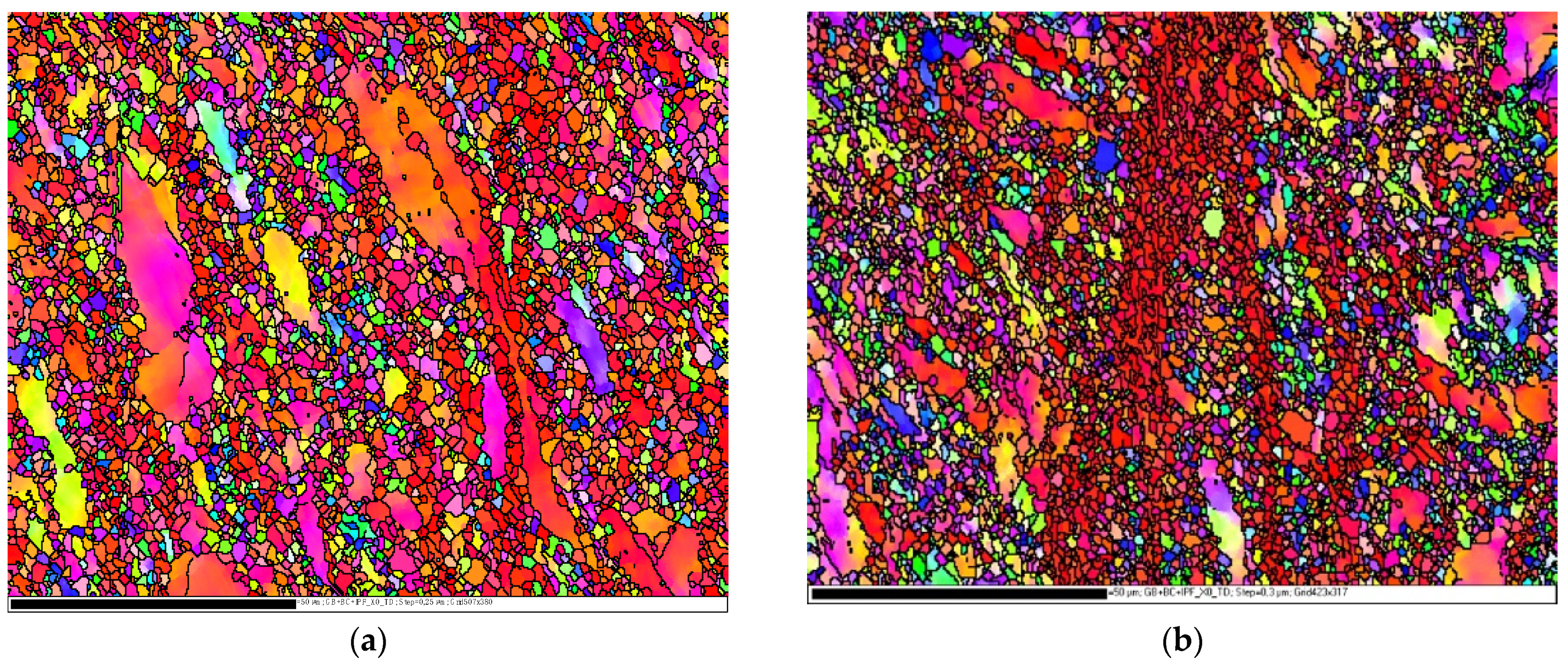

3.1. Microstructural Evolution

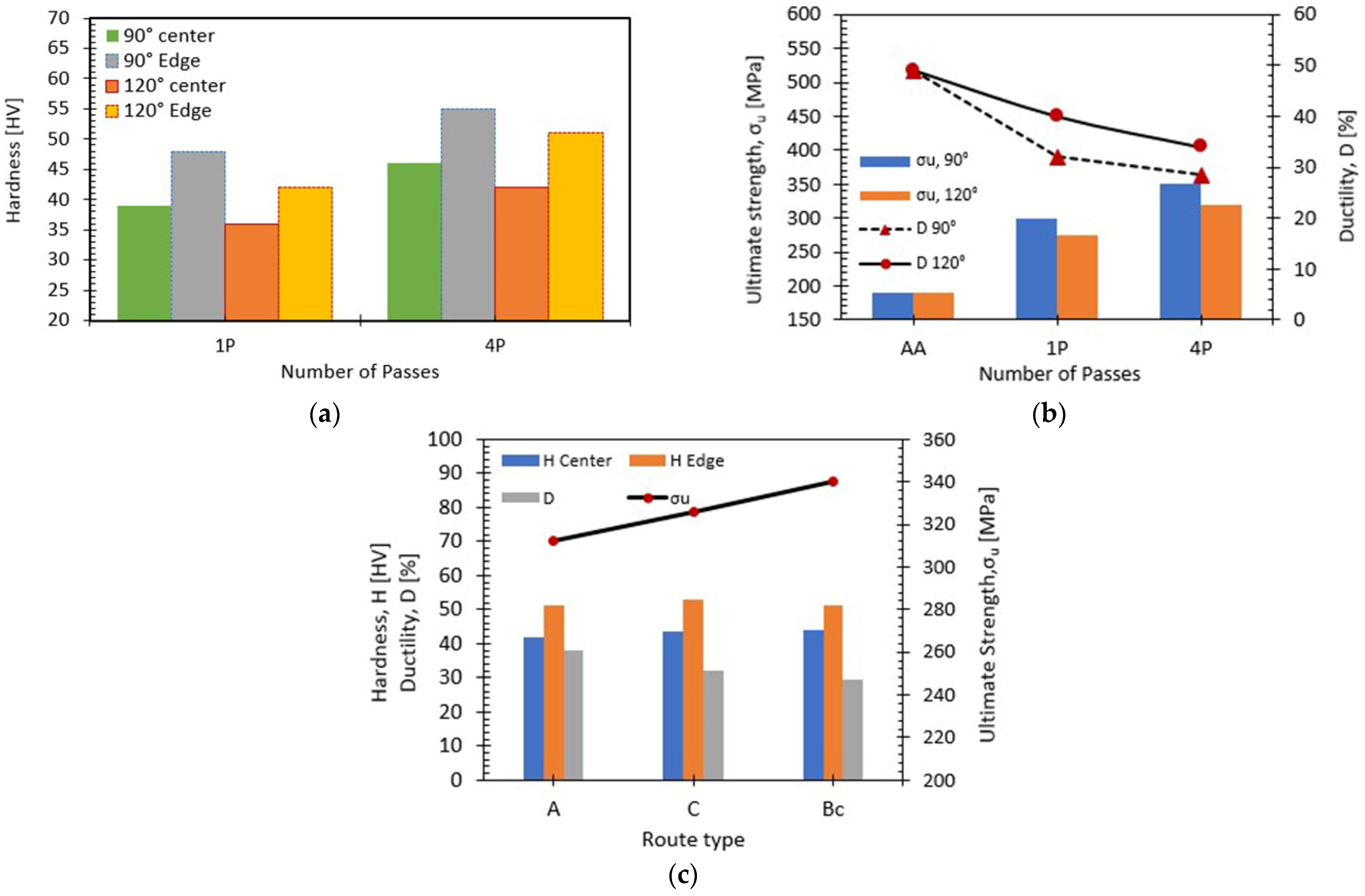

3.2. Mechanical Properties

× N × φ + 0.000507579 × N × X2

N × φ + 0.000288905 × N2

75.50000 × N × X1 − 49.75000 × N × X 2– 4.82500 × φ × X1 – 22.87500 × N2

X1 + 0.103333 × φ × X2 − 1.41667 × N2

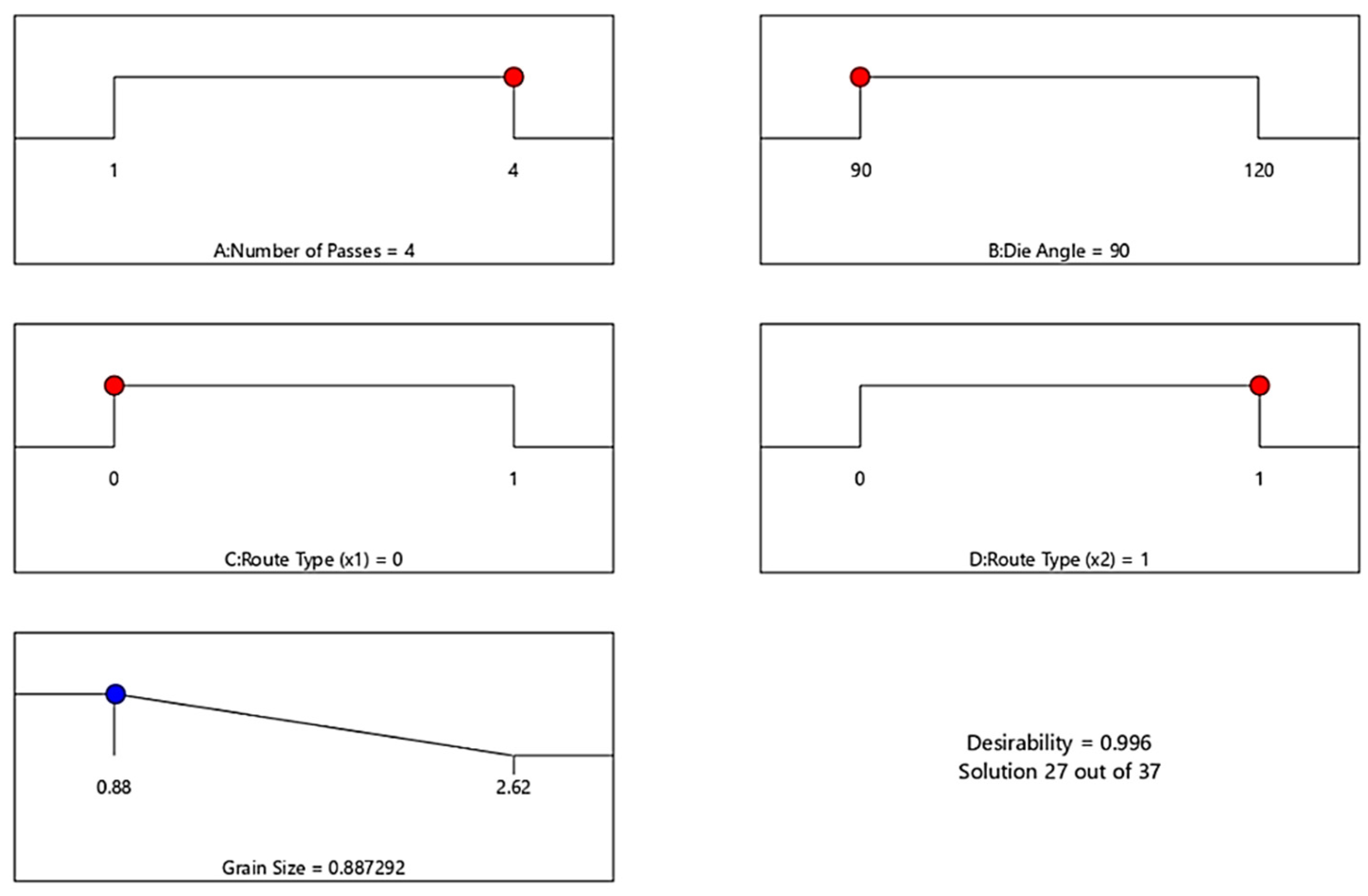

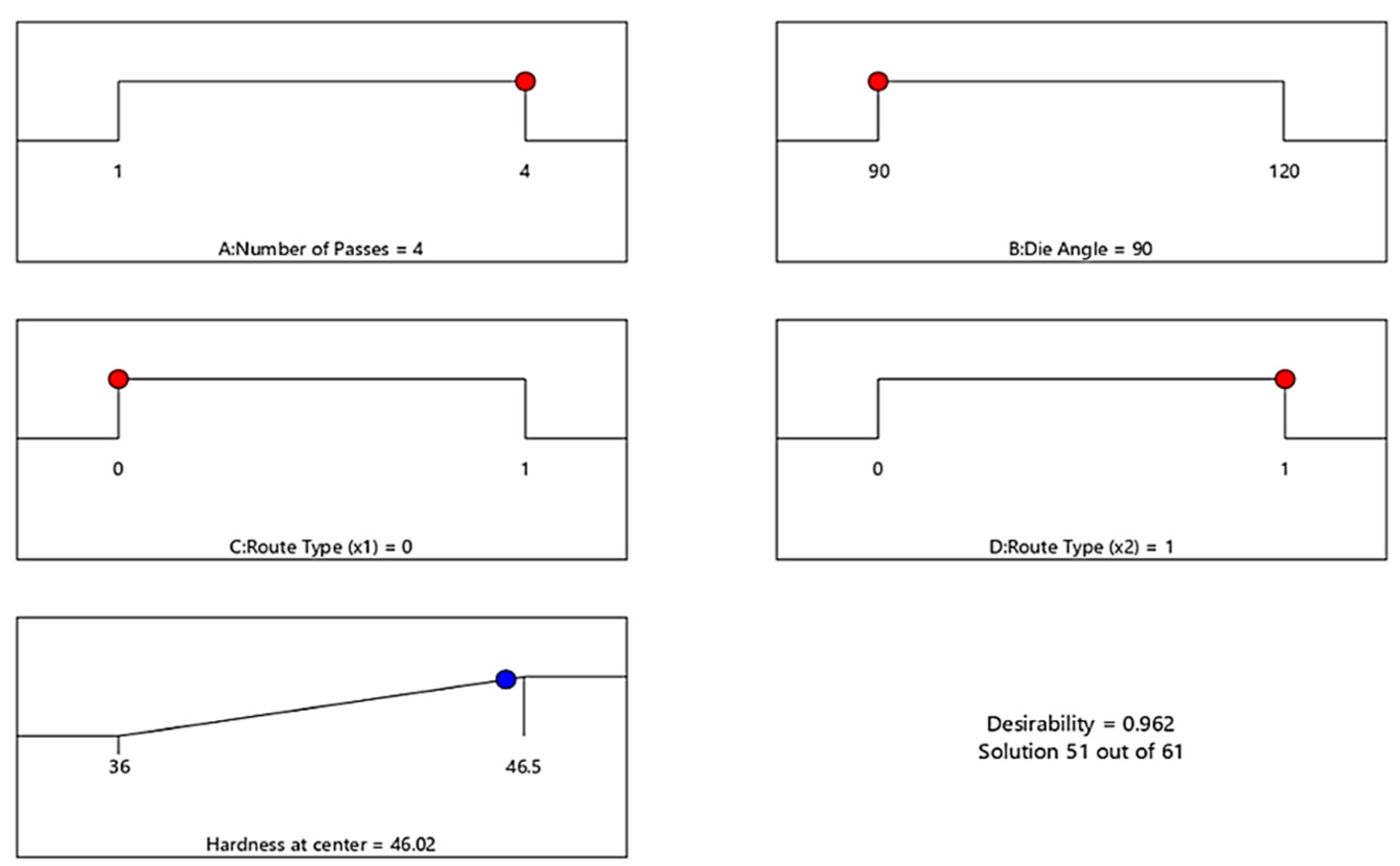

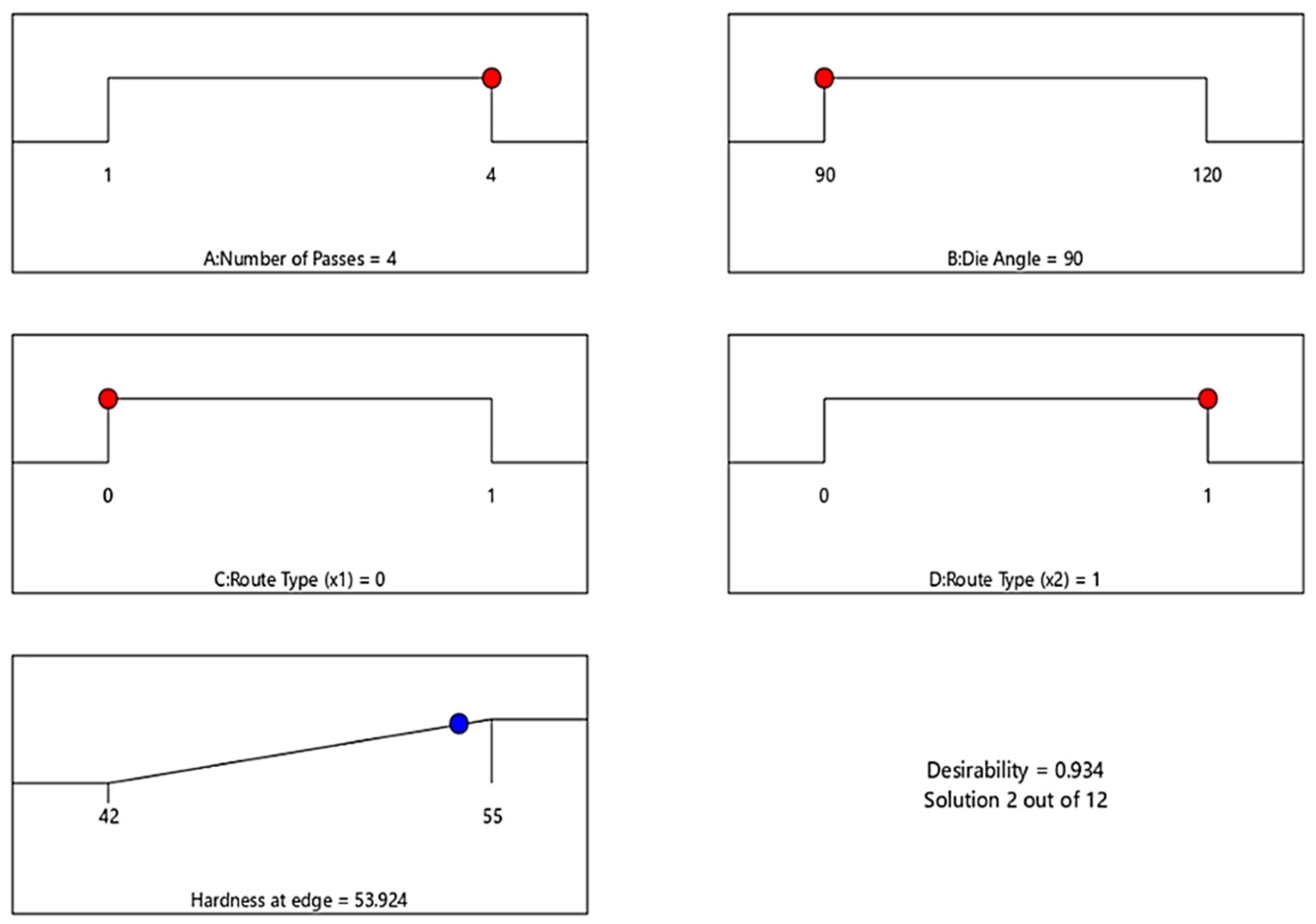

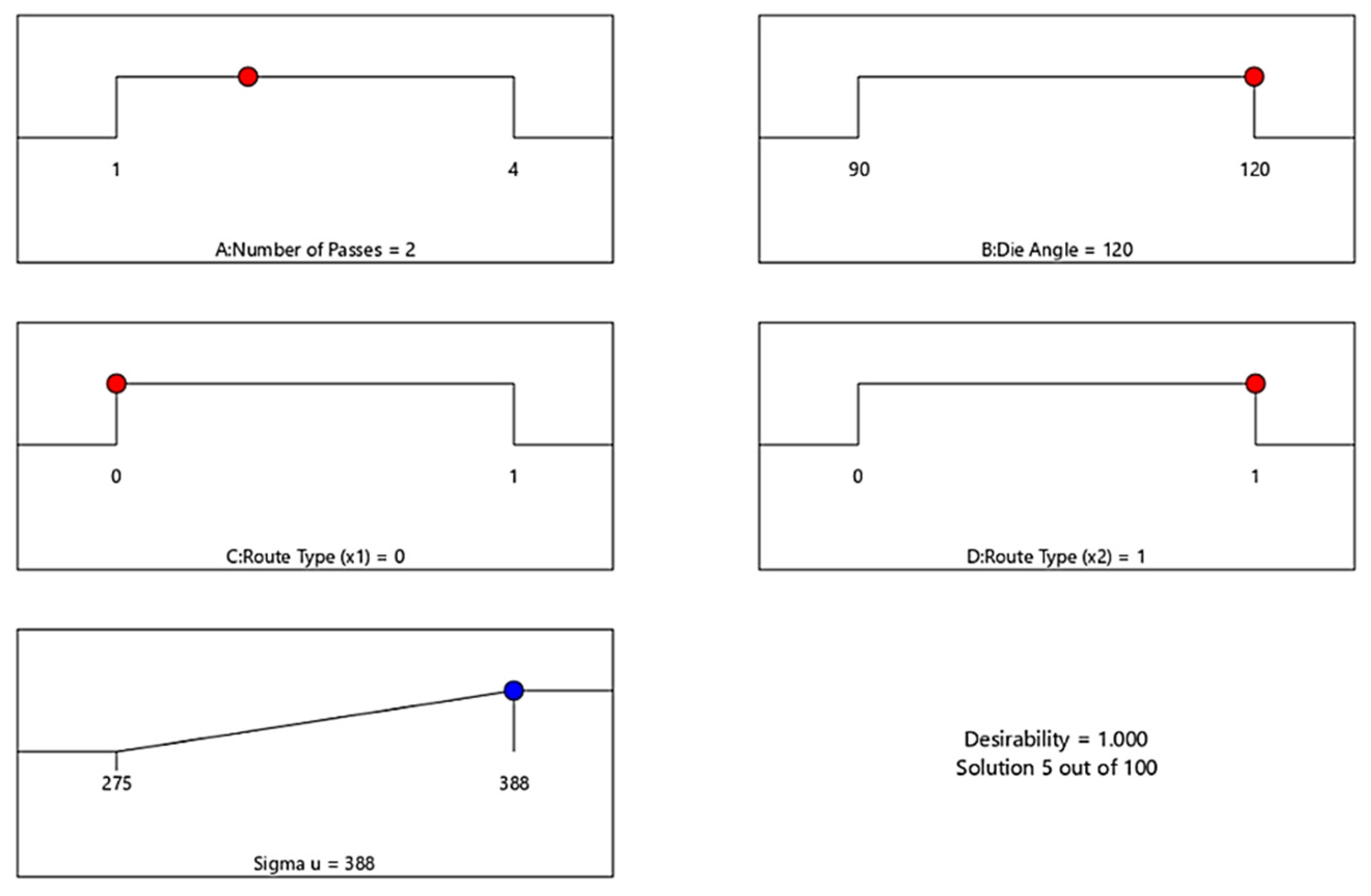

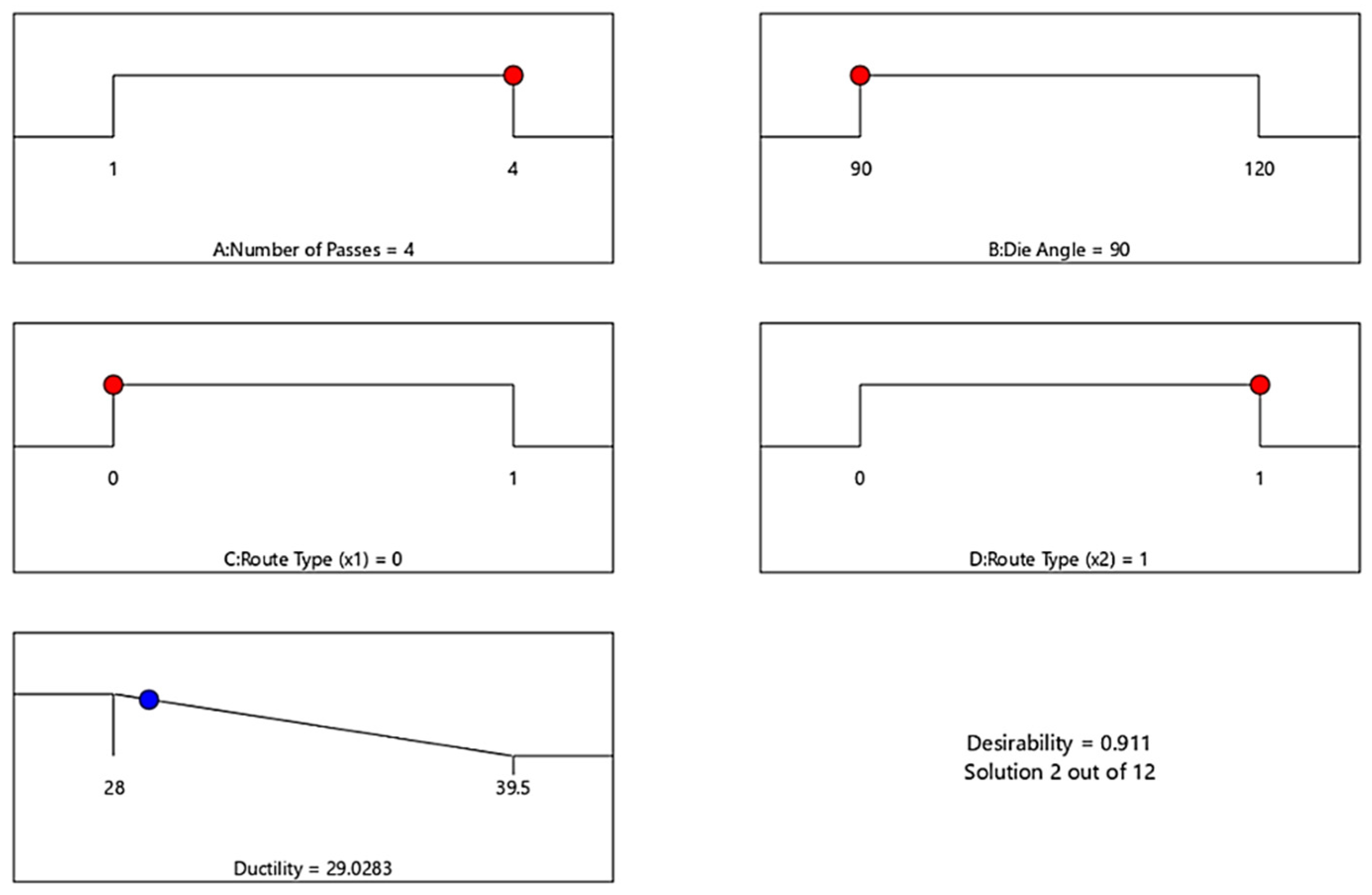

3.3. Optimization Results

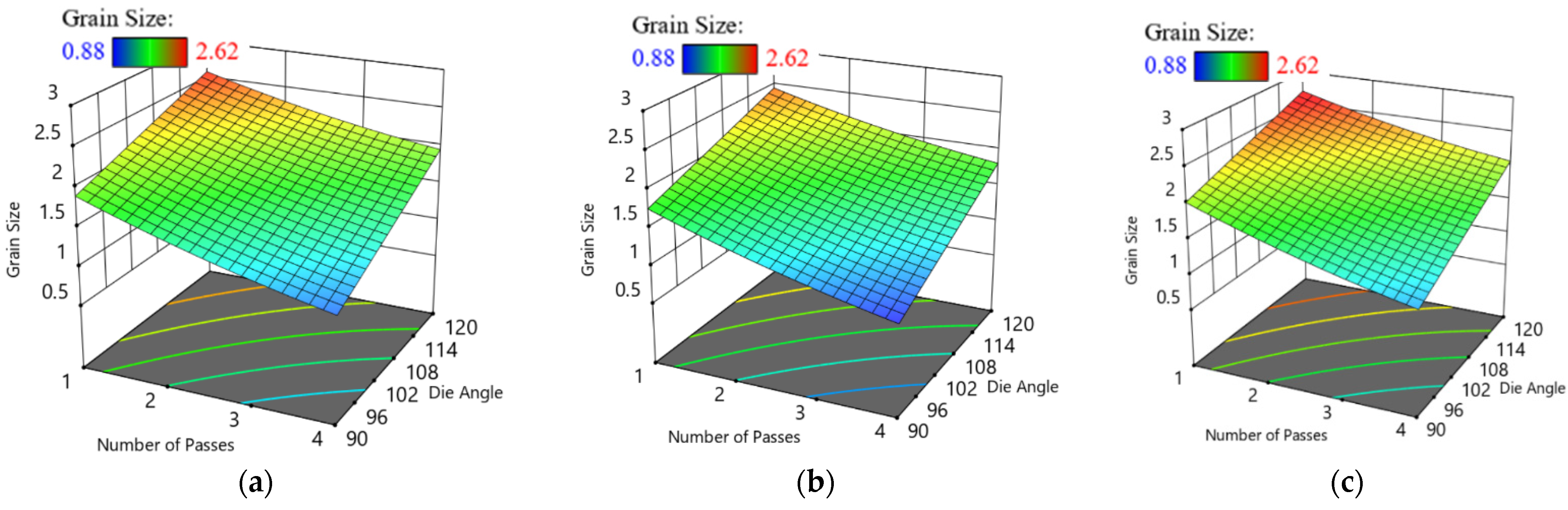

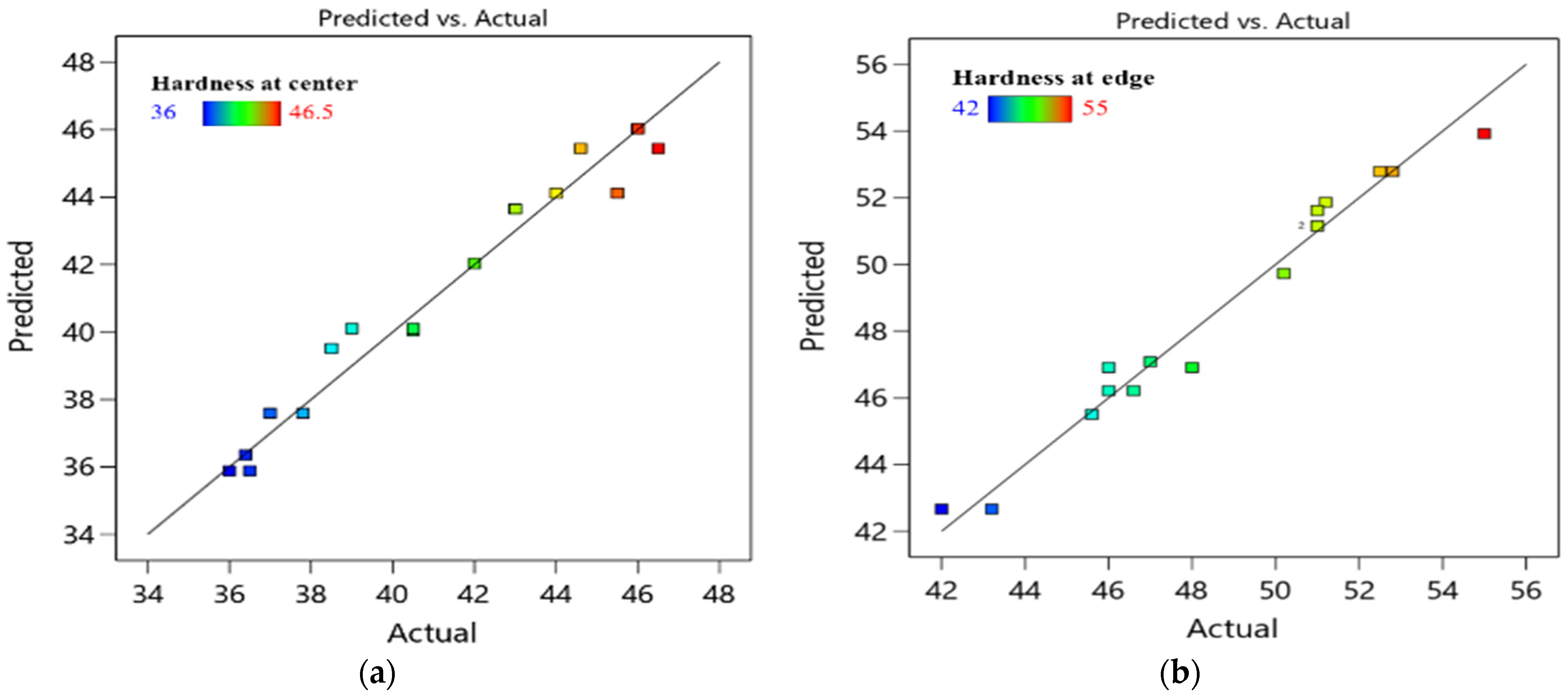

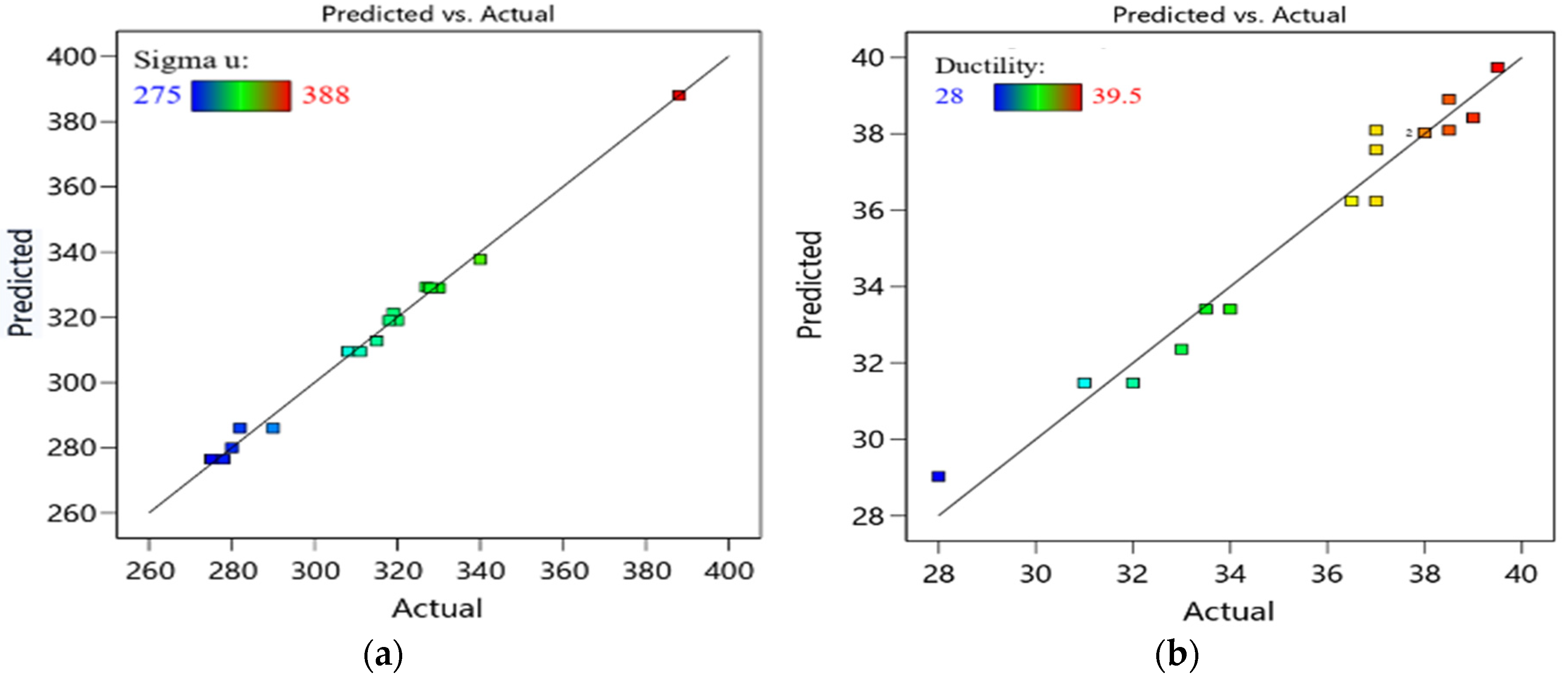

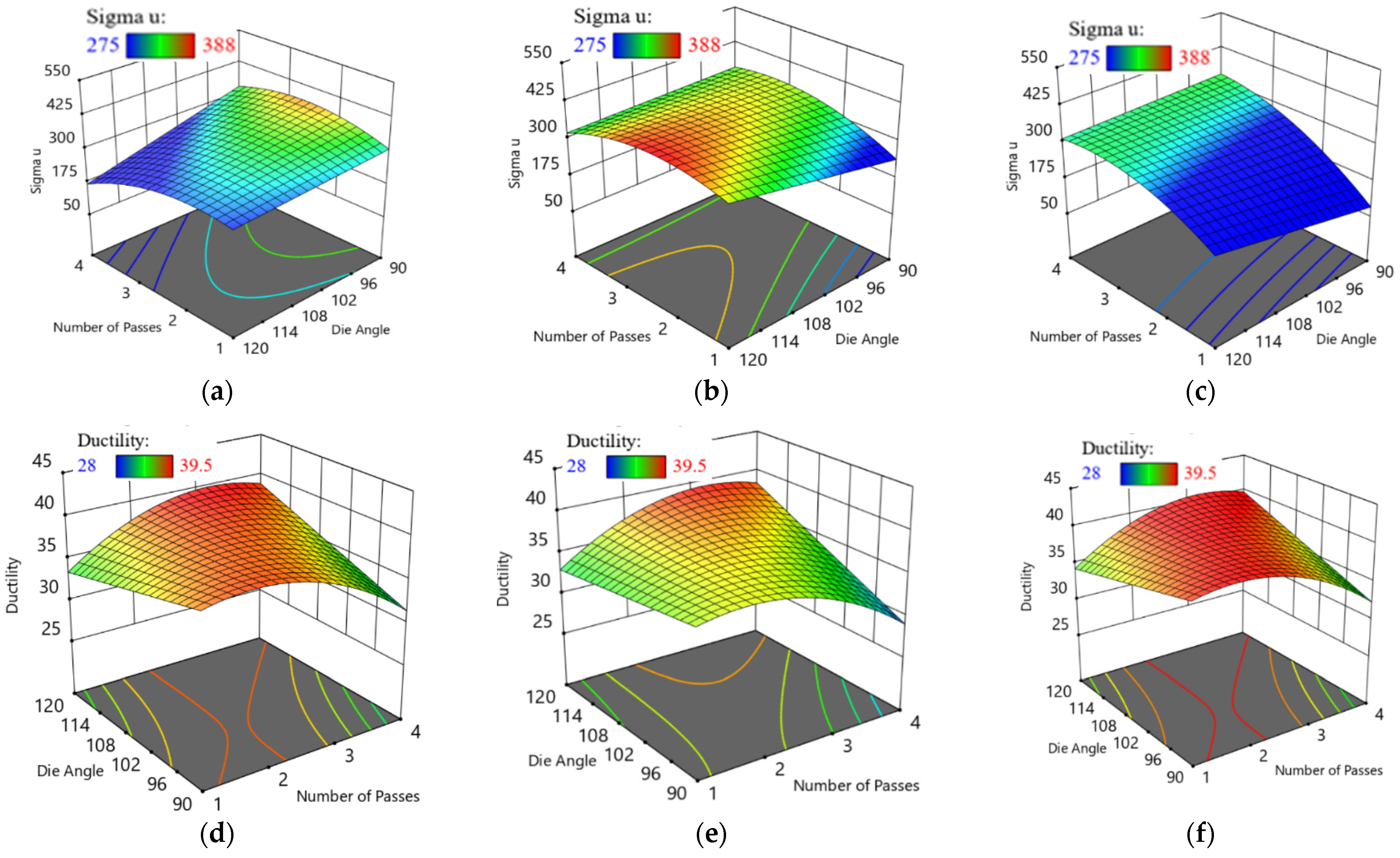

3.3.1. RSM Results

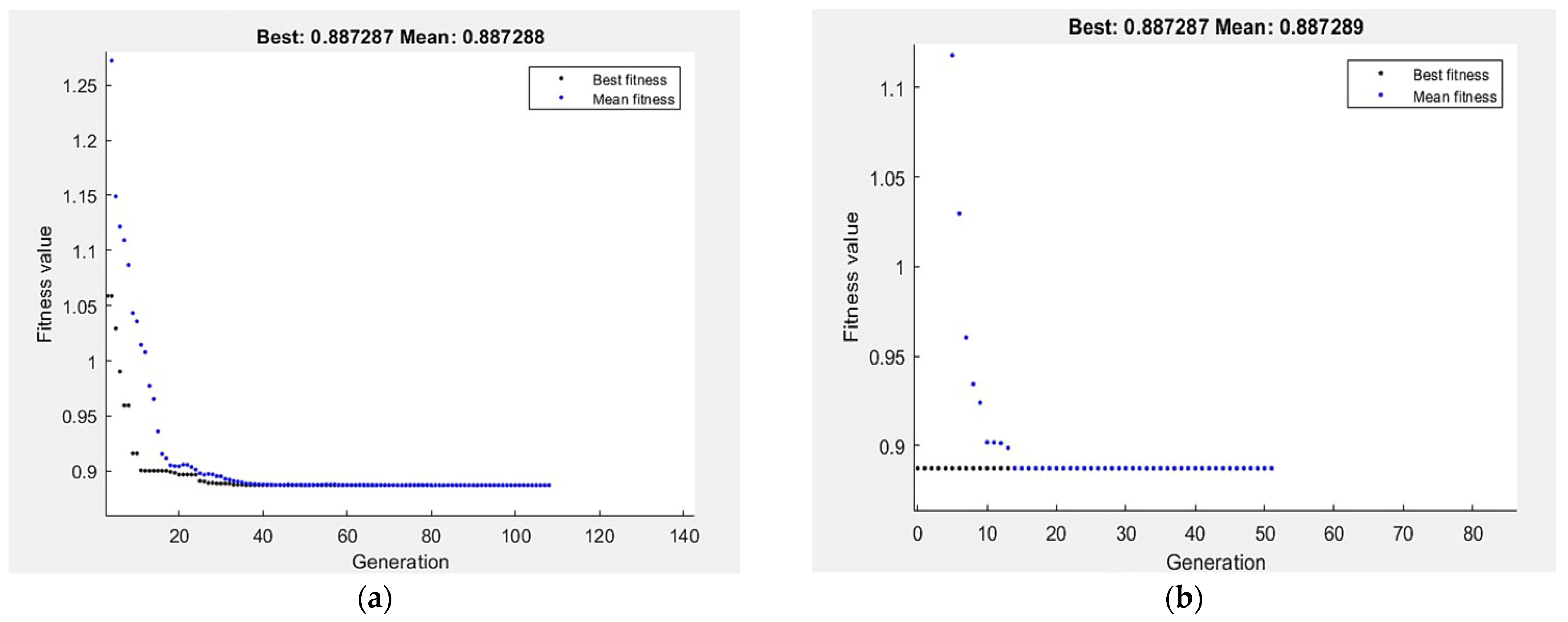

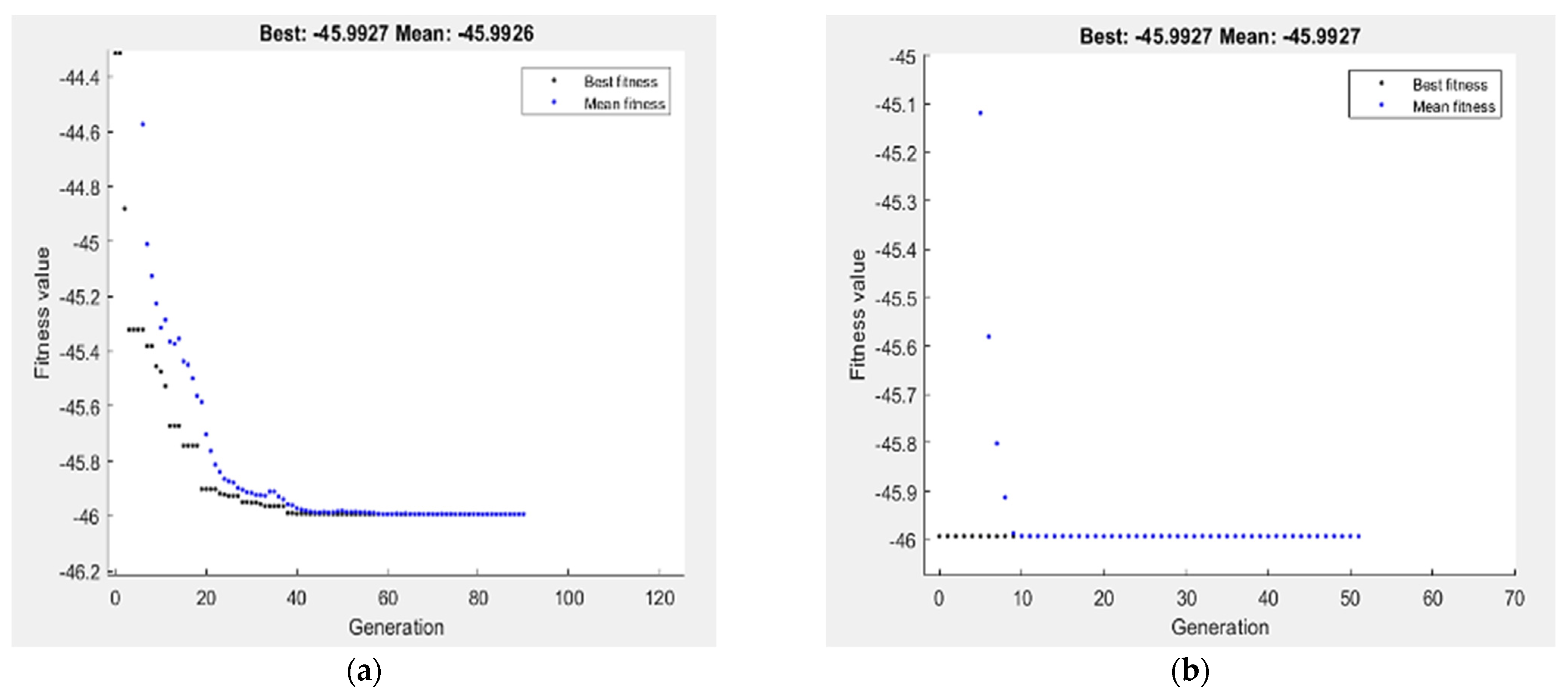

3.3.2. GA and Hybrid RSM-GA Results

3.3.3. Validation of GA

4. Conclusions

- ECAP parameters of four passes, ϕ = 90° and route Bc produce the most significant grain refinement.

- 4-Bc experienced a significant reduction in the grain size by 86% compared to the as-annealed counterparts.

- ECAP parameters of four passes, ϕ = 90° and route Bc resulted in the best Vicker’s microhardness values at both the central and the peripheral regions.

- 4-Bc processing through the 90° die angle recorded a significant HV increase at the edge and central areas by 112% and 78%, respectively, compared to the as-annealed counterpart.

- ECAP parameters of two passes, ϕ = 120° and route Bc resulted in the highest ultimate tensile strength.

- ECAP parameters of four passes, ϕ = 90° showed the most enhancement in the ductility at fracture of the Mg billets.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| ECAP | equal channel angular pressing |

| RSM | response surface methodology |

| ANOVA | analysis of variance |

| HCP | hexagonal close-packed |

| SPD | severe plastic deformation |

| UFG | ultra-fine grain |

| the equivalent strain | |

| ϕ | ecap die angle |

| Ψ | outer corner angle |

| N | number of passes |

| FESEM | field emission scanning electron microscope |

| EBSD | Electron back-scatter diffraction |

| 1P and 4P | one pass and 4 passes |

| AA | as-annealed |

| IPF | inverse pole figure |

| Hv | vicker’s microhardness |

| CCD | central composite design |

| DF | desirability function |

| GA | genetic algorithm |

| FDM | fused deposition modeling |

| GA-ANN | genetic algorithm-artificial neural network |

| GA-RSM | genetic algorithm-response surface methodology |

| GA-ANFIS | genetic algorithm-adaptive neuro fuzzy interface system |

| GR | grain size |

| HC | hardness measurement at center |

| HE | hardness measurement at edge |

| σu | ultimate tensile strength |

| D | ductility |

| X1 and X2 | dummy variables |

| R2 | regression coefficient |

| S/N | signal to noise |

Appendix A

| Run | ECAP Parameters | Response | ||||||

|---|---|---|---|---|---|---|---|---|

| A | B | C | Grain Size GR (μm) | Hardness | Tensile Strength | |||

| N | φ | Route Type | HE (HV) | HC (HV) | σu (MPa) | D (%) | ||

| 1 | 1 | 120 | A | 2.62 | 42 | 36 | 278 | 33.5 |

| 2 | 2 | 120 | A | 2.33 | 46.6 | 37 | 282 | 38 |

| 3 | 4 | 90 | C | 1.22 | 51.2 | 43 | 327 | 33 |

| 4 | 2 | 120 | C | 2.46 | 45.6 | 36.4 | 280 | 38.5 |

| 5 | 2 | 90 | Bc | 1.38 | 51 | 45.5 | 320 | 36.5 |

| 6 | 2 | 120 | A | 2.38 | 46 | 37.8 | 290 | 38 |

| 7 | 2 | 90 | Bc | 1.43 | 51 | 44 | 318 | 37 |

| 8 | 4 | 120 | Bc | 1.89 | 51 | 42 | 319 | 39 |

| 9 | 4 | 120 | C | 1.99 | 50.2 | 40.5 | 315 | 39.5 |

| 10 | 2 | 120 | Bc | 2.14 | 47 | 38.5 | 388 | 37 |

| 11 | 1 | 120 | A | 2.54 | 43.2 | 36.5 | 275 | 34 |

| 12 | 4 | 90 | Bc | 0.88 | 55 | 46 | 340 | 28 |

| 13 | 1 | 90 | A | 1.95 | 48 | 39 | 308 | 38.5 |

| 14 | 4 | 90 | A | 0.98 | 52.5 | 46.5 | 330 | 31 |

| 15 | 4 | 90 | A | 1.02 | 52.8 | 44.6 | 328 | 32 |

| 16 | 1 | 90 | A | 1.86 | 46 | 40.5 | 311 | 37 |

References

- Witte, F. The history of biodegradable magnesium implants: A review. Acta Biomater. 2010, 6, 1680–1692. [Google Scholar] [CrossRef] [PubMed]

- Mostaed, E.; Vedani, M.; Hashempour, M.; Bestetti, M. Influence of ECAP process on mechanical and corrosion properties of pure Mg and ZK60 magnesium alloy for biodegradable stent applications. Biomatter 2014, 4, e28283. [Google Scholar] [CrossRef] [Green Version]

- Amani, S.; Faraji, G. Recrystallization and mechanical properties of WE43 magnesium alloy processed via cyclic expansion extrusion. Int. J. Miner. Met. Mater. 2018, 25, 672–681. [Google Scholar] [CrossRef]

- Mordike, B.L.; Ebert, T. Magnesium: Properties—Applications—Potential. Mater. Sci. Eng. A 2001, 302, 37–45. [Google Scholar] [CrossRef]

- Shapiro, A.E. Magnesium and magnesium alloys. In ASM Speciality Handbook; ASM International: Almere, The Netherlands, 1999; pp. 106–118. [Google Scholar]

- Kainer, K.U. Magnesium Alloys and Their Applications; Wiley-VCH Verlag GmbH: Hoboken, NJ, USA, 2000. [Google Scholar]

- Gupta, M.; Sharon, N.M.L. Magnesium alloys. In Magnesium, Magnesium Alloys, and Magnesium Composites; John Wiley & Sons, Ltd: Hoboken, NJ, USA, 2011; pp. 39–85. [Google Scholar] [CrossRef]

- Kojima, Y. Platform Science and Technology for Advanced Magnesium Alloys. Mater. Sci. Forum 2000, 350–351, 3–18. [Google Scholar] [CrossRef]

- Kuwahara, H.; Al-Abdullat, Y.; Ohta, M.; Tsutsumi, S.; Ikeuchi, K.; Mazaki, N.; Aizawa, T. Surface Reaction of Magnesium in Hank’s Solutions. Mater. Sci. Forum 2000, 350–351, 349–358. [Google Scholar] [CrossRef]

- Kim, J.J.; Han, D.S. Recent Development and Applications of Magnesium Alloys in the Hyundai and Kia Motors Corporation. Mater. Trans. 2008, 49, 894–897. [Google Scholar] [CrossRef] [Green Version]

- Agnew, S.R.; Duygulu, Ö. Plastic anisotropy and the role of non-basal slip in magnesium alloy AZ31B. Int. J. Plast. 2005, 21, 1161–1193. [Google Scholar] [CrossRef]

- Agnew, S.R. Deformation mechanisms of magnesium alloys. In Advances in Wrought Magnesium Alloys; Bettles, C., Barnett, M., Eds.; Woodhead Publishing: Sawston, UK, 2012; pp. 63–104. [Google Scholar] [CrossRef]

- Chulist, R.; Czaja, P.; Tokarski, T.; Kuksgauzen, I.; Chumlyakov, Y. Orthogonal shear process in Ni-Mn-Sn single crystal. Int. J. Plast. 2019, 114, 63–71. [Google Scholar] [CrossRef]

- Sułkowski, B.; Chulist, R. Twin-induced stability and mechanical properties of pure magnesium. Mater. Sci. Eng. A 2019, 749, 89–95. [Google Scholar] [CrossRef]

- Hadadzadeh, A.; Wells, M.A. Analysis of the hot deformation of ZK60 magnesium alloy. J. Magnes. Alloy. 2017, 5, 369–387. [Google Scholar] [CrossRef]

- Rao, K.P.; Prasad, Y.V.R.K.; Dzwończyk, J.; Hort, N.; Kainer, K.U. Hot Deformation Mechanisms in AZ31 Magnesium Alloy Extruded at Different Temperatures: Impact of Texture. Metals 2012, 2, 292–312. [Google Scholar] [CrossRef] [Green Version]

- Al-Samman, T.; Molodov, K.D.; Molodov, D.A.; Gottstein, G.; Suwas, S. Softening and dynamic recrystallization in magnesium single crystals during c-axis compression. Acta Mater. 2012, 60, 537–545. [Google Scholar] [CrossRef]

- Wang, H.; Yu, Z.; Zhang, L.; Liu, C.; Zha, M.; Wang, C.; Jiang, Q. Achieving high strength and high ductility in magnesium alloy using hard-plate rolling (HPR) process. Sci. Rep. 2015, 5, 17100. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Xu, W.; Birbilis, N.; Sha, G.; Wang, Y.; Daniels, J.; Xiao, Y.; Ferry, M. A high-specific-strength and corrosion-resistant magnesium alloy. Nat. Mater. 2015, 14, 1229–1235. [Google Scholar] [CrossRef]

- Alateyah, A.; Aljohani, T.; Alawad, M.; Elkatatny, S.; El-Garaihy, W. Improving the Corrosion Behavior of Biodegradable AM60 Alloy through Plasma Electrolytic Oxidation. Metals 2021, 11, 953. [Google Scholar] [CrossRef]

- Wang, L.-P.; Chen, T.; Jiang, W.-Y.; Feng, Y.-C.; Cao, G.-J.; Zhu, Y. Microstructure and mechanical properties of AM60B magnesium alloy prepared by cyclic extrusion compression. Trans. Nonferrous Met. Soc. China 2013, 23, 3200–3205. [Google Scholar] [CrossRef]

- Chen, X.; Li, L.; Chen, W.; Zhang, W.; Zhang, L.; Qiao, Y.; Wang, E. Fine-grained structure and recrystallization at ambient temperature for pure magnesium subjected to large cold plastic deformation. Mater. Sci. Eng. A 2017, 708, 351–359. [Google Scholar] [CrossRef]

- Nassef, A.; Samy, S.; El-Garaihy, W.H. Enhancement of mechanical properties for Al-Mg-Si alloy using equal channel angular pressing. Int. J. Chem. Nucl. Mater. Metall. Eng. 2015, 9, 131–136. [Google Scholar]

- El-Garaihy, W.H.; Alateyah, A.I.; Alawad, M.O.; Aljohani, T.A. Improving the corrosion behavior and mechanical properties of biodegradable Mg-Zn-Zr alloys through ECAP for usage in biomedical applications. In The Minerals, Metals & Materials Series; Magnesium Technology; Springer: Berlin/Heidelberg, Germany, 2022; pp. 259–269. [Google Scholar] [CrossRef]

- Alateyah, A.; Alharbi, M.; El-Hafez, H.A.; El-Garaihy, W. The Effect of Equal-Channel Angular Pressing Processing on Microstructural Evolution, Hardness Homogeneity, and Mechanical Properties of Pure Aluminum. SAE Int. J. Mater. Manuf. 2021, 14, 113–125. [Google Scholar] [CrossRef]

- Alateyah, A.; Aljohani, T.; Alawad, M.; El-Hafez, H.; Almutairi, A.; Alharbi, E.; Alhamada, R.; El-Garaihy, B.; El-Garaihy, W. Improved Corrosion Behavior of AZ31 Alloy through ECAP Processing. Metals 2021, 11, 363. [Google Scholar] [CrossRef]

- Alateyah, A.; Ahmed, M.; Zedan, Y.; El-Hafez, H.; Alawad, M.; El-Garaihy, W. Experimental and Numerical Investigation of the ECAP Processed Copper: Microstructural Evolution, Crystallographic Texture and Hardness Homogeneity. Metals 2021, 11, 607. [Google Scholar] [CrossRef]

- El-Shenawy, M.; Ahmed, M.; Nassef, A.; El-Hadek, M.; Alzahrani, B.; Zedan, Y.; El-Garaihy, W. Effect of ECAP on the Plastic Strain Homogeneity, Microstructural Evolution, Crystallographic Texture and Mechanical Properties of AA2xxx Aluminum Alloy. Metals 2021, 11, 938. [Google Scholar] [CrossRef]

- Shuai, G.; Li, Z.; Zhang, D.; Tong, Y.; Li, L. The mechanical property and electrical conductivity evolution of Al–Fe alloy between room temperature and elevated temperature ECAP. Vacuum 2021, 183, 109813. [Google Scholar] [CrossRef]

- Alawadhi, M.Y.; Sabbaghianrad, S.; Huang, Y.; Langdon, T.G. Evaluating the paradox of strength and ductility in ultrafine-grained oxygen-free copper processed by ECAP at room temperature. Mater. Sci. Eng. A 2021, 802, 140546. [Google Scholar] [CrossRef]

- Segal, V. Materials processing by simple shear. Mater. Sci. Eng. A 1995, 197, 157–164. [Google Scholar] [CrossRef]

- Iwahashi, Y.; Wang, J.T.; Horita, Z.; Nemoto, M.; Langdon, T.G. Principle of equal-channel angular pressing for the processing of ultra-fine grained materials. Scr. Mater. 1996, 35, 143–146. [Google Scholar] [CrossRef]

- Naik, G.M.; Narendranath, S.; Kumar, S.S.S. Effect of ECAP Die Angles on Microstructure Mechanical Properties and Corrosion Behavior of AZ80 Mg Alloy. J. Mater. Eng. Perform. 2019, 28, 2610–2619. [Google Scholar] [CrossRef]

- Shaeri, M.H.; Salehi, M.T.; Seyyedein, S.; Abutalebi, M.; Park, J. Characterization of microstructure and deformation texture during equal channel Angular pressing of Al–Zn–Mg–Cu alloy. J. Alloy. Compd. 2013, 576, 350–357. [Google Scholar] [CrossRef]

- Lei, W.; Zhang, H. Analysis of microstructural evolution and compressive properties for pure Mg after room-temperature ECAP. Mater. Lett. 2020, 271, 127781. [Google Scholar] [CrossRef]

- Venkatachalam, P.; Kumar, S.R.; Ravisankar, B.; Paul, V.T.; Vijayalakshmi, M. Effect of processing routes on microstructure and mechanical properties of 2014 Al alloy processed by equal channel angular pressing. Trans. Nonferrous Met. Soc. China 2010, 20, 1822–1828. [Google Scholar] [CrossRef]

- Alateyah, A.; Ahmed, M.M.; Alawad, M.O.; Elkatatny, S.; Zedan, Y.; Nassef, A.; El-Garaihy, W. Effect of ECAP die angle on the strain homogeneity, microstructural evolution, crystallographic texture and mechanical properties of pure magnesium: Numerical simulation and experimental approach. J. Mater. Res. Technol. 2022, 17, 1491–1511. [Google Scholar] [CrossRef]

- Ghaedi, M.; Azad, F.N.; Dashtian, K.; Hajati, S.; Goudarzi, A.; Soylak, M. Central composite design and genetic algorithm applied for the optimization of ultrasonic-assisted removal of malachite green by ZnO Nanorod-loaded activated carbon. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2016, 167, 157–164. [Google Scholar] [CrossRef] [PubMed]

- Daryadel, M. Study on Equal Channel Angular Pressing Process of AA7075 with Copper Casing by Finite Element-response Surface Couple Method. Int. J. Eng. 2020, 33, 2538–2548. [Google Scholar]

- Abbas, A.T.; Taha, M.A.; Ragab, A.E.; El-Danaf, E.A.; El Aal, M.I.A. Effect of Equal Channel Angular Pressing on the Surface Roughness of Solid State Recycled Aluminum Alloy 6061 Chips. Adv. Mater. Sci. Eng. 2017, 2017, 5131403. [Google Scholar] [CrossRef] [Green Version]

- Deshwal, S.; Kumar, A.; Chhabra, D. Exercising hybrid statistical tools GA-RSM, GA-ANN and GA-ANFIS to optimize FDM process parameters for tensile strength improvement. CIRP J. Manuf. Sci. Technol. 2020, 31, 189–199. [Google Scholar] [CrossRef]

- Kilickap, E.; Huseyinoglu, M.; Yardimeden, A. Optimization of drilling parameters on surface roughness in drilling of AISI 1045 using response surface methodology and genetic algorithm. Int. J. Adv. Manuf. Technol. 2011, 52, 79–88. [Google Scholar] [CrossRef]

- Dadrasi, A.; Fooladpanjeh, S.; Gharahbagh, A.A. Interactions between HA/GO/epoxy resin nanocomposites: Optimization, modeling and mechanical performance using central composite design and genetic algorithm. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 63. [Google Scholar] [CrossRef]

- Hazir, E.; Ozcan, T. Response Surface Methodology Integrated with Desirability Function and Genetic Algorithm Approach for the Optimization of CNC Machining Parameters. Arab. J. Sci. Eng. 2019, 44, 2795–2809. [Google Scholar] [CrossRef]

- Munusamy, T.D.; Chin, S.Y.; Khan, M.R. Photoreforming hydrogen production by carbon doped exfoliated g-C3N4: Optimization using design expert®software. Mater. Today Proc. 2021, 57, 1162–1168. [Google Scholar] [CrossRef]

- Rezić, I. Prediction of the surface tension of surfactant mixtures for detergent formulation using Design Expert software. Mon. Für Chem.-Chem. Mon. 2011, 142, 1219–1225. [Google Scholar] [CrossRef]

- Makki, A.A.; Stewart, R.A.; Panuwatwanich, K.; Beal, C. Development of a domestic water end use consumption forecasting model for South-East Queensland, Australia. In Proceedings of the 6th IWA Specialist Conference on Efficient Use and Management of Water, Dead Sea, Jordan, 29 March–2 April 2011. [Google Scholar]

- Santhosh, A.J.; Tura, A.D.; Jiregna, I.T.; Gemechu, W.F.; Ashok, N.; Ponnusamy, M. Optimization of CNC turning parameters using face centred CCD approach in RSM and ANN-genetic algorithm for AISI 4340 alloy steel. Results Eng. 2021, 11, 100251. [Google Scholar] [CrossRef]

- Hughes, D.A.; Hansen, N. High angle boundaries formed by grain subdivision mechanisms. Acta Mater. 1997, 45, 3871–3886. [Google Scholar] [CrossRef]

- Tolaminejad, B.; Dehghani, K. Microstructural characterization and mechanical properties of nanostructured AA1070 aluminum after equal channel angular extrusion. Mater. Des. 2012, 34, 285–292. [Google Scholar] [CrossRef]

- Almenaif, O.; Alhumaydani, Y.; Alnafisah, M.; Aldhalaan, M.; Alateyah, A.; El-Garaihy, W. A Computational Investigation into the Effect of Equal Channel Angular Processing on the Mechanical Properties of Severely Deformed ZK 60 Alloy Validated by Experiments. Am. J. Eng. Appl. Sci. 2020, 13, 296–310. [Google Scholar] [CrossRef]

- El-Garaihy, W.; Rassoul, E.S.M.; Salem, H.G. Consolidation of High Performance AA6061 and AA6061-SiCp Composite Processed by High Pressure Torsion. Mater. Sci. Forum 2014, 783–786, 2623–2628. [Google Scholar] [CrossRef]

- Salem, H.G.; El-Garaihy, W.H.; Al-Rassoul, E.S.M. Influence of high pressure torsion on the consolidation behavior and mechanical properties of AA6061-SiCp composite powders. In Supplemental Proceedings; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2012; pp. 553–560. [Google Scholar] [CrossRef]

- El-Garaihy, W.H.; Fouad, D.M.; Salem, H.G. Multi-channel Spiral Twist Extrusion (MCSTE): A Novel Severe Plastic Deformation Technique for Grain Refinement. Met. Mater. Trans. A 2018, 49, 2854–2864. [Google Scholar] [CrossRef]

- Fouad, D.; Moataz, A.; El-Garaihy, W.; Salem, H. Numerical and experimental analysis of multi-channel spiral twist extrusion processing of AA5083. Mater. Sci. Eng. A 2019, 764, 138216. [Google Scholar] [CrossRef]

- Fouad, D.M.; El-Garaihy, W.H.; Ahmed, M.M.Z.; Seleman, M.E.-S.; Salem, H.G. Influence of multi-channel spiral twist extrusion (MCSTE) processing on structural evolution, crystallographic texture and mechanical properties of AA1100. Mater. Sci. Eng. A 2018, 737, 166–175. [Google Scholar] [CrossRef]

- Fouad, D.M.; El-Garaihy, W.H.; Ahmed, M.M.Z.; Albaijan, I.; Seleman, M.M.E.; Salem, H.G. Grain Structure Evolution and Mechanical Properties of Multi-Channel Spiral Twist Extruded AA5083. Metals 2021, 11, 1276. [Google Scholar] [CrossRef]

- Cheng, W.; Tian, L.; Ma, S.; Bai, Y.; Wang, H. Influence of Equal Channel Angular Pressing Passes on the Microstructures and Tensile Properties of Mg-8Sn-6Zn-2Al Alloy. Materials 2017, 10, 708. [Google Scholar] [CrossRef] [Green Version]

- Fan, G.; Zheng, M.; Hu, X.; Xu, C.; Wu, K.; Golovin, I. Improved mechanical property and internal friction of pure Mg processed by ECAP. Mater. Sci. Eng. A 2012, 556, 588–594. [Google Scholar] [CrossRef]

- Elsanabary, S.; Kouta, H.K. Optimization of Inertia Friction Welding of Dissimilar Polymeric PA6-PVC Hollow Cylinders by Genetic Algorithm. Port-Said Eng. Res. J. 2021, 25, 91–100. [Google Scholar] [CrossRef]

- Dritsa, V.; Rigas, F.; Doulia, D.; Avramides, E.J.; Hatzianestis, I. Optimization of Culture Conditions for the Biodegradation of Lindane by the Polypore Fungus Ganoderma australe. Water Air Soil Pollut. 2009, 204, 19–27. [Google Scholar] [CrossRef]

- Gopal, M. Optimization of Machining Parameters on Temperature Rise in CNC Turning Process of Aluminium–6061 Using RSM and Genetic Algorithm. Int. J. Mod. Manuf. Technol. 2020, 12, 36–43. [Google Scholar]

- Asghar, A.; Raman, A.A.A.; Daud, W.M.A.W. A Comparison of Central Composite Design and Taguchi Method for Optimizing Fenton Process. Sci. World J. 2014, 2014, 869120. [Google Scholar] [CrossRef] [Green Version]

- Yuan, Y.; Ma, A.; Gou, X.-F.; Jiang, J.; Arhin, G.; Song, D.; Liu, H. Effect of heat treatment and deformation temperature on the mechanical properties of ECAP processed ZK60 magnesium alloy. Mater. Sci. Eng. A 2016, 677, 125–132. [Google Scholar] [CrossRef]

- Mostaed, E.; Hashempour, M.; Fabrizi, A.; Dellasega, D.; Bestetti, M.; Bonollo, F.; Vedani, M. Microstructure, texture evolution, mechanical properties and corrosion behavior of ECAP processed ZK60 magnesium alloy for biodegradable applications. J. Mech. Behav. Biomed. Mater. 2014, 37, 307–322. [Google Scholar] [CrossRef] [PubMed]

- Huang, S.-J.; Chiu, C.; Chou, T.-Y.; Rabkin, E. Effect of equal channel angular pressing (ECAP) on hydrogen storage properties of commercial magnesium alloy AZ61. Int. J. Hydrog. Energy 2018, 43, 4371–4380. [Google Scholar] [CrossRef]

- Minárik, P.; Zimina, M.; Čížek, J.; Stráska, J.; Krajňák, T.; Cieslar, M.; Vlasák, T.; Bohlen, J.; Kurz, G.; Letzig, D. Increased structural stability in twin-roll cast AZ31 magnesium alloy processed by equal channel angular pressing. Mater. Charact. 2019, 153, 199–207. [Google Scholar] [CrossRef]

| ECAP Parameters | Parameters Levels | ||

|---|---|---|---|

| L1 | L2 | L3 | |

| Number of passes (N) | 1 | 2 | 4 |

| ECAP die angle (ϕ) | 90 | 120 | |

| Processing route type | A | Bc | C |

| Data, µm | AA-Mg | Route Bc | |||

|---|---|---|---|---|---|

| 1P | 4P | ||||

| ϕ 90° | ϕ 120° | ϕ 90° | ϕ 120° | ||

| Min. grain size | 1.106 | 0.507 | 0.505 | 0.21 | 0.81 |

| Max. grain size | 34.02 | 9.291 | 22.727 | 7.14 | 20.15 |

| Average grain size | 6.338 | 1.492 | 2.62 | 0.88 | 1.89 |

| Standard deviation | 5.815 | 0.945 | 1.433 | 0.73 | 1.11 |

| Significant Effect | ||

|---|---|---|

| Response | GR | N, φ, X1, X2, N φ |

| HC | N, φ, X2 | |

| HE | N, φ, X2, N φ, N2 | |

| σu | φ, X1, X2, N φ, N X1, N X2, φ X1, N2 | |

| D | φ, X2, N φ, φ X2, N2 | |

| Response | F-Value (F > 4) | Model Significant (p < 0.05) | Lack of Fit (p > 0.05) | Adeq Precision (Ratio > 4) | R2 | Adjusted R2 | Predicted R2 |

|---|---|---|---|---|---|---|---|

| GR | 224.52 | <0.0001 | 0.1395 | 41.3955 | 0.9934 | 0.9889 | 0.968 |

| HC | 42.22 | <0.0001 | 0.4739 | 17.4906 | 0.9657 | 0.9428 | 0.895 |

| HE | 56.44 | <0.0001 | 0.6959 | 22.39 | 0.9741 | 0.9569 | 0.9063 |

| σu | 126.59 | <0.0001 | 0.1939 | 42.7681 | 0.9948 | 0.9869 | 0.9894 |

| D | 34.41 | <0.0001 | 0.1372 | 18.5288 | 0.9752 | 0.9469 | 0.9553 |

| Response | Experimental | RSM | GA | RSM-GA | |

|---|---|---|---|---|---|

| GR | Value | 0.88 | 0.8872 | 0.8872 | 0.887287 |

| Cond. | 4passes, 90°, Route Bc | 4passes, 90°, Route Bc | 4passes, 90°, Route Bc | 4passes, 90°, Route Bc | |

| HC | Value | 46.5 | 46.02 | 45.9927 | 45.9927 |

| Cond. | 4passes, 90°, Route A | 4passes, 90°, Route Bc | 4passes, 90°, Route Bc | 4passes, 90°, Route Bc | |

| HE | Value | 55 | 53.924 | 53.9068 | 53.9068 |

| Cond. | 4passes, 90°, Route Bc | 4passes, 90°, Route Bc | 4passes, 90°, Route Bc | 4passes, 90°, Route Bc | |

| σu | Value | 388 | 388 | 388 | 388 |

| Cond. | 2passes, 120°, Route Bc | 2passes, 120°, Route Bc | 2passes, 120°, Route Bc | 2passes, 120°, Route Bc | |

| D | Value | 28 | 29.0283 | 28.9956 | 28.899 |

| Cond. | 4passes, 90°, Route Bc | 4passes, 90°, Route Bc | 4passes, 90°, Route Bc | 4passes, 90°, Route Bc | |

| Response | GA | RSM-GA | |

|---|---|---|---|

| GR (µm) | Value | 0.269927 | 0.269927 |

| Cond. | 4passes, 70°, Route Bc | 4passes, 70°, Route Bc | |

| HC (HV) | Value | 47.4951 | 47.4951 |

| Cond. | 4passes, 80°, Route Bc | 4passes, 80°, Route Bc | |

| HE (HV) | Value | 54.7207 | 54.7207 |

| Cond. | 4passes, 80°, Route Bc | 4passes, 80°, Route Bc | |

| σu (MPa) | Value | 422.5 | 422.5 |

| Cond. | 2passes, 135°, Route Bc | 2passes, 135°, Route Bc | |

| D (%) | Value | 4.0846 | 4.0846 |

| Cond. | 6passes, 80°, Route Bc | 6passes, 80°, Route Bc | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alateyah, A.I.; El-Garaihy, W.H.; Alawad, M.O.; Sanabary, S.E.; Elkatatny, S.; Dahish, H.A.; Kouta, H. The Effect of ECAP Processing Conditions on Microstructural Evolution and Mechanical Properties of Pure Magnesium—Experimental, Mathematical Empirical and Response Surface Approach. Materials 2022, 15, 5312. https://doi.org/10.3390/ma15155312

Alateyah AI, El-Garaihy WH, Alawad MO, Sanabary SE, Elkatatny S, Dahish HA, Kouta H. The Effect of ECAP Processing Conditions on Microstructural Evolution and Mechanical Properties of Pure Magnesium—Experimental, Mathematical Empirical and Response Surface Approach. Materials. 2022; 15(15):5312. https://doi.org/10.3390/ma15155312

Chicago/Turabian StyleAlateyah, Abdulrahman I., Waleed H. El-Garaihy, Majed O. Alawad, Samar El Sanabary, Sally Elkatatny, Hany A. Dahish, and Hanan Kouta. 2022. "The Effect of ECAP Processing Conditions on Microstructural Evolution and Mechanical Properties of Pure Magnesium—Experimental, Mathematical Empirical and Response Surface Approach" Materials 15, no. 15: 5312. https://doi.org/10.3390/ma15155312

APA StyleAlateyah, A. I., El-Garaihy, W. H., Alawad, M. O., Sanabary, S. E., Elkatatny, S., Dahish, H. A., & Kouta, H. (2022). The Effect of ECAP Processing Conditions on Microstructural Evolution and Mechanical Properties of Pure Magnesium—Experimental, Mathematical Empirical and Response Surface Approach. Materials, 15(15), 5312. https://doi.org/10.3390/ma15155312