Influence of Carbon Source on Microstructural and Mechanical Properties of High-Performance Reaction-Bonded Silicon Carbide

Abstract

1. Introduction

2. Experimental Procedure

3. Results and Discussion

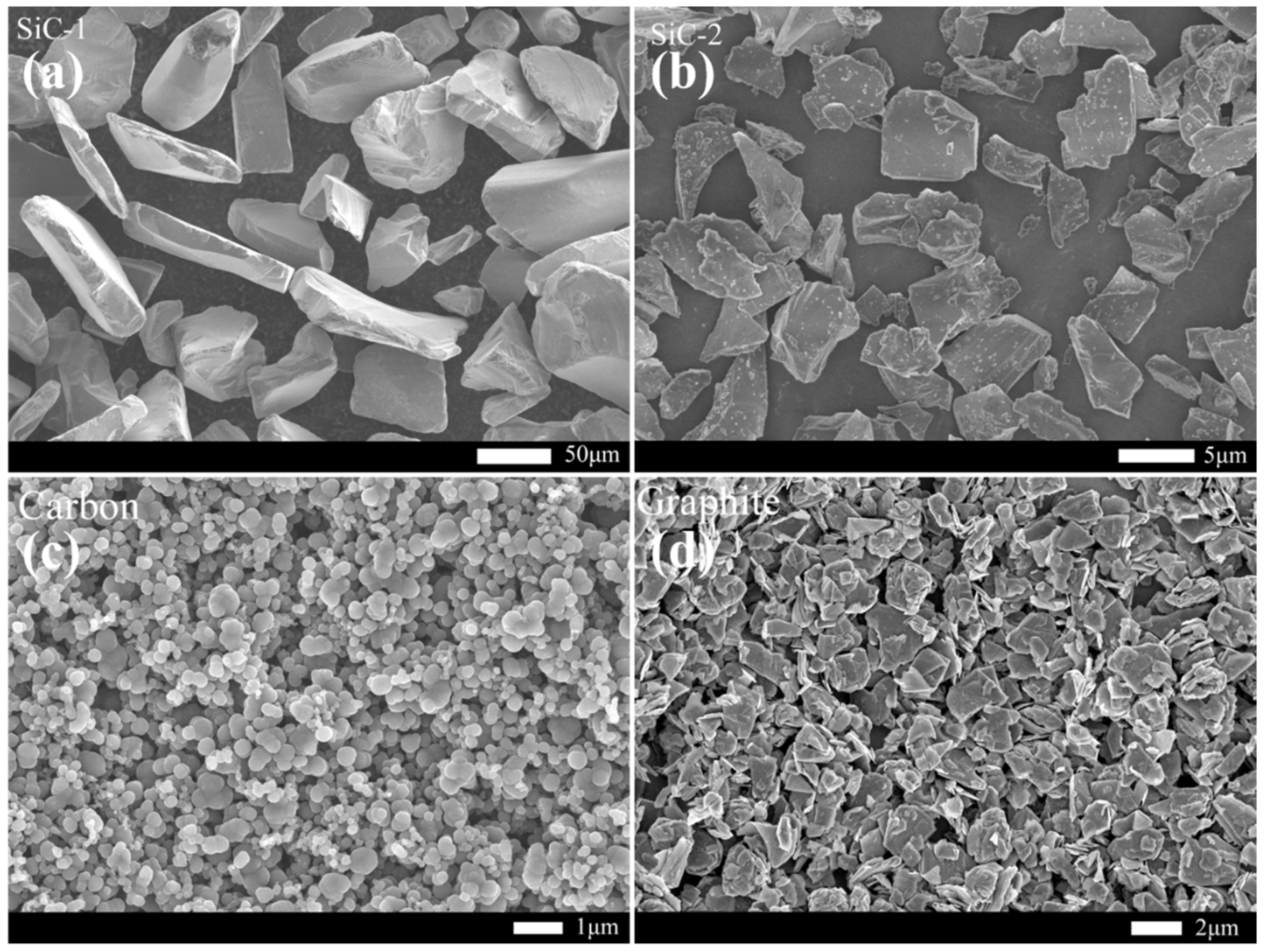

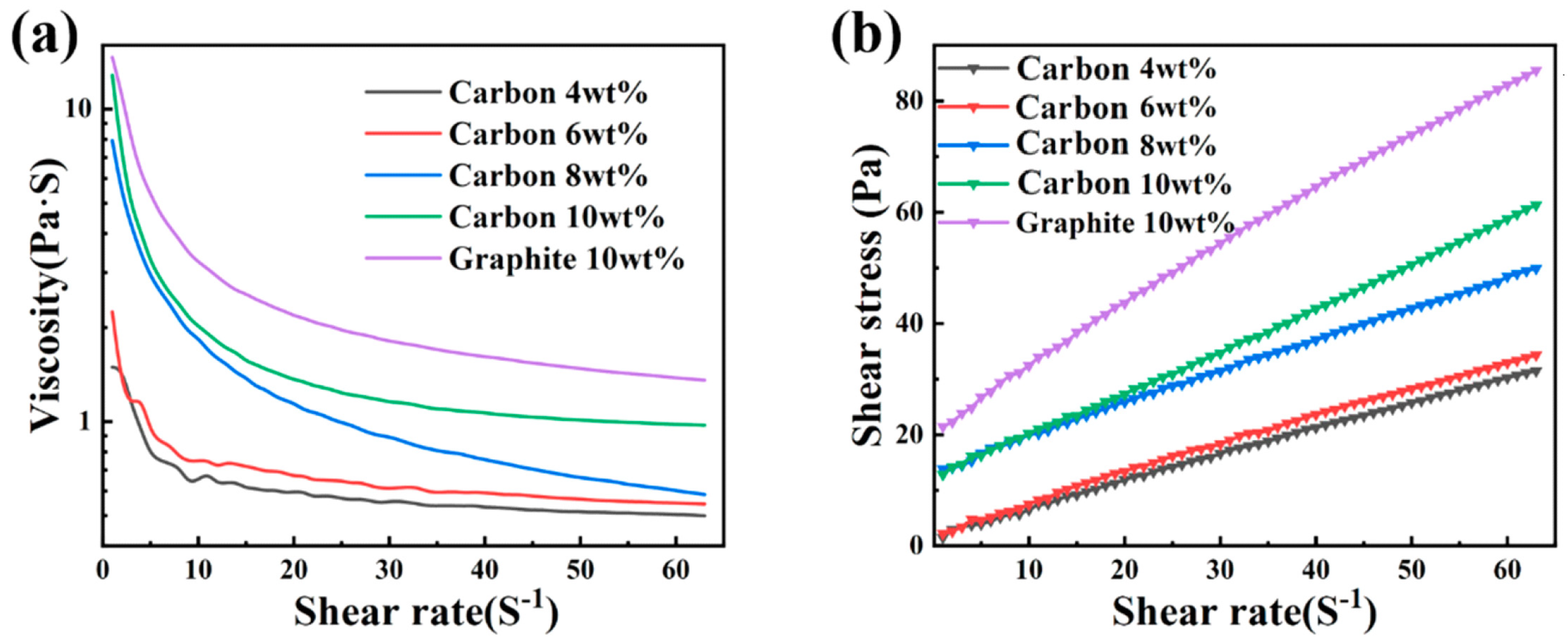

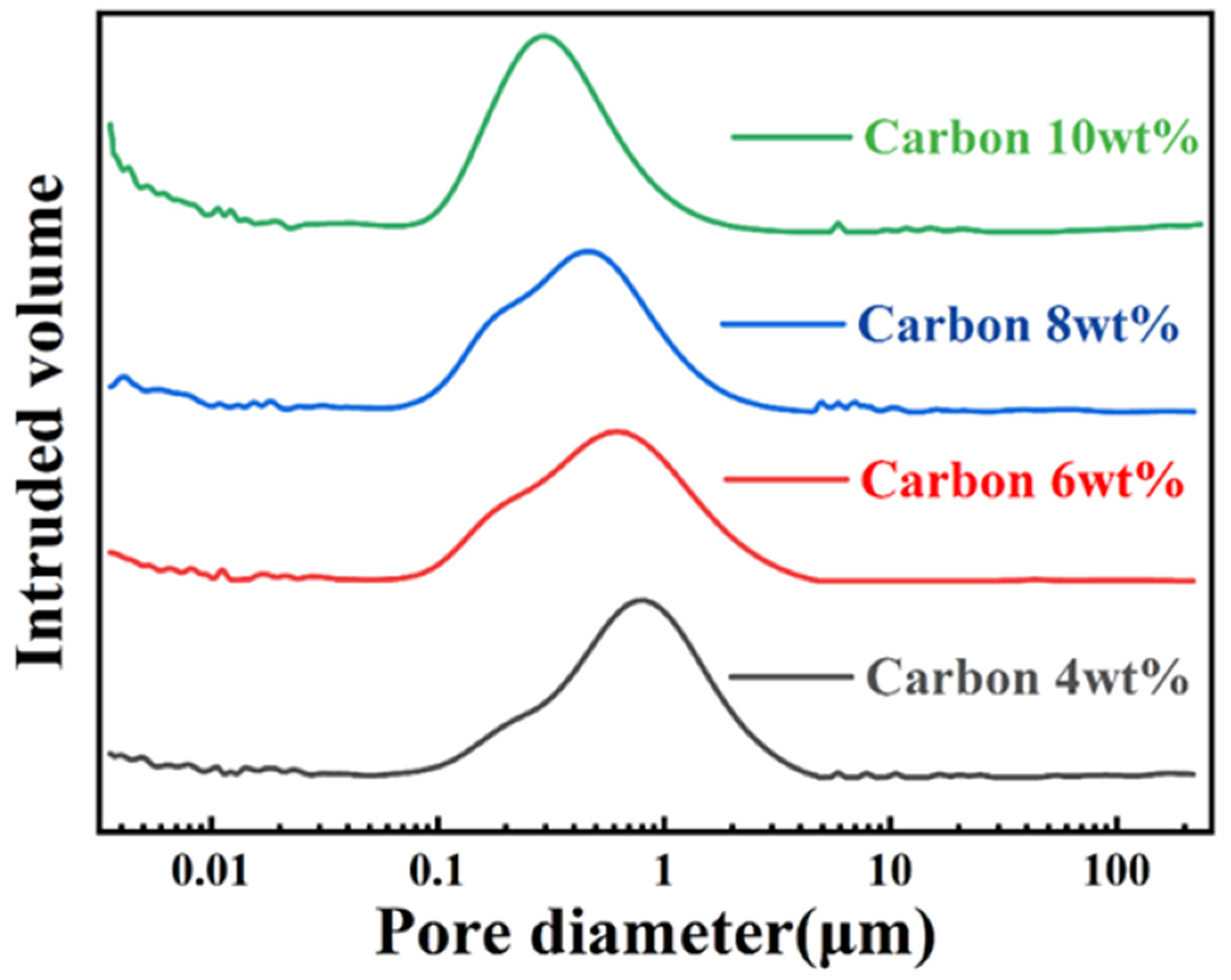

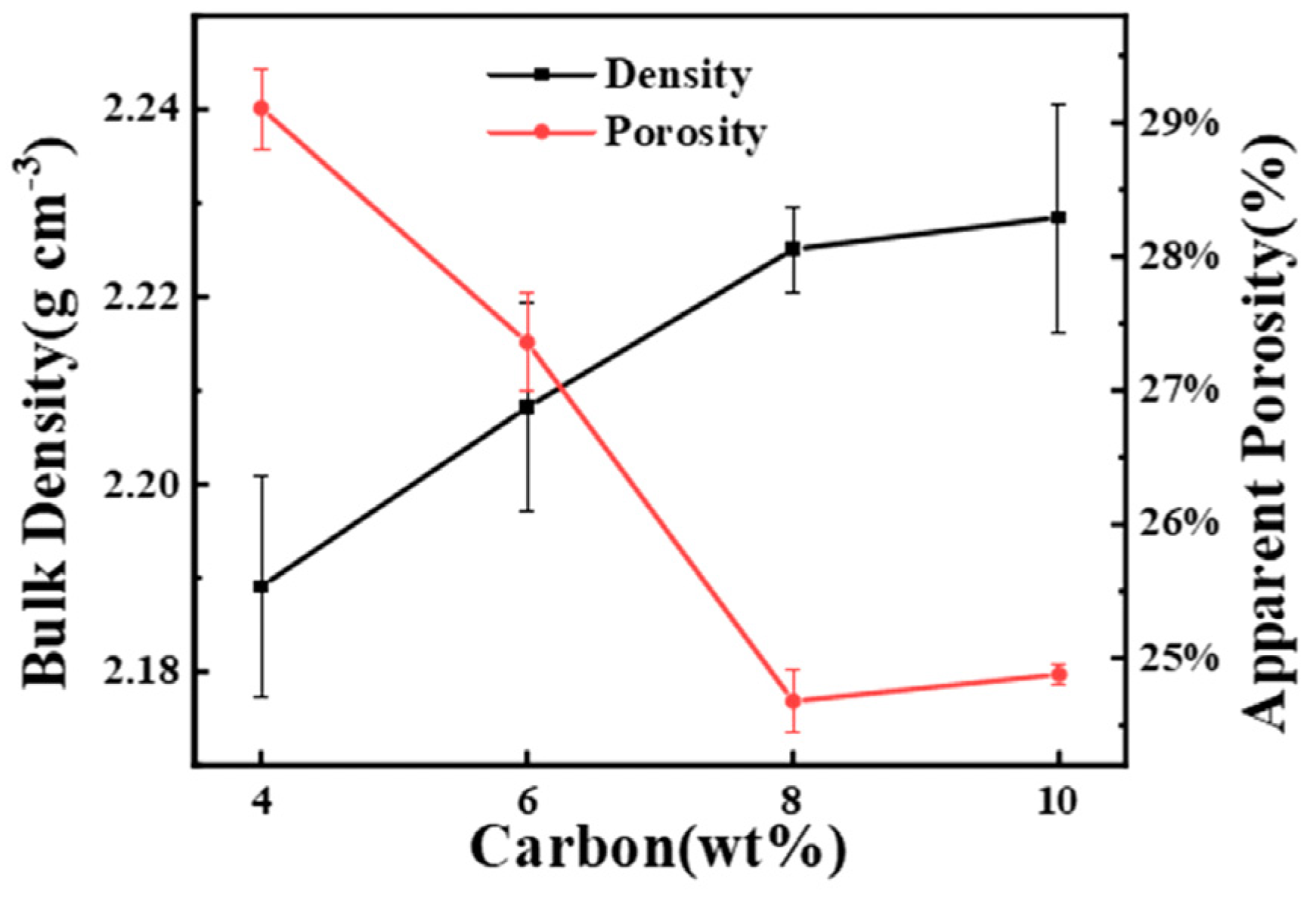

3.1. Characteristics of Raw Materials and Porous Preforms

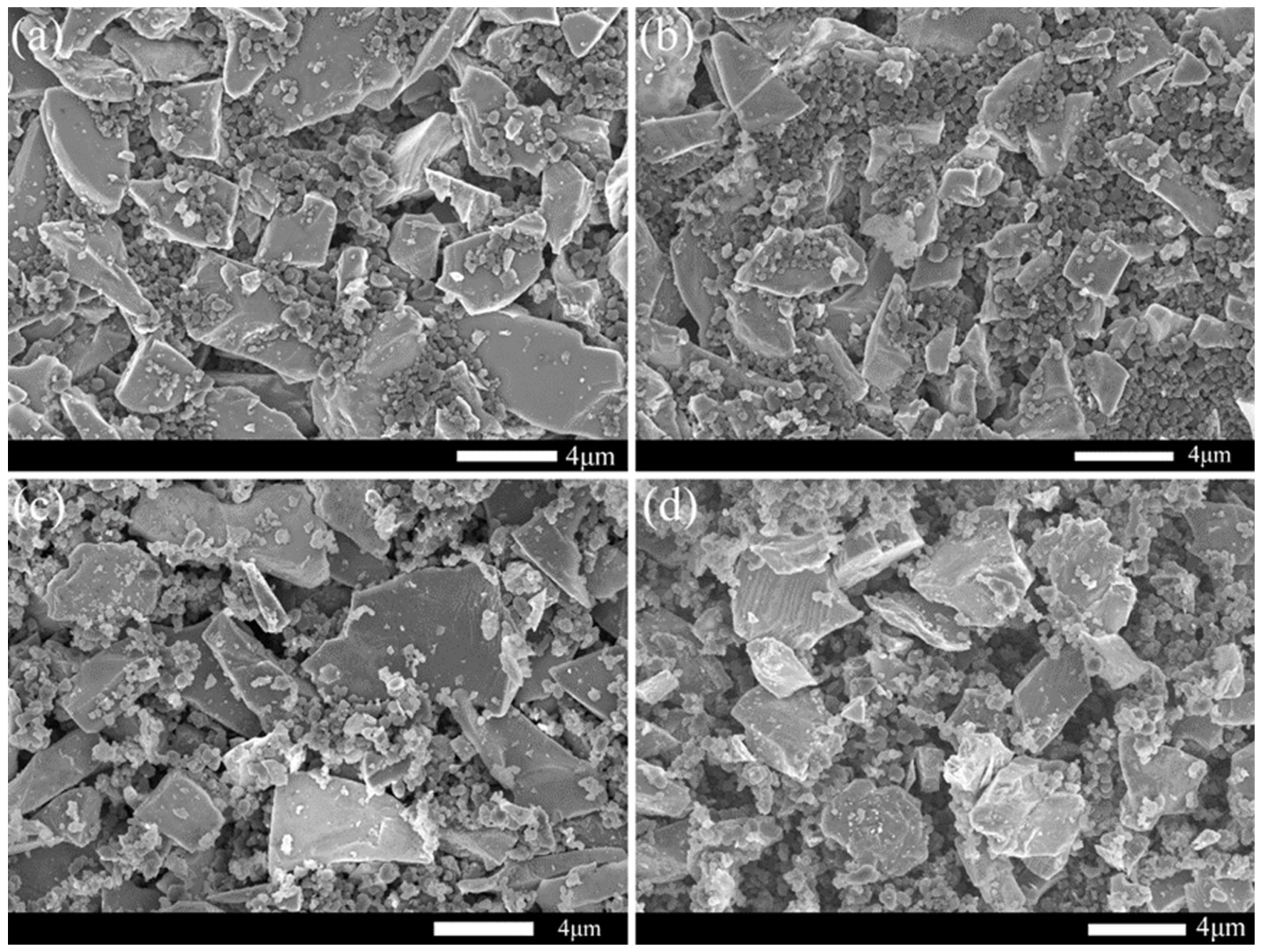

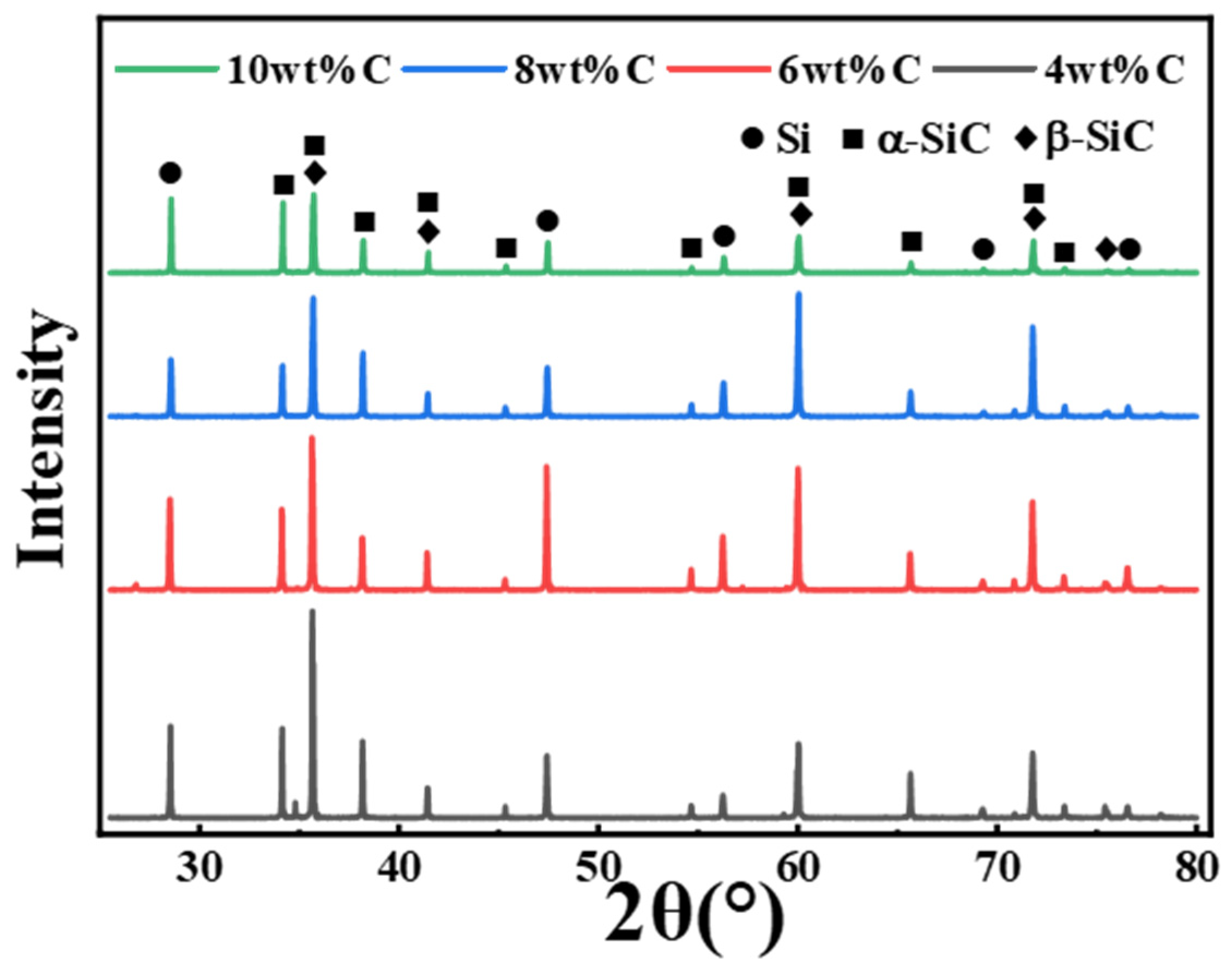

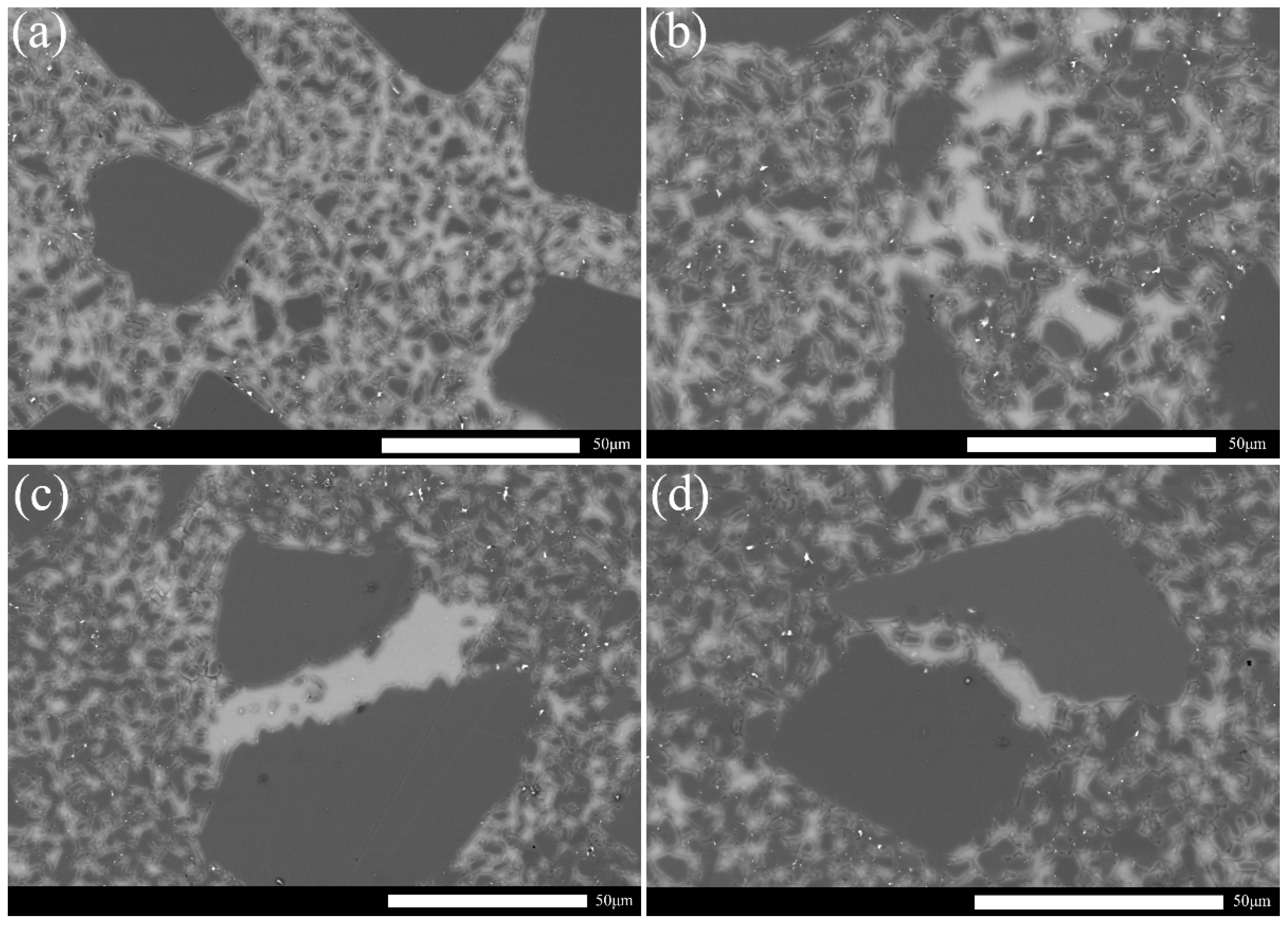

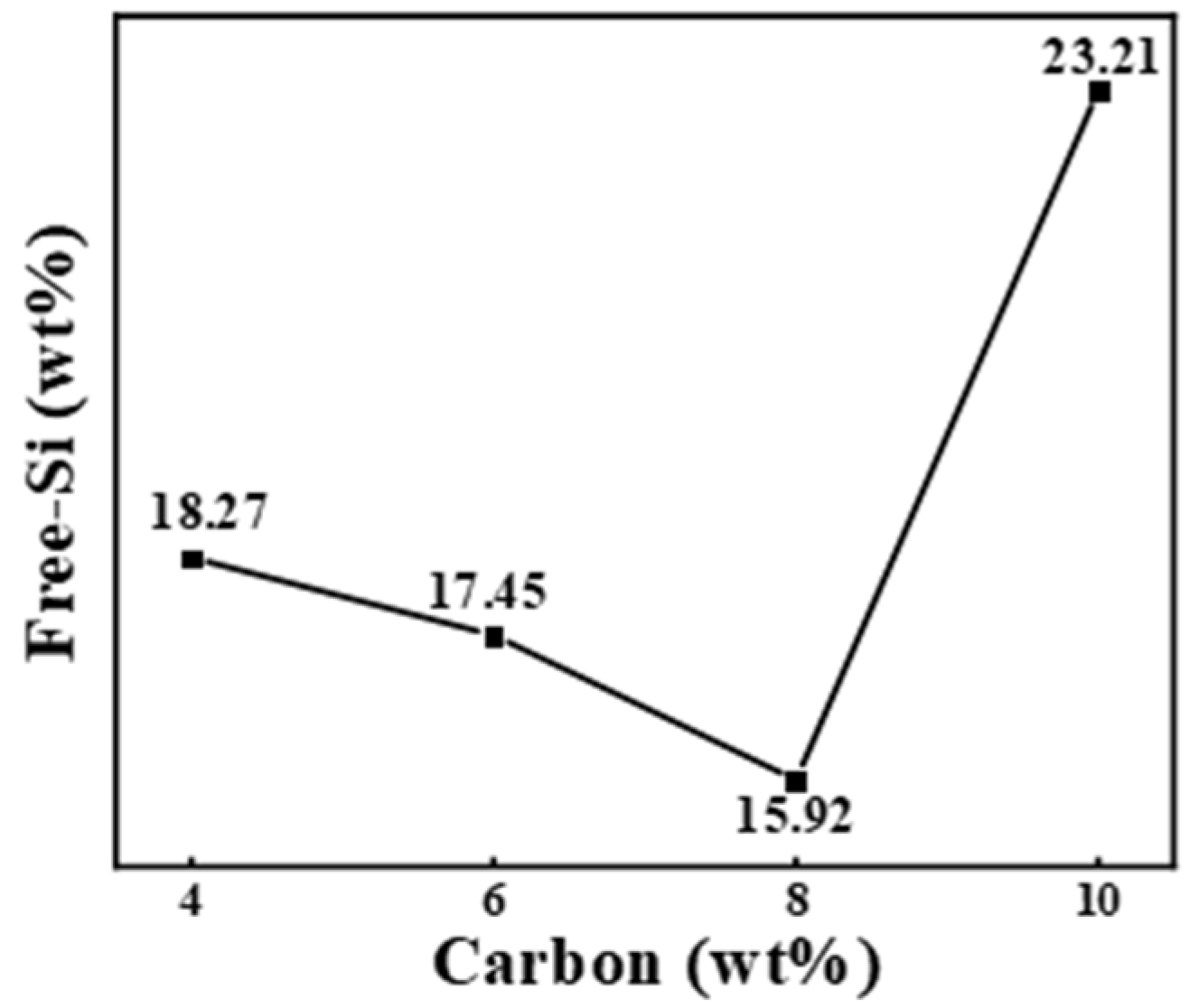

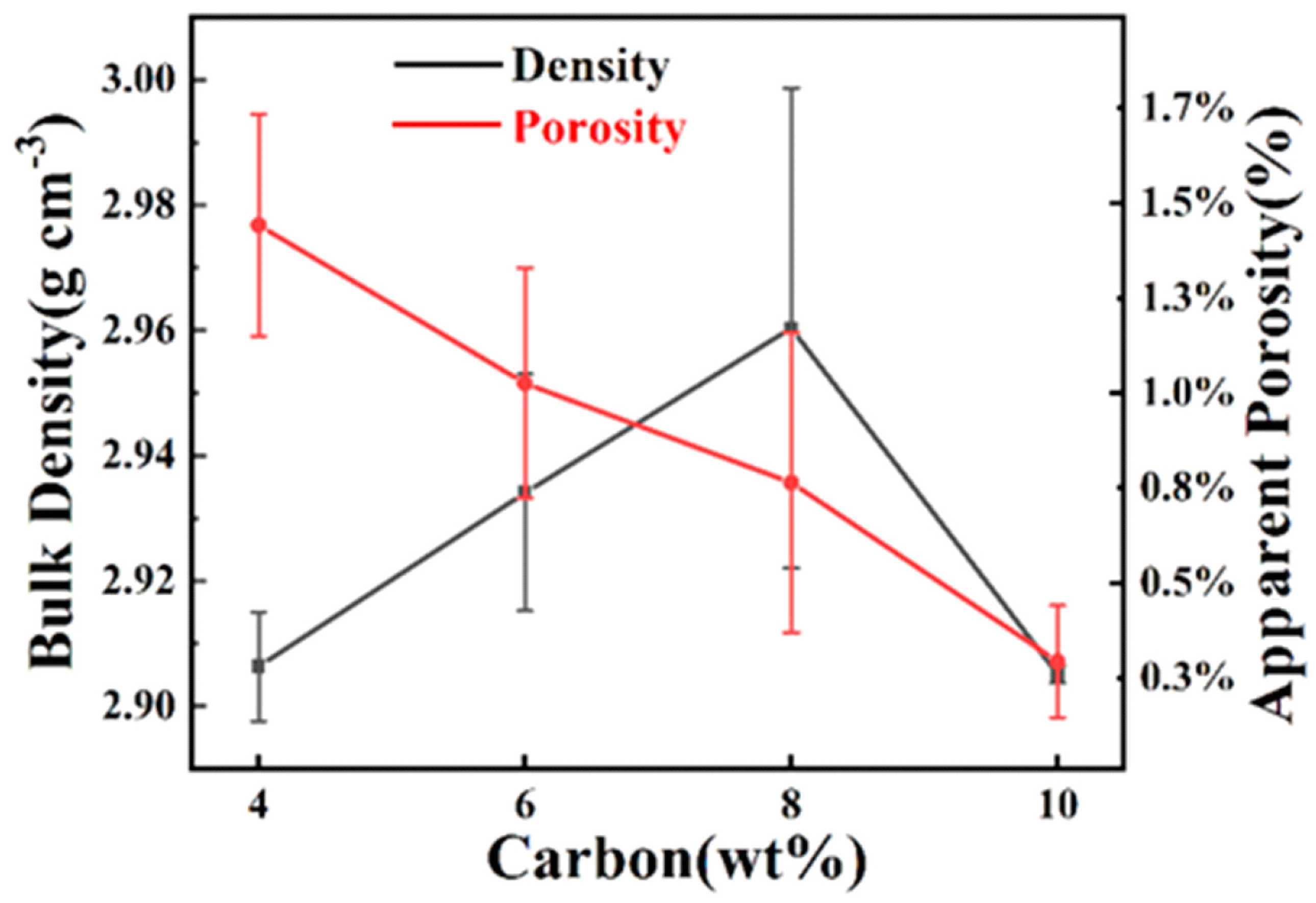

3.2. Microstructure Analysis of Preforms after LSI

3.3. Performance Analysis of RBSC Samples

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wu, Q.; Hong, X.; Huang, D. Development of Reaction-Bonded Silicon Carbide. Bull. Chin. Silic. Soc. 2002, 21, 29–33. [Google Scholar]

- Wei, R.; Li, F.; Liang, Y.; Li, Y.; Zhai, W.; Liu, X.; Zhang, W. Research progress in bulletproof SiC ceramic and its applications in armor protection field. Ordnance Mater. Sci. Eng. 2014, 37, 145–148. [Google Scholar]

- Han, Y.; Zhang, Y.; Han, J.; Zhang, J.; Yao, W.; Zhou, Y. Development of the Silicon Carbide Mirror and System in the World. J. Mater. Eng. 2005, 6, 59–63. [Google Scholar]

- Dai, P.; Zhou, P.; Wang, M.; Li, X.; Yang, J. Development of Preparation of Silicon Carbide Dense Ceramics. China’s Ceram. 2012, 48, 26. [Google Scholar]

- Yamamoto, T.; Kitaura, H.; Kodera, Y.; Ishii, T.; Ohyanagi, M.; Munir, Z.A. Consolidation of nanostructured beta-SiC by spark plasma sintering. J. Am. Ceram. Soc. 2004, 87, 1436–1441. [Google Scholar] [CrossRef]

- Tanaka, H.; Zhou, Y. Low temperature sintering and elongated grain growth of 6H-SiC powder with AlB2 and C additives. J. Mater. Res. 1999, 14, 518–522. [Google Scholar] [CrossRef]

- Zhang, B.R.; Marino, F.; Ferraris, M. LIQUID-PHASE HOT-PRESSING AND WC-PARTICLE REINFORCEMENT OF SIC-SI COMPOSITES. J. Eur. Ceram. Soc. 1994, 14, 549–555. [Google Scholar] [CrossRef]

- Cho, K.-S.; Whan, P.S. Fabrication of Porous Reaction Bonded Silicon Carbide with Multi-Layered Pore Structures. J. Korean Ceram. Soc. 2009, 46, 534–539. [Google Scholar] [CrossRef][Green Version]

- Ness, J.N.; Page, T.F. Microstructural evolution in reaction-bonded silicon carbide. J. Mater. Sci. 1986, 21, 1377–1397. [Google Scholar] [CrossRef]

- Tong, Y.G.; Bai, S.X.; Liang, X.B.; Qin, Q.H.; Zhai, J.T. Reactive melt infiltration fabrication of C/C-SiC composite: Wetting and infiltration. Ceram. Int. 2016, 42, 17174–17178. [Google Scholar] [CrossRef]

- Song, S.; Bao, C.; Ma, Y.; Wang, K. Fabrication and characterization of a new-style structure capillary channel in reaction bonded silicon carbide composites. J. Eur. Ceram. Soc. 2017, 37, 2569–2574. [Google Scholar] [CrossRef]

- Park, H.; Kim, K.T. Consolidation behavior of SiC powder under cold compaction. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2001, 299, 116–124. [Google Scholar] [CrossRef]

- Suzuki, T.S.; Uchikoshi, T.; Sakka, Y. Effect of sintering conditions on microstructure orientation in alpha-SiC prepared by slip casting in a strong magnetic field. J. Eur. Ceram. Soc. 2010, 30, 2813–2817. [Google Scholar] [CrossRef]

- Wang, Y.; Cheng, Y.; Chen, Y.; Wang, R.; Ping, Z. Lattice-structured SiC ceramics obtained via 3D printing, gel casting, and gaseous silicon infiltration sintering. Ceram. Int. 2021, 48, 6488–6496. [Google Scholar] [CrossRef]

- Ding, G.J.; He, R.J.; Zhang, K.Q.; Zhou, N.P.; Xu, H. Stereolithography 3D printing of SiC ceramic with potential for lightweight optical mirror. Ceram. Int. 2020, 46, 18785–18790. [Google Scholar] [CrossRef]

- Gao, Z.; Lv, X.; Cheng, L.; Ye, F.; Zhang, L. Combination of gel-casting and reactive melt infiltration for rapid fabrication of SiCw/SiC composites. Ceram. Int. 2021, 47, 14375–14381. [Google Scholar] [CrossRef]

- Meyers, S.; De Leersnijder, L.; Vleugels, J.; Kruth, J.-P. Direct laser sintering of reaction bonded silicon carbide with low residual silicon content. J. Eur. Ceram. Soc. 2018, 38, 3709–3717. [Google Scholar] [CrossRef]

- Cesconeto, F.; Frade, J. Cellular ceramics by slip casting of emulsified suspensions. J. Eur. Ceram. Soc. 2020, 40, 4949–4954. [Google Scholar] [CrossRef]

- Jang, B.-K.; Kim, S.-Y.; Han, I.-S.; Seo, D.-W.; Hong, K.-S.; Woo, S.-K.; Sakka, Y. Influence of uni and bi-modal SiC composition on mechanical properties and microstructure of reaction-bonded SiC ceramics. J. Ceram. Soc. Jpn. 2010, 118, 1028–1031. [Google Scholar] [CrossRef]

- Song, N.; Liu, H.; Fang, J. Fabrication and mechanical properties of multi-walled carbon nanotube reinforced reaction bonded silicon carbide composites. Ceram. Int. 2016, 42, 351–356. [Google Scholar] [CrossRef]

- Wilhelm, M.; Kornfeld, M.; Wruss, W. Development of SiC–Si composites with fine-grained SiC microstructures. J. Eur. Ceram. Soc. 1999, 19, 2155–2163. [Google Scholar] [CrossRef]

- Giuntini, D.; Bordia, R.K.; Olevsky, E.A. Feasibility of in situ de-agglomeration during powder consolidation. J. Am. Ceram. Soc. 2018, 102, 628–643. [Google Scholar] [CrossRef]

- Lee, J.; Kim, D.; Shin, D.; Lee, H.-G.; Park, J.Y.; Kim, W.-J. A new process for minimizing residual silicon and carbon of reaction-bonded silicon carbide via chemical vapor deposition. J. Eur. Ceram. Soc. 2021, 41, 4000–4005. [Google Scholar] [CrossRef]

- Li, S.; Zhang, Y.; Han, J.; Zhou, Y. Effect of carbon particle and carbon fiber on the microstructure and mechanical properties of short fiber reinforced reaction bonded silicon carbide composite. J. Eur. Ceram. Soc. 2013, 33, 887–896. [Google Scholar] [CrossRef]

- Favre, A.; Fuzellier, H.; Suptil, J. An original way to investigate the siliconizing of carbon materials. Ceram. Int. 2003, 29, 235–243. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, Y.; Sha, W.; Liu, Y.; Lyu, Y.; Huang, Y. Influence of Carbon Source on Microstructural and Mechanical Properties of High-Performance Reaction-Bonded Silicon Carbide. Materials 2022, 15, 5250. https://doi.org/10.3390/ma15155250

Zhou Y, Sha W, Liu Y, Lyu Y, Huang Y. Influence of Carbon Source on Microstructural and Mechanical Properties of High-Performance Reaction-Bonded Silicon Carbide. Materials. 2022; 15(15):5250. https://doi.org/10.3390/ma15155250

Chicago/Turabian StyleZhou, Yabin, Wenhao Sha, Yingying Liu, Yinong Lyu, and Yihua Huang. 2022. "Influence of Carbon Source on Microstructural and Mechanical Properties of High-Performance Reaction-Bonded Silicon Carbide" Materials 15, no. 15: 5250. https://doi.org/10.3390/ma15155250

APA StyleZhou, Y., Sha, W., Liu, Y., Lyu, Y., & Huang, Y. (2022). Influence of Carbon Source on Microstructural and Mechanical Properties of High-Performance Reaction-Bonded Silicon Carbide. Materials, 15(15), 5250. https://doi.org/10.3390/ma15155250