Frictional Characteristics of Deep-Drawing Quality Steel Sheets in the Flat Die Strip Drawing Test

Abstract

:1. Introduction

2. Material and Methods

2.1. Test Material

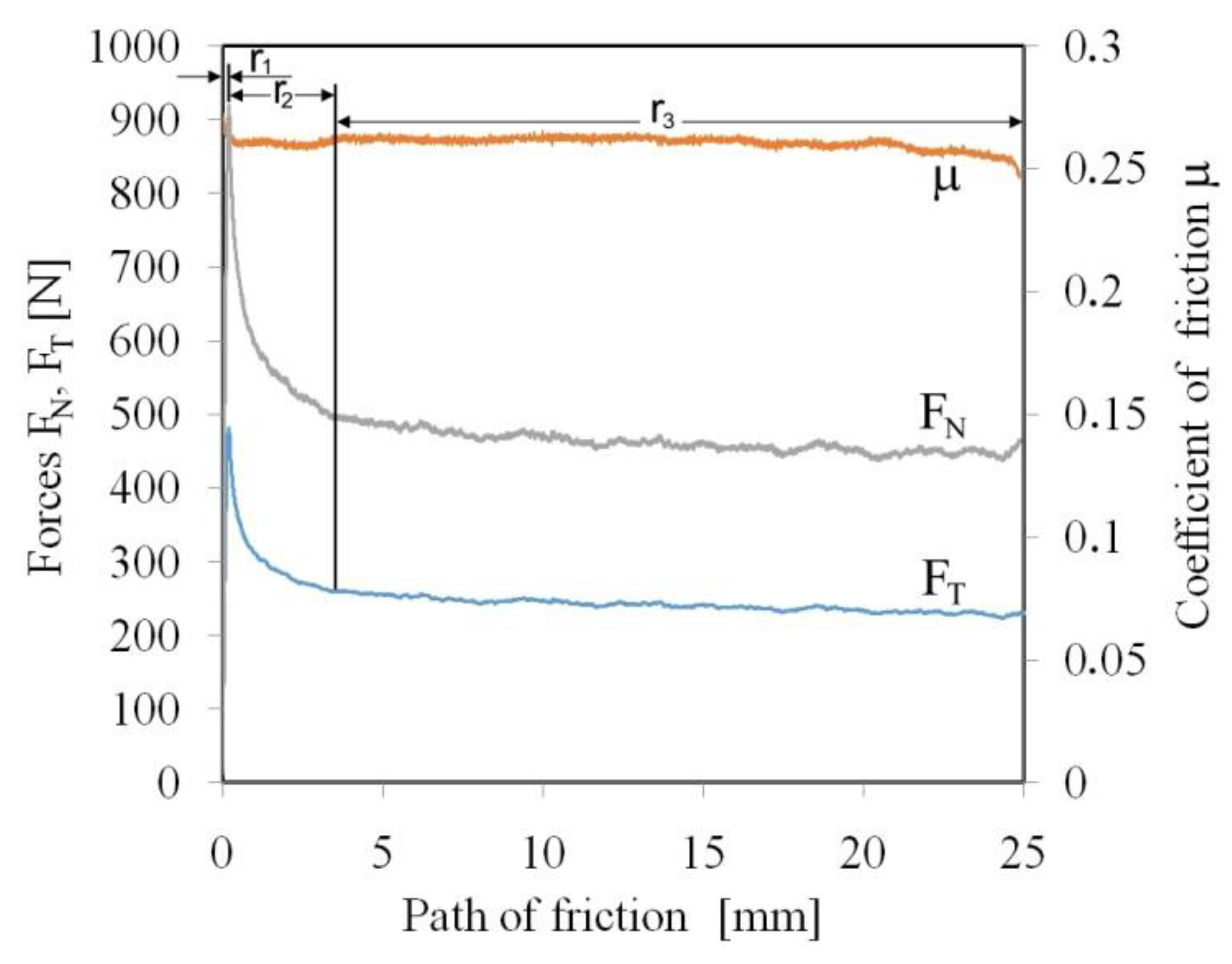

2.2. The Friction Test Process

3. Results and Discussion

4. Conclusions

- The value of the COF decreases with increasing nominal pressure for all analysed friction conditions.

- Use of 80W-90 gear oil ensured, depending on the value of the pressure, a reduction in the value of the COF in the range between 11.24% and 15.7% compared to dry friction conditions.

- In the entire range of nominal pressures examined, the engine oil decreased the value of the COF by only 3.84–8.87%.

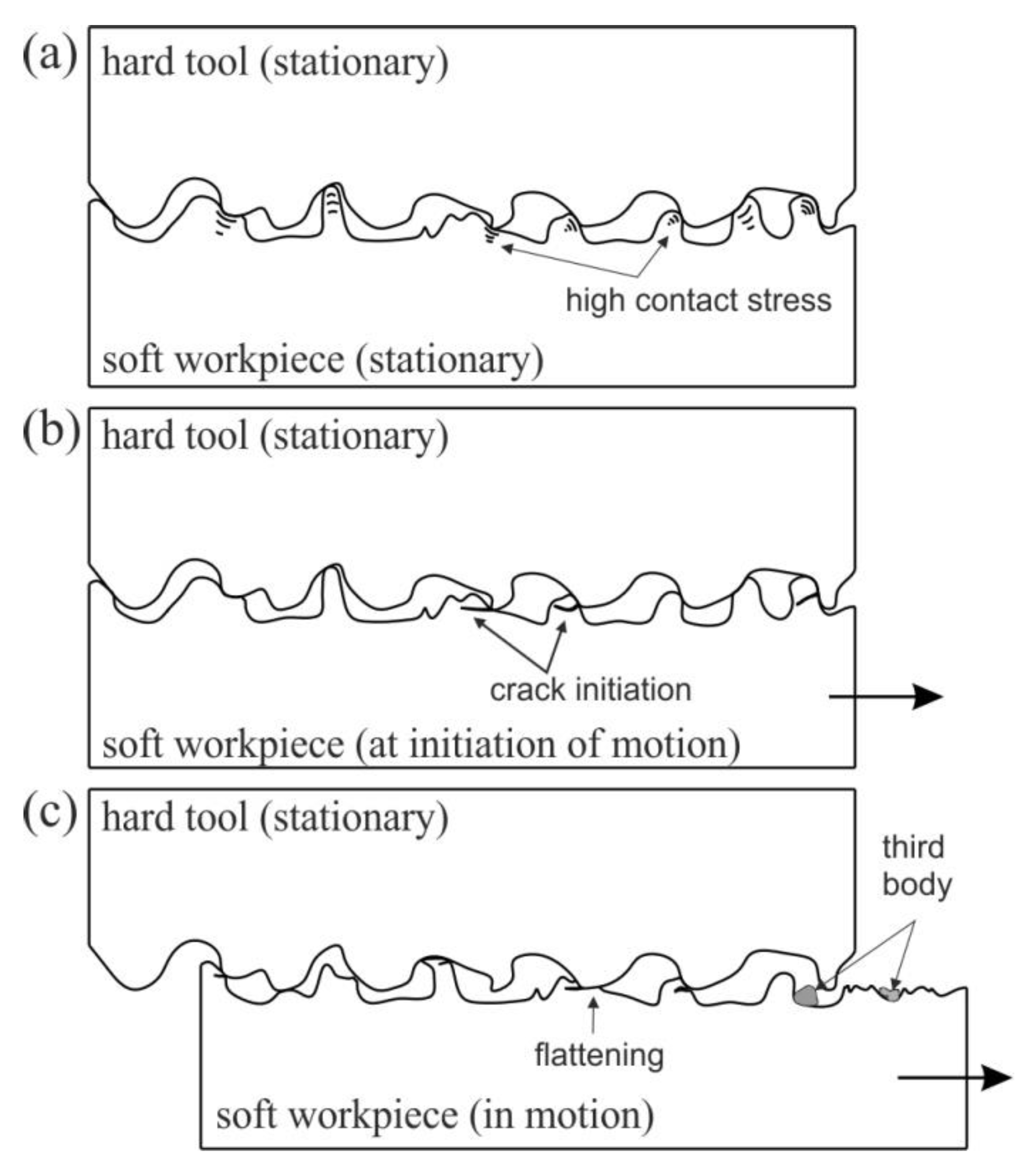

- In dry friction conditions, the average roughness Sa and the root mean square roughness Sq decrease in the pressure range of 3–6 MPa, and then an increase in these parameters is observed as a result of the intensification of the ploughing mechanism. On the other hand, when lubricating the sample surfaces there was a clear trend to a reduction of the Sa and Sq parameters with increasing nominal pressure in the whole range of pressures investigated.

- The occurrence of the flattening mechanism during cooperation of the relatively soft surface of the sheet metal with the hard surface of the countersamples causes a reduction in the highest peak of the surface Sp by over 50% in relation to the as-received surface.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Holmberg, K.; Erdemir, A. Influence of tribology on global energy consumption, costs and emissions. Friction 2017, 5, 263–284. [Google Scholar] [CrossRef]

- Bazan, A.; Trzepieciński, T. Effect of friction conditions on the change of sheet surface roughness during deep drawing. Zesz. Nauk. Pol. Rzesz.-Mech. 2013, 30, 375–386. [Google Scholar] [CrossRef] [Green Version]

- Trzepieciński, T.; Fejkiel, R.; Kubit, A. Experimental evaluation of value of friction coefficient in the drawbead region. Zesz. Nauk. Pol. Rzesz.-Mech. 2018, 35, 77–85. [Google Scholar] [CrossRef] [Green Version]

- Nielsen, C.V.; Bay, N. Overview of friction modelling in metal forming processes. Procedia Eng. 2017, 207, 2257–2262. [Google Scholar] [CrossRef] [Green Version]

- Trzepieciński, T.; Gelgele, H.L. Investigation of anisotropy problems in sheet metal forming using finite element method. Int. J. Mater. Form. 2011, 4, 357–369. [Google Scholar] [CrossRef]

- Trzepieciński, T. 3D elasto-plastic FEM analysis of the sheet drawing of anisotropic steel sheet. Arch. Civ. Mech. Eng. 2010, 10, 95–106. [Google Scholar] [CrossRef]

- Nie, N.; Su, L.; Deng, G.; Li, H.; Yu, H.; Tieu, A.K. A review on plastic deformation induced surface/interface roughening of sheet metallic materials. J. Mater. Res. Technol. 2021, 15, 6574–6607. [Google Scholar] [CrossRef]

- Costa, H.L.; Hutchings, I.M. Effects of die surface patterning on lubrication in strip drawing. J. Mater. Proc. Technol. 2009, 209, 1175–1180. [Google Scholar] [CrossRef]

- Wang, C.; Ma, R.; Zhao, J.; Zhao, J. Calculation method and experimental study of coulomb friction coefficient in sheet metal forming. J. Manuf. Process. 2017, 27, 126–137. [Google Scholar] [CrossRef]

- Bay, N.; Olsson, D.D.; Andreasen, J.L. Lubricant test methods for sheet metal forming. Tribol. Int. 2008, 41, 844–853. [Google Scholar] [CrossRef]

- Seshacharyulu, K.; Bandhavi, C.; Naik, B.B.; Rao, S.S.; Singh, S.K. Understanding Friction in sheet metal forming-A review. Mater. Today: Proc. 2018, 5, 18238–18244. [Google Scholar] [CrossRef]

- Sanchez-Caballero, S.; Selles, M.A.; Pla-Ferrando, R.; Seguí, J.; Peydro, M.A. Research on the Friction Properties of DP600 Stainless Steel as a Function of Bending Angle and Pin Diameter. Mater. Proc. 2021, 3, 17. [Google Scholar]

- Littlewood, M.; Wallace, J.F. The effect of surface finish and lubrication on the fictional variation involved in the sheet-metal-forming process. Sheet Met. Ind. 1964, 41, 925–1930. [Google Scholar]

- Sigvant, M.; Pilthammar, J.; Hol, J.; Wiebenga, J.H.; Chezan, T.; Carleer, B.; van den Boogaard, T. Friction in sheet metal forming: Influence of surface roughness and strain rate on sheet metal forming simulation results. Procedia Manuf. 2019, 29, 512–519. [Google Scholar] [CrossRef]

- Gierzyńska, M. Tarcie, Zużycie i Smarowanie w Obróbce Plastycznej Metali; Wydawnictwa Naukowo-Techniczne: Warszawa, Poland, 1983. [Google Scholar]

- Kim, H.; Han, S.; Yan, Q.; Altan, T. Evaluation of tool materials, coatings and lubricants in forming galvanized advanced high strength steels (AHSS). CIRP Annals-Manuf. Technol. 2008, 57, 299–304. [Google Scholar]

- Ludema, K.C. Friction, Wear, Lubrication. A Textbook in Tribology; CRC Press: Boca Raton, FL, USA, 2000. [Google Scholar]

- Wihlborg, A.H. The Influence of Steel Sheet Surface Topography on Friction in Stamping. Ph.D. Thesis, Göteborg University, Göteborg, Sweden, 1997. [Google Scholar]

- Trzepieciński, T.; FejkielR. On the influence of deformation of deep drawing quality steel sheet on surface topography and friction. Tribol. Int. 2017, 115, 78–88. [Google Scholar] [CrossRef]

- Masters, L.G.; Williams, D.K.; Roy, R. Friction behaviour in strip draw test of pre-stretched high strength automotive aluminium alloys. Int. J. Mach. Tools Manuf. 2013, 73, 17–24. [Google Scholar] [CrossRef]

- Evin, E.; Tomáš, M.; Výrostek, M. Verification the numerical simulation of the strip drawing test by its physical model. Acta Mechanica Slovaca 2016, 20, 14–21. [Google Scholar] [CrossRef]

- Trzepieciński, T. A study of the coefficient of friction in steel sheets forming. Metals 2019, 9, 988. [Google Scholar] [CrossRef] [Green Version]

- Trzepieciński, T. Tribological Performance of Environmentally Friendly Bio-Degradable Lubricants Based on a Combination of Boric Acid and Bio-Based Oils. Materials 2020, 13, 3892. [Google Scholar] [CrossRef]

- Severo, V.; Vilhena, L.; Silva, P.N.; Dias, J.P.; Becker, D.; Wagner, S.; Cavaleiro, A. Tribological behaviour of W–Ti–N coatings in semi-industrial strip-drawing tests. J. Mater. Process. Technol. 2009, 209, 4662–4667. [Google Scholar] [CrossRef] [Green Version]

- Tavares, A.F.; Lopes, A.P.O.; Mesquita, E.A.; Almeida, D.T.; Souza, J.H.C.; Costa, H.L. Effect of transfer layers on friction and wear mechanisms in strip drawing tests of commercially coated forming tools. Wear 2021, 476, 203733. [Google Scholar] [CrossRef]

- Schell, L.; Emele, M.; Holzbeck, A.; Groche, P. Investigation of different lubricant classes for aluminium warm and hot forming based on a strip drawing test. Tribol. Int. 2022, 168, 107449. [Google Scholar] [CrossRef]

- Sutcliffe, M.P.F.; Le, H.R.; Farrugia, D. Simulation of transfer layer formation in strip drawing of stainless steel. Wear 2003, 254, 523–531. [Google Scholar] [CrossRef]

- EN 10130:2006; Cold Rolled Low Carbon Steel Flat Products for Cold Forming. Technical Delivery Conditions; British Standard: London, UK, 2006.

- EN ISO 6892-1:2020; International Organization for Standardization: Geneva, Switzerland, 2020.

- Domitner, J.; Silvayeh, Z.; Sabet, A.S.; Öksüz, K.I.; Pelcastre, L.; Hardell, J. Characterization of wear and friction between tool steel and aluminum alloys in sheet forming at room temperature. J. Manuf. Proc. 2021, 64, 774–784. [Google Scholar] [CrossRef]

- Makhamov, A. Determination of the Friction Coefficient in the Flat Strip Drawing Test. Engineering 2021, 13, 595–604. [Google Scholar] [CrossRef]

- Prakash, V.; Kumar, D.R. Performance evaluation of bio-lubricants in strip drawing and deep drawing of an aluminium alloy. Adv. Mater. Process. Technol. 2020, 1–15. [Google Scholar] [CrossRef]

- Roizard, X.; Pothier, J.M.; Hihn, J.Y.; Monteil, G. Experimental device for tribological measurement aspects in deep drawing process. J. Mater. Processing Technol. 2009, 209, 1220–1230. [Google Scholar] [CrossRef]

- Le, H.R.; Sutcliffe, M.P.F. Measurements of friction in strip drawing under thin film lubrication. Tribol. Int. 2002, 35, 123–128. [Google Scholar] [CrossRef]

- Cillaurren, J.; Galdos, L.; Sanchez, M.; Zabala, A.; de Argandoña, S.; Mendiguren, J. Contact pressure and sliding velocity ranges in sheet metal forming simulations. In Proceedings of the 24th International Conference on Material Forming ESAFORM, Liege, Belgium, 14–16 April 2021. [Google Scholar]

- Erbel, S.; Kuczyński, K.; Marciniak, Z. Obróbka Plastyczna na Zimno; PWN: Warszawa, Poland, 1975. [Google Scholar]

- Trzepieciński, T. Wybrane Aspekty Oceny Tribologicznej Blach Odkształcanych Plastycznie; Oficyna Wydawnicza Politechniki Rzeszowskiej: Rzeszów, Poland, 2013. [Google Scholar]

- Trzepieciński, T.; Szpunar, M. Assessment of the effectiveness of lubrication of Ti-6Al-4V titanium alloy sheets using radial basis function neural networks. Acta Polytech. 2021, 61, 489–496. [Google Scholar] [CrossRef]

- Payen, G.R.; Felder, E.; Repoux, M.; Mataigne, J.M. Infuence of contact pressure and boundary films on the frictional behaviour and on the roughness changes of galvanized steel sheets. Wear 2012, 276–277, 48–52. [Google Scholar] [CrossRef]

- Kirkhorn, L.; Frogner, K.; Andersson, M.; Stahl, J.E. Improved tribotesting for sheet metal forming. Procedia CIRP 2012, 3, 507–512. [Google Scholar] [CrossRef] [Green Version]

- Trzepieciński, T.; Bazan, A.; Lemu, H.G. Frictional characteristics of steel sheets used in automotive industry. Int. J. Automot. Technol. 2015, 16, 849–863. [Google Scholar] [CrossRef]

- Vollertsen, F.; Hu, Z. Tribological Size Effects in Sheet Metal Forming Measured by a Strip Drawing Test. CIRP Annals 2006, 55, 291–294. [Google Scholar] [CrossRef]

- ten Thije, R.H.W.; Akkerman, R.; van der Meer, L.; Ubbink, M.P. Tool-ply friction in thermoplastic composite forming. Int. J. Mater. Form. 2008, 1, 953–956. [Google Scholar] [CrossRef]

- Jurkovic, M.; Jurkovic, Z.; Buljan, S. The tribological state test in metal forming processes using experiment and modelling. J. Achiev. Mater. Manuf. Eng. 2006, 18, 383–386. [Google Scholar]

- Wang, D.; Yang, H.; Li, H. Advance and trend of friction study in plastic forming. Trans. Nonferr. Met. Soc. China 2014, 24, 1263–1272. [Google Scholar] [CrossRef]

- Gåård, A. Wear in Sheet Metal Forming. Ph.D. Thesis, Kalstad University Studies, Karlstad, Sweden, 2018. [Google Scholar]

| C (Max.) | Mn (Max.) | P (Max.) | S (Max.) | Fe |

|---|---|---|---|---|

| 0.08 | 0.4 | 0.03 | 0.03 | balance |

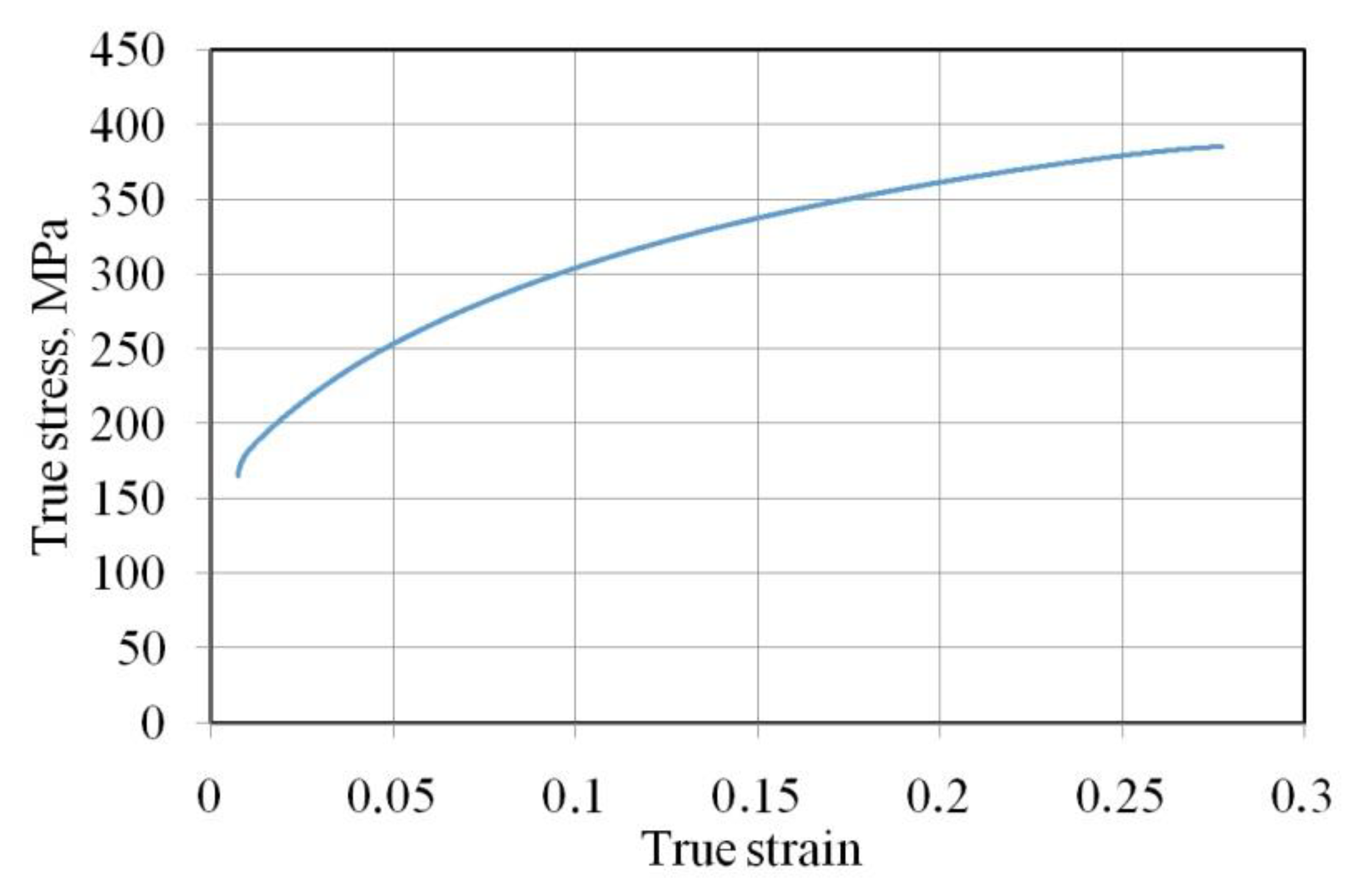

| Rp0.2, MPa | Rm, Mpa | A50, % | Z, % | K, Mpa | n |

|---|---|---|---|---|---|

| 165.2 | 309.3 | 37.1 | 45.7 | 526.9 | 0.23 |

| Oil | Property | Test Method | Value |

|---|---|---|---|

| Castrol Axle EPX 80W-90 | Density at 15 °C | ASTM D4052 | 0.896 g/mL |

| Kinematic viscosity at 40 °C | ASTM D445 | 134 mm2/s | |

| Viscosity index | ASTM D2270 | 101 | |

| Pour point | ASTM D97 | −33 °C | |

| Flash point | ASTM D92 | 222 °C | |

| Castrol EDGE 5W-30 | Density at 15 °C | ASTM D4052 | 0.851 g/ml |

| Kinematic viscosity at 40 °C | ASTM D445 | 70 mm2/s | |

| Viscosity index | ASTM D2270 | 169 | |

| Pour point | ASTM D97 | −42 °C | |

| Flash point | ASTM D93 | 202 °C |

| Sa, µm | Sq, µm | Sku | Ssk | Sp, µm | Sv, µm | Sz, µm |

|---|---|---|---|---|---|---|

| 0.636 | 0.810 | 3.76 | −0.544 | 4.89 | 5.11 | 10.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Szewczyk, M.; Szwajka, K.; Trzepieciński, T. Frictional Characteristics of Deep-Drawing Quality Steel Sheets in the Flat Die Strip Drawing Test. Materials 2022, 15, 5236. https://doi.org/10.3390/ma15155236

Szewczyk M, Szwajka K, Trzepieciński T. Frictional Characteristics of Deep-Drawing Quality Steel Sheets in the Flat Die Strip Drawing Test. Materials. 2022; 15(15):5236. https://doi.org/10.3390/ma15155236

Chicago/Turabian StyleSzewczyk, Marek, Krzysztof Szwajka, and Tomasz Trzepieciński. 2022. "Frictional Characteristics of Deep-Drawing Quality Steel Sheets in the Flat Die Strip Drawing Test" Materials 15, no. 15: 5236. https://doi.org/10.3390/ma15155236

APA StyleSzewczyk, M., Szwajka, K., & Trzepieciński, T. (2022). Frictional Characteristics of Deep-Drawing Quality Steel Sheets in the Flat Die Strip Drawing Test. Materials, 15(15), 5236. https://doi.org/10.3390/ma15155236