Wear Behavior between Aesthetic Restorative Materials and Bovine Tooth Enamel

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Characterization of Restorative Materials

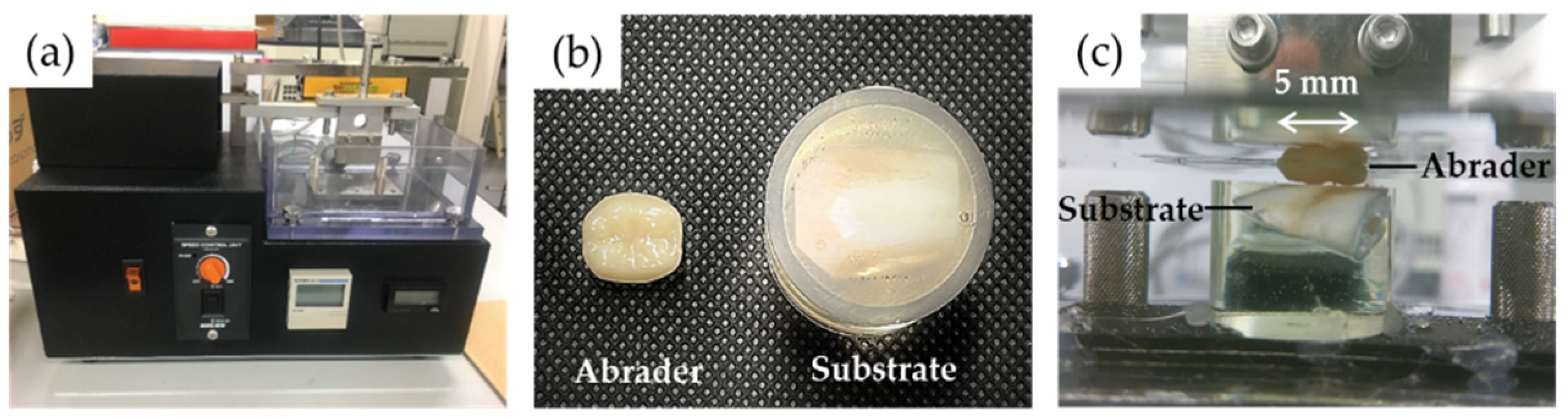

2.3. Two-Body Wear Test

2.3.1. Preparation of Abrader Specimens Using a Crown Model

2.3.2. Two-Body Wear Test

2.4. Statistical Analysis

3. Results

3.1. Vickers Hardness

3.2. Surface Roughness

3.3. Worn Width and Depth of the Substrate Specimens

3.4. Analysis of the 3D Laser Microscope Observation

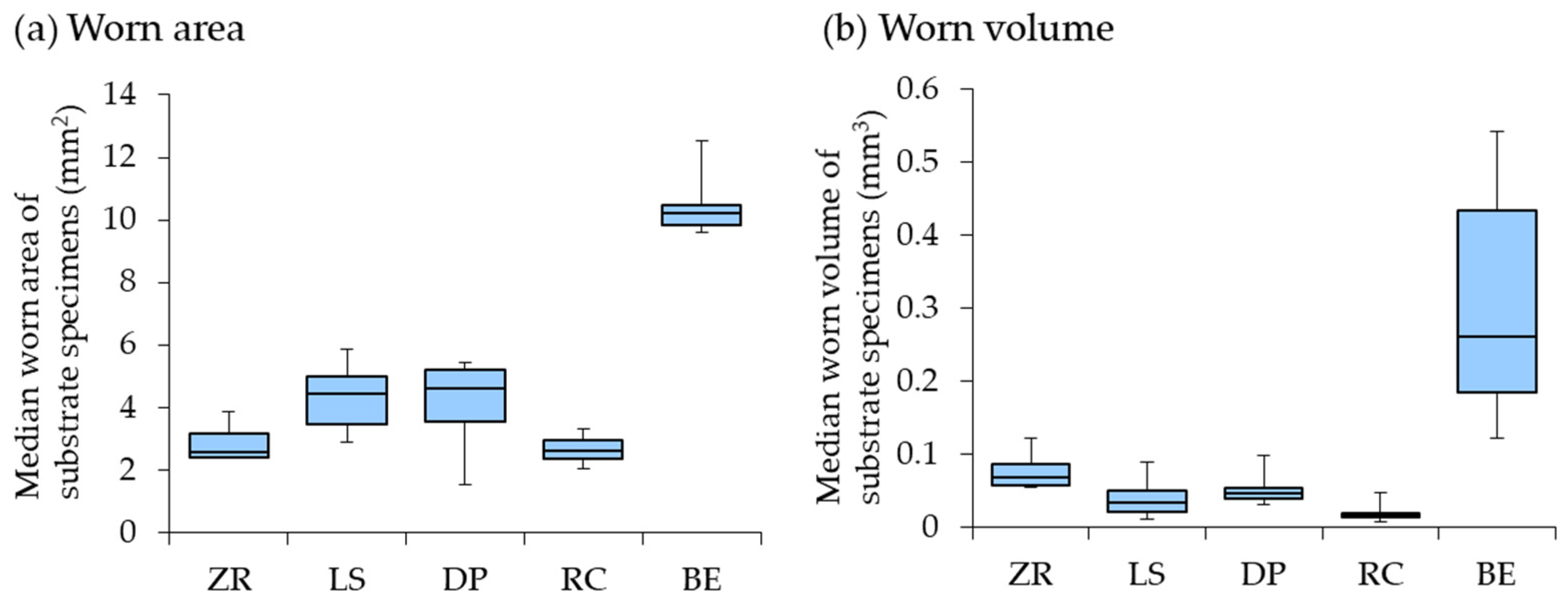

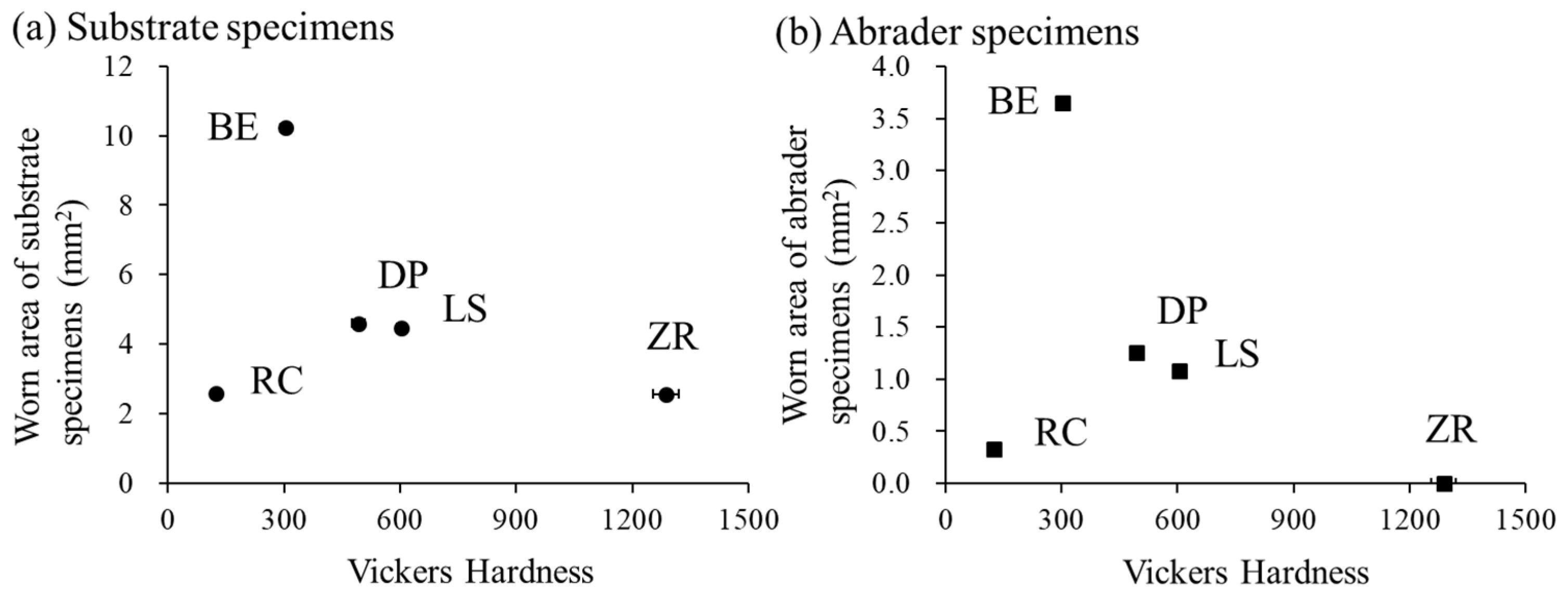

3.4.1. Worn Area and Volume of the Substrate Specimens

3.4.2. Worn Area of the Abrader Specimens

4. Discussion

5. Conclusions

- The tooth-colored restorative materials and bovine tooth enamel had similar surface roughness with different hardness, resulting in different wear behavior on their surfaces and against the opposite tooth enamel.

- Compared to the restorative materials, bovine teeth showed the largest wear area and/or volume in tooth–tooth contact as the abrader and substrate specimens.

- Zirconia, lithium disilicate glass ceramic, and dental porcelain showed larger hardness and less wear on their surfaces and less substrate wear of the opposite tooth enamel.

- Although there was no difference in the wear of the substrate specimen, the worn area of the abrader specimen in zirconia was significantly smaller than that of lithium disilicate glass ceramic and dental porcelain.

- Among the restorative materials, resin composite for indirect restorative showed the lowest hardness and intermediate wear on its surface, resulting in the lowest substrate wear.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Oh, W.S.; Delong, R.; Anusavice, K.J. Factors affecting enamel and ceramic wear: S literature review. J. Prosthet. Dent. 2002, 87, 451–459. [Google Scholar] [CrossRef] [PubMed]

- Fehmer, V.; Mühlemann, S.; Hämmerle, C.H.F.; Sailer, I. Criteria for the selection of restoration materials. Quintessence Int. 2014, 45, 723–730. [Google Scholar] [PubMed]

- Sailer, I.; Makarov, N.A.; Thoma, D.S.; Zwahlen, M.; Pjetursson, B.E. All-ceramic or metal-ceramic tooth-supported fixed dental prostheses (FDPs)? A systematic review of the survival and complication rates. Part I: Single crowns (SCs). Dent. Mater. 2015, 31, 603–623. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pjetursson, B.E.; Sailer, I.; Makarov, N.A.; Zwahlen, M.; Thoma, D.S. All-ceramic or metal-ceramic tooth-supported fixed dental prostheses (FDPs)? A systematic review of the survival and complication rates. Part II: Multiple-unit FDPs. Dent. Mater. 2015, 31, 624–639. [Google Scholar] [CrossRef] [Green Version]

- Frankenberger, R.; Hartmann, V.E.; Krech, M.; Krämer, N.; Reich, S.; Braun, A.; Roggendorf, M. Adhesive luting of new CAD/CAM materials. Int. J. Comput. Dent. 2015, 18, 9–20. [Google Scholar]

- Li, R.W.; Chow, T.W.; Matinlinna, J.P. Ceramic dental biomaterials and CAD/CAM technology: State of the art. J. Prosthodont. Res. 2014, 58, 208–216. [Google Scholar] [CrossRef] [Green Version]

- Ispas, A.; Iosif, L.; Popa, D.; Negucioiu, M.; Constantiniuc, M.; Bacali, C.; Buduru, S. Comparative assessment of the functional parameters for metal-ceramic and all-ceramic teeth restorations in prosthetic dentistry-A literature review. Biology 2022, 11, 556. [Google Scholar] [CrossRef]

- Lambrechts, P.; Braem, M.; Vuylsteke-Wauters, M.; Vanherle, G. Quantitative in vivo wear of human enamel. J. Dent. Res. 1989, 68, 1752–1754. [Google Scholar] [CrossRef]

- Mundhe, K.; Jain, V.; Pruthi, G.; Shah, N. Clinical study to evaluate the wear of natural enamel antagonist to zirconia and metal ceramic crowns. J. Prosthet. Dent. 2015, 114, 358–363. [Google Scholar] [CrossRef]

- Nakashima, J.; Taira, Y.; Sawase, T. In vitro wear of four ceramic materials and human enamel on enamel antagonist. Eur. J. Oral. Sci. 2016, 24, 295–300. [Google Scholar] [CrossRef]

- Zhi, L.; Bortolotto, T.; Krejci, I. Comparative in vitro wear resistance of CAD/CAM composite resin and ceramic materials. J. Prosthet. Dent. 2016, 115, 199–202. [Google Scholar] [CrossRef]

- Spitznagel, F.A.; Boldt, J.; Gierthmuehlen, P.C. CAD/CAM ceramic restorative materials for natural teeth. J. Dent. Res. 2018, 97, 1082–1091. [Google Scholar] [CrossRef]

- Sinmazisik, G.; Tarcin, B.; Demirbas, B.; Gulmez, T.; Bor, E.; Ozer, F. The effect of zirconia thickness on the biaxial flexural strength of zirconia ceramic bilayered discs. Dent. Mater. J. 2015, 34, 640–647. [Google Scholar] [CrossRef] [Green Version]

- Zarone, F.; Russo, S.; Sorrentino, R. From porcelain-fused-to-metal to zirconia: Clinical and experimental considerations. Dent. Mater. 2011, 27, 83–96. [Google Scholar] [CrossRef]

- Gracis, S.; Thompson, V.P.; Ferencz, J.L.; Silva, N.R.; Bonfante, E.A. A new classification system for all-ceramic and ceramic-like restorative materials. Int. J. Prosthodont. 2015, 28, 227–235. [Google Scholar] [CrossRef] [Green Version]

- Chong, B.J.; Thangavel, A.K.; Rolton, S.B.; Guazzato, M.; Klineberg, I.J. Clinical and laboratory surface finishing procedures for zirconia on opposing human enamel wear: A laboratory study. J. Mech. Behav. Biomed. Mater. 2015, 50, 93–103. [Google Scholar] [CrossRef]

- Mehzabeen, K.R.; Boughton, P.; Kan, W.H.; Ruys, A.J.; Guazzato, M. Two-body wear test of enamel against laboratory polished and clinically adjusted zirconia. J. Mech. Behav. Biomed. Mater. 2020, 108, 103760. [Google Scholar] [CrossRef]

- Aljomard, Y.R.M.; Altunok, E.Ç.; Kara, H.B. Enamel wear against monolithic zirconia restorations: A meta-analysis and systematic review of in vitro studies. J. Esthet. Restor. Dent. 2021, 34, 473–489. [Google Scholar] [CrossRef]

- Lohbauer, U.; Reich, S. Antagonist wear of monolithic zirconia crowns after 2 years. Clin. Oral. Investig. 2017, 21, 1165–1172. [Google Scholar] [CrossRef]

- Gou, M.; Chen, H.; Kang, J.; Wang, H. Antagonist enamel wear of tooth-supported monolithic zirconia posterior crowns in vivo: A systematic review. J. Prosthet. Dent. 2019, 121, 598–603. [Google Scholar] [CrossRef]

- Gao, W.M.; Geng, W.; Yan, Y.W.; Wang, Y. Antagonist wear of zirconia fixed restorations in vitro and in vivo- A systematic review. Int. J. Prosthodont. 2021, 34, 492–504. [Google Scholar] [CrossRef]

- Lawson, N.C.; Janyavula, S.; Syklawer, S.; McLaren, E.A.; Burgess, J.O. Wear of enamel opposing zirconia and lithium disilicate after adjustment, polishing and glazing. J. Dent. 2014, 42, 1586–1591. [Google Scholar] [CrossRef]

- Kwon, S.J.; Lawson, N.C.; McLaren, E.E.; Nejat, A.H.; Burgess, J.O. Comparison of the mechanical properties of translucent zirconia and lithium disilicate. J. Prosthet. Dent. 2018, 120, 132–137. [Google Scholar] [CrossRef]

- Sripetchdanond, J.; Leevailoj, C. Wear of human enamel opposing monolithic zirconia, glass ceramic, and composite resin: An in vitro study. J. Prosthet. Dent. 2014, 112, 1141–1150. [Google Scholar] [CrossRef]

- Tanaka, K.; Someya, T.; Kawada, E.; Ohyama, T.; Yoshinari, M.; Takemoto, S.; Hattori, M. In vitro wear behavior of restorative resin composites against bovine enamel. Dent. Mater. J. 2020, 39, 915–923. [Google Scholar] [CrossRef] [Green Version]

- Jang, Y.S.; Nguyen, T.D.T.; Ko, Y.H.; Lee, D.W.; Baik, B.J.; Lee, M.H.; Bae, T.S. In vitro wear behavior between enamel cusp and three aesthetic restorative materials: Zirconia, porcelain, and composite resin. J. Adv. Prosthodont. 2019, 11, 7–15. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Su, N.; Liao, Y.; Zhang, H.; Yue, L.; Lu, X.; Shen, J.; Wang, H. Effects of core-to-dentin thickness ratio on the biaxial flexural strength, reliability, and fracture mode of bilayered materials of zirconia core (Y-TZP) and veneer indirect composite resins. J. Prosthet. Dent. 2017, 117, 150–157. [Google Scholar] [CrossRef] [PubMed]

- Suese, K.; Kawazoe, T. Wear resistance of hybrid composite resin for crown material by the two-body sliding test. Dent. Mater. J. 2002, 21, 225–237. [Google Scholar] [CrossRef] [PubMed]

- Suzuki, S.; Nagai, E.; Taira, Y.; Minesaki, Y. In vitro wear of indirect composite restoratives. J. Prosthet. Dent. 2002, 88, 431–436. [Google Scholar] [CrossRef] [PubMed]

- Heintze, S.D.; Reichl, F.X.; Hickel, R. Wear of dental materials: Clinical significance and laboratory wear simulation methods-A review. Dent. Mater. J. 2019, 38, 343–353. [Google Scholar] [CrossRef] [Green Version]

- Branco, A.C.; Colaço, R.; Figueiredo-Pina, C.G.; Serro, A.P. A state-of-the-art review on the wear of the occlusal surfaces of natural teeth and prosthetic crowns. Materials 2020, 13, 3525. [Google Scholar] [CrossRef]

- Preis, V.; Behr, M.; Kolbeck, C.; Hanhel, S.; Handel, G.; Rosentritt, M. Wear performance of substructure ceramics and veneering porcelains. Dent. Mater. 2011, 27, 796–804. [Google Scholar] [CrossRef]

- Muts, E.J.; Van Pelt, H.; Edelhoff, D.; Krejci, I.; Cune, M. Tooth wear: A systematic review of treatment options. J. Prosthet. Dent. 2014, 112, 752–759. [Google Scholar] [CrossRef]

- ISO/TS 14569-2:2001; Dental Materials—Guidance on Testing of Wear—Part 2: Wear by Two- and/or Three Body Contact. International Organization for Standardization: Geneva, Switzerland, 2001.

- Heintze, S.D. How to qualify and validate wear simulation devices and methods. Dent. Mater. 2006, 22, 712–734. [Google Scholar] [CrossRef]

- Habib, S.R.; Alotaibi, A.; Hazza, N.A.; Allam, Y.; AlGhazi, M. Two-body wear behavior of human enamel versus monolithic zirconia, lithium disilicate, ceramometal and composite resin. J. Adv. Prosthodont. 2019, 11, 23–31. [Google Scholar] [CrossRef] [Green Version]

- Lee, A.; He, L.H.; Lyons, K.; Swain, M.V. Tooth wear and wear investigations in dentistry. J. Oral. Rehabil. 2012, 39, 217–225. [Google Scholar] [CrossRef]

- Hattab, F.N.; Yassin, O.M. Etiology and diagnosis of tooth wear: A literature review and presentation of selected cases. Int. J. Prosthodont. 2000, 13, 101–107. [Google Scholar]

- Lambrecht, P.; Debels, E.; Van Landuyt, K.; Peumans, M.; Van Meerbeek, B. How to simulate wear?: Overview of existing methods. Dent. Mater. 2006, 22, 693–701. [Google Scholar] [CrossRef]

- Kirsten, A.; Parkot, D.; Raith, S.; Fischer, H. A cusp supporting framework design can decrease critical stresses in veneered molar crowns. Dent. Mater. 2014, 30, 321–326. [Google Scholar] [CrossRef]

- Wang, M.; Mehta, N. A possible biomechanical role of occlusal cusp-fossa contact relationships. J. Oral. Rehabil. 2013, 40, 69–79. [Google Scholar] [CrossRef]

- Chun, K.; Choi, H.; Lee, J. Comparison of mechanical property and role between enamel and dentin in the human teeth. J. Dent. Biomech. 2014, 5, 1758736014520809. [Google Scholar] [CrossRef]

- Tokunaga, J.; Ikeda, H.; Nagamatsu, Y.; Awano, S.; Shimizu, H. Wear of polymer-infiltrated ceramic network materials against enamel. Materials 2022, 15, 2435. [Google Scholar] [CrossRef]

- Ban, S. Reliability and properties of core materials for all-ceramic dental restorations. Jpn. Dent. Sci. Rev. 2008, 44, 3–21. [Google Scholar] [CrossRef] [Green Version]

- Ban, S. Chemical durability of high translucent dental zirconia. Dent. Mater. J. 2020, 39, 12–23. [Google Scholar] [CrossRef] [Green Version]

- Goujat, A.; Abouelleil, H.; Colon, P.; Jeannin, C.; Pradelle, N.; Seux, D.; Grosgogeat, B. Mechanical properties and internal fit of 4 CAD-CAM block materials. J. Prosthet. Dent. 2018, 119, 384–389. [Google Scholar] [CrossRef]

- Fu, L.; Engqvist, H.; Xia, W. Glass–ceramics in dentistry: A review. Materials 2020, 13, 1049. [Google Scholar] [CrossRef] [Green Version]

- Ruales-Carrera, E.; Dal Bó, M.; das Neves, W.F.; Fredel, M.C.; Volpato, C.A.M.; Hotza, D. Chemical tempering of feldspathic porcelain for dentistry applications: A review. Open Ceram. 2022, 9, 100201. [Google Scholar] [CrossRef]

- Hara, M.; Takuma, Y.; Sato, T.; Koyama, T.; Yoshinari, M. Wear performance of bovine tooth enamel against translucent tetragonal zirconia polycrystals after different surface treatments. Dent. Mater. J. 2014, 33, 811–817. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Culp, L.; McLaren, E.A. Lithium disilicate: The restorative material of multiple options. Compend. Contin. Educ. Dent. 2010, 31, 716–725. [Google Scholar]

- Liu, J.; Zhang, H.; Sun, H.; Liu, Y.; Liu, W.; Su, B.; Li, S. The development of filler morphology in dental resin composites: A review. Materials 2021, 14, 5612. [Google Scholar] [CrossRef]

- Taira, Y.; Nakashima, J.; Sawase, T.; Sakihara, M. Wear of tooth enamel against silver-palladium-gold alloy and two other restorative materials in vitro. J. Prosthodont. Res. 2015, 59, 210–212. [Google Scholar] [CrossRef] [PubMed]

- Awada, A.; Nathanson, D. Mechanical properties of resin-ceramic CAD/CAM restorative materials. J. Prosthet. Dent. 2015, 114, 587–593. [Google Scholar] [CrossRef] [PubMed]

- Yassen, G.H.; Platt, J.A.; Hara, A.T. Bovine teeth as substitute for human teeth in dental research: A review of literature. J. Oral. Sci. 2011, 53, 273–282. [Google Scholar] [CrossRef] [Green Version]

- Turssi, C.P.; Messias, D.F.; Corona, S.M.; Serra, M.C. Viability of using enamel and dentin from bovine origin as a substitute for human counterparts in an intraoral erosion model. Braz. Dent. J. 2010, 21, 332–336. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.R.; Du, W.; Zhou, X.D.; Yu, H.Y. Review of research on the mechanical properties of the human tooth. Int. J. Oral. Sci. 2014, 6, 61–69. [Google Scholar] [CrossRef] [Green Version]

- Yahyazadehfar, M.; Bajaj, D.; Arola, D.D. Hidden contributions of the enamel rods on the fracture resistance of human teeth. Acta. Biomater. 2013, 9, 4806–4814. [Google Scholar] [CrossRef] [Green Version]

- Khanlar, L.N.; Salazar Rios, A.; Tahmaseb, A.; Zandinejad, A. Additive manufacturing of zirconia ceramic and its application in clinical dentistry: A review. Dent. J. 2021, 9, 104. [Google Scholar] [CrossRef]

| Material | Product | Composition * | Manufacturer | Lot No. | Code |

|---|---|---|---|---|---|

| Zirconia (3Y-TZP) | Cercon ht (A2) | ZrO2 (rest), Y2O3 (5 wt%), HfO2 (3 wt%), Al2O3, SiO2 (<1 wt%) | Dentsply Sirona | 18035989 | ZR |

| Lithium disilicate | e-max CAD HT (A2) | SiO2 (57.0–80.0 wt%), Li2O (11.0–19.0 wt%), K2O (<13.0 wt%), Other oxides (<8 wt%) | Ivoclar Vivadent | Y08507 | LS |

| Dental porcelain | Initial MC (E59) | Feldspathic ceramic (N.P.) | GC | 1812111 | DP |

| Resin composite | Gradia Forte (CT4) | UDMA (20 wt%), Multifunctional methacrylate (4 wt%), Inorganic fillers (73 wt%), Prepolymerized fillers (3 wt%), Photoinitiators, Stabilizers, Pigments | GC | 180591 | RC |

| Bovine tooth | - | - | - | - | BE |

| Experimental Group | ZR | LS | DP | RC | BE |

|---|---|---|---|---|---|

| Vickers hardness (Hv) | 1287 ± 33 a | 604 ± 12 b | 492 ± 16 c | 124 ± 4 d | 303 ± 14 e |

| Experimental Group | ZR | LS | DP | RC | BE |

|---|---|---|---|---|---|

| Sa (µm) | 7.9 ± 2.2 a | 8.9 ± 1.9 a | 8.1 ± 1.8 a | 10.6 ± 3.6 a | 6.1 ± 0.5 a |

| Experimental Group | ZR | LS | DP | RC | BE |

|---|---|---|---|---|---|

| Worn width (mm) | 0.61 A | 0.81 A | 0.93 A | 0.49 A | 1.67 B |

| Worn depth (µm) | 35.54 a | 1.57 c | 9.87 b | 0.94 c | 34.08 a |

| Experimental Group | ZR | LS | DP | RC | BE |

|---|---|---|---|---|---|

| Worn area (mm2) | 2.57 A | 4.46 A | 4.60 A | 2.62 A | 10.23 B |

| Worn volume (mm3) | 0.07 a | 0.03 a,b | 0.05 a,b | 0.02 b | 0.26 c |

| Experimental Group | ZR | LS | DP | RC | BE |

|---|---|---|---|---|---|

| Worn area (mm2) | 0.004 a | 1.077 b | 1.252 b | 0.326 c | 3.651 d |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hatanaka, A.; Sawada, T.; Sen, K.; Saito, T.; Sasaki, K.; Someya, T.; Hattori, M.; Takemoto, S. Wear Behavior between Aesthetic Restorative Materials and Bovine Tooth Enamel. Materials 2022, 15, 5234. https://doi.org/10.3390/ma15155234

Hatanaka A, Sawada T, Sen K, Saito T, Sasaki K, Someya T, Hattori M, Takemoto S. Wear Behavior between Aesthetic Restorative Materials and Bovine Tooth Enamel. Materials. 2022; 15(15):5234. https://doi.org/10.3390/ma15155234

Chicago/Turabian StyleHatanaka, Akihiko, Tomofumi Sawada, Kazuyo Sen, Takahiro Saito, Kaori Sasaki, Tomoko Someya, Masayuki Hattori, and Shinji Takemoto. 2022. "Wear Behavior between Aesthetic Restorative Materials and Bovine Tooth Enamel" Materials 15, no. 15: 5234. https://doi.org/10.3390/ma15155234

APA StyleHatanaka, A., Sawada, T., Sen, K., Saito, T., Sasaki, K., Someya, T., Hattori, M., & Takemoto, S. (2022). Wear Behavior between Aesthetic Restorative Materials and Bovine Tooth Enamel. Materials, 15(15), 5234. https://doi.org/10.3390/ma15155234