Experimental Investigation on the Potential Use of Magnetic Water as a Water Reducing Agent in High Strength Concrete

Abstract

:1. Introduction

2. Experimental Program

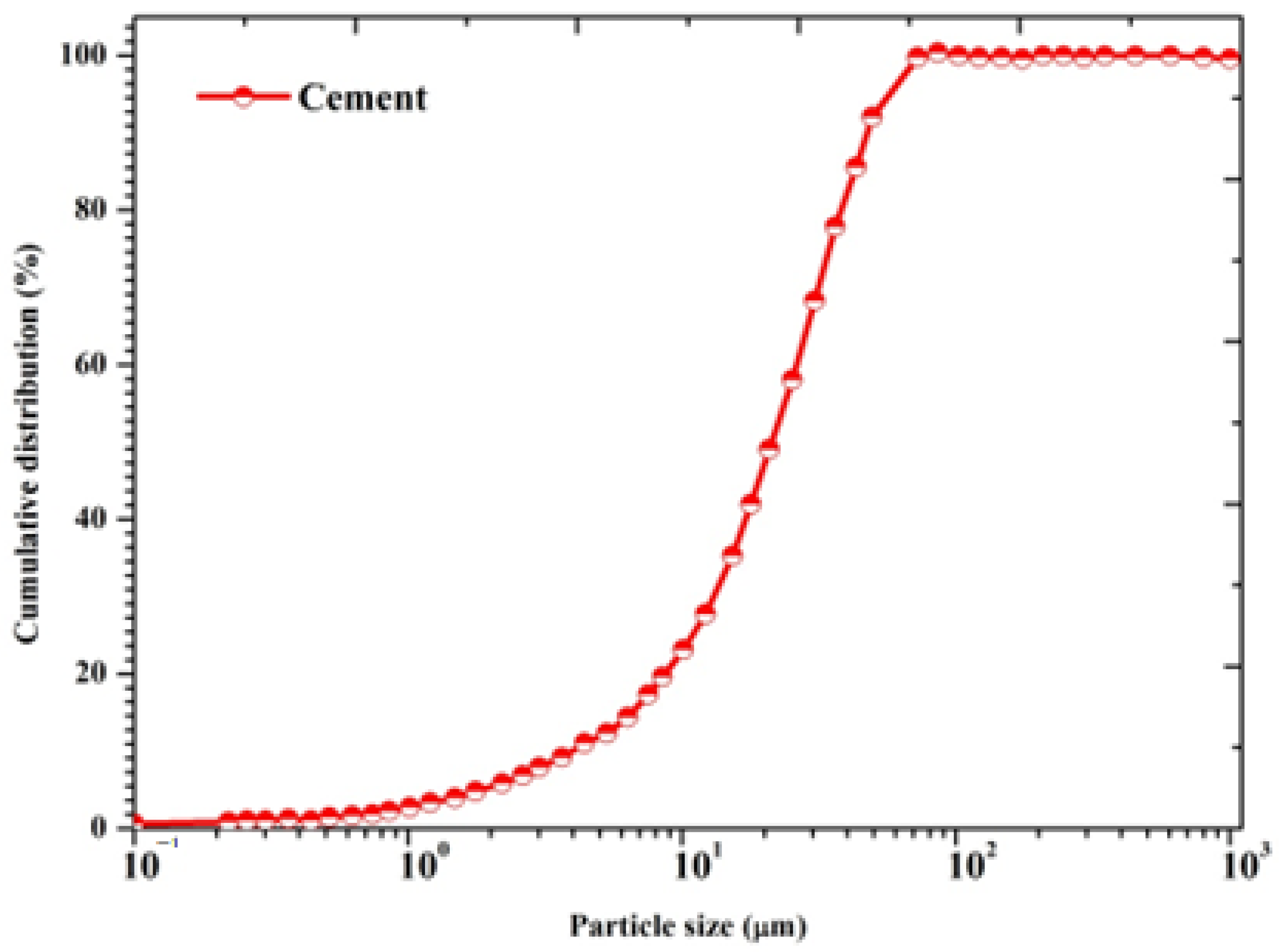

2.1. Materials and Mix Proportioning

2.2. Experimental Methodology

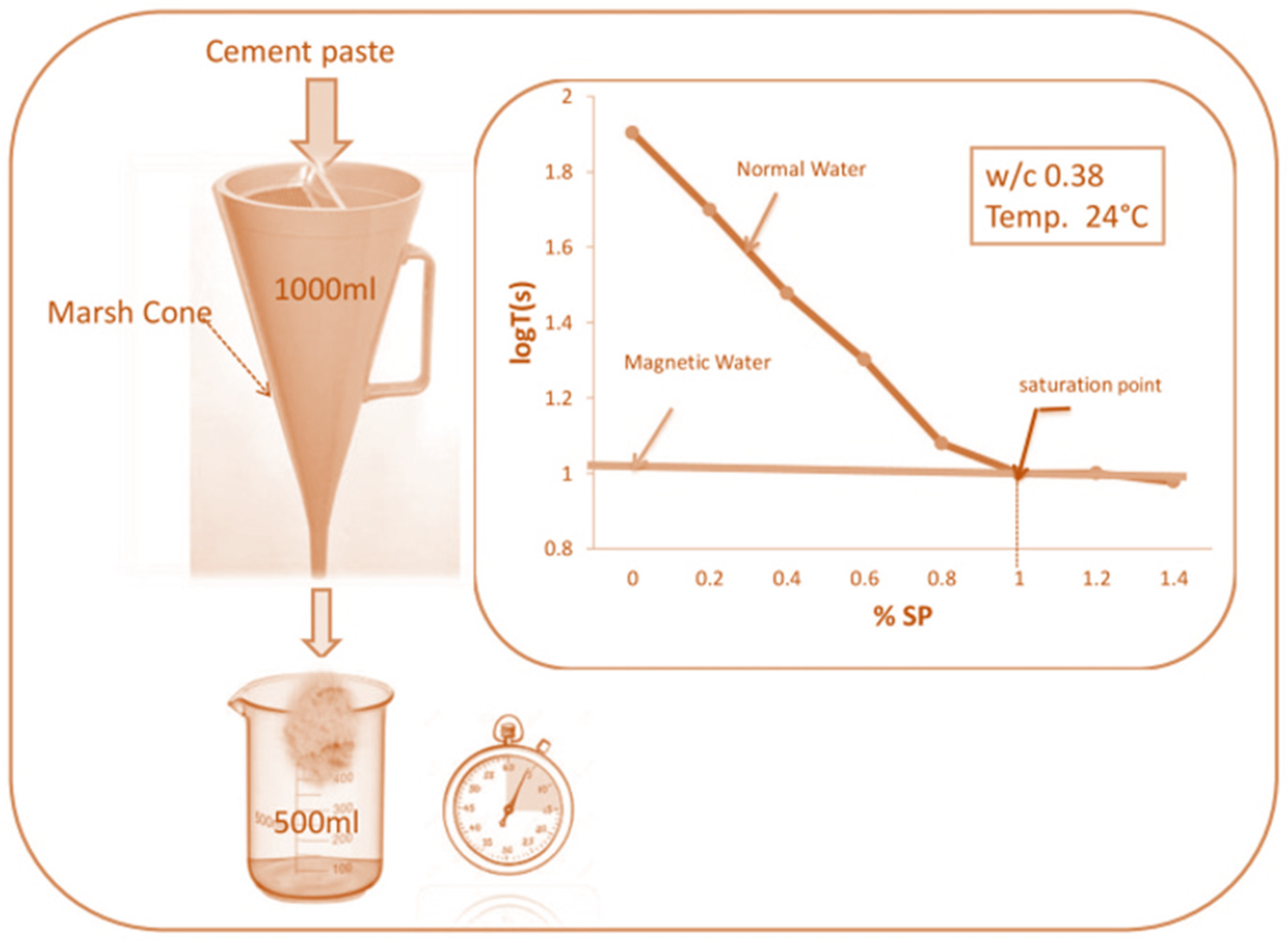

2.3. Marsh Cone Test

2.4. Fresh Concrete Properties

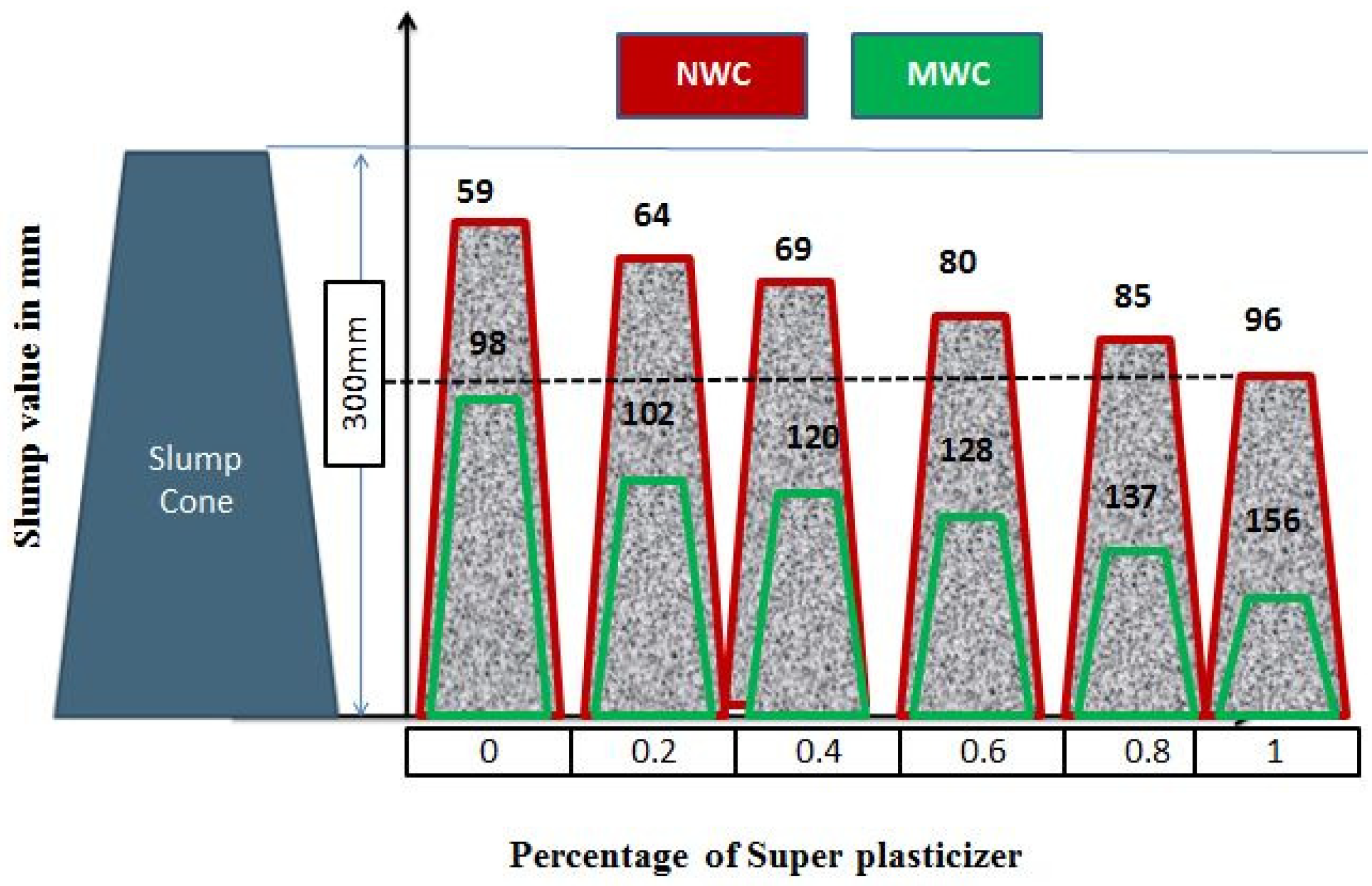

2.4.1. Slump Test

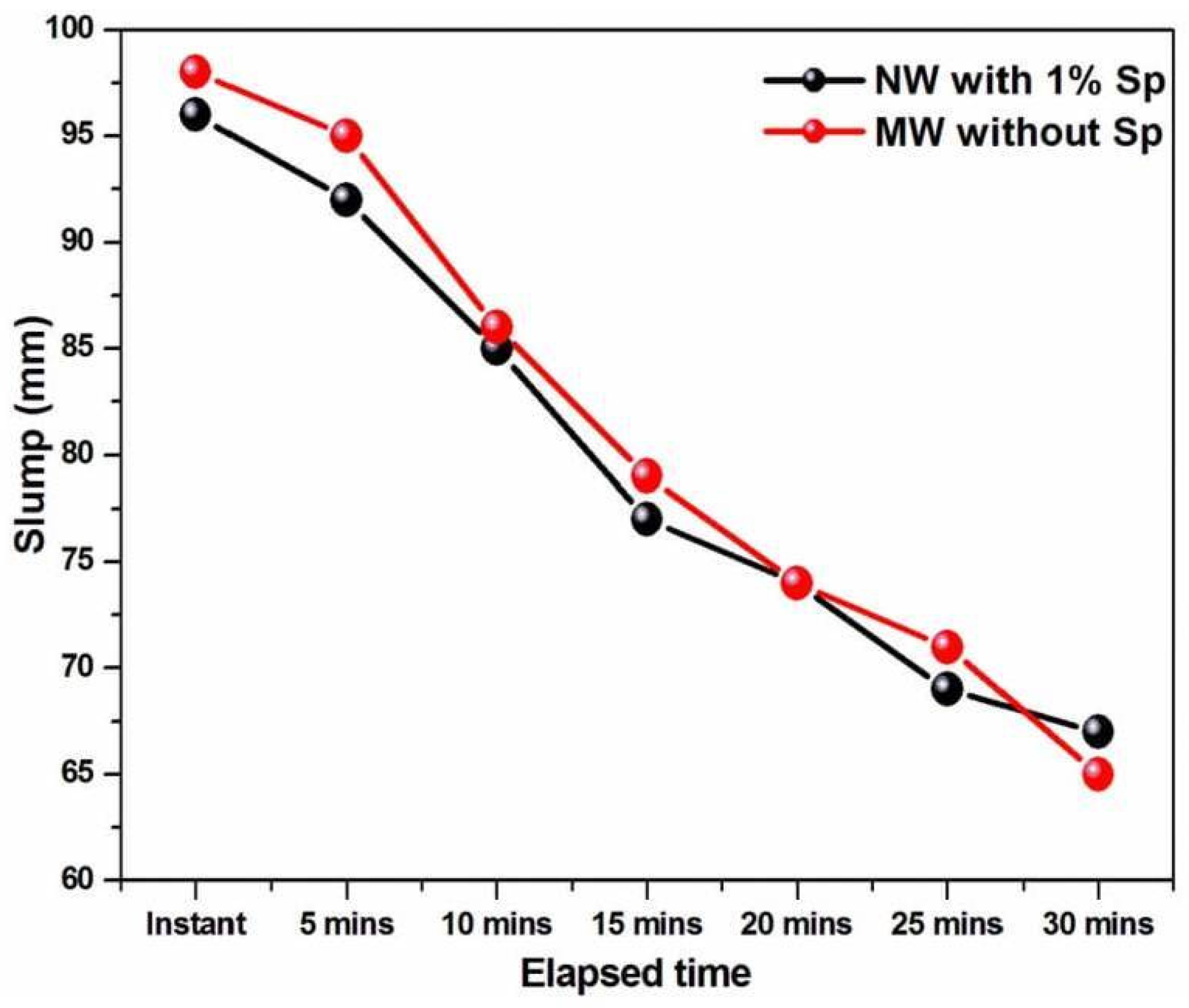

2.4.2. Slump Loss

2.4.3. Compaction Factor Test

2.4.4. Vee Bee Test

2.5. Hardened Concrete Properties

2.5.1. Compressive Strength Test

2.5.2. Split Tensile Test

2.6. Micro Structural Studies

3. Discussion of Results

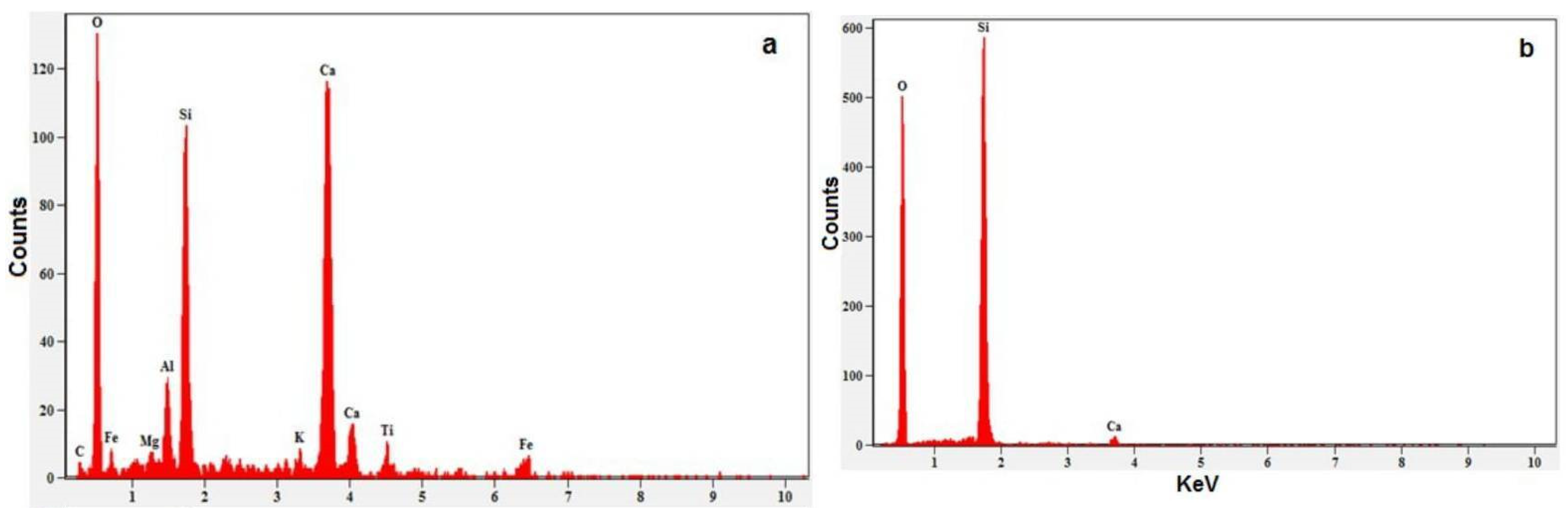

3.1. Characterization of Granite Powder

3.2. Marsh Cone Test

3.3. Fresh Concrete Properties

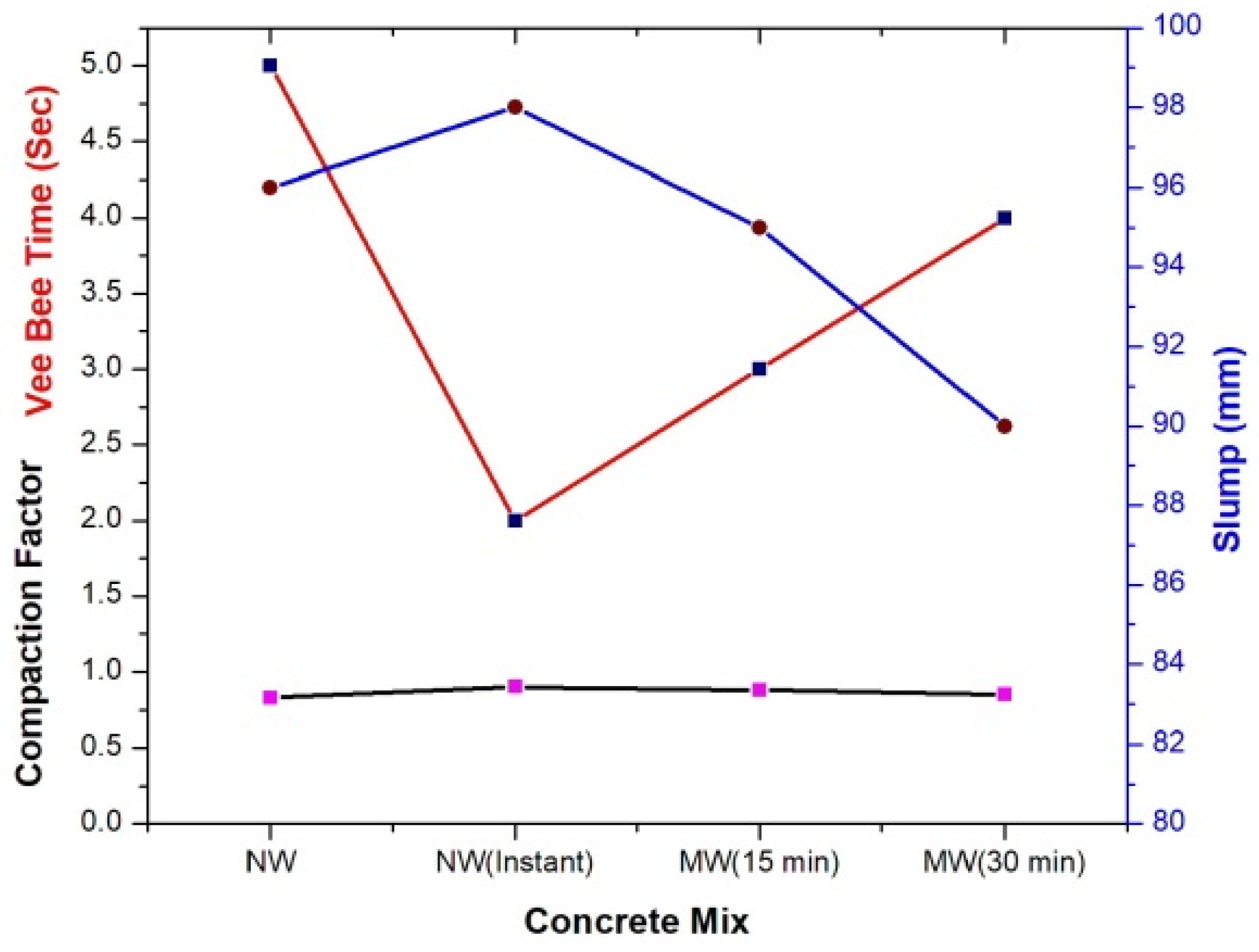

3.3.1. Slump Test

3.3.2. Effect of Resting Time on Slump Loss

3.3.3. Effect of Magnetic Water Storage Period on Its Fresh Concrete Property

3.3.3.1. Slump Cone Test

3.3.3.2. Compaction Factor Test

3.3.3.3. Vee-Bee Test

3.4. Hardened Concrete Properties

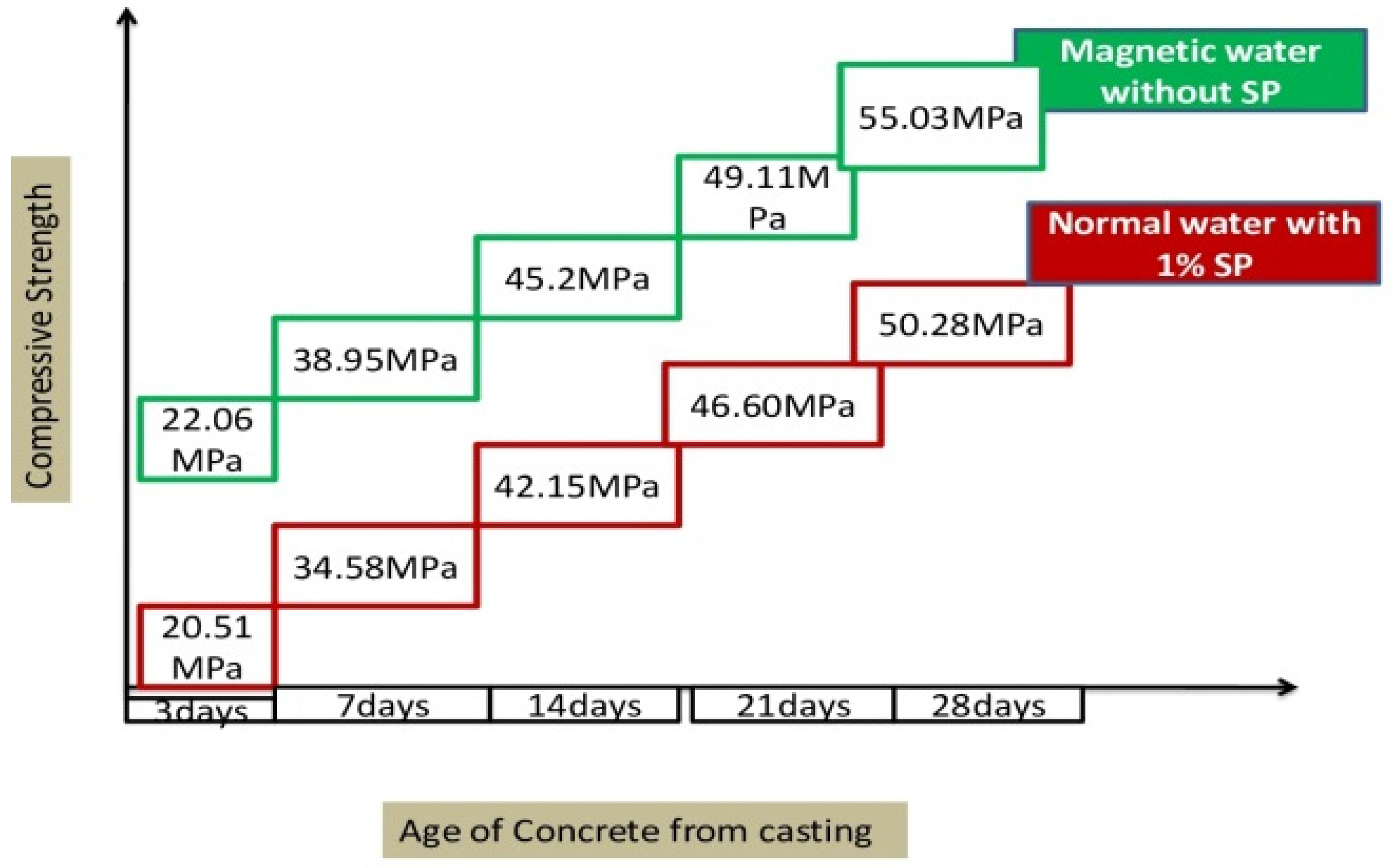

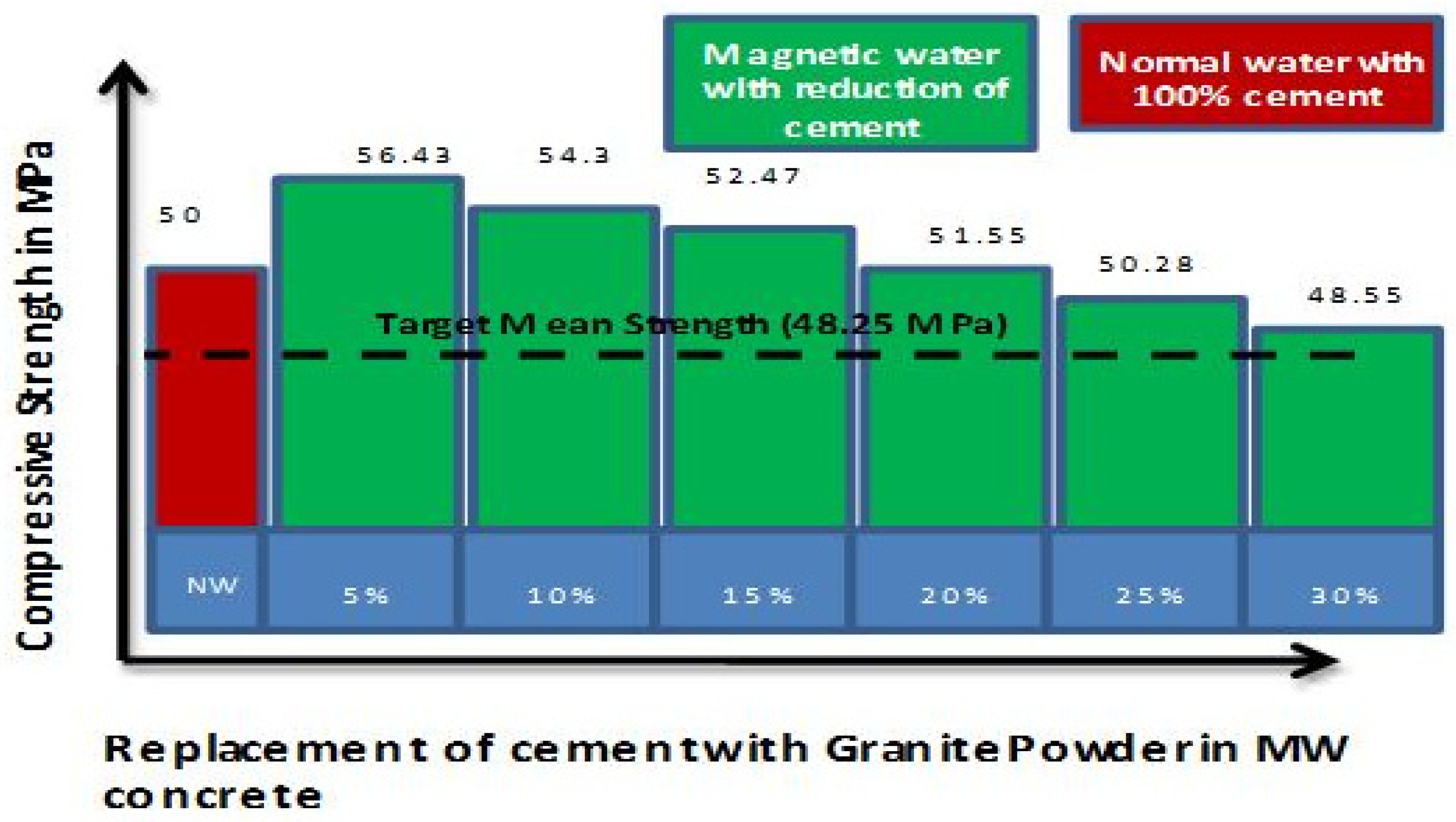

3.4.1. Compressive Strength Test

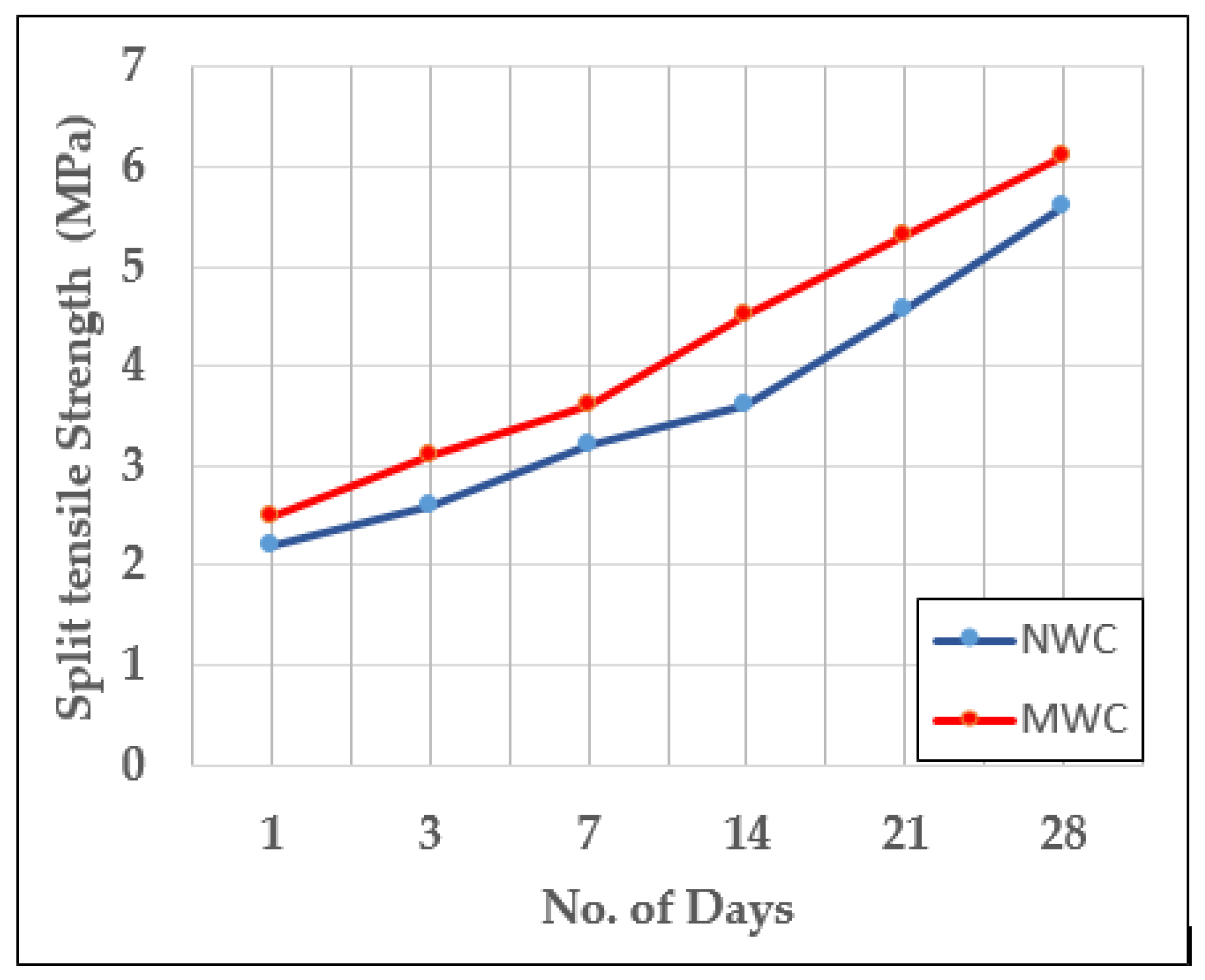

3.4.2. Split Tensile Test

3.5. Micro Structural Studies

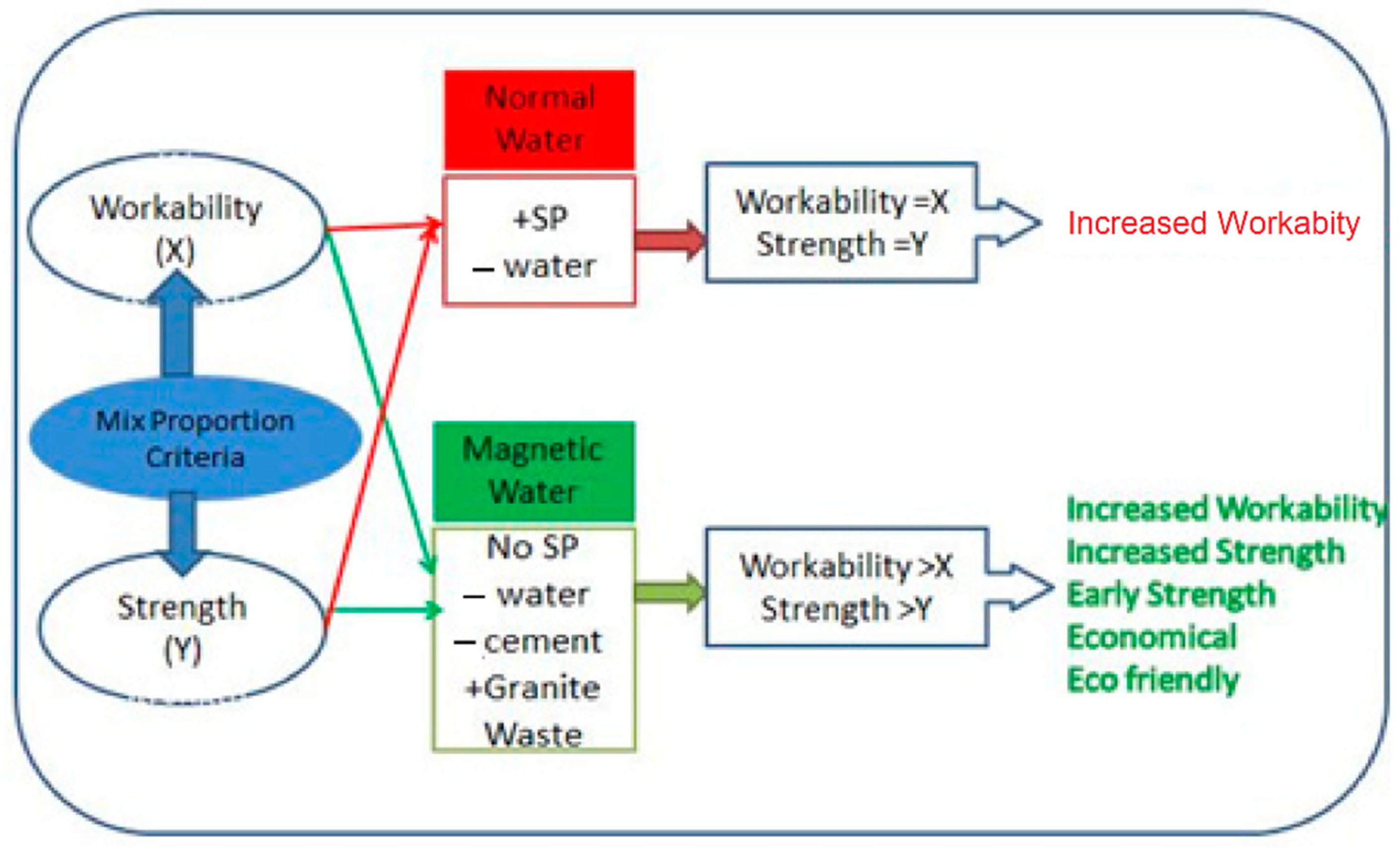

4. Mechanism

5. Conclusions

- Magnetized water acts as a water reducing agent. Hence it can be very well used in the preparation of concrete mix without the addition of super plasticizer (SP) to improve the workability of concrete mix.

- Increase in the exposure duration of water to magnetic field improves the workability of concrete mix as compared to the workability of NWC mix with 1% SP.

- The slump value of concrete mix prepared with magnetized water obtained from instant exposure to a magnetic field and without the addition of super plasticizer is 96 mm whereas the slump value of normal water concrete mix with 1% SP is 98 mm. This proves that magnetized water in concrete mix without the addition of SP helps to realise a slump value more or less equal to that of normal concrete mix with 1% SP.

- The slump value of the MWC with 1% SP is 37% greater than that of the NWC with 1% SP.

- Utilizing the MW within 20 min after magnetization can be recommended to achieve the desired workability without SP.

- The improvement in compressive strength and split tensile strength of magnetized water concrete specimens amounts to 12% and 8.9%, respectively, as compared to that of NWC with 1% SP specimens.

- Microstructure development shows that the amount of CSH is larger and its morphology becomes denser and less porous with MWC mix.

- When concrete consisting of MW without SP and 30% of cement volume is replaced using granite powder waste, this improves the strength properties of M40 grade concrete.

- The proposed approach helps improve water quality in the concrete industry due to the water magnetization, which directly enhances the quality and life span of the structures. Moreover, the proposed technology can be used to achieve a sustainable and eco-friendly building structure.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fu, W.; Wang, Z.B. The New Technology of Concrete Engineering; The Publishing House of Chinese Architectural Industry: Beijing, China, 1994; pp. 56–59. [Google Scholar]

- Wang, G.; Wu, Z. Magneto chemistry and Magneto medicine. Publ. House Ordnance Ind. 1999, 10, 82–90. [Google Scholar]

- Yuanbao, Z.; Liushui, Y.; Zhixiang, C.; Lingfei, W.; Zongzhang, C. Physical and chemical properties of magnetized water. J. Hunan Univ. 1990, 26, 290. [Google Scholar]

- Eshaghi, Z.; Gholizadeh, M. The effect of magnetic field on the stability of (18-crown-6) complexes with potassium ion. Talanta 2004, 64, 558–561. [Google Scholar] [CrossRef] [PubMed]

- Su, N.; Wu, Y.H.; Mar, C.Y. Effect of magnetic water on the engineering properties of concrete containing granulated blast-furnace slag. Cem. Concr. Res. 2000, 30, 599–605. [Google Scholar] [CrossRef]

- Su, N.; Wu, C.F. Effect of magnetic field treated water on mortar and concrete containing fly ash. Cem. Concr. Compos. 2003, 25, 681–688. [Google Scholar] [CrossRef]

- Loraine, A.; Huchler, P.E. Non-chemical water treatment systems: Histories, principles and literature review. Pap. Technol. (1989) 2006, 47, 23–34. [Google Scholar]

- Xiao-Feng, P.; Xing-Chun, Z. The Magnetization of Water Arising from a Magnetic-Field and Its Applications in Concrete Industry. Int. J. Eng. Res. Appl. 2013, 3, 1541–1552. [Google Scholar]

- Ubale, P.; Rahul Pandit, A.D.; Wadekar, A.P. Performance Evaluation of Magnetic Field Treated Water on Convectional Concrete Containing Fly Ash. Int. J. Sci. Technol. Manag. 2016, 5, 68–77. [Google Scholar]

- Al-Maliki, A.A.K.; Aswed, K.K.; Abraheem, A.K. Properties of concrete with magnetic mixing water. AIP Conf. Proc. 2020, 2213, 020146. [Google Scholar] [CrossRef]

- Ramezanianpour, A.A.; Sivasundaram, V.; Malhotra, V.M. Superplasticizers: Their effect on the strength properties of concrete. Concr. Int. 1995, 17, 30–35. [Google Scholar]

- Chan, N.; Young-Rojanschi, C.; Li, S. Effect of water-to-cement ratio and curing method on the strength, shrinkage and slump of the biosand filter concrete body. Water Sci. Technol. 2018, 77, 1744–1750. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, S. Effect of Magnetic Water on Engineering Properties of Concrete. Al-Rafidain Eng. J. (AREJ) 2009, 17, 71–82. [Google Scholar] [CrossRef]

- Banejad, H.; Abdosalehi, E. The Effect of Magnetic Field on Water Hardness Reducing. In Proceedings of the Thirteenth International Water Technology Conference, IWTC, Hurghada, Egypt, 12–15 March 2009; Volume 13, pp. 117–128. [Google Scholar]

- Abdel-Magid, T.I.M.; Hamdan, R.M.; Abdelgader, A.A.B.; Omer, M.E.A.; Ahmed, N.M.R.A. Effect of Magnetized Water on Workability and Compressive Strength of Concrete. Procedia Eng. 2017, 193, 494–500. [Google Scholar] [CrossRef]

- Jain, A.; Laad, A.; Singh, K.; Murari, K.; Student, U.G. Effect of Magnetic Water on Properties of Concrete. Int. J. Eng. Sci. Comput. 2017, 7, 11864–11866. [Google Scholar]

- Wei, H.; Wang, Y.; Luo, J. Influence of magnetic water on early-age shrinkage cracking of concrete. Constr. Build. Mater. 2017, 147, 91–100. [Google Scholar] [CrossRef]

- Esfahani, A.R.; Reisi, M.; Mohr, B. Magnetized Water Effect on Compressive Strength and Dosage of Superplasticizers and Water in Self-Compacting Concrete. J. Mater. Civ. Eng. 2018, 30, 04018008. [Google Scholar] [CrossRef]

- Sabapathy, Y.; Sooraj, K.; Krishna, K.S.L.; Nithish, V.; Varadan, S.V. A study on influence of magnetic water on the strength characteristics of concrete. Res. J. Pharm. Biol. Chem. Sci. 2019, 10, 247–253. [Google Scholar]

- Albahrani, H.S. Improvement of mechanical properties of concrete using magnetic water with different ages of magnetism. J. Eng. Appl. Sci. 2018, 13, 10384–10387. [Google Scholar] [CrossRef]

- Ahmed, S.M.; Manar, D.F. Effect of static magnetic field treatment on fresh concrete and water reduction potential. Case Stud. Constr. Mater. 2021, 14, e00535. [Google Scholar] [CrossRef]

- Hajforoush, M.; Kheyroddin, A.; Rezaifar, O. Investigation of engineering properties of steel fiber reinforced concrete exposed to homogeneous magnetic field. Constr. Build. Mater. 2020, 252, 119064. [Google Scholar] [CrossRef]

- Jouzdani, B.E.; Reisi, M. Effect of magnetized water characteristics on fresh and hardened properties of self-compacting concrete. Constr. Build. Mater. 2020, 242, 118196. [Google Scholar] [CrossRef]

- Vijayalakshmi, M.; Sekar, A.S.S. Strength and durability properties of concrete made with granite industry waste. Constr. Build. Mater. 2013, 46, 1–7. [Google Scholar] [CrossRef]

- Safiuddin, M.; Raman, S.N.; Zain, M.F.M. Flowing concretes with quarry waste fine aggregate. J. Civ. Eng. Res. Pract. 2007, 4, 17–25. [Google Scholar] [CrossRef]

- Torgal, F.P.; Castro-Gomes, J.P. Influence of physical and geometrical properties of granite and limestone aggregates on the durability of a C20/25 strength class concrete. Constr. Build. Mater. 2006, 20, 1079–1088. [Google Scholar] [CrossRef]

- IS: 12269-1987 (Reaffirmed 1999); Specification for 53 Grade Ordinary Portland Cement. Bureau of Indian Standards: New Delhi, India, 1999.

- Ahmed, A.; Mahmoud, A.A.; Elkatatny, S. The Use of the Granite Waste Material as an Alternative for Silica Flour in Oil-Well Cementing. ACS Omega 2020, 50, 32341–32348. [Google Scholar] [CrossRef] [PubMed]

- IS 383-1970; Specification for coarse and fine aggregates from natural sources for concrete. Bureau of Indian Standards: New Delhi, India, 1970.

- IS 10500-2012; Drinking Water- Specifications. Bureau of Indian Standards: New Delhi, India, 2012; pp. 1–12.

- IS 10262; Recommended Guidelines for Concrete Mix Design. Bureau of Indian Standards: New Delhi, India, 2009.

- IS 456-2000 (reaffirmed 2021); Plain and Reinforced Concrete–Code of Practice. Bureau of Indian Standards: New Delhi, India, 2021.

- ASTM D6910-19; Standard Test Method for Marsh Funnel Viscosity of Clay Construction Slurries. ASTM International: Conshohocken, PA, USA, 2019; pp. 1–4.

- IS 1199; Methods of sampling and analysis of concrete. Bureau of Indian Standards: New Delhi, India, 1959; pp. 1–49.

- Erdoǧdu, Ş. Effect of retempering with superplasticizer admixtures on slump loss and compressive strength of concrete subjected to prolonged mixing. Cem. Concr. Res. 2005, 35, 907–912. [Google Scholar] [CrossRef]

- IS 516-2014; IS: 516-1959 (Reaffirmed 2004); Method of Tests for Strength of Concrete. Bureau of Indian Standards: New Delhi, India, 2004.

- Soto-Bernal, J.J.; Gonzalez-Mota, R.; Rosales-Candelas, I.; Ortiz-Lozano, J.A. Effects of Static Magnetic Fields on the Physical, Mechanical, and Microstructural Properties of Cement Pastes. Adv. Mater. Sci. Eng. 2015, 2015, 934195. [Google Scholar] [CrossRef] [Green Version]

- Singh, S.; Nagar, R.; Agrawal, V. Performance of granite cutting waste concrete under adverse exposure conditions. J. Clean. Prod. 2016, 127, 172–182. [Google Scholar] [CrossRef]

- Lopes, M.M.S.; Alvarenga, R.D.C.S.S.; Pedroti, L.G.; Ribeiro, J.C.L.; de Carvalho, A.F.; Cardoso, F.D.P.; Mendes, B.C. Influence of the incorporation of granite waste on the hiding power and abrasion resistance of soil pigment-based paints. Constr. Build. Mater. 2019, 205, 463–474. [Google Scholar] [CrossRef]

- Song, H.; Zhao, S. Effect of admixtures treated by magnetic field on concrete. Adv. Mater. Res. 2011, 287–290, 934–938. [Google Scholar] [CrossRef]

- Reddy, S.K.; Ghorpade, V.G.; Rao, H.S. Effect of Magnetic Field Exposure Time on Workability and Compressive Strength of Magnetic Water Concrete. Int. J. Adv. Eng. Technol. 2013, 4, 120–122. [Google Scholar]

- Reddy Vempada, S.; Reddy, S.; Kumar, A.K.; Sumanth, A. Effect of Magnetic Field Treated Water on Fresh and Hardened Properties of Concrete. J. Civ. Eng. Environ. Technol. 2017, 4, 134–138. [Google Scholar]

- Afshin, H.; Gholizadeh, M.; Khorshidi, N. Improving Mechanical properties of high strength concrete by magnetic water technology. Sci. Iran. 2010, 17, 74–79. [Google Scholar]

- Reddy, B.S.K.; Ghorpade, V.G.; Rao, H.S. Influence of magnetic water on strength properties of concrete. Indian J. Sci. Technol. 2014, 7, 14–18. [Google Scholar] [CrossRef]

- Manjupriya, T.; Malathy, R. Experimental Investigation on Strength and Shrinkage Properties of Concrete Mixed with Magnetically Treated Water. Int. J. Eng. Adv. Res. Technol. 2016, 2, 46–50. [Google Scholar]

- Malathy, R.; Narayanan, K.; Masilamani, A.; Kathirvel, P.; Murali, G.; Vatin, N.I. Influence of Magnetic water on concrete properties with different magnetic field Exposure Times. Materials 2022, 15, 4291. [Google Scholar]

- Zhao, K.; Zhang, P.; Wang, B.; Tian, Y.; Xue, S.; Cong, Y. Preparation of electric- and magnetic-activated water and its influence on the workability and mechanical properties of cement mortar. Sustainability 2021, 13, 4546. [Google Scholar] [CrossRef]

- Bharath, S.; Subraja, S.; Kumar, P.A. Influence of magnetized water on concrete by replacing cement partially with copper slag. J. Chem. Pharm. Sci. 2016, 9, 2791–2795. [Google Scholar]

- Coey, J.M.D.; Cass, S. Magnetic Water Treatment. J. Magn. Magn. Mater. 2000, 209, 71–74. [Google Scholar] [CrossRef] [Green Version]

- Malathy, R.; Narayanan, K.; Mayakrishnan, P. Performance of prestressed concrete beams using magnetic water for concrete mixing. J. Adhes. Sci. Technol. 2022, 36, 666–684. [Google Scholar] [CrossRef]

| Physical Property | Test Value | Requirement as per IS: 12269-1987 [27] |

|---|---|---|

| Fineness | 236 m2/Kg | 225 m2/Kg |

| Setting time (Initial) | 32 min | 30 min (minimum) |

| Setting time (Final) | 337 min | 600 min (maximum) |

| Specific gravity | 3.15 | 3.2 |

| Standard consistency | 36% | 40% |

| Chemical Composition | Test Value (%) |

|---|---|

| 62.21 | |

| 23.72 | |

| 6.12 | |

| 3.27 | |

| 1.59 | |

| 0.12 | |

| 0.19 | |

| 0.98 | |

| 0.52 |

| Test | Coarse Aggregate | Fine Aggregate |

|---|---|---|

| Modules of fineness | 3.43 | 4.80 |

| Absorption (%) | 0.10 | 1.00 |

| Specific gravity | 2.90 | 2.69 |

| Parameter | Magnetization (mg/L) | ||

|---|---|---|---|

| Before | After | Allowable Limit | |

| pH | 8.1 | 8.5 | 6.5–8.5 |

| Total hardness | 600 | 380 | 600 |

| Sulphate | 134 | 115 | <200 |

| Chlorides | 1025 | 552 | 1000 |

| Total dissolved solids | 1900 | 1258 | 2000 |

| Iron | 0.1 | 0.1 | <1 |

| Mix | Cement (kg) | Granite Powder Waste (kg) | Potable Water (L) | Fine Aggregate (kg) | Coarse Aggregate (kg) | SP (%) |

|---|---|---|---|---|---|---|

| NW | 456.58 | - | 174 | 661.03 | 1235 | 0 |

| 456.58 | - | 174 | 661.03 | 1235 | 0.2 | |

| 456.58 | - | 174 | 661.03 | 1235 | 0.4 | |

| 456.58 | - | 174 | 661.03 | 1235 | 0.6 | |

| 456.58 | - | 174 | 661.03 | 1235 | 0.8 | |

| 456.58 | - | 174 | 661.03 | 1235 | 1 | |

| MW | 456.58 | - | 174 | 661.03 | 1235 | 0 |

| 456.58 | - | 174 | 661.03 | 1235 | 0.2 | |

| 456.58 | - | 174 | 661.03 | 1235 | 0.4 | |

| 456.58 | - | 174 | 661.03 | 1235 | 0.6 | |

| 456.58 | - | 174 | 661.03 | 1235 | 0.8 | |

| 456.58 | - | 174 | 661.03 | 1235 | 1 | |

| MW + Granite Waste | 456.58 | 174 | 661.03 | 1235 | 0 | |

| 433.76 | 22.82 | 174 | 661.03 | 1235 | ||

| 410.93 | 45.65 | 174 | 661.03 | 1235 | ||

| 388.1 | 68.48 | 174 | 661.03 | 1235 | ||

| 365.27 | 91.31 | 174 | 661.03 | 1235 | ||

| 342.44 | 114.14 | 174 | 661.03 | 1235 | ||

| 319.61 | 136.97 | 174 | 661.03 | 1235 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ramalingam, M.; Narayanan, K.; Sivamani, J.; Kathirvel, P.; Murali, G.; Vatin, N.I. Experimental Investigation on the Potential Use of Magnetic Water as a Water Reducing Agent in High Strength Concrete. Materials 2022, 15, 5219. https://doi.org/10.3390/ma15155219

Ramalingam M, Narayanan K, Sivamani J, Kathirvel P, Murali G, Vatin NI. Experimental Investigation on the Potential Use of Magnetic Water as a Water Reducing Agent in High Strength Concrete. Materials. 2022; 15(15):5219. https://doi.org/10.3390/ma15155219

Chicago/Turabian StyleRamalingam, Malathy, Karuppasamy Narayanan, Jagan Sivamani, Parthiban Kathirvel, Gunasekaran Murali, and Nikolai Ivanovich Vatin. 2022. "Experimental Investigation on the Potential Use of Magnetic Water as a Water Reducing Agent in High Strength Concrete" Materials 15, no. 15: 5219. https://doi.org/10.3390/ma15155219

APA StyleRamalingam, M., Narayanan, K., Sivamani, J., Kathirvel, P., Murali, G., & Vatin, N. I. (2022). Experimental Investigation on the Potential Use of Magnetic Water as a Water Reducing Agent in High Strength Concrete. Materials, 15(15), 5219. https://doi.org/10.3390/ma15155219