The Effect of Yttria Content on Microstructure, Strength, and Fracture Behavior of Yttria-Stabilized Zirconia

Abstract

:1. Introduction

2. Materials and Methods

3. Results

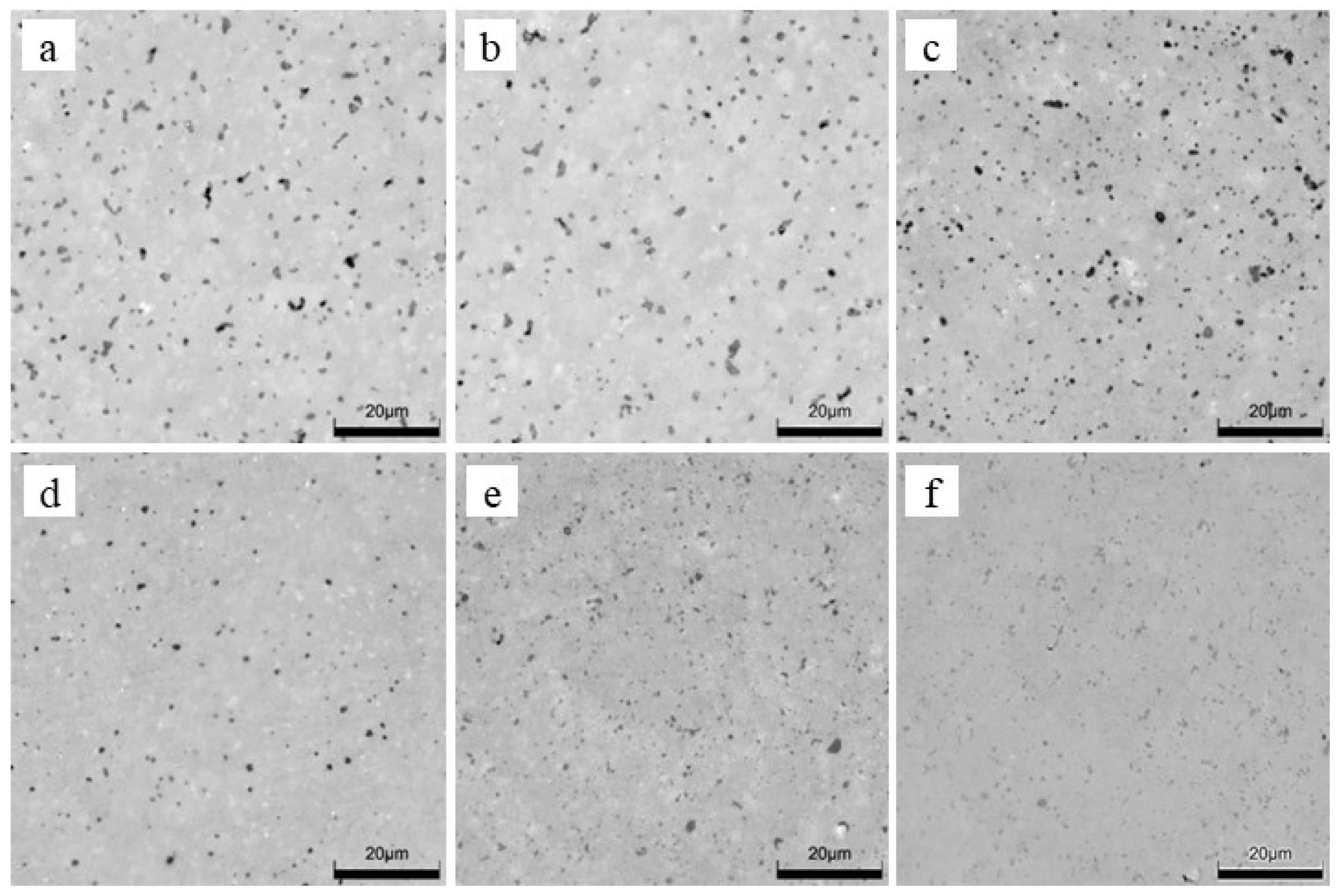

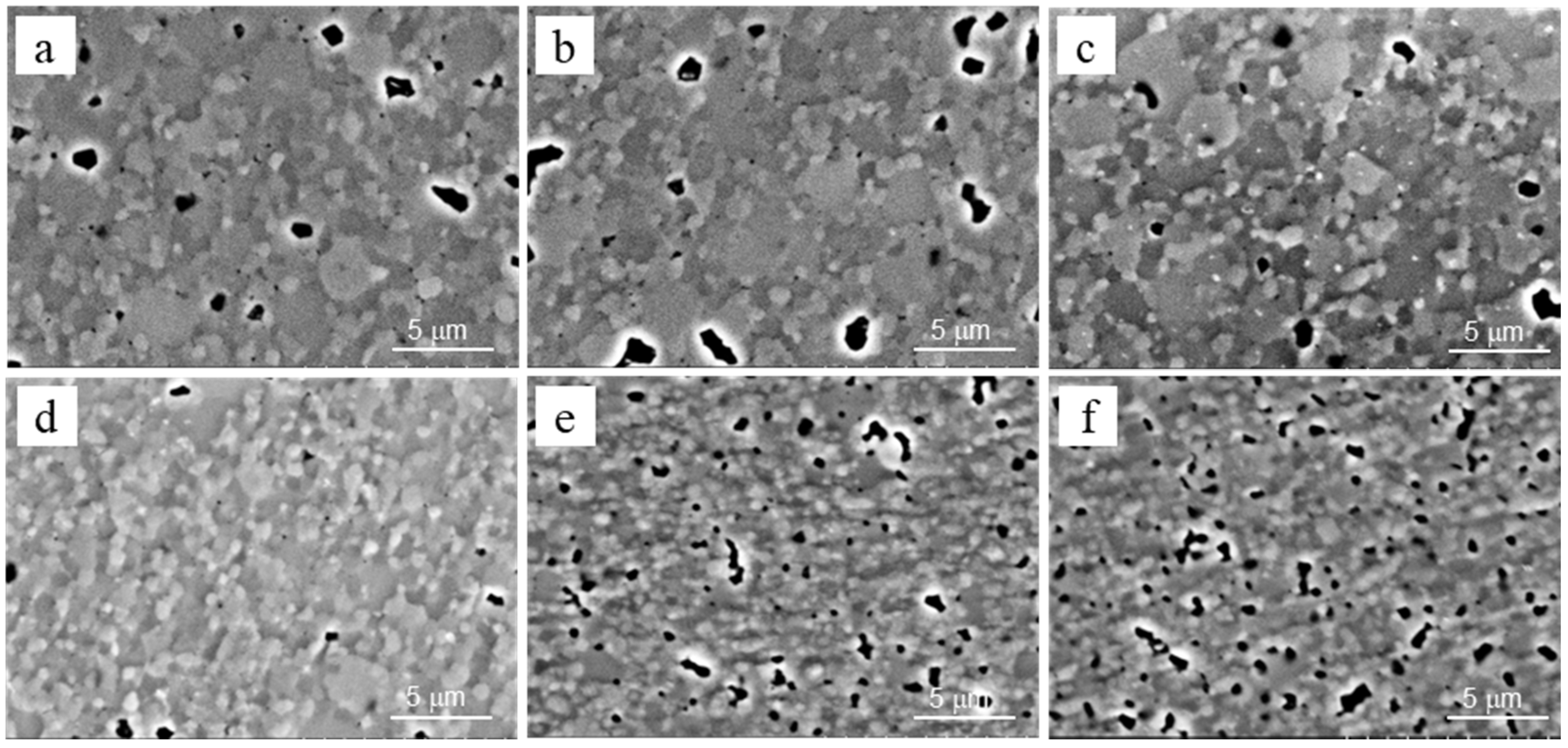

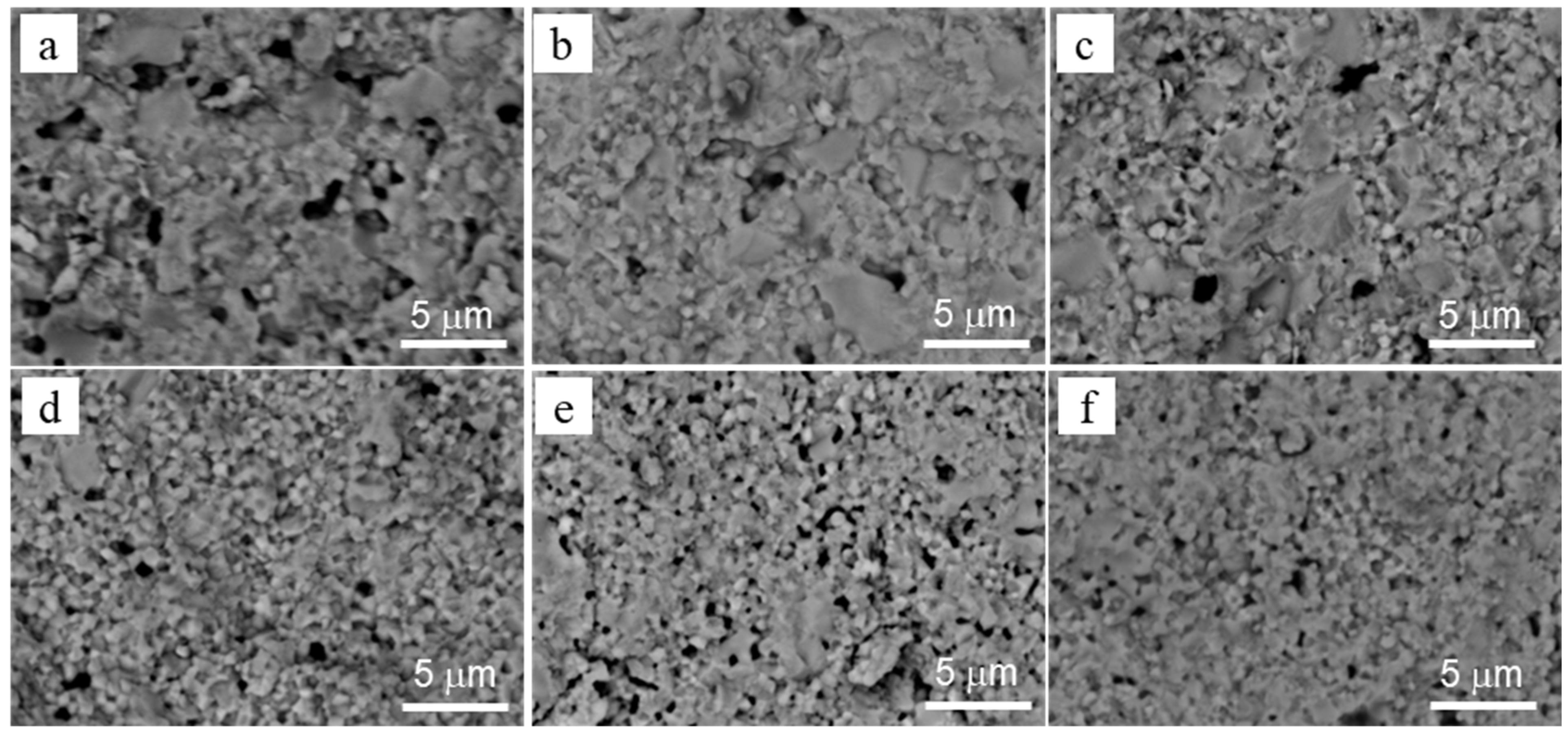

3.1. Grain Structure

- The grain structure became more homogeneous (notice the bimodality of grain size distributions for 3–5% Y2O3 and its disappearance for 6–8% Y2O3);

- The average size of the pores decreased by more than 2 times (Table 1).

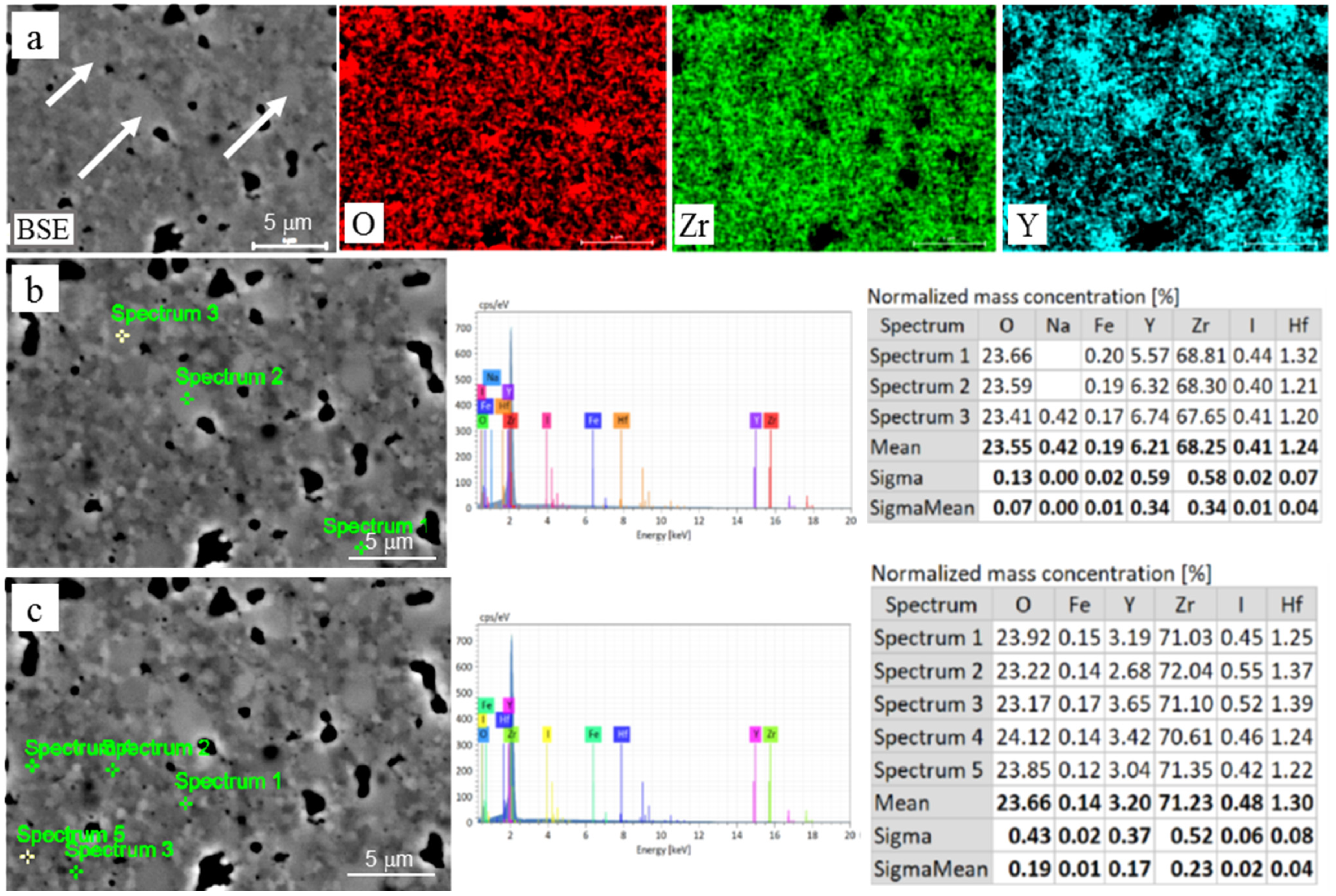

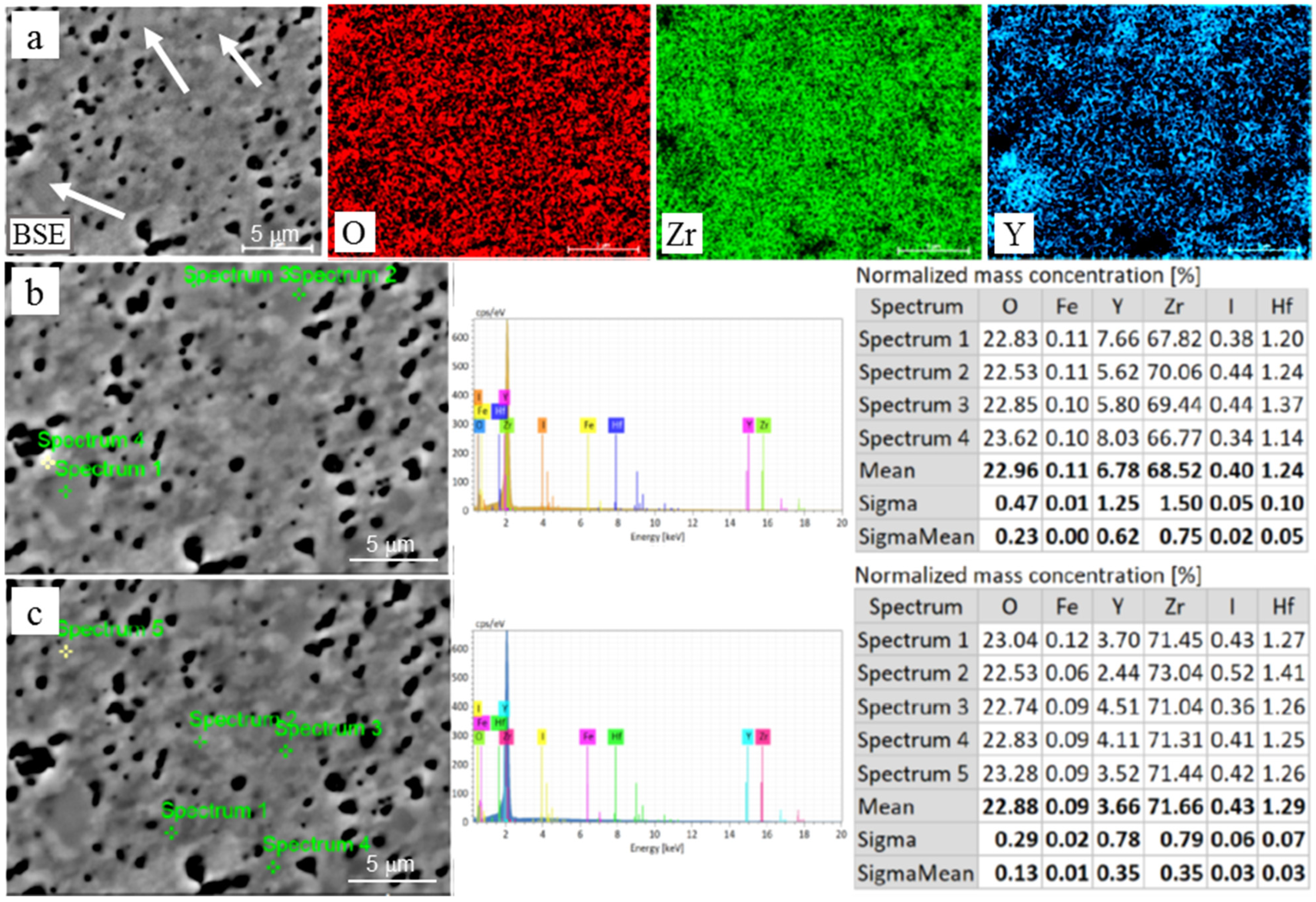

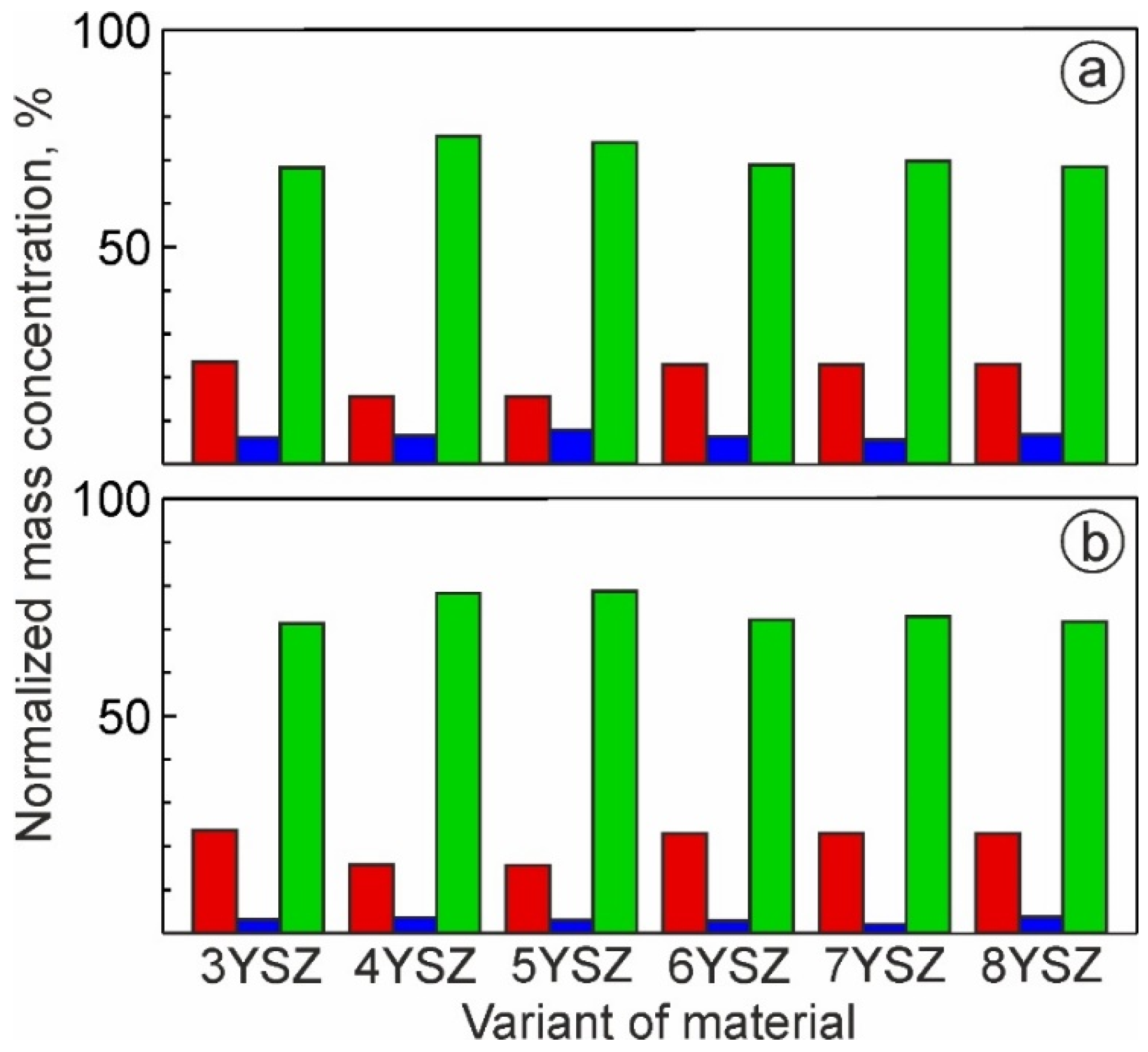

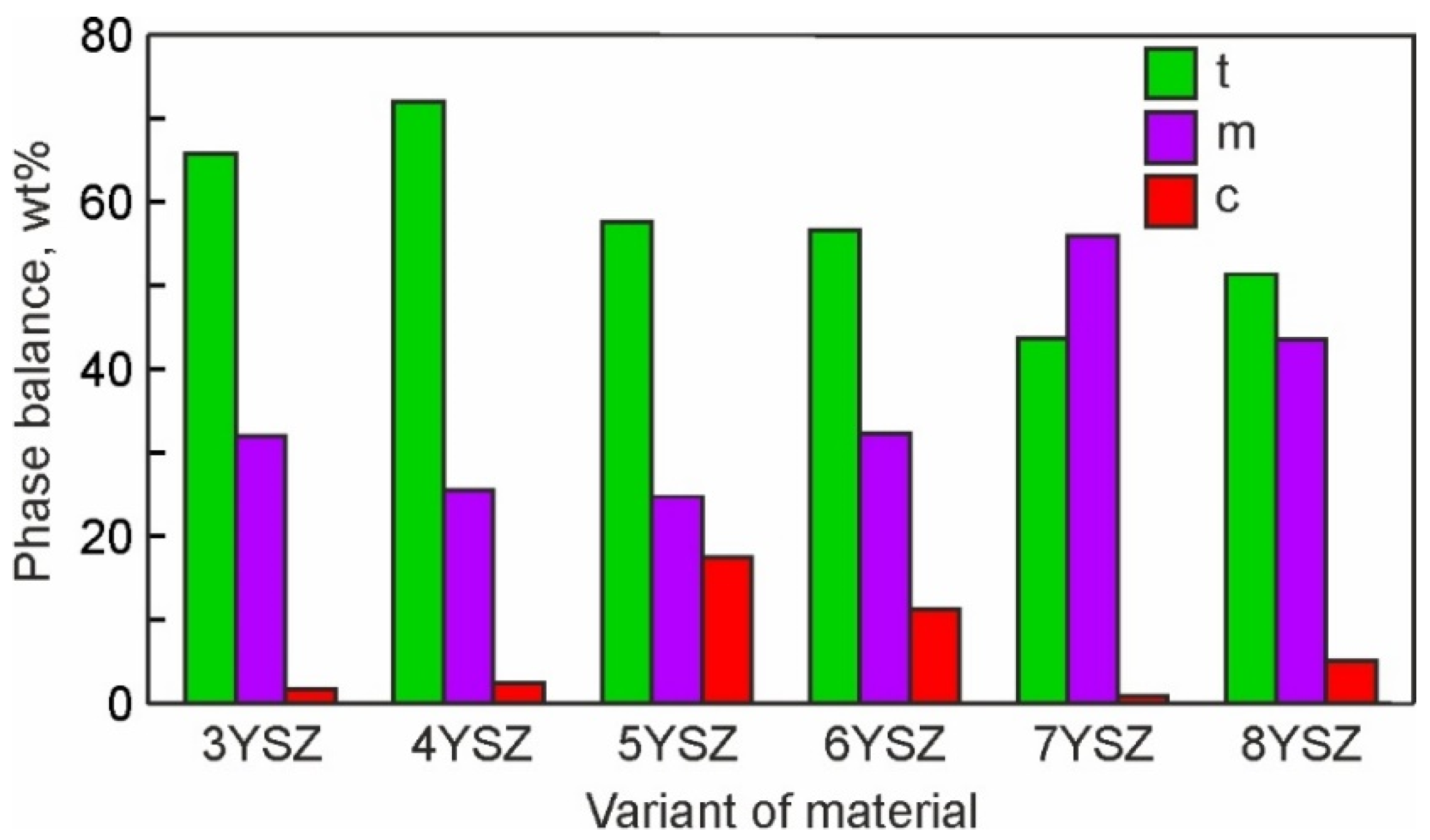

3.2. Chemical Analysis and Phase Balance

3.3. Strength and Fracture Analysis

- -

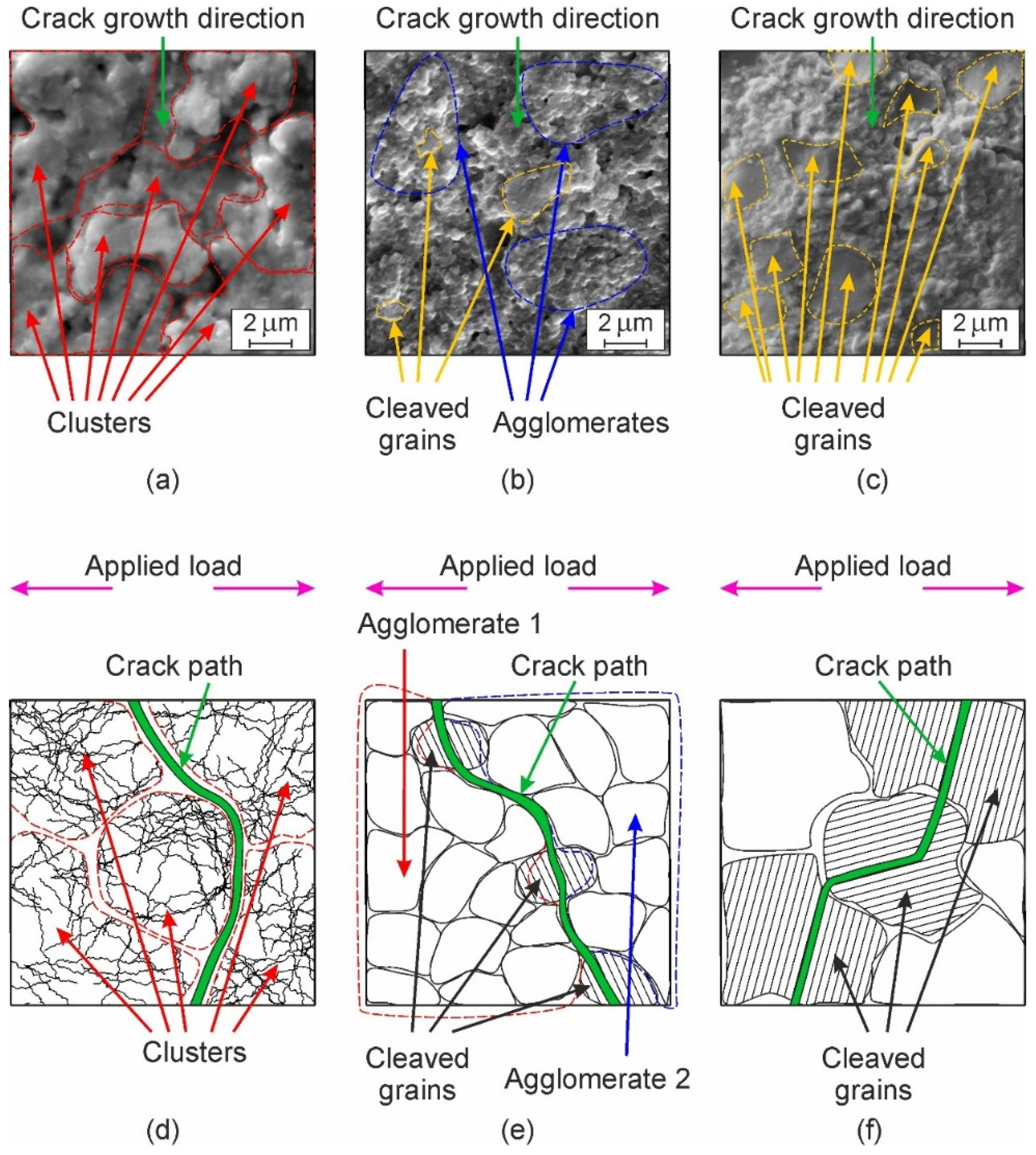

- The average size of fracture voids decreased by 2 times (Table 1), the standard deviation of size decreased by 3.5 times, and the number density of voids increased by 3.8 times—all of these mean that the fracture became more homogeneous with an increase in the Y2O3 content;

- -

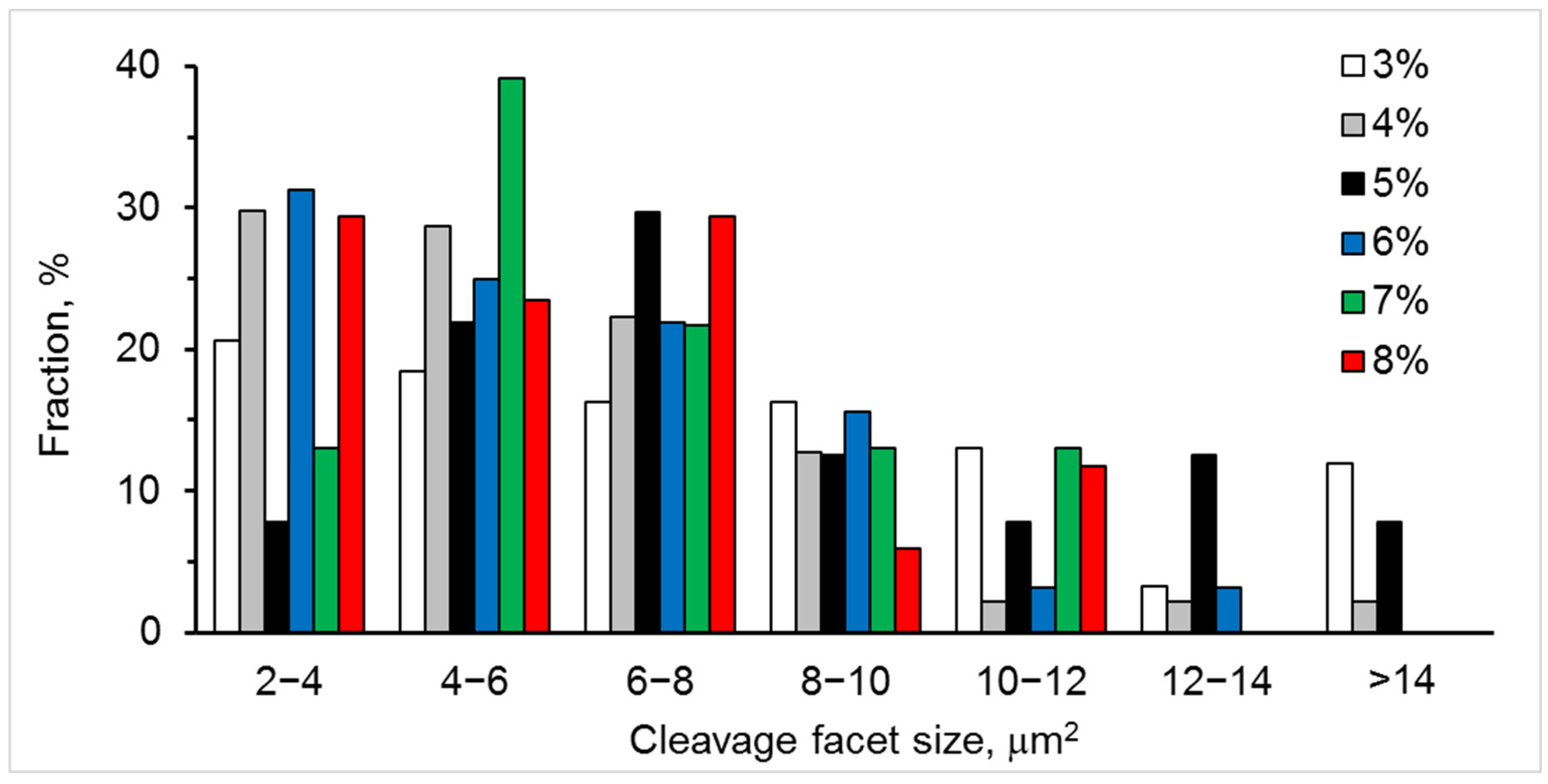

- The average size of cleavage facets (associated with a transgranular fracture) decreased by 30%, the number density of cleavage facets decreased by 5.4 times, and the transgranular fracture area decreased by 6.8 times—all of these indicated that the microstructure became finer, and cohesion between grains increased sufficiently to stimulate the fracture propagation along the boundaries of fine-grained agglomerates, except for occasional transgranular fracture through the larger grains with an increased Y content.

- ▪

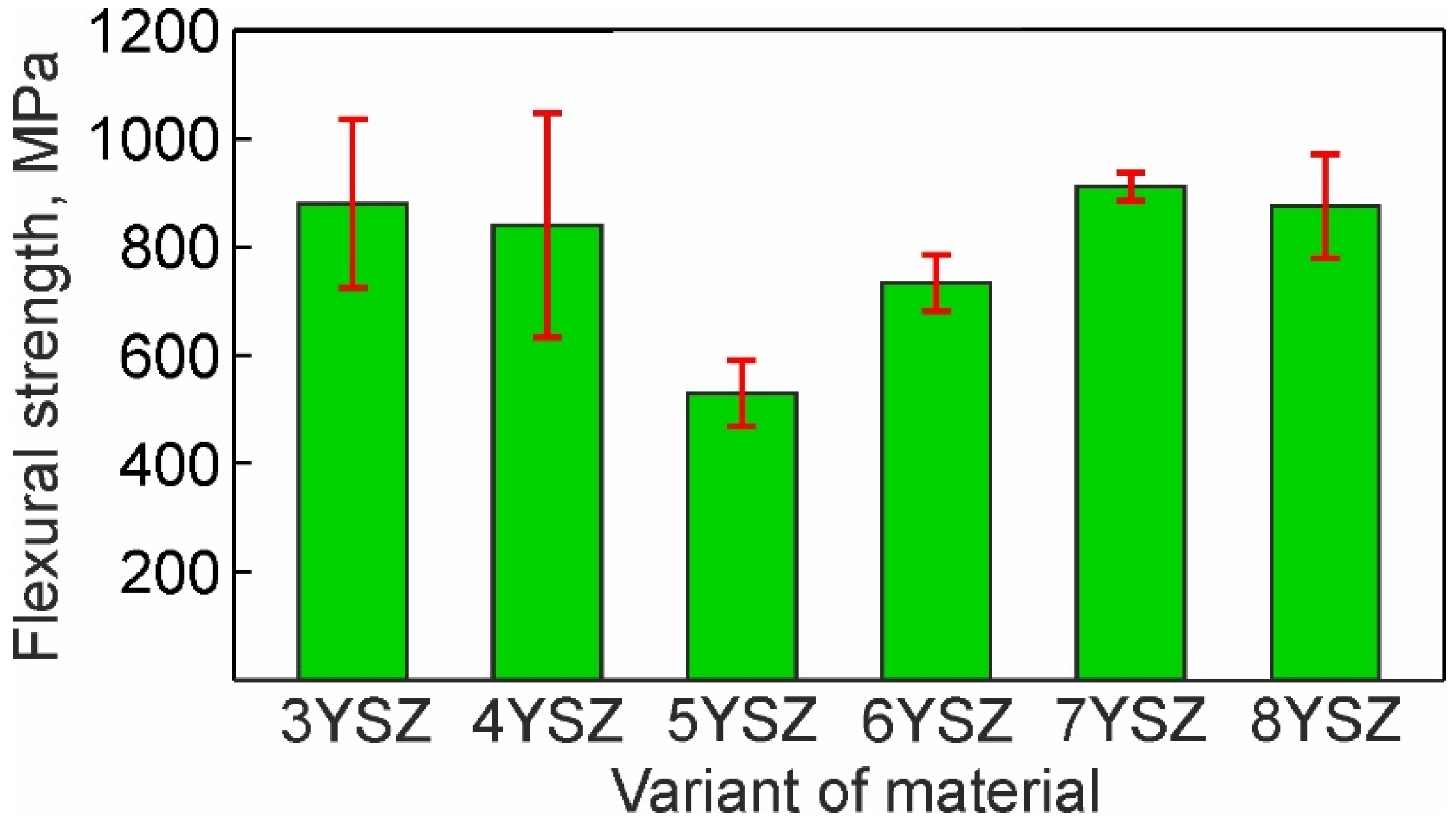

- The flexural strength dependence on yttria content (Figure 12) directly follows the variation in fraction of the monoclinic phase m-ZrO2 and inversely follows this of the cubic-phase c-ZrO2 (Figure 8). With the yttria percentage increasing from 3 to 5%, the strength decreases following a decrease in the fraction of m-ZrO2 and an increase in the fraction of c-ZrO2. The peak flexural strength for 7YSZ ceramics corresponds to the maximum of m-ZrO2 fraction and minima of c-ZrO2 and t-ZrO2 fractions;

- ▪

- ▪

- A maximal fraction of cleavage facets in the 6–8 µm2 size range observed in 5YSZ corresponds to the maximum of the partially stabilized c-ZrO2 phase fraction and the minimum of the m-ZrO2 phase fraction; this material has the lowest strength among the studied ceramics;

- ▪

- The maximal fraction of small 4–8 µm2 cleavage facets in 7YSZ and this of 2–8 µm2 facets in 8YSZ (Figure 11) correspond to the peaks of minimal grain size in the 0.3–0.9 µm size range (Figure 4) and the maximum fraction of m-ZrO2 phase (Figure 8); 7YSZ showed the highest strength among the studied ones due to the high cohesion between fine grains of both the t-ZrO2 and m-ZrO2 phases.

3.4. Fracture Micromechanisms

4. Conclusions

- With an increase in Y2O3 content, the average sizes of grains, pores, fracture voids, and cleavage facets all decreased. In addition, the size distributions of all the studied microstructural features became narrower. This indicates the formation of a more homogenous microstructure with an increase in Y2O3 content.

- The minimum flexural strength observed for 5YSZ ceramic is associated with the maximum fraction of the cubic ZrO2 phase.

- The highest level of flexural strength was shown for a fine-grained microstructure in the 7YSZ ceramic containing mainly the monoclinic and tetragonal ZrO2 phases.

- Fracture studies suggested the most favorable for practical applications fracture micromechanism operating in fine-grained microstructures with high fraction of the monoclinic ZrO2 phase. In this case, the crack propagates along the boundaries of fine grains and their agglomerates, although occasionally cleavage takes place through larger grains, which may be enriched with Y and exhibit a partially stabilized tetragonal or cubic crystal structure.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chevalier, J. What future for zirconia as a biomaterial? Biomaterials 2006, 27, 535–543. [Google Scholar] [CrossRef]

- Kim, M.-J.; Ahn, J.-S.; Kim, J.-H.; Kim, H.-Y.; Kim, W.-C. Effects of the sintering conditions of dental zirconia ceramics on the grain size and translucency. J. Adv. Prosthodont. 2013, 5, 161–166. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gautam, C.; Joyner, J.; Gautam, A.; Rao, J.; Vajtai, R. Zirconia based dental ceramics: Structure, mechanical properties, biocompatibility and applications. Dalton Trans. 2016, 45, 19194–19215. [Google Scholar] [CrossRef]

- Vasyliv, B.; Milewski, J.; Podhurska, V.; Wejrzanowski, T.; Kulyk, V.; Skibiński, J.; Vira, V.; Szabłowski, Ł.; Szczęśniak, A.; Dybiński, O. Study of the degradation of a fine-grained YSZ–NiO anode material during reduction in hydrogen and reoxidation in air. Appl. Nanosci. 2022, 12, 965–975. [Google Scholar] [CrossRef]

- Vasyliv, B.; Kulyk, V.; Duriagina, Z.; Mierzwinski, D.; Kovbasiuk, T.; Tepla, T. Estimation of the effect of redox treatment on microstructure and tendency to brittle fracture of anode materials of YSZ–NiO(Ni) system. East. Eur. J. Enterp. Technol. 2020, 6, 61–71. [Google Scholar] [CrossRef]

- Santos, A.J.; Garcia-Segura, S.; Dosta, S.; Cano, I.G.; Martínez-Huitle, C.A.; Brillas, E. A ceramic electrode of ZrO2-Y2O3 for the generation of oxidant species in anodic oxidation. Assessment of the treatment of Acid Blue 29 dye in sulfate and chloride media. Sep. Purif. Technol. 2019, 228, 115747. [Google Scholar] [CrossRef]

- Yan, Y.; Maa, Z.; Sun, J.; Bu, M.; Huo, Y.; Wang, Z.; Li, Y.; Hu, N. Surface microstructure-controlled ZrO2 for highly sensitive room-temperature NO2 sensors. Nano Mater. Sci. 2021, 3, 268–275. [Google Scholar] [CrossRef]

- Jiang, S.; Huang, X.; He, Z.; Buyers, A. Phase transformation and lattice parameter changes of non-trivalent rare earth-doped YSZ as a function of temperature. J. Mater. Eng. Perform. 2018, 27, 2263–2270. [Google Scholar] [CrossRef]

- Schaedler, T.A.; Leckie, R.M.; Kramer, S.; Evans, A.G.; Levi, C.G. Toughening of nontransformable t’-YSZ by addition of titania. J. Am. Ceram. Soc. 2007, 90, 3896–3901. [Google Scholar] [CrossRef]

- Zhao, M.; Pan, W.; Wan, C.; Qu, Z.; Li, Z.; Yang, J. Defect engineering in development of low thermal conductivity materials: A review. J. Eur. Ceram. Soc. 2016, 37, 1–13. [Google Scholar] [CrossRef]

- Duriagina, Z.; Kulyk, V.; Kovbasiuk, T.; Vasyliv, B.; Kostryzhev, A. Synthesis of functional surface layers on stainless steels by laser alloying. Metals 2021, 11, 434. [Google Scholar] [CrossRef]

- Hannink, R.H.J.; Kelly, P.M.; Muddle, B.C. Transformation toughening in zirconia-containing ceramics. J. Am. Ceram. Soc. 2000, 83, 461–487. [Google Scholar] [CrossRef]

- Piconi, C.; Maccauro, G. Zirconia as a ceramic biomaterial. Biomaterials 1999, 20, 1–25. [Google Scholar] [CrossRef]

- Chevalier, J.; Deville, S.; Munch, E.; Jullian, R.; Lair, F. Critical effect of cubic phase on aging in 3 mol% yttria-stabilized zirconia ceramics for hip replacement prosthesis. Biomaterials 2004, 25, 5539–5545. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ersoy, N.M.; Aydoğdu, H.M.; Değirmenci, B.Ü.; Çökük, N.; Sevimay, M. The effects of sintering temperature and duration on the flexural strength and grain size of zirconia. Acta Biomater. Odontol. Scand. 2015, 1, 43–50. [Google Scholar] [CrossRef] [Green Version]

- Fassina, P.; Zaghini, N.; Bukat, A.; Piconi, C.; Greco, F.; Piantelli, S. Yttria and calcia partially stabilized zirconia for biomedical applications. In Bioceramics and the Human Body; Ravagliogli, A., Krajewski, A., Eds.; Springer: Dordrecht, The Netherlands, 1992; pp. 223–229. [Google Scholar] [CrossRef]

- Garvie, R.C.; Urbani, C.; Kennedy, D.R. Biocompatibility of magnesia partially stabilized zirconia (Mg-PSZ) ceramics. J. Mater. Sci. 1984, 19, 3224–3228. [Google Scholar] [CrossRef]

- Deville, S.; Gremillard, L.; Chevalier, J.; Fantozzi, G. A critical comparison of methods for the determination of the aging sensitivity in biomedical grade yttria-stabilized zirconia. J. Biomed. Mater. Res. B Appl. Biomater. 2005, 72, 239–245. [Google Scholar] [CrossRef] [PubMed]

- Vojtko, M.; Puchy, V.; Múdra, E.; Milkovič, O.; Kovalčíková, A. Coarse-grain CeO2 doped ZrO2 ceramic prepared by spark plasma sintering. J. Eur. Ceram. Soc. 2020, 40, 4844–4852. [Google Scholar] [CrossRef]

- Tekeli, S.; Erdogan, M. A quantitative assessment of cavities in 3 mol% yttria-stabilized tetragonal zirconia specimens containing various grain size. Ceram. Int. 2002, 28, 785–789. [Google Scholar] [CrossRef]

- Guazzato, M.; Quach, L.; Albakry, M.; Swain, M.V. Influence of surface and heat treatments on the flexural strength of Y-TZP dental ceramic. J. Dent. 2005, 33, 9–18. [Google Scholar] [CrossRef]

- Matsui, K.; Horikoshi, H.; Ohmichi, N.; Ohgai, M.; Yoshida, H.; Ikuhara, Y. Cubic-formation and grain-growth mechanisms in tetragonal zirconia polycrystal. J. Am. Ceram. Soc. 2003, 86, 1401–1408. [Google Scholar] [CrossRef]

- Matsui, K.; Ohmichi, N.; Ogai, M.; Yoshida, H.; Ikuhara, Y. Grain boundary segregation-induced phase transformation in yttria-stabilized tetragonal zirconia polycrystal. J. Ceram. Soc. Jpn. 2006, 114, 230–237. [Google Scholar] [CrossRef] [Green Version]

- Matsui, K.; Ohmichi, N.; Ogai, M.; Yoshida, H.; Ikuhara, Y. Effect of alumina-doping on grain boundary segregation-induced phase transformation in yttria-stabilized tetragonal zirconia polycrystal. J. Mater. Res. 2006, 21, 2278–2289. [Google Scholar] [CrossRef]

- Matsui, K.; Yoshida, H.; Ikuhara, Y. Grain-boundary structure and microstructure development mechanism in 2–8 mol% yttria-stabilized zirconia polycrystals. Acta Mater. 2008, 56, 1315–1325. [Google Scholar] [CrossRef]

- Matsui, K.; Yoshida, H.; Ikuhara, Y. Isothermal sintering effects on phase separation and grain growth in yttria-stabilized tetragonal zirconia polycrystal. J. Am. Ceram. Soc. 2009, 92, 467–475. [Google Scholar] [CrossRef]

- Stawarczyk, B.; Özcan, M.; Hallmann, L.; Ender, A.; Mehl, A.; Hämmerlet, C.H.F. The effect of zirconia sintering temperature on flexural strength, grain size, and contrast ratio. Clin. Oral Investig. 2012, 17, 269–274. [Google Scholar] [CrossRef] [Green Version]

- Stawarczyk, B.; Emslander, A.; Roos, M.; Sener, B.; Noack, F.; Keul, C. Zirconia ceramics, their contrast ratio and grain size depending on sintering parameters. Dent. Mater. J. 2014, 33, 591–598. [Google Scholar] [CrossRef] [Green Version]

- Casolco, S.R.; Xu, J.; Garay, J.E. Transparent/translucent polycrystalline nanostructured yttria stabilized zirconia with varying colors. Scr. Mater. 2008, 58, 516–519. [Google Scholar] [CrossRef]

- Wang, Z.-G.; Ouyang, J.-H.; Ma, Y.-H.; Wang, Y.-J.; Xie, L.-Y.; Liu, Z.-G.; Henniche, A.; Wang, Y. Grain size dependence, mechanical properties and surface nanoeutectic modification of Al2O3-ZrO2 ceramic. Ceram. Int. 2019, 45, 14297–14304. [Google Scholar] [CrossRef]

- Romaniv, O.M.; Zalite, I.V.; Simin’Kovych, V.M.; Tkach, O.N.; Vasyliv, B.D. Effect of the concentration of zirconium dioxide on the fracture resistance of Al2O3–ZrO2 ceramics. Mater. Sci. 1996, 31, 588–594. [Google Scholar] [CrossRef]

- Romaniv, O.M.; Vasyliv, B.D. Some features of formation of the structural strength of ceramic materials. Mater. Sci. 1998, 34, 149–161. [Google Scholar] [CrossRef]

- Kulyk, V.V.; Duriagina, Z.A.; Vasyliv, B.D.; Vavrukh, V.I.; Lyutyy, P.Y.; Kovbasiuk, T.M.; Holovchuk, M.Y. Effects of yttria content and sintering temperature on the microstructure and tendency to brittle fracture of yttria-stabilized zirconia. Arch. Mater. Sci. Eng. 2021, 109, 65–79. [Google Scholar] [CrossRef]

- Kulyk, V.; Duriagina, Z.; Vasyliv, B.; Vavrukh, V.; Kovbasiuk, T.; Lyutyy, P.; Vira, V. The effect of sintering temperature on the phase composition, microstructure, and mechanical properties of yttria-stabilized zirconia. Materials 2022, 15, 2707. [Google Scholar] [CrossRef]

- Li, Q.-L.; Jiang, Y.-Y.; Wei, Y.-R.; Swain, M.V.; Yao, M.-F.; Li, D.-S.; Wei, T.; Jian, Y.-T.; Zhao, K.; Wang, X.-D. The influence of yttria content on the microstructure, phase stability and mechanical properties of dental zirconia. Ceram. Int. 2022, 48, 5361–5368. [Google Scholar] [CrossRef]

- Gere, J.M.; Timoshenko, S.P. Mechanics of Materials, 4th ed.; PWS Publishing Company: Boston, MA, USA, 1997; 912p. [Google Scholar]

- Kumar, A.; Kumar, P.; Dhaliwal, A.S. Structural studies of zirconia and yttria doped zirconia for analysing it phase stabilization criteria. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1033, 012052. [Google Scholar] [CrossRef]

- Tsai, Y.-Y.; Lee, T.-M.; Kuo, J.-C. Hydrothermal-aging-induced lattice distortion in yttria-stabilized zirconia using EBSD technique. Micron 2021, 145, 103053. [Google Scholar] [CrossRef]

- Gupta, T.K.; Bechtold, J.H.; Kuznicki, R.C.; Cadoff, L.H.; Rossing, B.R. Stabilization of tetragonal phase in polycrystalline zirconia. J. Mater. Sci. 1977, 12, 2421–2426. [Google Scholar] [CrossRef]

- Wojteczko, K.; Pędzich, Z.; Zientara, D.; Berent, K.; Haberko, K. Phenomena occurring upon the sintering of a mixture of yttria–zirconia nanometric powder and sub-micrometric pure zirconia powder. Materials 2021, 14, 6937. [Google Scholar] [CrossRef]

- Chevalier, J.; Gremillard, L.; Virkar, A.V.; Clarke, D.R. The tetragonal-monoclinic transformation in zirconia: Lessons learned and future trends. J. Am. Ceram. Soc. 2009, 92, 1901–1920. [Google Scholar] [CrossRef]

- Scott, H.G. Phase relationships in the zirconia–yttria system. J. Mater. Sci. 1975, 10, 1527–1535. [Google Scholar] [CrossRef]

- Delaforce, P.M.; Yeomans, J.A.; Filkin, N.C.; Wright, G.J.; Thomson, R.C. Effect of NiO on the phase stability and microstructure of yttria-stabilized zirconia. J. Am. Ceram. Soc. 2007, 90, 918–924. [Google Scholar] [CrossRef] [Green Version]

- Dub, S.N.; Gogotsi, G.A.; Lomonova, E.E. Hardness and fracture toughness of tetragonal zirconia single crystals. J. Mater. Sci. Lett. 1995, 14, 46–49. [Google Scholar] [CrossRef]

- Din, S.-U.; Kaleem, A. Vickers hardness study of zirconia partially stabilized with lanthanide group oxides. Mater. Chem. Phys. 1998, 53, 48–54. [Google Scholar] [CrossRef]

| % Y2O3 | Average Grain Size, mm | Pores | Fracture Voids | Cleavage Facets | |||||

|---|---|---|---|---|---|---|---|---|---|

| Average Size, mm | Number Density, mm−2 | Area Fraction, % | Average Size, mm | Number Density, mm−2 | Size, mm2 | Number Density, mm−2 | Area Fraction, % | ||

| 3 | 1.0 ± 0.5 | 0.91 ± 0.56 | 0.0328 | 2.9 | 0.67 ± 0.38 | 0.039 | 8.0 ± 4.9 | 0.043 | 34 |

| 4 | 1.0 ± 0.5 | 0.90 ± 0.69 | 0.0287 | 2.9 | 0.67 ± 0.29 | 0.032 | 5.8 ± 3.0 | 0.044 | 25 |

| 5 | 1.0 ± 0.5 | 0.52 ± 0.42 | 0.0466 | 1.6 | 0.58 ± 0.29 | 0.031 | 8.5 ± 4.1 | 0.030 | 25 |

| 6 | 0.7 ± 0.3 | 0.49 ± 0.28 | 0.0200 | 0.5 | 0.36 ± 0.14 | 0.030 | 6.1 ± 2.9 | 0.015 | 9 |

| 7 | 0.7 ± 0.2 | 0.41 ± 0.21 | 0.0459 | 0.8 | 0.34 ± 0.13 | 0.090 | 6.4 ± 2.6 | 0.011 | 7 |

| 8 | 0.6 ± 0.2 | 0.41 ± 0.19 | 0.0520 | 0.8 | 0.32 ± 0.11 | 0.147 | 6.0 ± 2.6 | 0.008 | 5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kulyk, V.; Duriagina, Z.; Kostryzhev, A.; Vasyliv, B.; Vavrukh, V.; Marenych, O. The Effect of Yttria Content on Microstructure, Strength, and Fracture Behavior of Yttria-Stabilized Zirconia. Materials 2022, 15, 5212. https://doi.org/10.3390/ma15155212

Kulyk V, Duriagina Z, Kostryzhev A, Vasyliv B, Vavrukh V, Marenych O. The Effect of Yttria Content on Microstructure, Strength, and Fracture Behavior of Yttria-Stabilized Zirconia. Materials. 2022; 15(15):5212. https://doi.org/10.3390/ma15155212

Chicago/Turabian StyleKulyk, Volodymyr, Zoia Duriagina, Andrii Kostryzhev, Bogdan Vasyliv, Valentyna Vavrukh, and Olexandra Marenych. 2022. "The Effect of Yttria Content on Microstructure, Strength, and Fracture Behavior of Yttria-Stabilized Zirconia" Materials 15, no. 15: 5212. https://doi.org/10.3390/ma15155212

APA StyleKulyk, V., Duriagina, Z., Kostryzhev, A., Vasyliv, B., Vavrukh, V., & Marenych, O. (2022). The Effect of Yttria Content on Microstructure, Strength, and Fracture Behavior of Yttria-Stabilized Zirconia. Materials, 15(15), 5212. https://doi.org/10.3390/ma15155212