Fatigue Damage Behaviors of TRC-Strengthened RC Beams

Abstract

:1. Introduction

2. Materials and Methods

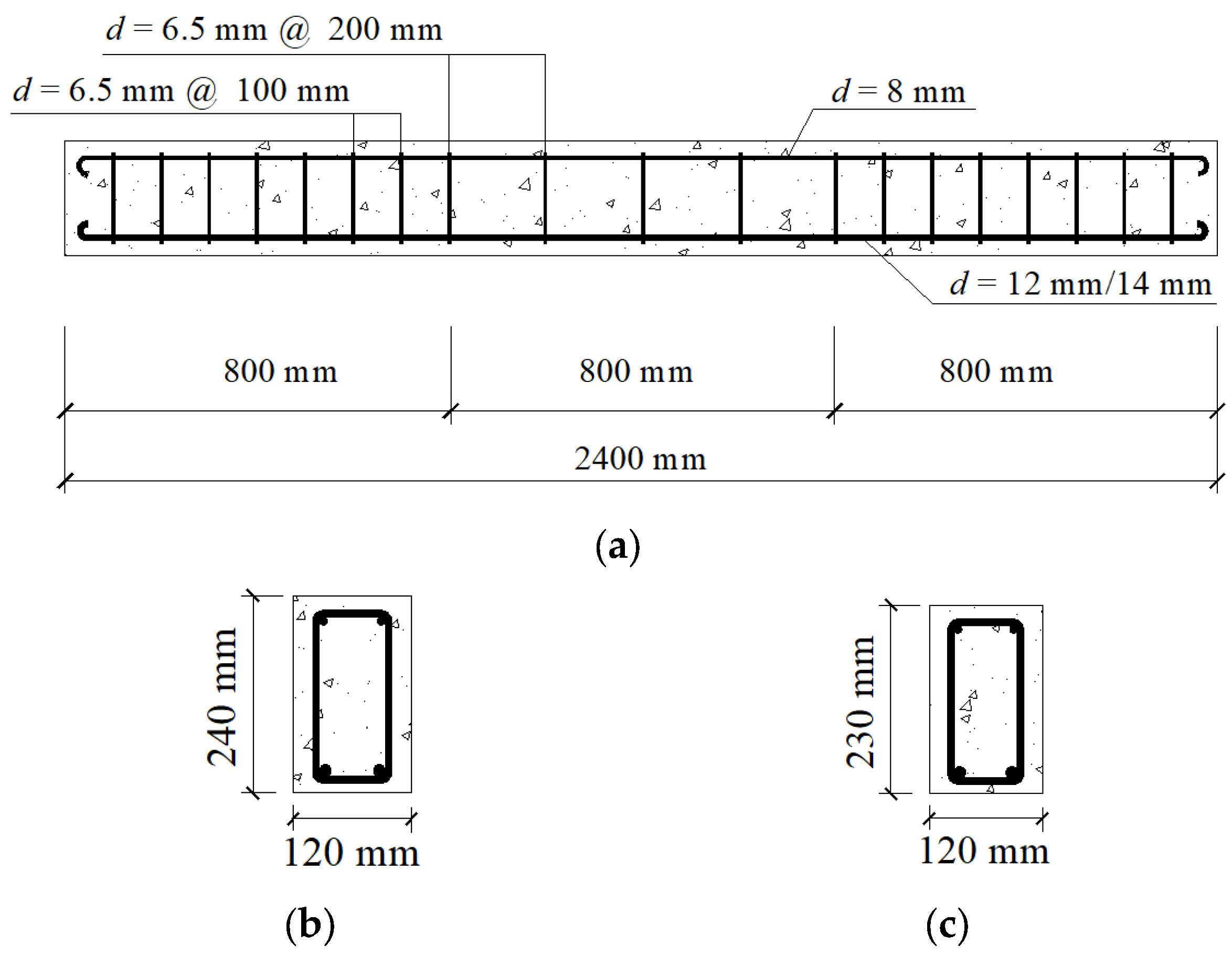

2.1. RC Beam Design

2.2. Strengthening Scheme

2.3. Materials

2.3.1. Concrete

2.3.2. Steel Bar

2.3.3. Textile

2.3.4. Matrix of TRC

2.4. Loading Scheme

3. Results and Discussion

3.1. Failure Modes

3.2. Fatigue Life

3.3. Midspan Deflection Corresponding to Maximum Fatigue Load

3.4. Residual Deflection

3.5. Load–Strain Response

4. Conclusions

- (1)

- The TRC-strengthened RC beams’ fatigue failure mode was affected by the textile ratio. When the textile ratio was less than 0.036%, the TRC-strengthened beam’s failure was characterized by textile snapping and concrete crushing but not steel fracture. When the textile ratio was greater than 0.036%, the TRC-strengthened beam’s failure was characterized by textile snapping and steel fracture but not concrete crushing.

- (2)

- Both the U-wrapped and single-side strengthening methods improved the RC beam’s fatigue life. When the textile ratio is same, the single-side strengthening method performed better than the U-wrapped strengthening method in terms of improvement in the RC beam’s fatigue life. The TRC-strengthened RC beam’s fatigue life was increased with the textile and reinforcement ratios.

- (3)

- The TRC-strengthened beam’s midspan deflection was characterized by three stages of development as the number of cycles increased: rapid development stage (Stage I), stable development stage (Stage II), and destabilized development stage (Stage III). Specifically, Stage II accounted for 85–90% of the overall fatigue life. The third stage of development was not obvious when the textile ratio of the TRC-strengthened beams was lower than 0.018%.

- (4)

- The fatigue damage accumulation rate of TRC-strengthened beam can be decreased by increasing textile ratio or reinforcement ratio, which extend the fatigue life of RC beam.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Nie, J.; Wang, Y.; Cai, C.S. Experimental Research on Fatigue Behavior of RC Beams Strengthened with Steel Plate-Concrete Composite Technique. J. Struct. Eng. 2011, 137, 772–781. [Google Scholar] [CrossRef]

- Al-Saadi, N.; Mohammed, A.; Al-Mahaidi, R.; Sanjayan, J. A state-of-the-art review: Near-surface mounted FRP composites for reinforced concrete structures. Constr. Build. Mater. 2019, 209, 748–769. [Google Scholar] [CrossRef]

- Shaw, I.; Andrawes, B. Repair of damaged end regions of PC beams using externally bonded FRP shear reinforcement. Constr. Build. Mater. 2017, 148, 184–194. [Google Scholar] [CrossRef]

- Choobbor, S.S.; Hawileh, R.A.; Abu-Obeidah, A.; Abdalla, J.A. Performance of Hybrid Carbon and Basalt FRP Sheets in Strengthening Concrete Beams in Flexure. Compos. Struct. 2019, 227, 111337. [Google Scholar] [CrossRef]

- Zhu, Z.; Zhu, E.; Ni, Y.; Li, D. Flexural fatigue behavior of large-scale beams strengthened with side near surface mounted (SNSM) CFRP strips. Eng. Struct. 2019, 180, 134–147. [Google Scholar] [CrossRef]

- Raoof, S.M.; Bournas, D.A. TRM versus FRP in flexural strengthening of RC beams: Behaviour at high temperatures. Constr. Build. Mater. 2017, 154, 424–437. [Google Scholar] [CrossRef]

- Scheerer, S.; Zobel, R.; Müller, E.; Senckpiel-Peters, T.; Schmidt, A.; Curbach, M. Flexural Strengthening of RC Structures with TRC—Experimental Observations, Design Approach and Application. Appl. Sci. 2019, 9, 1322. [Google Scholar] [CrossRef] [Green Version]

- Yin, S.P.; Na, M.W.; Yu, Y.L.; Wu, J. Research on the flexural performance of RC beams strengthened with TRC under the coupling action of load and marine environment. Constr. Build. Mater. 2017, 132, 251–261. [Google Scholar] [CrossRef]

- Koutas, L.N.; Tetta, Z.; Bournas, D.A.; Triantafillou, T.C. Strengthening of concrete structures with textile reinforced mortars: State-of-the-art review. J. Compos. Constr. ASCE 2019, 23, 03118001. [Google Scholar] [CrossRef]

- Zhu, D.; Liu, S.; Yao, Y.; Li, G.; Du, Y.; Shi, C. Effects of short fiber and pre-tension on the tensile behavior of basalt textile reinforced concrete. Cem. Concr. Compos. 2019, 96, 33–45. [Google Scholar] [CrossRef]

- Ebead, U.; Shrestha, K.C.; Afzal, M.S.; El Refai, A.; Nanni, A. Effectiveness of fabric-reinforced cementitious matrix in strengthening reinforced concrete beams. J. Compos. Constr. ASCE 2017, 21, 04016084. [Google Scholar] [CrossRef]

- Larbi, A.S.; Contamine, R.; Ferrier, E.; Hamelin, P. Shear strengthening of RC beams with textile reinforced concrete (TRC) plate. Constr. Build. Mater. 2010, 24, 1928–1936. [Google Scholar] [CrossRef]

- Verbruggen, S.; Tysmans, T.; Wastiels, J. Bending crack behaviour of plain concrete beams externally reinforced with TRC. Mater. Struct. 2016, 49, 5303–5314. [Google Scholar] [CrossRef]

- Yin, S.; Xu, S.; Lv, H. Flexural Behavior of Reinforced Concrete Beams with TRC Tension Zone Cover. J. Mater. Civ. Eng. ASCE 2014, 27, 320–330. [Google Scholar] [CrossRef]

- Calabrese, A.S.; Colombi, P.; D’Antino, T. Analytical solution of the bond behavior of FRCM composites using a rigid-softening cohesive material law. Compos. Part B-Eng. 2019, 174, 107051. [Google Scholar] [CrossRef]

- Sneed, L.H.; Verre, S.; Carloni, C.; Ombres, L. Flexural behaviour of RC beams strengthened with steel-FRCM composite. Eng. Struct. 2016, 127, 686–699. [Google Scholar] [CrossRef]

- Raoof, S.M.; Koutas, L.N.; Bournas, D.A. Textile-reinforced mortar (TRM) versus fibre-reinforced polymers (FRP) in flexural strengthening of RC beams. Constr. Build. Mater. 2017, 151, 279–291. [Google Scholar] [CrossRef]

- Yin, S.; Jing, L.; Lv, H. Experimental analysis of bond between corroded steel bar and concrete confined with textile reinforced concrete. J. Mater. Civ. Eng. ASCE 2019, 31, 04019208. [Google Scholar] [CrossRef]

- Sheng, J.; Wang, L.; Yin, S. Study on the mechanical performance of TRC-strengthened RC beams under a salt freeze–thaw environment. Cold Reg. Sci. Technol. 2021, 192, 103384. [Google Scholar] [CrossRef]

- Pino, V.; Hadad, H.A.; Basalo, F.D.Y.; Nanni, A.; Ebead, U.A.; El Refai, A. Performance of FRCM-strengthened RC beams subject to fatigue. J Bridge Eng. ASCE 2017, 22, 04017079. [Google Scholar] [CrossRef]

- Hadad, H.A.; Nanni, A.; Ebead, U.A.; El Refai, A. Static and fatigue performance of FRCM-strengthened concrete beams. J. Compos. Constr. ASCE 2018, 22, 04018033. [Google Scholar] [CrossRef]

- Aljazaeri, Z.R.; Myers, J.J. Fatigue and Flexural Behavior of Reinforced-Concrete Beams Strengthened with Fiber-Reinforced Cementitious Matrix. J. Compos. Constr. ASCE 2017, 21, 04016075. [Google Scholar] [CrossRef]

- Myroslava, H. Peculiarities of bond strength degradation in reinforced concrete induced by accelerated electrochemical methods. Proced. Struct. Integr. 2018, 13, 1657–1662. [Google Scholar]

- Elghazy, M.; El Refai, A.; Ebead, U.; Nanni, A. Fatigue and monotonic behaviors of corrosion- damaged reinforced concrete beams strengthened with FRCM composites. J. Compos. Constr. ASCE 2018, 22, 04018040. [Google Scholar] [CrossRef]

- Bressan, J.; Ghrib, F.; El Ragaby, A. FRCM Strengthening of Corrosion-Damaged RC Beams Subjected to Monotonic and Cyclic Loading. J. Compos. Constr. ASCE 2022, 26, 04021063. [Google Scholar] [CrossRef]

- D’Antino, T.; Carloni, C.; Sneed, L.H.; Pellegrino, C. Fatigue and post-fatigue behavior of PBO FRCM-concrete joints. Int. J. Fatigue 2015, 81, 91–104. [Google Scholar] [CrossRef]

- Peng, H.; Zhang, J.; Shang, S.; Liu, Y.; Cai, C.S. Experimental study of flexural fatigue performance of reinforced concrete beams strengthened with prestressed CFRP plates. Eng. Struct. 2016, 127, 62–72. [Google Scholar] [CrossRef]

| Specimen | Strengthening Method | d/mm | ρs | Layers of Textile | ρt |

|---|---|---|---|---|---|

| M-0-12 | Non-strengthened | 12 | 0.95% | - | - |

| M-0-14 | Non-strengthened | 14 | 1.30% | - | - |

| F-0-14 | Non-strengthened | 14 | 1.70% | - | - |

| F-B1-14 | Single-side | 14 | 1.70% | 1 | 0.018% |

| F-B2-14 | Single-side | 14 | 1.70% | 2 | 0.036% |

| F-U2-14 | U-wrapped | 14 | 1.70% | 3 | 0.036% |

| F-B3-12 | Single-side | 12 | 0.95% | 3 | 0.054% |

| F-B3-14 | Single-side | 14 | 1.30% | 3 | 0.054% |

| Diameter of Rebar/mm | 12 | 14 |

|---|---|---|

| Average yield strength/MPa | 546 | 500 |

| Average tensile strength/MPa | 639 | 635 |

| Average elongation | 21.67% | 28.1% |

| Fiber Type | Number of Filaments per Bundle | Filament Tensile Strength (MPa) | Elastic Modulus (GPa) | Ultimate Strain | Quality of Unit Length (Tex) | Density (g/cm3) |

|---|---|---|---|---|---|---|

| Toray carbon | 12k | 4660 | 231 | 0.023 | 801 | 1.78 |

| E-glass | 4k | 3200 | 65 | 0.045 | 600 | 2.58 |

| Cement | Fly Ash | Silica Fume | Water | Fine Sand | Coarse Sand | Superplasticizer |

|---|---|---|---|---|---|---|

| 475 | 168 | 35 | 262 | 460 | 920 | 9.1 |

| Num. | Fmax/kN | Fmin/kN | Failure Modes | Nu/×104 |

|---|---|---|---|---|

| F-0-14 | 59.5 | 10.5 | A | 31.55 |

| F-B1-14 | 59.5 | 10.5 | B | 29.62 |

| F-B2-14 | 59.5 | 10.5 | B | 41.53 |

| F-U2-14 | 59.5 | 10.5 | B | 38.10 |

| F-B3-12 | 49.0 | 9.8 | C | 41.42 |

| F-B3-14 | 59.5 | 10.5 | C | 49.80 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sheng, J.; Yu, Z.; Dou, G.; Liu, H. Fatigue Damage Behaviors of TRC-Strengthened RC Beams. Materials 2022, 15, 5113. https://doi.org/10.3390/ma15155113

Sheng J, Yu Z, Dou G, Liu H. Fatigue Damage Behaviors of TRC-Strengthened RC Beams. Materials. 2022; 15(15):5113. https://doi.org/10.3390/ma15155113

Chicago/Turabian StyleSheng, Jie, Zongjian Yu, Guotao Dou, and Hao Liu. 2022. "Fatigue Damage Behaviors of TRC-Strengthened RC Beams" Materials 15, no. 15: 5113. https://doi.org/10.3390/ma15155113

APA StyleSheng, J., Yu, Z., Dou, G., & Liu, H. (2022). Fatigue Damage Behaviors of TRC-Strengthened RC Beams. Materials, 15(15), 5113. https://doi.org/10.3390/ma15155113