Shear Strength of Ultra-High-Performance Concrete (UHPC) Beams without Transverse Reinforcement: Prediction Models and Test Data

Abstract

:1. Introduction

2. Materials and Methods

2.1. Prediction Models

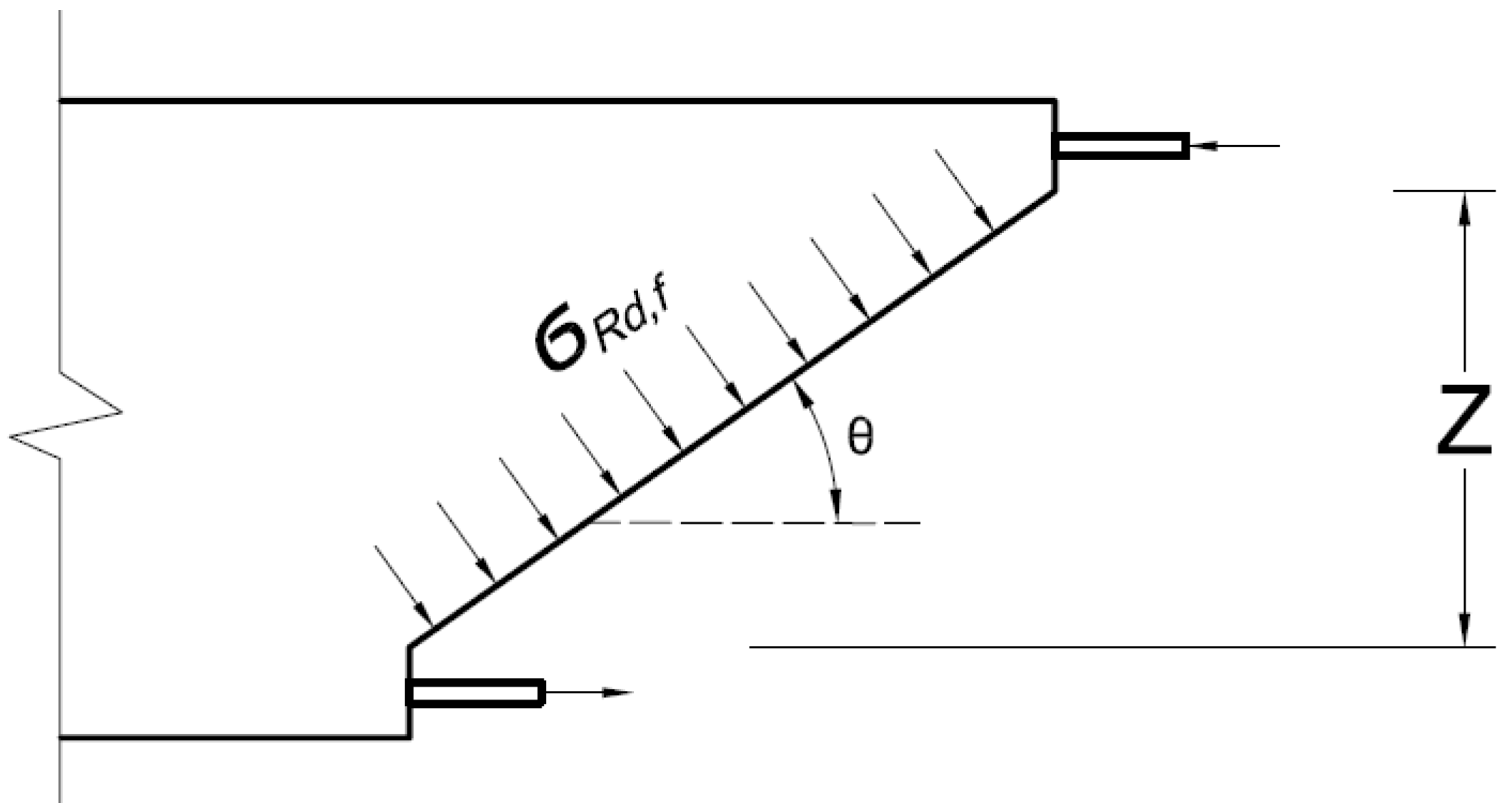

2.1.1. RILEM TC 162-TDF, 2003

2.1.2. Fib Model Code, 2010

2.1.3. French Standard, NF P 18-710, 2016

2.1.4. PCI-UHPC Structures Design Guide, 2021

2.1.5. Draft of AASHTO Guide Specification for Structural Design with UHPC, 2021

2.2. Shear Experiments

3. Results

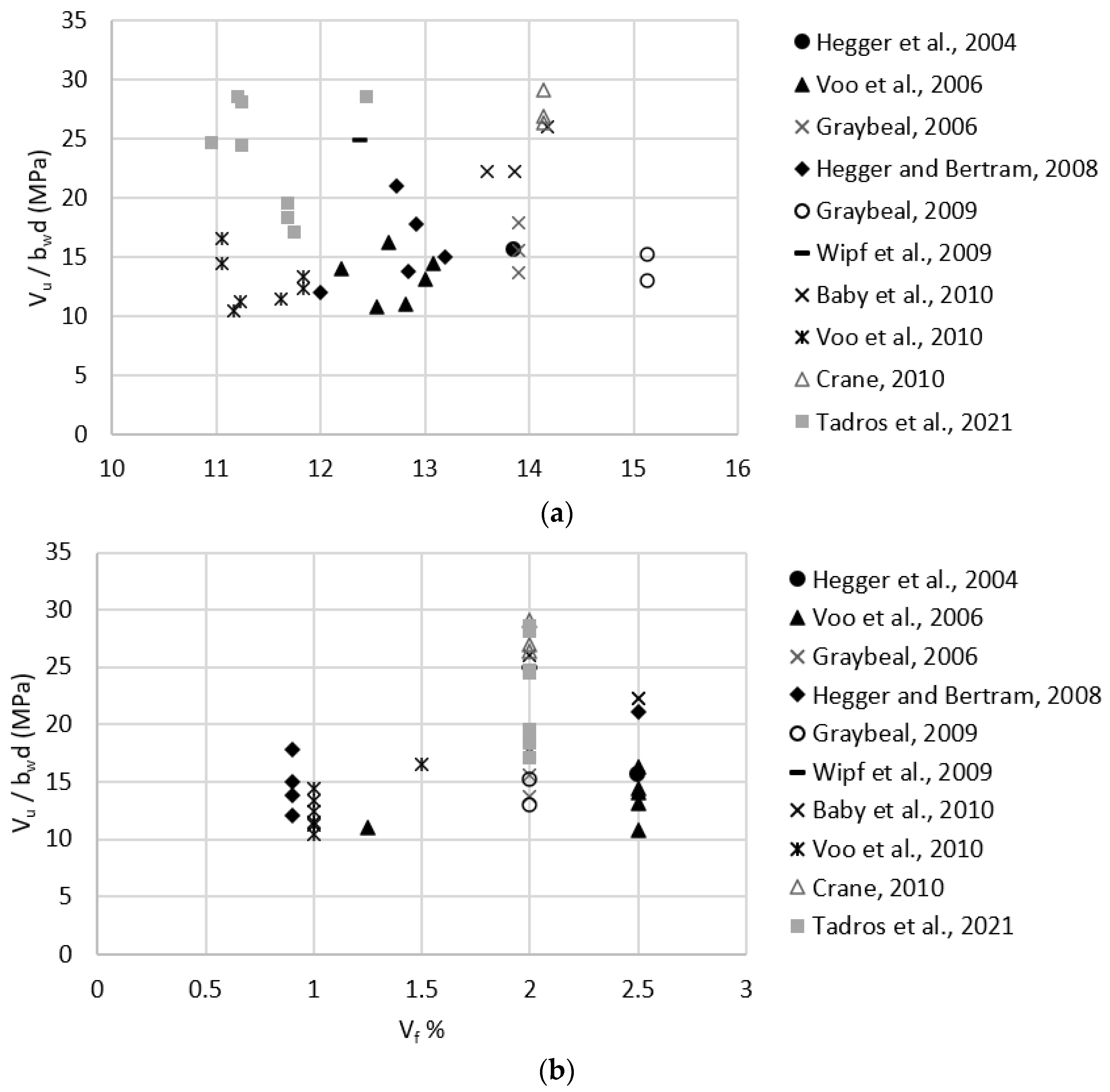

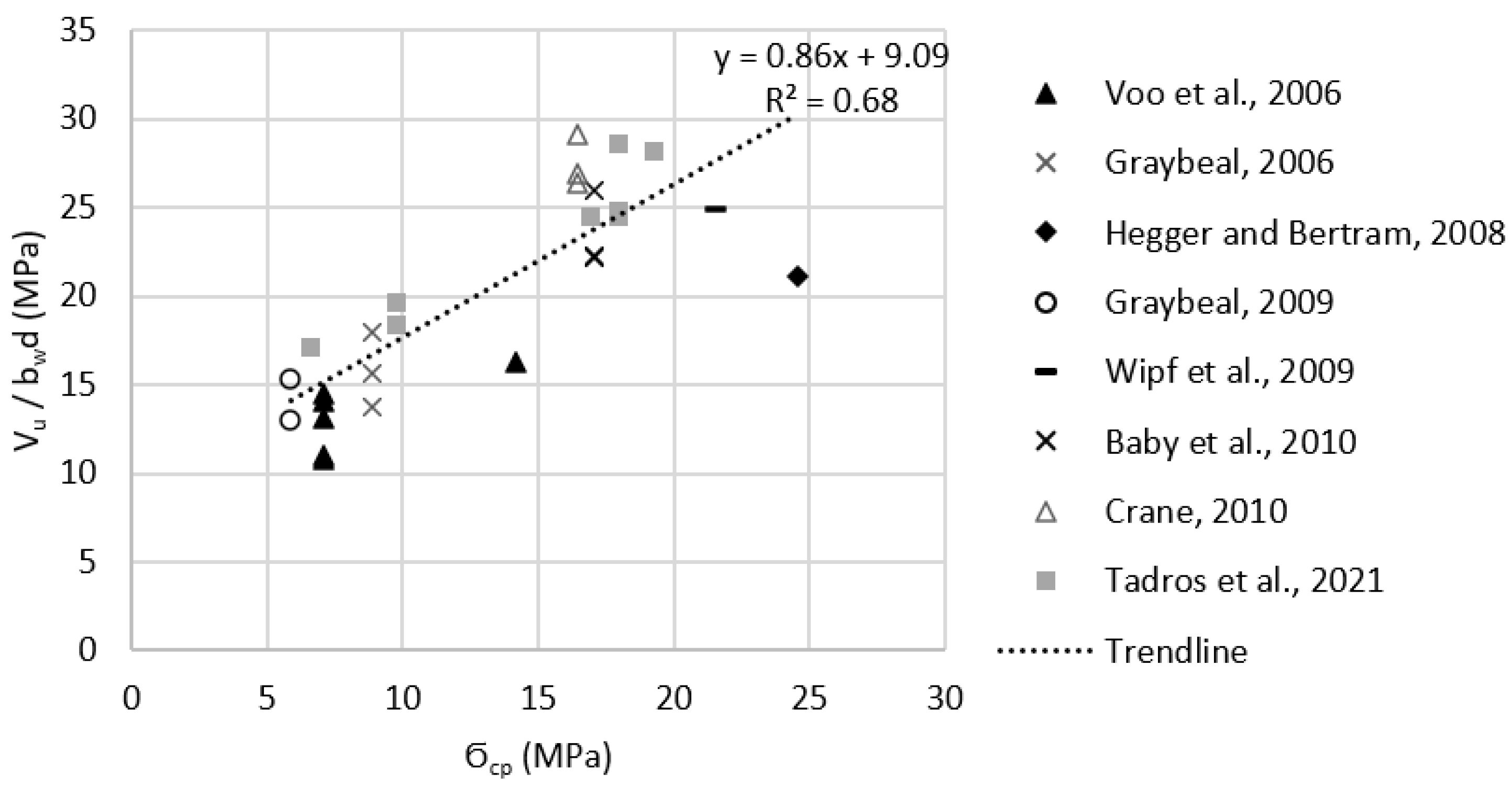

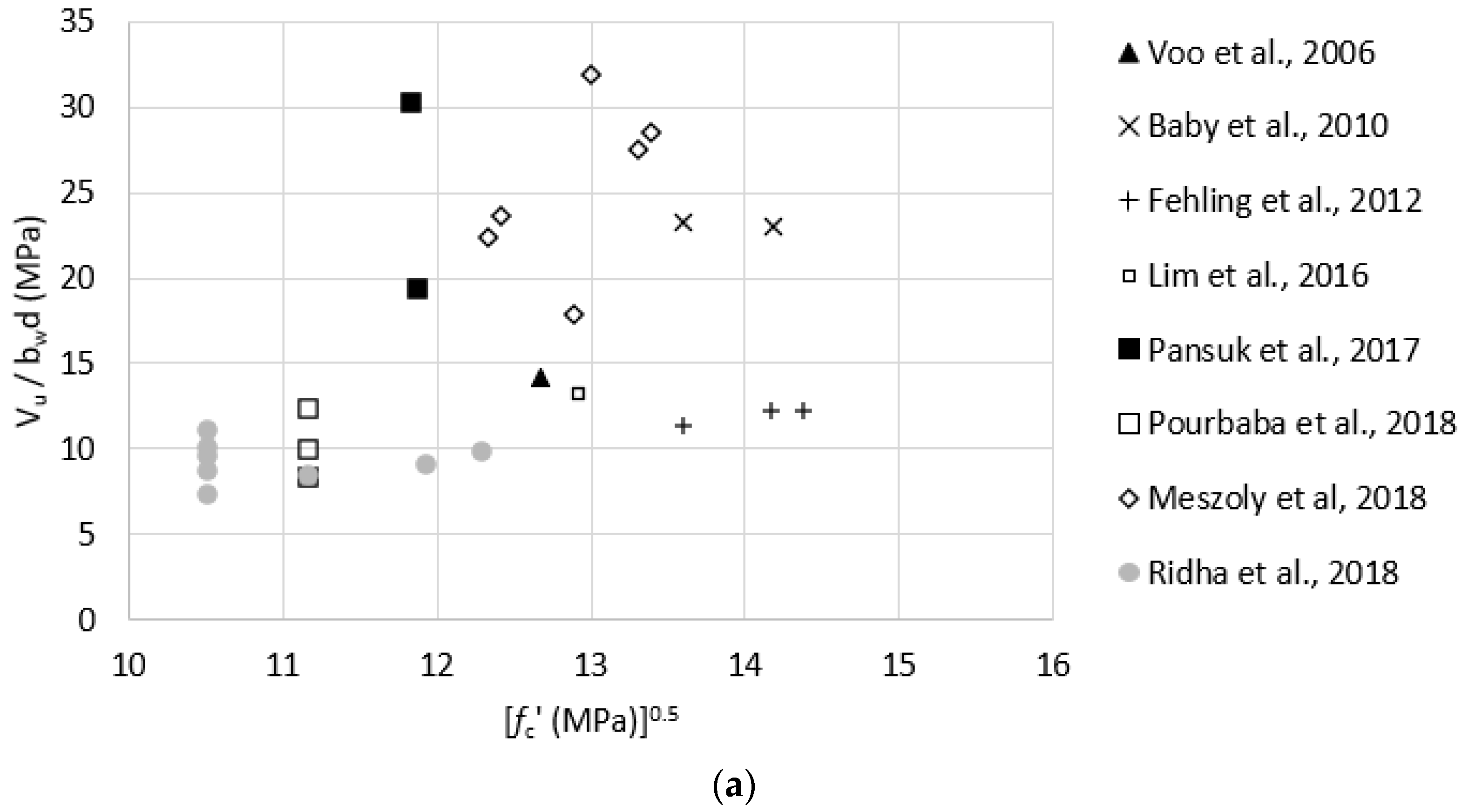

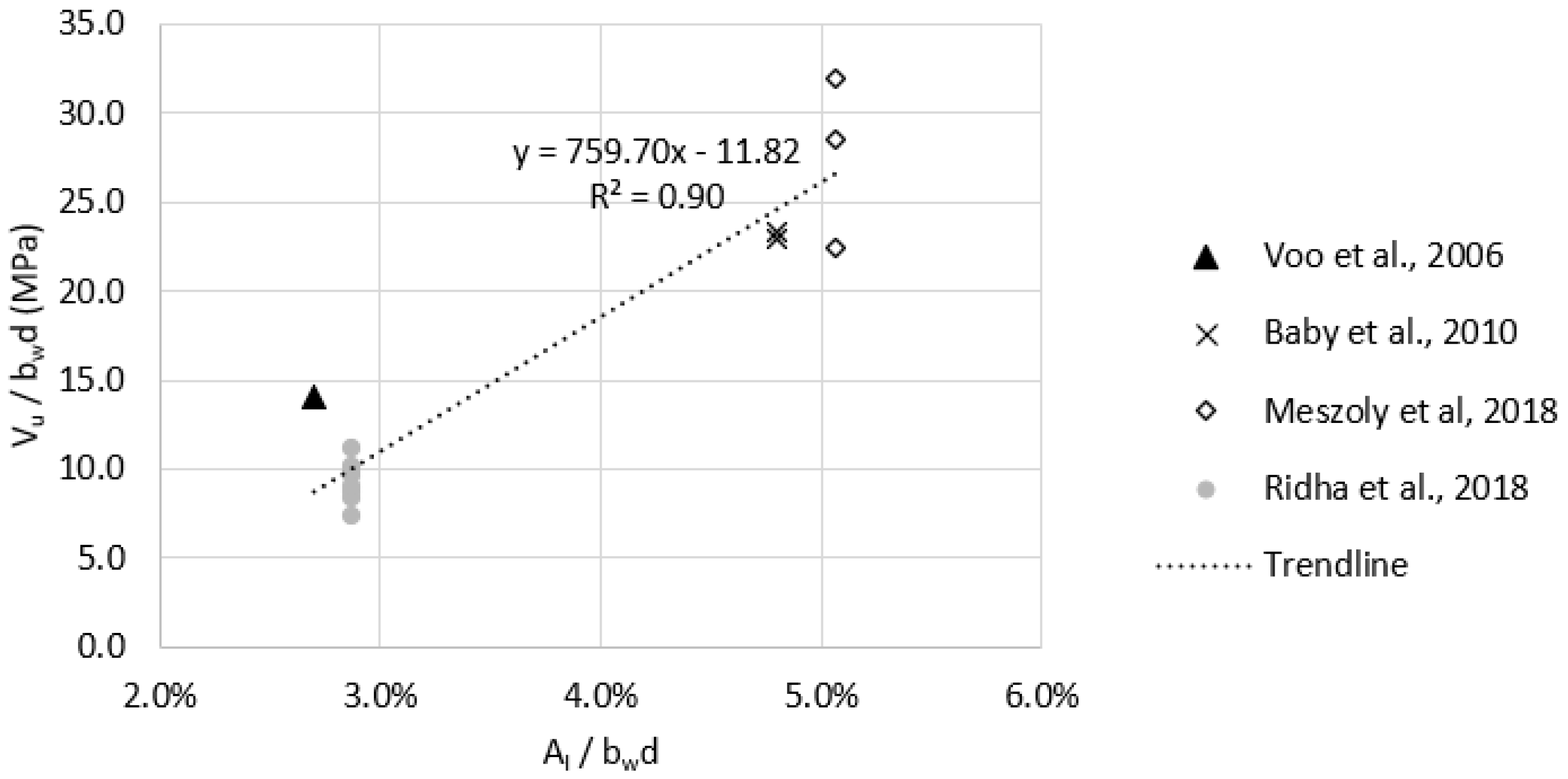

3.1. Shear Strength Parameters

3.2. Comparison to Model Predictions

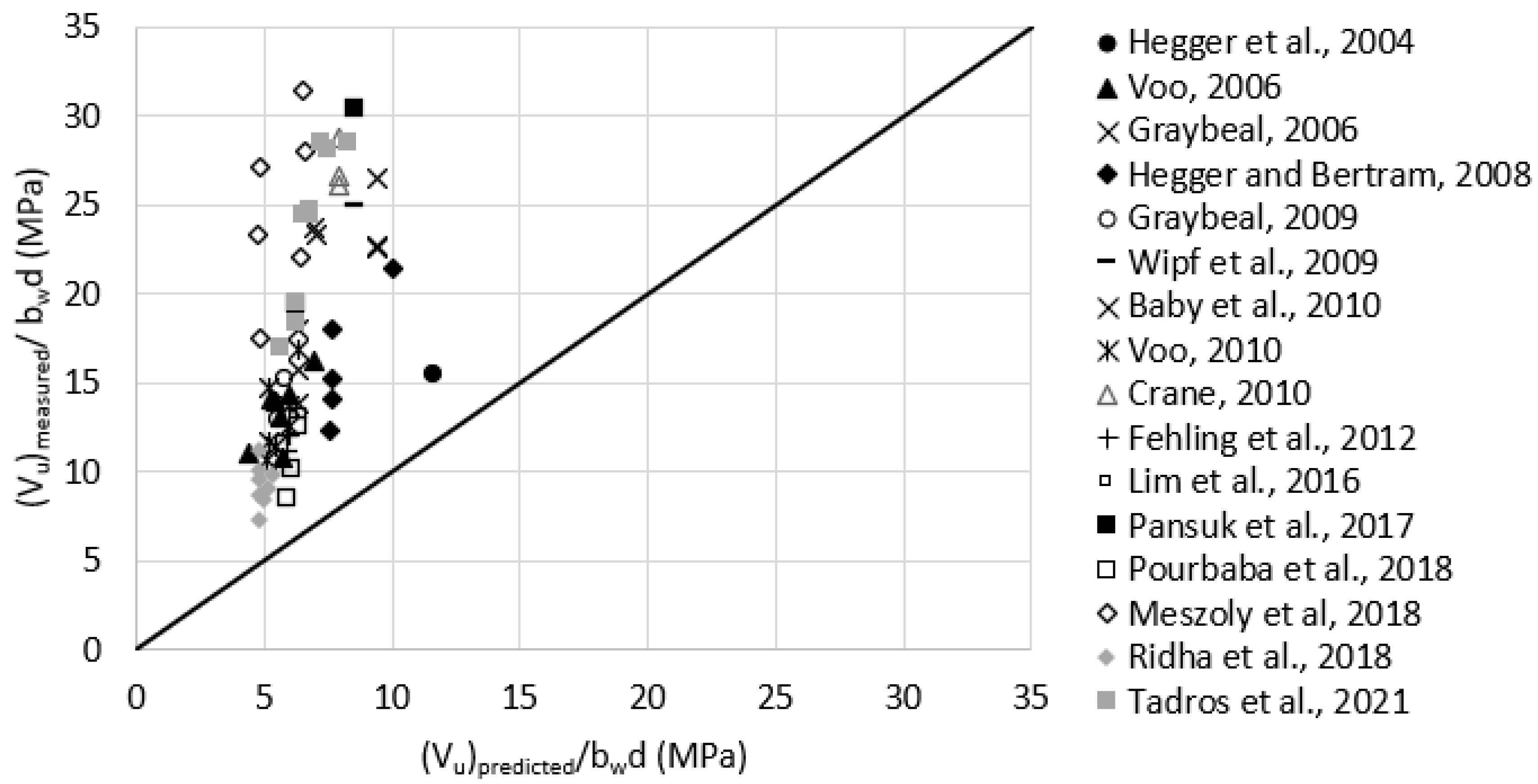

3.2.1. RILEM TC 162-TDF, 2003

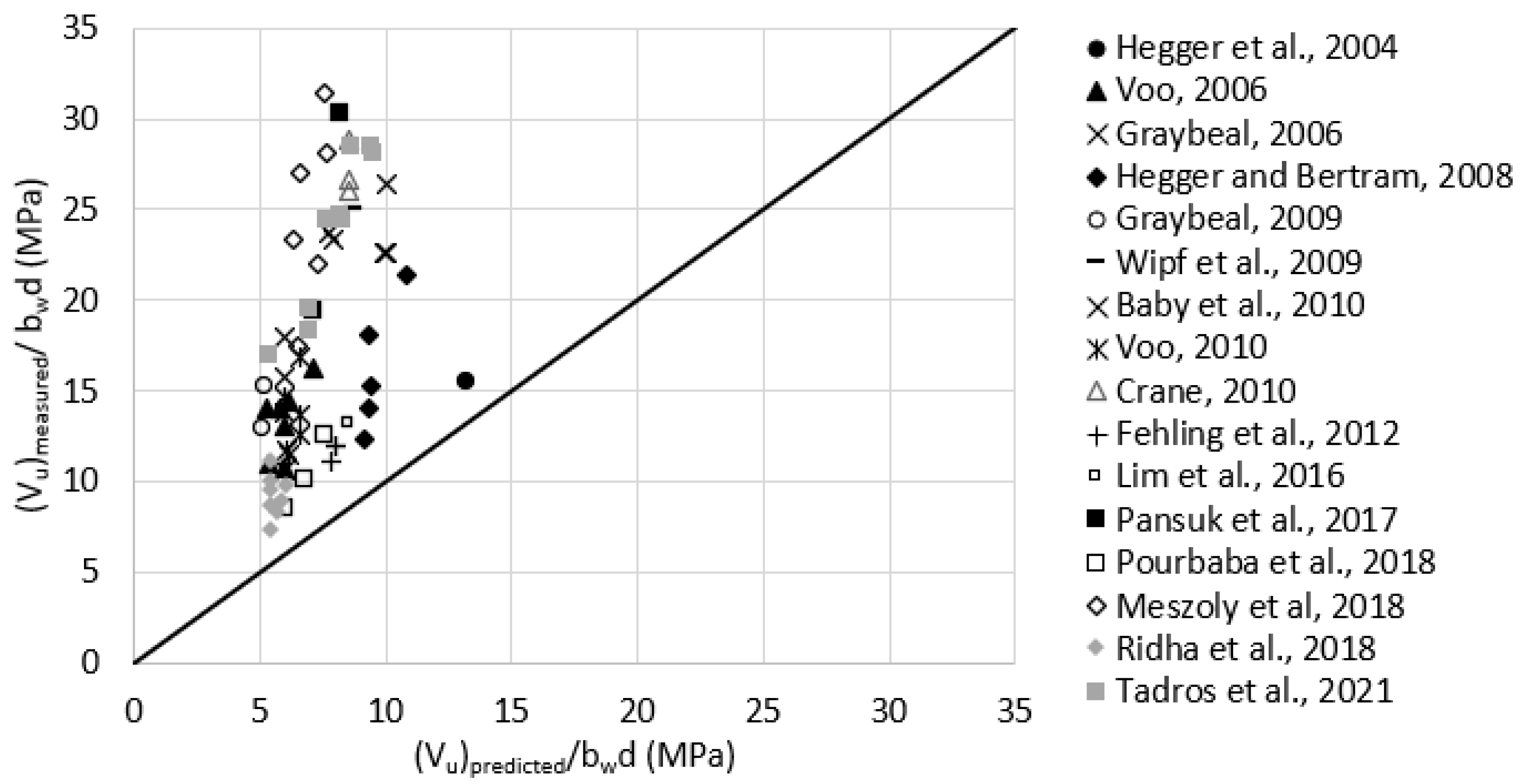

3.2.2. Fib Model Code, 2010

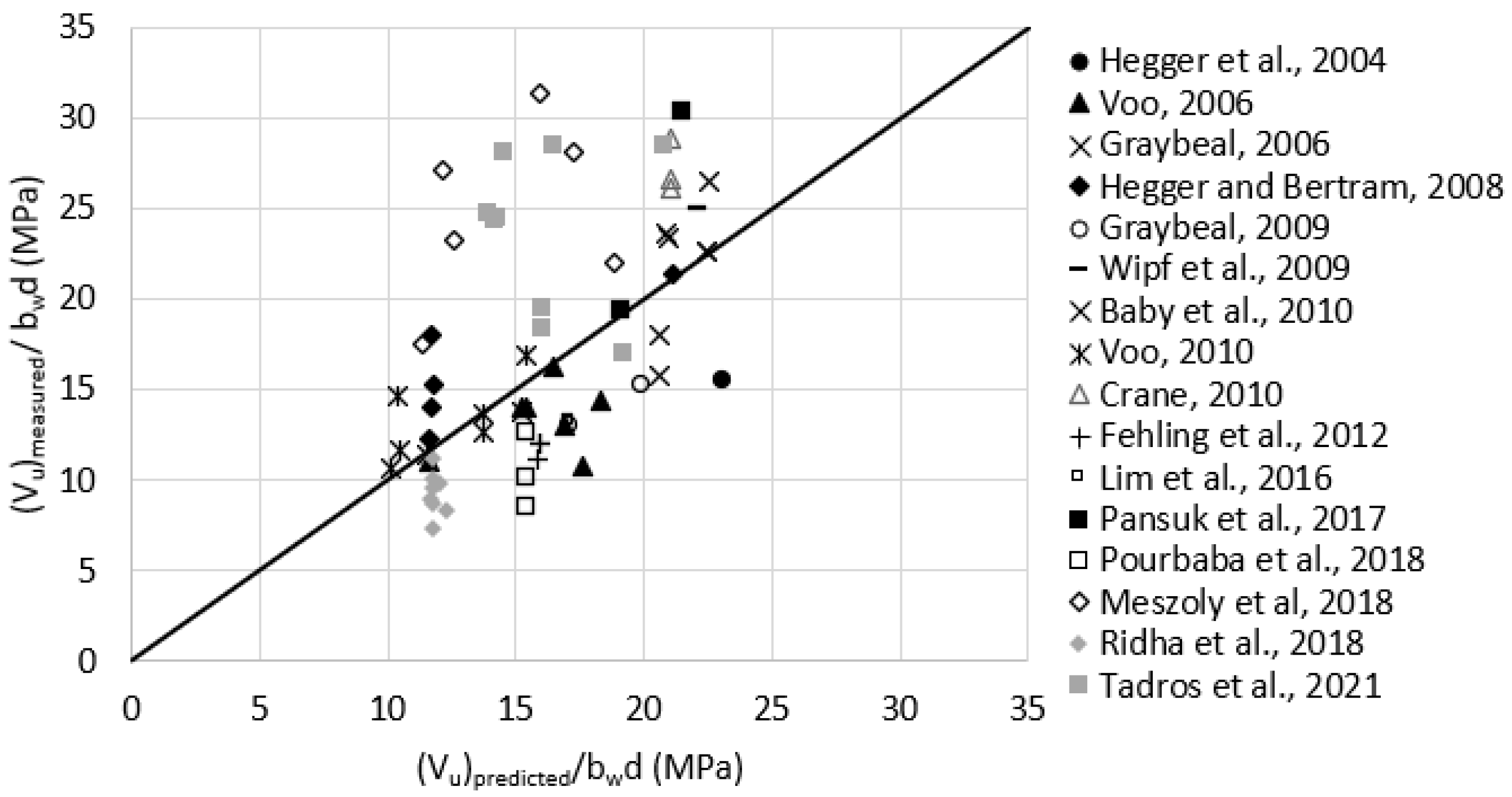

3.2.3. French Standard, NF P 18-710, 2016

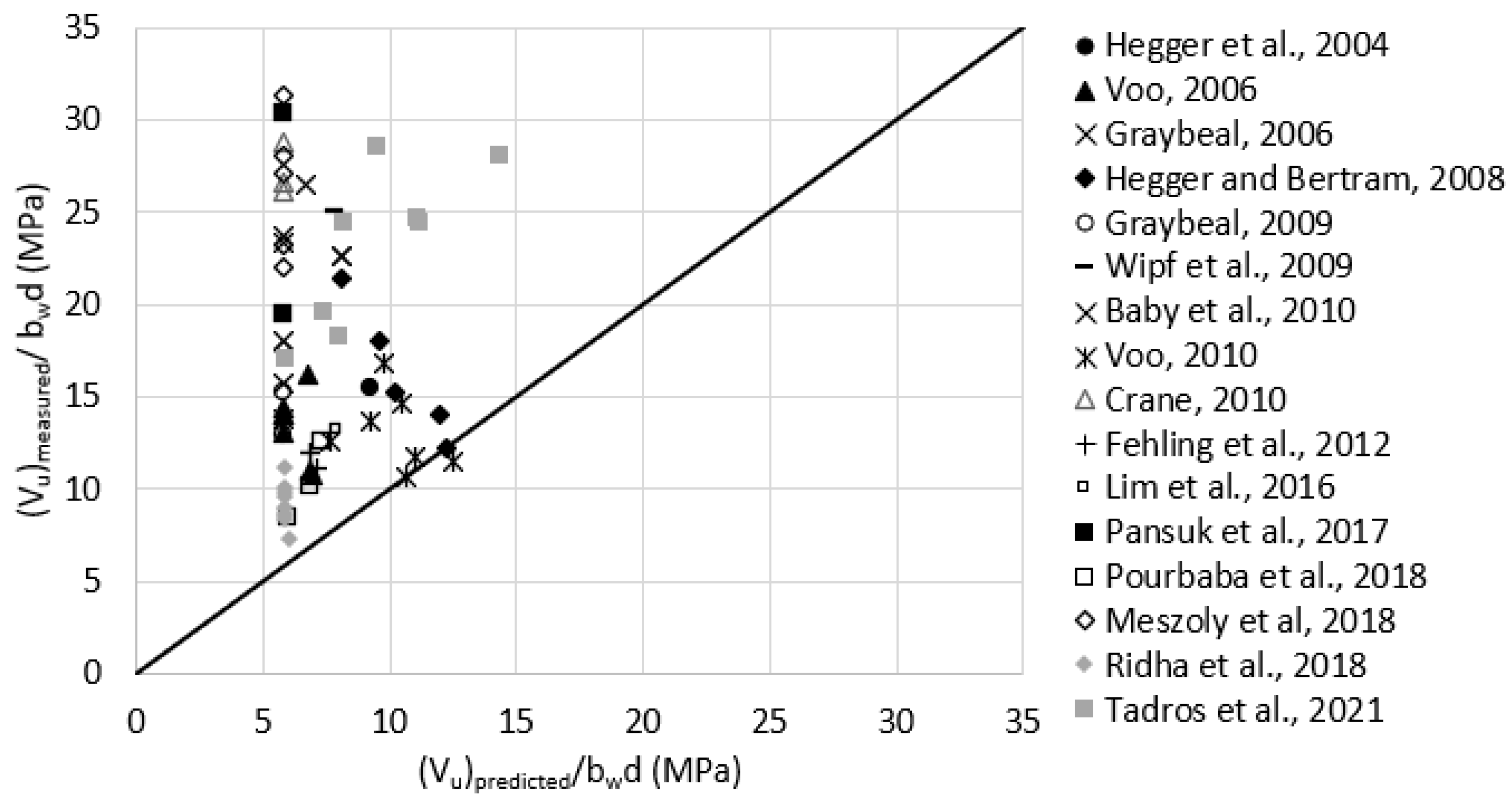

3.2.4. PCI-UHPC Structures Design Guide, 2021

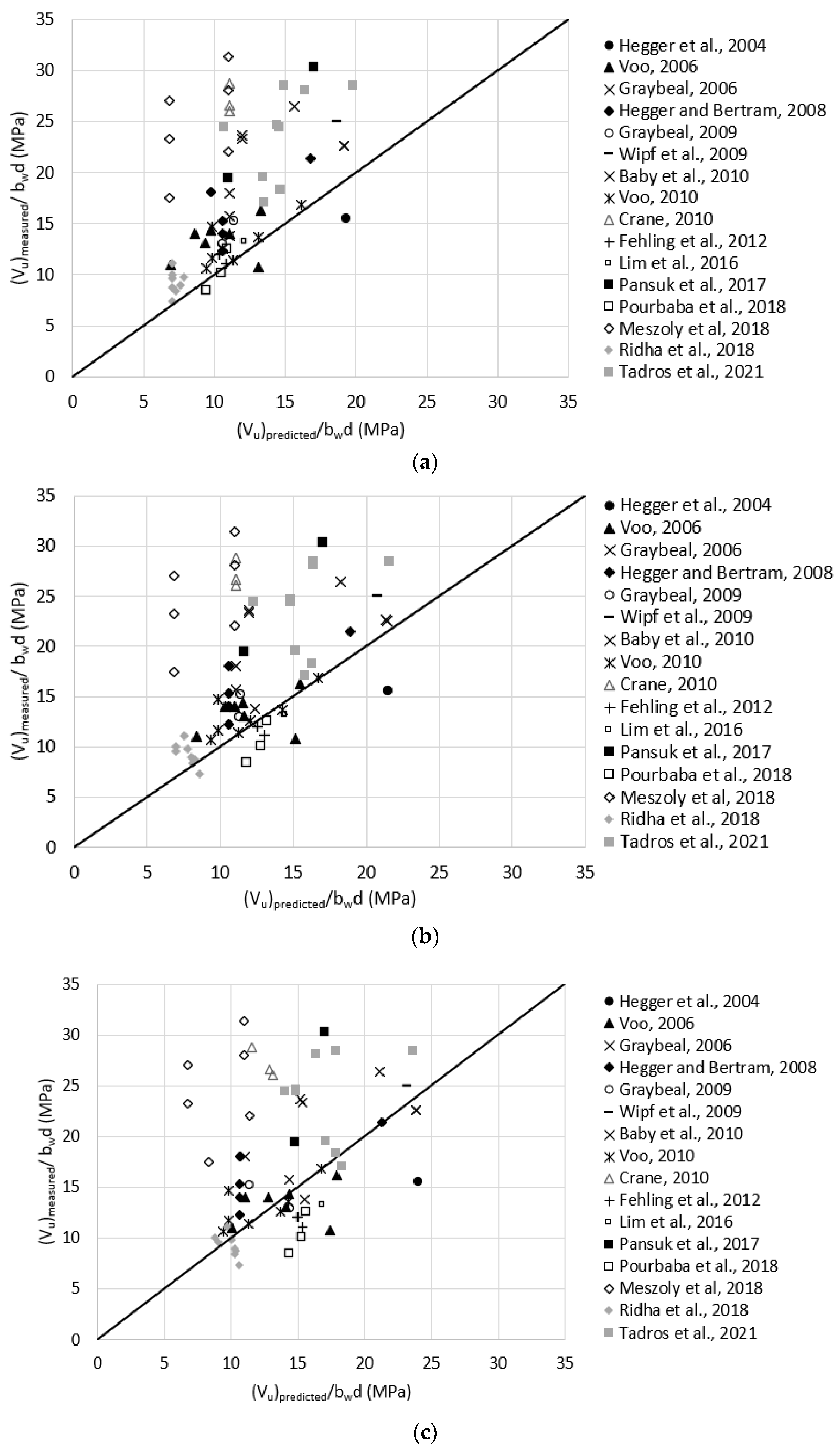

3.2.5. Draft of AASHTO Guide Specification for Structural Design with UHPC, 2021

4. Discussion and Recommendation

5. Conclusions

- Among the parameters affecting the shear strength of prestressed and non-prestressed beams, the tensile strength of UHPC () was found to have a significant positive correlation with the shear strength of UHPC beams.

- For UHPC beams with a fiber volume fraction of at least 2%, the level of prestressing () and longitudinal reinforcement ratio () were found to have a significant effect on the shear strength of prestressed and non-prestressed beams, respectively.

- The French Standard model provided the closest prediction to the measured shear strength of UHPC beams with the highest consistency of prediction, followed by the Draft of AASHTO model.

- The PCI-UHPC Structures Design Guide prediction model significantly underestimates the shear strength due to the limitation of UHPC residual tensile strength to 5.2 MPa. This value is significantly smaller than what is typically achieved by the commonly used UHPC mixes. However, the model procedure is much simpler compared to the other models.

- The RILEM and fib Model Code, 2010 prediction models were developed primarily for fiber-reinforced concrete and significantly underestimate the shear strength of UHPC beams.

- Residual tensile strength of UHPC is an essential parameter in all UHPC prediction models. The method of its determination is not unified between the shear experiments and prediction models. Moreover, the variability in residual tensile strength among specimens is large, which requires several direct tension or flexure tests to yield reliable predictions.

Author Contributions

Funding

Conflicts of Interest

Appendix A

| Reference | Specimen ID | Specimen Shape | bw (mm) | d (mm) | h (mm) | a/d | Aps/bwd | (MPa) | lf (mm) | Φf (mm) | (MPa) | Vu (kN) | (MPa) | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Hegger et al., 2004 [24] | 1 | I-beam | 70 | 250 | 300 | 2.5 | 5.4 | 6.80% | 26.9 | 192 | 13 | 0.15 | 12.1 | 31 | 271.3 | 15.9 |

| Voo et al., 2006 [23] | SB2 | I-beams | 50 | 600 | 650 | 2.5 | 3.3 | 2.70% | 14.5 | 160 | 13 (Type I) 30 (Type II) | 0.20 (Type I) 0.50 (Type II) | 9.8 | 34 | 496.8 | 16.6 |

| SB3 | 6.9 | 149 | 8.6 | 32 | 427.9 | 13.8 | ||||||||||

| SB4 | 1.25 | 164 | 5.5 | 26 | 336.3 | 11.0 | ||||||||||

| SB5 | 2.5 | 171 | 9.7 | 29 | 439.9 | 14.5 | ||||||||||

| SB6 | 157 | 9.3 | 24 | 330 | 11.0 | |||||||||||

| SB7 | 169 | 8.8 | 21 | 399.9 | 13.1 | |||||||||||

| Graybeal, 2006 [27] | 28S | AASHTO Type II | 155 | 803 | 910 | 2.0 | 2.5 | 1.90% | 9.0 | 193 | 13 | 0.20 | 11.0 | 40 | 1707.6 | 13.8 |

| 24S | 2.8 | 11.0 | 28 | 2232.5 | 17.9 | |||||||||||

| 14S | 2.3 | 11.0 | 25 | 1946.9 | 15.9 | |||||||||||

| Hegger and Bertram, 2008 [25] | T1a | I-beams | 60 | 318 | 400 | 0.9 2.5 0.9 | 3.8 | 4.60% | 24.8 | 144 | 18 | 0.15 | 5.0 | 30 | 234 | 12.4 |

| T1b | 165 | 5.0 | 30 | 266.9 | 13.8 | |||||||||||

| T3b | 162 | 9 | 11.0 | 30 | 407.9 | 21.4 | ||||||||||

| T4a | 167 | 18 | 5.0 | 30 | 343.8 | 17.9 | ||||||||||

| T4b | 4.4 | 174 | 5.0 | 30 | 290.9 | 15.2 | ||||||||||

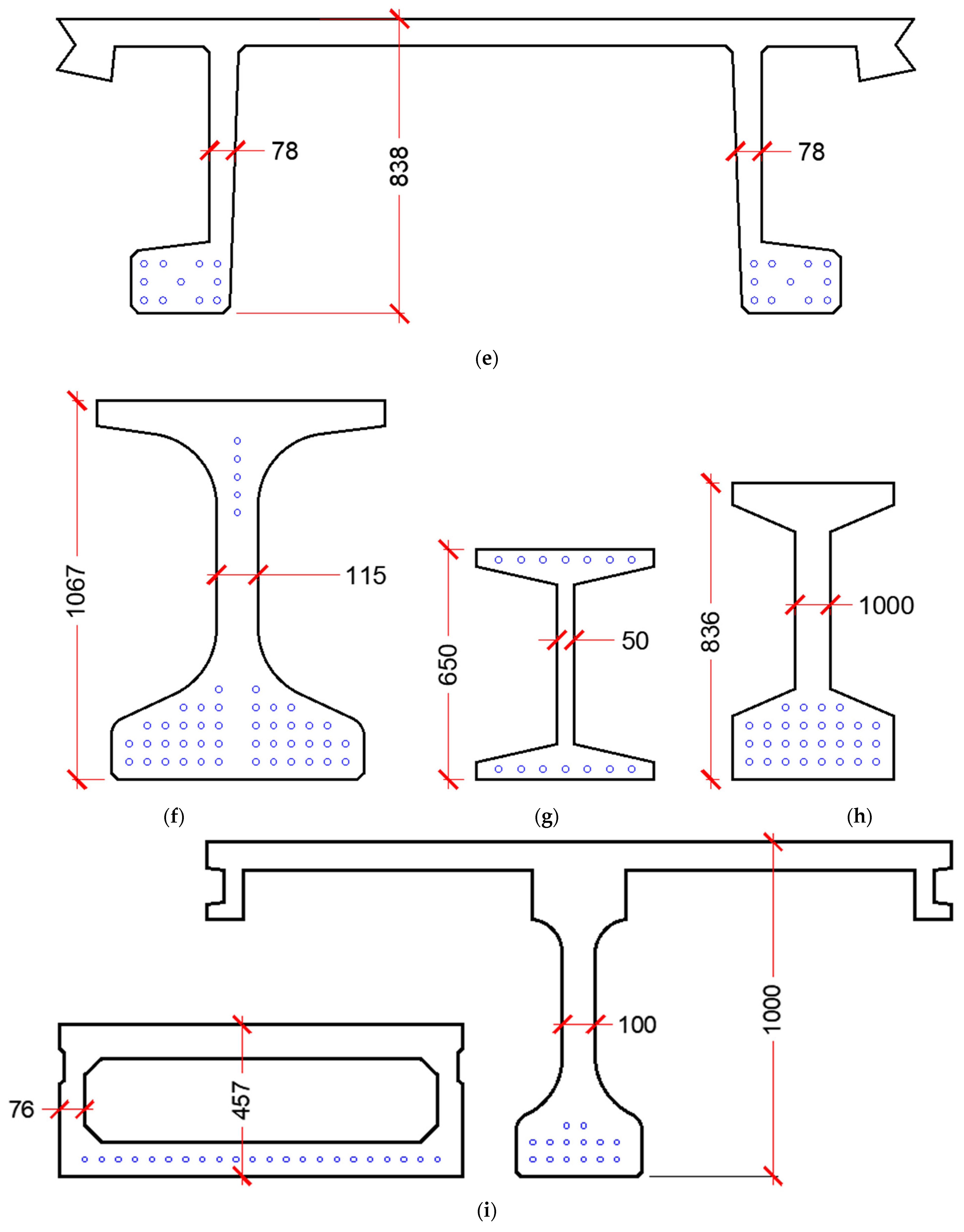

| Graybeal, 2009 [28] | P 2-21S | Pi-girders | 170 | 750 | 838 | 2.0 | 2.9 | 1.73% | 6.2 | 229 | 13 | 0.20 | 11.4 | 32 | 1912.6 | 15.2 |

| P4-57SH | 2.4 | 10.6 | 35 | 1628.0 | 13.1 | |||||||||||

| Wipf et al., 2009 [29] | 1 | I-beams | 115 | 927 | 1067 | 2.0 | 2.5 | 5.6% | 21.4 | 153 | 13 | 0.20 | 11.7 | 25 | 2642.1 | 24.8 |

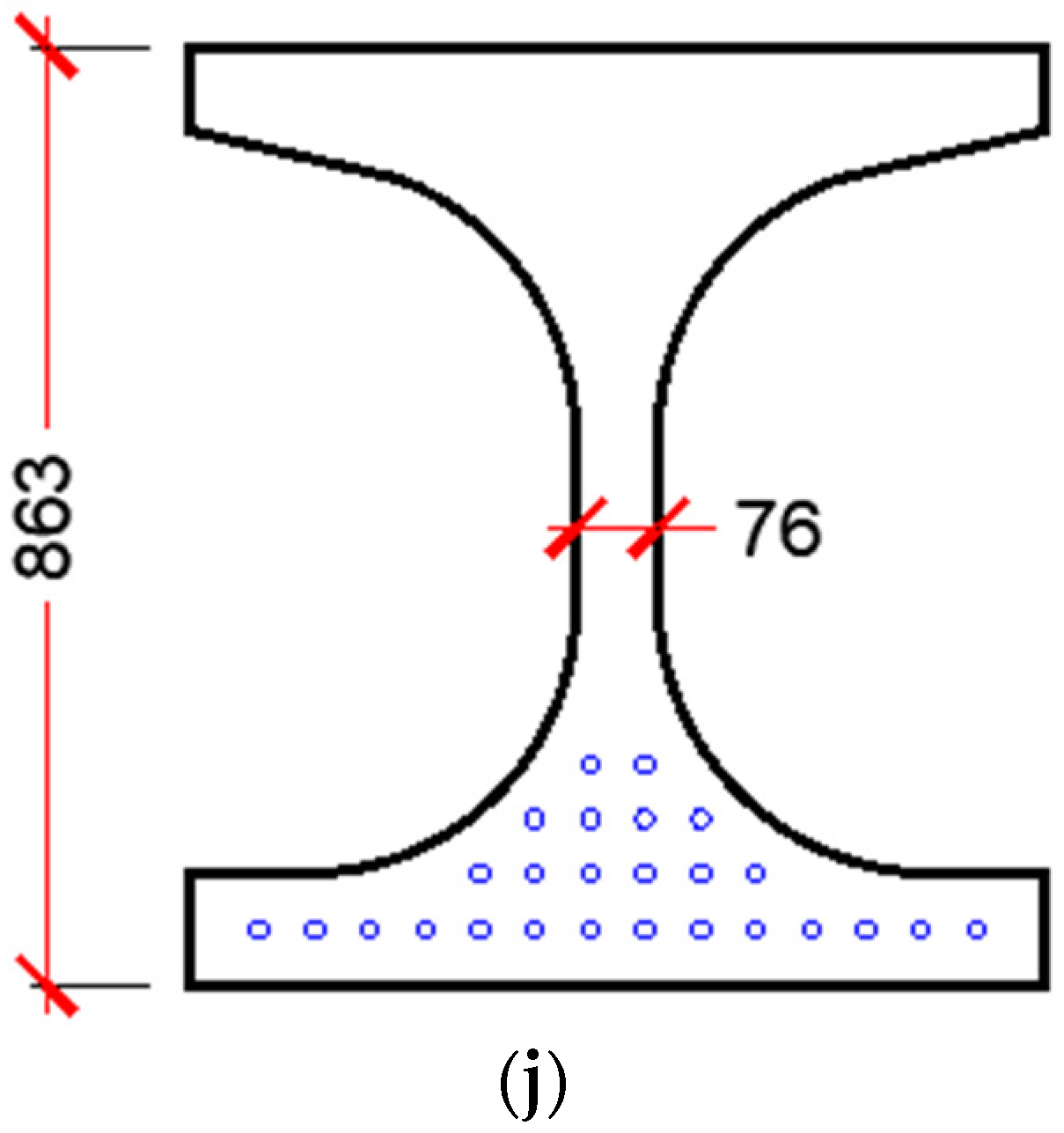

| Baby et al., 2010 [31] | Beam 1-A | I-beams | 65 | 305 | 380 | 2.5 | 2.5 | 4.10% | 17.2 | 185 | 20 | 0.30 | 12.0 | 30 | 441.2 | 22.1 |

| Beam 1-A-bis | 192 | 12.0 | 30 | 440.4 | 22.1 | |||||||||||

| Beam 1-B | 2.0 | 201 | 13 | 0.20 | 12.0 | 30 | 515.5 | 26.2 | ||||||||

| Voo et al., 2010 [30] | X-B1 | I-beams with Symmetric Prestressing | 50 | 620 | 650 | 1.0 | 3.2 | 2.60% | 15.2 | 125 | 15 | 0.20 | 4.4 | 26 | 330.0 | 10.4 |

| X-B2 | 126 | 5.3 | 24 | 355.0 | 11.0 | |||||||||||

| X-B3 | 135 | 4.6 | 22 | 362.1 | 11.7 | |||||||||||

| X-B4 | 2.5 | 122 | 4.6 | 26 | 455.5 | 14.5 | ||||||||||

| X-B5 | 3.5 | 140 | 6.6 | 24 | 422.6 | 13.1 | ||||||||||

| X-B6 | 4.5 | 140 | 6.6 | 24 | 390.5 | 12.4 | ||||||||||

| X-B7 | 1.5 | 2.5 | 122 | 7.8 | 29 | 521.3 | 16.6 | |||||||||

| Crane, 2010 [15] | 1-2 | Bulb-Tee Girders | 101 | 720 | 835 | 2.0 | 3.4 | 3.90% | 16.5 | 200 | 13 | 0.20 | 11.0 | 26 | 1917.1 | 26.9 |

| 2-1 | 23 | 2072.8 | 29.0 | |||||||||||||

| 3-1 | 25 | 1877.1 | 26.2 | |||||||||||||

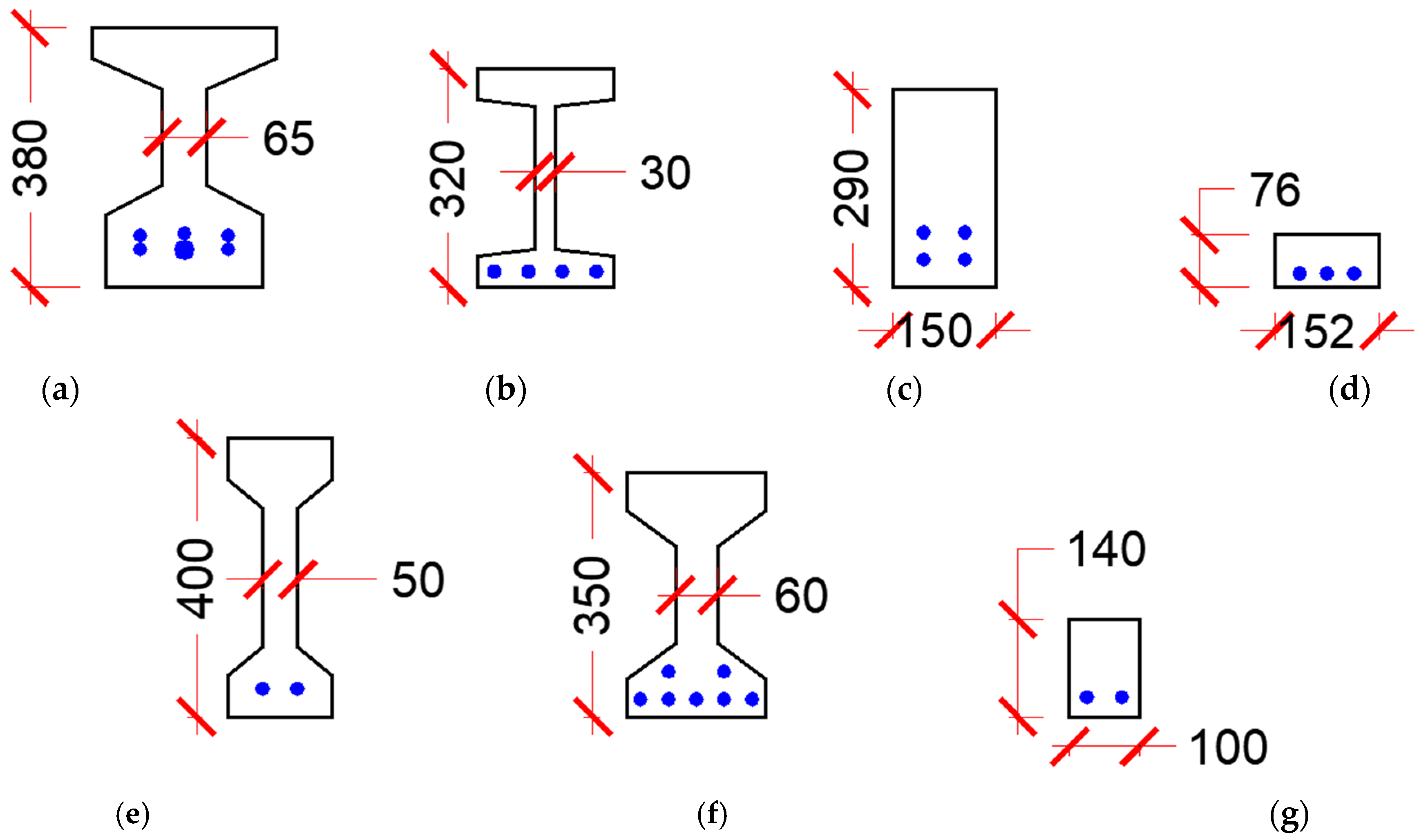

| Tadros et al., 2021 [8] | IA1 | I-beams | 76.2 | 734.0 | 863.6 | 2% | 2.9 | 6.5% | 18.0 | 154.6 | 13 | 0.20 | 11.0 | 26.8 | 1596.9 | 28.3 |

| IA2 | 120.1 | 6.9 | 30.8 | 1383.4 | 24.8 | |||||||||||

| IA3 | 126.3 | 6.9 | 28.3 | 1370.0 | 24.8 | |||||||||||

| IA8 | 125.6 | 8.3 | 28.0 | 1596.9 | 28.3 | |||||||||||

| IA13 | 50.8 | 9.8% | 19.3 | 126.3 | 7.6 | 32.0 | 1049.8 | 28.3 | ||||||||

| IA14 | 101.6 | 4.9% | 16.9 | 126.3 | 6.9 | 28.0 | 1823.8 | 24.2 | ||||||||

| DIB—Test 1 | Decked I-Beam | 100 | 924.0 | 1000 | 2.7 | 2.2% | 6.4 | 138.0 | 10.4 | 28.0 | 1579.1 | 17.3 | ||||

| BX-1 | Box Section | 152.4 | 406.4 | 457.2 | 2.8 | 3.5% | 9.8 | 136.6 | 8.3 | 25.0 | 1214.4 | 19.3 | ||||

| BX-2 | 1138.7 | 18.4 | ||||||||||||||

| Maximum | 170 | 927 | 1067 | 2.5 | 5.4 | 9.80% | 26.9 | 229 | 30 | 0.50 | 12.1 | 40 | 2642.1 | 29.0 | ||

| Minimum | 50 | 250 | 300 | 0.9 | 2.3 | 1.73% | 6.2 | 122 | 9 | 0.15 | 4.4 | 22 | 234 | 10.4 |

| Reference | Specimen ID | Specimen Shape | bw (mm) | d (mm) | h (mm) | % | a/d | (MPa) | lf (mm) | Φf (mm) | (MPa) | Vu (kN) | (MPa) | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Voo et al., 2006 [23] | SB1 | I-beams | 50 | 600 | 650 | 2.5 | 3.3 | 2.70% | 161 | 13(Type I) 30 (Type II) | 0.20 (Type I) 0.50 (Type II) | 11.0 | 37 | 430.1 | 13.8 |

| Baby et al., 2010 [31] | Beam 3-A | I-beams | 65 | 305 | 380 | 2.5 | 2.5 | 4.80% | 185 | 20 | 0.30 | 12.0 | 30 | 461.3 | 23.5 |

| Beam 3-B | 2.0 | 2.5 | 4.80% | 201 | 13 | 0.20 | 12.0 | 30 | 455.0 | 22.8 | |||||

| Fehling et al., 2012 [33] | Q-F1-2 | Shear span was I-shaped | 30 | 295 | 320 | 1.0 | 4.1 | 6.60% | 201 | 13 | 0.18 | 8.7 | 30 | 108.1 | 12.4 |

| Q-F1-3 | 207 | 8.7 | 30 | 108.1 | 12.4 | ||||||||||

| Q2-F1-1 | 185 | 8.7 | 30 | 100.1 | 11.0 | ||||||||||

| Lim et al., 2016 [26] | SB1 | Rectangular Beams | 150 | 240 | 290 | 1.5 | 2.8 | 7.30% | 167 | 16 and 19 | 0.20 | 9.6 | 27 | 475.9 | 13.1 |

| Pourbaba et al., 2018 [34] | B35 | Rectangular Beams | 152 | 56 | 76 | 1.5 | 2.7 | 5.60% | 125 | 13 | 0.18 | 9.4 | 32 | 105.9 | 12.4 |

| B36 | 4.00% | 9.4 | 32 | 85.0 | 9.7 | ||||||||||

| B37 | 2.70% | 9.4 | 32 | 71.2 | 8.3 | ||||||||||

| Pansuk et al., 2017 [36] | NS08 | I-beams | 50 | 350 | 400 | 0.8 | 2.9 | 5.50% | 141 | 13 | 0.20 | 11.0 | 30 | 339.8 | 19.3 |

| NS16 | 1.6 | 140 | 17.0 | 38 | 531.1 | 30.4 | |||||||||

| Meszoly et al., 2018 [37] | B19 | I-beams | 60 | 295 | 350 | 2.0 | 3.7 | 5.06% | 152 | 15 | 0.20 | 11.0 | 30 | 396.8 | 22.8 |

| B20 | 1.0 | 154 | 6.8 | 29 | 419.0 | 23.5 | |||||||||

| B24 | 166 | 6.8 | 34 | 314.9 | 17.9 | ||||||||||

| B25 | 2.0 | 179 | 11.0 | 33 | 504.8 | 28.3 | |||||||||

| B29 | 177 | 6.8 | 31 | 487.1 | 27.6 | ||||||||||

| B30 | 2.0 | 169 | 11.0 | 36 | 564.9 | 31.7 | |||||||||

| Ridha et al., 2018 [38] | B5 | Rectangular Beams | 100 | 112 | 140 | 2.0 | 3.5 | 2.90% | 110 | 13 | 0.20 | 7.0 | 32 | 82.3 | 7.6 |

| B6 | 7.0 | 32 | 107.6 | 9.7 | |||||||||||

| B7 | 7.0 | 32 | 112.5 | 10.4 | |||||||||||

| B10 | 2.5 | 7.0 | 32 | 125 | 11.0 | ||||||||||

| B11 | 3.0 | 7.0 | 32 | 97.4 | 9.0 | ||||||||||

| B16 | 3.5 | 125 | 7.3 | 32 | 93.9 | 8.3 | |||||||||

| B17 | 142 | 7.6 | 35 | 101.0 | 9.0 | ||||||||||

| B18 | 151 | 7.8 | 35 | 109.9 | 9.7 | ||||||||||

| Maximum | 152 | 600 | 650 | 2.5 | 4.1 | 7.30% | 207 | 30 | 0.50 | 17.0 | 38 | 564.9 | 30.4 | ||

| Minimum | 30 | 56 | 76 | 0.8 | 2.5 | 2.70% | 110 | 9 | 0.15 | 6.8 | 27 | 71.2 | 7.6 |

References

- Kodsy, A.M. Repair and Strengthening of Concrete Bridges Using Ultra-High-Performance Concrete (UHPC). Ph.D. Thesis, The University of Nebraska-Lincoln, Lincoln, NE, USA, 2022. [Google Scholar]

- Wang, C.; Xiao, J.; Liu, W.; Ma, Z. Unloading and reloading stress-strain relationship of recycled aggregate concrete reinforced with steel/polypropylene fibers under uniaxial low-cycle loadings. Cem. Concr. Compos. 2022, 131, 104597. [Google Scholar] [CrossRef]

- Graybeal, B.A. Material Property Characterization of Ultra-High Performance Concrete; Publication No. FHWA-HRT-06-United States; Federal Highway Administration, Office of Infrastructure Research and Development: Washington, DC, USA, 2006. [Google Scholar]

- Florent, B.; Marchand, P.; Toutlemonde, F. Shear behavior of ultrahigh performance fiber-reinforced concrete beams. I: Experimental investigation. J. Struct. Eng. 2013, 140, 04013111. [Google Scholar]

- Lucie, V. Recommendations of RILEM TC 162-TDF: Test and design methods for steel fibre reinforced concrete. Mater. Struct./Mater. Constr. 2000, 33, 3–5. [Google Scholar]

- International Federation for Structural Concrete CEB-fib. CEB-FIP Model Code 2010, Final Draft; International Federation for Structural Concrete CEB-fib: Lausanne, Switzerland, 2012; Volume 1. [Google Scholar]

- NF P 18-710; National Addition to Eurocode 2—Design of Concrete Structures: Specific Rules for Ultra-High Performance Fibre-Reinforced Concrete (UHPFRC). French Standard: Metropolitan, French, 2016.

- Tadros, M.; Lawler, J.; Abo El-Khier, M.; Gee, D.; Kurt, A.; Lucier, G.; Wagner, E. Implementation of Ultra-High Performance Concrete in Long-Span Precast Pretensioned Elements for Concrete Buildings and Bridges; Phase II Report; Precast/Prestressed Concrete Institute: Chicago, CA, USA, 2021. [Google Scholar] [CrossRef]

- American Association of State Highway and Transportation Officials. Structural Design with Ultra-High Performance Concrete. In AASHTO Guide Specification; Document developed for consideration by AASHTO CBS T-10 committee (Structural Concrete Design), Draft; American Association of State Highway and Transportation Officials: Washington, DC, USA, 2021. [Google Scholar]

- ENV 1992-1-1; Eurocode 2: Design of Concrete Structures—Part 1: General Rules and Rules for Buildings. European Pre-Standard: Brussels, Belgium, 1991.

- Vandewalle, L. Design method for steel fiber reinforced concrete proposed by RILEM TC 162-TDF. In Proceedings of the Fifth International RILEM Symposium on Fibre-Reinforced Concrete (FRC), Lyon, France, 13–15 September 2000; RILEM Publications SARL: Reykjavik, Iceland, 2000; pp. 51–64. [Google Scholar]

- 14651; Test Method for Metallic Fibre Concrete-Measuring the Flexural Tensile Strength (Limit of Proportionality (LOP), Residual). EN, BS: London, UK, 2007; pp. 1–20.

- AFGC (Association Francaise de Génie Civil). Ultra High Performance Fibre-Reinforced Concretes, Recommendations; AFGC Publication: Paris, France, 2013. [Google Scholar]

- AASHTO LRFD. Bridge Design Specifications, 8th ed.; American Association of State Highway and Transportation Officials: Washington, DC, USA, 2017. [Google Scholar]

- Crane, C.K. Shear and Shear Friction of Ultra-High Performance Concrete Bridge Girders; Georgia Institute of Technology: Atlanta, GA, USA, 2010. [Google Scholar]

- Degen, B.E. Shear Design and Behavior of Ultra-High Performance Concrete. Master’s Thesis, Iowa State University, Ames, IA, USA, 2006. [Google Scholar]

- ASTM C1609/C1609M-19; Standard Test Method for Flexural Performance of Fiber-Reinforced Concrete (Using Beam with Third-Point Loading). ASTM International: West Conshohocken, PA, USA, 2019. Available online: www.astm.org (accessed on 30 May 2021).

- Ultra-High Performance Concrete. DAfStb-Guideline; Draft; German Committee for Structural Concrete: Berlin, Germany, 2017. [Google Scholar]

- SIA 2052; Standard: Ultra-High Performance Fibre Reinforced Cement-Based Composites (UHPFRC) Construction Material, Dimensioning and Application. EPFL-Swiss Federal Institute of Technology: Vaud, Switzerland, 2016.

- El-Helou, R.G.; Graybeal, B.A. The ultra girder: A design concept for a 300-foot single span prestressed ultra-high performance concrete bridge girder. In International Interactive Symposium on Ultra-High Performance Concrete; Iowa State University Digital Press: Ames, IA, USA, 2019; Volume 2. [Google Scholar]

- Graybeal, B.A. Flexural behavior of an ultra high-performance concrete I-girder. J. Bridge Eng. 2008, 13, 602–610. [Google Scholar] [CrossRef]

- Kodsy, A.; Morcous, G. Flexural strength prediction models of non-prestressed Ultra-High Performance Concrete (UHPC) components. Structures 2021, 34, 4532–4547. [Google Scholar] [CrossRef]

- Voo, Y.L.; Foster, S.J.; Gilbert, R.I. Shear Strength of Fiber Reinforced Reactive Powder Concrete Prestressed Girders without Stirrups. J. Adv. Concr. Technol. 2006, 4, 123–132. [Google Scholar] [CrossRef] [Green Version]

- Josef, H.; Tuchlinski, D.; Kommer, B. Bond anchorage behavior and shear capacity of ultra high performance concrete beams. In Proceedings of the International Symposium on Ultra High Performance Concrete, Kassel, Germany, 13–15 September 2004. [Google Scholar]

- Hegger, J.; Bertram, G. Shear carrying capacity of Ultra-High Performance Concrete beams. In Proceedings of the International FIB Symposium 2008—Tailor Made Concrete Structures: New Solutions for Our Society, 96, Amsterdam, The Netherlands, 7 May 2008. [Google Scholar]

- Lim, W.-Y.; Hong, S.-G. Shear Tests for Ultra-High Performance Fiber Reinforced Concrete (UHPFRC) Beams with Shear Reinforcement. Int. J. Concr. Struct. Mater. 2016, 10, 177–188. [Google Scholar] [CrossRef] [Green Version]

- Graybeal, B.A. Structural Behavior of Ultra-High Performance Concrete Prestressed I-Girders; Publication No. FHWA-HRT-06-United States; Federal Highway Administration, Office of Infrastructure Research and Development: Washington, DC, USA, 2006. [Google Scholar]

- Graybeal, B.A. Structural Behavior of a Prototype UHPC Pi-Girder. In TechBrief FHWA; Turner-Fairbank Highway Research Center: McLean, VA, USA, 6 November 2009; pp. 1–4. [Google Scholar] [CrossRef]

- Wipf, T.; Phares, B.; Sritharan, S.; Degen, B.; Giesmann, M.T. Design and Evaluation of a Single-Span Bridge Using Ultra-High Performance Concrete; Institute for Transportation, Iowa State University: Ames, IA, USA, 2009. [Google Scholar]

- Voo, Y.L.; Poon, W.K.; Foster, S.J. Shear Strength of Steel Fiber-Reinforced Ultrahigh-Performance Concrete Beams without Stirrups. J. Struct. Eng. 2010, 136, 1393–1400. [Google Scholar] [CrossRef]

- Baby, F.; Marchand, P.; Toutlemonde, F.; Billo, J.; Simon, A. Shear resistance of ultra high performance fibre-reinforced concrete I-beams. In Fracture Mechanics of Concrete and Concrete Structures-High Performance, Fiber Reinforced Concrete, Special Loadings and Structural Application; Korea Concrete Institute: Seoul, Korea, 2010; pp. 1411–1417. [Google Scholar]

- Baby, F.; Marchand, P.; Toutlemonde, F. Shear behavior of ultrahigh performance fiber-reinforced concrete beams. II: Analysis and design provisions. J. Struct. Eng. 2013, 140, 04013112. [Google Scholar] [CrossRef]

- Fehling, E.; Thiemicke, J. Experimental investigations on I-Shaped UHPC-Beams with combined reinforcement under shear load. In Ultra High Performance Concrete and Nanotechnology in Construction, 3rd Intl. Symp. on Ultra High Performance Concrete and Nanotechnology for High Performance Construction Materials; Kassel University Press GmbH: Kassel, Germany, 2012. [Google Scholar]

- Pourbaba, M.; Joghataie, A.; Mirmiran, A. Shear behavior of ultra-high performance concrete. Constr. Build. Mater. 2018, 183, 554–564. [Google Scholar] [CrossRef]

- Pourbaba, M.; Joghataie, A. Determining Shear Capacity of Ultra-high Performance Concrete Beams by Experiments and Comparison with Codes. Sci. Iran. 2019, 26, 273–282. [Google Scholar] [CrossRef] [Green Version]

- Pansuk, W.; Nguyen, T.N.; Sato, Y.; Uijl, J.D.; Walraven, J. Shear capacity of high performance fiber reinforced concrete I-beams. Constr. Build. Mater. 2017, 157, 182–193. [Google Scholar] [CrossRef]

- Mészöly, T.; Randl, N. Shear behavior of fiber-reinforced ultra-high performance concrete beams. Eng. Struct. 2018, 168, 119–127. [Google Scholar] [CrossRef]

- Ridha, M.M.S.; Al-Shaarbaf, I.A.S.; Sarsam, K.F. Experimental study on shear resistance of reactive powder concrete beams without stirrups. Mech. Adv. Mater. Struct. 2018, 27, 1006–1018. [Google Scholar] [CrossRef]

- Haber, Z.B.; De la Varga, I.; Graybeal, B.A.; Nakashoji, B.; El-Helou, R. Properties and Behavior of UHPC-Class Materials (No. FHWA-HRT-18-036); Federal Highway Administration, Office of Infrastructure Research and Development: Washington, DC, USA, 2018. [Google Scholar]

- Prem, P.R.; Bharatkumar, B.H.; Iyer, N.R. Mechanical properties of ultra high performance concrete. World Acad. Sci. Eng. Technol. 2012, 68, 1969–1978. [Google Scholar]

- Yang, I.H.; Joh, C.; Kim, B.-S. Structural behavior of ultra high performance concrete beams subjected to bending. Eng. Struct. 2010, 32, 3478–3487. [Google Scholar] [CrossRef]

- Zagon, R.; Matthys, S.; Kiss, Z. Shear behaviour of SFR-UHPC I-shaped beams. Constr. Build. Mater. 2016, 124, 258–268. [Google Scholar] [CrossRef]

| Reference | Fiber Volume | Fiber Length (lf) (mm) | Fiber Diameter (Φf) (mm) | Cylinder Compressive Strength | Prism Cross Section (b × h) (mm2) | Notch Height (mm) | Span (mm) | Residual Flexural Tensile Strengths | |||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Prem et al., 2012 [40] (R1 Mix) | 2.5% | 13 | × | 180.0 | 70 × 70 | 21.0 | 300 | 45.5 | 49.6 | 42.7 | 40.0 |

| Prem et al., 2012 [40] (R2 Mix) | 2% | 13 | 0.15 | 170.0 | 70 × 70 | 21.0 | 300 | 37.2 | 40.0 | 37.2 | 34.5 |

| Yang et al., 2010 [41] (average) | 2% | 13 | 0.2 | 190.9 | 100 × 100 | 10.0 | 300 | 26.9 | 30.3 | 27.6 | 24.8 |

| Graybeal, 2006 [3] (M2P02) | 2% | 13 | 0.2 | 126.2 | 50 × 100 | 25.4 | 406 | 22.1 | 20.7 | -- | -- |

| Zagon et al., 2016 [42] (average) | 1% | 10 | 0.18 | 141.3 | 100 × 100 | 27.0 | 400 | 11.7 | 6.2 | 4.1 | 2.8 |

| Prediction Model | Standard Deviation | |

|---|---|---|

| RILEM TC 162-TDF, 2003 [5] | 2.7 | 0.88 |

| fib Model Code, 2010 [6] | 2.4 | 0.75 |

| French Standard NF P 18-710, 2016 [7] | 1.1 | 0.38 |

| PCI-UHPC Structures Design Guide, 2021 [8] | 2.5 | 1.15 |

| Draft of AASHTO Guide Specification for Structural Design with UHPC, 2021 [9]—Case (a) | 1.6 | 0.60 |

| Draft of AASHTO Guide Specification for Structural Design with UHPC, 2021 [9]—Case (b) | 1.5 | 0.63 |

| Draft of AASHTO Guide Specification for Structural Design with UHPC, 2021 [9]—Case (c) | 1.3 | 0.64 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kodsy, A.; Morcous, G. Shear Strength of Ultra-High-Performance Concrete (UHPC) Beams without Transverse Reinforcement: Prediction Models and Test Data. Materials 2022, 15, 4794. https://doi.org/10.3390/ma15144794

Kodsy A, Morcous G. Shear Strength of Ultra-High-Performance Concrete (UHPC) Beams without Transverse Reinforcement: Prediction Models and Test Data. Materials. 2022; 15(14):4794. https://doi.org/10.3390/ma15144794

Chicago/Turabian StyleKodsy, Antony, and George Morcous. 2022. "Shear Strength of Ultra-High-Performance Concrete (UHPC) Beams without Transverse Reinforcement: Prediction Models and Test Data" Materials 15, no. 14: 4794. https://doi.org/10.3390/ma15144794

APA StyleKodsy, A., & Morcous, G. (2022). Shear Strength of Ultra-High-Performance Concrete (UHPC) Beams without Transverse Reinforcement: Prediction Models and Test Data. Materials, 15(14), 4794. https://doi.org/10.3390/ma15144794