Improving Numerical Modeling Accuracy for Fiber Orientation and Mechanical Properties of Injection Molded Glass Fiber Reinforced Thermoplastics

Abstract

:1. Introduction

2. Theoretical Background

2.1. Fiber Orientation Models

2.2. Nonlinear Anisotropic Structural Model

- the reinforcing fibers exhibit a linear elastic response without any fracture;

- the polymeric matrix exhibits both plasticity and fracture;

- the matrix plasticity and fracture account for any fiber debonding;

- all nonlinearity exhibited by the composite material is due to the polymeric matrix nonlinearity;

- plasticity and fracture of the polymeric matrix are driven by stress in the matrix instead of homogenized stress in the composite;

- the plasticity and fracture of the polymeric matrix strongly depend on the orientation of the reinforcing fibers, and this dependence increases with the degree of fiber alignment.

3. Materials and Methods

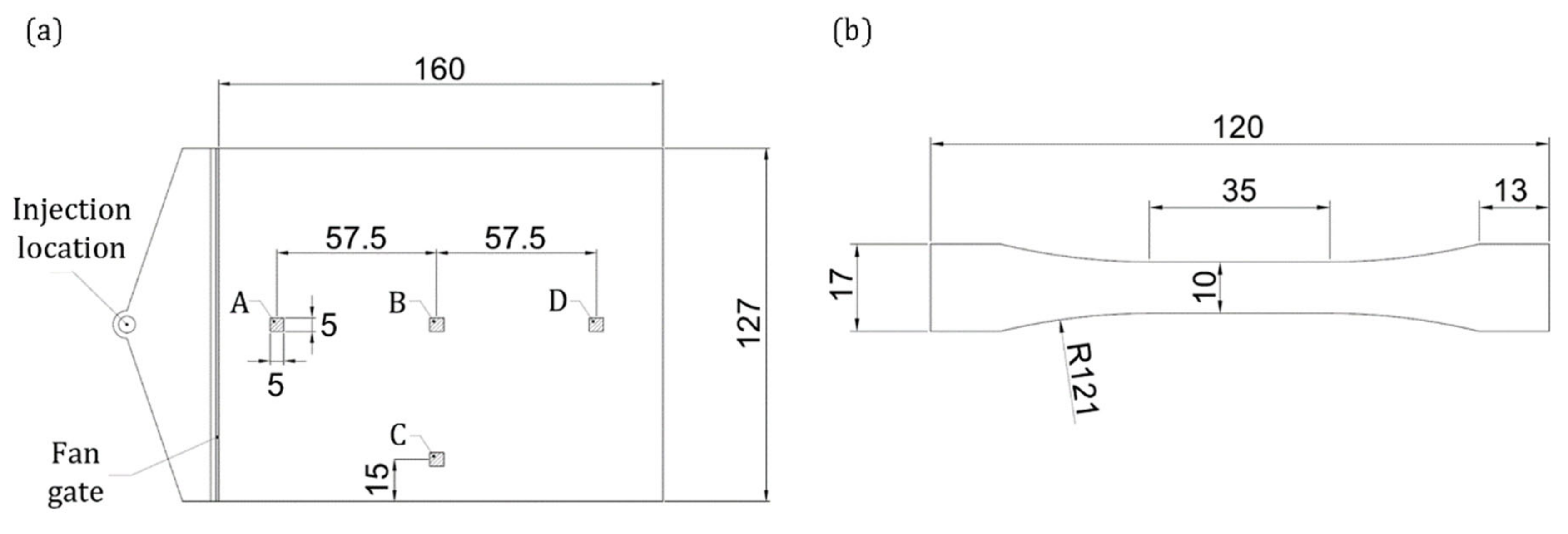

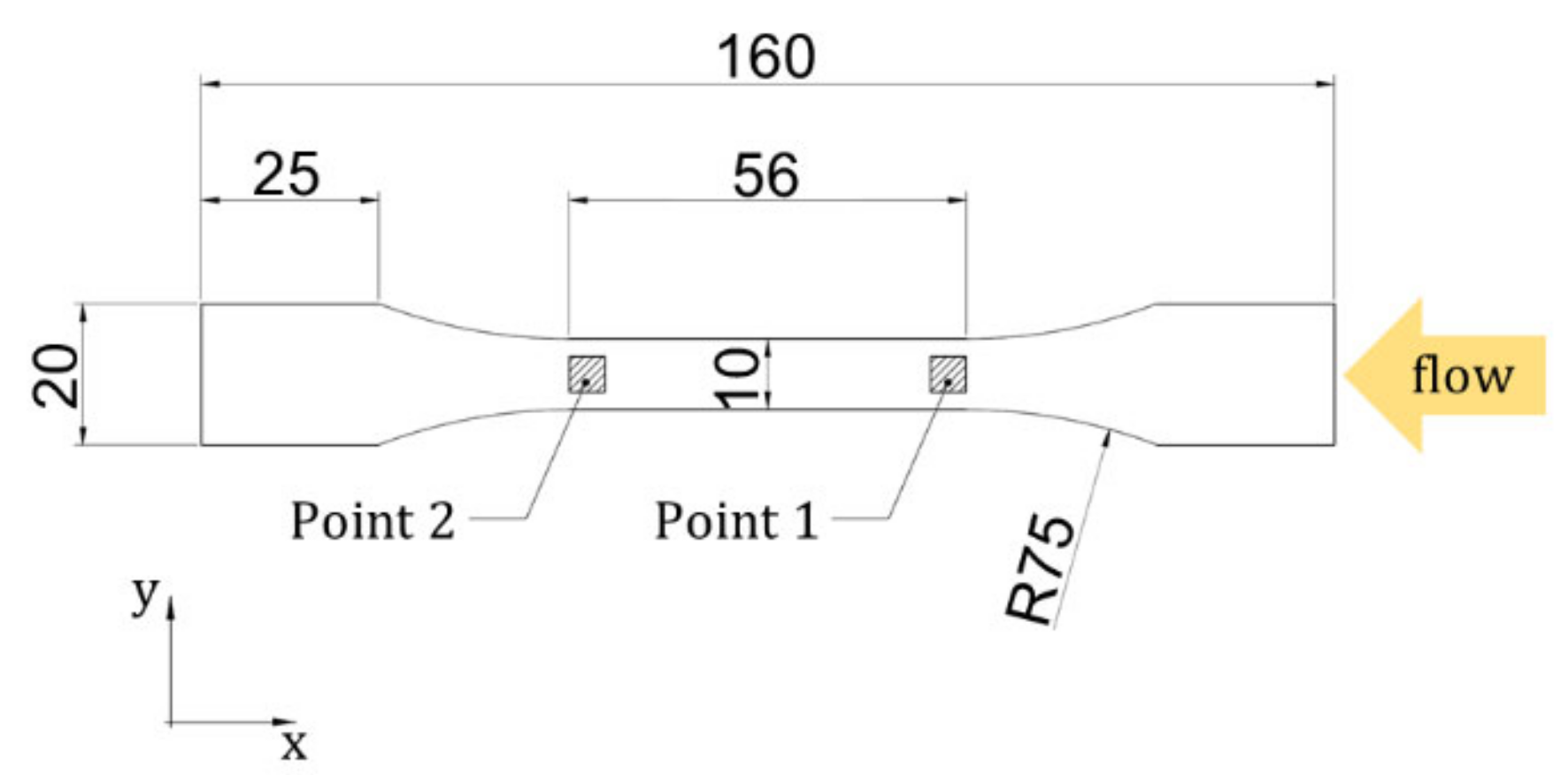

3.1. Material and Plate Design

3.2. Numerical Simulation of the Plate Molding

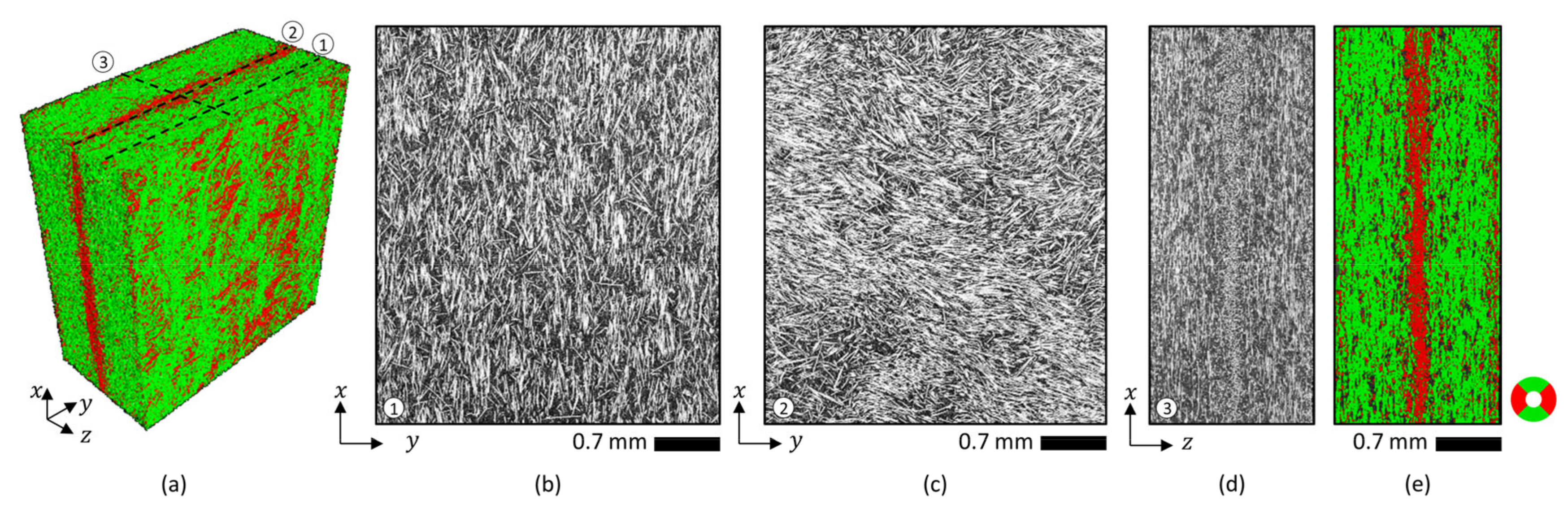

3.3. FOD Measurements

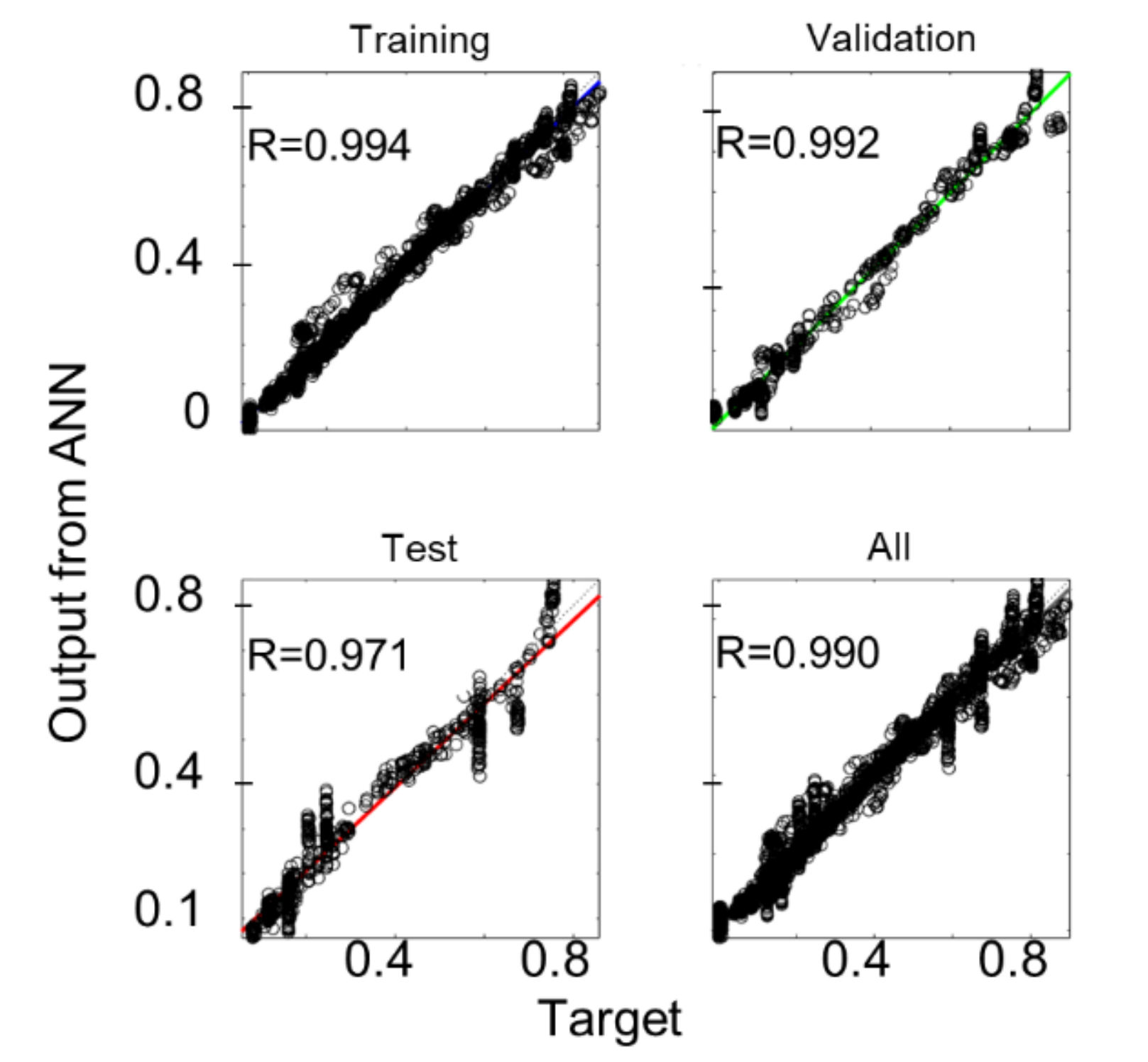

3.4. Optimization of the FOD Prediction

3.5. Identification of the Ramberg–Osgood Model Parameters

- The elastic modulus and Poisson ratio values for the polymeric matrix and the glass fibers were determined by requiring the model to accurately fit the initial elastic responses of the 0°, 90°, and 45° tensile test specimens.

- The four plastic coefficients, σ0, n, α, and β, and the effective strength, Seff, were then determined by fitting the model to the complete stress-strain curve for all three tensile tests.

3.6. Validation

4. Results and Discussion

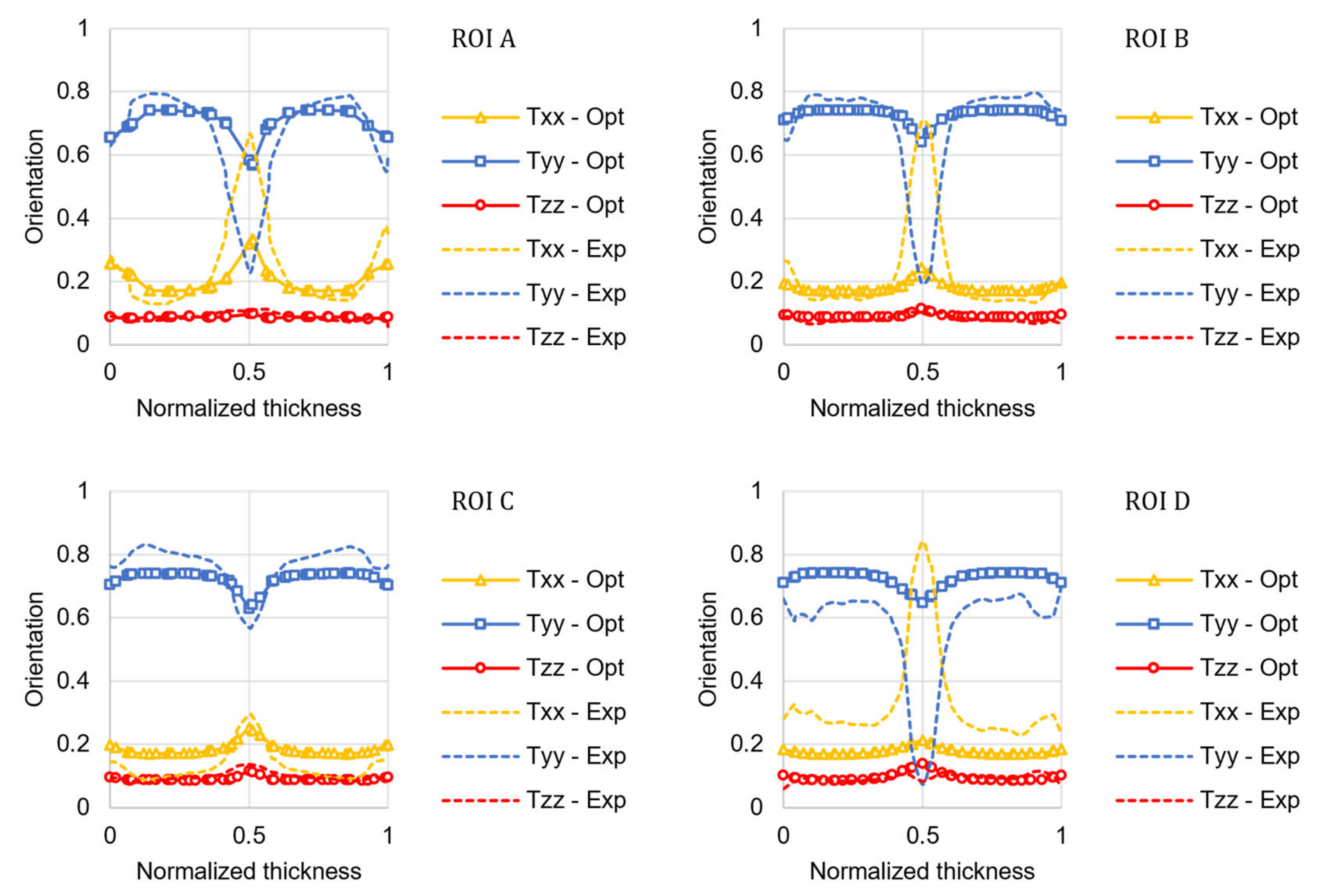

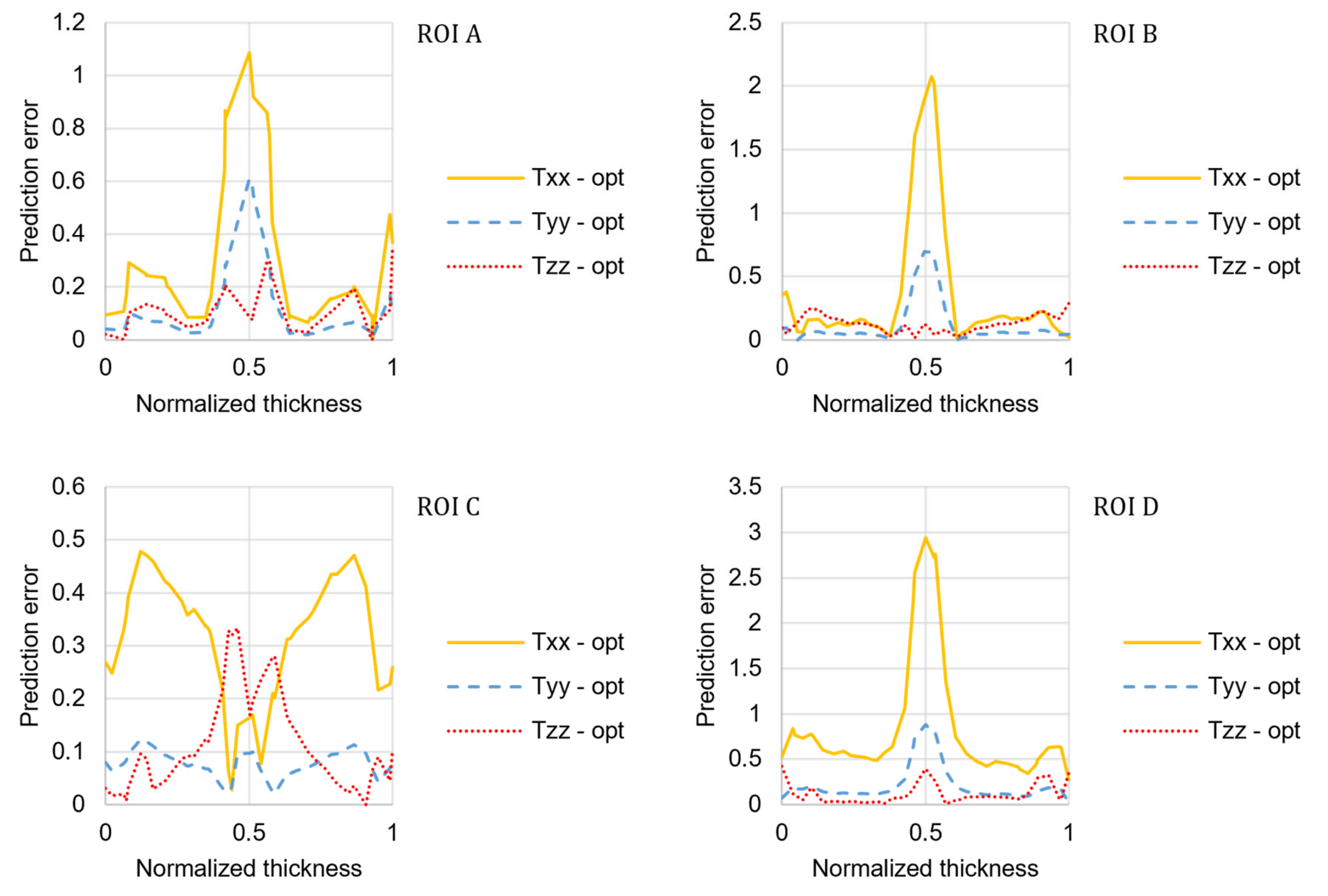

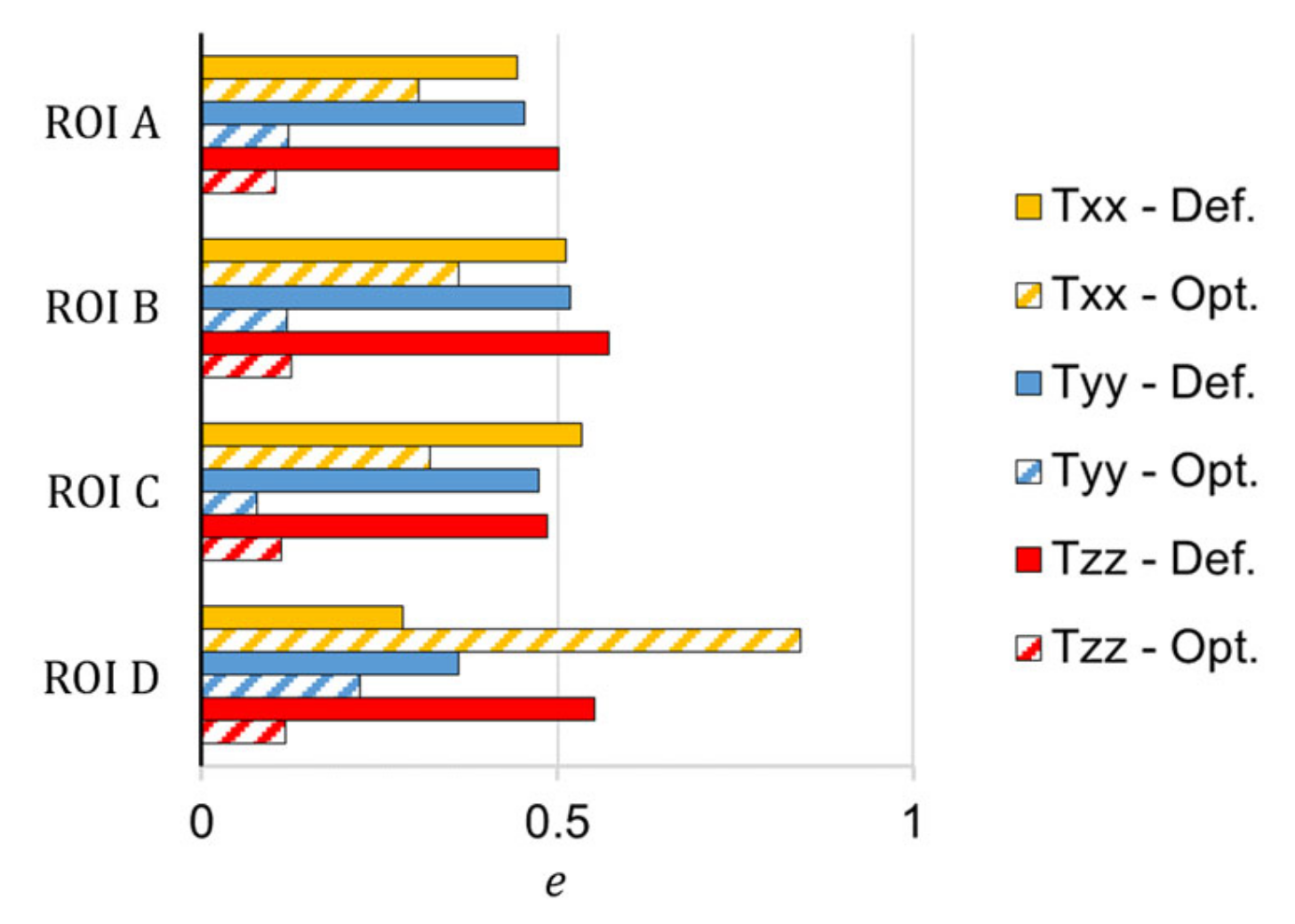

4.1. Optimization of the RSC Model Coefficients

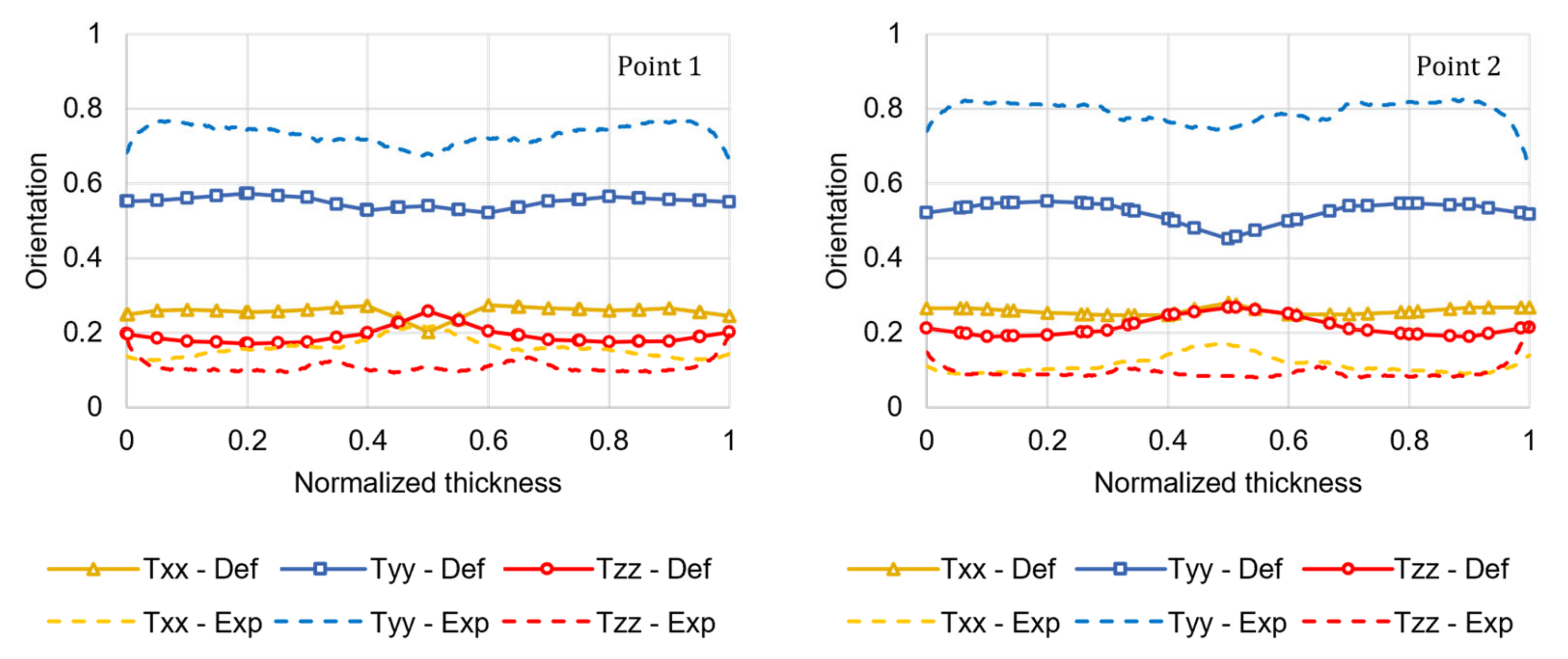

4.2. Properties Prediction for the Injection-Molded Tensile Specimen

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Fiorotto, M.; Lucchetta, G. Experimental Investigation of a New Hybrid Molding Process to Manufacture High-Performance Composites. Int. J. Mater. Form. 2013, 6, 179–185. [Google Scholar] [CrossRef]

- Mortazavian, S.; Fatemi, A. Effects of Fiber Orientation and Anisotropy on Tensile Strength and Elastic Modulus of Short Fiber Reinforced Polymer Composites. Compos. Part B Eng. 2015, 72, 116–129. [Google Scholar] [CrossRef]

- Jeffery, G.B. The Motion of Ellipsoidal Particles Immersed in a Viscous Fluid. Proc. R. Soc. Lond. Ser. A Contain. Pap. A Math. Phys. Character 1922, 102, 161–179. [Google Scholar]

- Advani, S.G.; Tucker, C.L., III. The Use of Tensors to Describe and Predict Fiber Orientation in Short Fiber Composites. J. Rheol. 2000, 31, 751–784. [Google Scholar] [CrossRef]

- Wang, J.; O’Gara, J.F.; Tucker, C.L. An Objective Model for Slow Orientation Kinetics in Concentrated Fiber Suspensions: Theory and Rheological Evidence. J. Rheol. 2008, 52, 1179–1200. [Google Scholar] [CrossRef]

- Kugler, S.K.; Lambert, G.M.; Cruz, C.; Kech, A.; Osswald, T.A.; Baird, D.G. Macroscopic Fiber Orientation Model Evaluation for Concentrated Short Fiber Reinforced Polymers in Comparison to Experimental Data. Polym. Compos. 2020, 41, 2542–2556. [Google Scholar] [CrossRef]

- Folgar, F.; Tucker, C.L. Orientation Behavior of Fibers in Concentrated Suspensions. J. Reinf. Plast. Compos. 1984, 3, 98–119. [Google Scholar] [CrossRef]

- Eberle, A.P.R.; Vélez-García, G.M.; Baird, D.G.; Wapperom, P. Fiber Orientation Kinetics of a Concentrated Short Glass Fiber Suspension in Startup of Simple Shear Flow. J. Non-Newton. Fluid Mech. 2010, 165, 110–119. [Google Scholar] [CrossRef]

- Perumal, V.; Gupta, R.K.; Bhattacharya, S.N.; Costa, F.S. Fiber Orientation Prediction in Nylon-6 Glass Fiber Composites Using Transient Rheology and 3-dimensional X-ray Computed Tomography. Polym. Compos. 2019, 40, E392–E398. [Google Scholar] [CrossRef]

- Cieslinski, M.J.; Wapperom, P.; Baird, D.G. Fiber Orientation Evolution in Simple Shear Flow from a Repeatable Initial Fiber Orientation. J. Non-Newton. Fluid Mech. 2016, 237, 65–75. [Google Scholar] [CrossRef]

- Morak, M.; Tscharnuter, D.; Lucyshyn, T.; Hahn, W.; Göttlinger, M.; Kummer, M.; Steinberger, R.; Gross, T. Optimization of Fiber Prediction Model Coefficients in Injection Molding Simulation Based on Micro Computed Tomography. Polym. Eng. Sci. 2019, 59, E152–E160. [Google Scholar] [CrossRef]

- Li, T.; Luyé, J.-F. Optimization of Fiber Orientation Model Parameters in the Presence of Flow-Fiber Coupling. J. Compos. Sci. 2018, 2, 73. [Google Scholar] [CrossRef] [Green Version]

- Cintra, J.S.; Tucker, C.L. Orthotropic Closure Approximations for Flow-induced Fiber Orientation. J. Rheol. 1995, 39, 1095–1122. [Google Scholar] [CrossRef]

- Kenik, D.; Robbins, D.; Morrison, A.; Gies, J. Bridging The Gap: As-Manufactured Structural Simulation Of Injection Molded Plastics. In Proceedings of the Society of Plastics Engineers, Automotive Composites Conference, Novi, MI, USA, 9–11 September 2015. [Google Scholar]

- Yang, Q.-S.; Qin, Q.-H. Fiber Interactions and Effective Elasto-Plastic Properties of Short-Fiber Composites. Compos. Struct. 2001, 54, 523–528. [Google Scholar] [CrossRef]

- Meraghni, F.; Benzeggagh, M.L. Micromechanical Modelling of Matrix Degradation in Randomly Oriented Discontinuous-Fibre Composites. Compos. Sci. Technol. 1995, 55, 171–186. [Google Scholar] [CrossRef]

- Benveniste, Y. A New Approach to the Application of Mori-Tanaka’s Theory in Composite Materials. Mech. Mater. 1987, 6, 147–157. [Google Scholar] [CrossRef]

- Nghiep Nguyen, B.; Bapanapalli, S.K.; Kunc, V.; Phelps, J.H.; Tucker, C.L. Prediction of the Elastic—Plastic Stress/Strain Response for Injection-Molded Long-Fiber Thermoplastics. J. Compos. Mater. 2009, 43, 217–246. [Google Scholar] [CrossRef]

- Ramberg, W.; Osgood, W.R. Description of Stress-Strain Curves by Three Parameters; Technical Note No. 902; NASA: Washington, DC, USA, 1943.

- Monte, S.J. Titanate coupling agents. In Functional Fillers for Plas-Tics; Xanthos, M., Ed.; Wiley-VCH Verlag GmbH: Weinheim, Germany, 2005. [Google Scholar]

- Crema, L.; Sorgato, M.; Zanini, F.; Carmignato, S.; Lucchetta, G. Experimental Analysis of Mechanical Properties and Microstructure of Long Glass Fiber Reinforced Polypropylene Processed by Rapid Heat Cycle Injection Molding. Compos. Part A Appl. Sci. Manuf. 2018, 107, 366–373. [Google Scholar] [CrossRef]

- Montana, D.J.; Davis, L. Training Feedforward Neural Networks Using Genetic Algorithms. IJCAI 1989, 89, 762–767. [Google Scholar]

- Costa, F.S. Fiber Orientation Accuracy Validation Report; 2017. [Google Scholar]

- Demuth, H.; Beale, M. MATLAB Neural Networks Toolbox v4 User’s Guide; Mathworks Inc.: Natick, MA, USA, 2005. [Google Scholar]

- Sadeghi, B.H.M. A BP-Neural Network Predictor Model for Plastic Injection Molding Process. J. Mater. Process. Technol. 2000, 103, 411–416. [Google Scholar] [CrossRef]

- Quagliarella, D. Genetic Algorithms and Evolution Strategy in Engineering and Computer Science. Comput. Math. Appl. 1998, 35, 143. [Google Scholar]

- Antunes Oliveira, A. Structural Analysis of Components Obtained by the Injection Molding Process. Mater. Sci. 2016, 1–11. [Google Scholar]

- Liu, G.; Han, X. Computational Inverse Techniques in Nondestructive Evaluation; CRC Press: Boca Raton, FL, USA, 2003; ISBN 9780203494486. [Google Scholar]

- Borzenko, E.I.; Shrager, G.R. Flow of a Non-Newtonian Liquid with a Free Surface. J. Eng. Phys. Thermophys. 2016, 89, 902–910. [Google Scholar] [CrossRef]

- Kleindel, S.; Salaberger, D.; Eder, R.; Schretter, H.; Hochenauer, C. Prediction and Validation of Short Fiber Orientation in a Complex Injection Molded Part with Chunky Geometry. Int. Polym. Process. 2015, 30, 366–380. [Google Scholar] [CrossRef]

| Values | Error | |||

|---|---|---|---|---|

| E, MPa | Stress at Failure, MPa | E, % | Stress at Failure, % | |

| Experimental values | 16,414 | 185 | - | - |

| Predicted with default RSC coefficients and curve-fitted RO parameters | 9822 | 106 | 67% | 75% |

| Predicted with optimized coefficients and curve-fitted RO parameters | 11,972 | 132 | 37% | 40% |

| Predicted with optimized RSC coefficients and inverse modeling from experimental data | 13,256 | 160 | 24% | 16% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ivan, R.; Sorgato, M.; Zanini, F.; Lucchetta, G. Improving Numerical Modeling Accuracy for Fiber Orientation and Mechanical Properties of Injection Molded Glass Fiber Reinforced Thermoplastics. Materials 2022, 15, 4720. https://doi.org/10.3390/ma15134720

Ivan R, Sorgato M, Zanini F, Lucchetta G. Improving Numerical Modeling Accuracy for Fiber Orientation and Mechanical Properties of Injection Molded Glass Fiber Reinforced Thermoplastics. Materials. 2022; 15(13):4720. https://doi.org/10.3390/ma15134720

Chicago/Turabian StyleIvan, Riccardo, Marco Sorgato, Filippo Zanini, and Giovanni Lucchetta. 2022. "Improving Numerical Modeling Accuracy for Fiber Orientation and Mechanical Properties of Injection Molded Glass Fiber Reinforced Thermoplastics" Materials 15, no. 13: 4720. https://doi.org/10.3390/ma15134720

APA StyleIvan, R., Sorgato, M., Zanini, F., & Lucchetta, G. (2022). Improving Numerical Modeling Accuracy for Fiber Orientation and Mechanical Properties of Injection Molded Glass Fiber Reinforced Thermoplastics. Materials, 15(13), 4720. https://doi.org/10.3390/ma15134720