Characterization of Co-Cr-W Dental Alloys with Veneering Materials Manufactured via Subtractive Milling and Additive Manufacturing LDED Methods

Abstract

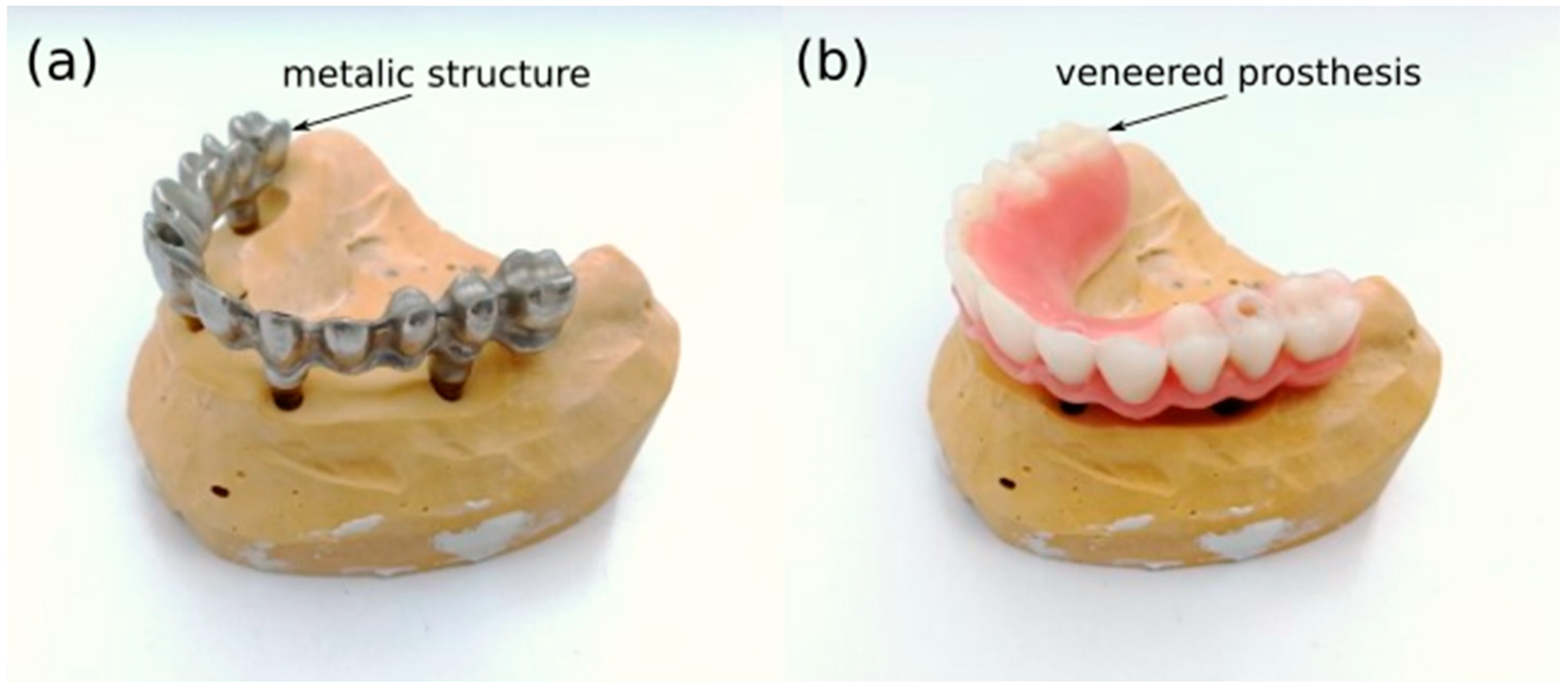

:1. Introduction

2. Materials and Methods

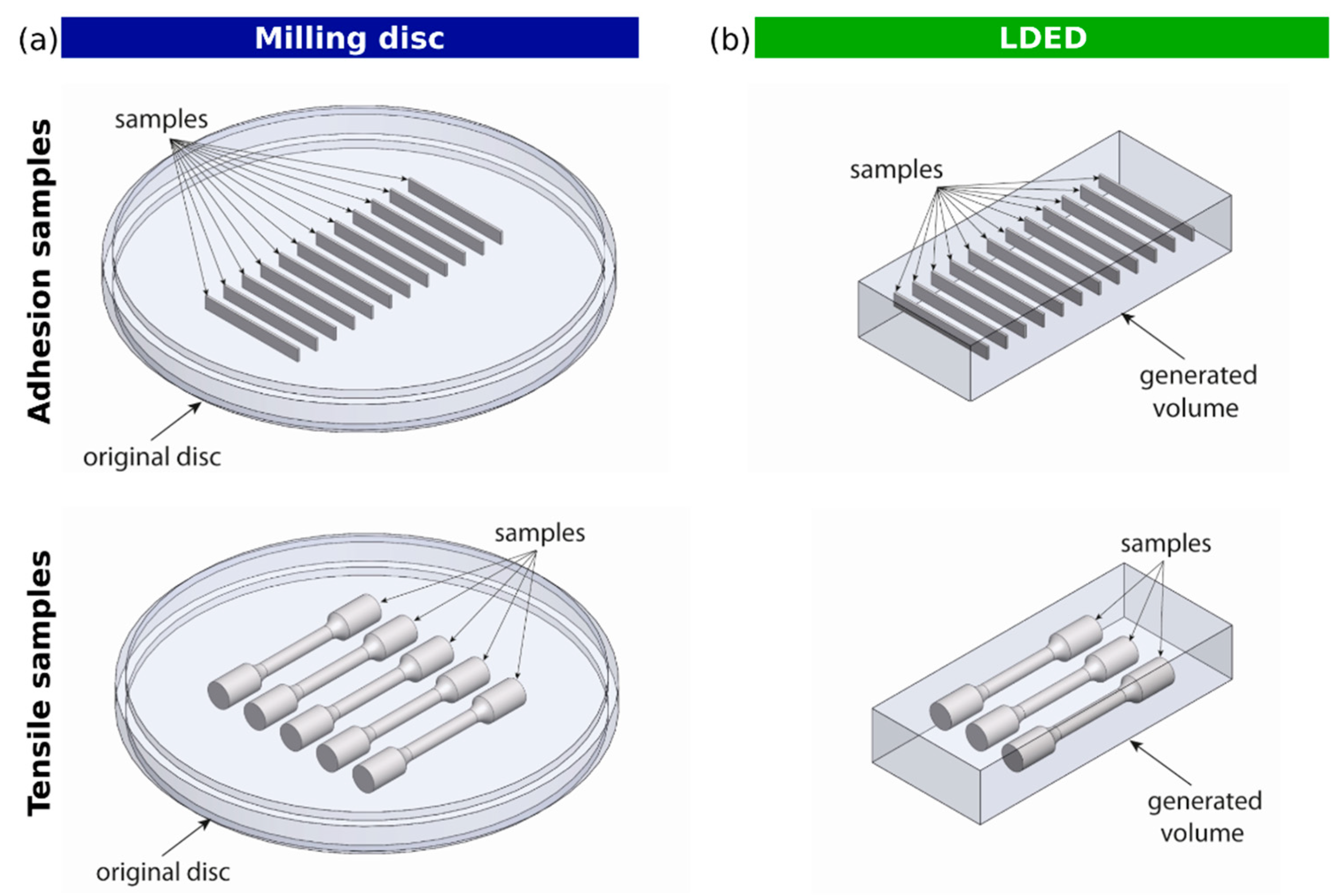

2.1. Metallic Specimen Generation

2.2. Veneering Materials

2.3. Microstructural Characterization

2.3.1. SEM-EDS Analysis

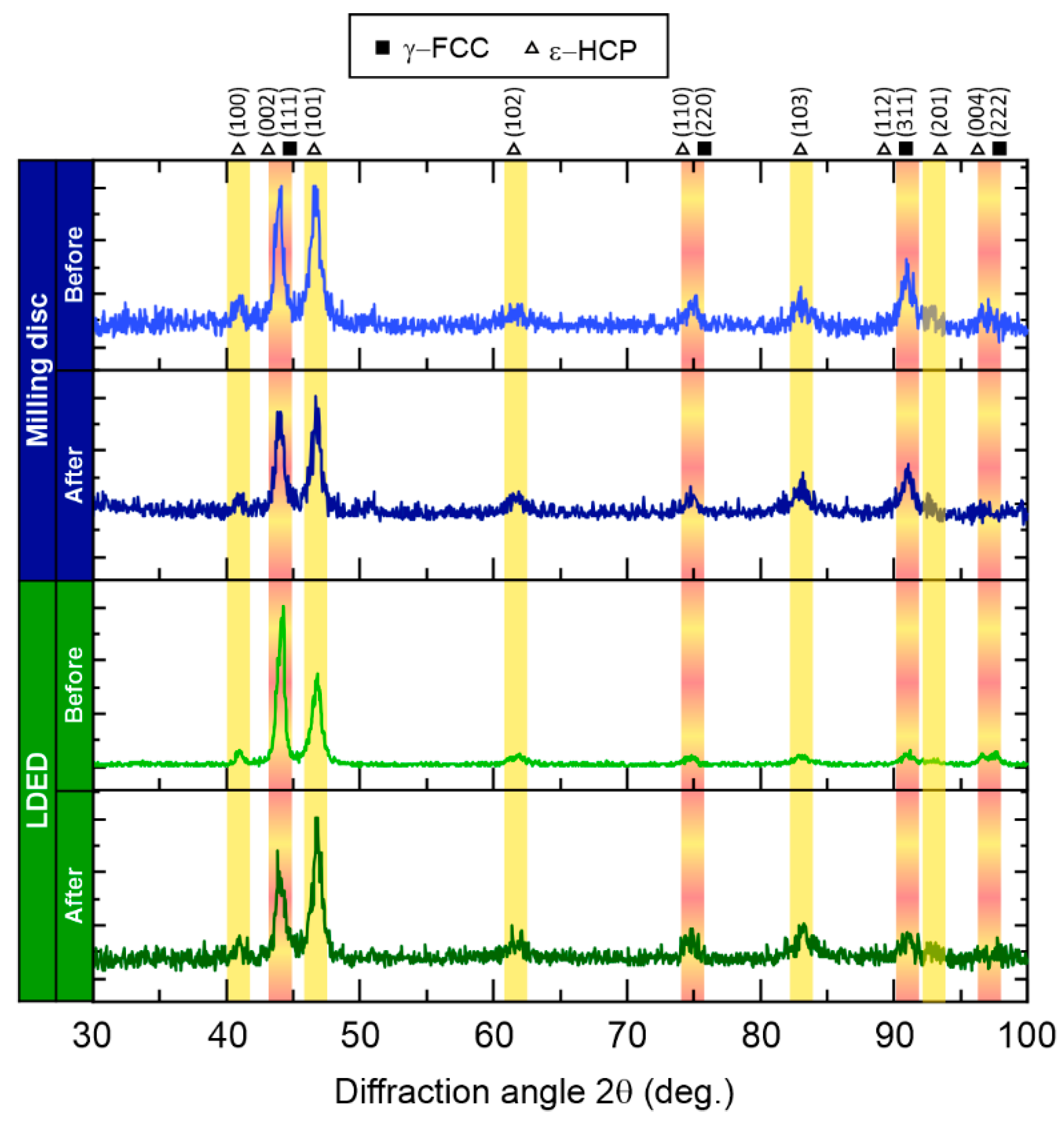

2.3.2. XRD Analysis

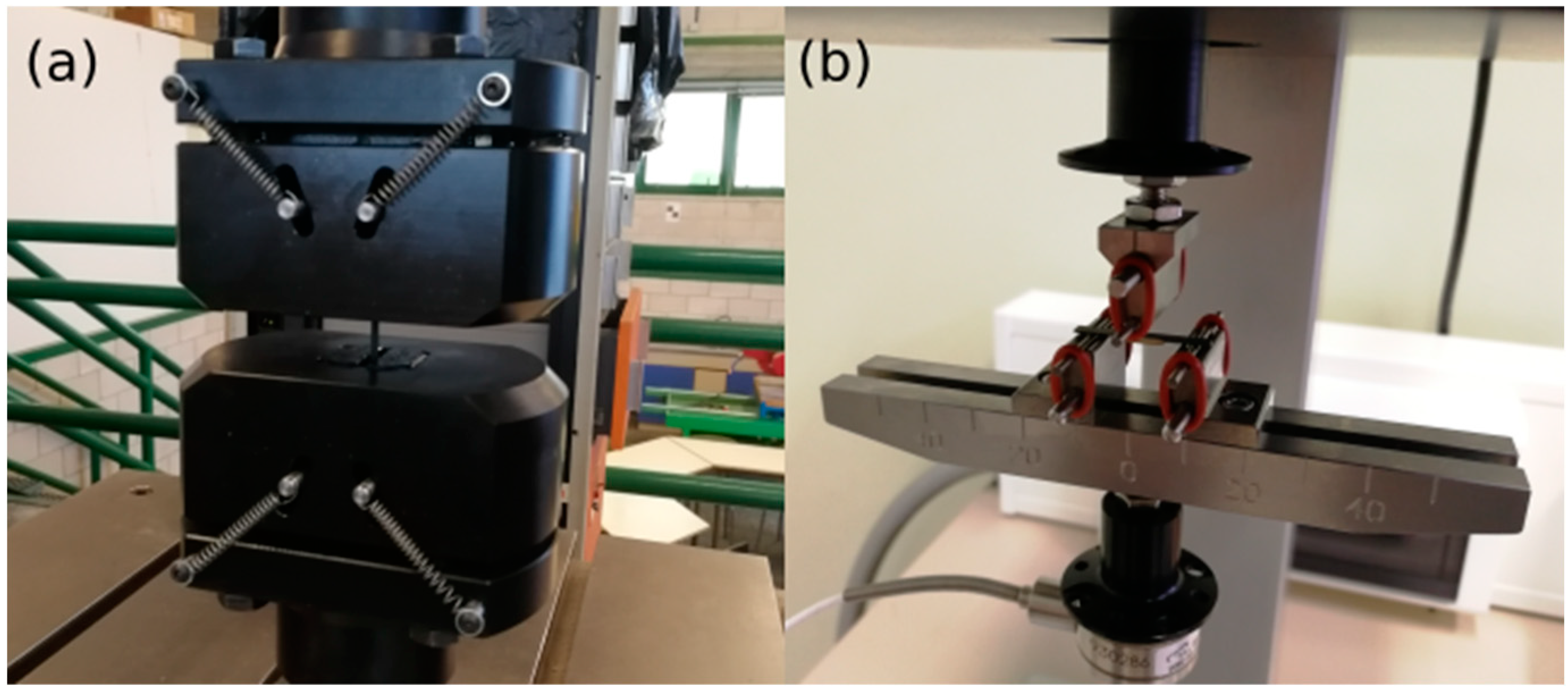

2.4. Mechanical Analysis

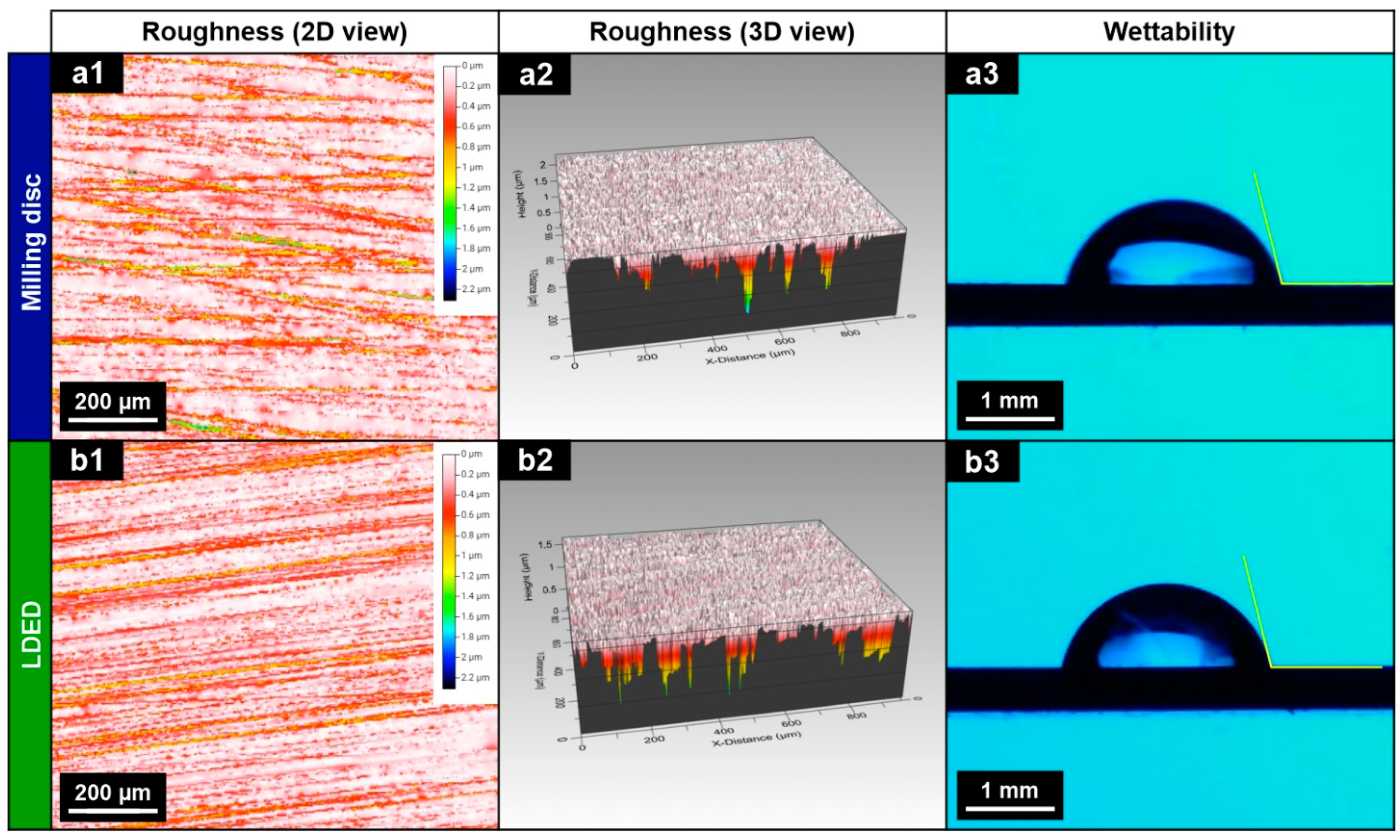

2.5. Surface Analysis

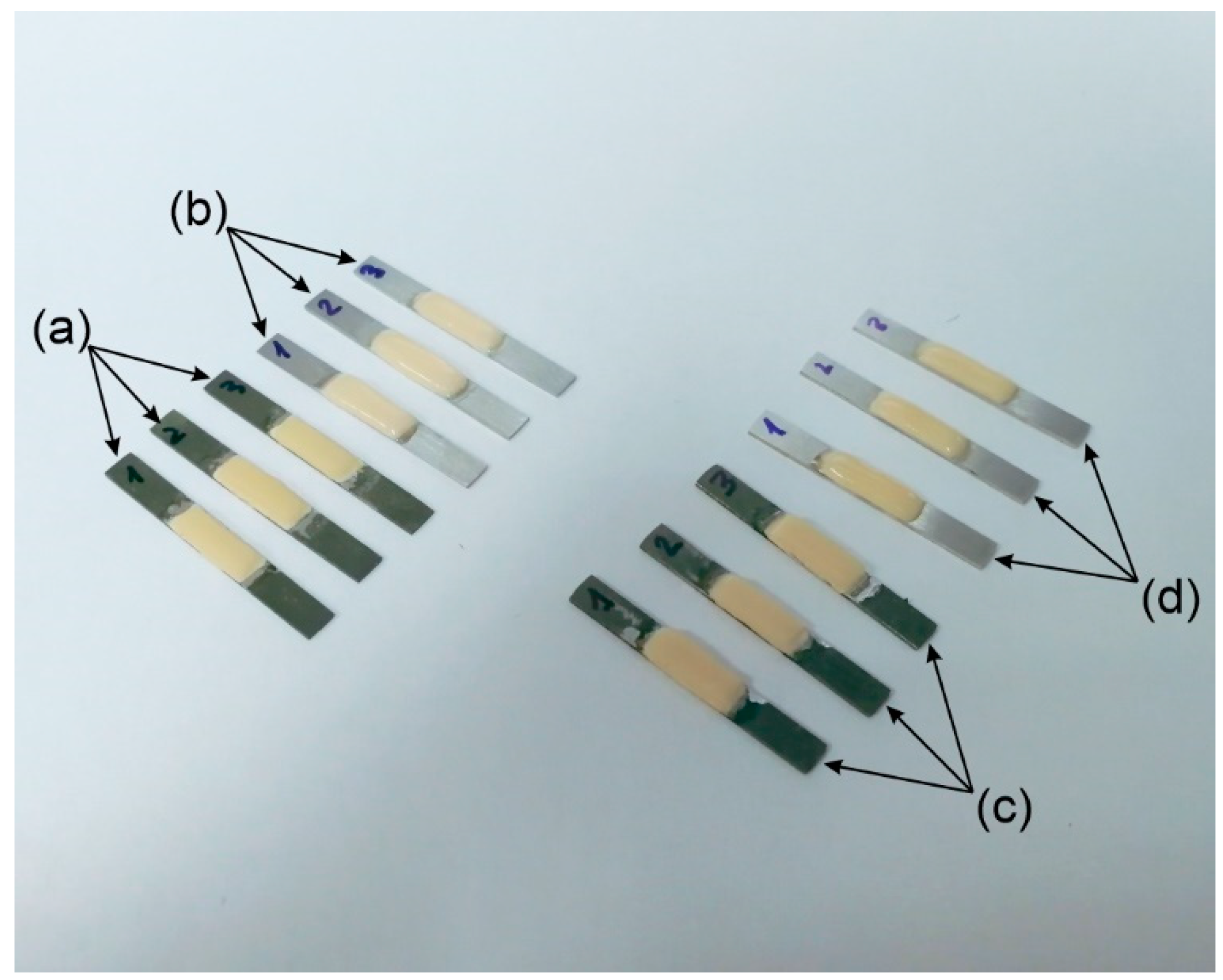

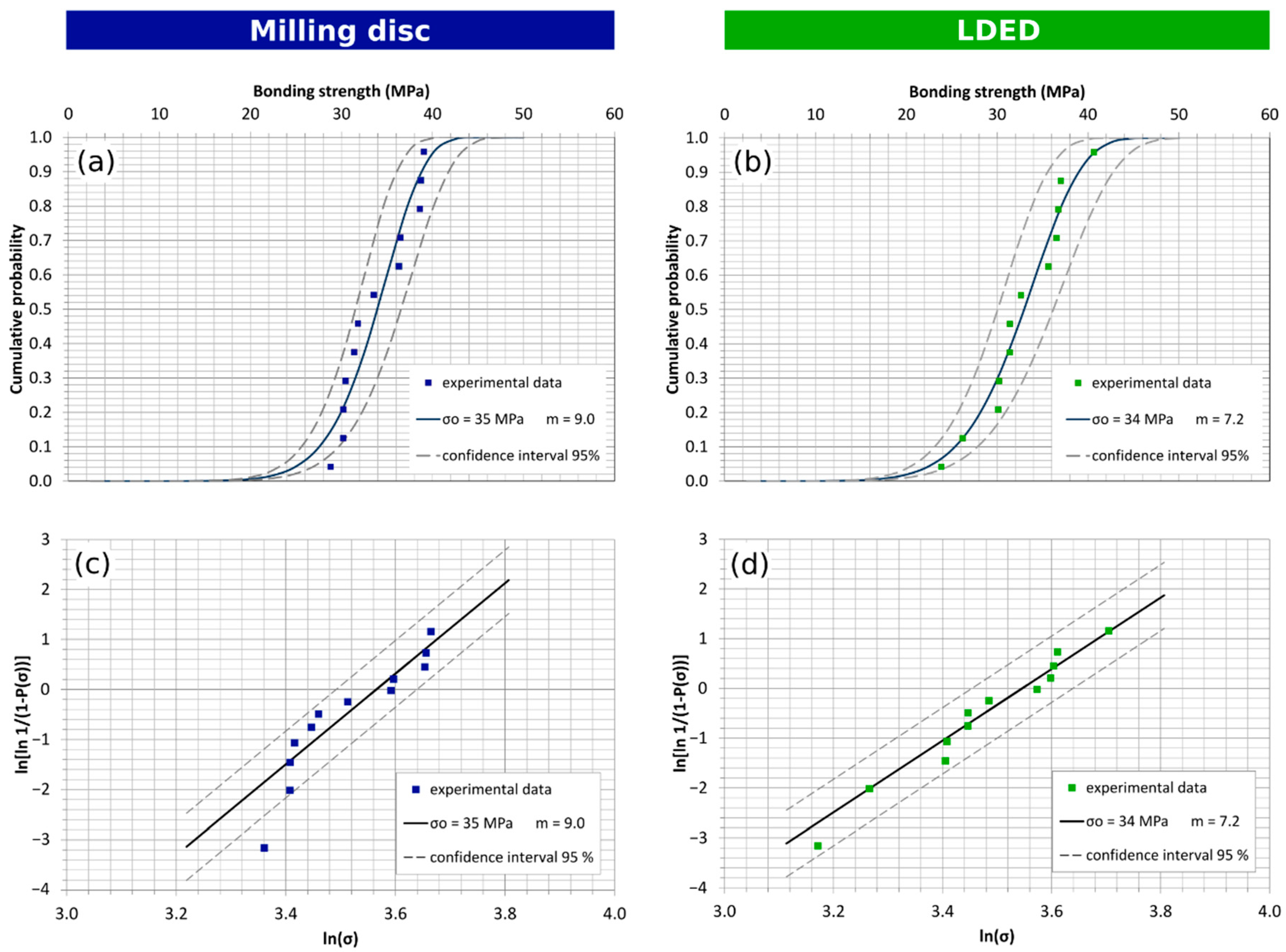

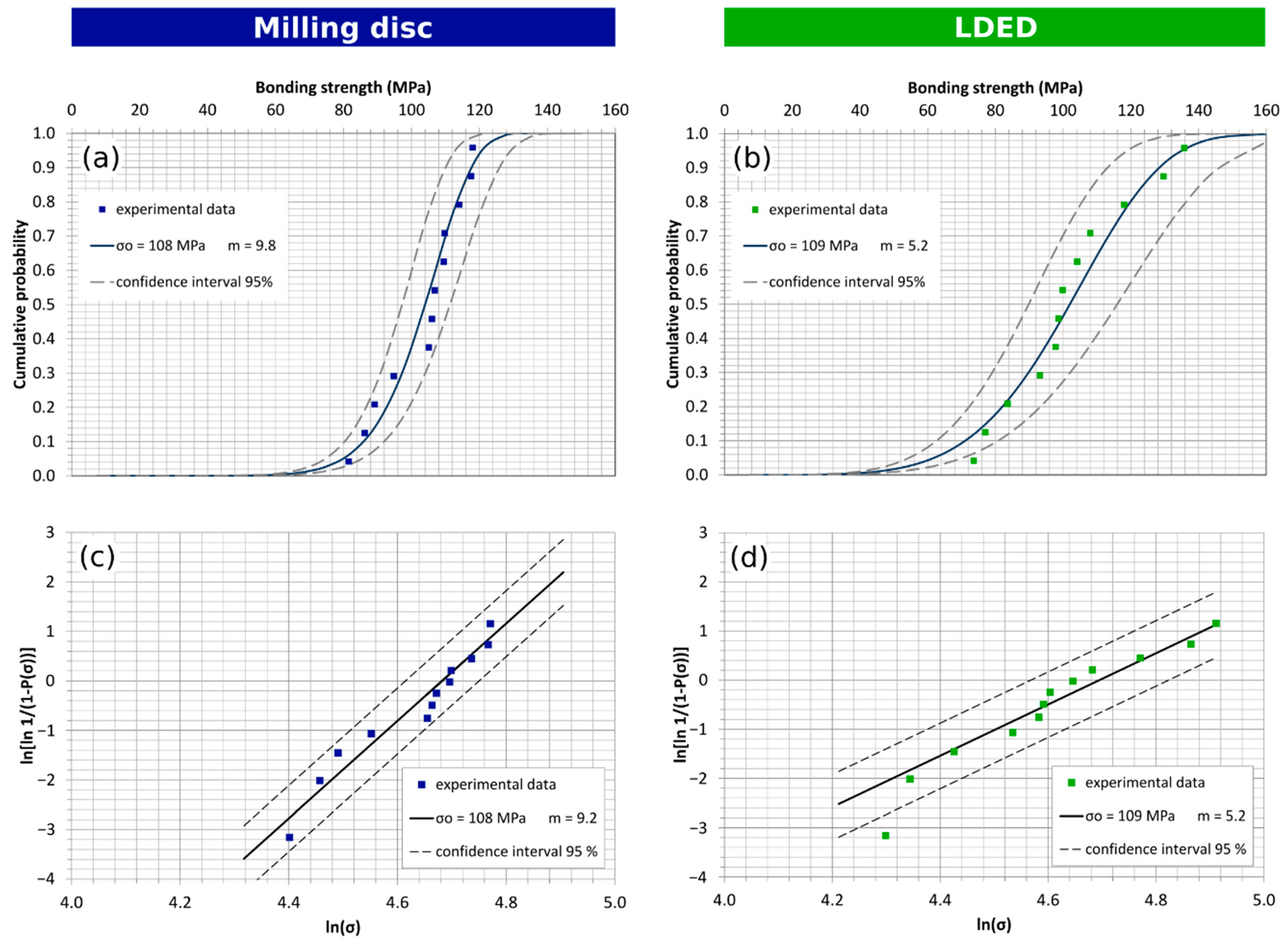

2.6. Veneering Coating Adhesion Analysis

2.7. Statistical Analysis

3. Results and Discussion

3.1. Microstructural Analysis of Co-Cr-W Alloys

3.2. Mechanical Properties of Co-Cr-W Alloys

3.3. Surface Roughness and Wettability of Co-Cr-W Alloys

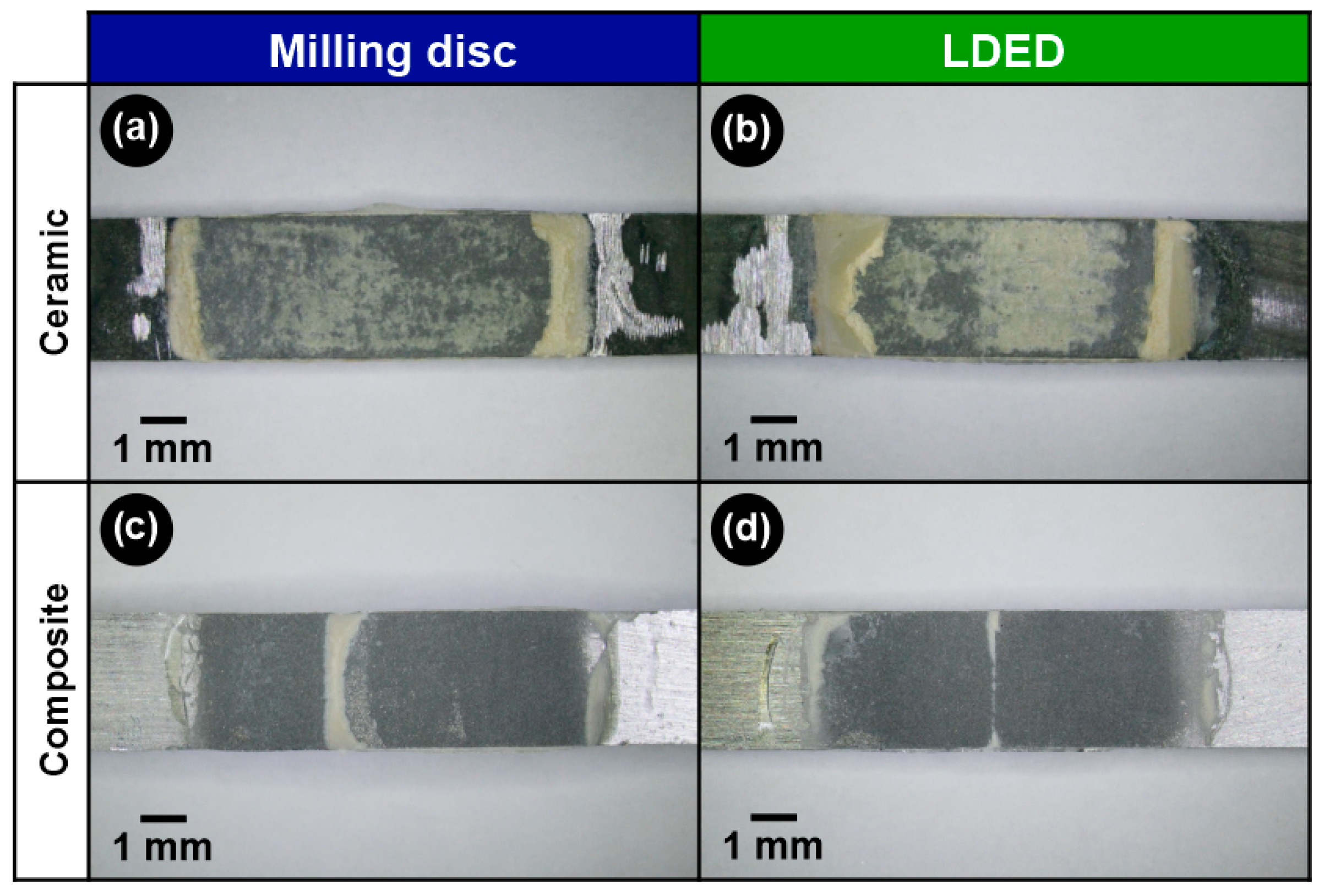

3.4. Veneering Coating Adhesion to Co-Cr-W Alloys

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Johnson, M. Human Biology: Concepts and Current Issues, 6th ed.; Pearson Education: Upper Saddle River, NJ, USA, 2012; ISBN 978-0134042435. [Google Scholar]

- Chen, H.; Liu, Y. Teeth; Elsevier Inc.: Amsterdam, The Netherlands, 2014; ISBN 9780123946195. [Google Scholar]

- Schnitman, P.A.; Wöhrle, P.S.; Rubenstein, J.E.; DaSilva, J.D.; Wang, N.H. Ten-year results for Brånemark implants immediately loaded with fixed prostheses at implant placement. Int. J. Oral. Maxillofac. Implant. 1997, 12, 495–503. [Google Scholar]

- D’Amico, C.; Bocchieri, S.; Sambataro, S.; Surace, G.; Stumpo, C.; Fiorillo, L. Occlusal Load Considerations in Implant-Supported Fixed Restorations. Prosthesis 2020, 2, 252–265. [Google Scholar] [CrossRef]

- Bandyopadhyay, A.; Traxel, K.D.; Avila, J.D.; Mitra, I.; Bose, S. CoCr Alloys. In Biomaterials Science; Elsevier: Amsterdam, The Netherlands, 2020; pp. 257–269. [Google Scholar]

- Steinemann, S.; Perren, S.M. Titanium alloys as metallic biomaterials. Titan. Sci. Technol. 1984, 2, 1327–1334. [Google Scholar]

- Helsen, J.A.; Jürgen Breme, H. Metals as Biomaterials; Wiley-VCH: Chichester, UK, 1998; ISBN 978-0-471-96935-8. [Google Scholar]

- Ratner, B.; Hoffman, A.; Schoen, F.; Lemons, J. Biomaterials Science: An Introduction to Materials in Medicine, 2nd ed.; Academic Press: San Diego, CA, USA, 2004; ISBN 9780080470368. [Google Scholar]

- Oyagüe, R.C.; Sánchez-Turrión, A.; López-Lozano, J.F.; Montero, J.; Albaladejo, A.; Suárez-García, M.J. Evaluation of fit of cement-retained implant-supported 3-unit structures fabricated with direct metal laser sintering and vacuum casting techniques. Odontology 2012, 100, 249–253. [Google Scholar] [CrossRef]

- Sakaguchi, R.L.; Powers, J.M. Craig’s Restorative Dental Materials, 13th ed.; Elsevier: Philadelphia, PA, USA, 2012; ISBN 9780323081085. [Google Scholar]

- Sarafianou, A.; Seimenis, I.; Papadopoulos, T. Effectiveness of different adhesive primers on the bond strength between an indirect composite resin and a base metal alloy. J. Prosthet. Dent. 2008, 99, 377–387. [Google Scholar] [CrossRef]

- Fernandes, C.A.; Ribeiro, J.C.; Larson, B.S.; Bonfante, E.A.; Silva, N.R.; Suzuki, M.; Thompson, V.P.; Coelho, P.G. Microtensile bond strength of resin-based composites to Ti-6Al-4V. Dent. Mater. 2009, 25, 655–661. [Google Scholar] [CrossRef]

- Yoshida, K.; Taira, Y.; Matsumura, H.; Atsuta, M. Effect of adhesive primers on bonding a prosthetic composite resin to metals. J. Prosthet. Dent. 1993, 69, 357–362. [Google Scholar] [CrossRef]

- Shimoe, S.; Tanoue, N.; Yanagida, H.; Atsuta, M.; Koizumi, H.; Matsumura, H. Comparative strength of metal-ceramic and metal-composite bonds after extended thermocycling. J. Oral Rehabil. 2004, 31, 689–694. [Google Scholar] [CrossRef]

- Suzuki, S.; Nagai, E.; Taira, Y.; Minesaki, Y. In vitro wear of indirect composite restoratives. J. Prosthet. Dent. 2002, 88, 431–436. [Google Scholar] [CrossRef]

- Ghazal, M.; Albashaireh, Z.S.; Kern, M. Wear resistance of nanofilled composite resin and feldspathic ceramic artificial teeth. J. Prosthet. Dent. 2008, 100, 441–448. [Google Scholar] [CrossRef]

- Kim, H.; Jang, S.-H.; Kim, Y.; Son, J.; Min, B.; Kim, K.-H.; Kwon, T.-Y. Microstructures and Mechanical Properties of Co-Cr Dental Alloys Fabricated by Three CAD/CAM-Based Processing Techniques. Materials 2016, 9, 596. [Google Scholar] [CrossRef] [PubMed]

- Nesse, H.; Ulstein, D.M.Å.; Vaage, M.M.; Eilo, M. Internal and marginal fit of cobalt-chromium fixed dental prostheses fabricated with 3 different techniques. J. Prosthet. Dent. 2015, 114, 686–692. [Google Scholar] [CrossRef] [PubMed]

- Han, X.; Sawada, T.; Schille, C.; Schweizer, E.; Scheideler, L.; Geis-Gerstorfer, J.; Rupp, F.; Spintzyk, S. Comparative analysis of mechanical properties and metal-ceramic bond strength of Co-Cr dental alloy fabricated by different manufacturing processes. Materials 2018, 11, 1081. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Øilo, M.; Nesse, H.; Lundberg, O.J.; Gjerdet, N.R. Mechanical properties of cobalt-chromium 3-unit fixed dental prostheses fabricated by casting, milling, and additive manufacturing. J. Prosthet. Dent. 2018, 120, 156.e1–156.e7. [Google Scholar] [CrossRef]

- Padrós, R.; Punset, M.; Molmeneu, M.; Velasco, A.B.; Herrero-Climent, M.; Rupérez, E.; Gil, F.J. Mechanical Properties of CoCr Dental-Prosthesis Restorations Made by Three Manufacturing Processes. Influence of the Microstructure and Topography. Metals 2020, 10, 788. [Google Scholar] [CrossRef]

- Viderščak, D.; Schauperl, Z.; Šolić, S.; Ćatić, A.; Godec, M.; Kocijan, A.; Paulin, I.; Donik, Č. Additively manufactured commercial Co-Cr dental alloys: Comparison of microstructure and mechanical properties. Materials 2021, 14, 7350. [Google Scholar] [CrossRef]

- Arias-González, F.; Barro, O.; del Val, J.; Lusquiños, F.; Fernández-Arias, M.; Comesaña, R.; Riveiro, A.; Pou, J. Laser Directed Energy Deposition. Principles and applications. In Additive Manufacturing; Pou, J., Riveiro, A., Davim, J.P., Eds.; Elsevier: Amsterdam, The Netherlands, 2021; pp. 121–157. [Google Scholar]

- Zhong, C.; Gasser, A.; Schopphoven, T.; Poprawe, R. Experimental study of porosity reduction in high deposition-rate Laser Material Deposition. Opt. Laser Technol. 2015, 75, 87–92. [Google Scholar] [CrossRef]

- Arias-gonzález, F.; Val, J.; Comesaña, R.; Penide, J.; Lusquiños, F.; Quintero, F.; Riveiro, A.; Boutinguiza, M.; Pou, J. Surface & Coatings Technology Laser cladding of phosphor bronze. Surf. Coat. Technol. 2017, 313, 248–254. [Google Scholar] [CrossRef]

- Huang, Y.; Ansari, M.; Asgari, H.; Farshidianfar, M.H.; Sarker, D.; Khamesee, M.B.; Toyserkani, E. Rapid prediction of real-time thermal characteristics, solidification parameters and microstructure in laser directed energy deposition (powder-fed additive manufacturing). J. Mater. Process. Technol. 2019, 274, 116286. [Google Scholar] [CrossRef]

- Yamanaka, K.; Mori, M.; Chiba, A. Assessment of precipitation behavior in dental castings of a Co-Cr-Mo alloy. J. Mech. Behav. Biomed. Mater. 2015, 50, 268–276. [Google Scholar] [CrossRef] [Green Version]

- Schmidt, M.; Merklein, M.; Bourell, D.; Dimitrov, D.; Hausotte, T.; Wegener, K.; Overmeyer, L.; Vollertsen, F.; Levy, G.N. Laser based additive manufacturing in industry and academia. CIRP Ann. 2017, 66, 561–583. [Google Scholar] [CrossRef]

- Janaki Ram, G.D.; Esplin, C.K.; Stucker, B.E. Microstructure and wear properties of LENS® deposited medical grade CoCrMo. J. Mater. Sci. Mater. Med. 2008, 19, 2105–2111. [Google Scholar] [CrossRef] [PubMed]

- Arias-González, F.; Del Val, J.; Comesaña, R.; Penide, J.; Lusquiños, F.; Quintero, F.; Riveiro, A.; Boutinguiza, M.; Pou, J. Fiber laser cladding of nickel-based alloy on cast iron. Appl. Surf. Sci. 2016, 374, 197–205. [Google Scholar] [CrossRef]

- Arias-González, F.; Rodríguez-Contreras, A.; Punset, M.; Manero, J.M.; Barro, Ó.; Fernández-Arias, M.; Lusquiños, F.; Gil, F.J.; Pou, J. In-situ laser directed energy deposition of biomedical ti-nb and ti-zr-nb alloys from elemental powders. Metals 2021, 11, 1205. [Google Scholar] [CrossRef]

- Lusquiños, F.; del Val, J.; Arias-González, F.; Comesaña, R.; Quintero, F.; Riveiro, A.; Boutinguiza, M.; Jones, J.R.; Hill, R.G.; Pou, J. Bioceramic 3D Implants Produced by Laser Assisted Additive Manufacturing. Phys. Procedia 2014, 56, 309–316. [Google Scholar] [CrossRef] [Green Version]

- Comesaña, R.; Lusquiños, F.; Del Val, J.; Quintero, F.; Riveiro, A.; Boutinguiza, M.; Jones, J.R.; Hill, R.G.; Pou, J. Toward smart implant synthesis: Bonding bioceramics of different resorbability to match bone growth rates. Sci. Rep. 2015, 5, srep10677. [Google Scholar] [CrossRef] [Green Version]

- Barro, Ó.; Arias-González, F.; Lusquiños, F.; Comesaña, R.; del Val, J.; Riveiro, A.; Badaoui, A.; Gómez-Baño, F.; Pou, J. Effect of Four Manufacturing Techniques (Casting, Laser Directed Energy Deposition, Milling and Selective Laser Melting) on Microstructural, Mechanical and Electrochemical Properties of Co-Cr Dental Alloys, Before and After PFM Firing Process. Metals 2020, 10, 1291. [Google Scholar] [CrossRef]

- Hong, J.-K.; Kim, S.-K.; Heo, S.-J.; Koak, J.-Y. Mechanical Properties and Metal-Ceramic Bond Strength of Co-Cr Alloy Manufactured by Selective Laser Melting. Materials 2020, 13, 5745. [Google Scholar] [CrossRef]

- Revilla-León, M.; Gómez-Polo, M.; Park, S.H.; Barmak, B.A.; Özcan, M. Adhesion of veneering porcelain to cobalt-chromium dental alloys processed with casting, milling, and additive manufacturing methods: A systematic review and meta-analysis. J. Prosthet. Dent. 2021, 1–14. [Google Scholar] [CrossRef]

- International Organization for Standardization ISO 9693-1:2012; Dentistry-Compatibility Testing-Part 1: Metal-Ceramic Systems. ISO: Geneva, Switzerland, 2012.

- Yamanaka, K.; Mori, M.; Kuramoto, K.; Chiba, A. Development of new Co-Cr-W-based biomedical alloys: Effects of microalloying and thermomechanical processing on microstructures and mechanical properties. Mater. Des. 2014, 55, 987–998. [Google Scholar] [CrossRef]

- Reclaru, L.; Ardelean, L.C. Alternative Processing Techniques for CoCr Dental Alloys. In Encyclopedia of Biomedical Engineering; Elsevier: Amsterdam, The Netherlands, 2019; pp. 213–224. ISBN 9780128012383. [Google Scholar]

- Yamanaka, K.; Mori, M.; Chiba, A. Dynamic recrystallization of a biomedical Co–Cr–W-based alloy under hot deformation. Mater. Sci. Eng. A 2014, 592, 173–181. [Google Scholar] [CrossRef]

- Akram, J.; Chalavadi, P.; Pal, D.; Stucker, B. Understanding grain evolution in additive manufacturing through modeling. Addit. Manuf. 2018, 21, 255–268. [Google Scholar] [CrossRef]

- Shishkovsky, I.; Missemer, F.; Smurov, I. Metal matrix composites with ternary intermetallic inclusions fabricated by laser direct energy deposition. Compos. Struct. 2018, 183, 663–670. [Google Scholar] [CrossRef]

- Arias-González, F.; del Val, J.; Comesaña, R.; Penide, J.; Lusquiños, F.; Quintero, F.; Riveiro, A.; Boutinguiza, M.; Gil, F.J.; Pou, J. Microstructure and crystallographic texture of pure titanium parts generated by laser additive manufacturing. Met. Mater. Int. 2018, 24, 231–239. [Google Scholar] [CrossRef]

- Al Jabbari, Y.S.; Koutsoukis, T.; Barmpagadaki, X.; Zinelis, S. Metallurgical and interfacial characterization of PFM Co–Cr dental alloys fabricated via casting, milling or selective laser melting. Dent. Mater. 2014, 30, e79–e88. [Google Scholar] [CrossRef]

- Zeng, L.; Zhang, Y.; Liu, Z.; Wei, B. Effects of repeated firing on the marginal accuracy of Co-Cr copings fabricated by selective laser melting. J. Prosthet. Dent. 2015, 113, 135–139. [Google Scholar] [CrossRef]

- Zhou, Y.; Li, N.; Yan, J.; Zeng, Q. Comparative analysis of the microstructures and mechanical properties of Co-Cr dental alloys fabricated by different methods. J. Prosthet. Dent. 2018, 120, 617–623. [Google Scholar] [CrossRef]

- Rodrigo, A.; Perillo, P.; Ichimura, H. On the correlation of substrate microhardness with the critical load of scratch adherence for hard coatings. Surf. Coat. Technol. 2000, 124, 87–92. [Google Scholar] [CrossRef]

- Sedlaček, M.; Podgornik, B.; Vižintin, J. Correlation between standard roughness parameters skewness and kurtosis and tribological behaviour of contact surfaces. Tribol. Int. 2012, 48, 102–112. [Google Scholar] [CrossRef]

- Gadelmawla, E.S.; Koura, M.M.; Maksoud, T.M.A.; Elewa, I.M.; Soliman, H.H. Roughness parameters. J. Mater. Process. Technol. 2002, 123, 133–145. [Google Scholar] [CrossRef]

- Xiang, N.; Xin, X.-Z.; Chen, J.; Wei, B. Metal–ceramic bond strength of Co–Cr alloy fabricated by selective laser melting. J. Dent. 2012, 40, 453–457. [Google Scholar] [CrossRef] [PubMed]

| Group | Name | Information | Co | Cr | W | Mo | Si | Mn | Fe | Manufacturer |

|---|---|---|---|---|---|---|---|---|---|---|

| Disc milling | Kera®-Disc | Manufacturer | Bal. | 27.75 | 8.45 | - | - | 0.25 | 0.2 | Eisenbacher Dentalwaren ED GmbH, Wörth am Main, Germany |

| XRF | Bal. | 24.1 | 8.59 | <0.01 | 2.64 | 0.18 | 0.1 | |||

| LDED | Starbond Easy Powder 30+ | Manufacturer | Bal. | 27.5 | 8.5 | - | 1.6 | <1 | <1 | Scheftner GmbH, Mainz, Germany |

| XRF | Bal. | 22.41 | 7.84 | 0.04 | 1.3 | 0.23 | 0.17 |

| Process | Pre-Heating Temp. (°C) | Drying Time (min) | Heating Rate (°C/min) | Final Temp (°C) | Holding Time (min) | Vacuum |

|---|---|---|---|---|---|---|

| Bonding | 650 | 6 | 55 | 980 | 1 | Yes |

| Opaque | 550 | 6 | 80 | 940 | 1 | Yes |

| Dentin | 580 | 6 | 55 | 900 | 1 | Yes |

| Glaze | 600 | 2 | 55 | 860 | 1 | Yes |

| Material | Maximum Peak Height Sp (µm) | Maximum Pit Height Sv (µm) | Maximum Height Sz (µm) | Arithmetic Mean Height Sa (µm) | Root mean Square Height Sq (µm) | Skewness Ssk | Kurtosis Sku | Angle of Wettability (°) |

|---|---|---|---|---|---|---|---|---|

| Milling disc | 0.24 (0.03) | 1.97 (0.40) | 2.21 (0.43) | 0.17 (0.01) | 0.23 (0.01) | −2.10 (0.11) | 8.6 (1.0) | 69.9 (6.9) |

| LDED | 0.25 (0.03) | 1.35 (0.15) | 1.60 (0.17) | 0.17 (0.01) | 0.22 (0.01) | −1.57 (0.21) | 5.6 (0.6) | 74.3 (2.8) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Barro, Ó.; Arias-González, F.; Lusquiños, F.; Comesaña, R.; del Val, J.; Riveiro, A.; Badaoui, A.; Gómez-Baño, F.; Pou, J. Characterization of Co-Cr-W Dental Alloys with Veneering Materials Manufactured via Subtractive Milling and Additive Manufacturing LDED Methods. Materials 2022, 15, 4624. https://doi.org/10.3390/ma15134624

Barro Ó, Arias-González F, Lusquiños F, Comesaña R, del Val J, Riveiro A, Badaoui A, Gómez-Baño F, Pou J. Characterization of Co-Cr-W Dental Alloys with Veneering Materials Manufactured via Subtractive Milling and Additive Manufacturing LDED Methods. Materials. 2022; 15(13):4624. https://doi.org/10.3390/ma15134624

Chicago/Turabian StyleBarro, Óscar, Felipe Arias-González, Fernando Lusquiños, Rafael Comesaña, Jesús del Val, Antonio Riveiro, Aida Badaoui, Félix Gómez-Baño, and Juan Pou. 2022. "Characterization of Co-Cr-W Dental Alloys with Veneering Materials Manufactured via Subtractive Milling and Additive Manufacturing LDED Methods" Materials 15, no. 13: 4624. https://doi.org/10.3390/ma15134624

APA StyleBarro, Ó., Arias-González, F., Lusquiños, F., Comesaña, R., del Val, J., Riveiro, A., Badaoui, A., Gómez-Baño, F., & Pou, J. (2022). Characterization of Co-Cr-W Dental Alloys with Veneering Materials Manufactured via Subtractive Milling and Additive Manufacturing LDED Methods. Materials, 15(13), 4624. https://doi.org/10.3390/ma15134624