Potential Method to Distinguish Copper Molten Marks Using Boundary and Grain Characteristics

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Apparatus

2.2. Fabrication of Molten Marks

2.3. Specimen-Measurement Method and Analysis Tool

3. Results and Discussion

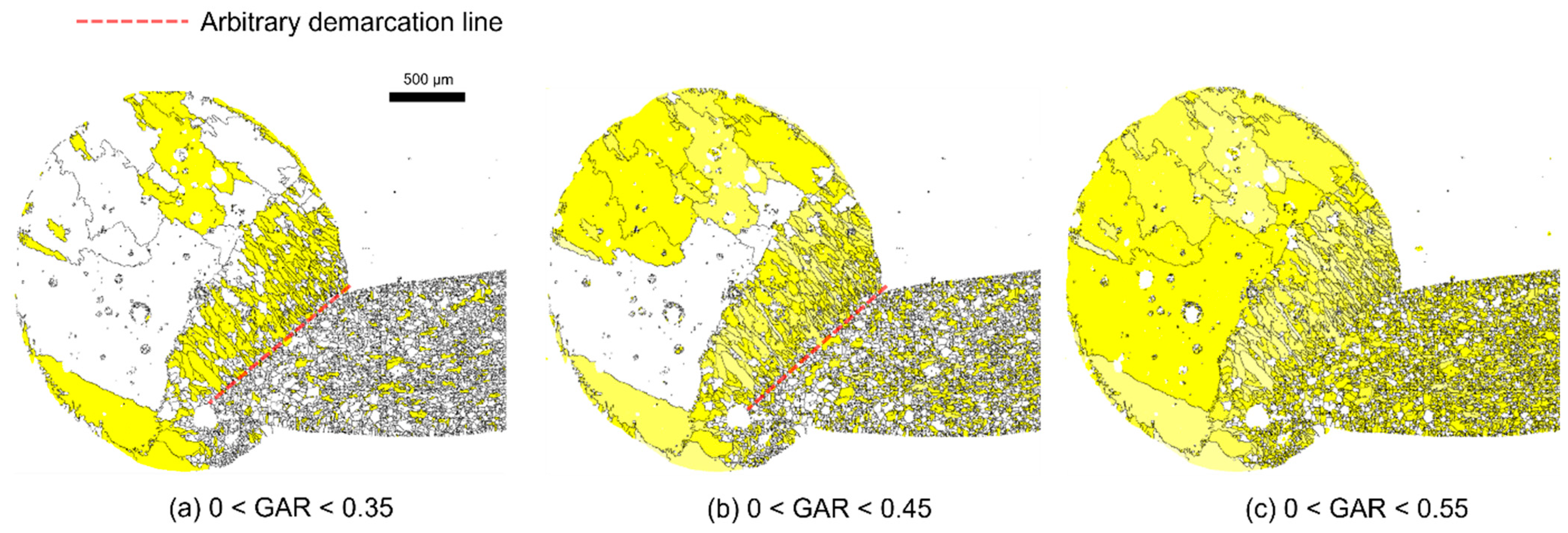

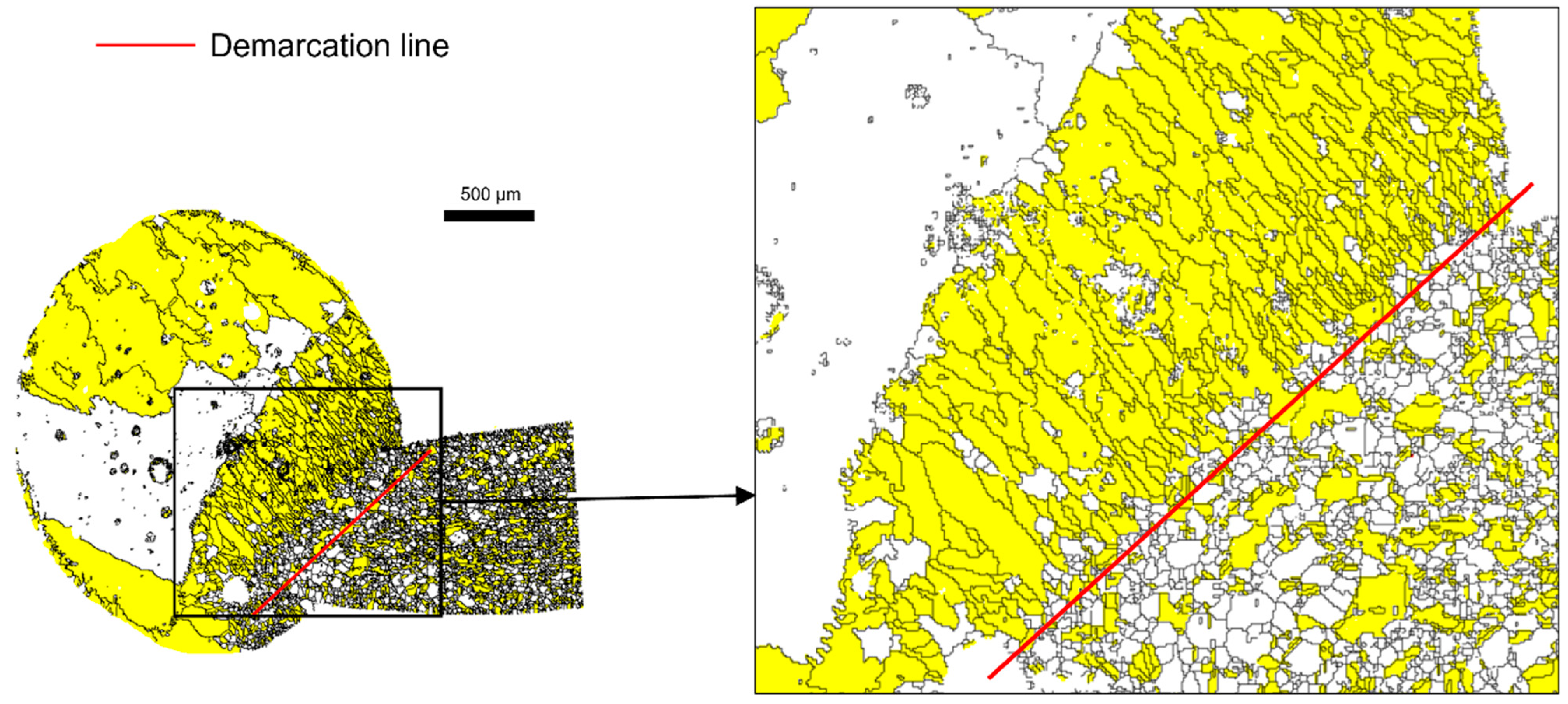

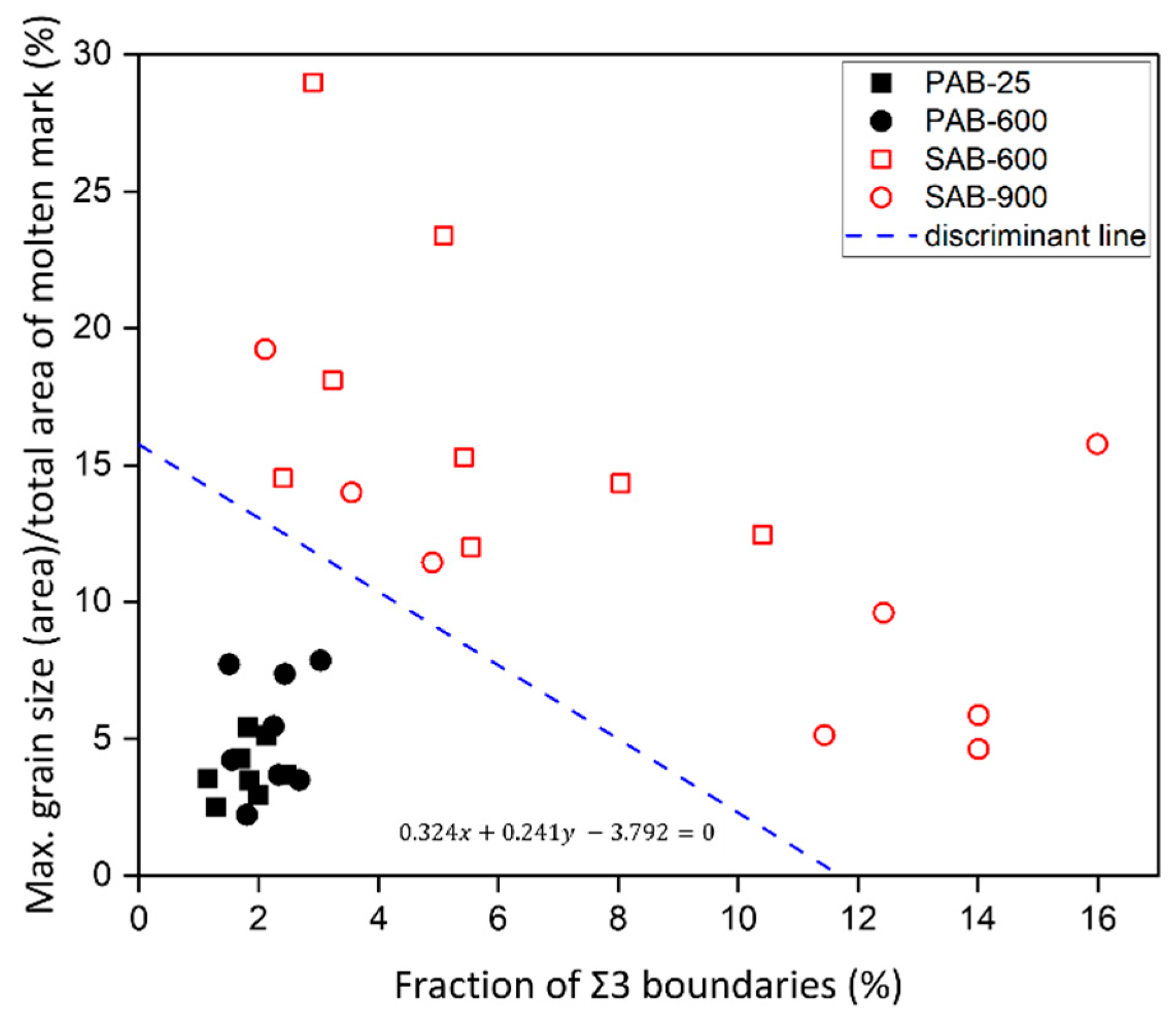

3.1. Decision of the Demarcation Line

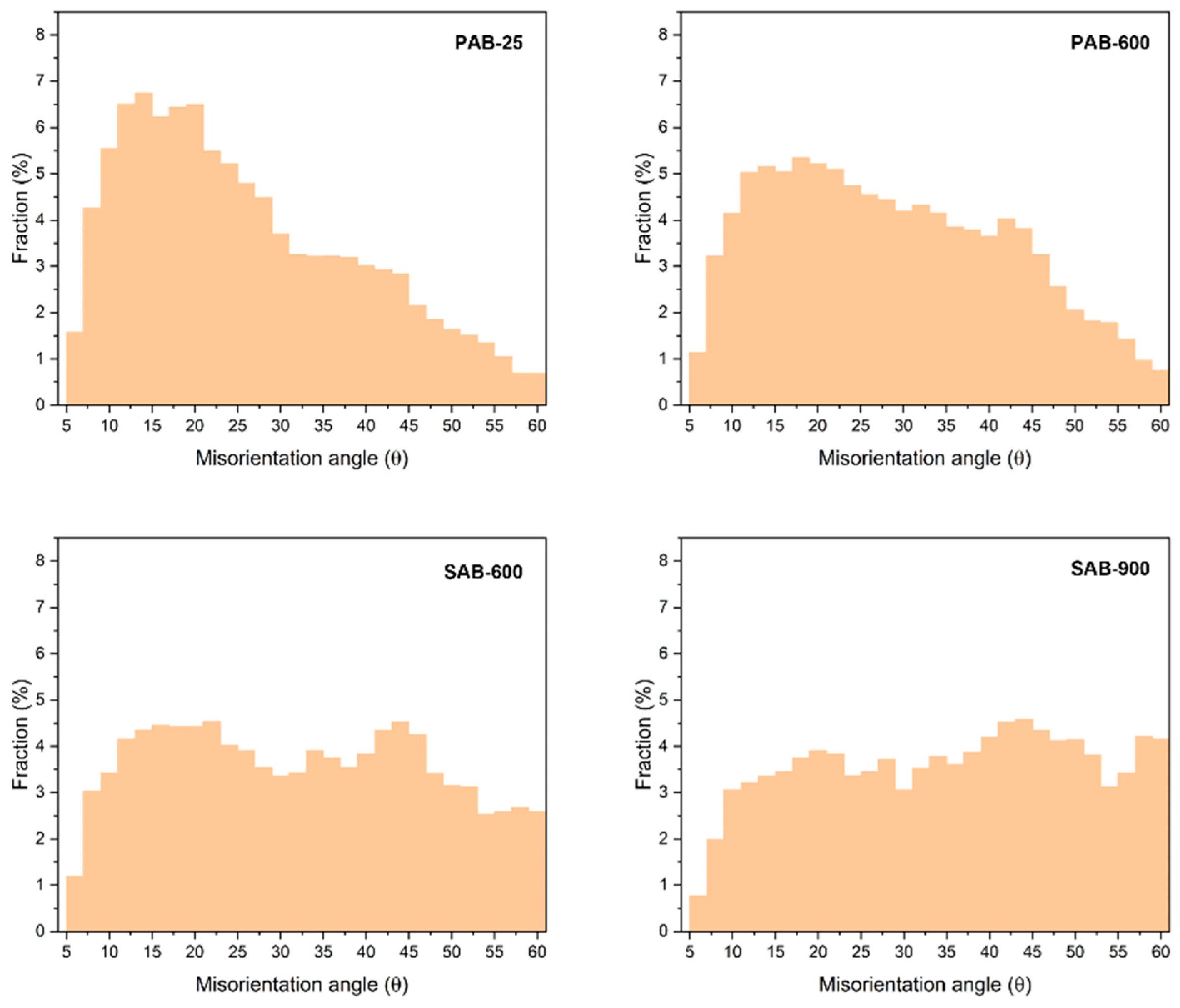

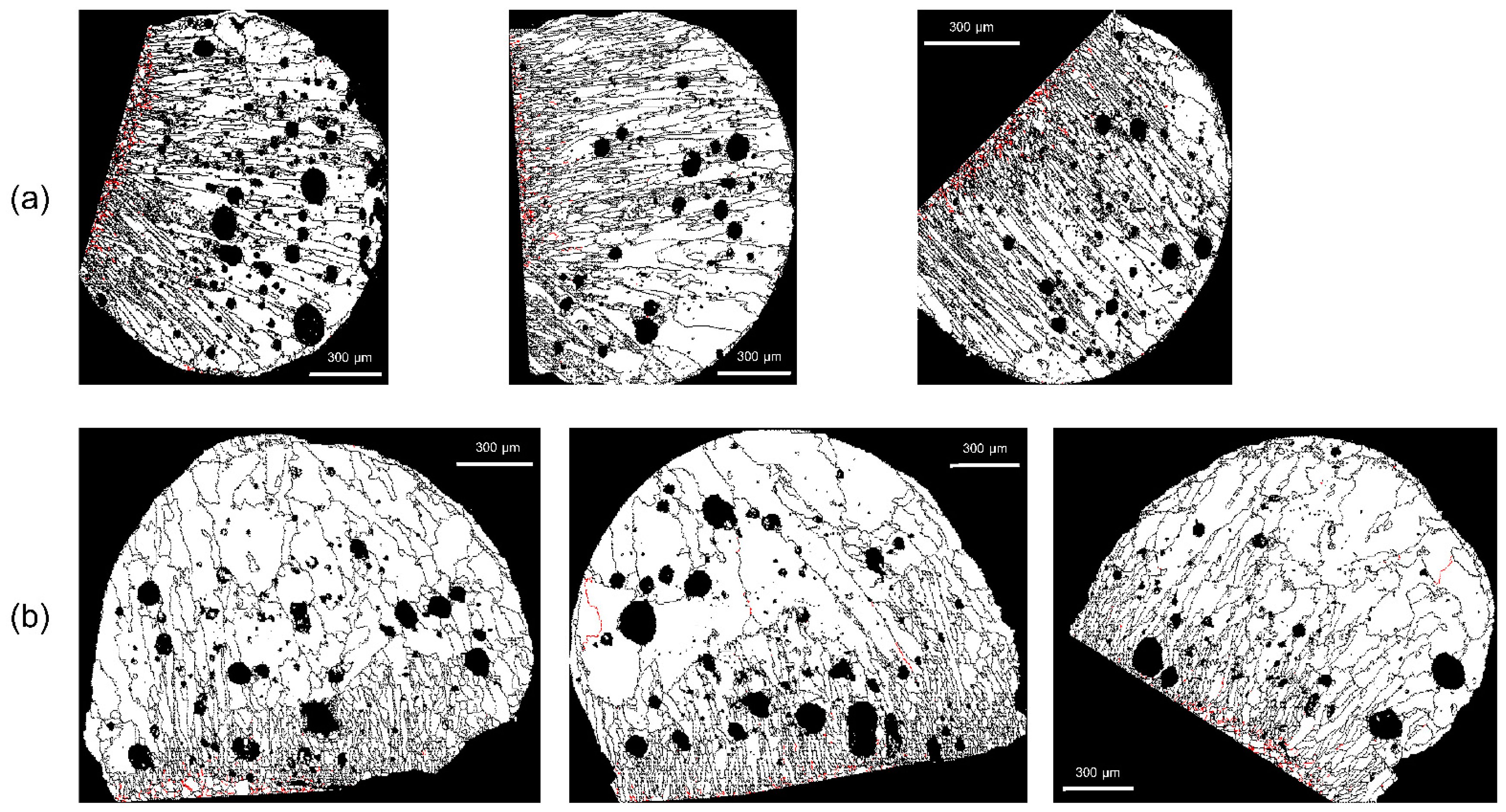

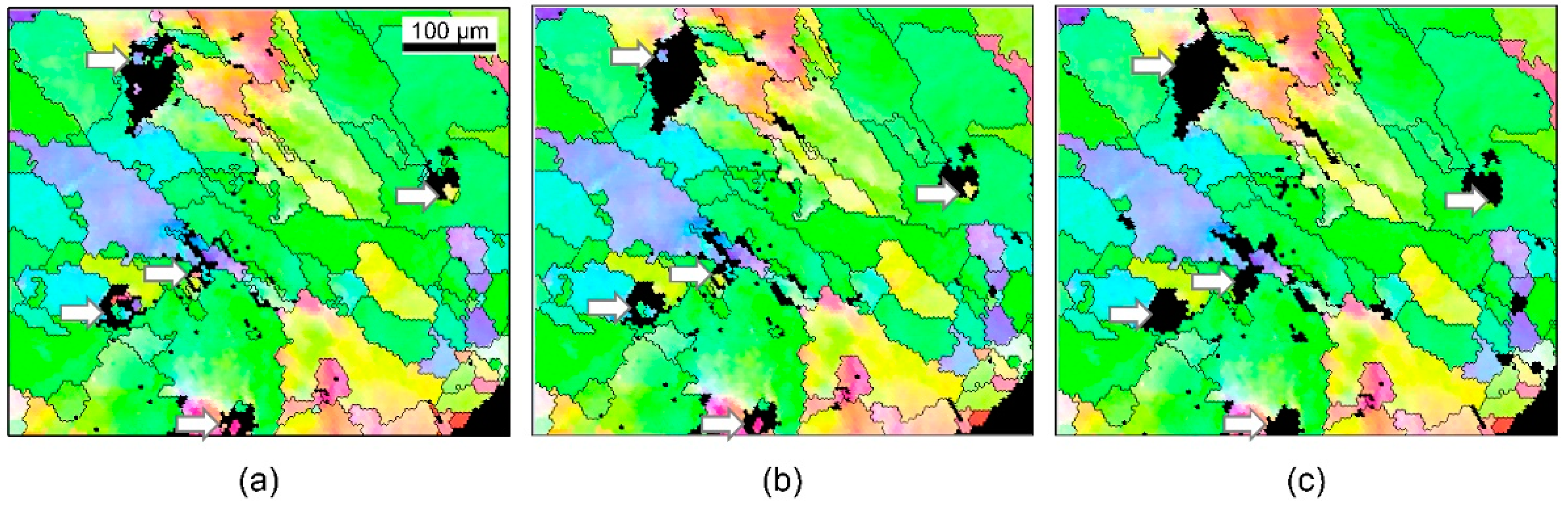

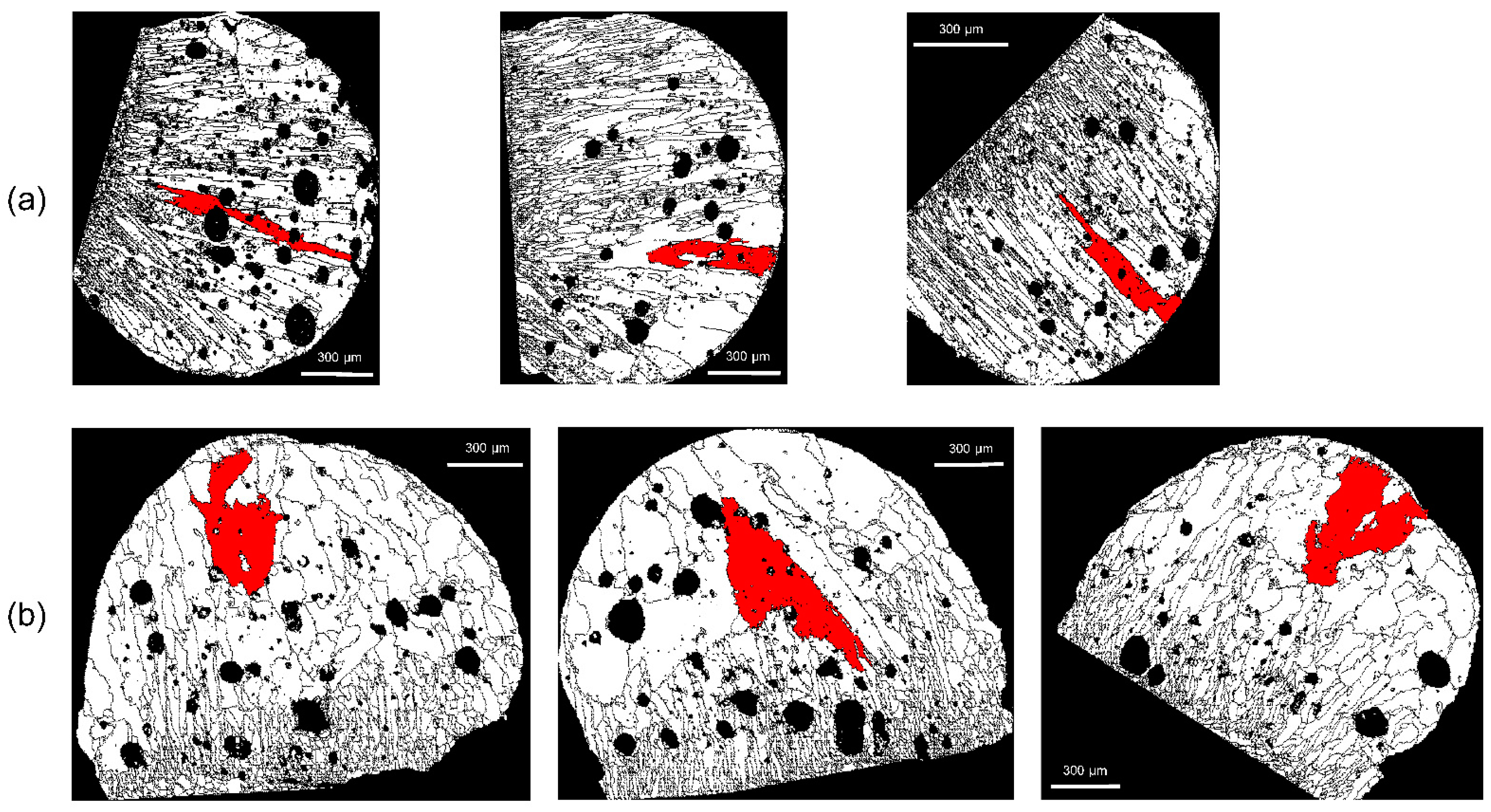

3.2. Boundary Characteristics Analysis

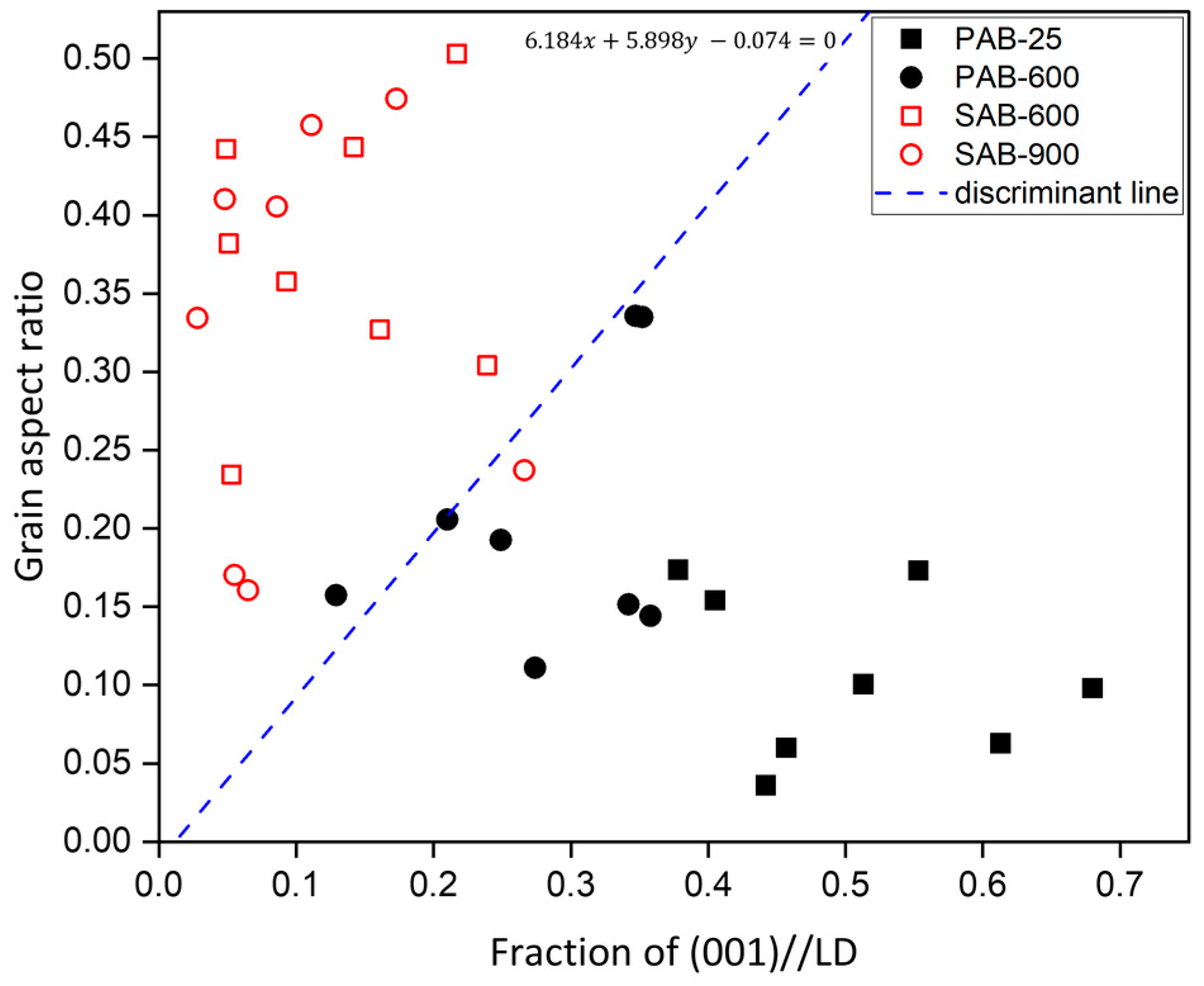

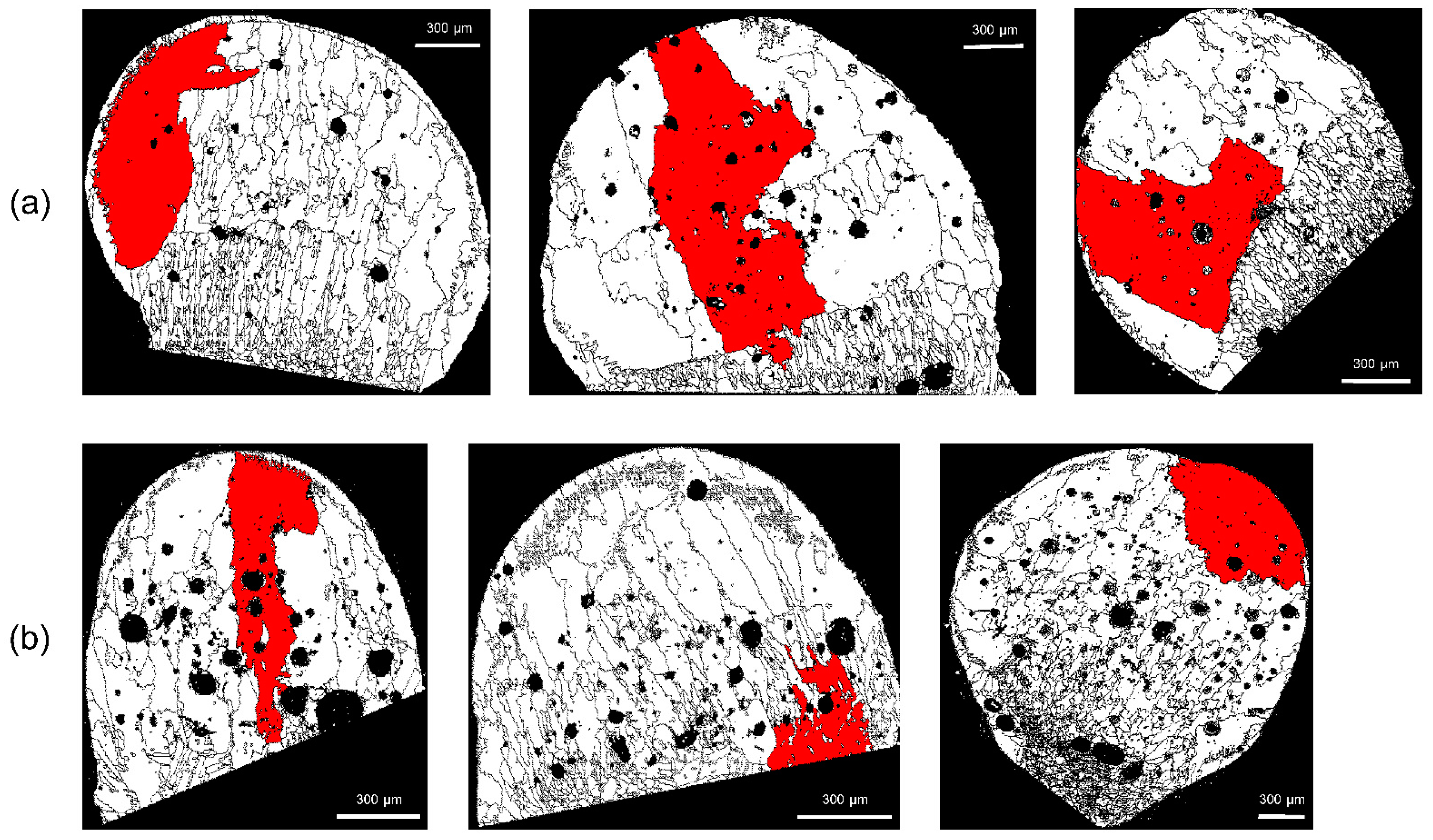

3.3. Grain Size Analysis

3.4. Identification of Molten Marks by Classification

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Troitzsch, J.H. Fire, statistics, ignition sources, and passive fire protection measures. J. Fire Sci. 2016, 34, 171–198. [Google Scholar] [CrossRef]

- Richard, C. Home Fires Caused by Electrical Failure or Malfunction: November 2021; National Fire Protection Association (NFPA): Quincy, MA, USA, 2021; Available online: https://www.nfpa.org//-/media/Files/News-and-Research/Fire-statistics-and-reports/Electrical/osHomeFiresCausedbyElectricalFailureMalfunction.pdf (accessed on 20 January 2022).

- Liu, K.-H.; Shih, Y.-H.; Chen, G.-J.; Chou, J.-M. Microstructural study on molten marks of fire-causing copper wires. Materials 2015, 8, 3776–3790. [Google Scholar] [CrossRef] [Green Version]

- National Fire Protection Association (NFPA). NFPA 921: Guide for Fire and Explosion Investigations 2017. Available online: https://www.nfpa.org/codes-and-standards/all-codes-and-standards/list-of-codes-and-standards/detail?code=921&year=2017 (accessed on 10 December 2020).

- Erlandsson, R.; Strand, G. Investigation of physical characteristics indicating primary or secondary electrical damage. Fire Saf. J. 1985, 8, 97–103. [Google Scholar] [CrossRef]

- Ibashi, Y.; Kishida, J. Research on first and second fused mark discrimination of electric wires. In Proceedings of the 1990 JAFSE Annual Symposium, Tokyo, Japan, 17–18 May 1990; pp. 83–90. [Google Scholar]

- Nobuo, M. Discrimination between primary and secondary arc marks on electric wires by micro-void distribution. Rep. Natl. Police Coll. Res. J. 1995, 48, 20–26. [Google Scholar]

- Miyoshi, S. Internal cavity analysis of electrical arc beads. In Proceedings of the 4th Asia-Oceania Symposium on Fire Science & Technology, Asia-Oceania Assn. for Fire Science & Technology/Japan Assn, for Fire Science & Engineering, Tokyo, Japan, 24–26 May 2000. [Google Scholar]

- Lee, E.-P.; Ohtani, H.; Seki, T.; Hasegawa, H.; Imada, S. Discrimination between primary and secondary molten marks on electric wires by DAS. J. Appl. Fire Sci. 2000, 9, 361–379. [Google Scholar]

- Lee, E.-P.; Ohtani, H.; Matsubara, Y.; Seki, T.; Hasegawa, H.; Imada, S.; Yashiro, I. Study on discrimination between primary and secondary molten marks using carbonized residue. Fire Saf. J. 2002, 37, 353–368. [Google Scholar] [CrossRef]

- Satoh, K.; Sugisaki, M.; Kakizaki, S.; Itoh, C.; Saitoh, K.; Iwaki, M. Secondary ion mass spectroscopy (SIMS) and auger electron spectroscopy (AES) applied to the fire investigation for short circuit. In Proceedings of the 1996 Annual Meeting of Japan Association for Fire Science and Engineering, Tokyo, Japan; 1996; pp. 282–285. [Google Scholar]

- Anderson, R.N. Which came first … the arcing or the fire? Review of auger analysis of electrical arc residues. Fire Arson Investig. 1996, 46, 38–40. [Google Scholar]

- Babrauskas, V. Arc beads from fires: Can ‘cause’ beads be distinguished from ‘victim’ beads by physical or chemical testing? J. Fire Prot. Eng. 2004, 14, 125–147. [Google Scholar] [CrossRef]

- Park, J.; Kang, J.-H.; Lee, E.P.; Ko, Y.H.; Bang, S.B. New approach to distinguish copper molten marks based on quantitative microstructure analysis using electron backscatter diffraction. Fire Technol. 2021, 57, 1667–1682. [Google Scholar] [CrossRef]

- UL 1699; Standard for Arc-Fault Circuit-Interrupters 2019. Underwriters Laboratories Inc. (UL): Northbrook, IL, USA, 2019. Available online: https://standardscatalog.ul.com/productDetail.aspx?UniqueKey=35800 (accessed on 11 October 2020).

- Weinschenk, C.; Madrzykowski, D.; Courtney, P. Impact of flashover fire conditions on exposed energized electrical cords/cables. Fire Technol. 2020, 56, 959–991. [Google Scholar] [CrossRef] [Green Version]

- Samuels, L.E. Metallographic Polishing by Mechanical Methods, 4th ed.; ASM International: Cleveland, OH, USA, 2003; pp. 153–196. ISBN 978-08-7170-779-6. [Google Scholar]

- Kang, J.-H.; Kim, S.-H. Sample preparation for EBSD analysis: Tips for metals with delicate surfaces. Kor. J. Met. Mater. 2010, 48, 730–740. [Google Scholar] [CrossRef]

- Wright, S.A.; Loud, J.D.; Blanchard, R.A. Globules and beads: What do they indicate about small-diameter copper conductors that have been through a fire. Fire Technol. 2015, 51, 1051–1070. [Google Scholar] [CrossRef]

- Roby, R.J.; McAllister, J. Forensic Investigation Techniques for Inspecting Electrical Conductors Involved in Fire; Combustion Science & Engineering Inc.: Columbia, MD, USA, 2012; Available online: https://www.ojp.gov/pdffiles1/nij/grants/239052.pdf (accessed on 28 October 2020).

- Burke, J.E. The formation of annealing twins. JOM 1950, 2, 1324–1328. [Google Scholar] [CrossRef]

- Carpenter, H.C.H.; Tamura, S. The formation of twinned metallic crystals. Proc. R. Soc. Lond. A 1962, 113, 161–182. [Google Scholar] [CrossRef] [Green Version]

- Brandon, D.G. The structure of high-angle grain boundaries. Acta Metall. Mater. 1966, 14, 1479–1484. [Google Scholar] [CrossRef]

- Bozzolo, N.; Bernacki, M. Viewpoint on the formation and evolution of annealing twins during thermomechanical processing of FCC metals and alloys. Metall. Mater. Trans. A 2020, 51, 2665–2684. [Google Scholar] [CrossRef]

- Baker, I.; Li, J. Directional annealing of cold-rolled copper single crystals. Acta Mater. 2002, 50, 805–813. [Google Scholar] [CrossRef]

- Kim, S.-H.; Kang, J.-H.; Han, S.Z. Grain size determination of copper film by electron backscatter diffraction. Korean J. Met. Mater. 2010, 48, 847–855. [Google Scholar] [CrossRef]

- ASTM E2627-13; Standard Practice for Determining Average Grain Size Using Electron Backscatter Diffraction (EBSD) in Fully Polycrystalline Materials. ASTM International: West Conshohocken, PA, USA, 2019. [CrossRef]

- Humphreys, F.J. Review grain and subgrain characterization by electron backscatter diffraction. J. Mater. Sci. 2001, 36, 3833–3854. [Google Scholar] [CrossRef]

- Zhang, T.; Liu, F.; Wang, H.F.; Yang, G.C. Grain refinement in highly undercooled solidification of Ni85Cu15 alloy melt: Direct evidence for recrystallization mechanism. Scr. Mater. 2010, 63, 43–46. [Google Scholar] [CrossRef]

- Feng, L.; Gencang, Y. Stress-induced recrystallization mechanism for grain re-finement in highly undercooled superalloy. J. Cryst. Growth 2001, 231, 295–305. [Google Scholar] [CrossRef]

- Van der Maaten, L.; Hinton, G. Visualizing Data using t-SNE. J. Mach. Learn. Res. 2008, 9, 2579–2605. Available online: https://jmlr.org/papers/volume9/vandermaaten08a/vandermaaten08a.pdf (accessed on 12 January 2022).

- McKinney, W. pandas: A foundational Python library for data analysis and statistics. Python High Perform. Sci. Comput. 2011, 14, 1–9. Available online: https://dlr.de/sc/portaldata/15/resources/dokumente/pyhpc2011/submissions/pyhpc2011_submission_9.pdf (accessed on 15 January 2022).

| Molten Marks | Number of Samples | Heating Temperature(°C) | Heating Time (Minutes) | |

|---|---|---|---|---|

| Before Short Circuit | After Short Circuit | |||

| PAB-25 | 8 | Ambient | - | - |

| PAB-600 | 8 | 600 | - | 5 |

| SAB-600 | 8 | 600 | 2 | 5 |

| SAB-600 | 8 | 900 | 2 | 5 |

| Molten Mark | PAB-25 | PAB-600 | SAB-600 | SAB-900 |

|---|---|---|---|---|

| Fraction of Σ3 (%) | 1.796 | 2.197 | 5.378 | 9.801 |

| Molten Mark | PAB-25 | PAB-600 | SAB-600 | SAB-900 |

|---|---|---|---|---|

| Fraction of maximum grain size (%) | 3.877 | 5.258 | 17.380 | 10.240 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, J.; Kang, J.-H.; Jang, H.-S.; Ko, Y.H.; Bang, S.B. Potential Method to Distinguish Copper Molten Marks Using Boundary and Grain Characteristics. Materials 2022, 15, 4534. https://doi.org/10.3390/ma15134534

Park J, Kang J-H, Jang H-S, Ko YH, Bang SB. Potential Method to Distinguish Copper Molten Marks Using Boundary and Grain Characteristics. Materials. 2022; 15(13):4534. https://doi.org/10.3390/ma15134534

Chicago/Turabian StylePark, Jinyoung, Joo-Hee Kang, Hyo-Sun Jang, Young Ho Ko, and Sun Bae Bang. 2022. "Potential Method to Distinguish Copper Molten Marks Using Boundary and Grain Characteristics" Materials 15, no. 13: 4534. https://doi.org/10.3390/ma15134534

APA StylePark, J., Kang, J.-H., Jang, H.-S., Ko, Y. H., & Bang, S. B. (2022). Potential Method to Distinguish Copper Molten Marks Using Boundary and Grain Characteristics. Materials, 15(13), 4534. https://doi.org/10.3390/ma15134534