High-Temperature Tribological Behavior of HDPE Composites Reinforced by Short Carbon Fiber under Water-Lubricated Conditions

Abstract

:1. Introduction

2. Materials and Experiment

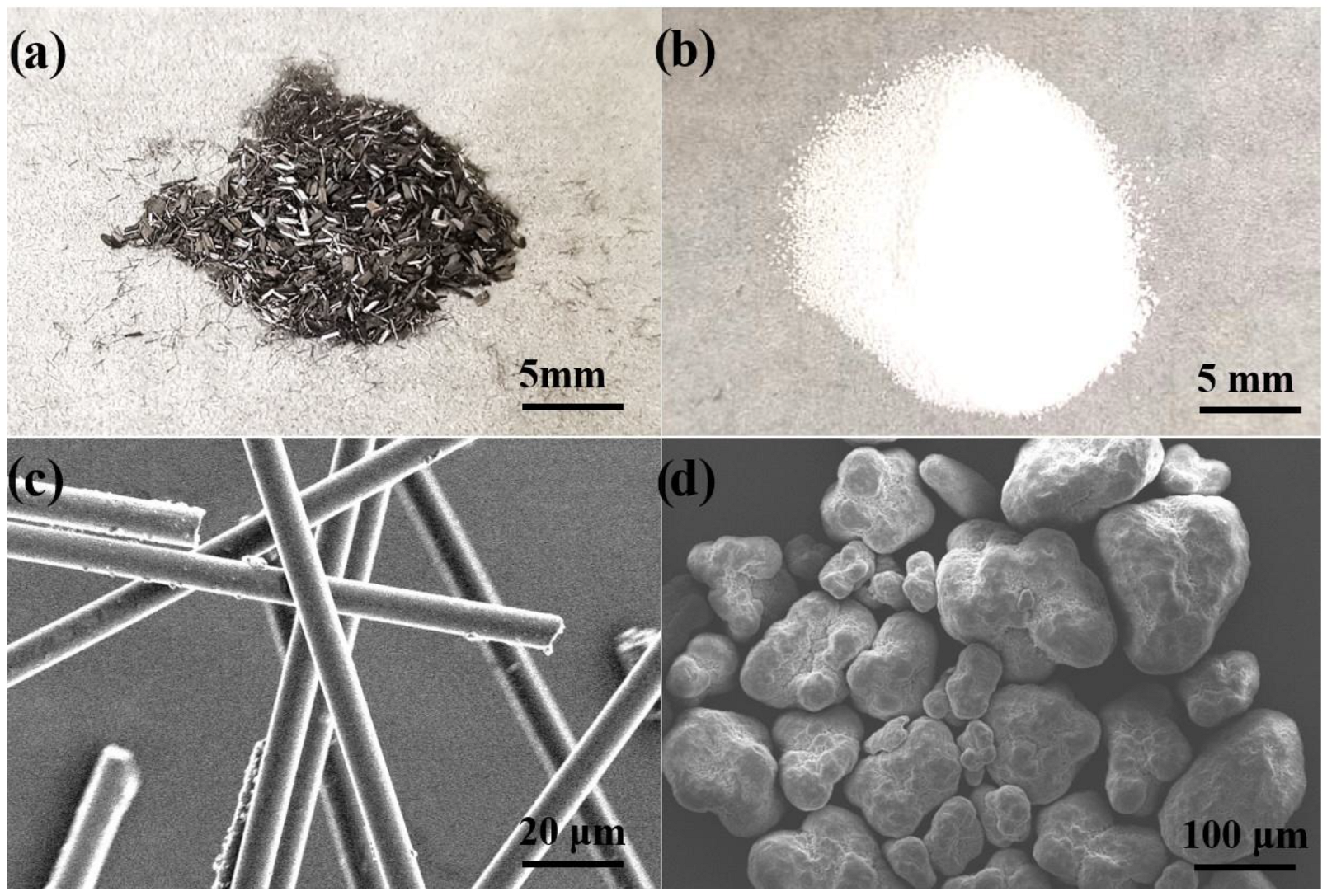

2.1. Materials

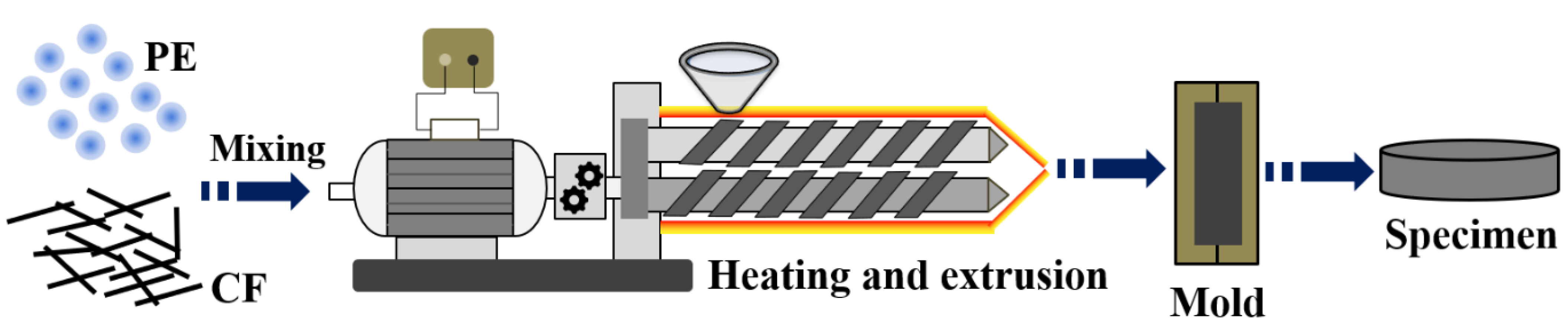

2.2. Preparation of HDPE Composites

2.3. Characterization

3. Result and Discussion

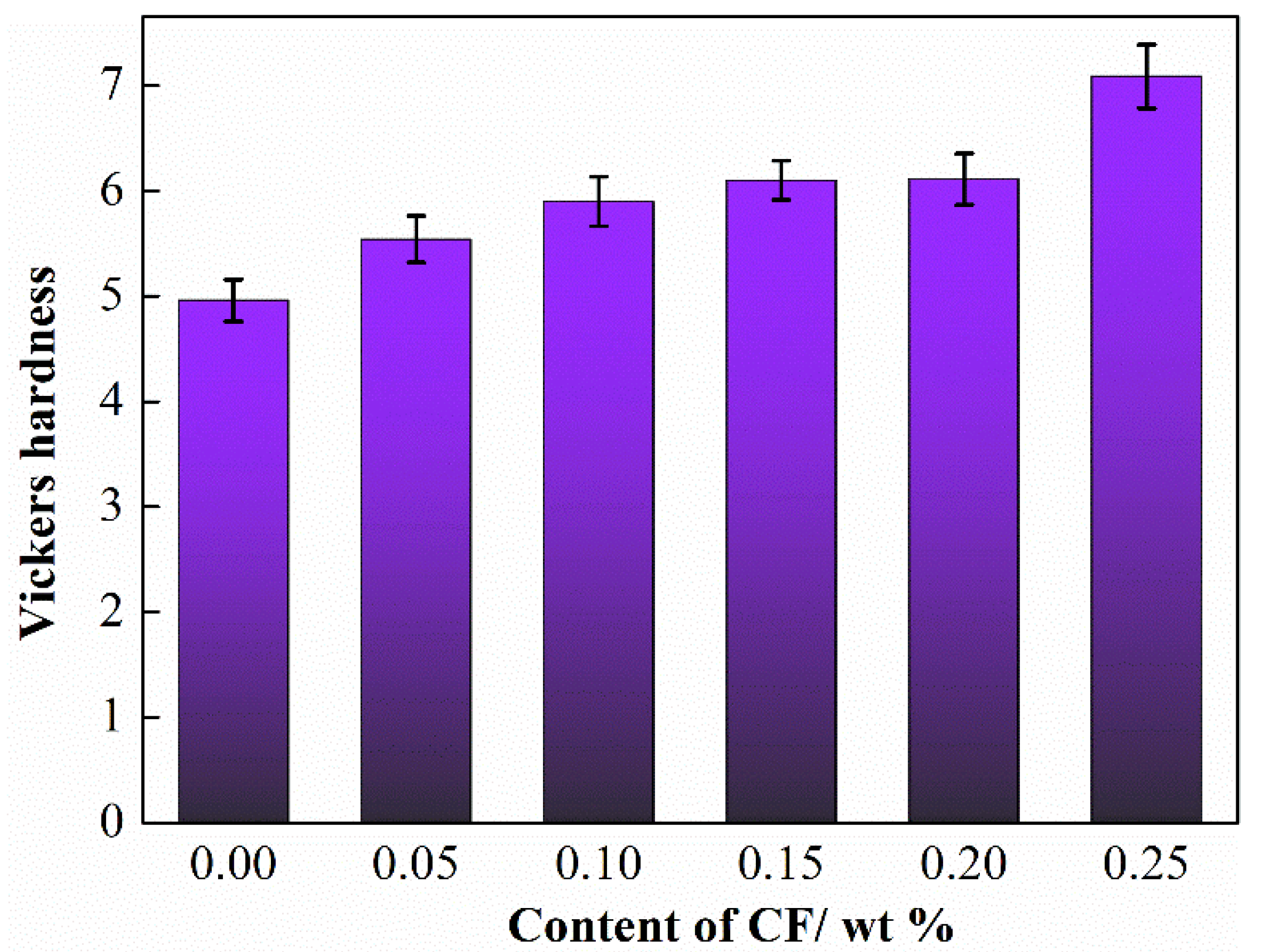

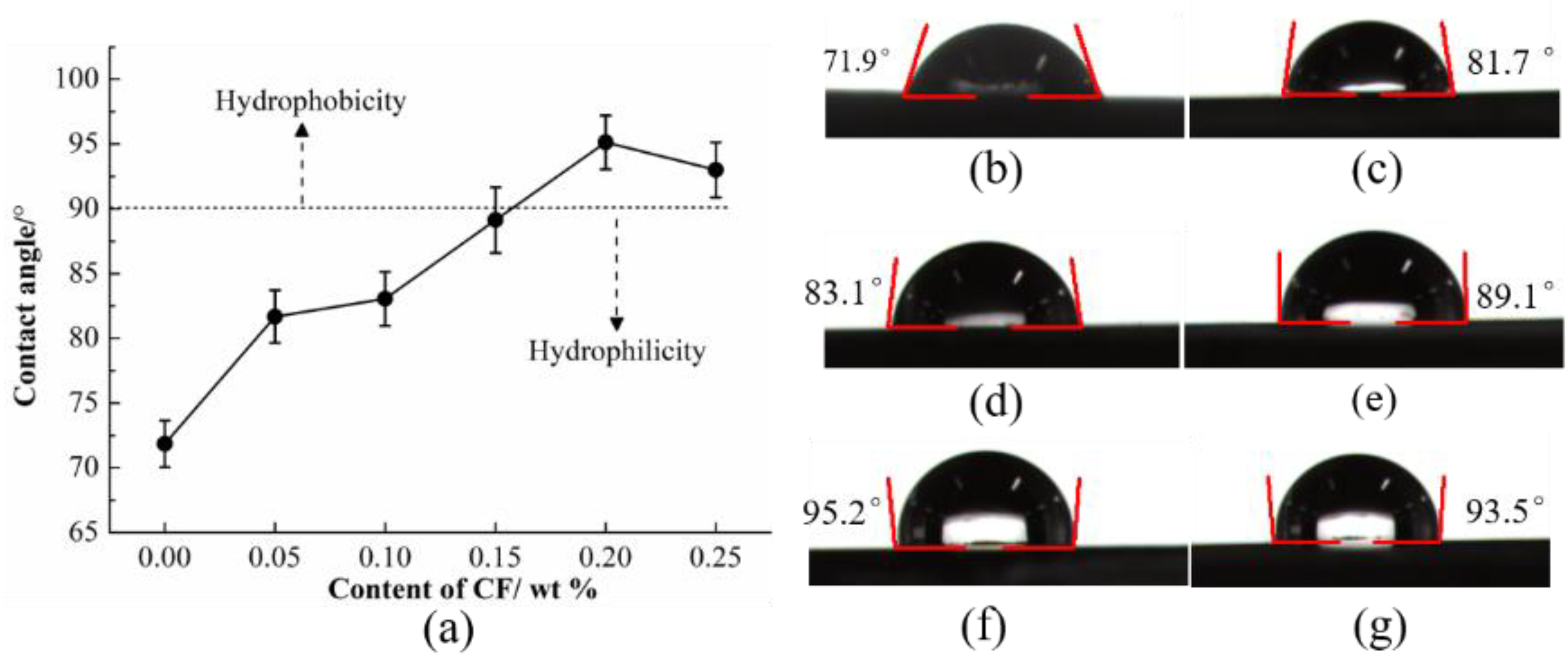

3.1. Effects of SCFs on the Hardness and Wettability of HDPE Composites

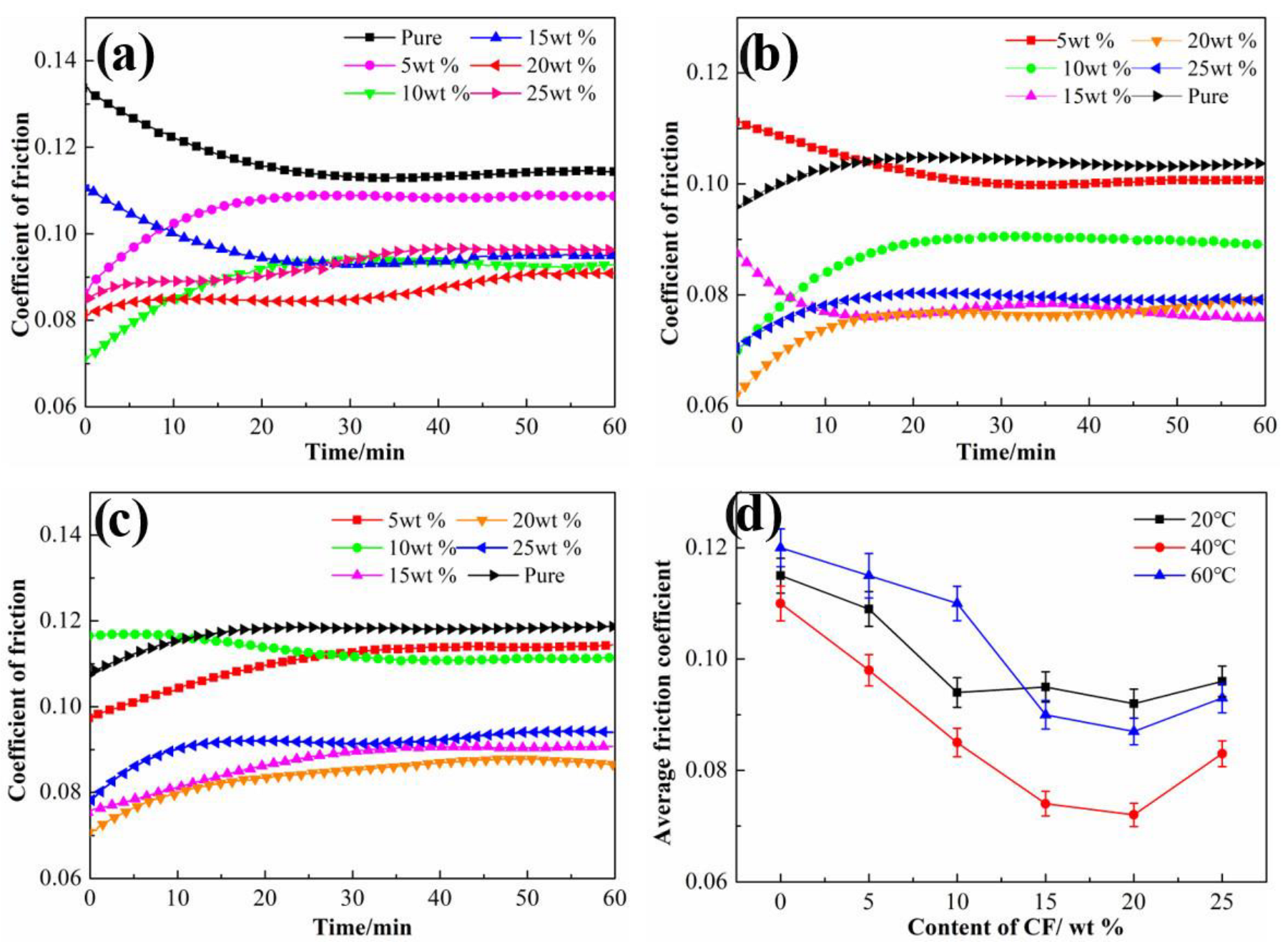

3.2. Effects of Temperature on Tribological Properties

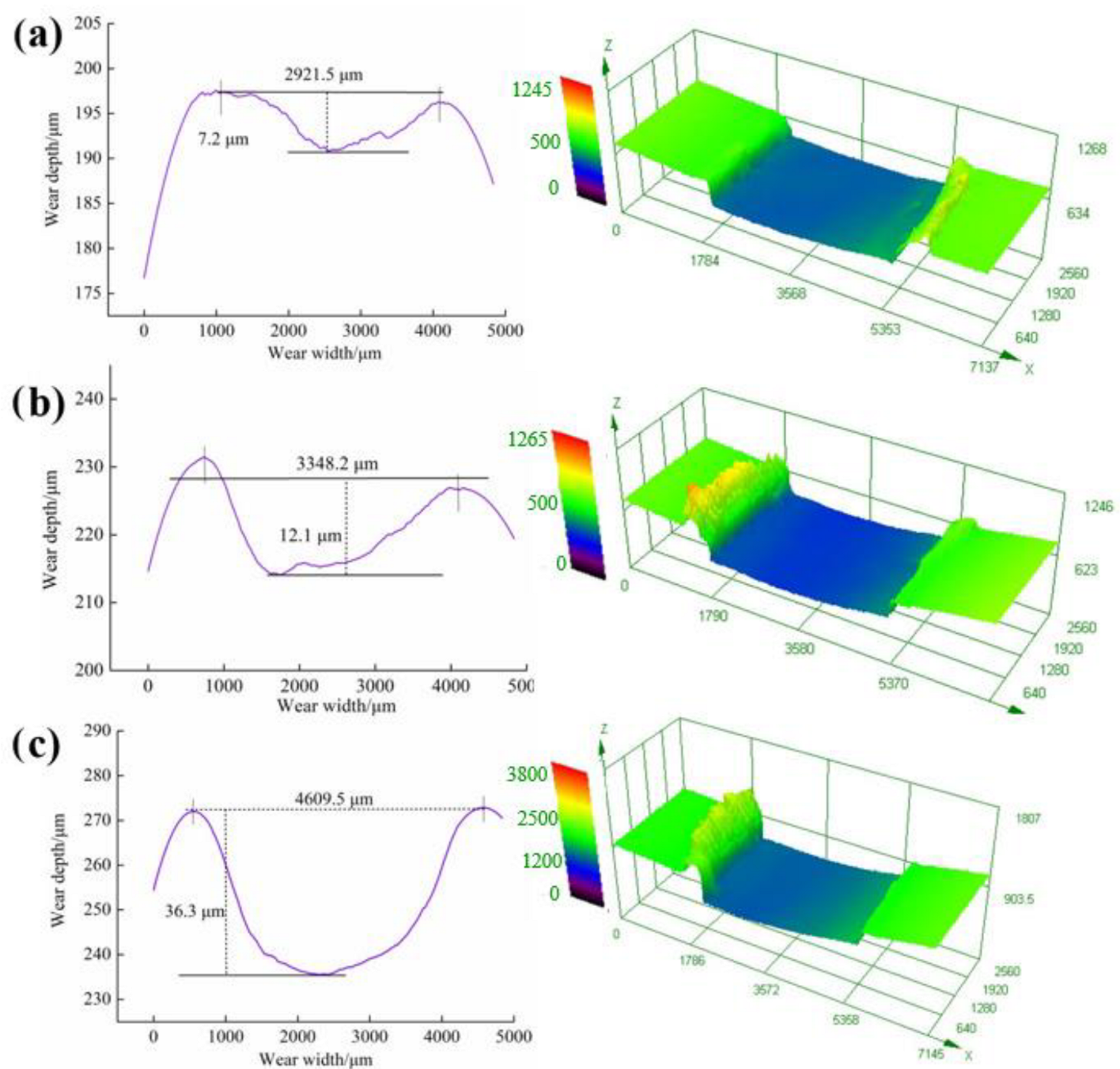

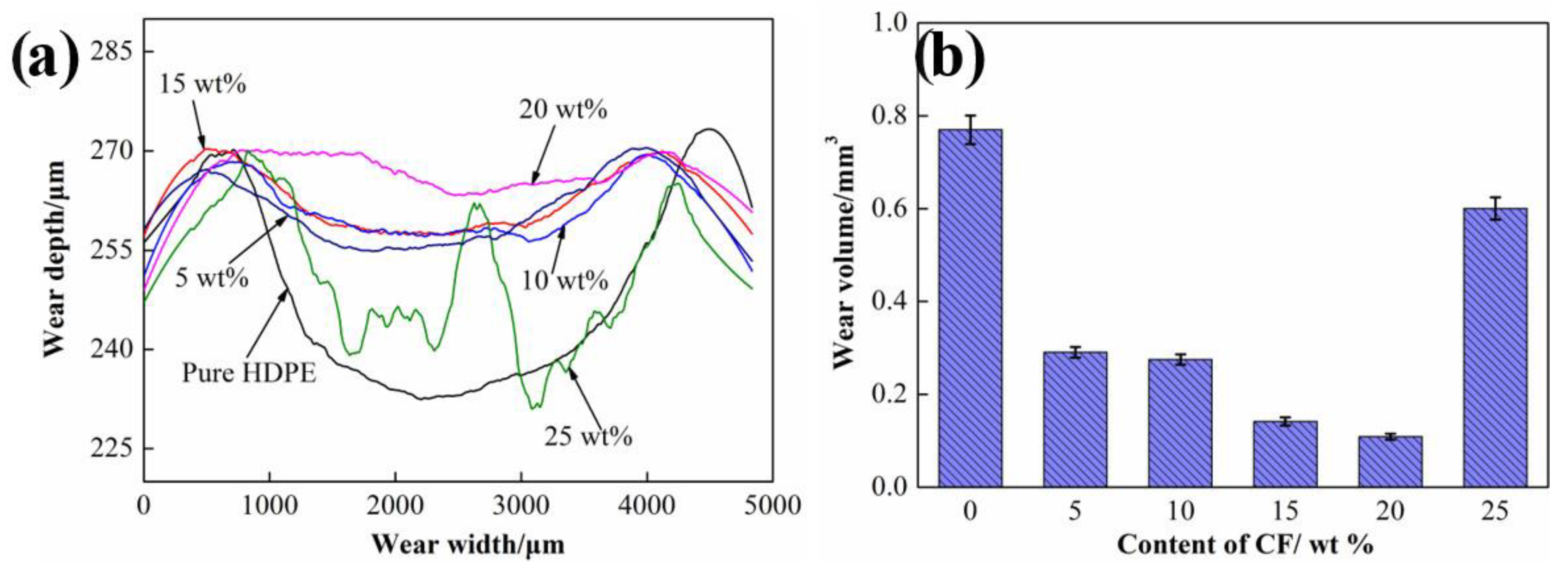

3.3. High Temperature Wear Properties

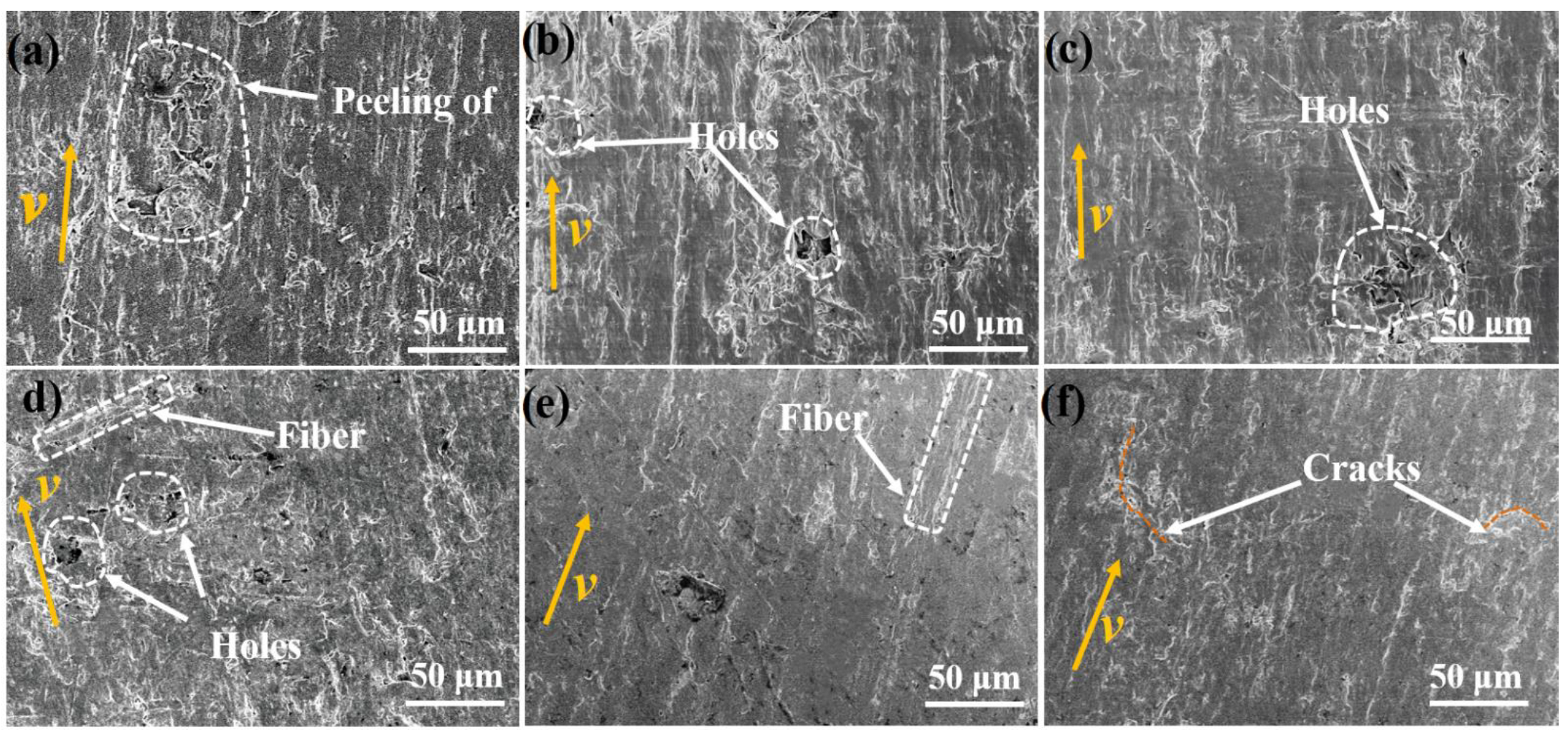

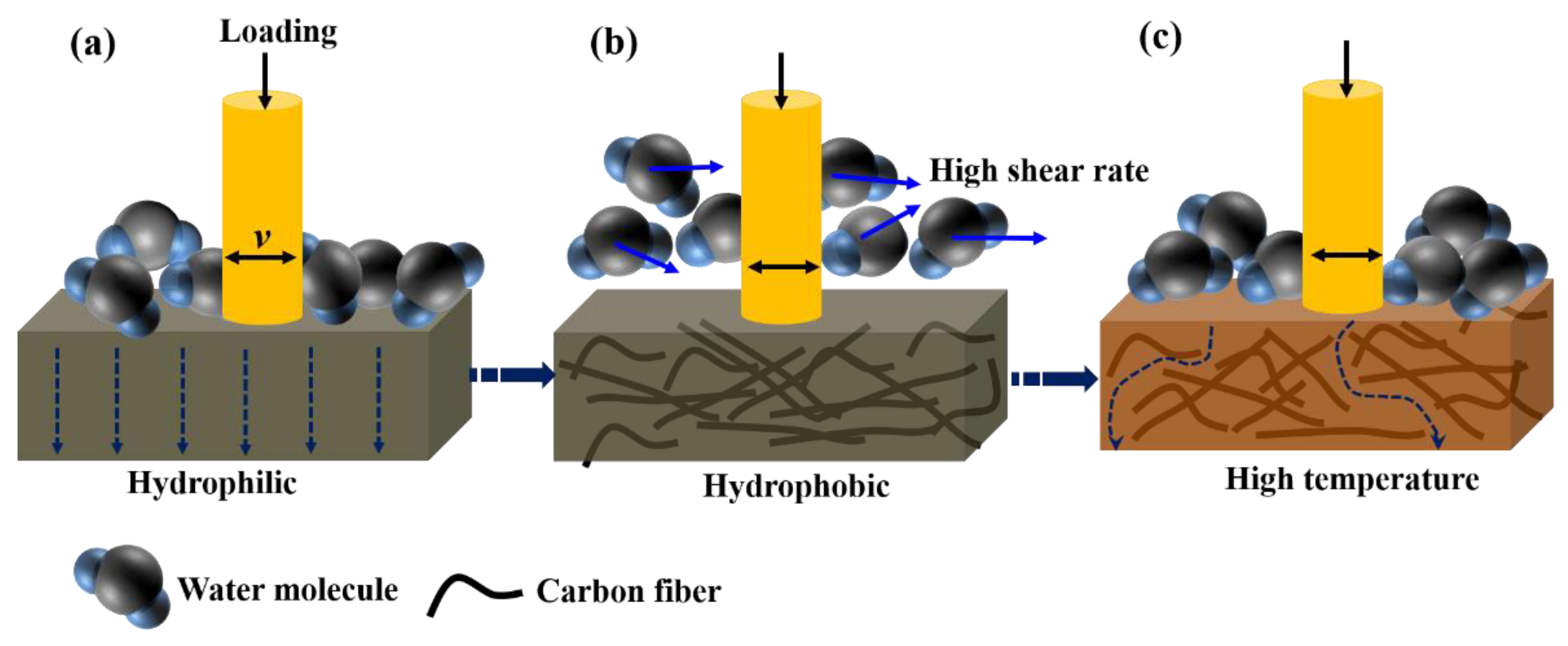

3.4. Water Lubrication and Wear Mechanism of SCFs

4. Conclusions

- (a)

- The incorporation of SCFs increased the hardness of HDPE composites, and simultaneously improved the contact angle. The hardness increased by 42.9% after adding 25 wt % SCFs, and the contact angle achieved the maximum of 95.2° when the content of SCFs was 20 wt %.

- (b)

- The HDPE composites exhibited the reduction in friction coefficient and wear loss compared with neat HDPE, and showed the lowest friction coefficient of 0.076 when the content of SCFs was 20 wt %. The addition of SCFs improved the hardness and bearing capacity of HDPE, resulting in the smaller contact area of composites and counterpart, so wear loss and friction coefficient were reduced. The incorporation of SCFs decreased the surface energy of HDPE composites, which cause the faster water flow near the surface of composites, and the matrix adhesion and heat diffusion decreased.

- (c)

- The friction coefficient and wear resistance achieved reduction for each type of HDPE composites at the higher temperature. The enhanced plasticity caused by temperature rise decreases the shear force for the matrix and leads to low friction coefficient. However, the decline in hardness and increase in stress disaccord at high temperatures do not contribute to increased wear resistance. Moreover, the high temperature changes the water flow state in near surface of HDPE composites, which also results in the poor lubrication.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhou, H.; Hao, X.; Wang, X.; Liu, T.; Sun, L.; Yi, X.; Wang, Q.; Ou, R. Comparative study on the effects of silica size and dispersion mode on the fire retardancy of extruded wood fiber/ HDPE composites. Polym. Compos. 2020, 41, 4920–4932. [Google Scholar] [CrossRef]

- Cheng, B.; Duan, H.; Chen, S.; Shang, H.; Li, J.; Shao, T. Phase morphology and tribological properties of PI/UHMWPE blend composites. Polymer 2020, 202, 122658. [Google Scholar] [CrossRef]

- Wang, C.; Bai, X.; Dong, C.; Guo, Z.; Yuan, C.; Neville, A. Designing soft/hard double network hydrogel microsphere/UHMWPE composites to promote water lubrication performance. Friction 2020, 9, 551–568. [Google Scholar] [CrossRef]

- Wang, C.; Bai, X.; Guo, Z.; Dong, C.; Yuan, C. Friction and wear behaviours of polyacrylamide hydrogel microsphere/UHMWPE composite under water lubrication. Wear 2021, 477, 203841. [Google Scholar] [CrossRef]

- Furlan, K.P.; de Mello, J.D.B.; Klein, A.N. Self-lubricating composites containing MoS2: A review. Tribol. Int. 2018, 120, 280–298. [Google Scholar] [CrossRef]

- Xu, S.; Tangpong, X.W. Review: Tribological behavior of polyethylene-based nanocomposites. J. Mater. Sci. 2012, 48, 578–597. [Google Scholar] [CrossRef]

- Tong, Z.; Lu, H.; Guo, F.; Lei, W.; Dong, M.; Dong, G. Preparation of small CNTs@Fe3O4 and alignment in carbon fabrics/epoxy composites to improve mechanical and tribological properties. J. Mater. Sci. 2020, 56, 1386–1400. [Google Scholar] [CrossRef]

- Tavakkoli, O.; Kamyab, H.; Junin, R.; Ashokkumar, V.; Shariati, A.; Mohamed, A.M. SDS–Aluminum Oxide Nanofluid for Enhanced Oil Recovery: IFT, Adsorption, and Oil Displacement Efficiency. ACS Omega 2022, 7, 14022–14030. [Google Scholar] [CrossRef]

- Shi, Y.; Liang, M.; Wu, H.; Chen, Y.; Zhou, S.; Zou, H.; Sun, T.; Zhang, H. Hybridization of Polytetrafluorethylene Fibers and Multiscale Short Carbon Fibers to Significantly Improve the Tribological Performance of Polyphenylene Sulfide. Adv. Eng. Mater. 2020, 23, 2000787. [Google Scholar] [CrossRef]

- Huang, R.; Xu, X.; Lee, S.; Zhang, Y.; Kim, B.-J.; Wu, Q. High Density Polyethylene Composites Reinforced with Hybrid Inorganic Fillers: Morphology, Mechanical and Thermal Expansion Performance. Materials 2013, 6, 4122–4138. [Google Scholar] [CrossRef] [Green Version]

- Sun, Z.; Zhao, Z.-K.; Zhang, Y.-Y.; Li, Y.-Q.; Fu, Y.-Q.; Sun, B.-G.; Shi, H.-Q.; Huang, P.; Hu, N.; Fu, S.-Y. Mechanical, tribological and thermal properties of injection molded short carbon fiber/expanded graphite/polyetherimide composites. Compos. Sci. Technol. 2020, 201, 108498. [Google Scholar] [CrossRef]

- Chen, B.; Li, X.; Li, X.; Jia, Y.; Yang, J.; Yang, G.; Li, C. Friction and Wear Properties of Polyimide-Based Composites with a Multiscale Carbon Fiber-Carbon Nanotube Hybrid. Tribol. Lett. 2017, 65, 111. [Google Scholar] [CrossRef]

- Zare, Y.; Rhee, K.Y. Tensile modulus of polymer/CNT nanocomposites by effective volume fraction of nanoparticles as a function of CNT properties in the network. Polym. Adv. Technol. 2017, 28, 1448–1452. [Google Scholar] [CrossRef]

- Papadopoulos, A.; Gkikas, G.; Paipetis, A.; Barkoula, N.-M. Effect of CNTs addition on the erosive wear response of epoxy resin and carbon fibre composites. Compos. Part A Appl. Sci. Manuf. 2016, 84, 299–307. [Google Scholar] [CrossRef]

- Nie, P.; Min, C.; Chen, X.; Shen, C.; Tu, W.; Song, H. Effect of MWCNTs-COOH Reinforcement on Tribological Behaviors of PI/MWCNTs-COOH Nanocomposites Under Seawater Lubrication. Tribol. Trans. 2016, 59, 89–98. [Google Scholar] [CrossRef]

- Wu, J.; Cui, G.; Kou, Z.; Wu, G. Friction and Wear Behavior of Several Fe Matrix Alloys in Distilled Water. Tribol. Trans. 2014, 58, 97–105. [Google Scholar] [CrossRef]

- Cui, G.; Bi, Q.; Yang, J.; Liu, W. The bronze–silver self-lubricating composite under sea water condition. Tribol. Int. 2012, 60, 83–92. [Google Scholar] [CrossRef]

- Golchin, A.; Friedrich, K.; Noll, A.; Prakash, B. Tribological behavior of carbon-filled PPS composites in water lubricated contacts. Wear 2015, 328–329, 456–463. [Google Scholar] [CrossRef]

- Dong, C.; Yuan, C.; Wang, L.; Liu, W.; Bai, X.; Yan, X. Tribological Properties of Water-lubricated Rubber Materials after Modification by MoS2 Nanoparticles. Sci. Rep. 2016, 6, 35023. [Google Scholar] [CrossRef]

- Gao, C.; Zhang, G.; Wang, T.; Wang, Q. Enhancing the tribological performance of PEEK exposed to water-lubrication by filling goethite (α-FeOOH) nanoparticles. RSC Adv. 2016, 6, 51247–51256. [Google Scholar] [CrossRef]

- Liu, N.; Wang, J.; Yang, J.; Han, G.; Yan, F. Combined effect of nano-SiO 2 and nano-Al 2 O 3 on improving the tribological properties of Kevlar fabric/phenolic laminate in water. Tribol. Trans. 2016, 59, 163–169. [Google Scholar] [CrossRef]

- Farfan-Cabrera, L.I.; Pérez-González, J.; Iniestra-Galindo, M.G.; Marín-Santibáñez, B.M. Production and tribological evaluation of polypropylene nanocomposites with reduced graphene oxide (rGO) for using in water-lubricated bearings. Wear 2021, 477, 203860. [Google Scholar] [CrossRef]

- Golchin, A.; Villain, A.; Emami, N. Tribological behaviour of nanodiamond reinforced UHMWPE in water-lubricated contacts. Tribol. Int. 2017, 110, 195–200. [Google Scholar] [CrossRef]

- Golchin, A.; Wikner, A.; Emami, N. An investigation into tribological behaviour of multi-walled carbon nanotube/graphene oxide reinforced UHMWPE in water lubricated contacts. Tribol. Int. 2016, 95, 156–161. [Google Scholar] [CrossRef]

- Krishnan, S.; Zulkapli, N.S.; Kamyab, H.; Taib, S.M.; Bin Din, M.F.; Majid, Z.A.; Chaiprapat, S.; Kenzo, I.; Ichikawa, Y.; Nasrullah, M.; et al. Current technologies for recovery of metals from industrial wastes: An overview. Environ. Technol. Innov. 2021, 22, 101525. [Google Scholar] [CrossRef]

- Tavakkoli, O.; Kamyab, H.; Shariati, M.; Mohamed, A.M.; Junin, R. Effect of nanoparticles on the performance of polymer/surfactant flooding for enhanced oil recovery: A review. Fuel 2021, 312, 122867. [Google Scholar] [CrossRef]

- Pang, W.; Ni, Z.; Wu, J.; Zhao, Y. Investigation of tribological properties of graphene oxide reinforced ultrahigh molecular weight polyethylene under artificial seawater lubricating condition. Appl. Surf. Sci. 2018, 434, 273–282. [Google Scholar] [CrossRef]

- Salem, A.; Bensalah, W.; Mezlini, S. Effect of hygrothermal aging on the tribological behavior of HDPE composites for bio-implant application. Polym. Test. 2021, 94, 107050. [Google Scholar] [CrossRef]

- Dong, F.; Hou, G.; Cao, F.; Yan, F.; Liu, L.; Wang, J. The lubricity and reinforcement of carbon fibers in polyimide at high temperatures. Tribol. Int. 2016, 101, 291–300. [Google Scholar] [CrossRef]

- Huang, Q.; Guo, Z.; Wu, Z.; Yuan, C. Insight into the tribological performance of polyurethane composites under high temperature water lubrication. Tribol. Int. 2020, 155, 106784. [Google Scholar] [CrossRef]

- Dong, C.; Yuan, C.; Bai, X.; Tian, Y. A novel approach to reduce deformation behaviors of HDPE polymer during friction. Appl. Surf. Sci. 2020, 503, 144311. [Google Scholar] [CrossRef]

- Li, S.; Dong, C.; Yuan, C.; Liu, S.; Bai, X. Effects of CeO2 nano-particles on anti-aging performance of HDPE polymer during friction. Wear 2021, 477, 203832. [Google Scholar] [CrossRef]

- Makowiec, M.E.; Gionta, G.L.; Bhargava, S.; Ozisik, R.; Blanchet, T.A. Wear resistance effects of alumina and carbon nanoscale fillers in PFA, FEP, and HDPE polymers. Wear 2022, 502–503, 204376. [Google Scholar] [CrossRef]

- Jang, M.G.; Ryu, S.C.; Juhn, K.J.; Kim, S.K.; Kim, W.N. Effects of carbon fiber modification with multiwall CNT on the electrical conductivity and EMI shielding effectiveness of polycarbonate/carbon fiber/CNT composites. J. Appl. Polym. Sci. 2018, 136, 47302. [Google Scholar] [CrossRef]

- Hu, C.; Liao, X.; Qin, Q.-H.; Wang, G. The fabrication and characterization of high density polyethylene composites reinforced by carbon nanotube coated carbon fibers. Compos. Part A Appl. Sci. Manuf. 2019, 121, 149–156. [Google Scholar] [CrossRef]

- O’Connor, H.; Dowling, D.P. Evaluation of the protective performance of hydrophobic coatings applied on carbon-fibre epoxy composites. J. Compos. Mater. 2019, 54, 1327–1338. [Google Scholar] [CrossRef]

- Wang, J.; Zhou, W.; Luo, F.; Zhu, D.; Qing, Y. Mechanical performance of nanosilica filled quartz fiber/polyimide composites at room and elevated temperatures. J. Mater. Sci. 2017, 52, 12207–12220. [Google Scholar] [CrossRef]

- Feldmann, M. The effects of the injection moulding temperature on the mechanical properties and morphology of polypropylene man-made cellulose fibre composites. Compos. Part A Appl. Sci. Manuf. 2016, 87, 146–152. [Google Scholar] [CrossRef]

- Kwon, S.; Adachi, T.; Araki, W. Temperature dependence of fracture toughness of silica/epoxy composites: Related to microstructure of nano- and micro-particles packing. Compos. Part B Eng. 2008, 39, 773–781. [Google Scholar] [CrossRef]

- Golchin, A.; Simmons, G.; Glavatskih, S.; Prakash, B. Tribological behaviour of polymeric materials in water-lubricated contacts. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2013, 227, 811–825. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, W.; Liang, H.; Zhao, Z. Layered oil slip model for investigation of film thickness behaviours at high speed conditions. Tribol. Int. 2018, 131, 137–147. [Google Scholar] [CrossRef]

- Huang, P.; Breuer, K.S. Direct measurement of slip length in electrolyte solutions. Phys. Fluids 2007, 19, 028104. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhong, W.; Chen, S.; Tong, Z. High-Temperature Tribological Behavior of HDPE Composites Reinforced by Short Carbon Fiber under Water-Lubricated Conditions. Materials 2022, 15, 4508. https://doi.org/10.3390/ma15134508

Zhong W, Chen S, Tong Z. High-Temperature Tribological Behavior of HDPE Composites Reinforced by Short Carbon Fiber under Water-Lubricated Conditions. Materials. 2022; 15(13):4508. https://doi.org/10.3390/ma15134508

Chicago/Turabian StyleZhong, Wen, Siqiang Chen, and Zhe Tong. 2022. "High-Temperature Tribological Behavior of HDPE Composites Reinforced by Short Carbon Fiber under Water-Lubricated Conditions" Materials 15, no. 13: 4508. https://doi.org/10.3390/ma15134508

APA StyleZhong, W., Chen, S., & Tong, Z. (2022). High-Temperature Tribological Behavior of HDPE Composites Reinforced by Short Carbon Fiber under Water-Lubricated Conditions. Materials, 15(13), 4508. https://doi.org/10.3390/ma15134508