Recent Advances in Materials for Wearable Thermoelectric Generators and Biosensing Devices

Abstract

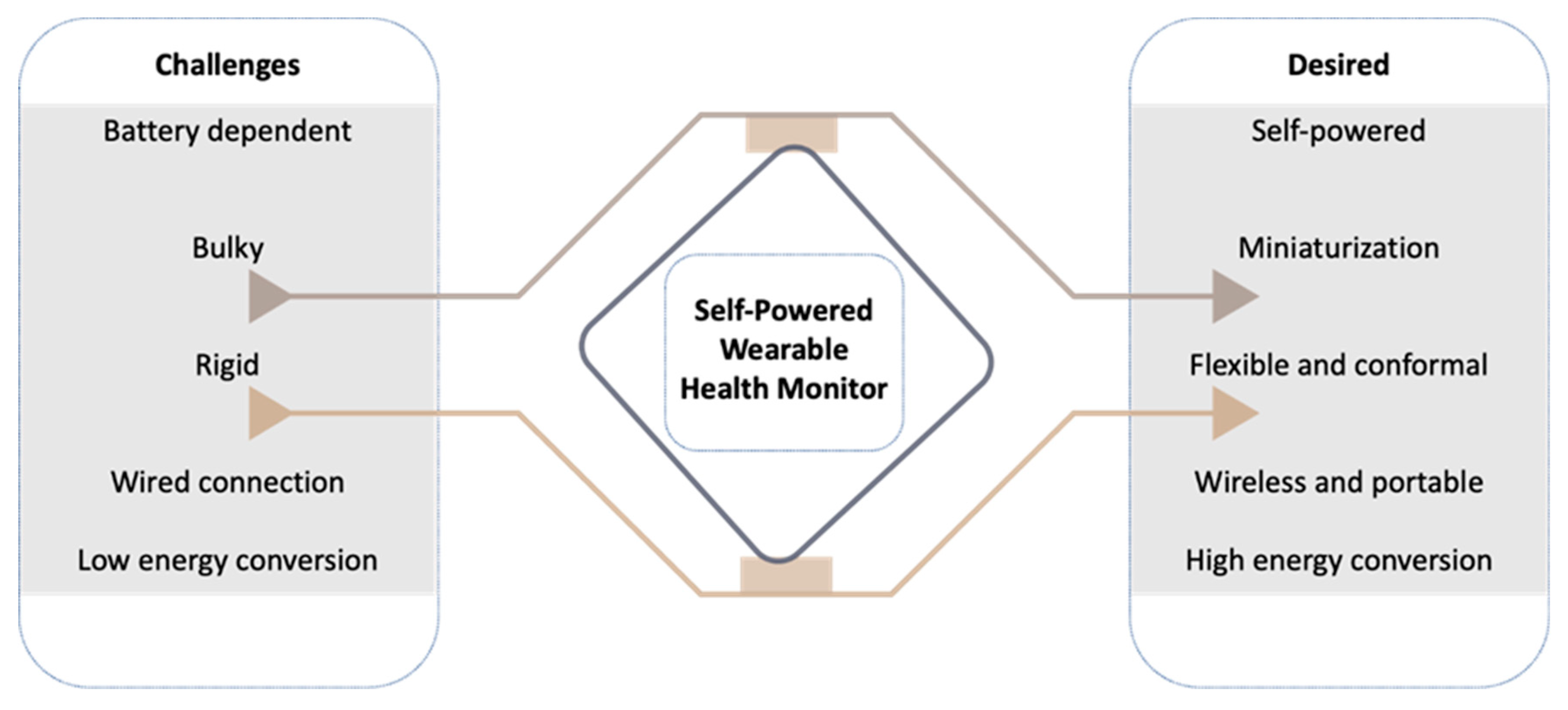

:1. Introduction

2. Why Thermoelectrics?

3. An Overview of Key Challenges in Developing WTEG

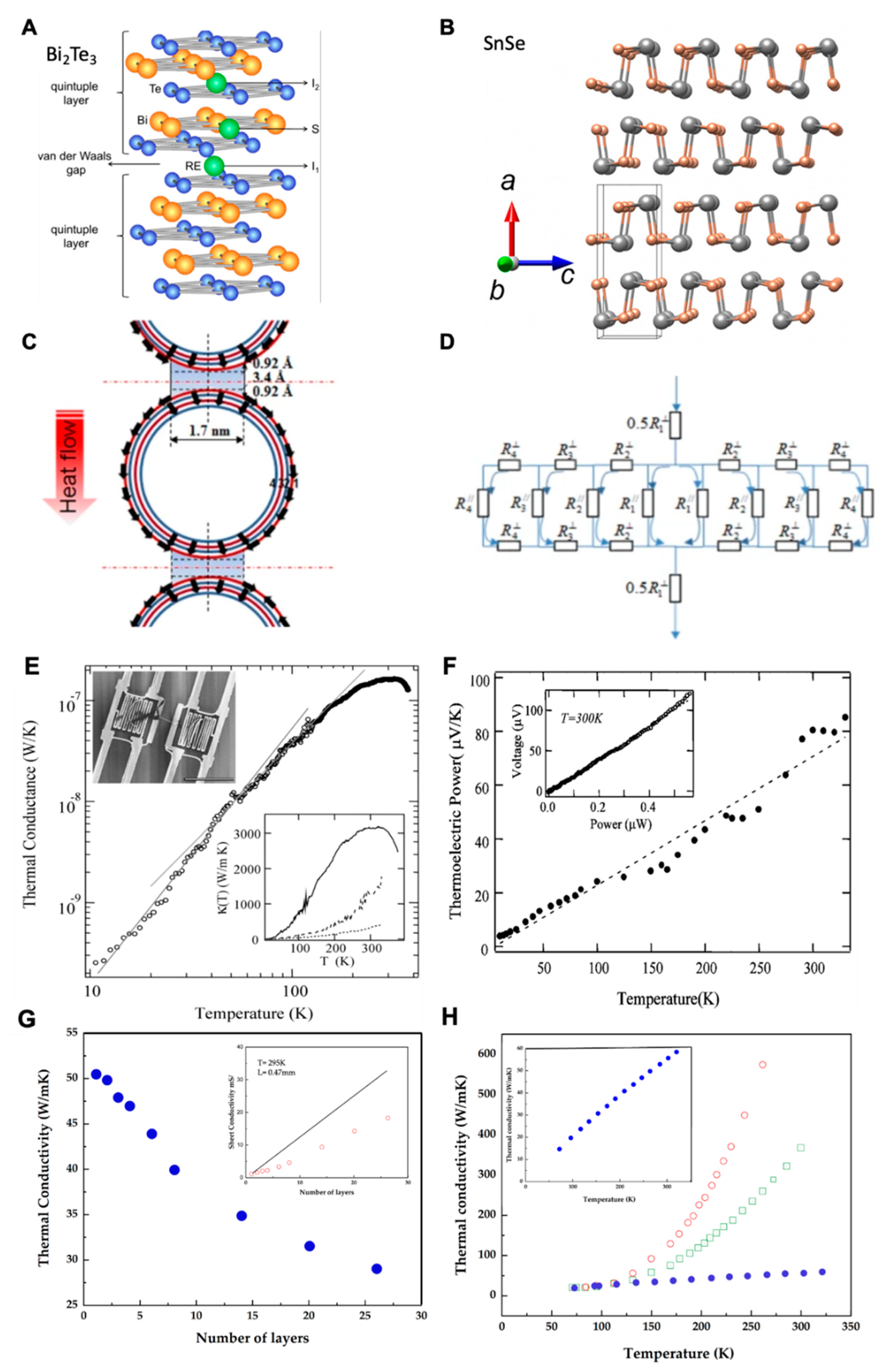

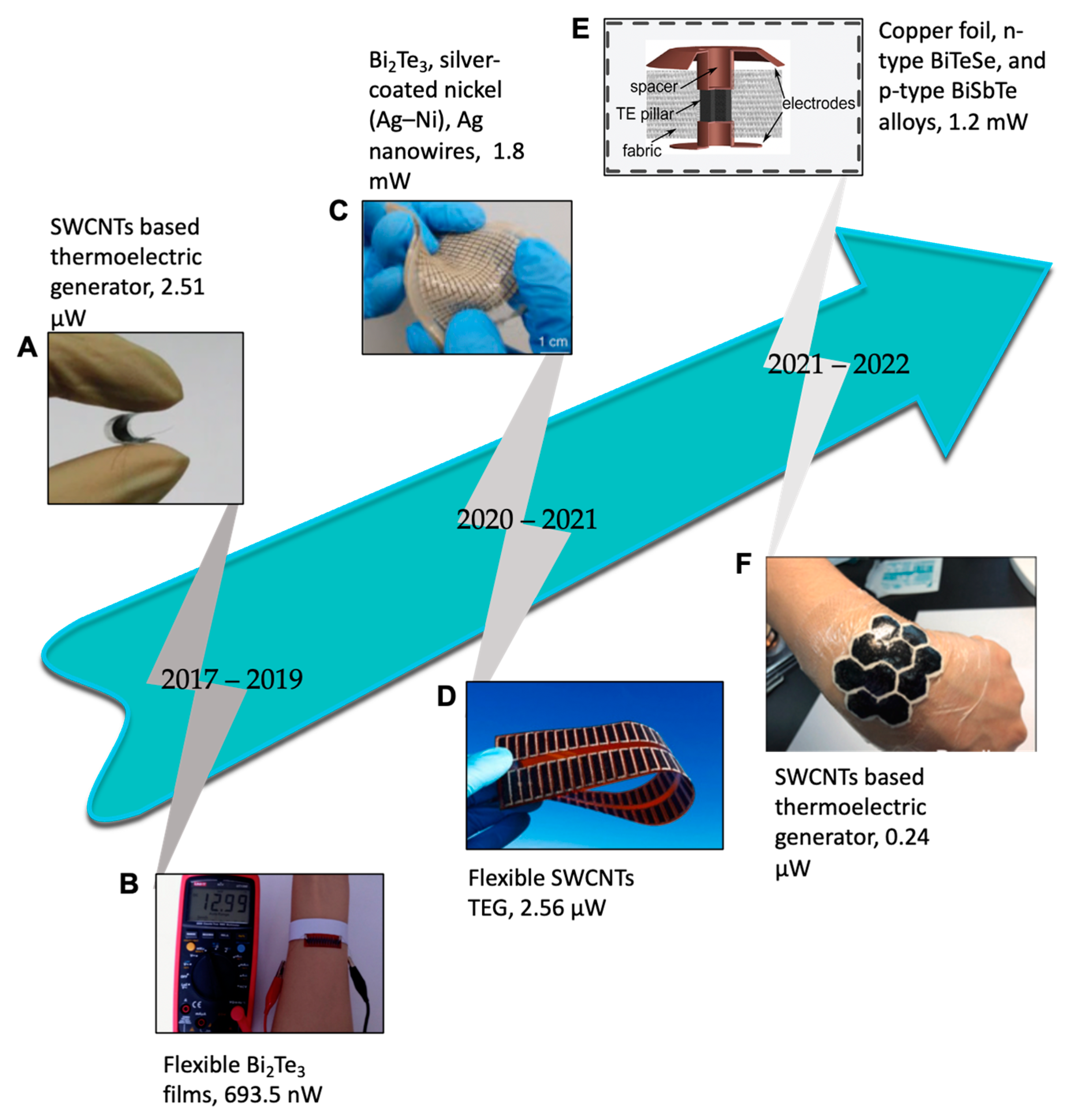

4. Thermoelectric Materials

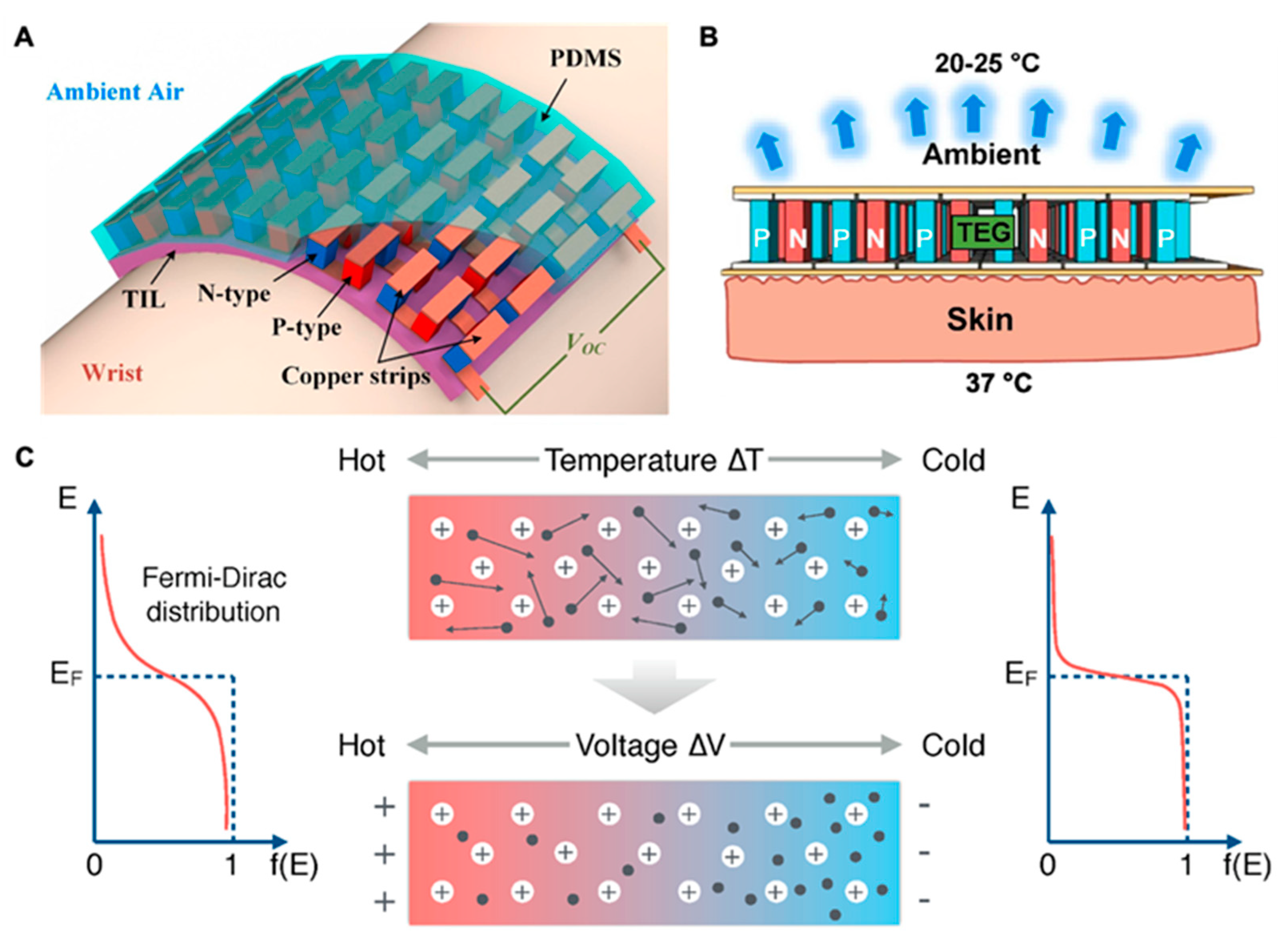

4.1. Inorganic TE Materials

4.2. Carbon-Based TE Materials

4.3. Organic-Inorganic and Hybrid Matrix

5. Thermoelectric Challenges in CNTs

6. TE Systems Architecture and Design

6.1. Effects of the Geometric Parameters on TE Performance

6.2. Conformal Contact with Human Skin

7. Future Perspective for WTEG Design and Performance

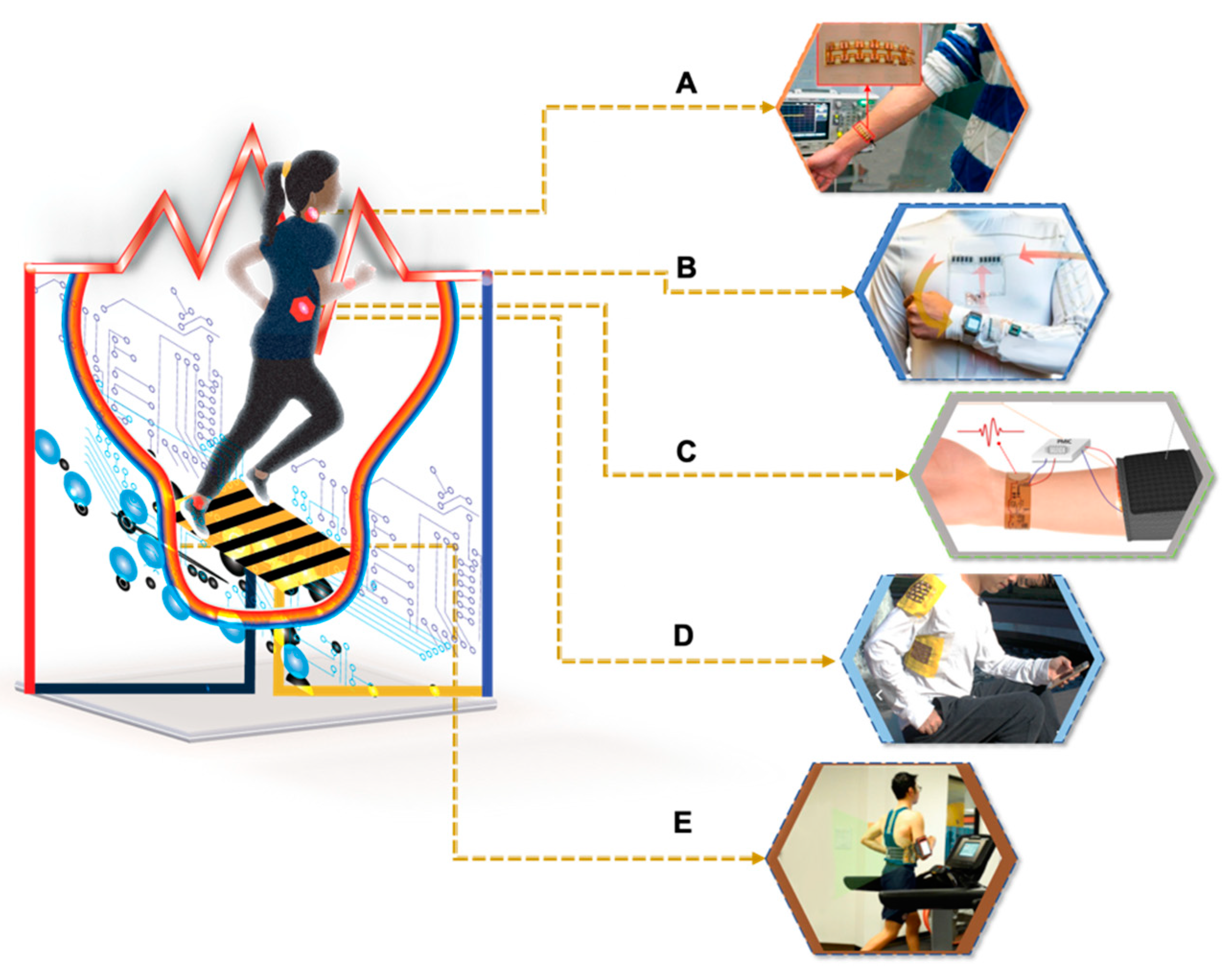

8. Self-Powered Health Monitoring System

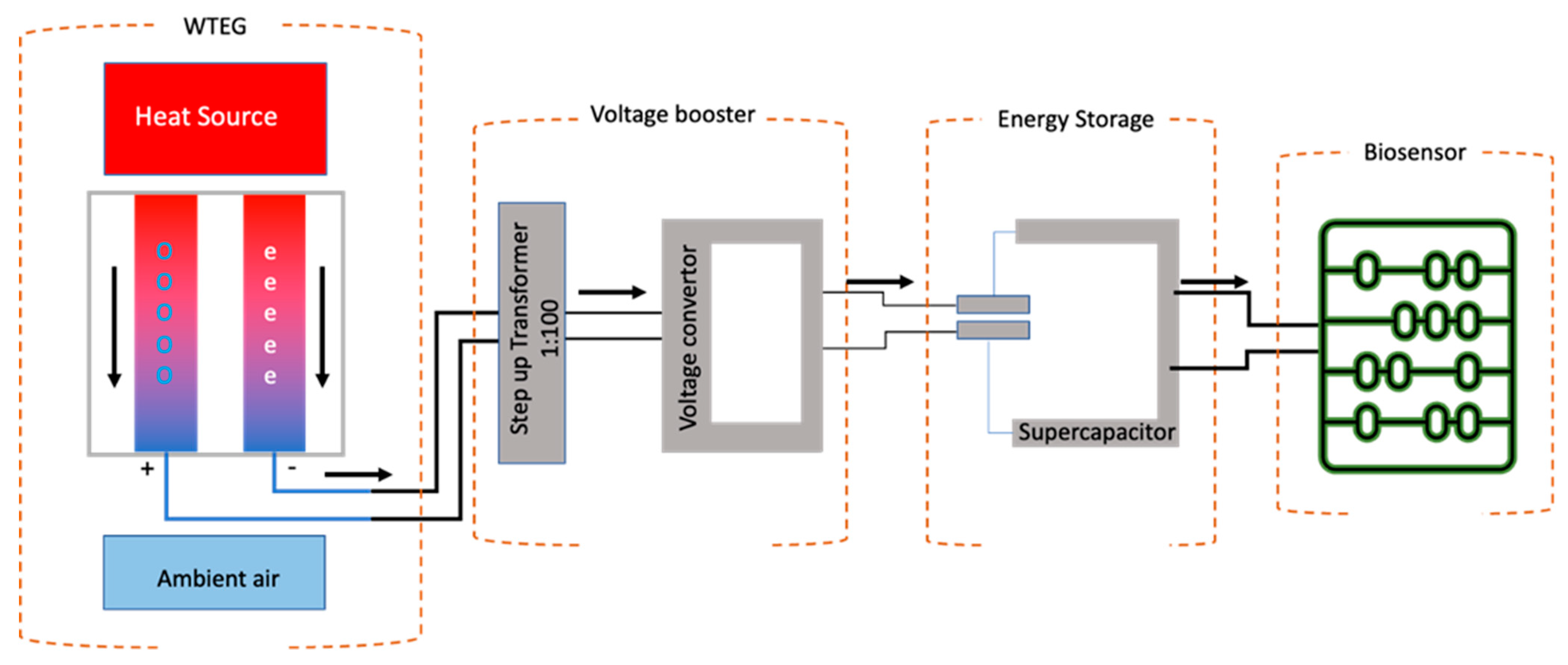

9. Integrating the WTEG with Biosensing Devices

10. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhao, J.; Zha, J.; Zeng, Z.; Tan, C. Recent advances in wearable self-powered energy systems based on flexible energy storage devices integrated with flexible solar cells. J. Mater. Chem. A 2021, 9, 18887–18905. [Google Scholar] [CrossRef]

- Nozariasbmarz, A.; Collins, H.; Dsouza, K.; Polash, M.H.; Hosseini, M.; Hyland, M.; Liu, J.; Malhotra, A.; Ortiz, F.M.; Mohaddes, F.; et al. Review of wearable thermoelectric energy harvesting: From body temperature to electronic systems. Appl. Energy 2019, 258, 114069. [Google Scholar] [CrossRef]

- Faraj, A.; Jaber, H.; Chahine, K.; Faraj, J.; Ramadan, M.; El Hage, H.; Khaled, M. New Concept of Power Generation Using TEGs: Thermal Modeling, Parametric Analysis, and Case Study. Entropy 2020, 22, 503. [Google Scholar] [CrossRef]

- Yuan, J.; Zhu, R. A fully self-powered wearable monitoring system with systematically optimized flexible thermoelectric generator. Appl. Energy 2020, 271, 115250. [Google Scholar] [CrossRef]

- Alluri, N.R.; Chandrasekhar, A.; Vivekananthan, V.; Purusothaman, Y.; Selvarajan, S.; Jeong, J.H.; Kim, S.-J. Scavenging Biomechanical Energy Using High-Performance, Flexible BaTiO3 Nanocube/PDMS Composite Films. ACS Sustain. Chem. Eng. 2017, 5, 4730–4738. [Google Scholar] [CrossRef]

- Wu, H.; Huang, Y.; Xu, F.; Duan, Y.; Yin, Z. Energy Harvesters for Wearable and Stretchable Electronics: From Flexibility to Stretchability. Adv. Mater. 2016, 28, 9881–9919. [Google Scholar] [CrossRef]

- Tsikriteas, Z.M.; Roscow, J.I.; Bowen, C.R.; Khanbareh, H. Flexible ferroelectric wearable devices for medical applications. iScience 2020, 24, 101987. [Google Scholar] [CrossRef]

- Jung, W.-S.; Lee, M.-J.; Kang, M.G.; Moon, H.G.; Yoon, S.-J.; Baek, S.-H.; Kang, C.-Y. Powerful curved piezoelectric generator for wearable applications. Nano Energy 2015, 13, 174–181. [Google Scholar] [CrossRef]

- Zhang, S.; Lin, X.; Liu, H.; Yuan, Z.; Huan, Y.; Yuan, X.; Huang, S.; Cheng, X. High-performance flexible piezoelectric nanogenerator based on n ecklace-like PZT particle chains. Int. J. Energy Res. 2020, 45, 6213–6226. [Google Scholar] [CrossRef]

- Chun, J.; Kim, J.W.; Jung, W.-S.; Kang, C.-Y.; Kim, S.-W.; Wang, Z.L.; Baik, J.M. Mesoporous pores impregnated with Au nanoparticles as effective dielectrics for enhancing triboelectric nanogenerator performance in harsh environments. Energy Environ. Sci. 2015, 8, 3006–3012. [Google Scholar] [CrossRef]

- Fan, F.-R.; Lin, L.; Zhu, G.; Wu, W.; Zhang, R.; Wang, Z.L. Transparent Triboelectric Nanogenerators and Self-Powered Pressure Sensors Based on Micropatterned Plastic Films. Nano Lett. 2012, 12, 3109–3114. [Google Scholar] [CrossRef] [Green Version]

- Kim, C.S.; Yang, H.M.; Lee, J.; Lee, G.S.; Choi, H.; Kim, Y.J.; Lim, S.H.; Cho, S.H.; Cho, B.J. Self-Powered Wearable Electrocardiography Using a Wearable Thermoelectric Power Generator. ACS Energy Lett. 2018, 3, 501–507. [Google Scholar] [CrossRef]

- Siddique, A.R.M.; Mahmud, S.; Van Heyst, B. A review of the state of the science on wearable thermoelectric power generators (TEGs) and their existing challenges. Renew. Sustain. Energy Rev. 2017, 73, 730–744. [Google Scholar] [CrossRef]

- Shen, Z.-G.; Tian, L.-L.; Liu, X. Automotive exhaust thermoelectric generators: Current status, challenges and future prospects. Energy Convers. Manag. 2019, 195, 1138–1173. [Google Scholar] [CrossRef]

- Kong, D.; Zhu, W.; Guo, Z.; Deng, Y. High-performance flexible Bi2Te3 films based wearable thermoelectric generator for energy harvesting. Energy 2019, 175, 292–299. [Google Scholar] [CrossRef]

- Park, H.; Eom, Y.; Lee, D.; Kim, J.; Kim, H.; Park, G.; Kim, W. High power output based on watch-strap-shaped body heat harvester using bulk thermoelectric materials. Energy 2019, 187, 115935. [Google Scholar] [CrossRef]

- Mytafides, C.K.; Tzounis, L.; Karalis, G.; Formanek, P.; Paipetis, A.S. High-Power All-Carbon Fully Printed and Wearable SWCNT-Based Organic Thermoelectric Generator. ACS Appl. Mater. Interfaces 2021, 13, 11151–11165. [Google Scholar] [CrossRef]

- Zhou, W.; Fan, Q.; Zhang, Q.; Cai, L.; Li, K.; Gu, X.; Yang, F.; Zhang, N.; Wang, Y.; Liu, H.; et al. High-performance and compact-designed flexible thermoelectric modules enabled by a reticulate carbon nanotube architecture. Nat. Commun. 2017, 8, 14886. [Google Scholar] [CrossRef]

- Poudel, B.; Hao, Q.; Ma, Y.; Lan, Y.; Minnich, A.; Yu, B.; Yan, X.; Wang, D.; Muto, A.; Vashaee, D.; et al. High-Thermoelectric Performance of Nanostructured Bismuth Antimony Telluride Bulk Alloys. Science 2008, 320, 634–638. [Google Scholar] [CrossRef] [Green Version]

- Rösch, A.G.; Gall, A.; Aslan, S.; Hecht, M.; Franke, L.; Mallick, M.; Penth, L.; Bahro, D.; Friderich, D.; Lemmer, U. Fully printed origami thermoelectric generators for energy-harvesting. NPJ Flex. Electron. 2021, 5, 1. [Google Scholar] [CrossRef]

- Lee, B.; Cho, H.; Park, K.T.; Kim, J.-S.; Park, M.; Kim, H.; Hong, Y.; Chung, S. High-performance compliant thermoelectric generators with magnetically self-assembled soft heat conductors for self-powered wearable electronics. Nat. Commun. 2020, 11, 5948. [Google Scholar] [CrossRef]

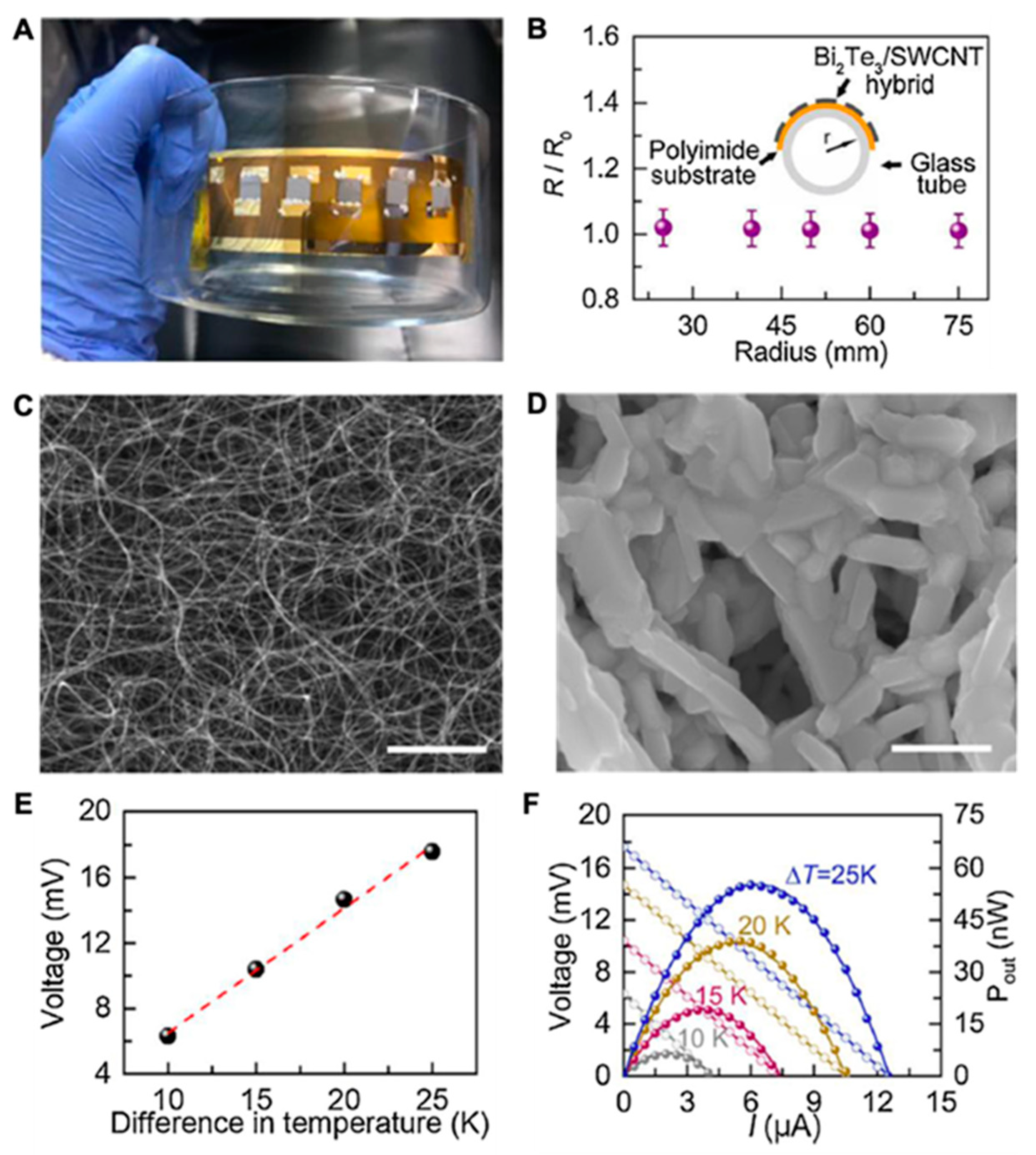

- Li, Y.; Qiao, J.; Zhao, Y.; Lan, Q.; Mao, P.; Qiu, J.; Tai, K.; Liu, C.; Cheng, H. A flexible thermoelectric device based on a Bi2Te3-carbon nanotube hybrid. J. Mater. Sci. Technol. 2020, 58, 80–85. [Google Scholar] [CrossRef]

- Shang, H.; Li, T.; Luo, D.; Yu, L.; Zou, Q.; Huang, D.; Xiao, L.; Gu, H.; Ren, Z.; Ding, F. High-Performance Ag-Modified Bi0.5Sb1.5Te3 Films for the Flexible Thermoelectric Generator. ACS Appl. Mater. Interfaces 2020, 12, 7358–7365. [Google Scholar] [CrossRef]

- Mytafides, C.K.; Tzounis, L.; Karalis, G.; Formanek, P.; Paipetis, A.S. Fully printed and flexible carbon nanotube-based thermoelectric generator capable for high-temperature applications. J. Power Sources 2021, 507, 230323. [Google Scholar] [CrossRef]

- Xu, Q.; Deng, B.; Zhang, L.; Lin, S.; Han, Z.; Zhou, Q.; Li, J.; Zhu, Y.; Jiang, F.; Li, Q.; et al. High-performance, flexible thermoelectricgenerator based on bulk materials. Cell Rep. Phys. Sci. 2022, 3, 100780. [Google Scholar] [CrossRef]

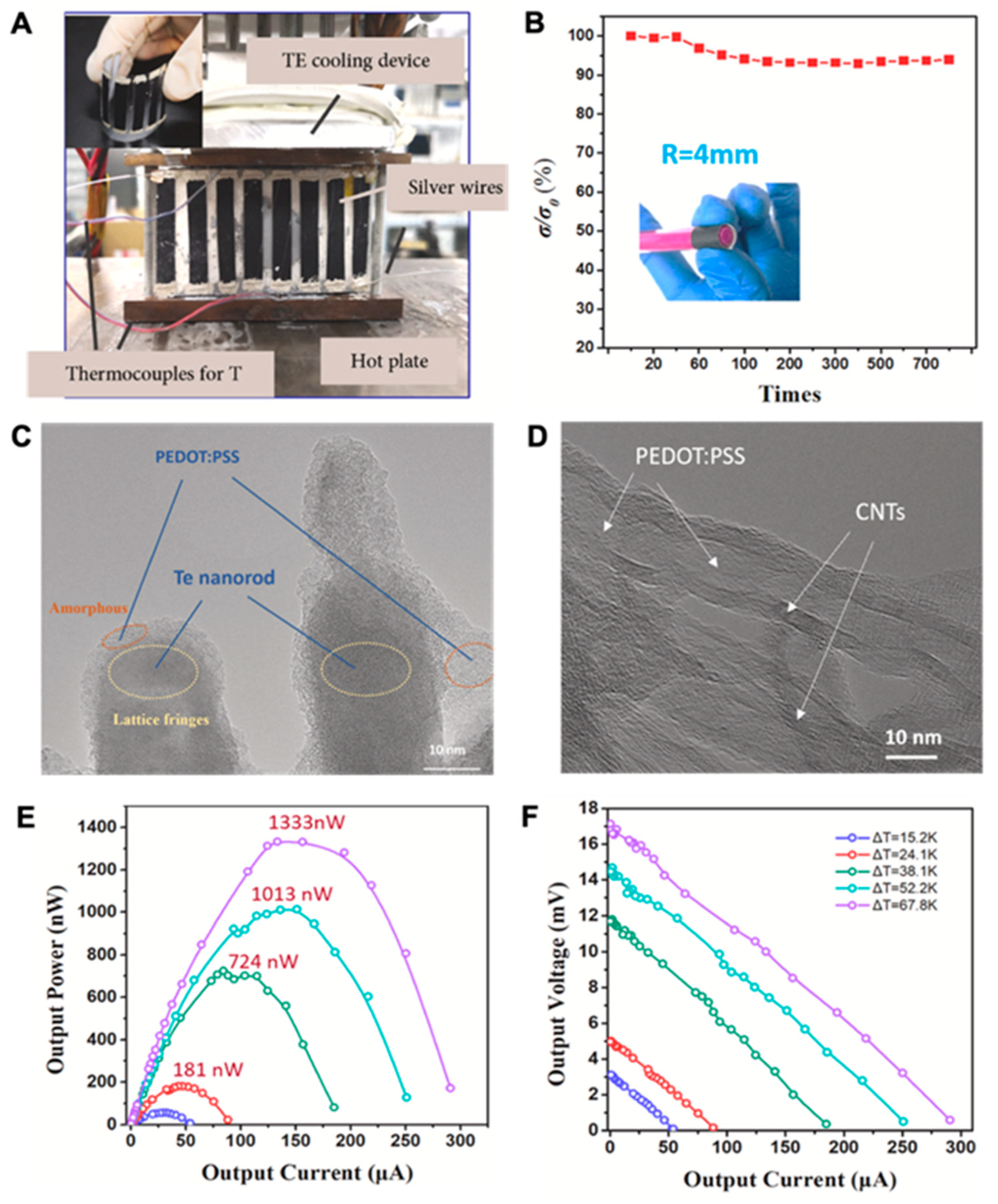

- Kim, M.H.; Cho, C.H.; Kim, J.S.; Nam, T.U.; Kim, W.-S.; Lee, T.I.; Oh, J.Y. Thermoelectric energy harvesting electronic skin (e-skin) Patch with reconfigurable carbon nanotube clays. Nano Energy 2021, 87, 106156. [Google Scholar] [CrossRef]

- Koroleva, L.; Morozov, A.; Jakhina, E.; Balbashov, A. Connection of thermopower and giant magnetothermopower with magnetic and structural heterogeneity in Sm0.55Sr0.45MnO3 manganite. J. Magn. Magn. Mater. 2015, 396, 146–152. [Google Scholar] [CrossRef]

- Das, R.; Mahendiran, R. Magnetoresistance, magnetothermopower, magnetothermal conductivity and magnetostriction in La1-Na MnO3 (0 ≤ x ≤ 0.05). Ceram. Int. 2020, 47, 393–399. [Google Scholar] [CrossRef]

- Park, K.T.; Choi, J.; Lee, B.; Ko, Y.; Jo, K.; Lee, Y.M.; Lim, J.A.; Park, C.R.; Kim, H. High-performance thermoelectric bracelet based on carbon nanotube ink printed directly onto a flexible cable. J. Mater. Chem. A 2018, 6, 19727–19734. [Google Scholar] [CrossRef]

- Qiu, L.; Wang, X.; Su, G.; Tang, D.; Zheng, X.; Zhu, J.; Wang, Z.; Norris, P.M.; Bradford, P.; Zhu, Y. Remarkably enhanced thermal transport based on a flexible horizontally-aligned carbon nanotube array film. Sci. Rep. 2016, 6, 21014. [Google Scholar] [CrossRef] [Green Version]

- Ren, W.; Sun, Y.; Zhao, D.; Aili, A.; Zhang, S.; Shi, C.; Zhang, J.; Geng, H.; Zhang, J.; Zhang, L.; et al. High-performance wearable thermoelectric generator with self-healing, recycling, and Lego-like reconfiguring capabilities. Sci. Adv. 2021, 7, eabe0586. [Google Scholar] [CrossRef]

- Annual Energy Outlook 2021. EIA. 2021. Available online: www.eia.gov (accessed on 11 November 2021).

- Li, C.; Jiang, F.; Liu, C.; Liu, P.; Xu, J. Present and future thermoelectric materials toward wearable energy harvesting. Appl. Mater. Today 2019, 15, 543–557. [Google Scholar] [CrossRef]

- Dargusch, M.; Liu, W.; Chen, Z. Thermoelectric Generators: Alternative Power Supply for Wearable Electrocardiographic Systems. Adv. Sci. 2020, 7, 2001362. [Google Scholar] [CrossRef]

- Zoui, M.A.; Bentouba, S.; Stocholm, J.G.; Bourouis, M. A Review on Thermoelectric Generators: Progress and Applications. Energies 2020, 13, 3606. [Google Scholar] [CrossRef]

- Liu, Z.; Sun, B.; Zhong, Y.; Liu, X.; Han, J.; Shi, T.; Tang, Z.; Liao, G. Novel integration of carbon counter electrode based perovskite solar cell with thermoelectric generator for efficient solar energy conversion. Nano Energy 2017, 38, 457–466. [Google Scholar] [CrossRef]

- Toberer, E. Solar thermoelectric generators: Pushing the efficiency up. Nat. Energy 2016, 1, 16172. [Google Scholar] [CrossRef]

- Xia, C.; Zhang, D.; Pedrycz, W.; Fan, K.; Guo, Y. Human Body Heat Based Thermoelectric Harvester with Ultra-Low Input Power Management System for Wireless Sensors Powering. Energies 2019, 12, 3942. [Google Scholar] [CrossRef] [Green Version]

- Park, J.; Bhat, G.; Nk, A.; Geyik, C.S.; Ogras, U.Y.; Lee, H.G. Energy per Operation Optimization for Energy-Harvesting Wearable IoT Devices. Sensors 2020, 20, 764. [Google Scholar] [CrossRef] [Green Version]

- Jouhara, H.; Żabnieńska-Góra, A.; Khordehgah, N.; Doraghi, Q.; Ahmad, L.; Norman, L.; Axcell, B.; Wrobel, L.; Dai, S. Thermoelectric generator (TEG) technologies and applications. Int. J. Thermofluids 2021, 9, 100063. [Google Scholar] [CrossRef]

- Hung, N.T.; Nugraha, A.R.T.; Saito, R. Thermoelectric Properties of Carbon Nanotubes. Energies 2019, 12, 4561. [Google Scholar] [CrossRef] [Green Version]

- Fermi, E. On the Quantization of the Monoatomic IdealGas. Rend. Lincei. 1926, 145, 1–9. [Google Scholar]

- Dirac, P.A.M. On the theory of quantum mechanics. Proc. R. Soc. Lond. Ser. A Math. Phys. Sci. 1926, 112, 661–677. [Google Scholar] [CrossRef] [Green Version]

- Reif, F. Fundamentals of Statistical and Thermal Physics; Waveland Press Inc.: Long Grove, IL, USA, 1965. [Google Scholar]

- Wang, Y.; Shi, Y.; Mei, D.; Chen, Z. Wearable thermoelectric generator for harvesting heat on the curved human wrist. Appl. Energy 2017, 205, 710–719. [Google Scholar] [CrossRef]

- Zhang, Y.; Gao, X.; Wu, Y.; Gui, J.; Guo, S.; Zheng, H.; Wang, Z.L. Self-powered technology based on nanogenerators for biomedical applications. Exploration 2021, 1, 90–114. [Google Scholar] [CrossRef]

- Yang, Y.; Xu, G.D.; Liu, J. A Prototype of an Implantable Thermoelectric Generator for Permanent Power Supply to Body Inside a Medical Device. J. Med. Devices 2013, 8, 014507. [Google Scholar] [CrossRef]

- Beltrán-Pitarch, B.; Prado-Gonjal, J.; Powell, A.V.; Ziolkowski, P.; García-Cañadas, J. Thermal conductivity, electrical resistivity, and dimensionless figure of merit (ZT) determination of thermoelectric materials by impedance spectroscopy up to 250 °C. J. Appl. Phys. 2018, 124, 025105. [Google Scholar] [CrossRef] [Green Version]

- Ouyang, Z.; Li, D. Modelling of segmented high-performance thermoelectric generators with effects of thermal radiation, electrical and thermal contact resistances. Sci. Rep. 2016, 6, 24123. [Google Scholar] [CrossRef]

- Jaziri, N.; Boughamoura, A.; Müller, J.; Mezghani, B.; Tounsi, F.; Ismail, M. A comprehensive review of Thermoelectric Generators: Technologies and common applications. Energy Rep. 2019, 6, 264–287. [Google Scholar] [CrossRef]

- Lv, H.; Liang, L.; Zhang, Y.; Deng, L.; Chen, Z.; Liu, Z.; Wang, H.; Chen, G. A flexible spring-shaped architecture with optimized thermal design for wearable thermoelectric energy harvesting. Nano Energy 2021, 88, 106260. [Google Scholar] [CrossRef]

- Chen, J.; Li, K.; Liu, C.; Li, M.; Lv, Y.; Jia, L.; Jiang, S. Enhanced Efficiency of Thermoelectric Generator by Optimizing Mechanical and Electrical Structures. Energies 2017, 10, 1329. [Google Scholar] [CrossRef] [Green Version]

- Wan, K.; Liu, Y.; Santagiuliana, G.; Barandun, G.; Junior, P.T.; Güder, F.; Bastiaansen, C.W.; Baxendale, M.; Fenwick, O.; Papageorgiou, D.G.; et al. Self-powered ultrasensitive and highly stretchable temperature–strain sensing composite yarns. Mater. Horiz. 2021, 8, 2513–2519. [Google Scholar] [CrossRef]

- Ouyang, H.; Jiang, D.; Fan, Y.; Wang, Z.L.; Li, Z. Self-powered technology for next-generation biosensor. Sci. Bull. 2021, 66, 1709–1712. [Google Scholar] [CrossRef]

- Yin, L.; Kim, K.N.; Lv, J.; Tehrani, F.; Lin, M.; Lin, Z.; Moon, J.-M.; Ma, J.; Yu, J.; Xu, S.; et al. A self-sustainable wearable multi-modular E-textile bioenergy microgrid system. Nat. Commun. 2021, 12, 1542. [Google Scholar] [CrossRef]

- Wen, Z.; Yeh, M.-H.; Guo, H.; Wang, J.; Zi, Y.; Xu, W.; Deng, J.; Zhu, L.; Wang, X.; Hu, C.; et al. Self-powered textile for wearable electronics by hybridizing fiber-shaped nanogenerators, solar cells, and supercapacitors. Sci. Adv. 2016, 2, e1600097. [Google Scholar] [CrossRef] [Green Version]

- Song, Y.; Min, J.; Yu, Y.; Wang, H.; Yang, Y.; Zhang, H.; Gao, W. Wireless battery-free wearable sweat sensor powered by human motion. Sci. Adv. 2020, 6, eaay9842. [Google Scholar] [CrossRef]

- Wang, Y.; Shi, Y.; Mei, D.; Chen, Z. Wearable thermoelectric generator to harvest body heat for powering a miniaturized accelerometer. Appl. Energy 2018, 215, 690–698. [Google Scholar] [CrossRef]

- You, H.; Li, Z.; Shao, Y.; Yuan, X.; Liu, W.; Tang, H.; Zhang, Q.; Yan, Y.; Tang, X. Flexible Bi2Te3-based thermoelectric generator with an ultra-high power density. Appl. Therm. Eng. 2021, 202, 117818. [Google Scholar] [CrossRef]

- Pires, A.L.; Cruz, I.F.; Silva, J.; Oliveira, G.N.P.; Ferreira-Teixeira, S.; Lopes, A.M.L.; Araújo, J.P.; Fonseca, J.; Pereira, C.; Pereira, A.M. Printed Flexible μ-Thermoelectric Device Based on Hybrid Bi2Te3/PVA Composites. ACS Appl. Mater. Interfaces 2019, 11, 8969–8981. [Google Scholar] [CrossRef]

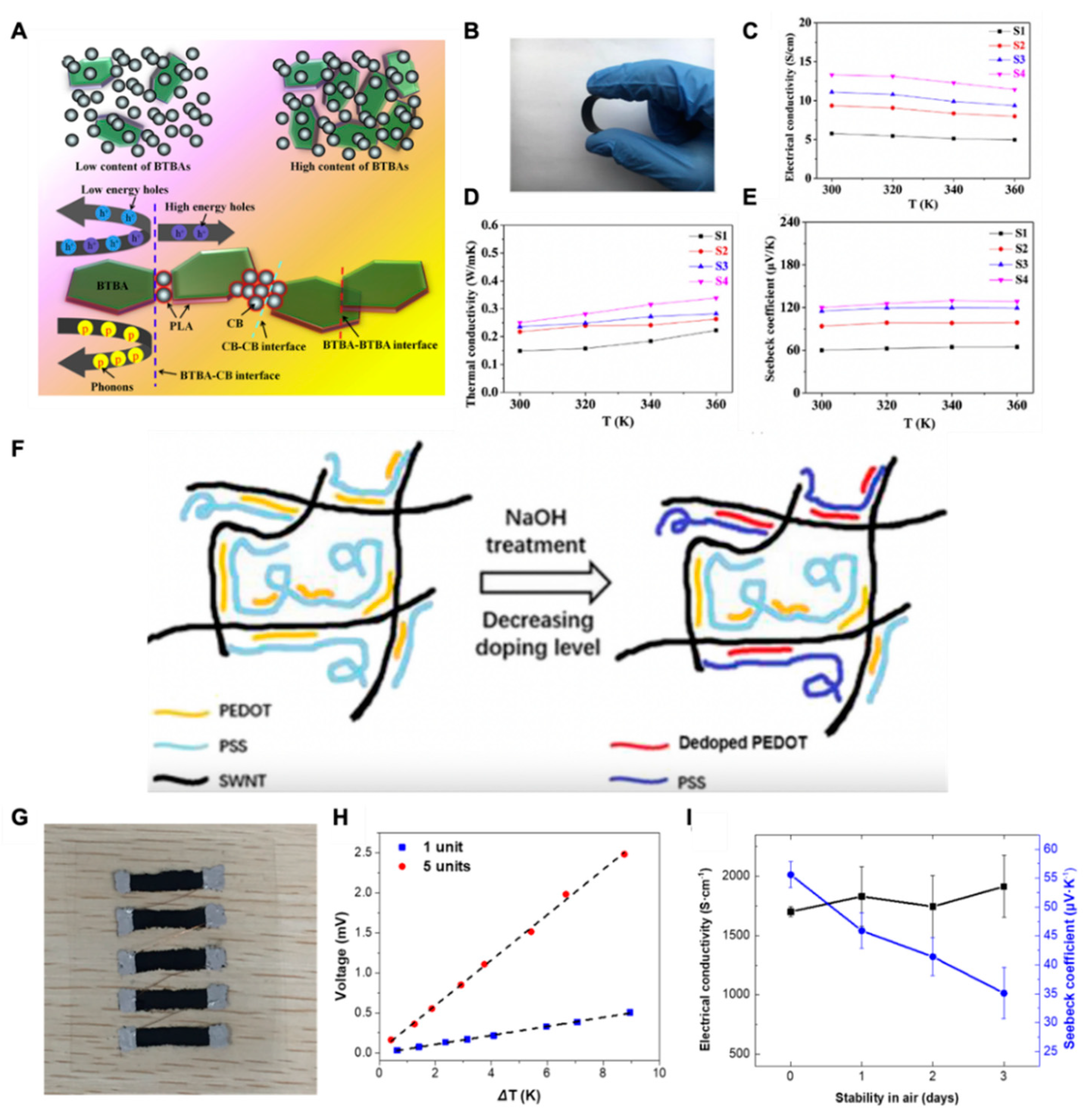

- Du, Y.; Chen, J.; Meng, Q.; Xu, J.; Paul, B.; Eklund, P. Flexible ternary carbon black/Bi2Te3 based alloy/polylactic acid thermoelectric composites fabricated by additive manufacturing. J. Mater. 2020, 6, 293–299. [Google Scholar] [CrossRef]

- Tzounis, L.; Petousis, M.; Grammatikos, S.; Vidakis, N. 3D Printed Thermoelectric Polyurethane/Multiwalled Carbon Nanotube Nanocomposites: A Novel Approach towards the Fabrication of Flexible and Stretchable Organic Thermoelectrics. Materials 2020, 13, 2879. [Google Scholar] [CrossRef]

- Liu, S.; Li, H.; He, C. Simultaneous enhancement of electrical conductivity and seebeck coefficient in organic thermoelectric SWNT/PEDOT:PSS nanocomposites. Carbon 2019, 149, 25–32. [Google Scholar] [CrossRef]

- Yang, Y.; Wei, X.-J.; Liu, J. Suitability of a thermoelectric power generator for implantable medical electronic devices. J. Phys. D Appl. Phys. 2007, 40, 5790. [Google Scholar] [CrossRef]

- Nozariasbmarz, A.; Kishore, R.A.; Poudel, B.; Saparamadu, U.; Li, W.; Cruz, R.; Priya, S. High Power Density Body Heat Energy Harvesting. ACS Appl. Mater. Interfaces 2019, 11, 40107–40113. [Google Scholar] [CrossRef]

- Dong, Z.; Liu, H.; Yang, X.; Fan, J.; Bi, H.; Wang, C.; Zhang, Y.; Luo, C.; Chen, X.; Wu, X. Facile fabrication of paper-based flexible thermoelectric generator. NPJ Flex. Electron. 2021, 5, 6. [Google Scholar] [CrossRef]

- Tsuji, M.; Imajo, T.; Saitoh, N.; Yoshizawa, N.; Suemasu, T.; Toko, K. Improved thermoelectric performance of flexible p-type SiGe films by B-doped Al-induced layer exchange. J. Phys. D-Appl. Phys. 2020, 53, 5. [Google Scholar] [CrossRef]

- Li, H.; Zong, Y.; Ding, Q.; Han, W.; Li, X. Paper-based thermoelectric generator based on multi-walled carbon nanotube/carboxylated nanocellulose. J. Power Sources 2021, 500, 229992. [Google Scholar] [CrossRef]

- Elyamny, S.; Dimaggio, E.; Magagna, S.; Narducci, D.; Pennelli, G. High Power Thermoelectric Generator Based on Vertical Silicon Nanowires. Nano Lett. 2020, 20, 4748–4753. [Google Scholar] [CrossRef]

- Li, D.; Gong, Y.; Chen, Y.; Lin, J.; Khan, Q.; Zhang, Y.; Li, Y.; Zhang, H.; Xie, H. Recent Progress of Two-Dimensional Thermoelectric Materials. Nano-Micro Lett. 2020, 12, 36. [Google Scholar] [CrossRef] [Green Version]

- Figueroa, A.I.; Van Der Laan, G.; Harrison, S.E.; Cibin, G.; Hesjedal, T. Oxidation Effects in Rare Earth Doped Topological Insulator Thin Films. Sci. Rep. 2016, 6, 22935. [Google Scholar] [CrossRef] [Green Version]

- Liu, S.; Sun, N.; Liu, M.; Sucharitakul, S.; Gao, X.P.A. Nanostructured SnSe: Synthesis, doping, and thermoelectric properties. J. Appl. Phys. 2018, 123, 115109. [Google Scholar] [CrossRef]

- Lee, S. Transport of Phonons and Electrons in Thermoelectric Materials and Graphene. Ph.D. Dissertation, Massachusetts Institute of Technology, Cambridge, MA, USA, 2015. [Google Scholar]

- Nonoguchi, Y.; Nakano, M.; Murayama, T.; Hagino, H.; Hama, S.; Miyazaki, K.; Matsubara, R.; Nakamura, M.; Kawai, T. Simple Salt-Coordinated n-Type Nanocarbon Materials Stable in Air. Adv. Funct. Mater. 2016, 26, 3021–3028. [Google Scholar] [CrossRef] [Green Version]

- Słoma, M.; Głód, M.; Wałpuski, B. Printed Flexible Thermoelectric Nanocomposites Based on Carbon Nanotubes and Polyaniline. Materials 2021, 14, 4122. [Google Scholar] [CrossRef] [PubMed]

- Wu, R.; Yuan, H.; Liu, C.; Lan, J.-L.; Yang, X.; Lin, Y.-H. Flexible PANI/SWCNT thermoelectric films with ultrahigh electrical conductivity. RSC Adv. 2018, 8, 26011–26019. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Iijima, S. Helical microtubules of graphitic carbon. Nature 1991, 354, 56–58. [Google Scholar] [CrossRef]

- Berber, S.; Kwon, Y.-K.; Tomanek, D. Unusually High Thermal Conductivity of Carbon Nanotubes. Phys. Rev. Lett. 2000, 84, 4613–4616. [Google Scholar] [CrossRef] [Green Version]

- Kumanek, B.; Janas, D. Thermal conductivity of carbon nanotube networks: A review. J. Mater. Sci. 2019, 54, 7397–7427. [Google Scholar] [CrossRef] [Green Version]

- Kim, P.; Shi, L.; Majumdar, A.; McEuen, P.L. Thermal Transport Measurements of Individual Multiwalled Nanotubes. Phys. Rev. Lett. 2001, 87, 215502. [Google Scholar] [CrossRef] [Green Version]

- Chalopin, Y.; Volz, S.; Mingo, N. Upper bound to the thermal conductivity of carbon nanotube pellets. J. Appl. Phys. 2009, 105, 084301. [Google Scholar] [CrossRef]

- Prasher, R.S.; Hu, X.J.; Chalopin, Y.; Mingo, N.; Lofgreen, K.; Volz, S.; Cleri, F.; Keblinski, P. Turning Carbon Nanotubes from Exceptional Heat Conductors into Insulators. Phys. Rev. Lett. 2009, 102, 105901. [Google Scholar] [CrossRef]

- Aliev, A.; Guthy, C.; Zhang, M.; Fang, S.; Zakhidov, A.; Fischer, J.E.; Baughman, R.H. Thermal transport in MWCNT sheets and yarns. Carbon 2007, 45, 2880–2888. [Google Scholar] [CrossRef]

- Zhao, Y.; Li, Y.; Qiao, J.; Jiang, S.; Mao, P.; Qiu, J.; Kang, S.; Tan, J.; Tai, K.; Liu, C. Decoupling phonon and carrier scattering at carbon nanotube/Bi2Te3 interfaces for improved thermoelectric performance. Carbon 2020, 170, 191–198. [Google Scholar] [CrossRef]

- Yao, Q.; Wang, Q.; Wang, L.; Chen, L. Abnormally enhanced thermoelectric transport properties of SWNT/PANI hybrid films by the strengthened PANI molecular ordering. Energy Environ. Sci. 2014, 7, 3801–3807. [Google Scholar] [CrossRef]

- Yang, C.-Y.; Stoeckel, M.-A.; Ruoko, T.-P.; Wu, H.-Y.; Liu, X.; Kolhe, N.B.; Wu, Z.; Puttisong, Y.; Musumeci, C.; Massetti, M.; et al. A high-conductivity n-type polymeric ink for printed electronics. Nat. Commun. 2021, 12, 2354. [Google Scholar] [CrossRef]

- Liao, Y.; Tian, Y.; Ma, X.; Zhao, M.; Qian, J.; Wang, X. Screen-Printed High-Performance Flexible Electrothermal Films Based on Three-Dimensional Intercalation Graphene Nanosheets/MWCNT/Carbon Black Composite. ACS Appl. Mater. Interfaces 2020, 12, 48077–48083. [Google Scholar] [CrossRef]

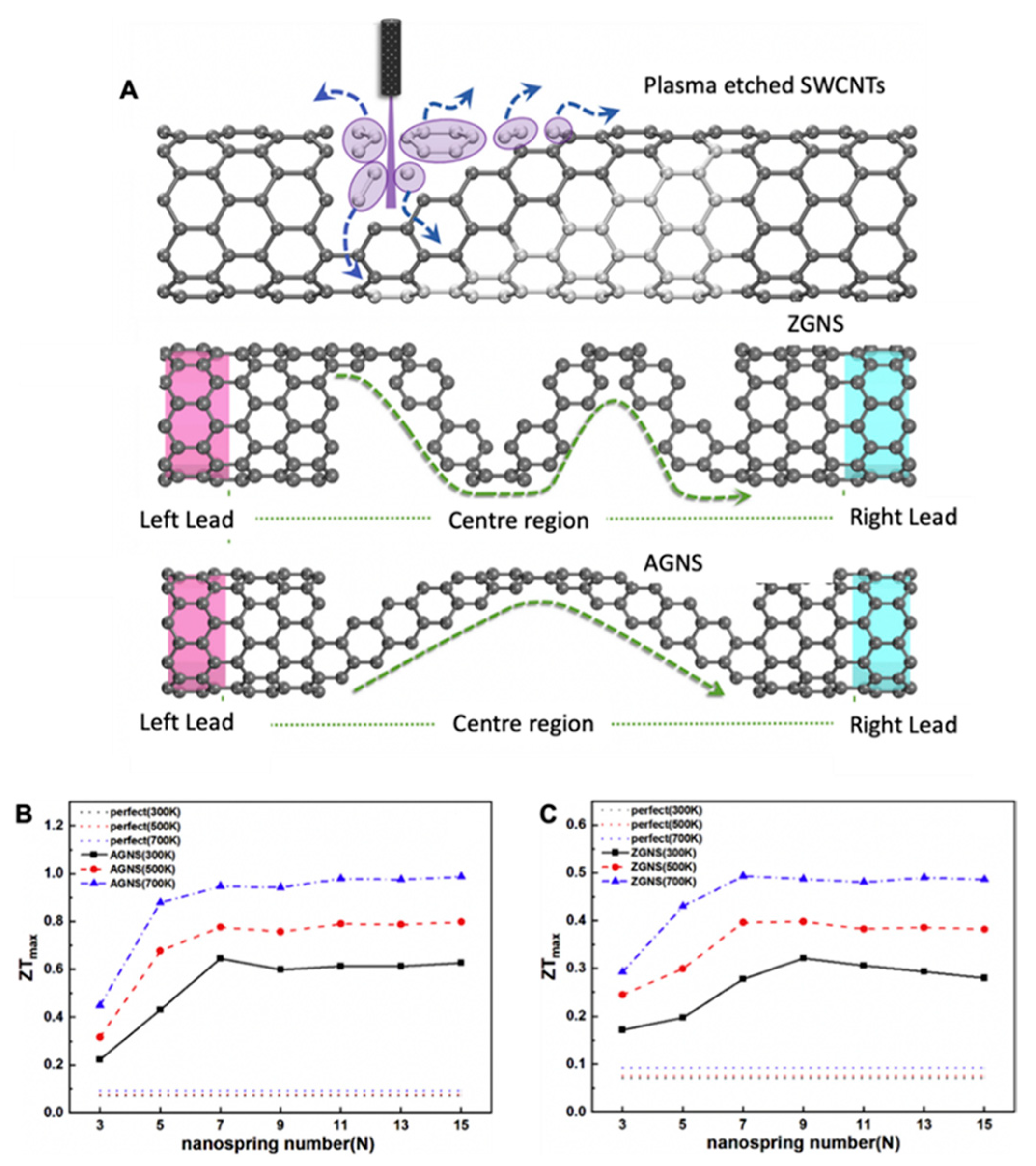

- Xu, X.; Xiao, H.; Ouyang, T.; Zhong, J. Improving the thermoelectric properties of carbon nanotubes through introducing graphene nanosprings. Curr. Appl. Phys. 2019, 20, 150–154. [Google Scholar] [CrossRef]

- Gordiz, K.; Menon, A.K.; Yee, S.K. Interconnect patterns for printed organic thermoelectric devices with large fill factors. J. Appl. Phys. 2017, 122, 124507. [Google Scholar] [CrossRef]

- Dickey, M.; Chiechi, R.; Larsen, R.J.; Weiss, E.A.; Weitz, D.A.; Whitesides, G.M. Eutectic Gallium-Indium (EGaIn): A Liquid Metal Alloy for the Formation of Stable Structures in Microchannels at Room Temperature. Adv. Funct. Mater. 2008, 18, 1097–1104. [Google Scholar] [CrossRef]

- Kazem, N.; Hellebrekers, T.; Majidi, C. Soft Multifunctional Composites and Emulsions with Liquid Metals. Adv. Mater. 2017, 29, 1605985. [Google Scholar] [CrossRef]

- Zadan, M.; Malakooti, M.H.; Majidi, C. Soft and Stretchable Thermoelectric Generators Enabled by Liquid Metal Elastomer Composites. ACS Appl. Mater. Interfaces 2020, 12, 17921–17928. [Google Scholar] [CrossRef]

- Hong, S.; Gu, Y.; Seo, J.K.; Wang, J.; Liu, P.; Meng, Y.S.; Xu, S.; Chen, R. Wearable thermoelectrics for personalized thermoregulation. Sci. Adv. 2019, 5, eaaw0536. [Google Scholar] [CrossRef] [Green Version]

- Zhao, X.; Han, W.; Zhao, C.; Wang, S.; Kong, F.; Ji, X.; Li, Z.; Shen, X. Fabrication of Transparent Paper-Based Flexible Thermoelectric Generator for Wearable Energy Harvester Using Modified Distributor Printing Technology. ACS Appl. Mater. Interfaces 2019, 11, 10301–10309. [Google Scholar] [CrossRef]

- Choi, J.; Jung, Y.; Dun, C.; Park, K.T.; Gordon, M.P.; Haas, K.; Yuan, P.; Kim, H.; Park, C.R.; Urban, J.J. High-Performance, Wearable Thermoelectric Generator Based on a Highly Aligned Carbon Nanotube Sheet. ACS Appl. Energy Mater. 2019, 3, 1199–1206. [Google Scholar] [CrossRef] [Green Version]

- Fan, S.; Gao, Y.; Rezania, A. Thermoelectric performance and stress analysis on wearable thermoelectric generator under bending load. Renew. Energy 2021, 173, 581–595. [Google Scholar] [CrossRef]

- Dongxu, J.; Zhongbao, W.; Pou, J.; Mazzoni, S.; Rajoo, S.; Romagnoli, A. Geometry optimization of thermoelectric modules: Simulation and experimental study. Energy Convers. Manag. 2019, 195, 236–243. [Google Scholar] [CrossRef]

- Wu, Q.; Hu, J. A novel design for a wearable thermoelectric generator based on 3D fabric structure. Smart Mater. Struct. 2017, 26, 045037. [Google Scholar] [CrossRef]

- Liu, C.; Shan, D.-L.; Shen, Z.-H.; Ren, G.-K.; Wang, Y.; Zhou, Z.-F.; Li, J.-Y.; Yi, D.; Lan, J.-L.; Chen, L.-Q.; et al. Role of interfaces in organic–inorganic flexible thermoelectrics. Nano Energy 2021, 89, 106380. [Google Scholar] [CrossRef]

- Kim, D.-H.; Lu, N.; Ma, R.; Kim, Y.-S.; Kim, R.-H.; Wang, S.; Wu, J.; Won, S.M.; Tao, H.; Islam, A.; et al. Epidermal Electronics. Science 2011, 333, 838–843. [Google Scholar] [CrossRef] [Green Version]

- Jeong, J.-W.; Yeo, W.-H.; Akhtar, A.; Norton, J.J.S.; Kwack, Y.-J.; Li, S.; Jung, S.-Y.; Su, Y.; Lee, W.; Xia, J.; et al. Materials and Optimized Designs for Human-Machine Interfaces Via Epidermal Electronics. Adv. Mater. 2013, 25, 6839–6846. [Google Scholar] [CrossRef]

- Xu, C.; Song, Y.; Han, M.; Zhang, H. Portable and wearable self-powered systems based on emerging energy harvesting technology. Microsyst. Nanoeng. 2021, 7, 25. [Google Scholar] [CrossRef]

- Lin, W.-Y.; Chen, C.-H.; Lee, M.-Y. Design and Implementation of a Wearable Accelerometer-Based Motion/Tilt Sensing Internet of Things Module and Its Application to Bed Fall Prevention. Biosensors 2021, 11, 428. [Google Scholar] [CrossRef]

- Leonov, V. Human Machine and Thermoelectric Energy Scavenging for Wearable Devices. ISRN Renew. Energy 2011, 2011, 1785380. [Google Scholar] [CrossRef] [Green Version]

- Kwon, K.; Kwon, S.; Yeo, W.-H. Automatic and Accurate Sleep Stage Classification via a Convolutional Deep Neural Network and Nanomembrane Electrodes. Biosensors 2022, 12, 155. [Google Scholar] [CrossRef]

- Kim, H.; Kwon, S.; Kwon, Y.-T.; Yeo, W.-H. Soft Wireless Bioelectronics and Differential Electrodermal Activity for Home Sleep Monitoring. Sensors 2021, 21, 354. [Google Scholar] [CrossRef]

- Iezzi, B.; Ankireddy, K.; Twiddy, J.; Losego, M.D.; Jur, J. Printed, metallic thermoelectric generators integrated with pipe insulation for powering wireless sensors. Appl. Energy 2017, 208, 758–765. [Google Scholar] [CrossRef]

- Texas Instruments. CC2650 SimpleLink™ 32-Bit Arm Cortex-M3 Multiprotocol 2.4 GHz Wireless MCU with 128kB Flash; Texas Instruments: Dallas, TX, USA, 2016. [Google Scholar]

- STMicroelectronics. Ultra-Low-Power with FPU Arm Cortex-M4 MCU 80 MHz with 1 Mbyte of Flash Memory, LCD, USB OTG, DFSDM; STMicroelectronics: Geneva, Switzerland, 2022. [Google Scholar]

- Infineon Technologies. PSoC™ 4 MCU with AIROC™ Bluetooth LE. Available online: https://www.infineon.com/cms/en/product/microcontroller/32-bit-psoc-arm-cortex-microcontroller/psoc-4-32-bit-arm-cortex-m0-mcu/psoc-4-ble-bluetooth-smart/#!boards (accessed on 15 March 2022).

| Energy Source | Energy Harvester | Power Density | Sensor | Power Required for Biosensor | Reference |

|---|---|---|---|---|---|

| Human Body Heat | w-TEG | 38 (µW/cm2) | ECG | <15 (µW) | [12] |

| Solar | PV module | 2.8 (mW/ cm2) | Accelerometer + gyroscope | 1.3–4.3 (mW) | [39] |

| Human Body Heat | f-TEG | 3.5 (µW/cm2) | Accelerometer + temperature + humidity sensor | 2 (mW) | [4] |

| Human Body Heat | w-TEG | 0.5 (µW) (no area information is given in this reference) | Temperature and strain sensor | (10 µW) | [53] |

| Materials | K (W/m·K) | S (µV/K) | Film Thickness (nm) | Power Factor (µW/cm·K2) | ZT | Reference | |

|---|---|---|---|---|---|---|---|

| Bi2Te3 (n-type film) | 6.9 × 104 | - | −177 | 800 | 21.7 | 0.05 | [15] |

| Bi0.5Sb1.5Te3 and Bi2Te2.7Se0.3 | 5.95 × 104 | 1.03 | 211.15 | - | - | - | [16] |

| Ag-Modified Bi0.5Sb1.5Te3 | 7.5 × 104 | - | 128.98 | 750 | 12.4 | - | [23] |

| Bi-Te alloy (nanodots) | 1.35 × 105 | 1.157 | 186.54 | - | ~43 | 1.2 | [19] |

| L-MWCNTs/PU (12–25 µm) | 133.1 | 12–17 | 19.8 | - | 0.0004 | [62] | |

| n-type SWCNT film (in-plane TE) | 2.05 × 103 | 39 ± 12 | −33 | - | 2.3 | 0.002 | [74] |

| n-type SWCNT film (through-plane TE) | 69 | 0.12 ± 0.001 | −63 | - | 0.27 | 0.07 | [74] |

| PANI/MWCNTS | 405.45 | - | 15.4 | - | 852 × 10−6 | - | [75] |

| SWCNTs/ Bi2Te3 | 1.1 × 104 | 0.33 | −152.1094 | 180 | 2.03 | 0.23 | [22] |

| As grown SWCNT film | 3.02 × 105 | - | 78 | 200 | 18.40 | - | [18] |

| SWCNTs/PEI (1 wt%) | 3.63 × 105 | - | −64 | 200 | 15 | - | [18] |

| SWCNTs/PANI | 4 × 105 | - | 17 | - | 1.0 | - | [76] |

| SWCNTs/PEDOT:PSS | 17.01 × 104 | 0.4–0.6 | 55.6 | 5.26 | 0.39 | [63] |

| TE Architecture | TE Materials | ΔT(K) | Open Circuit Voltage | Power Density | Main Features | Application | Reference |

|---|---|---|---|---|---|---|---|

| Conformal film Lego-thermo-electric chips 112 TE legs | Bi0.5Sb1.5Te3 and Bi2Te2.8Se0.3 | 95 and 93 | 1 V/cm2 | 19 μW/cm2 | Self-powered, Self-healing, Stretchable-120%, Recyclable, Eco-friendly | Various targets | [31] |

| Conformal, magnetic soft-connect 440 TE legs | Bi2Te3, silver-coated nickel (Ag–Ni), Ag nanowires | 3–6 | 266 mV | 6.96 μW/cm2 | Self-powered, Flexible, Stretchable-20% | Wearables | [21] |

| Thermoelectric Film 4 TE legs | Ag-Modified Bi0.5Sb1.5Te3 | 60 | 31.2 mV | 1.4 × 103 μW/cm2 | Flexible | Flexible/wearable substrates | [23] |

| Double elastomer layer design 12 × 12 array | TE alloys | 10 | - | 25.1 μW/cm2 | Flexible, Stretchable | Wearables | [93] |

| TEG module 6–18 pairs of n-type and p-type module | Bi2Te3 legs with nickel coating, aluminum nitride, gold-coated copper interconnects | 2.5 and 1.2 | - | 35 μW/cm2 and 18 μW/cm2 | - | Wearables and implantable systems | [65] |

| Pelletized and FPCB 40 TE elements | Bi0.5Sb1.5Te3 and Bi2Te2.7Se0.3, Ni coating, Au coating | 1.43 | 12.1 mV | 6.97 μW/cm2 | Flexible | Wearables and implantable systems | [16] |

| Paper-based TEGs | Bi0.5Sb1.5Te3 and Bi2Te2.7Se0.3, Paper | 35 | 8.0 mV | 0.530 × 10−3 μW/cm2 | Flexible, Stretchable, Eco-friendly | Wearables | [94] |

| Film-based WTEG | SWCNTs | 6 | 71 mV | 5.517 × 10−3 μW/cm2 | Flexible | Wearables | [17] |

| Film-based TEG | Bi2Te3 | 24 | 48.9 mV | 0.693 μW (no area information) | Flexible | Wearables | [15] |

| CNT-based TENG | SWCNTS and PMDS | 50 | 23 mV | 0.166 μW/cm2 | Flexible, Stretchable, Eco-friendly | Wearables | [95] |

| Hybrid | Bi2Te3—SWCNTs | 25 | 17 mV | 930 μW/cm2 | Flexible | Wearables | [22] |

| Hybrid | PEDOT:PSS/TiS2 | 30 | 534 mV | 47.8 µW/cm2 | Flexible | Flexible systems | [20] |

| Operational Modes | Power Requirement of MCU–BLE | ||

|---|---|---|---|

| TI CC2650 [108] | STM32L476RG [109] | PSoC™ 4 BLE [110] | |

| VBAT, supply for RTC and 32X32-bit backup registers | 513–1080 nW | - | |

| Shutdown mode (5 wakeup pins) | 170–380 nW | 51.3–108 nW | 285–825 nW |

| Standby mode (5 wakeup pins) | 205.2–432 nW | - | |

| Standby mode with RTC | 1.7–3.8 μW | 718.2–1512 nW | 2.47–6.5 μW |

| Stop mode | 1.881–3.96 μW | - | |

| Stop with RTC | 2.394–5.04 μW | 114–300 nW | |

| Run mode | 10.03–22.42 mW (RX) | 171–360 μW/MHz (LDO mode) | - |

| Run mode | 103.7–231.8 μW/MHz | 66.69–140.4 μW/MHz (@3.3 v SMPS mode) | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sattar, M.; Yeo, W.-H. Recent Advances in Materials for Wearable Thermoelectric Generators and Biosensing Devices. Materials 2022, 15, 4315. https://doi.org/10.3390/ma15124315

Sattar M, Yeo W-H. Recent Advances in Materials for Wearable Thermoelectric Generators and Biosensing Devices. Materials. 2022; 15(12):4315. https://doi.org/10.3390/ma15124315

Chicago/Turabian StyleSattar, Maria, and Woon-Hong Yeo. 2022. "Recent Advances in Materials for Wearable Thermoelectric Generators and Biosensing Devices" Materials 15, no. 12: 4315. https://doi.org/10.3390/ma15124315

APA StyleSattar, M., & Yeo, W.-H. (2022). Recent Advances in Materials for Wearable Thermoelectric Generators and Biosensing Devices. Materials, 15(12), 4315. https://doi.org/10.3390/ma15124315