Figure 1.

Schematic diagram of the new non-uniform corrosion method.

Figure 1.

Schematic diagram of the new non-uniform corrosion method.

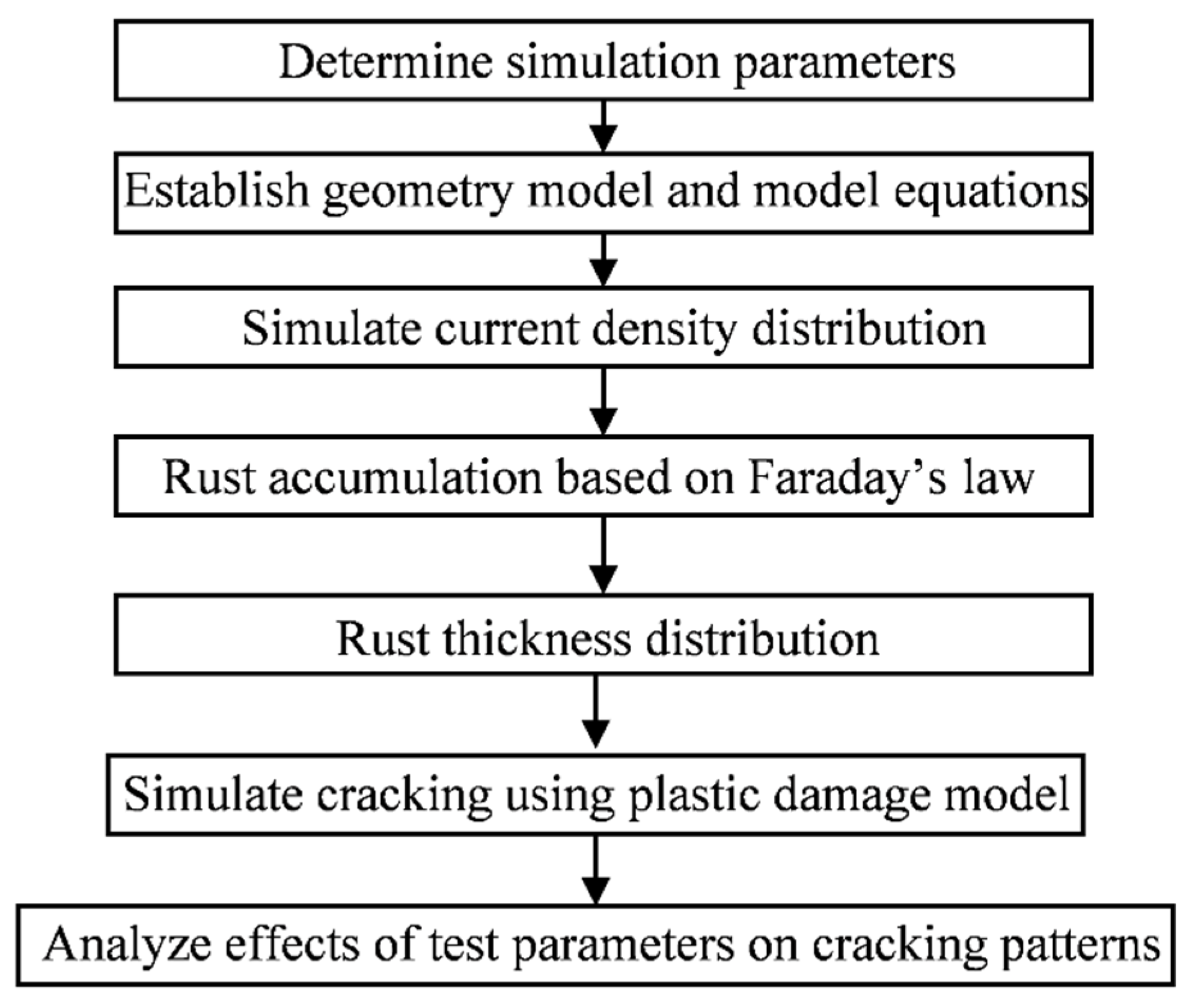

Figure 2.

Flowchart for the modeling work.

Figure 2.

Flowchart for the modeling work.

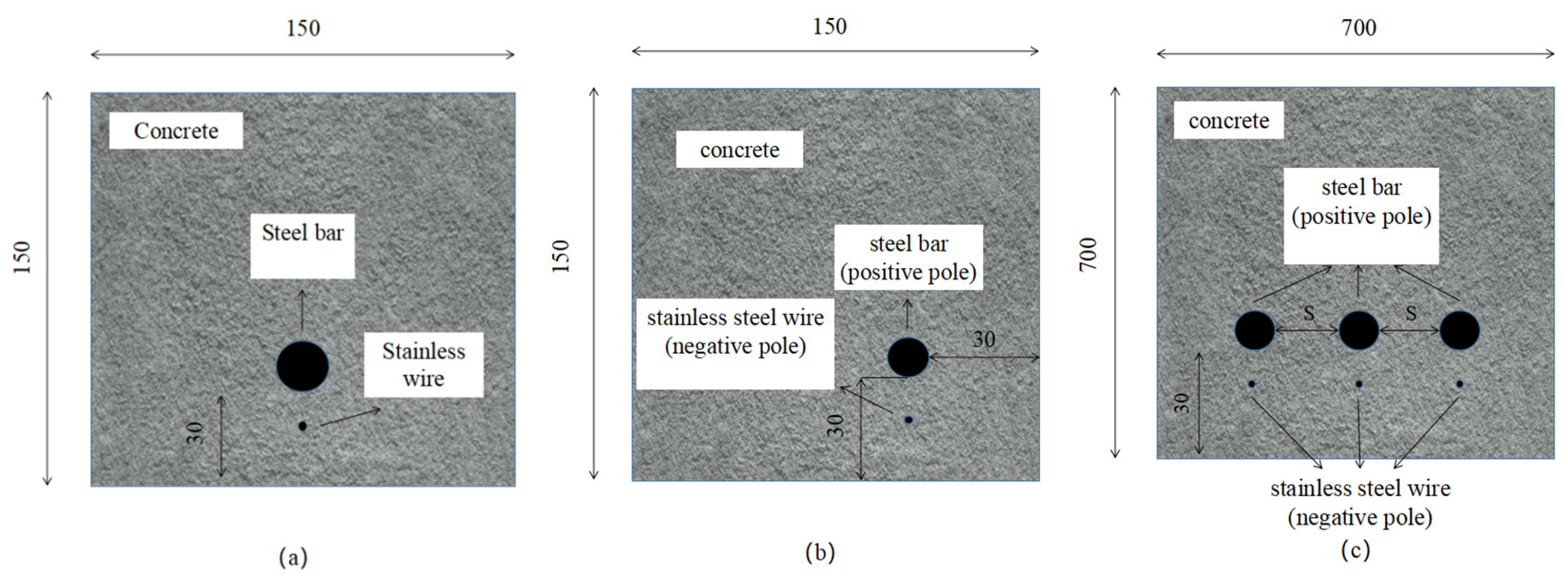

Figure 3.

Geometric model of finite element simulation of electric corrosion: (a) single steel bar in unilateral middle; (b) unilateral corner single reinforcement; (c) single row of multiple reinforcements.

Figure 3.

Geometric model of finite element simulation of electric corrosion: (a) single steel bar in unilateral middle; (b) unilateral corner single reinforcement; (c) single row of multiple reinforcements.

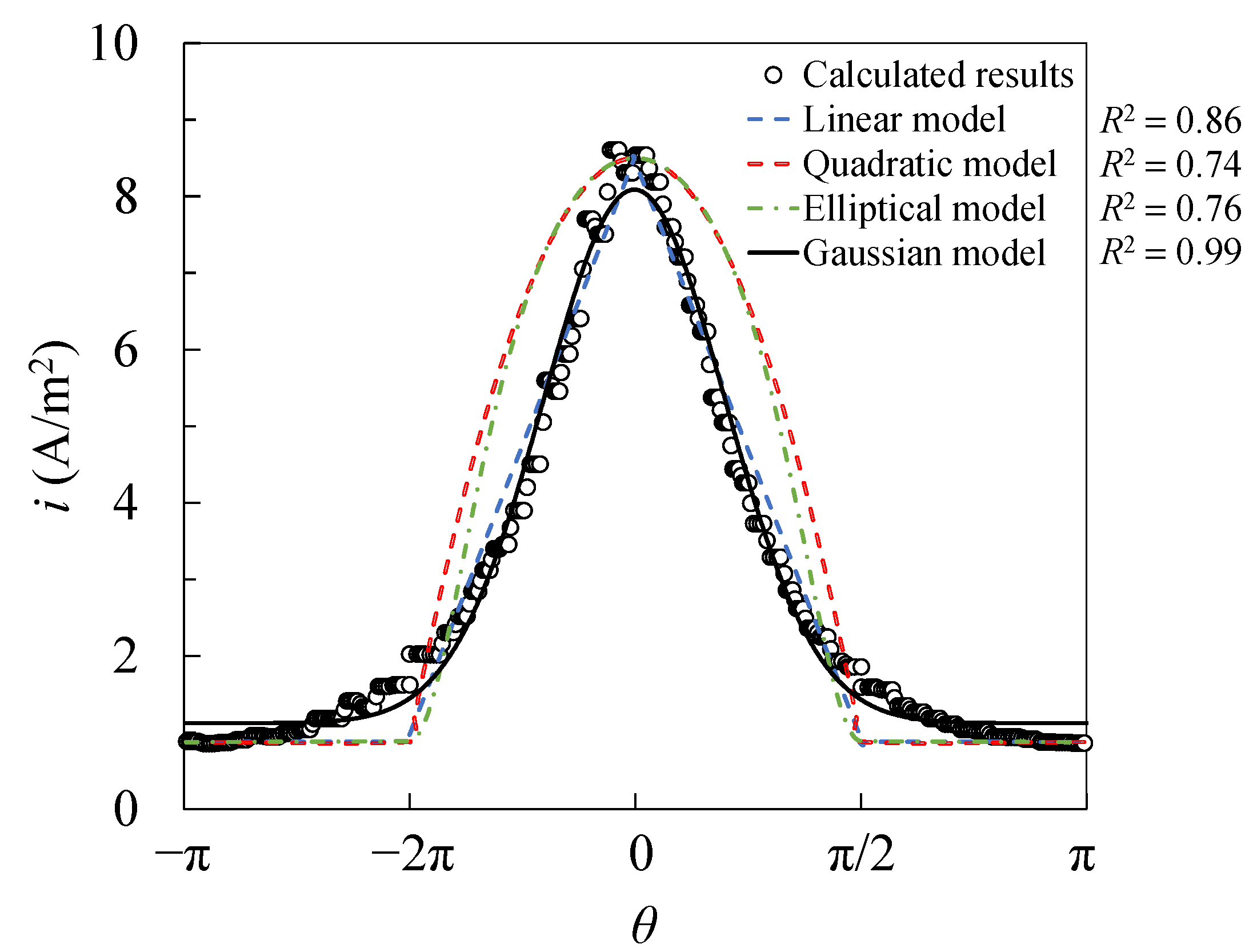

Figure 4.

Regression analysis of the proposed model with calculation results.

Figure 4.

Regression analysis of the proposed model with calculation results.

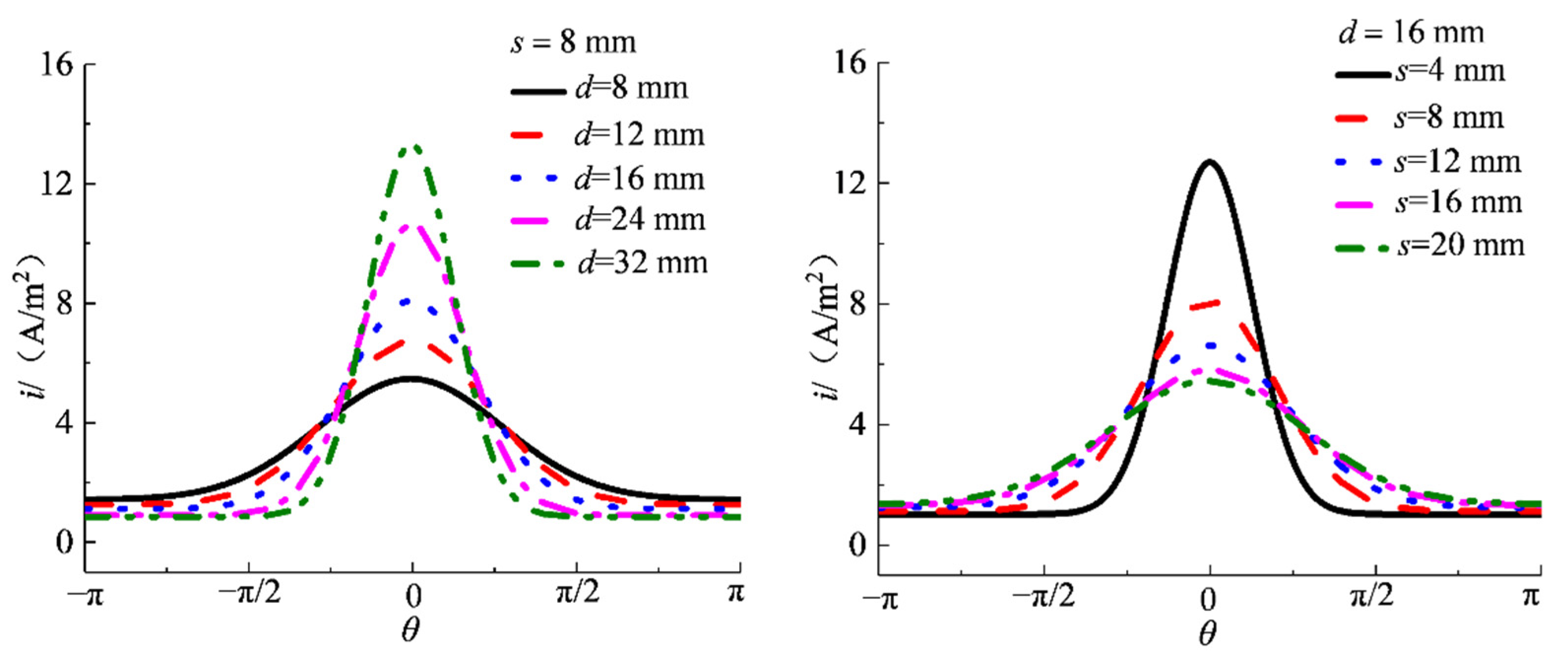

Figure 5.

Current density distribution with d and s.

Figure 5.

Current density distribution with d and s.

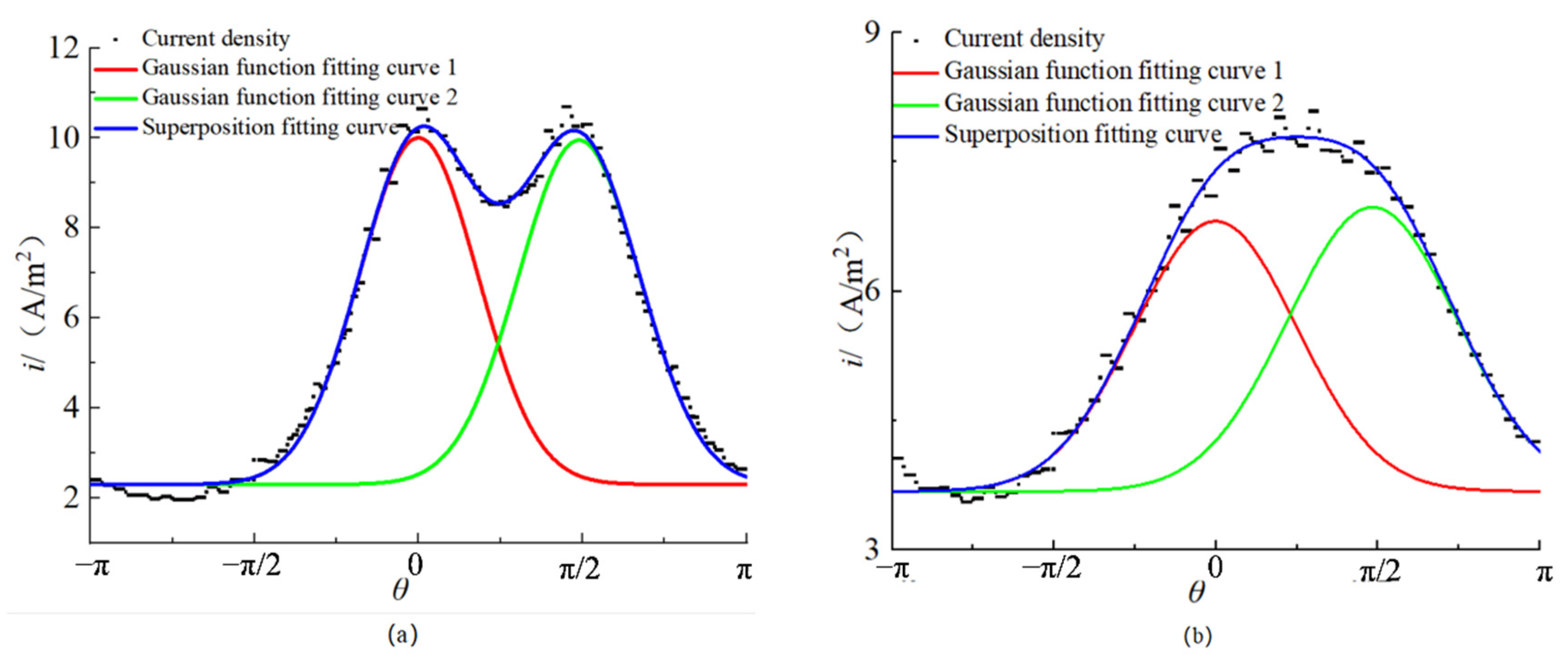

Figure 6.

The surface current density distribution of single corner reinforcement: (a) double peaks; (b) single peak.

Figure 6.

The surface current density distribution of single corner reinforcement: (a) double peaks; (b) single peak.

Figure 7.

Variation of current density distribution on steel bar surface with S/d.

Figure 7.

Variation of current density distribution on steel bar surface with S/d.

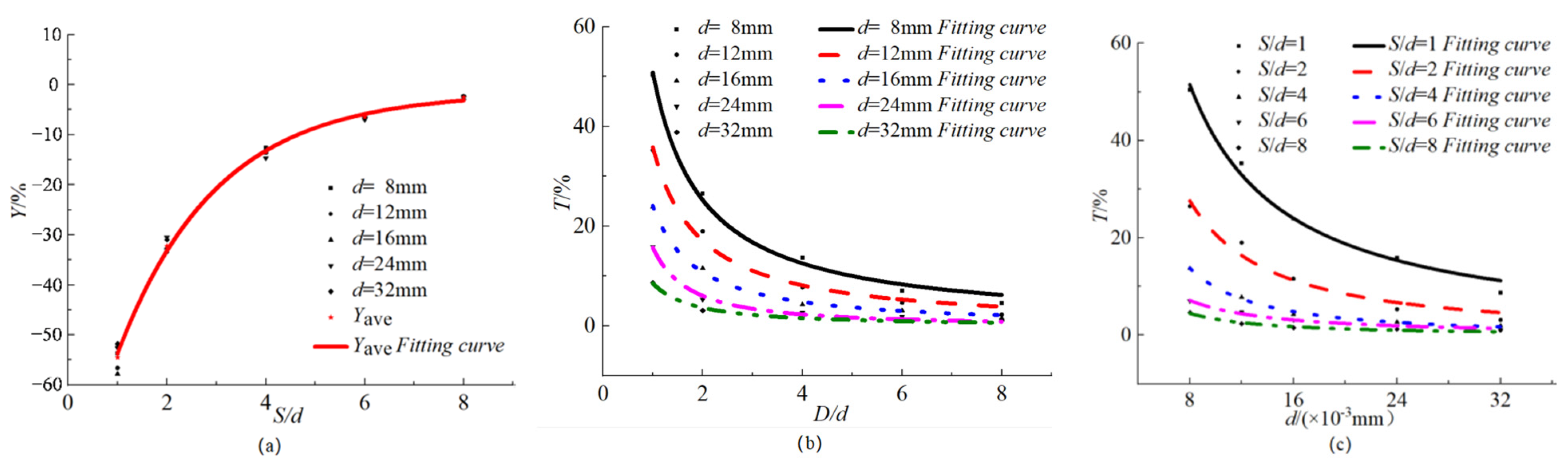

Figure 8.

Variation of Y, T, C with S/d and d: (a) variation of Y with S/d; (b) variation of T with S/d; (c) variation of T with d.

Figure 8.

Variation of Y, T, C with S/d and d: (a) variation of Y with S/d; (b) variation of T with S/d; (c) variation of T with d.

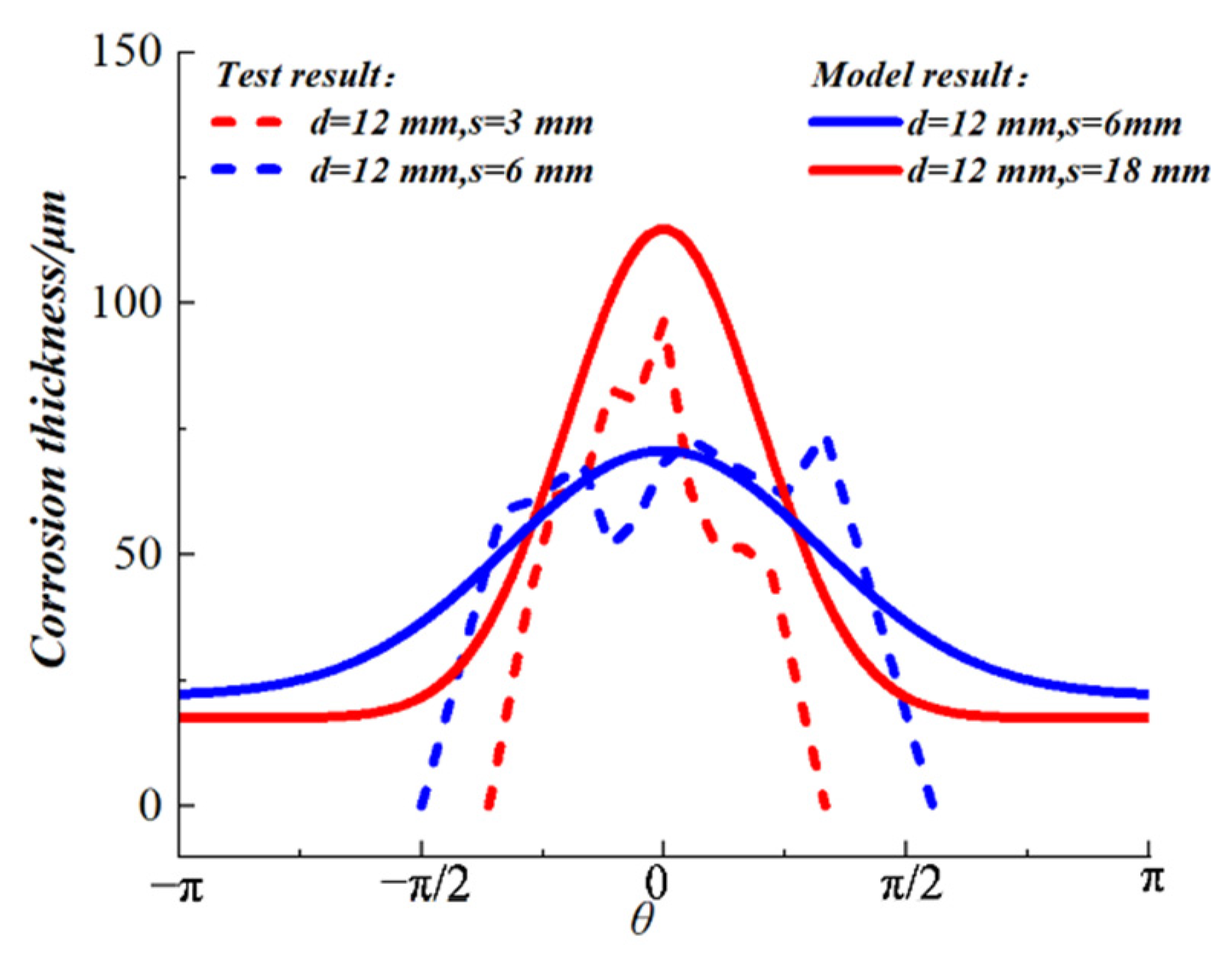

Figure 9.

Comparison of the thickness distribution of the rust layer obtained by test and model.

Figure 9.

Comparison of the thickness distribution of the rust layer obtained by test and model.

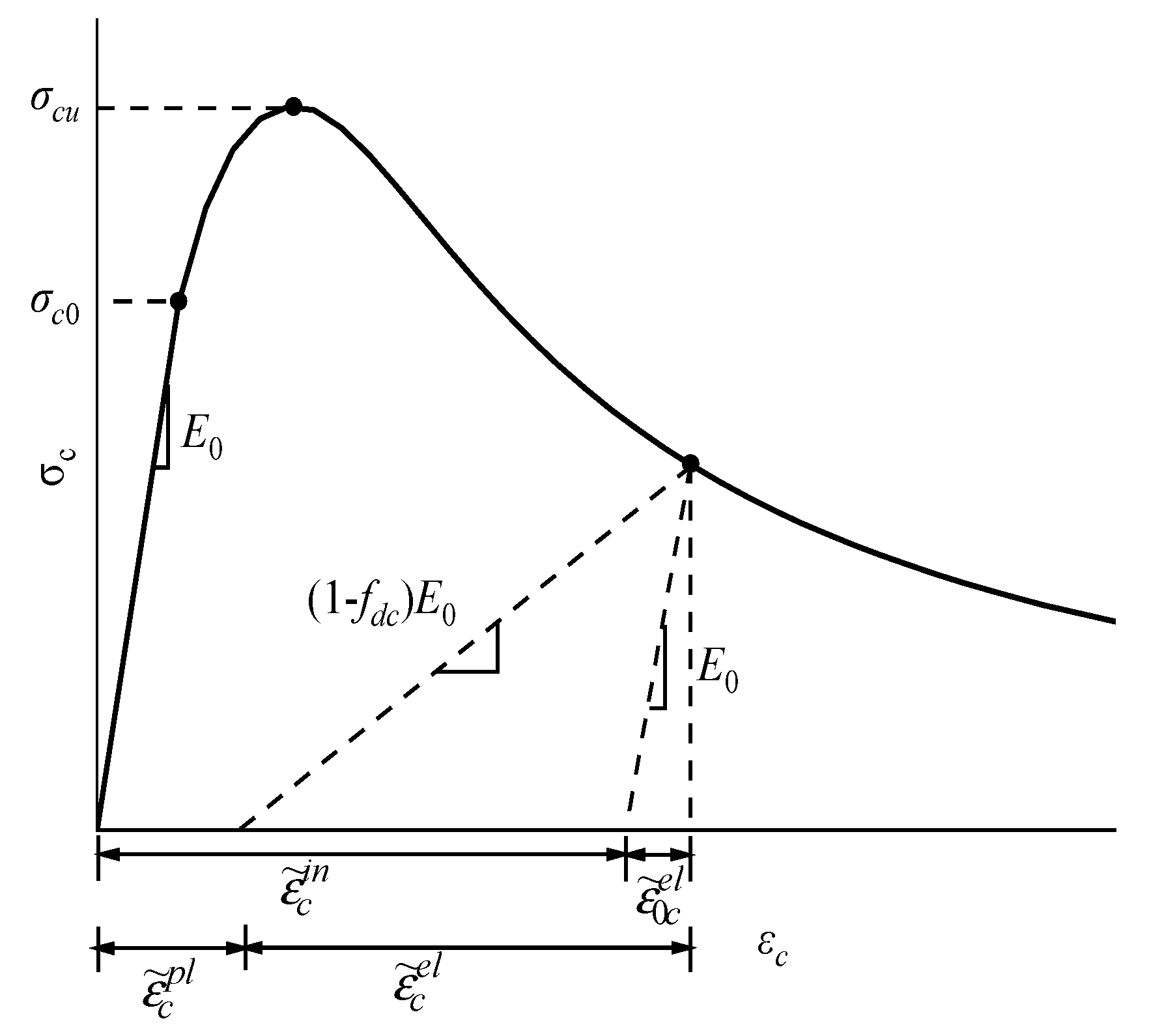

Figure 10.

Stress–strain curve of concrete under uniaxial compression based on plastic damage model.

Figure 10.

Stress–strain curve of concrete under uniaxial compression based on plastic damage model.

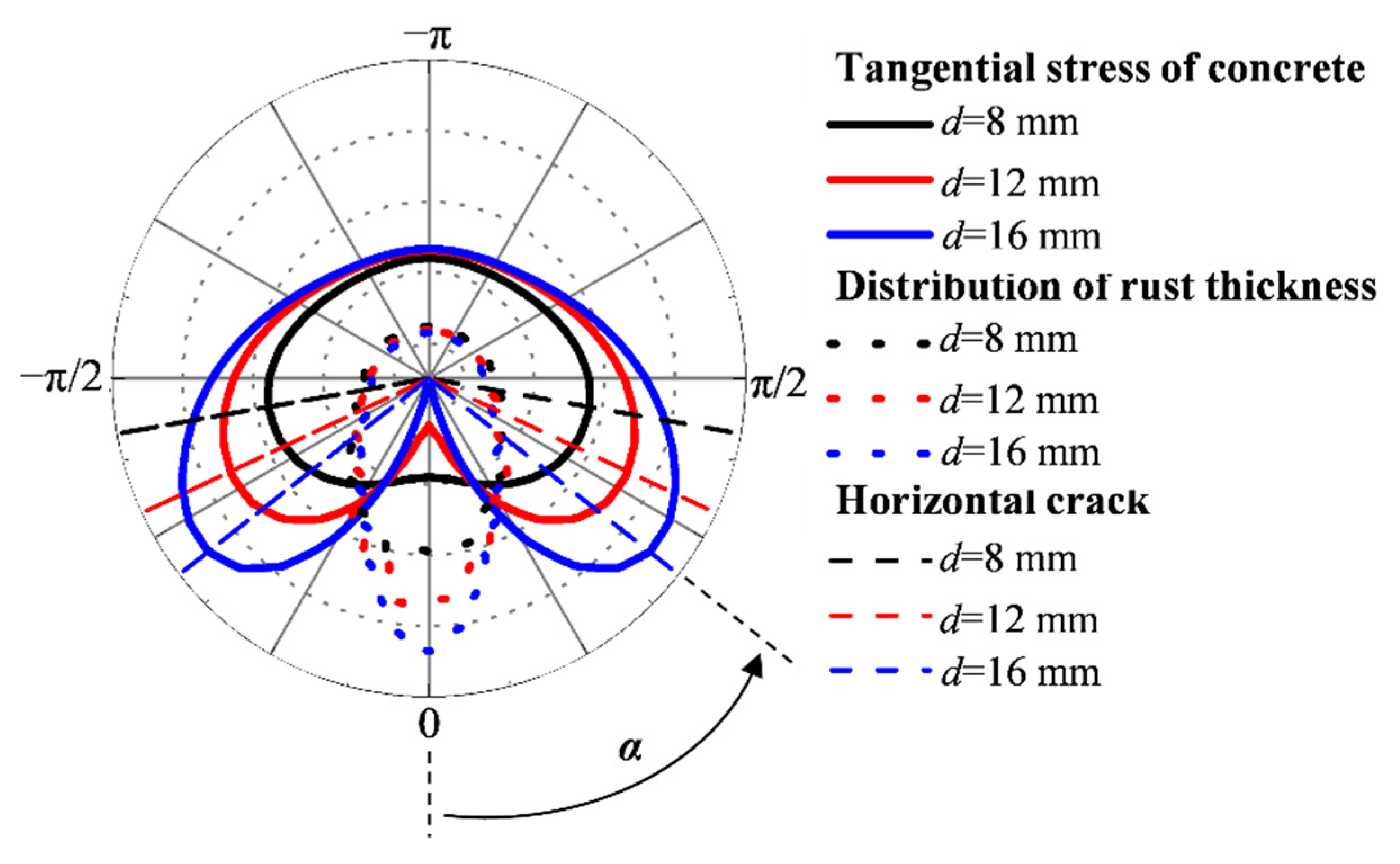

Figure 11.

Rust layer distribution and crack morphology of steel bars with different diameters.

Figure 11.

Rust layer distribution and crack morphology of steel bars with different diameters.

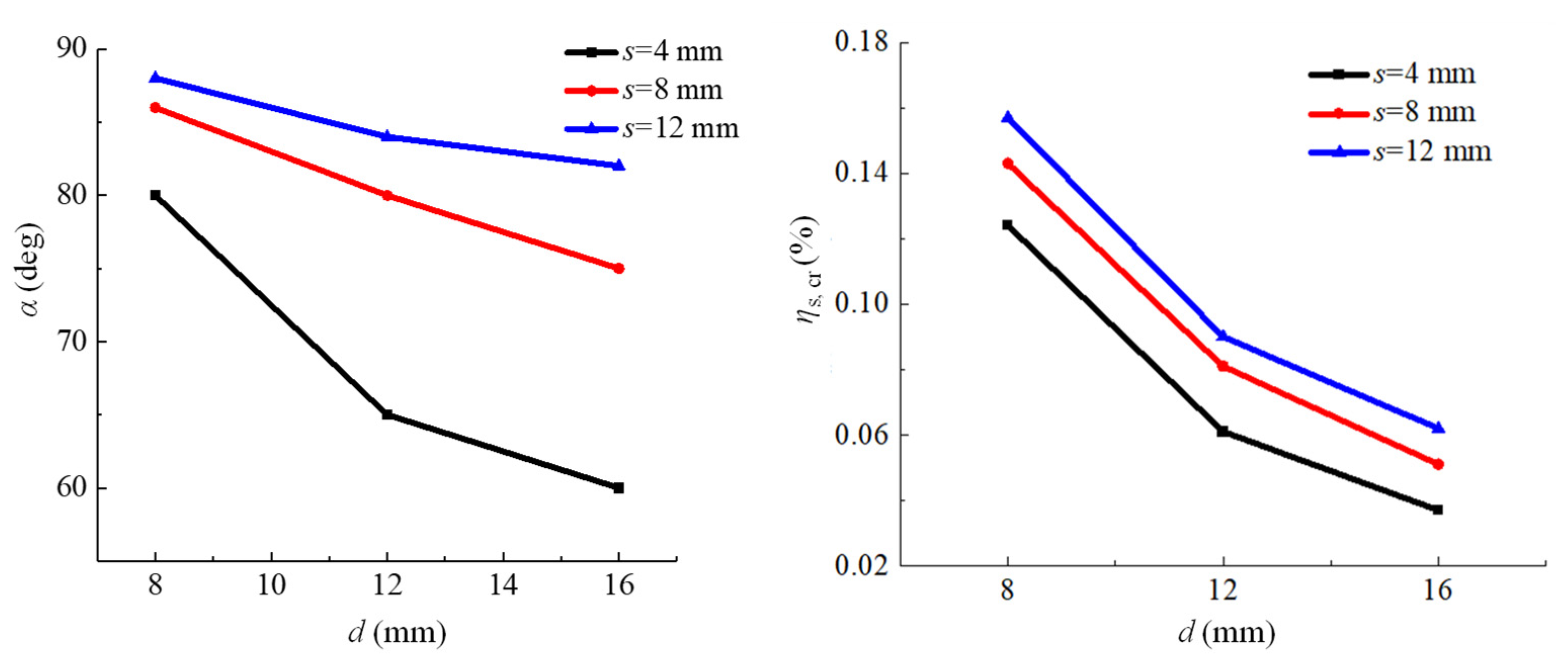

Figure 12.

Relationship between horizontal crack angle (α) and critical corrosion degree (ηs, cr) and steel bar diameter (d).

Figure 12.

Relationship between horizontal crack angle (α) and critical corrosion degree (ηs, cr) and steel bar diameter (d).

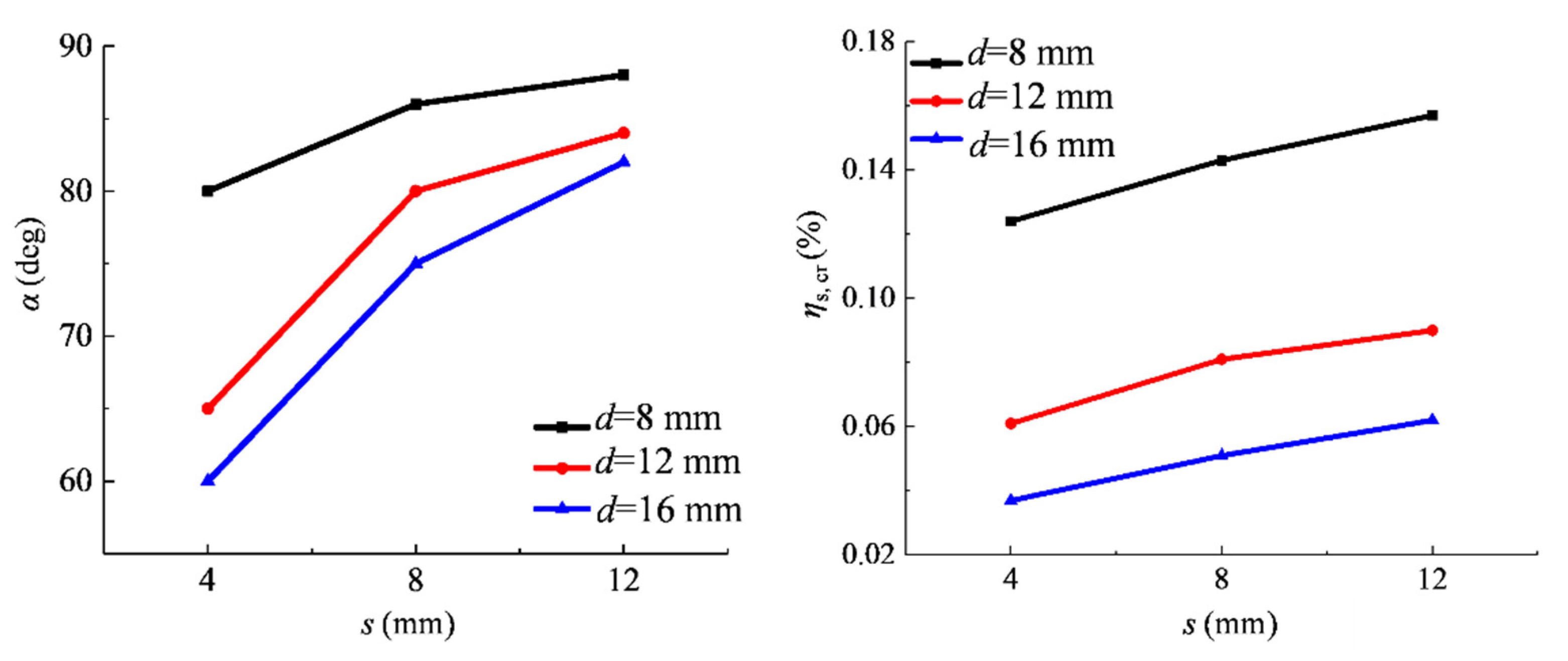

Figure 13.

Relationship between angle (α) and critical corrosion degree (ηs, cr) of horizontal cracks and distance (s) between steel bars and stainless steel wires.

Figure 13.

Relationship between angle (α) and critical corrosion degree (ηs, cr) of horizontal cracks and distance (s) between steel bars and stainless steel wires.

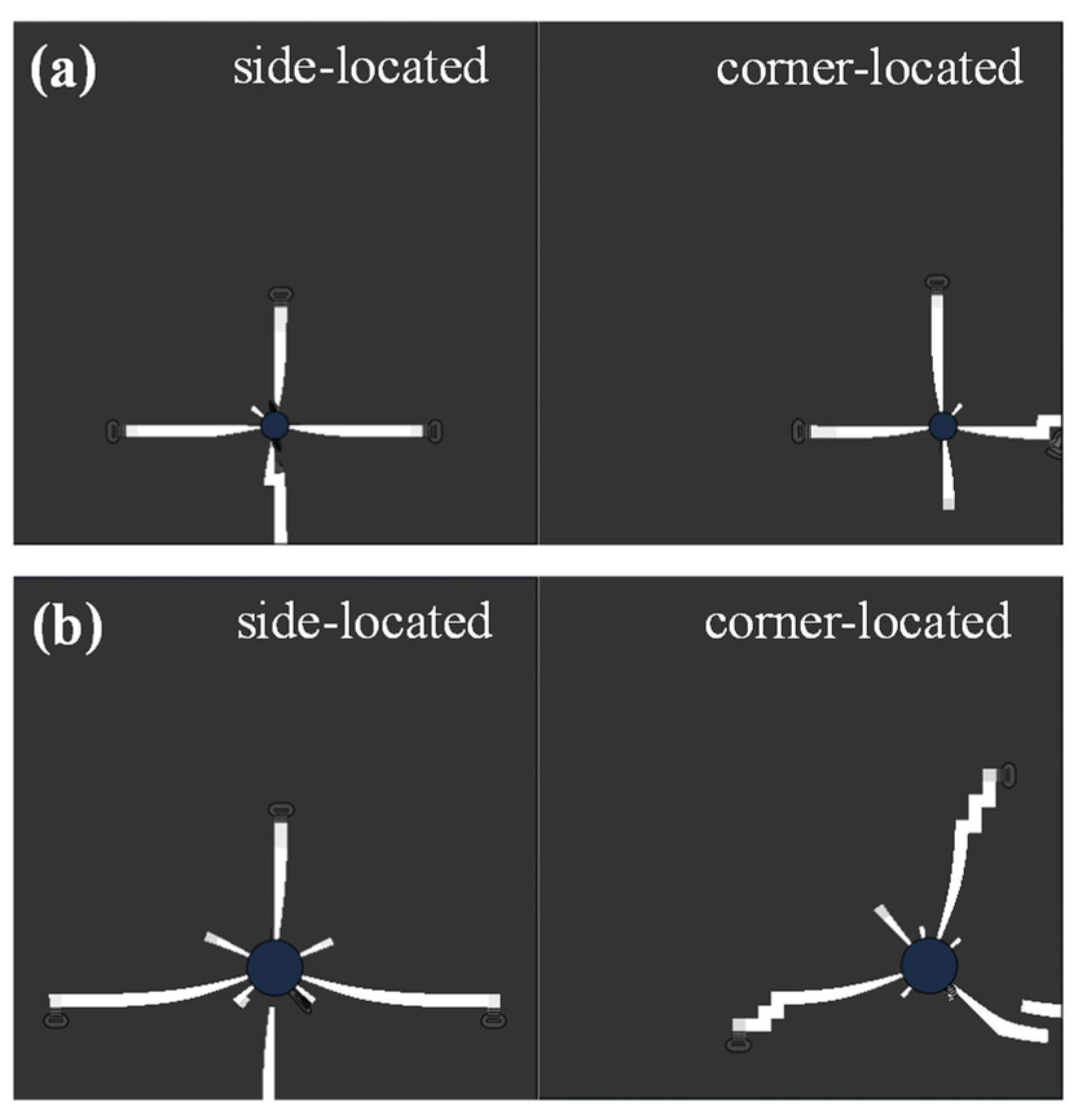

Figure 14.

Crack morphology of side and corner of steel bar: (a) s = 12 mm, d = 8 mm, c = 30 mm; (b) s = 8 mm, d = 16 mm, c = 30 mm.

Figure 14.

Crack morphology of side and corner of steel bar: (a) s = 12 mm, d = 8 mm, c = 30 mm; (b) s = 8 mm, d = 16 mm, c = 30 mm.

Figure 15.

Distribution of rust layer and crack pattern of corner-located steel under non-uniform accelerated corrosion.

Figure 15.

Distribution of rust layer and crack pattern of corner-located steel under non-uniform accelerated corrosion.

Figure 16.

Typical crack distribution of concrete reinforced by multiple steels: (a) d = 16 mm, S = 6d, c = 20 mm; (b) d = 16 mm, S = 6d, c = 30 mm; (c) d = 16 mm, S = 6d, c = 40 mm; (d) d = 16 mm, S = 4d, c = 20 mm; (e) d = 16 mm, S = 2d, c = 20 mm; (f) d = 8 mm, S = 4d, c = 20 mm; (g) d = 12 mm, S = 4d, c = 20 mm.

Figure 16.

Typical crack distribution of concrete reinforced by multiple steels: (a) d = 16 mm, S = 6d, c = 20 mm; (b) d = 16 mm, S = 6d, c = 30 mm; (c) d = 16 mm, S = 6d, c = 40 mm; (d) d = 16 mm, S = 4d, c = 20 mm; (e) d = 16 mm, S = 2d, c = 20 mm; (f) d = 8 mm, S = 4d, c = 20 mm; (g) d = 12 mm, S = 4d, c = 20 mm.

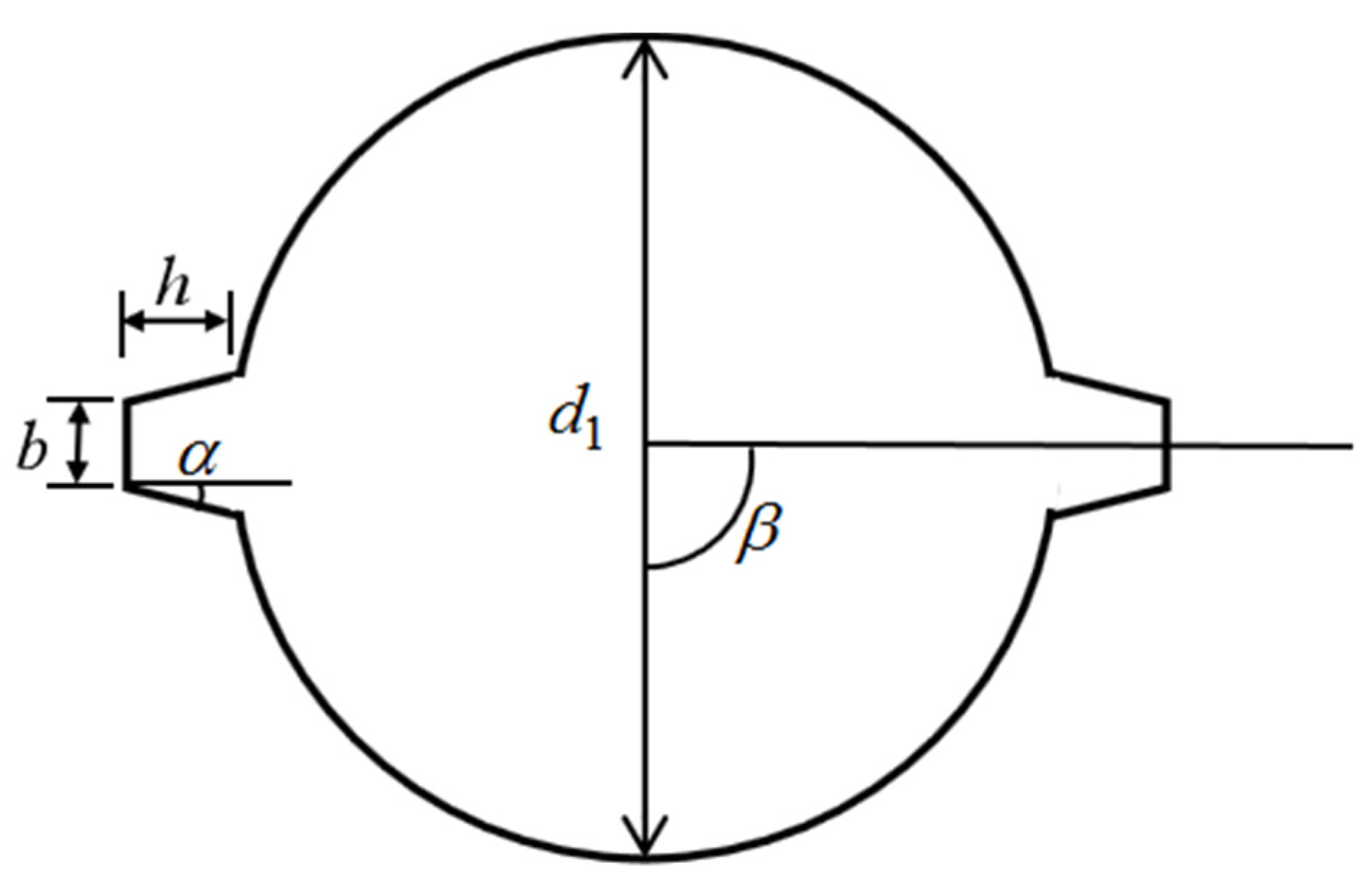

Figure 17.

Schematic diagram of ribbed steel bar cross section.

Figure 17.

Schematic diagram of ribbed steel bar cross section.

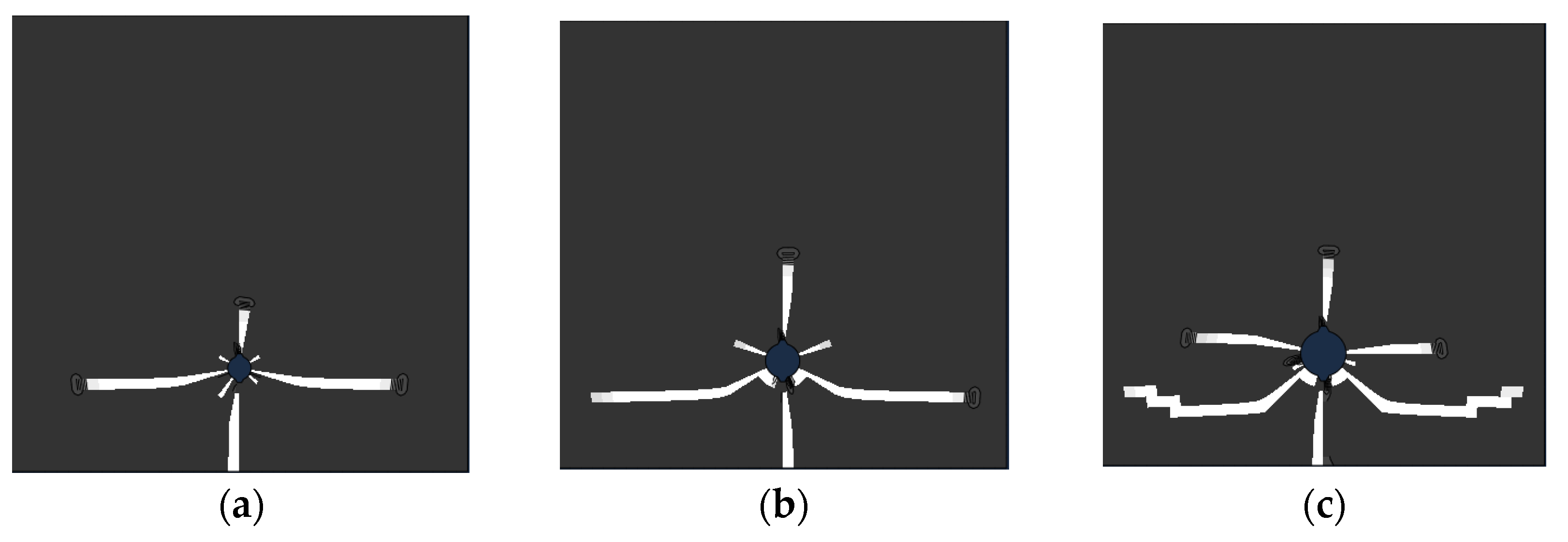

Figure 18.

Crack distribution of single central-ribbed reinforced concrete (β = 0): (a) s = 4 mm, d = 8 mm; (b) s = 4 mm, d = 12 mm; (c) s = 4 mm, d = 16 mm; (d) s = 8 mm, d = 16 mm; (e) s = 12 mm, d = 16 mm.

Figure 18.

Crack distribution of single central-ribbed reinforced concrete (β = 0): (a) s = 4 mm, d = 8 mm; (b) s = 4 mm, d = 12 mm; (c) s = 4 mm, d = 16 mm; (d) s = 8 mm, d = 16 mm; (e) s = 12 mm, d = 16 mm.

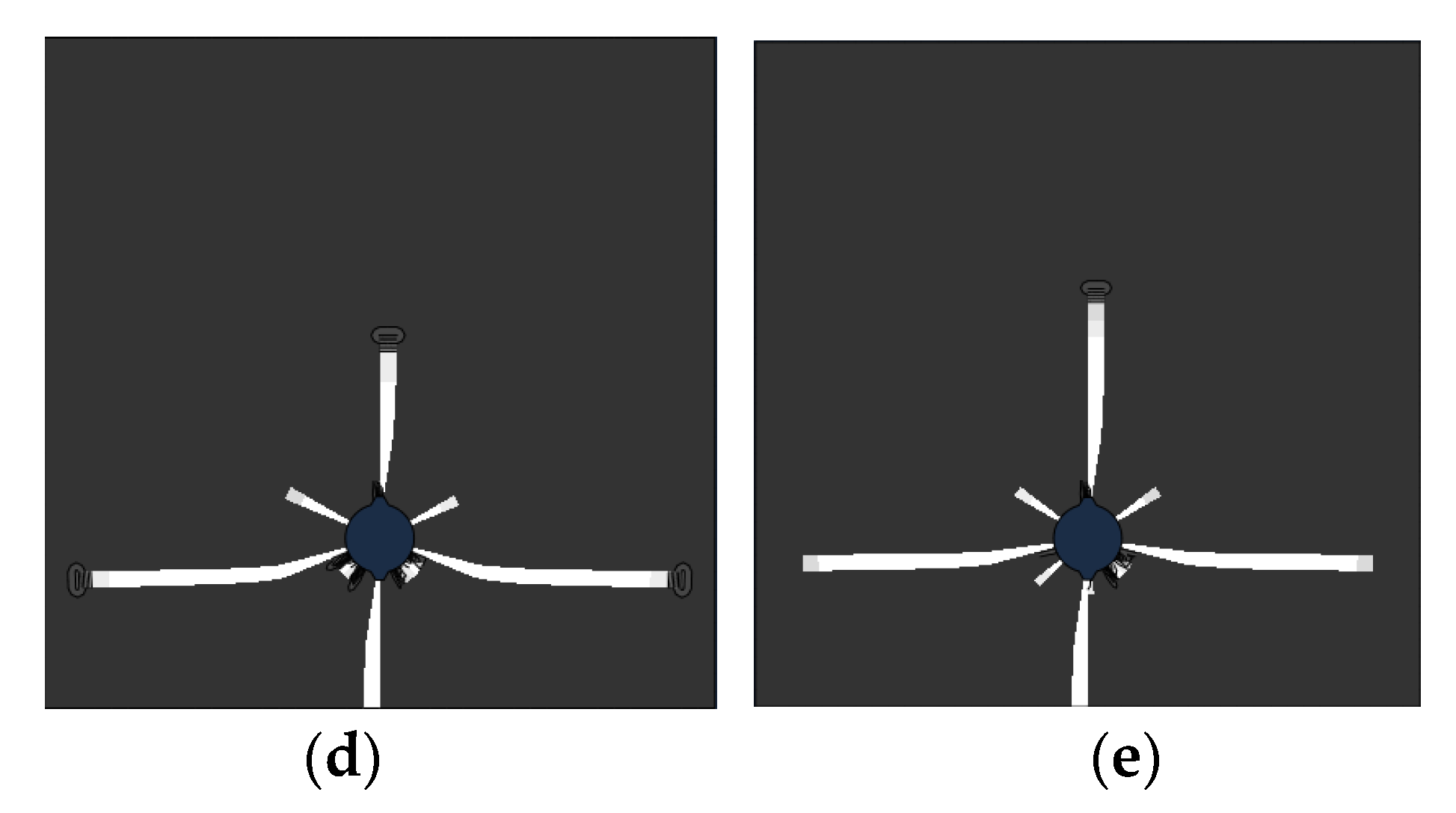

Figure 19.

Critical corrosion degree under different rib angles (s = 8 mm, d = 16 mm, c = 30 mm).

Figure 19.

Critical corrosion degree under different rib angles (s = 8 mm, d = 16 mm, c = 30 mm).

Table 1.

Finite element simulation parameters of galvanic corrosion of steel bars.

Table 1.

Finite element simulation parameters of galvanic corrosion of steel bars.

| Parameter | Symbol | Value | Unit |

|---|

| External current density | i | 3 | A/m2 |

| Anode equilibrium potential | E0a | −0.618 | V |

| Cathode equilibrium potential | E0c | −0.414 | V |

| Anode exchange current density | I0a | 7.1 | A/m2 |

| Cathodic exchange current density | I0c | 110 | A/m2 |

| Anode charge transfer coefficient | α | 0.5 | 1 |

| Cathode charge transfer coefficient | γ | 0.5 | 1 |

| Temperature | T | 298 | K |

Table 2.

Fitting values of parameters of Gauss model for side laying reinforcement.

Table 2.

Fitting values of parameters of Gauss model for side laying reinforcement.

| s (×10−3 m) | d (×10−3 m) | y | Tm | c |

|---|

| 4 | 8 | 1.277 | 6.457 | 0.655 |

| | 12 | 1.140 | 8.822 | 0.511 |

| | 16 | 1.039 | 11.656 | 0.409 |

| | 24 | 0.912 | 16.657 | 0.298 |

| | 32 | 0.860 | 21.530 | 0.242 |

| 8 | 8 | 1.450 | 4.269 | 0.873 |

| | 12 | 1.281 | 5.483 | 0.744 |

| | 16 | 1.145 | 6.909 | 0.636 |

| | 24 | 0.951 | 9.639 | 0.498 |

| | 32 | 0.881 | 12.552 | 0.411 |

| 12 | 8 | 1.623 | 3.330 | 0.986 |

| | 12 | 1.399 | 4.485 | 0.843 |

| | 16 | 1.228 | 5.343 | 0.768 |

| | 24 | 1.015 | 7.216 | 0.645 |

| | 32 | 0.916 | 9.322 | 0.551 |

| 16 | 8 | 1.756 | 2.887 | 1.132 |

| | 12 | 1.486 | 3.606 | 0.979 |

| | 16 | 1.305 | 4.549 | 0.863 |

| | 24 | 1.083 | 6.257 | 0.723 |

| | 32 | 0.937 | 7.945 | 0.640 |

| 20 | 8 | 1.852 | 2.482 | 1.206 |

| | 12 | 1.547 | 3.200 | 1.028 |

| | 16 | 1.336 | 4.0307 | 0.935 |

| | 24 | 1.117 | 5.552 | 0.785 |

| | 32 | 0.957 | 7.177 | 0.700 |

Table 3.

Fitting of current density distribution on the surface of single corner bar.

Table 3.

Fitting of current density distribution on the surface of single corner bar.

s

(×10−3 m) | d

(×10−3 m) | Fitted Coefficients |

|---|

| y1 | Tm1 | Tm2 | c1 | c2 |

|---|

| 4 | 8 | 2.517 | 6.641 | 6.587 | 0.655 | 0.688 |

| | 12 | 2.238 | 8.851 | 8.739 | 0.535 | 0.498 |

| | 16 | 1.834 | 12.340 | 12.218 | 0.400 | 0.422 |

| | 24 | 1.800 | 16.770 | 16.715 | 0.282 | 0.293 |

| | 32 | 1.705 | 21.543 | 21.466 | 0.236 | 0.240 |

| 8 | 8 | 3.012 | 4.261 | 4.281 | 0.805 | 0.832 |

| | 12 | 2.659 | 5.548 | 5.671 | 0.746 | 0.751 |

| | 16 | 2.299 | 7.203 | 7.151 | 0.606 | 0.620 |

| | 24 | 1.822 | 9.669 | 9.632 | 0.494 | 0.485 |

| | 32 | 1.778 | 12.274 | 12.257 | 0.411 | 0.417 |

| 12 | 8 | 3.279 | 3.335 | 3.296 | 0.989 | 0.920 |

| | 12 | 2.873 | 4.496 | 4.584 | 0.824 | 0.836 |

| | 16 | 2.524 | 5.486 | 5.351 | 0.782 | 0.784 |

| | 24 | 2.046 | 7.259 | 7.283 | 0.647 | 0.631 |

| | 32 | 1.772 | 9.271 | 9.455 | 0.530 | 0.519 |

| 16 | 8 | 3.465 | 2.868 | 2.841 | 1.007 | 1.010 |

| | 12 | 3.030 | 3.745 | 3.665 | 0.979 | 0.907 |

| | 16 | 2.691 | 4.602 | 4.584 | 0.858 | 0.866 |

| | 24 | 2.189 | 6.402 | 6.311 | 0.698 | 0.710 |

| | 32 | 1.800 | 8.142 | 8.151 | 0.622 | 0.639 |

| 20 | 8 | 3.885 | 2.461 | 2.416 | 1.131 | 1.103 |

| | 12 | 3.056 | 3.187 | 3.210 | 1.084 | 1.093 |

| | 16 | 2.688 | 4.137 | 4.147 | 0.947 | 0.940 |

| | 24 | 2.263 | 5.588 | 5.467 | 0.781 | 0.771 |

| | 32 | 1.902 | 7.126 | 7.123 | 0.691 | 0.696 |

Table 4.

Fitting the distribution of current density on the surface of steel bars in the case of multiple steel bars.

Table 4.

Fitting the distribution of current density on the surface of steel bars in the case of multiple steel bars.

d

(×10−3 m) | S/d | Fitted Coefficients | Change Rate |

|---|

| y1 | Tm1 | c1 | Y (%) | T (%) | C (%) |

|---|

| 8 | 1 | 0.671 | 6.419 | 0.886 | −53.724 | 50.363 | 1.489 |

| 2 | 0.966 | 5.399 | 0.872 | −33.379 | 26.470 | −0.115 |

| 4 | 1.267 | 4.855 | 0.848 | −12.621 | 13.727 | −2.864 |

| 6 | 1.351 | 4.566 | 0.834 | −6.828 | 6.957 | −4.467 |

| 8 | 1.411 | 4.467 | 0.832 | −2.690 | 4.638 | −4.696 |

| 12 | 1 | 0.556 | 7.416 | 0.752 | −56.596 | 35.254 | 1.075 |

| 2 | 0.853 | 6.523 | 0.742 | −33.411 | 18.968 | −0.269 |

| 4 | 1.107 | 5.913 | 0.724 | −13.583 | 7.842 | −2.688 |

| 6 | 1.203 | 5.741 | 0.715 | −6.089 | 4.705 | −3.898 |

| 8 | 1.251 | 5.607 | 0.708 | −2.342 | 2.262 | −4.839 |

| 16 | 1 | 0.483 | 8.559 | 0.654 | −57.817 | 23.882 | 2.830 |

| 2 | 0.773 | 7.708 | 0.653 | −32.489 | 11.565 | 2.673 |

| 4 | 0.992 | 7.206 | 0.621 | −13.362 | 4.299 | −2.358 |

| 6 | 1.075 | 7.124 | 0.606 | −6.114 | 3.112 | −4.717 |

| 8 | 1.114 | 7.012 | 0.605 | −2.707 | 1.491 | −4.874 |

| 24 | 1 | 0.451 | 11.175 | 0.522 | −52.576 | 15.935 | 4.819 |

| 2 | 0.661 | 10.153 | 0.507 | −30.494 | 5.333 | 1.807 |

| 4 | 0.811 | 9.901 | 0.489 | −14.721 | 2.718 | −1.807 |

| 6 | 0.884 | 9.819 | 0.482 | −7.045 | 1.867 | −3.213 |

| 8 | 0.928 | 9.756 | 0.475 | −2.419 | 1.214 | −4.618 |

| 32 | 1 | 0.425 | 13.648 | 0.430 | −51.759 | 8.732 | 4.623 |

| 2 | 0.608 | 12.941 | 0.419 | −30.988 | 3.099 | 1.946 |

| 4 | 0.766 | 12.789 | 0.403 | −13.053 | 1.888 | −1.946 |

| 6 | 0.824 | 12.686 | 0.400 | −6.470 | 1.068 | −2.676 |

| 8 | 0.860 | 12.682 | 0.400 | −2.384 | 1.036 | −2.676 |

Table 5.

Chemical composition of steel (mass %).

Table 5.

Chemical composition of steel (mass %).

| | C | Si | Mn | P | S |

|---|

| Steel | 0.25 | 0.55 | 1.5 | 0.045 | 0.05 |

Table 6.

Chemical composition of cement (mass %).

Table 6.

Chemical composition of cement (mass %).

| Composition | Content |

|---|

| CaO | 57.00 |

| SiO2 | 23.41 |

| Al2O3 | 5.50 |

| SO3 | 2.56 |

| Fe2O3 | 3.60 |

| MgO | 2.75 |

| Loss on ignition | 5.14 |

Table 7.

Parameters of concrete materials.

Table 7.

Parameters of concrete materials.

| Ψ | ε | σb0/σc0 | K | µ | Ec (MPa) | v | Ft,r | Et,r |

|---|

| 30° | 0.1 | 1.16 | 2/3 | 0.0005 | 30,000 | 0.2 | 2.01 | 9.524 × 10−5 |

Table 8.

Influencing parameters of corrosion-cracking model of single plain reinforced concrete.

Table 8.

Influencing parameters of corrosion-cracking model of single plain reinforced concrete.

| Position | d/mm | c/mm | s/mm |

|---|

| Central | 6 | 20 | 4 |

| | 12 | 30 | 8 |

| Corner | 16 | 40 | 12 |

Table 9.

Affecting parameters of corrosion cracking for multiple plain reinforced concrete.

Table 9.

Affecting parameters of corrosion cracking for multiple plain reinforced concrete.

| d/mm | c/mm | S/mm |

|---|

| 8 | 20 | 2 |

| 12 | 30 | 4 |

| 16 | 40 | 6 |

Table 10.

Details of ribbed steel bar.

Table 10.

Details of ribbed steel bar.

| Position of Steel | d (mm) | s (mm) | β (deg) |

|---|

| Side-located | 16 | 8 | 0 |

| | 16 | 8 | π/4 |

| | 16 | 8 | π/2 |

| Corner-located | 16 | 8 | 0 |

| | 16 | 8 | π/4 |

| | 16 | 8 | 3π/4 |