Deformation, Failure, and Acoustic Emission Characteristics under Different Lithological Confining Pressures

Abstract

:1. Introduction

2. Engineering Background

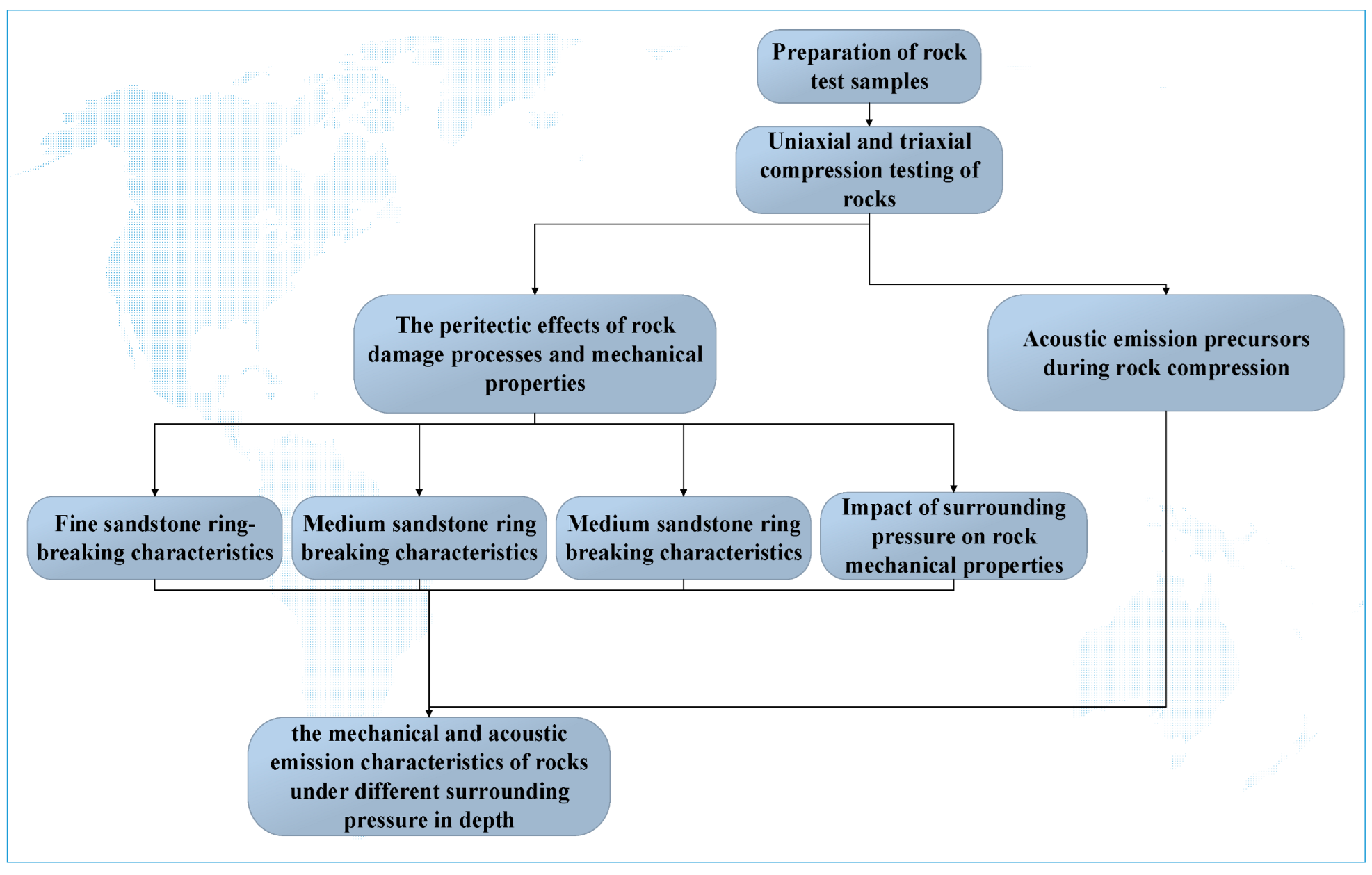

3. Test Protocol

3.1. Preparation of Rock Test Samples

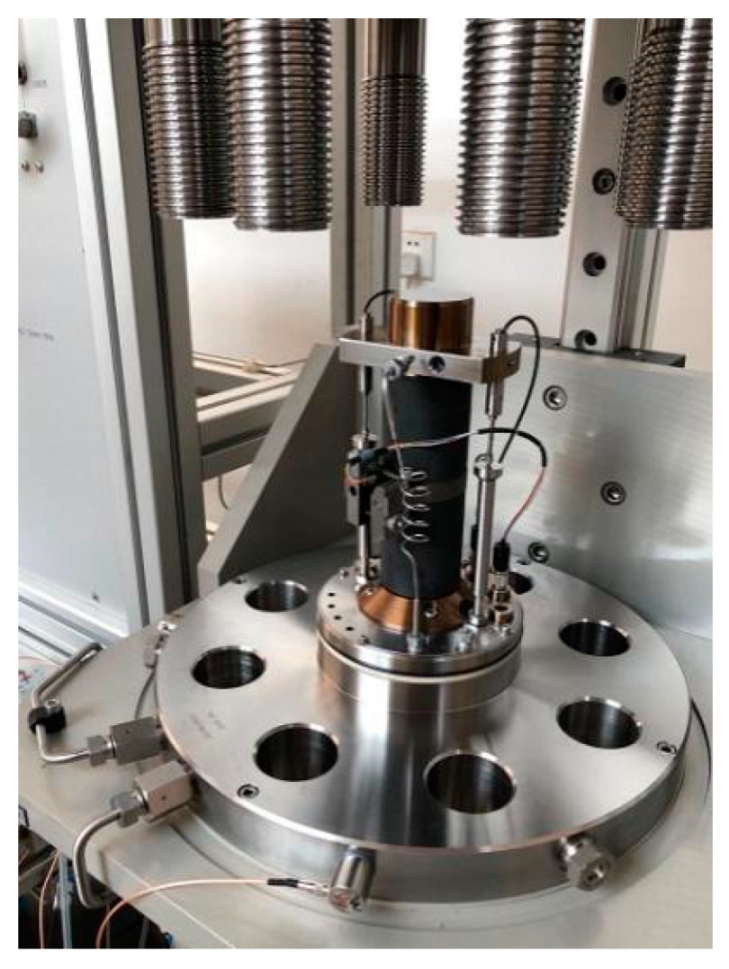

3.2. Test Equipment

4. Rock Failure and Mechanical Characteristics under Different Surrounding Pressures

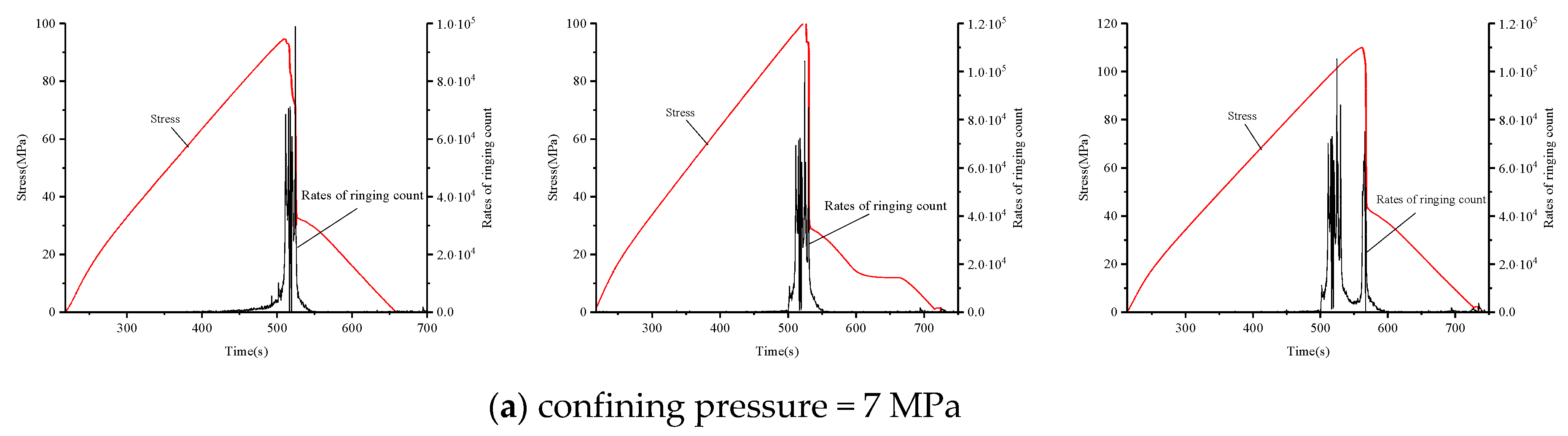

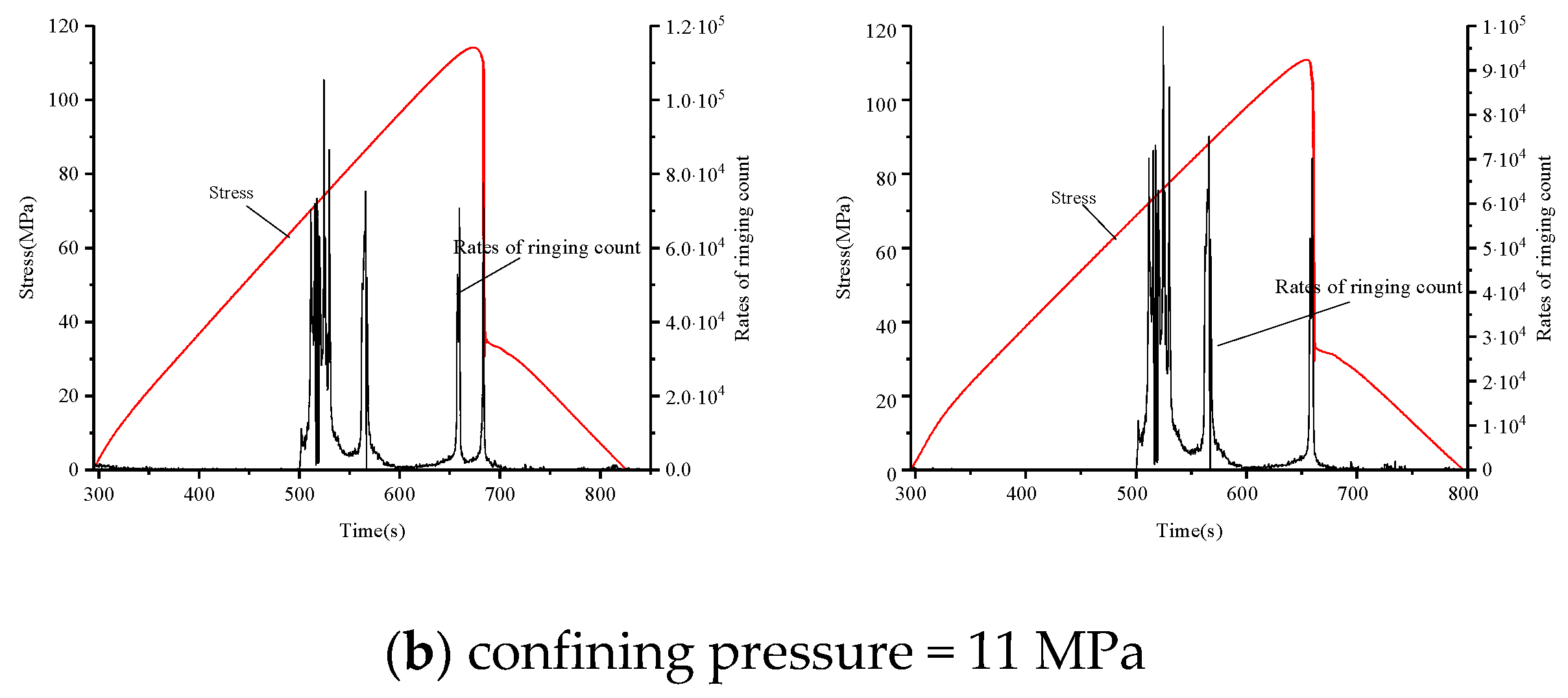

4.1. Fine Sandstone Ring-Breaking Characteristics

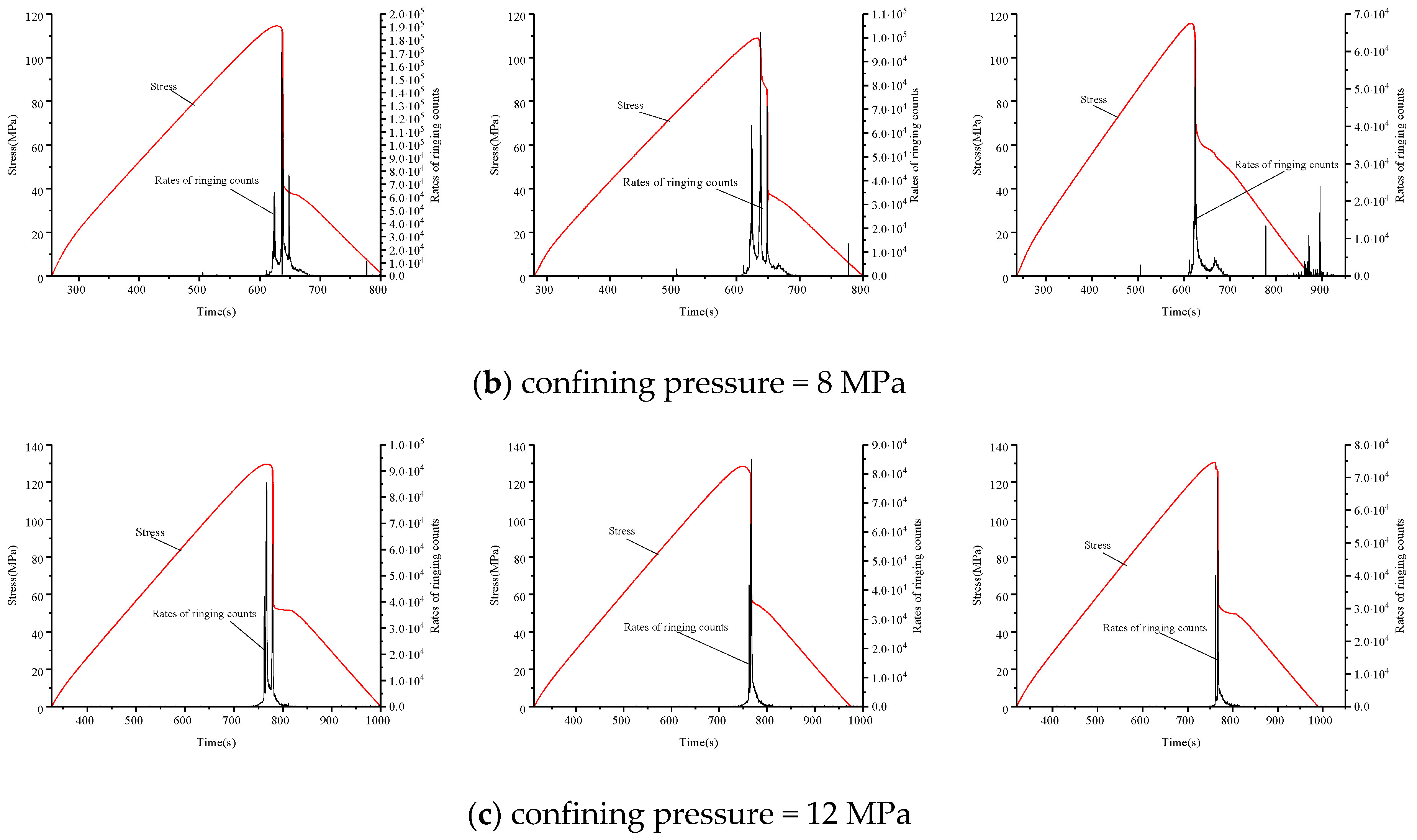

4.2. Medium Sandstone Ring Breaking Characteristics

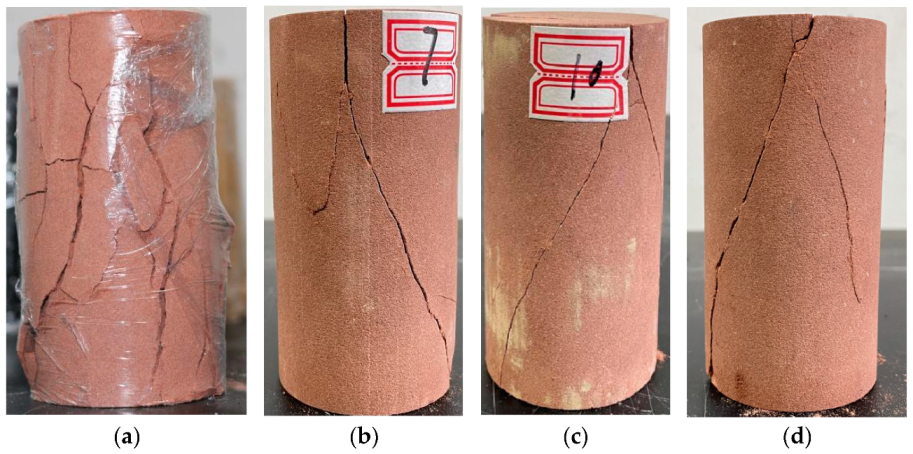

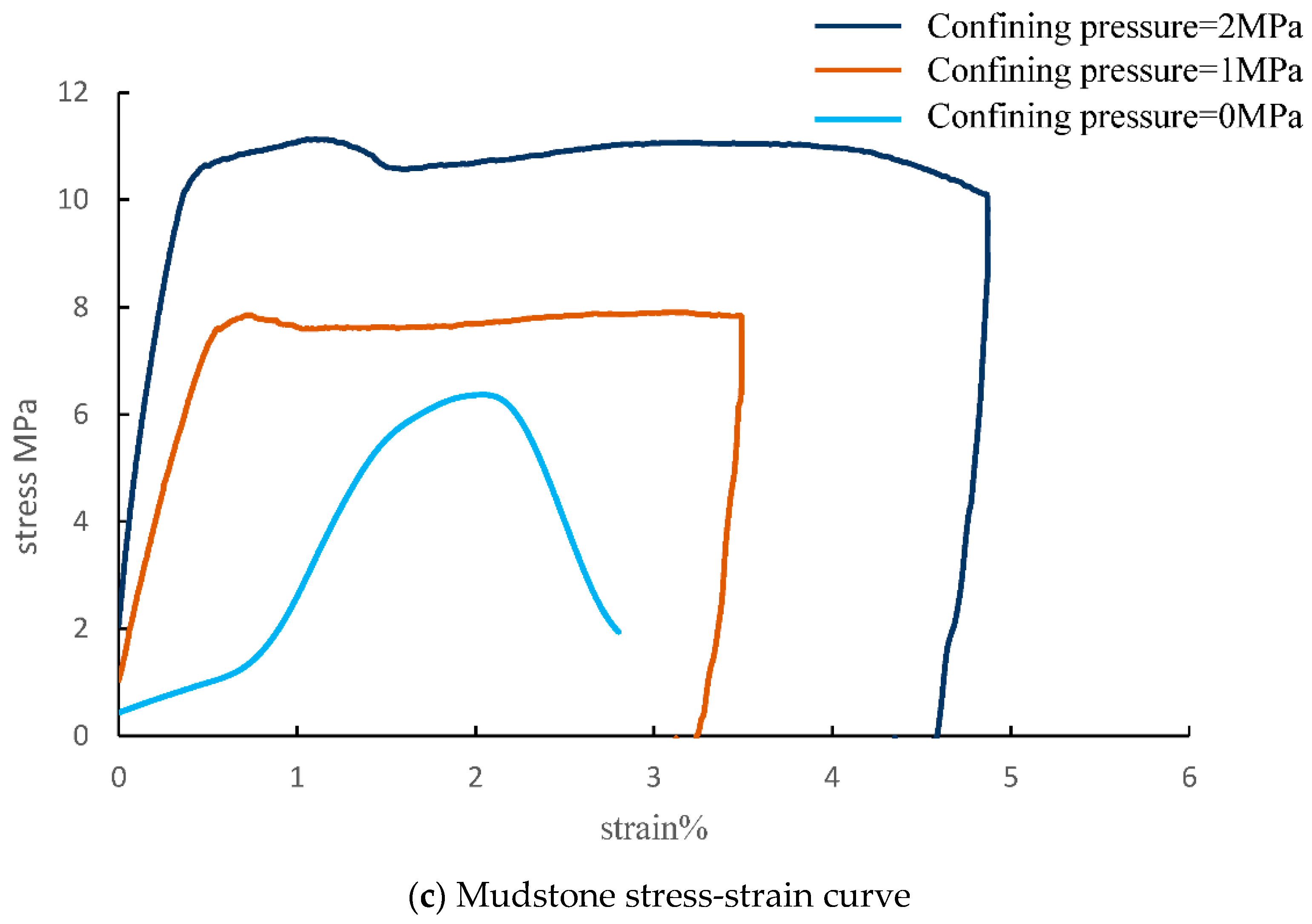

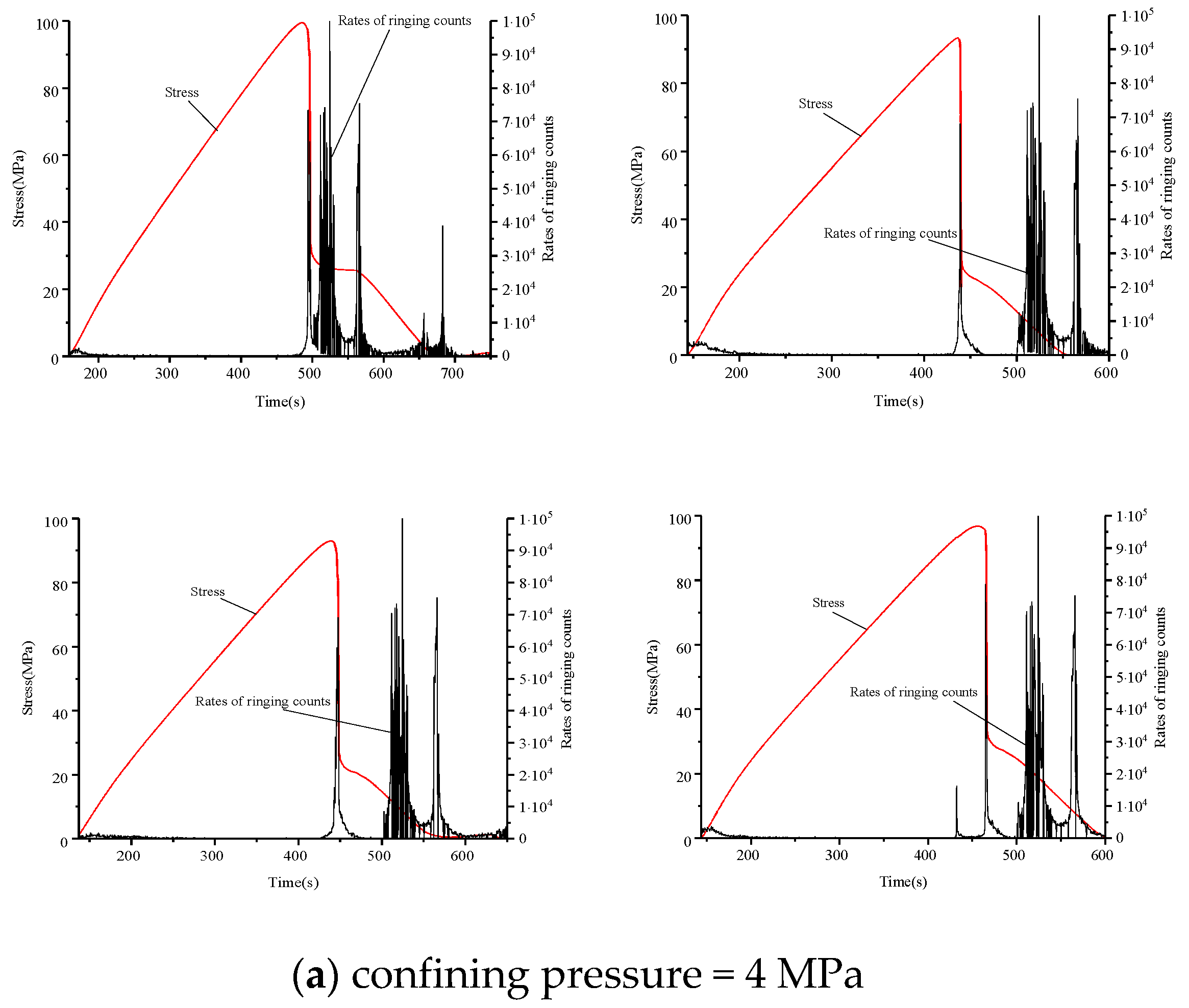

4.3. Mudstone Ring Breaking Characteristics

4.4. Impact of Surrounding Pressure on Rock Mechanical Properties

4.5. Summary of the Chapter

5. Acoustic Emission Precursors during Rock Compression

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xie, H.; Zhou, H.; Xue, D. Research and consideration on deep coal mining and critical mining depth. J. China Coal Soc. 2012, 37, 535–542. [Google Scholar]

- Jiang, Y.D.; Pan, Y.S.; Jiang, F.X.; Dou, L.M.; Ju, Y. State of the art review on mechanism and prevention of coal bumps in China. J. China Coal Soc. 2014, 39, 205–213. [Google Scholar]

- Deng, J.; Li, S.; Jiang, Q.; Chen, B. Probabilistic analysis of shear strength of intact rock in triaxial compression:a case study of J INPING Ⅱ project. Tunn. Undergr. Space Technol. 2021, 111, 103833. [Google Scholar] [CrossRef]

- Zhang, J.C.; Lin, Z.N.; Dong, B.; Guo, R.X. Triaxial compression testing at constant and reducing confining pressure for the mechanical characterization of a specific type of sandstone. Rock Mech. Rock Eng. 2021, 41, 1999–2012. [Google Scholar] [CrossRef]

- Zhang, H.M.; Xia, H.J.; Yang, G.S.; Zhang, M.J.; Peng, C.; Ye, W.J.; Shen, Y.J. Experimental research of influences of freeze-thaw cycles and confining pressure on physical-mechanical characteristics of rocks. Rock Mech. Rock Eng. 2018, 43, 441–448. [Google Scholar]

- Mu, K.; Li, T.; Yu, J. Visual simulation of the relationship between sandstone acoustic emission and compression deformation under peripressure effect. J. Rock Mech. Eng. 2014, 33, 2786–2793. [Google Scholar]

- Gao, L.; Gao, F.; Zhang, Z.; Xing, Y. Research on the energy evolution characteristics and the failure intensity of rocks. Int. J. Min. Sci. Technol. 2020, 30, 705–713. [Google Scholar] [CrossRef]

- Cheng, H.; Yang, X.; Liu, J. Confining pressure effect on energy parameters of sandstones based on damage evolution. J. Min. Sci. Technol. 2020, 5, 249–256. (In Chinese) [Google Scholar]

- Ji, H.; Lu, X. Characteristics acoustic emission and rock fracture precursors of granite under conventional triaxial compression. Chin. J. Rock Mech. Eng. 2015, 34, 694–702. [Google Scholar]

- Gong, Y.X.; He, M.C.; Wang, Z.H.; Yin, Y. Research on time-frequency analysis algorithm and instantaneous frequency precursors for acoustic emission data from rock failure experiment. Chin. J. Rock Mech. Eng. 2013, 32, 787–799. [Google Scholar]

- Zhang, Y.B.; Liang, P.; Liu, X.; Liu, S.; Tian, B. Experimental study on precursor of rock burst based on acoustic emission signal dominant-frequency and entropy. Chin. J. Rock Mech. Eng. 2015, 34, 2959–2967. [Google Scholar]

- Wang, Y.F.; Su, H.; Wang, L.P.; Jiao, H.Z.; Li, Z. Study on the difference of deformation and strength characteristics of three kinds of sandstone. J. China Coal Soc. 2020, 45, 1367–1374. [Google Scholar]

- Wang, Z.; Gu, Y.; Li, Q. Research on confining pressure effect on acoustic emission of shale and its main fracture precursor information. Chin. J. Undergr. Space Eng. 2018, 14, 78–85. [Google Scholar]

- Lai, X.P.; Zhang, S.; Cui, F.; Wang, Z.; Xu, H.; Fang, X. Energy release law during the damage evolution of water-bearing coal and rock and pick-up of AE signals of key pregnancy disasters. Chin. J. Rock Mech. Eng. 2020, 39, 433–444. [Google Scholar]

- Zhang, Y.B.; Yang, Z.; Yao, X.L.; Tian, B.; Liu, X.; Liang, P. Experimental study on rock burst acoustic emission signal and fracture characteristics in granite roadway. J. China Coal Soc. 2018, 43, 95–104. [Google Scholar]

- Zhao, H.; Liang, Z.; Liu, X. Acoustic Emission Evolution Characteristics of Rock Under Three-point Bending Tests. J. Water Resour. Archit. Eng. 2020, 18, 6–12. [Google Scholar]

- Xia, D.; Yang, T.H.; Xu, T.; Wang, P.; Zhao, Y. Experimental study on AE properties during the damage process of water-saturated rock specimens based on time effect. J. China Coal Soc. 2015, 40, 337–345. [Google Scholar]

- Ye, W.J.; Wu, Y.T.; Yang, G.S.; Jing, H.; Chang, S.; Chen, M. Study on microstructure and macro-mechanical properties of pale sol under dry-wet cycles. Chin. J. Rock Mech. Eng. 2019, 38, 2126–2137. (In Chinese) [Google Scholar]

- Li, S.L.; Zhou, M.J.; Gao, Z.P.; Chen, D.X.; Zhang, J.L.; Hu, J.Y. Experimental study on acoustic emission characteristics before the peak strength of rocks under incrementally cyclic loading-unloading methods. Chin. J. Rock Mech. Eng. 2019, 38, 724–735. (In Chinese) [Google Scholar]

- Jiang, J.D.; Chen, S.S.; Xu, J.; Liu, Q.S. Mechanical properties and energy characteristics of mudstone under different containing moisture states. J. China Coal Soc. 2018, 43, 2217–2224. (In Chinese) [Google Scholar]

- Yao, X.; Zhang, Y.; Liu, X.; Liang, P.; Sun, L. Optimization method for key characteristic signal of acoustic emission in rock fracture. Rock Soil Mech. 2018, 39, 375–384. (In Chinese) [Google Scholar]

- Teng, J.; Tang, J.; Wang, J.; Zhang, Y. The evolution law of the damage of bedded composite rock and its fractal characteristics. Chin. J. Rock Mech. Eng. 2018, 37, 3263–3278. [Google Scholar]

- Liu, X.H.; Zhang, R.; Liu, J. Dynamic test study of coal rock under different strain rates. J. China Coal Soc. 2012, 37, 1528–1534. [Google Scholar]

- Mei, Z.; Hu, Y.; Bao, C. Numerical Simulation of Mechanical and Acoustic Emission Characteristics in Rock Compression Under Different Confining Pressures. J. Shaoxing Univ. 2017, 37, 15–19. [Google Scholar]

- Yang, Y.J.; Wang, D.C.; Guo, M.F.; Li, B. Study of rock damage characteristics based on acoustic emission tests un-der triaxial compression. Chin. J. Rock Mech. Eng. 2014, 33, 98–104. [Google Scholar]

| Thickness (m) | Depth (m) | Formation |

|---|---|---|

| 1.85 | 52.66 | Medium sandstone |

| 9.0 | 61.66 | Fine sandstone |

| 10 | 71.66 | Medium sandstone |

| 5 | 76.66 | Siltstone |

| 0.3 | 76.96 | Mudstone |

| 5.5 | 82.46 | coal seam |

| 0.3 | 82.76 | Mudstone |

| 5.12 | 87.88 | Siltstone |

| 0.15 | 88.03 | Mudstone |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, S.; Qin, G.; Cao, J. Deformation, Failure, and Acoustic Emission Characteristics under Different Lithological Confining Pressures. Materials 2022, 15, 4257. https://doi.org/10.3390/ma15124257

Wu S, Qin G, Cao J. Deformation, Failure, and Acoustic Emission Characteristics under Different Lithological Confining Pressures. Materials. 2022; 15(12):4257. https://doi.org/10.3390/ma15124257

Chicago/Turabian StyleWu, Shuo, Guangpeng Qin, and Jing Cao. 2022. "Deformation, Failure, and Acoustic Emission Characteristics under Different Lithological Confining Pressures" Materials 15, no. 12: 4257. https://doi.org/10.3390/ma15124257

APA StyleWu, S., Qin, G., & Cao, J. (2022). Deformation, Failure, and Acoustic Emission Characteristics under Different Lithological Confining Pressures. Materials, 15(12), 4257. https://doi.org/10.3390/ma15124257