Multi-Scale Modeling of Plastic Waste Gasification: Opportunities and Challenges

Abstract

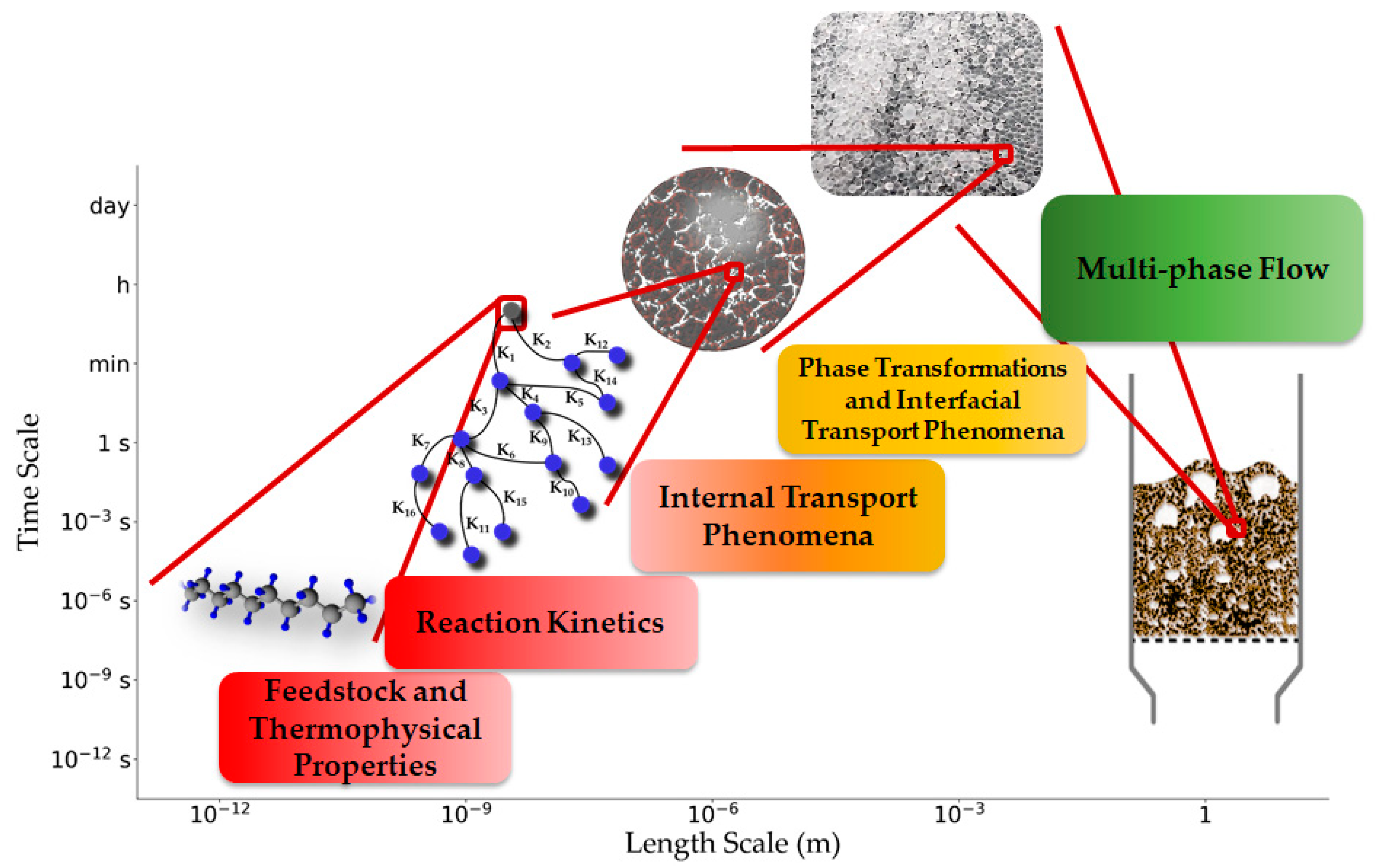

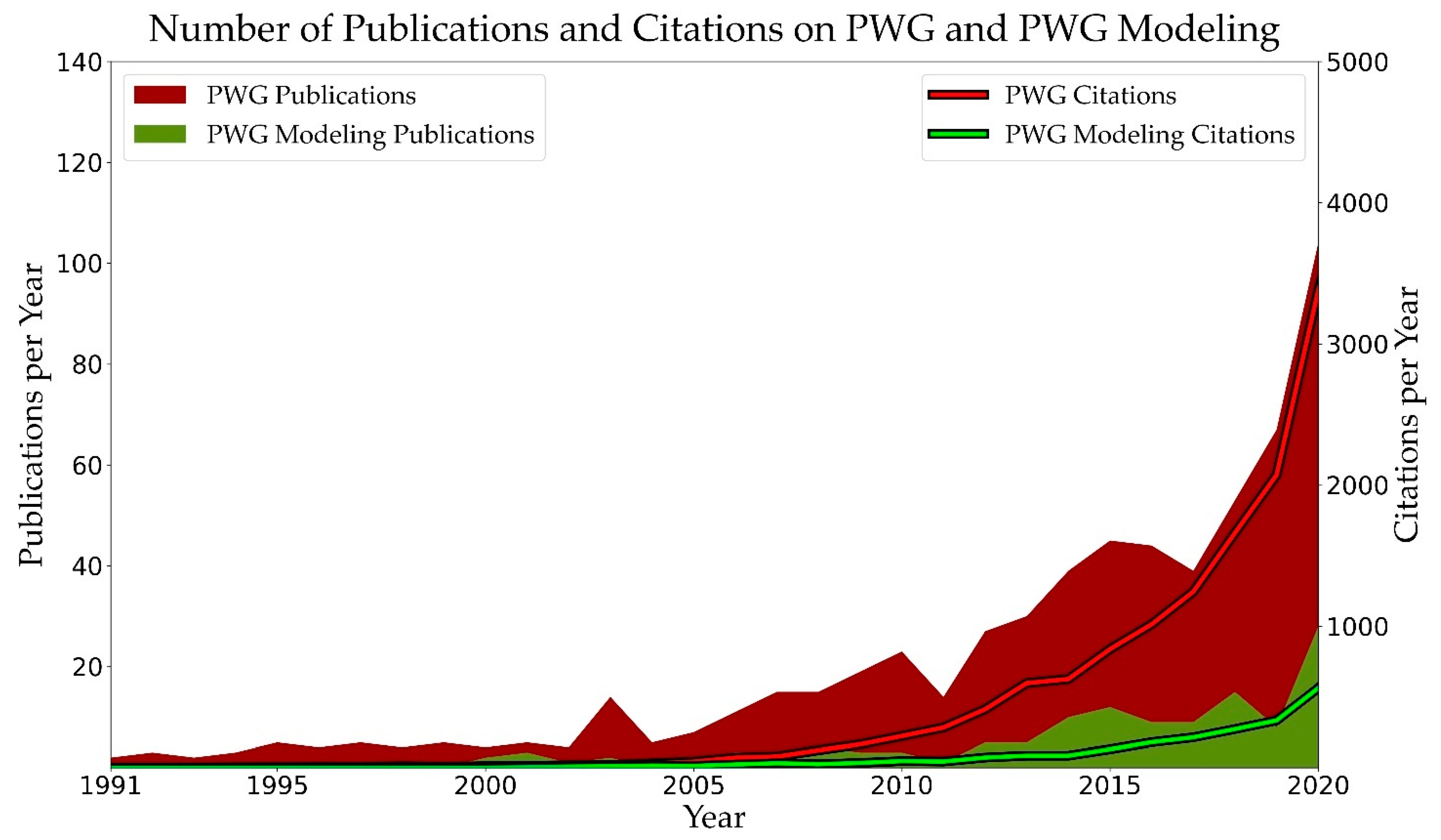

1. Introduction

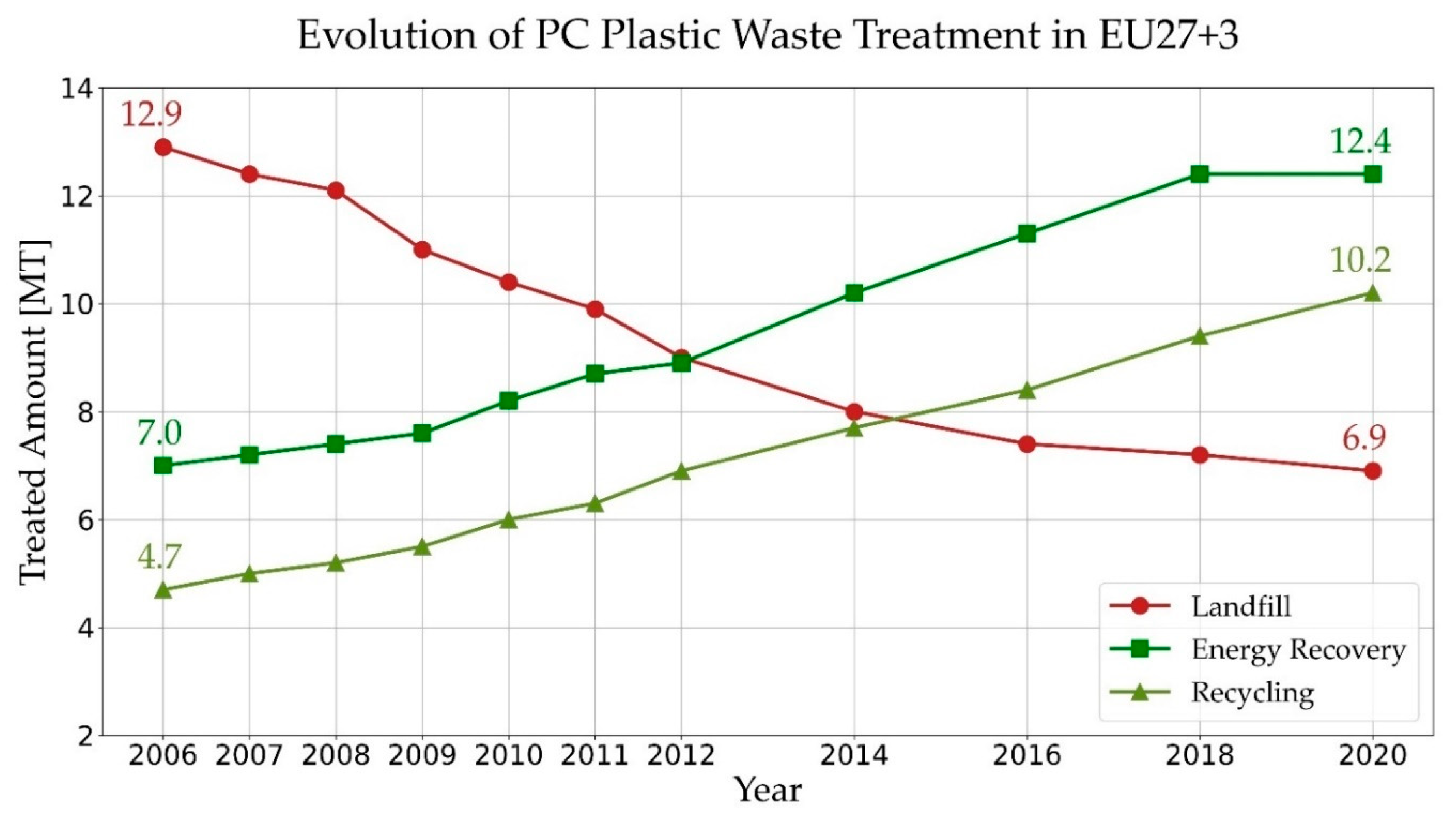

2. Plastic Waste Gasification: A Promising, but Less Mature Recycling Route

2.1. Opportunities and Challenges of PWG

2.2. Numerical Modeling

2.3. Multi-Scale Modeling of Plastic Waste Gasification

- The plastic, in the solid phase, is fed into the reactor

- The plastic is melted first and then fed into the reactor to cover the fluidization agent or to be present as liquid droplets. The latter is reported very rarely [66].

- The plastic is melted first but fed as a layer into a falling film reactor [67].

3. Thermophysical Properties

3.1. Individual Species

3.1.1. Conventional Methods

3.1.2. Advanced Numerical Methods

3.2. Effective Properties

- Structural effects

- The presence of impurities, or

- Internal motions (in the liquid phase)

3.3. Mixture Properties

4. Reaction Kinetics

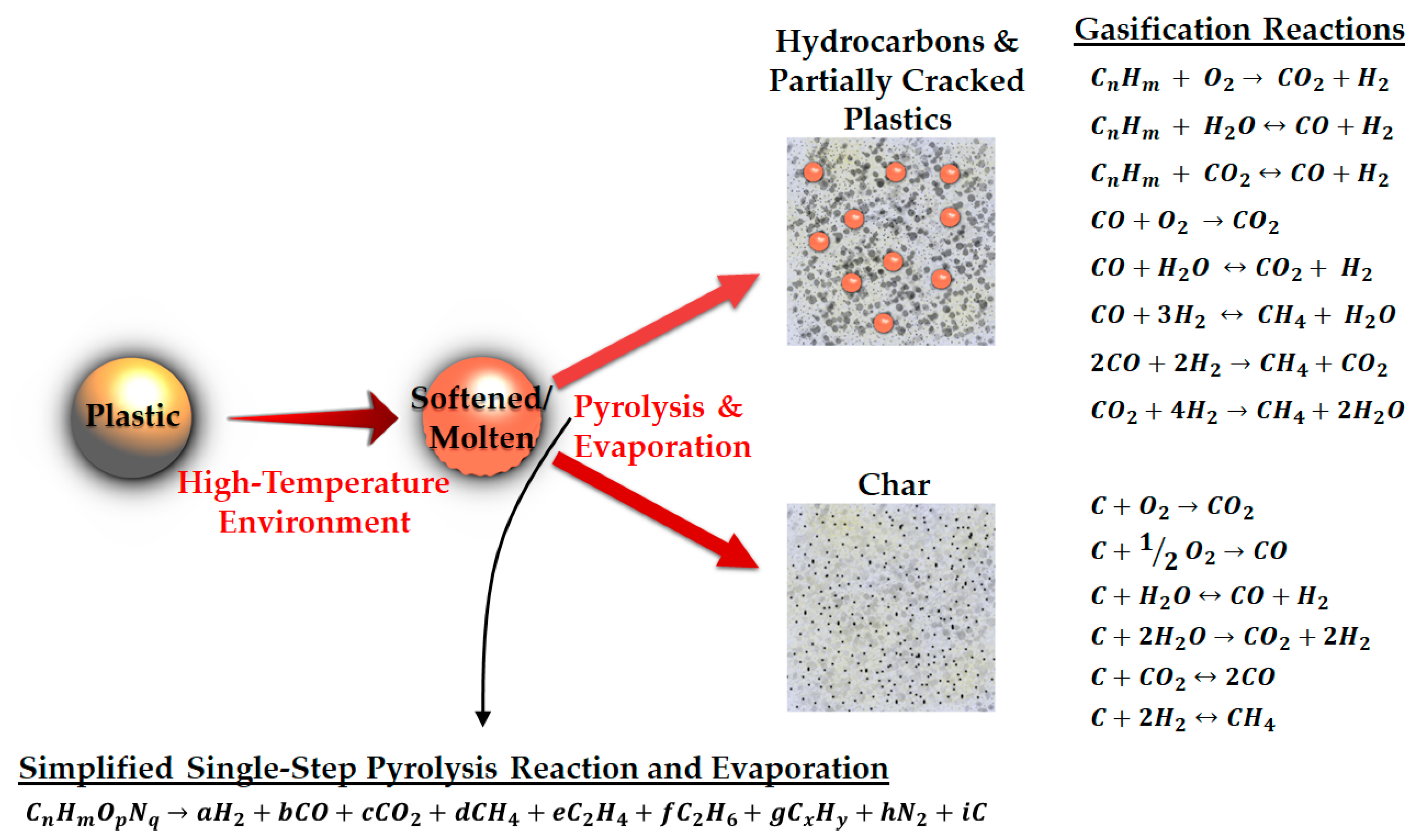

4.1. Challenges Faced in Gasification and/vs. Pyrolysis

4.1.1. Diverse Micro-Scale Characteristics of Plastics

4.1.2. Coupling of Available Kinetic Models

4.1.3. Presence of Char

4.2. Global vs. Detailed Kinetic Models

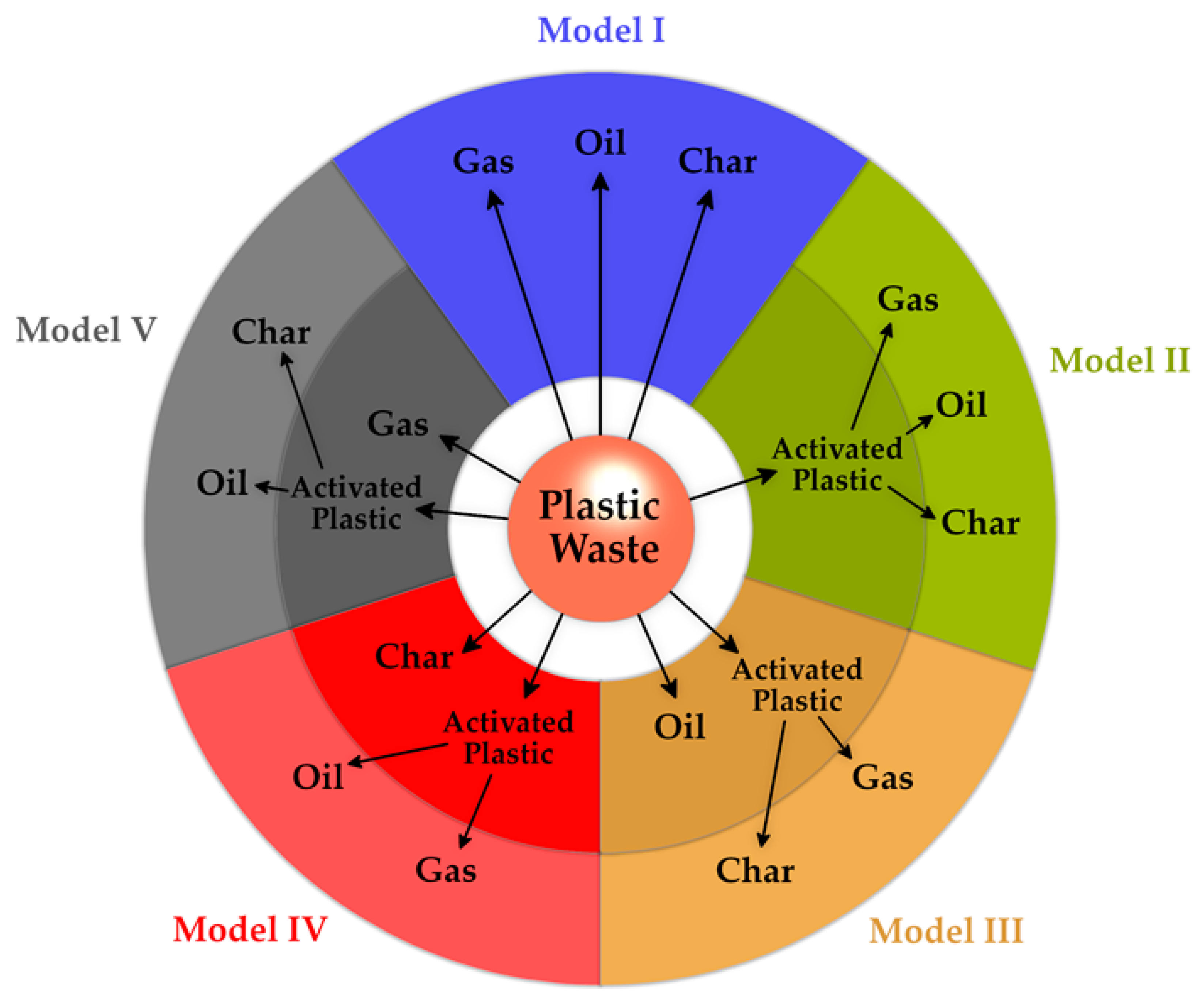

4.2.1. Global Kinetic Models

4.2.2. Detailed Kinetic Models

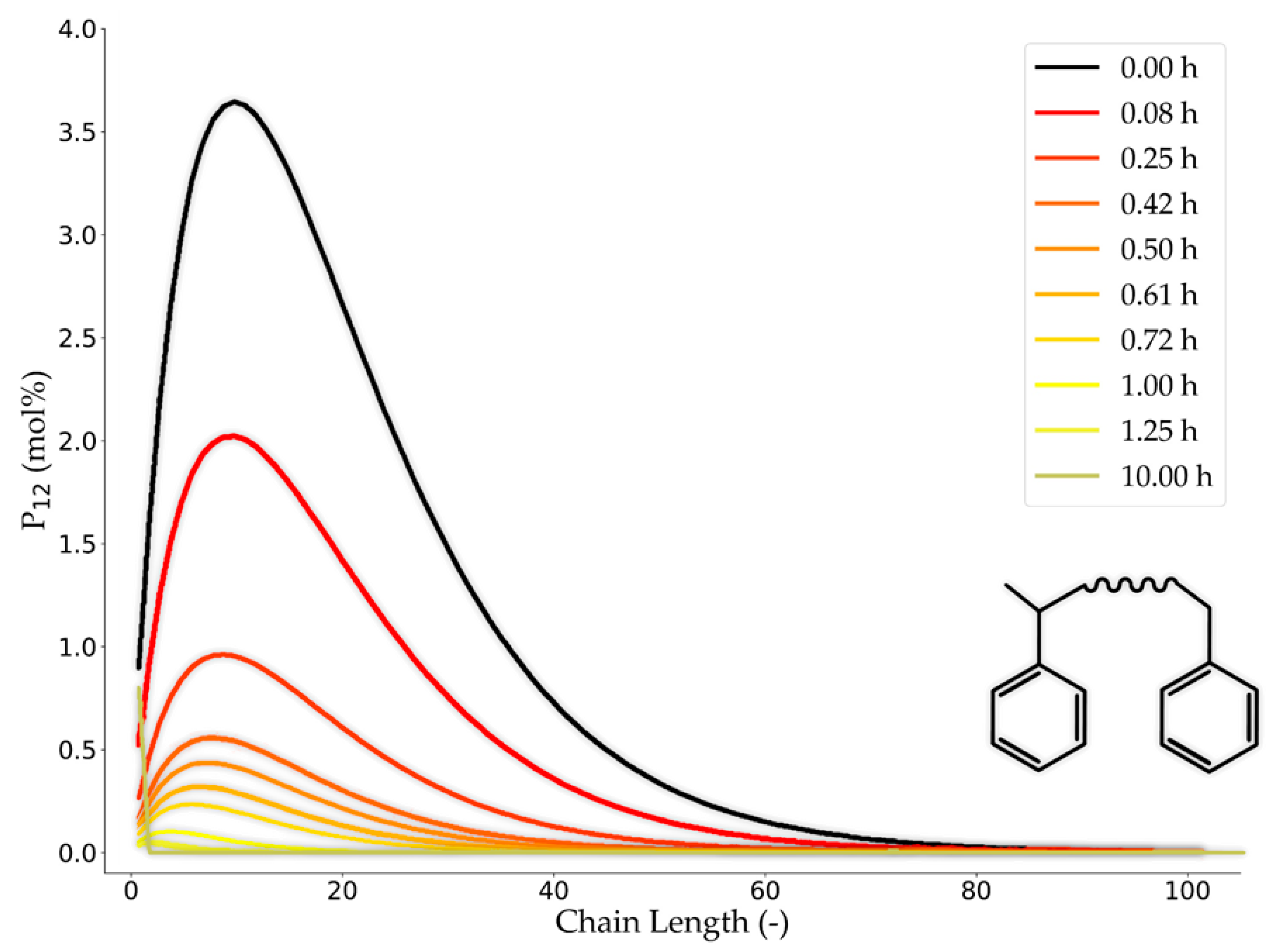

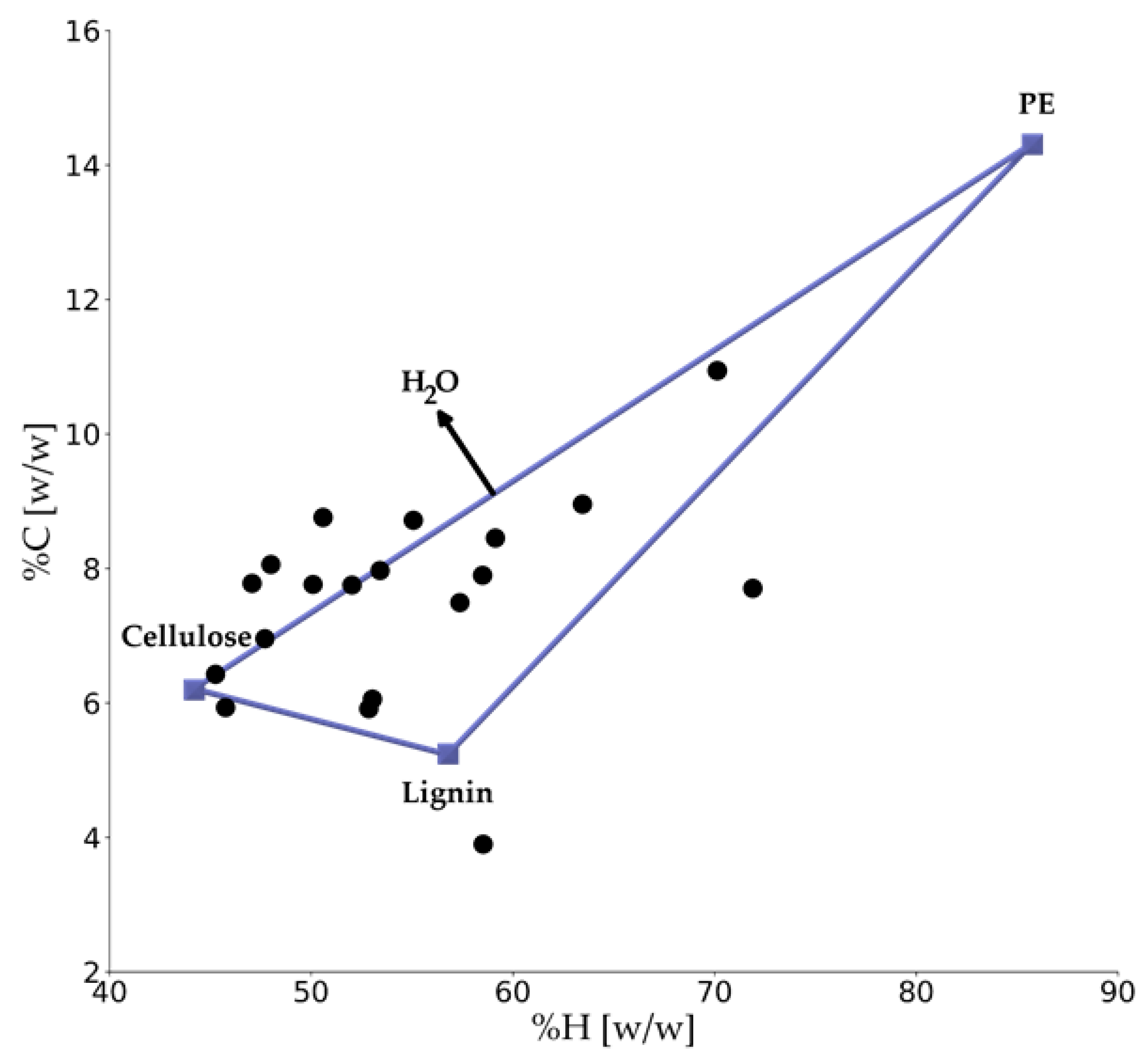

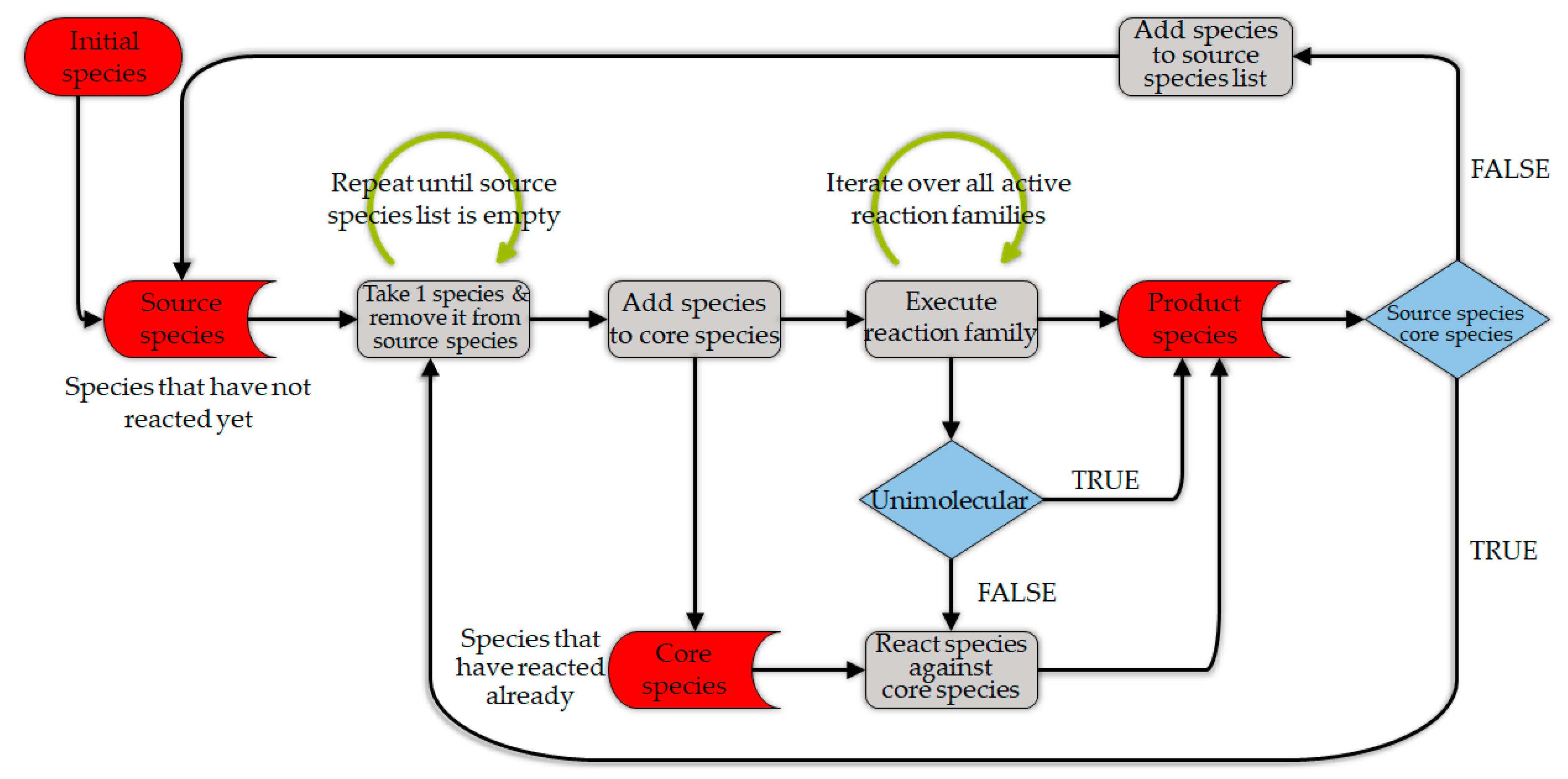

Feedstock Description

Devolatilization

Gasification

Challenges and Opportunities

- Coupling

- The mechanistic models are feedstock independent. Hence, they are supposed to perform properly for different compositions and feedstock characteristics. Moreover, the similarities in the polymer segments and reaction families make it less burdensome to introduce new polymer types.

- The presence of different gasification agents with different concentrations can be taken into account in a single model. This may also reflect the synergistic effects as a result of gasification with multiple gasification agents. As it can be seen in the developed detailed kinetic models [137], all the gasification agents are present and based on their concentration, their contribution to the overall gasification process is accounted for.

- To introduce new species, only the initial propagation and decomposition steps should be defined [107]. Hence, reliable modification of the model can be done easily in this approach.

- Size of the Reaction Network

| Global Modeling | Mechanistic (Detailed) Modeling | ||

|---|---|---|---|

| MOM | kMC | ||

| Requires detailed feedstock description | No (pre-defined lumps) | Yes | |

| Degree of complexity | Low | Medium | High |

| Degree of details on the product description | Low | Medium (average properties) [98] | High (full molecular detail) [98] |

| Computational cost | Low | Medium | High |

| OM of number of species | 50 | 100–1000 [154] (Reduced: 10–100) | 1000–10,000 [154] (Reduced: 10–100) |

| OM of number of reactions | 50 | 1000–50,000 [154] (Reduced: 100–1000) | 1000-50,000 [154] (Reduced: 100–1000) |

| Common application | CFD/1D Models | 1D Models (Reduced: CFD) | |

| Feedstock independent | No | Yes | |

| Reliable coupling to other kinetic models | No | Yes | |

| Adaptability to new species (and gasification agents) | No | Yes | |

| Reliable temperature extrapolation | No | Yes | |

| Needs reaction network generator (extra complexity) | No | Yes | |

| Ability to consider dynamic char activity | No | Yes | |

4.2.3. Validation Challenges

- TGA data include the evaporation rates, which are not equal to the degradation rates. So, if a kinetic model is validated against it, in FB regimes with higher evaporation rates, it is supposed to underestimate the devolatilization rate (if the evaporation and degradation models are not decoupled).

- The reactive environment affects the degradation and the evaporation rate of polymers, as was discussed in Section 4.1.2.

- It can include the internal heat and mass transfer limitations, which are not considered in the kinetic models. For large sample sizes [161], providing the isothermal conditions is not possible, and for samples with weak mass transfer properties, concentration gradients are observed within them [162]. Even if in a kinetic model, the effect of diffusion limits on the kinetic parameters is considered [111], two other problems can be raised: First, this shows the incapability in deriving the pure intrinsic kinetic data; and second, the mixing degree and mass transfer limitations can be different from the conditions in which this kinetic model is derived. Hence, this increases the uncertainty in using this kinetic model in different conditions.

- It is not possible to measure the concentration of reacting species in the liquid phase, or the products right after being produced in the gas phase. Hence, secondary reactions can and will happen.

- The uncertainty related to enough sensitivity of the balance used in the TGA instrument is another challenge [162].

- The effect of radiation on the sample in high temperatures is different for the samples with different absorption properties [162].

5. Internal Transport Limitations

5.1. Internal Mass Transfer

5.1.1. Solid Phase

5.1.2. Liquid Phase

Simplifying Assumptions

5.2. Internal Heat Transfer

5.2.1. Solid Phase

5.2.2. Liquid Phase

- A weaker effect of Marangoni convection (and hence weaker internal motions or circulative heat transfer); and

- Monotonically decreasing temperature profile toward the center of the droplet.

6. Phase Transformations and Interfacial Transport Phenomena

6.1. Melting

6.1.1. Melting Phenomenon

6.1.2. Melting Models

Extrusion Models

Enthalpy-Based Models

Phase-Field Models

Reaction-Type Models

6.1.3. Application in the Multi-Scale Framework

6.2. Evaporation

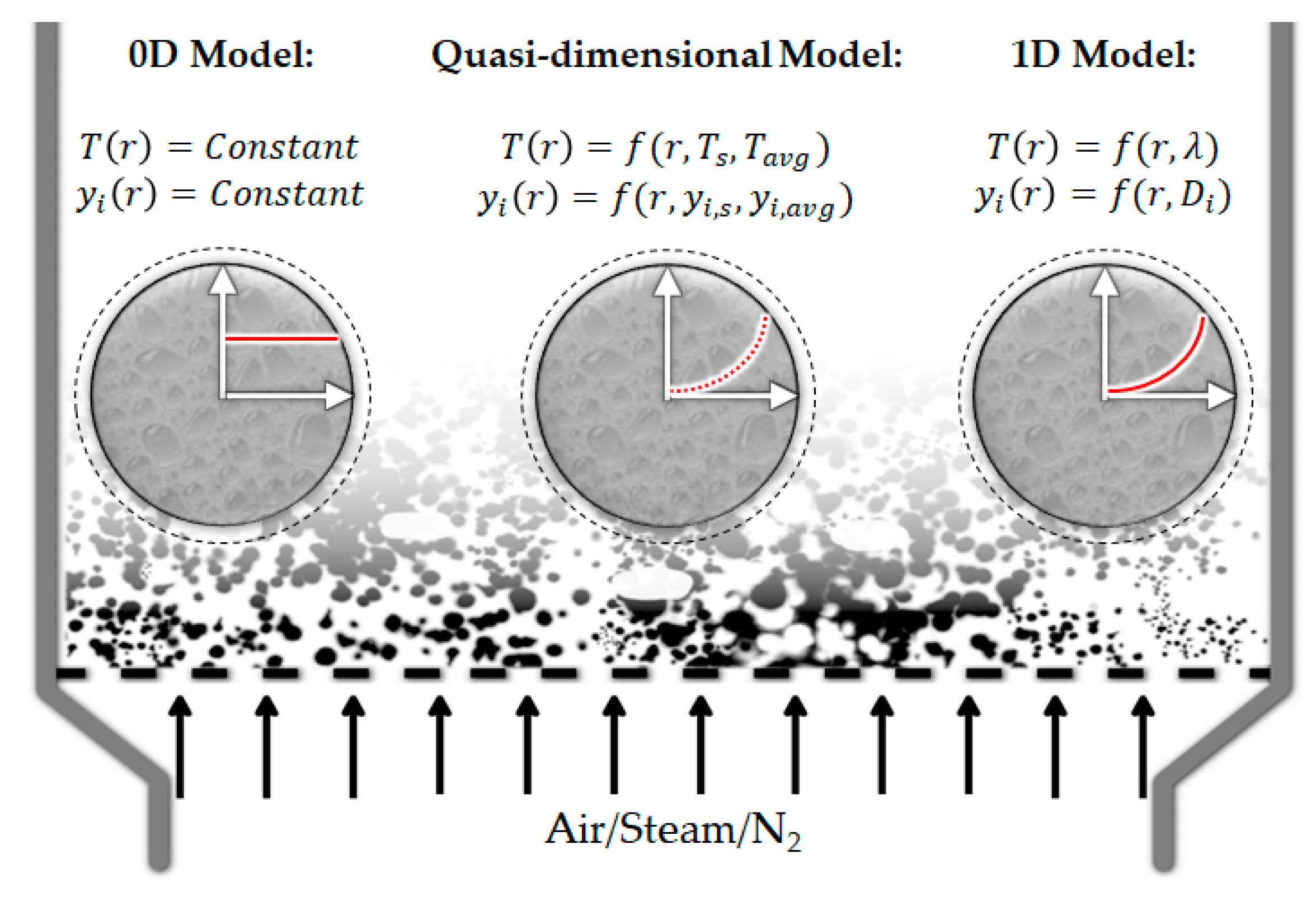

6.2.1. From 0D to 1D Models

6.2.2. Modeling Complexities for PWG

Multiple Components

Mass Fraction at the Interface

Non-Ideal Behavior

Role of Radiation

Role of Surface Area

6.2.3. Simplifying Assumptions

- Considering the liquid as a spherical droplet

- The presence of an inert atmosphere

- Negligible diffusion of the gas to the liquid

- Negligible mass diffusion due to temperature and pressure gradients

- The heaviest component that has been implemented in these simulations is C20. Although the table doesn’t cover all the available studies in this regard, it can demonstrate that in general, not all the components available in the liquid phase of PW during the pyrolysis have been assessed extensively. Hence, one of the main areas to be focused on is the assessment of the cases that, from the components’ point of view, are closer to what is happening in PWG.

- The shape of the liquid phase is important in simulations. In each study, either spherical or film shape is assessed. This is while different shapes can be simultaneously present in PWG, e.g., it can be droplet, agglomerate, or the liquid film on the wall. Besides, in all cases in the table, a uniform characteristic length of the liquid phase is considered, while the shapes that are present in the PWG are not perfect spheres or liquid film. This demonstrates the complexity that is faced in PWG due to the shape imperfections.

- Most of the cases consider the ideal gas assumptions and this can be true due to the high temperature and low pressure [172,219]. However, for the liquid phase, due to the presence of multiple components with different properties, this is not necessarily true. Implementing the non-ideal conditions for a large number of components is a challenge itself.

- Many of the studies use the DMC approach. This demonstrates that the simulation of the evaporation in the PWG can also be done in this approach at a logical computational expense and hence, can be coupled to the available detailed kinetic models for the plastic pyrolysis.

6.3. Interfacial Heat and Mass Transfer

6.3.1. Empirical-Based Correlations

6.3.2. Numerical-Based Correlations

- Each of them is derived for a specific range of void fraction and Reynolds and Prandtl numbers

- For the particles with different shapes, the Nusselt correlations have been developed, including the incident angle of the particles [233]

- Depending on the direction of heat flow, the Nusselt correlation is different, due to the different behavior of water properties in the heating and cooling process at supercritical conditions [234]

- The application of the classical empirical correlations for the complex systems is in doubt because it has been shown that for each case, a different correlation (which has been validated against the experimental data) should be developed

- The numerical tools have been advanced enough to be used for developing new correlations for each specific condition of PWG process. This way, it is possible to increase the precision of the interfacial heat and mass transfer models used in this process.

| Feedstock | Liquid Shape | Ideality | Spherical Droplet/Uniform Film Thickness | 0D/1D | Internal Heat/Mass Transfer | External Heat/Mass Transfer | Reactive | Radiation | Equilibrium | Approach | Ref |

|---|---|---|---|---|---|---|---|---|---|---|---|

| H2O, CH3OH, C2H5OH, 1-C4H9OH, n-C7H16, n-C10H22 | Droplet | Real fluid (UNIFAC), ideal gas | Yes | 0D | No/No | No/No | No | No | Yes | DMC | [175] |

| C2H5OH, n-C5H12, cyclo-C5H10, 1-C6H12, n-C7H16, C7H8, iso-C8H18 | Droplet | Real fluid (UNIFAC), Ideal mixture for the gas phase | Yes | 1D | Yes/Yes | Yes/Yes | Yes | Yes | Yes | DMC | [172] |

| iso-C6H14, n-C7H16, iso-C8H18, cyclo-C9H18, n-C10H22, ben-C10H14, n-C11H24, n-C12H26, ben-C12H18, n-C13H28, n-C14H30, n-C15H32, n-C16H34, n-C17H36, n-C18H38, n-C19H40, n-C20H42, n-C21H44, n-C22H46, n-C30H62 | Droplet | Real fluid, Real gas | Yes | 1D | Yes/Yes | Yes/Yes | No | - | No | DMC | [216] |

| n-C6H14, n-C7H16, iso-C8H18, n-C10H22 | Film | Ideal fluid, Ideal gas | Yes | 1D | Yes/No | - | No | - | Yes | DMC | [176] |

| C4H9OH, C7H8, n-C10H22 | Droplet | Non-Ideal fluid (UNIFAC) | Yes | 1D | Yes/Yes | Yes/Yes | No | Yes | Yes | DMC | [219] |

| n-C7H16, n-C16H34 | Film | Ideal gas | Yes | 1D | Yes/Yes (polynomial expressions) | Yes/Yes | No | - | Yes | DMC | [181] |

| C10H22, C16H34 | Film | Ideal and Non-Ideal Gas | Yes | 1D /Quasi-Dimensional | Yes/Yes (polynomial expressions) | Yes/Yes | No | - | Yes | DMC | [213] |

| C7H16, C10H22, C16H34 | Droplet | Ideal Gas | Yes | 1D | Yes/Yes | Yes/Yes | No | - | Yes | DMC | [173] |

| n-C5H12, iso-C5H12, C7H16, iso-C8H18, C9H20, C10H22, C12H18, C12H26, C16H34, C20H42 | Droplet | Ideal and Non-Ideal Gas | Yes | 1D /Quasi-Dimensional | Yes/Yes (polynomial expressions) | Yes/Yes | No | Yes | Yes | DMC | [209] |

| H2O, CH3OH, C2H5OH, C3H6O, C4H9OH, 3-C5H10O, C8H18, C10H22, C12H26, C14H30, C16H34 | Droplet | - | 1D | No/No | No (Isothermal)/Yes (Stefan-Maxwell approach) | No | - | - | DMC | [177] | |

| Air, H2O | Droplet | Ideal Gas | Yes (Including the number of droplets) | 1D | Yes/Yes | Yes/Yes | No | - | - | DMC | [221] |

| C7H8, tr-C10H18, C12H26, iso-C16H34 | Droplet | Ideal/Real Gas/Liquid | Yes | 0D | Yes/Yes | Yes/Yes | Yes | No | Yes | DMC | [235] |

| n-Paraffin, Iso-Paraffin, Cyclo-Paraffin, Aromatics, Olefin | Droplet | Real Fluid, Ideal Gas (Modified) | Yes | 1D | Yes/No | Yes/Yes | No | No | Yes | DMC | [179] |

| C2H6O (DME), C7H16 | Droplet | Real Fluid (UNIFAC), Ideal Gas | - | 0D | - | - | No | - | No (LK) | DMC | [217] |

| C2H5OH, iso-C5H12, iso-C6H14, iso-C7H16, iso-C8H18, C9H20, C10H22, C12H26 | Droplet | Real Fluid (Wilson equation), Ideal Gas | Yes | 1D | Yes/Yes | Yes/Yes | No | No | Yes | DMC | [182] |

| C7H16, C10H22 | Droplet | Real/Ideal Gas | Yes | 1D | No/No | Yes/Yes | No | No | Yes | DMC | [178] |

| iso-C5H12, iso-C6H14, iso-C7H16, C7H8, iso-C8H18, C9H20, C10H22, C12H26, C14H30, C16H32, C18H34 | Droplet | Ideal Fluid | Yes | 1D (Implemented in multi-dimensional CFD) | Yes/No | Yes/Yes | No | No | Yes | DMC (Derived from CMC) | [236] |

6.3.3. Determining the Limiting Step

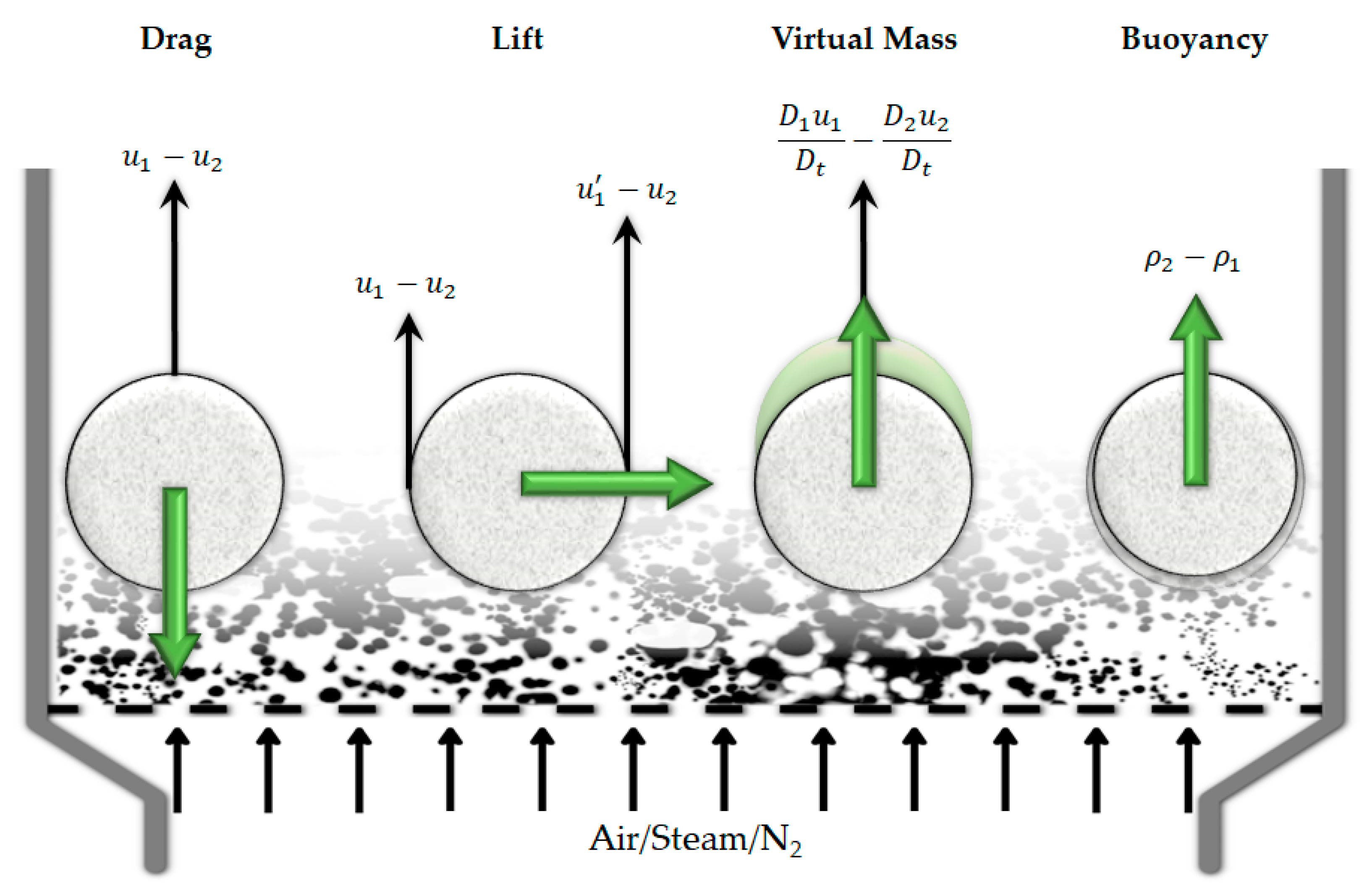

6.4. Momentum Transfer

- The role that it plays in the interaction between the particle/droplet/bubbles and change in the interfacial area and shapes as the result of agglomeration, coalescence, and breakup

- The drag force is the main contributing force in the momentum transfer, which acts against the fluid flow direction to resist the motion of a particle, droplet, or bubble. This force is a function of fluid density, dispersed phase diameter, the slip velocity (difference between the velocity of the continuous and discrete phase), and a drag coefficient.

- The lift force acts perpendicular to the flow direction and is the result of turning of the fluid because of the presence of the discrete phase.

- The virtual mass force is the result of acceleration of the discrete phase, i.e., change of its relative motion compared to the fluid phase. This imposes an extra force as an extra mass or “added mass” in the acceleration force.

- The buoyancy force acts against the gravity force as the result of the difference between the density of the fluid and the discrete phase

6.4.1. Drag Force

| Correlation | Method | Limit | Year | Ref | |||

|---|---|---|---|---|---|---|---|

| Shape/Conditions | |||||||

| DNS | 0.4–0.9 | 10–100 | 1.0 | Spherical | 2014 | [255] | |

| PR-DNS | 0.5–0.9 | 1–100 | 0.7 | Spherical | 2015 | [256] | |

| PR-DNS | 0.351–0.367 | 9–180 | 0.5–1.0 | Spherical | 2017 | [257] | |

| PR-DNS | 0.418–0.526 | 9–180 | 0.5–1.0 | Cylindrical | 2017 | [258] | |

| PR-DNS | 0.65–0.9 | 10–200 | 0.74 | Ellipsoidal | 2017 | [259] | |

| DNS | 0.877–0.948 | 0–550 | 1 | Cellular porous media | 2018 | [260] | |

| LBM | 0.5–0.9 | 1–100 | 0.7 | Sphere | 2019 | [261] | |

| DNS-LBM | 0.6–1.0 | 20–500 | 0.5–1.5 | Sphere | 2019 | [262] | |

| PR-DNS | - | 10–200 | 3.07 | Spheroid (Ar = 0.5–2.5)/SCW | 2019 | [232] | |

| PR-DNS | - | 10–200 | 0.744, 3.07 | Spheroid (Ar = 0.5–2.5)/SCW | 2019 | [233] | |

| PR-DNS | - | 10–200 | 0.7–380 | Spherical/SCW/Cold particle | 2020 | [234] | |

6.4.2. Non-Drag Forces

7. Multi-Phase Flow Modeling

7.1. Reactor Modeling Approaches

7.1.1. Complex vs. Ideal Models

7.1.2. Engineering Models

7.1.3. 3D Computational Fluid Dynamics

Eulerian-Eulerian

Eulerian-Langrangian

| Feed | Gasification Agent | Time (Reaction/ Space/Residence) (s) | Plant Size (OM-m3) | Bed Material | Temperature (°C) | Kinetic | Software/Code | Ref |

|---|---|---|---|---|---|---|---|---|

| Plastic (PVC) | Steam | - | Lab | Alumina | ~900 | - | Inhouse | [299] |

| Plastic (Poly Olefin) | Air-Steam | Pyrolysis: 0.02 Mixing: 5.4 | Pilot (0.02 & 0.67) | - | 700–850 | Global | Inhouse | [122] |

| Coal, petcoke | Oxygen-Steam | - | Commercial (72) | - | 1100 (Non-isothermal) | Global | Inhouse | [314] |

| Coal, limestone, inert material | Air-Steam-Carbon Dioxide | Devolatilization: <10 | Pilot (0.07) | Limestone, Sand | 600–1000 | Global | Inhouse (FORTRAN) | [315] |

| Coal | Air-Steam | - | Lab & Pilot (2.6) | Dolomite | 750–950 (Non-isothermal) | Global | Inhouse | [296] |

| Coal | Oxygen-Steam | Particle residence: 3600 | - | - | 700–900 (Isothermal) | Global | Inhouse | [295] |

| Biomass (Wood) | Air-Steam | - | Pilot (0.57) | - | 900–950 | Global | Inhouse | [297] |

| Biomass (Wood powder) | Air-Steam | - | - | - | 700–900 | Global | Inhouse (MATLAB) | [316] |

| Biomass (Straw) | Air-Steam | - | - | - | - | Equilibrium | Inhouse (FORTRAN) | [317] |

| Biomass (Sawdust) | Air | - | - | Sand | 600–1600 | Global | Inhouse | [318] |

| Biomass (Sawdust) | Air-Oxygen-Steam | Reaction: 140–3000 | Pilot (0.06 & 2) | Ofite, Quartz & Silica Sand | 700–900 | Global | Inhouse | [319] |

| Biomass (Pine Sawdust, Rice husk) | Air-Steam | - | Lab (0.003) & Pilot (0.2) | - | 665–900 | Global | Inhouse (FORTRAN) | [298] |

| Biomass (Beech Wood) | Air-Steam | Gas residence time in the freebord: 2–4 | Pilot (0.02) | Silica Sand | 800–815 | Global | Inhouse | [320] |

| Feed | Type | Gasification Agent/Process Gas | Gas Residence/ Space Time (s) | Plant Size (OM-m3) | Bed Material | Temperature (°C) | Phase | Software/Code | Ref |

|---|---|---|---|---|---|---|---|---|---|

| Plastic (Waste) | Circulating FB | Air | 1–3 | 0.1 m3 | Sand | - | GS | MFIX | [313] |

| Plastic (PE) | Conical Spouted Bed | Air-Steam | ~3 | Lab (0.001) Pilot (0.03) | Sand | 800–900 | GS | Fluent + Aspen Plus | [61] |

| Molten Plastics (mix PE, PP, and PS) 1 | Falling Film | Nitrogen | - | Lab (0.002) | - | 550–650 | GL | OpenFOAM | [169] |

| Molten Plastic (PP) 1 | Falling Film | Nitrogen | - | Lab (0.00004) | - | 460–500 | GL | Fluent | [311] |

| Molten Plastic (PE, PP, PS, mix) 1 | Falling Film | Nitrogen | - | Lab (0.002) | - | 550–625 | GL | - | [67] |

| MSW, RDF | Plasma (Fixed Bed) | Air-Steam | - | - | - | ~2200 (max) | GS | Inhouse (COMMENT) | [330] |

| MSW, Biomass (Coffee husk, Forest residues, Vines pruning) | Bubbling FB | Air-Steam | - | Semi-Industrial (0.8) | Dolomite (Experimentally) | 500–1000 | GS | Fluent | [278] |

| MSW | Bubbling FB | Steam | - | Semi-Industrial | - | 850 | GS | - | [331] |

| MSW | Bubbling FB | Air | - | Semi-Industrial (0.8) | Dolomite (Experimentally) | 700–900 | GS | Fluent | [332] |

| MSW | Bubbling FB | Air-Carbon Dioxide | - | Semi-Industrial (0.8) | Dolomite (Experimentally) | 500–900 | GS | Fluent | [279] |

| MSW | Bubbling FB | Air-Steam-Carbon Dioxide | - | Semi-Industrial (0.8) | Dolomite, NiO/MD Catalyst | 700–900 | GS | Fluent | [333] |

| MSW | Bubbling FB | Air | - | Semi-Industrial (0.8) | - | 500–700 | GS | Fluent | [280] |

| MSW | Bubbling FB | Air | - | Semi-Industrial (0.8) | Dolomite (Experimentally) | ~ 500–700 | GS | Fluent | [224] |

| MSW | Plasma/Melting | Air-Steam | - | Pilot (2.7) | - | ~2200 max | GS | Fluent | [225] |

| MSW | Plasma/Melting | Air | - | - | - | - | GS | - | [65] |

| Biomass & Plastic (Wood, PE) 1 | Rotary Kiln | - | - | - | - | - | GS | Fluent | [310] |

| Biomass | Circulating FB | Air | - | Pilot (0.2) | - | ~400–1000 | GS | Fluent | [334] |

| Biomass (Bagasse, Rice husk, Switchgrass) | Bubbling FB | Nitrogen | - | Lab (0.006) | Sand | 400–600 | GS | Fluent | [335] |

| Biomass (Coffee husk) | Bubbling FB | Air | - | Pilot | - | ~600–1400 | GS | Inhouse (COMMENT) | [336] |

| Biomass (Forest residues) | Bubbling FB | Air | - | Pilot (1) | Dolomite | ~ 800 | GS | Fluent | [337] |

| Biomass (Forest residues, Peach Pits, Ground Coffee) | Plasma | Air-Steam | - | - | - | 1000–2000 | GS | Inhouse (COMMENT) | [338] |

| Biomass (Pinewood) | Vortex Reactor | Nitrogen | <1 (order of ms) | Lab (0.0001) | - | 500–600 | GS | Fluent | [339] |

| Biomass (Wood) | Bubbling FB | Air | - | Lab (0.0004) | Sand | ~ 900 | GS | Inhouse (FORTRAN) | [340] |

| Biomass (Wood) | Bubbling FB | Air | - | Lab-Pilot (0.01) | - | 700–750 | GS | ModifiedK-FIX | [341] |

| Biomass (Wood) | Bubbling FB | Air | - | Lab (0.0004) | Sand | 850 | GS | MFIX-based | [342] |

| Biomass (Wood) | Bubbling FB | Air | - | Lab-Pilot (0.01) | - | ~400–800 | GS | - | [343] |

| Biomass (Wood) | Fixed Bed | Air-Steam | - | Pilot (0.22) | - | ~450–1000 | GS | Fluent | [344] |

| Biomass (Wood) | Fixed Bed | Air-Steam | <1 (order of ms) | - | - | ~650–1300 | GS | - | [345] |

| Coal | Bubbling FB | Air-Steam | - | Pilot (0.07) | - | ~400 | GS | OpenFOAM | [306] |

| Coal | Bubbling FB | Air-Oxygen-Steam | - | Pilot (1) | Silica Sand | ~900 | GS | Fluent | [346] |

| Coal | Bubbling FB | Air | - | Lab (0.1) | - | ~600–1000 | GS | Fluent | [347] |

| Coal | Bubbling FB | Air-Steam | - | Lab (0.07) | Limestone | 812, 855 | GS | ANSYS | [270] |

| Coal | Bubbling FB | Air-Steam | - | Lab (0.07) | Sand | 821, 846, 855 | GS | - | [348] |

| Coal | Bubbling FB | Air-Steam | - | Lab (0.07) | - | 812-866 | GS | - | [349] |

| Coal | Entrained Flow | Air | - | Commercial (15) | - | ~370–2000 | GS | CFC code PHOENICS (Inhouse) | [350] |

| Coal | Fixed Bed | Air-Steam | - | Lab (0.01) | - | ~600–1300 | GS | MFIX | [351] |

| Glycerin solutions containing xanthan gum 2 | Bubble Column | Air | - | Lab (0.01) | - | 25 | GL | CFX (MUSIG) | [352] |

| Glycerol | FB | Steam | - | 0.001 | Sand | 600–750 | GS | Fluent | [353] |

| Manure Slurry 2 | Anaerobic Digester | - | - | Industrial (791) | - | 35 | GL | Fluent | [354] |

| Water | Bubble Column | Air | - | - | - | - | GL | OpenFOAM | [355] |

| Water | Bubble Column | Air | - | Lab (0.01) | - | Room | GL | OpenFOAM | [286] |

| Water 3 | Bubble Column | Air | - | Lab (0.007) Pilot (4) | - | - | GL | OpenFOAM (OpenQBMM) | [356] |

| Water | Laboratory Tank | Air | - | Lab (0.02) | - | 22 | GL | OpenFOAM | [274] |

| Water 3 | Vertical Tube | Air | - | Lab (0.01) | - | - | GL | OpenFOAM (twoWayGPBEFoam) | [357] |

| Water 4 | Bubble Column | Air | - | Lab (0.07) | - | - | GL | - | [358] |

| Water 4 | Bubble Column | - | - | - | - | - | GL | - | [359] |

| Water 4 | Bubble Column | Air | - | Lab (0.007) Pilot (0.27) | - | 30 | GL | CFX | [360] |

7.2. Multi-Phase Flow Modeling Challenges and Possible Solutions

7.2.1. Irregular Shape

| Feed | Type | Gasification Agent/Process Gas | SRT (s) | Plant Size (OM-m3) | Bed Material | Temperature (K) | Lagrangian Approach | Software | Ref |

|---|---|---|---|---|---|---|---|---|---|

| Plastic (PE, PP, PS, mix) | Entrained Flow | Air | - | Lab (0.005) | - | ~50–1100 | - | Fluent | [29] |

| Pitch-water slurry | Entrained Flow | Oxygen | 0–50 | Pilot (0.2)/Industrial (33) | - | ~1500 | - | Fluent | [226] |

| - | Conical Spouted Bed | Air | - | Lab (0.001) | ZiO2 | 25 | DEM | Fluent | [363] |

| Biomass | Bubbling FB | Air-Steam | - | Lab (0.003) | Sand | ~800–900 | DEM | - | [323] |

| Biomass | Spouted Bed + DFB | Steam | - | SB Lab (0.01)/DFB Pilot (0.3) | Silica Sand | 820–870 | MP-PIC | OpenFOAM | [364] |

| Biomass (Almond prunings) | DFB | Steam | Up to ~100 | Pilot (0.7) | Sand | ~400–900 | MP-PIC | OpenFOAM | [365] |

| Biomass (Glucose) | FB | Super Critical Water | - | Lab (0.001) | Quartz Sand | ~500–600 | DEM | Fluent | [366] |

| Biomass (Pinewood) | Bubbling FB | Steam-Nitrogen | - | Lab (0.06) | Sand | 820–920 | CGM & DEM | STAR-CGM+12.02 | [367] |

| Biomass (Pinewood) | Bubbling FB | Steam-Nitrogen | - | Lab (0.0005) | Sand | 820–920 | DEM | OpenFOAM | [368] |

| Biomass (Pine, Beech, Holm oak, Eucalyptus) | Conical Spouted Bed | Steam-Argon | - | Lab (0.01) | Sand | 770–920 | MP-PIC | OpenFOAM | [369] |

| Biomass (Pine, Beech, Holm oak, Eucalyptus) | Entrained Flow | Air-Steam | Up to ~2.5 | Lab (0.01) | - | 1000–1400 | - | OpenFOAM | [370] |

| Biomass (Raw, Torrefied) | FB | Air-Nitrogen-Steam | - | Lab (0.0001) | Olivine | 750–850 | DEM | OpenFOAM | [371] |

| Biomass (Raw, Torrefied) (Forest residues, Spruce) | Entrained Flow | Air-Steam | - | Lab (0.01) | - | 1400 | - | OpenFOAM | [372] |

| Biomass (Rice husk) | Entrained Flow | Oxygen-Steam-Carbon Dioxide | - | Lab (0.01) | - | 1400 | - | OpenFOAM | [373] |

| Biomass (Rice husk, Cotton stalks, Sugarcane bagasse, Sawdust) | Concentric tube entrained flow | Oxygen | - | Pilot (0.25) | - | ~900–2300 | DPM | Fluent | [374] |

| Biomass (Sawdust) | Entrained Flow | Air | Lab (0.015) | - | 800–1000 | DPM | Fluent | [375] | |

| Biomass (Sawdust, Cotton trash) | Entrained Flow | Air-Steam | - | Pilot (4) | - | ~800–1100 | - | CFX | [376] |

| Biomass (Wood pellet) | FB | Steam | Up to ~36 | Lab (0.02) | Sand | ~600–800 | CGM-DEM | Fluent | [377] |

| Biomass (Wood) | Bubbling FB | Steam | - | Lab (0.06) | Sand | 820 | DEM | Inhouse (MFIX-DEM) | [378] |

| Biomass (Wood) | FB | Air | Up to ~84 | Lab (0.01) | Charcoal | ~500–700 | DEM | - | [379] |

| Coal | Bubbling FB | Air-Steam | Up to ~20 | Lab (0.07) | Sand | ~ 800 | MP-PIC | OpenFOAM | [380] |

| Coal | Circulating FB | Air | - | Pilot (0.2) | Sand | ~600–850 | MP-PIC | - | [381] |

| Coal | Circulating FB | Carbon Dioxide-Oxygen-Nitrogen | - | Pilot (0.03) | Sand | ~950 (max) | DPM + MP-PIC | Fluent + CPFD Barracuda | [382] |

| Coal | Entrained Flow | Oxygen-Steam | - | Industrial | - | 1370–1620 | - | Fluent | [383] |

| Coal | Entrained Flow | Air-Steam | - | Lab (0.004) | - | ~200–1850 | - | Fluent | [384] |

| Coal | Entrained Flow | Air | - | Pilot (0.26) | - | ~700–1900 | - | CFX + FORTRAN | [385] |

| Coal | Two-stage Entrained Flow | Oxygen | - | Industrial (32) | - | ~700–2100 | DPM | Fluent | [386] |

| Coal | Updraft gasifier | Air-Steam | - | Industrial (60) | - | ~500 (mean) | DPM | Fluent | [387] |

| Water 1 | Bubble Column | Air | - | Lab (0.01) | - | - | DEM | OpenFOAM | [388] |

| Water 1 | Bubble Column | Air | - | Lab (0.01) | - | - | DEM | OpenFOAM | [389] |

7.2.2. Roughness

7.2.3. Polydispersity

7.2.4. Aggregation, Coalescence, and Breakup

7.2.5. Regime Transition

7.2.6. Non-Newtonian Behavior

7.3. Multi-Scale Frameworks and Computational Efficiency

8. Conclusions

- It does not require extensive sorting of PW.

- It does not necessarily require a catalyst that could be easily deactivated by impurities present in PW.

- The wide variety of plastic types and elements in PW that result in the necessity of substantial upgrading of the syngas, e.g., removal of HCl, or dealing with the fluctuations in the feedstock composition.

- PWG setups are studied and designed based on the existing knowledge when gasifying coal or biomass, and hence are believed to be not optimal for PW. In particular, the presence of liquid is usually neglected.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Acronyms | |

| CFB | Circulating Fluidized Bed |

| CGM | Coarse Grain Model |

| CMC | Continuous Multi-component |

| DAEM | Distributed Activation Energy Model |

| DFB | Dual Fluidized Bed reactor |

| DPM | Discrete Particle Method/Discrete Phase Method |

| DQMOM | Direct Quadrature Method of Moments |

| E-E | Eulerian-Eulerian approach |

| E-L | Eulerian-Lagrangian approach |

| ERN | Equivalent Reactor Network |

| FB | Fluidized Bed |

| FCMOM | Finite-size Domain Complete Set of Trial Functions Method of Moments |

| FTS | Fischer-Tropsch Synthesis |

| GL | Gas-Liquid |

| GS | Gas-Solid |

| KTGF | Kinetic Theory of Granular Flow |

| LBM | Lattice-Boltzmann Method |

| LK | Langmuir-Knudsen Model |

| MD | Molecular Dynamics |

| MOM | Method of Moments |

| MP-PIC | MultiPhase Particle-in-Cell |

| MSW | Municipal Solid Waste |

| OM | Order of Magnitude |

| PBE | Population Balance Equation |

| PR | Particle Resolved |

| PW | Plastic Waste |

| PWG | Plastic Waste Gasification |

| RDF | Refuse-Derived Fuel |

| SB | Spouted Bed |

| SCW | Super Critical Water |

| SRT | Solid Residence Time |

| Roman and Greek Letters | |

| Pre-exponential factor/Surface area | |

| Ar | Aspect ratio of spheroids |

| Biot number | |

| Specific heat capacity | |

| Courant number | |

| Diffusivity coefficient | |

| Damköhler number | |

| E | Activation energy |

| Force | |

| Gravity acceleration | |

| Convective heat transfer coefficient | |

| H | Enthalpy |

| Reaction kinetic constant | |

| L | Latent heat/Characteristic length |

| Mass | |

| Ma | Dimensionless Marangoni number |

| Number of droplets per mass of liquid | |

| Number of particles | |

| Nu | Nusselt number |

| Pressure | |

| The perimeter of the circle equivalent to the maximum projection area of a particle | |

| Maximum projection perimeter | |

| Pr | Prandtl number |

| Py | Pyrolysis number |

| Heat | |

| Generated or consumed heat due to reaction | |

| Radius | |

| R | Production rate/Universal gas constant |

| Re | Reynolds number |

| Solid-liquid interface position | |

| Heat transfer between phases | |

| Momentum transfer between phases | |

| Species transfer between phases | |

| Net mass transfer rate between phases | |

| SP | Particle-based mass source term |

| Sc | Schmidt number |

| Time | |

| T | Temperature |

| Velocity | |

| V | Volume |

| Spatial coordinate/Interface position | |

| Monomer conversion | |

| Mass fraction | |

| Volume fraction | |

| Porosity, void fraction | |

| Incident angle | |

| Thermal conductivity | |

| Dynamic viscosity | |

| Kinematic viscosity | |

| Density | |

| Surface tension | |

| Stress-strain tensor | |

| Sphericity parameter | |

| Circularity | |

| Shape factor/Particle-based species transfer rate between phases | |

| Sub/Superscripts | |

| Initial | |

| First | |

| Second | |

| Bulk | |

| Contact | |

| Conduction | |

| Convection | |

| Drag | |

| Effective | |

| Fluid | |

| The ith species | |

| Liquid | |

| Particle/Particle surface | |

| Pressure gradient | |

| Radiation | |

| Reaction | |

| Solid | |

| Turbulent | |

References

- PlasticsEurope. Plastics—The Facts 2020, an Analysis of European Plastics Production, Demand and Waste Data; PlasticsEurope, Association of Plastics Manufacturers: Brussels, Belgium, 2020. [Google Scholar]

- PlasticsEurope. Plastics—The Facts 2019, an Analysis of European Plastics Production, Demand and Waste Data; PlasticsEurope, Association of Plastics Manufacturers: Brussels, Belgium, 2019. [Google Scholar]

- PlasticsEurope. Plastics—The Facts 2018, an Analysis of European Plastics Production, Demand and Waste Data; PlasticsEurope, Association of Plastics Manufacturers: Brussels, Belgium, 2018. [Google Scholar]

- PlasticsEurope. Plastics—The Facts 2021, an Analysis of European Plastics Production, Demand and Waste Data; PlasticsEurope, Association of Plastics Manufacturers: Brussels, Belgium, 2021. [Google Scholar]

- Cordier, M.; Uehara, T. How much innovation is needed to protect the ocean from plastic contamination? Sci. Total Environ. 2019, 670, 789–799. [Google Scholar] [CrossRef]

- Mastellone, M.L.; Arena, U. Olivine as a tar removal catalyst during fluidized bed gasification of plastic waste. AlChE J. 2008, 54, 1656–1667. [Google Scholar] [CrossRef]

- Da Silva, T.R.; De Azevedo, A.R.G.; Cecchin, D.; Marvila, M.T.; Amran, M.; Fediuk, R.; Vatin, N.; Karelina, M.; Klyuev, S.; Szelag, M. Application of Plastic Wastes in Construction Materials: A Review Using the Concept of Life-Cycle Assessment in the Context of Recent Research for Future Perspectives. Materials 2021, 14, 3549. [Google Scholar] [CrossRef] [PubMed]

- Awoyera, P.O.; Adesina, A. Plastic wastes to construction products: Status, limitations and future perspective. Case Stud. Constr. Mater. 2020, 12, e00330. [Google Scholar] [CrossRef]

- Aneke, F.I.; Shabangu, C. Green-efficient masonry bricks produced from scrap plastic waste and foundry sand. Case Stud. Constr. Mater. 2021, 14, e00515. [Google Scholar] [CrossRef]

- Roosen, M.; Mys, N.; Kusenberg, M.; Billen, P.; Dumoulin, A.; Dewulf, J.; Van Geem, K.M.; Ragaert, K.; De Meester, S. Detailed Analysis of the Composition of Selected Plastic Packaging Waste Products and Its Implications for Mechanical and Thermochemical Recycling. Environ. Sci. Technol. 2020, 54, 13282–13293. [Google Scholar] [CrossRef] [PubMed]

- Santander, P.; Cruz Sanchez, F.A.; Boudaoud, H.; Camargo, M. Closed loop supply chain network for local and distributed plastic recycling for 3D printing: A MILP-based optimization approach. Resour. Conserv. Recycl. 2020, 154, 104531. [Google Scholar] [CrossRef]

- Ragaert, K.; Delva, L.; Van Geem, K. Mechanical and chemical recycling of solid plastic waste. Waste Manag. (Oxford UK) 2017, 69, 24–58. [Google Scholar] [CrossRef] [PubMed]

- Williams, P.T. Hydrogen and Carbon Nanotubes from Pyrolysis-Catalysis of Waste Plastics: A Review. Waste Biomass Valorization 2020, 12, 1–28. [Google Scholar] [CrossRef]

- Al-Salem, S.M.; Lettieri, P.; Baeyens, J. The valorization of plastic solid waste (PSW) by primary to quaternary routes: From re-use to energy and chemicals. Prog. Energy Combust. Sci. 2010, 36, 103–129. [Google Scholar] [CrossRef]

- Ügdüler, S.; Van Geem, K.M.; Roosen, M.; Delbeke, E.I.P.; De Meester, S. Challenges and opportunities of solvent-based additive extraction methods for plastic recycling. Waste Manag. (Oxford) 2020, 104, 148–182. [Google Scholar] [CrossRef] [PubMed]

- ClarivateTM. Web of Science. Available online: https://www.webofknowledge.com (accessed on 1 February 2022).

- Wang, M.; Smith, J.M.; McCoy, B.J. Continuous kinetics for thermal degradation of polymer in solution. AlChE J. 1995, 41, 1521–1533. [Google Scholar] [CrossRef]

- Zolghadr, A.; Sidhu, N.; Mastalski, I.; Facas, G.; Maduskar, S.; Uppili, S.; Go, T.; Neurock, M.; Dauenhauer, P.J. On the Method of Pulse-Heated Analysis of Solid Reactions (PHASR) for Polyolefin Pyrolysis. ChemSusChem 2021, 14, 4214–4227. [Google Scholar] [CrossRef] [PubMed]

- Aznar, M.P.; Caballero, M.A.; Sancho, J.A.; Frances, E. Plastic waste elimination by co-gasification with coal and biomass in fluidized bed with air in pilot plant. Fuel Process. Technol. 2006, 87, 409–420. [Google Scholar] [CrossRef]

- Lopez, G.; Artetxe, M.; Amutio, M.; Alvarez, J.; Bilbao, J.; Olazar, M. Recent advances in the gasification of waste plastics. A critical overview. Renew. Sustain. Energy Rev. 2018, 82, 576–596. [Google Scholar] [CrossRef]

- Wu, C.; Williams, P.T. Pyrolysis-gasification of plastics, mixed plastics and real-world plastic waste with and without Ni-Mg-Al catalyst. Fuel 2010, 89, 3022–3032. [Google Scholar] [CrossRef]

- Na, J.I.; Park, S.J.; Kim, Y.K.; Lee, J.G.; Kim, J.H. Characteristics of oxygen-blown gasification for combustible waste in a fixed-bed gasifier. Appl. Energy 2003, 75, 275–285. [Google Scholar] [CrossRef]

- Tsuji, T.; Hatayama, A. Gasification of waste plastics by steam reforming in a fluidized bed. J. Mater. Cycles Waste Manag. 2009, 11, 144–147. [Google Scholar] [CrossRef]

- Tsuji, T.; Sasaki, A.; Okajima, S.; Masuda, T. Steam reforming of the oils produced from waste plastics. Kagaku Kogaku Ronbunshu 2004, 30, 705–709. [Google Scholar] [CrossRef]

- Janajreh, I.; Adeyemi, I.; Raza, S.S.; Ghenai, C. A review of recent developments and future prospects in gasification systems and their modeling. Renew. Sustain. Energy Rev. 2021, 138, 110505. [Google Scholar] [CrossRef]

- Wilk, V.; Hofbauer, H. Conversion of mixed plastic wastes in a dual fluidized bed steam gasifier. Fuel 2013, 107, 787–799. [Google Scholar] [CrossRef]

- Baloch, H.A.; Yang, T.; Li, R.; Nizamuddin, S.; Kai, X.; Bhutto, A.W. Parametric study of co-gasification of ternary blends of rice straw, polyethylene and polyvinylchloride. Clean Technol. Environ. Policy 2016, 18, 1031–1042. [Google Scholar] [CrossRef]

- Interreg. PSYCHE, Production of Basic Chemicals from Plastic Waste for Reuse in the Chemical Industry. Available online: https://psycheplastics.eu/ (accessed on 10 July 2020).

- Janajreh, I.; Adeyemi, I.; Elagroudy, S. Gasification feasibility of polyethylene, polypropylene, polystyrene waste and their mixture: Experimental studies and modeling. Sustain. Energy Technol. Assess. 2020, 39, 100684. [Google Scholar] [CrossRef]

- Tukker, A.; de Groot, H.; Simons, L.; Wiegersma, S. Chemical Recycling of Plastics Waste (PVC and Other Resins); TNO Institute of Strategy, Technology and Policy: Delft, The Nedtherlands, 1999. [Google Scholar]

- Hoang, Q.N.; Vanierschot, M.; Blondeau, J.; Croymans, T.; Pittoors, R.; Van Caneghem, J. Review of numerical studies on thermal treatment of municipal solid waste in packed bed combustion. Fuel Commun. 2021, 7, 100013. [Google Scholar] [CrossRef]

- Harmon, R.E.; SriBala, G.; Broadbelt, L.J.; Burnham, A.K. Insight into Polyethylene and Polypropylene Pyrolysis: Global and Mechanistic Models. Energy Fuels 2021, 35, 6765–6775. [Google Scholar] [CrossRef]

- Sharma, S.S.; Batra, V.S. Production of hydrogen and carbon nanotubes via catalytic thermo-chemical conversion of plastic waste: Review. J. Chem. Technol. Biotechnol. 2020, 95, 11–19. [Google Scholar] [CrossRef]

- Ciuffi, B.; Chiaramonti, D.; Rizzo, A.M.; Frediani, M.; Rosi, L. A Critical Review of SCWG in the Context of Available Gasification Technologies for Plastic Waste. Appl. Sci. 2020, 10, 6307. [Google Scholar] [CrossRef]

- Salaudeen, S.A.; Arku, P.; Dutta, A. Gasification of Plastic Solid Waste and Competitive Technologies. In Plastics to Energy; William Andrew Publishing: Norwich, NY, USA, 2019; pp. 269–293. [Google Scholar]

- Ramos, A.; Monteiro, E.; Rouboa, A. Numerical approaches and comprehensive models for gasification process: A review. Renew. Sustain. Energy Rev. 2019, 110, 188–206. [Google Scholar] [CrossRef]

- Dedeyne, J.; Virgilio, M.; Arts, T.; Marin, G.B.; Van Geem, K.M. Design and Optimization of 3D Reactor Technologies for the Production of Light Olefins. In Proceedings of the AIChE Annual Meeting (19AIChE), Orlando, FL, USA, 10–15 November 2019. [Google Scholar]

- Nakhaei, M.; Wu, H.; Grévain, D.; Jensen, L.S.; Glarborg, P.; Clausen, S.; Dam–Johansen, K. Experiments and modeling of single plastic particle conversion in suspension. Fuel Process. Technol. 2018, 178, 213–225. [Google Scholar] [CrossRef]

- Ponzio, A.; Kalisz, S.; Blasiak, W. Effect of operating conditions on tar and gas composition in high temperature air/steam gasification (HTAG) of plastic containing waste. Fuel Process. Technol. 2006, 87, 223–233. [Google Scholar] [CrossRef]

- Luo, S.; Zhou, Y.; Yi, C. Hydrogen-rich gas production from biomass catalytic gasification using hot blast furnace slag as heat carrier and catalyst in moving-bed reactor. Int. J. Hydrogen Energy 2012, 37, 15081–15085. [Google Scholar] [CrossRef]

- Erkiaga, A.; Lopez, G.; Barbarias, I.; Artetxe, M.; Amutio, M.; Bilbao, J.; Olazar, M. HDPE pyrolysis-steam reforming in a tandem spouted bed-fixed bed reactor for H2 production. J. Anal. Appl. Pyrolysis 2015, 116, 34–41. [Google Scholar] [CrossRef]

- Lopez, G.; Erkiaga, A.; Amutio, M.; Bilbao, J.; Olazar, M. Effect of polyethylene co-feeding in the steam gasification of biomass in a conical spouted bed reactor. Fuel 2015, 153, 393–401. [Google Scholar] [CrossRef]

- Alvarez, J.; Kumagai, S.; Wu, C.; Yoshioka, T.; Bilbao, J.; Olazar, M.; Williams, P.T. Hydrogen production from biomass and plastic mixtures by pyrolysis-gasification. Int. J. Hydrogen Energy 2014, 39, 10883–10891. [Google Scholar] [CrossRef]

- Lopez, G.; Erkiaga, A.; Amutio, M.; Alvarez, J.; Barbarias, I.; Bilbao, J.; Olazar, M. Steam gasification of waste plastics in a conical spouted bed reactor. In Proceedings of the the 14th International Conference on Fluidization—From Fundamentals to Products, NH Conference Centre Leeuwenhorst Noordwijkerhout, Noordwijkerhout, The Netherlands, 26–31 May 2013; pp. 945–952. [Google Scholar]

- Artetxe, M.; Lopez, G.; Amutio, M.; Elordi, G.; Olazar, M.; Bilbao, J. Operating Conditions for the Pyrolysis of Poly-(ethylene terephthalate) in a Conical Spouted-Bed Reactor. Ind. Eng. Chem. Res. 2010, 49, 2064–2069. [Google Scholar] [CrossRef]

- Vandewalle, L.A.; Gonzalez-Quiroga, A.; Perreault, P.; Van Geem, K.M.; Marin, G.B. Process Intensification in a Gas–Solid Vortex Unit: Computational Fluid Dynamics Model Based Analysis and Design. Ind. Eng. Chem. Res. 2019, 58, 12751–12765. [Google Scholar] [CrossRef]

- De Wilde, J. Gas-solid fluidized beds in vortex chambers. Chem. Eng. Process. 2014, 85, 256–290. [Google Scholar] [CrossRef]

- Tang, L.; Huang, H. Decomposition of polyethylene in radio-frequency nitrogen and water steam plasmas under reduced pressures. Fuel Process. Technol. 2007, 88, 549–556. [Google Scholar] [CrossRef]

- Kikuchi, R.; Sato, H.; Matsukura, Y.; Yamamoto, T. Semi-pilot scale test for production of hydrogen-rich fuel gas from different wastes by means of a gasification and smelting process with oxygen multi-blowing. Fuel Process. Technol. 2005, 86, 1279–1296. [Google Scholar] [CrossRef]

- Lee, J.W.; Yu, T.U.; Lee, J.W.; Moon, J.H.; Jeong, H.J.; Park, S.S.; Yang, W.; Lee, U.D. Gasification of Mixed Plastic Wastes in a Moving-Grate Gasifier and Application of the Producer Gas to a Power Generation Engine. Energy Fuels 2013, 27, 2092–2098. [Google Scholar] [CrossRef]

- Wong, S.-C.; Lin, A.-C. Internal temperature distributions of droplets vaporizing in high-temperature convective flows. J. Fluid Mech. 1992, 237, 671–687. [Google Scholar] [CrossRef]

- Floyd, S.; Choi, K.Y.; Taylor, T.W.; Ray, W.H. Polymerization of olefins through heterogeneous catalysis. III. Polymer particle modelling with an analysis of intraparticle heat and mass transfer effects. J. Appl. Polym. Sci. 1986, 32, 2935–2960. [Google Scholar] [CrossRef]

- Calfa, B.A. Multi-Scale Process Systems Engineering. In Proceedings of the AIChE Annual Meeting, Salt Lake City, UT, USA, 8–13 November 2015. [Google Scholar]

- Fu, Z.; Zhu, J.; Barghi, S.; Zhao, Y.; Luo, Z.; Duan, C. On the two-phase theory of fluidization for Geldart B and D particles. Powder Technol. 2019, 354, 64–70. [Google Scholar] [CrossRef]

- Plehiers, P. Multi-Scale Modeling of Chemical Processes via Machine Learning. Ph.D. Thesis, Ghent University, Ghent, Belgium, 2020. [Google Scholar]

- Alli, R. Performance Prediction of Waste Polyethylene Gasification Using CO2 in a Bubbling Fluidized Bed: A Modelling Study. Chem. Biochem. Eng. Q. 2018, 32, 349–358. [Google Scholar] [CrossRef]

- Horton, S.R.; Woeckener, J.; Mohr, R.; Zhang, Y.; Petrocelli, F.; Klein, M.T. Molecular-Level Kinetic Modeling of the Gasification of Common Plastics. Energy Fuels 2016, 30, 1662–1674. [Google Scholar] [CrossRef]

- Ramos, A.; Tavares, R.; Rouboa, A. Microplastics co-gasification with biomass: Modelling syngas characteristics at low temperatures. AIP Conf. Proc. 2018, 1968, 020016. [Google Scholar] [CrossRef]

- Donskoy, I. Mathematical modelling and optimization of biomass-plastic fixed-bed downdraft co-gasification process. EPJ Web Conf. 2017, 159, 00010. [Google Scholar] [CrossRef][Green Version]

- Horton, S.R.; Zhang, Y.; Mohr, R.; Petrocelli, F.; Klein, M.T. Implementation of a Molecular-Level Kinetic Model for Plasma-Arc Municipal Solid Waste Gasification. Energy Fuels 2016, 30, 7904–7915. [Google Scholar] [CrossRef]

- Du, Y.; Yang, Q.; Berrouk, A.S.; Yang, C.; Al Shoaibi, A.S. Equivalent Reactor Network Model for Simulating the Air Gasification of Polyethylene in a Conical Spouted Bed Gasifier. Energy Fuels 2014, 28, 6830–6840. [Google Scholar] [CrossRef]

- Grana, R.; Sommariva, S.; Maffei, T.; Cuoci, A.; Faravelli, T.; Frassoldati, A.; Pierucci, S.; Ranzi, E. Detailed kinetics in the mathematical model of fixed bed gasifiers. Comput.-Aided Chem. Eng. 2010, 28, 829–834. [Google Scholar]

- Mazzoni, L.; Janajreh, I. Plasma gasification of municipal solid waste with variable content of plastic solid waste for enhanced energy recovery. Int. J. Hydrogen Energy 2017, 42, 19446–19457. [Google Scholar] [CrossRef]

- Janajreh, I.; Raza, S.S. Numerical simulation of waste tyres gasification. Waste Manag. Res. 2015, 33, 460–468. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Dor, L.; Yang, W.; Blasiak, W. CFD modeling of municipal solid waste gasification in a fixed-bed plasma gasification melting reactor. In Proceedings of the International Conference on Thermal Treatment Technologies and Hazardous Waste Combustors, Jacksonville, FL, USA, 10–13 May 2011; pp. 252–278. [Google Scholar]

- Yuan, G.; Chen, D.; Yin, L.; Wang, Z.; Zhao, L.; Wang, J.Y. High efficiency chlorine removal from polyvinyl chloride (PVC) pyrolysis with a gas–liquid fluidized bed reactor. Waste Manag. (Oxford) 2014, 34, 1045–1050. [Google Scholar] [CrossRef]

- Jin, Z.; Yin, L.; Chen, D.; Jia, Y.; Yuan, J.; Yu, B. Heat transfer characteristics of molten plastics in a vertical falling film reactor. Chin. J. Chem. Eng. 2019, 27, 1015–1020. [Google Scholar] [CrossRef]

- Bockhorn, H.; Hornung, A.; Hornung, U. Stepwise pyrolysis for raw material recovery from plastic waste. J. Anal. Appl. Pyrolysis 1998, 46, 1–13. [Google Scholar] [CrossRef]

- Lopez, G.; Artetxe, M.; Amutio, M.; Bilbao, J.; Olazar, M. Thermochemical routes for the valorization of waste polyolefinic plastics to produce fuels and chemicals. A review. Renew. Sustain. Energy Rev. 2017, 73, 346–368. [Google Scholar] [CrossRef]

- Mazloum, S.; Awad, S.; Allam, N.; Aboumsallem, Y.; Loubar, K.; Tazerout, M. Modelling plastic heating and melting in a semi-batch pyrolysis reactor. Appl. Energy 2021, 283, 116375. [Google Scholar] [CrossRef]

- Mikulionok, I.; Gavva, O.; Kryvoplias-Volodina, L. Modeling of melting process in a single screw extruder for polymer processing. East.-Eur. J. Enterp. Technol. 2018, 2, 4–11. [Google Scholar] [CrossRef]

- Kim, Y.; Hossain, A.; Nakamura, Y. Numerical modeling of melting and dripping process of polymeric material subjected to moving heat flux: Prediction of drop time. Proc. Combust. Inst. 2015, 35, 2555–2562. [Google Scholar] [CrossRef]

- Liu, D.; Zhong, C. Modeling of the Heat Capacity of Polymers with the Variable Connectivity Index. Polym. J. 2002, 34, 954–961. [Google Scholar] [CrossRef]

- Algaer, E.A.; Müller-Plathe, F. Molecular Dynamics Calculations of the Thermal Conductivity of Molecular Liquids, Polymers, and Carbon Nanotubes. Soft Mater. 2012, 10, 42–80. [Google Scholar] [CrossRef]

- Kiessling, A.; Simavilla, D.N.; Vogiatzis, G.G.; Venerus, D.C. Thermal conductivity of amorphous polymers and its dependence on molecular weight. Polymer 2021, 228, 123881. [Google Scholar] [CrossRef]

- Zhao, J.; Jiang, J.-W.; Wei, N.; Zhang, Y.; Rabczuk, T. Thermal conductivity dependence on chain length in amorphous polymers. J. Appl. Phys. 2013, 113, 184304. [Google Scholar] [CrossRef]

- Gorensek, M.B.; Shukre, R.; Chen, C.-C. Development of a Thermophysical Properties Model for Flowsheet Simulation of Biomass Pyrolysis Processes. ACS Sustain. Chem. Eng. 2019, 7, 9017–9027. [Google Scholar] [CrossRef]

- Ungerer, P.; Nieto-Draghi, C.; Rousseau, B.; Ahunbay, G.; Lachet, V. Molecular simulation of the thermophysical properties of fluids: From understanding toward quantitative predictions. J. Mol. Liq. 2007, 134, 71–89. [Google Scholar] [CrossRef]

- Gavoille, T.; Pannacci, N.; Bergeot, G.; Marliere, C.; Marre, S. Microfluidic approaches for accessing thermophysical properties of fluid systems. React. Chem. Eng. 2019, 4, 1721–1739. [Google Scholar] [CrossRef]

- ANSYS Chemkin Theory Manual 17.0 (15151); Reaction Design: San Diego, CA, USA; ANSYS, Inc.: Carnotsburg, PA, USA, 2015.

- Dadgostar, N.; Shaw, J.M. A predictive correlation for the constant-pressure specific heat capacity of pure and ill-defined liquid hydrocarbons. Fluid Phase Equilib. 2012, 313, 211–226. [Google Scholar] [CrossRef]

- Detar, D.F. Theoretical ab Initio Calculation of Entropy, Heat Capacity, and Heat Content. J. Phys. Chem. A 1998, 102, 5128–5141. [Google Scholar] [CrossRef]

- Li, C.; Strachan, A. Molecular scale simulations on thermoset polymers: A review. J. Polym. Sci. Part B Polym. Phys. 2015, 53, 103–122. [Google Scholar] [CrossRef]

- Kumar, A.; Sundararaghavan, V.; Browning, A.R. Study of temperature dependence of thermal conductivity in cross-linked epoxies using molecular dynamics simulations with long range interactions. Model. Simul. Mater. Sci. Eng. 2014, 22, 025013. [Google Scholar] [CrossRef]

- Henry, A.; Chen, G. High Thermal Conductivity of Single Polyethylene Chains Using Molecular Dynamics Simulations. Phys. Rev. Lett. 2008, 101, 235502. [Google Scholar] [CrossRef] [PubMed]

- Lautenberger, C.; Fernandez-Pello, C. Generalized pyrolysis model for combustible solids. Fire Saf. J. 2009, 44, 819–839. [Google Scholar] [CrossRef]

- Wu, D.; Xu, F.; Sun, B.; Fu, R.; He, H.; Matyjaszewski, K. Design and Preparation of Porous Polymers. Chem. Rev. 2012, 112, 3959–4015. [Google Scholar] [CrossRef] [PubMed]

- Zhai, S.; Zhang, P.; Xian, Y.; Zeng, J.; Shi, B. Effective thermal conductivity of polymer composites: Theoretical models and simulation models. Int. J. Heat Mass Transf. 2018, 117, 358–374. [Google Scholar] [CrossRef]

- Sakiyama, T.; Akutsu, M.; Miyawaki, O.; Yano, T. Effective thermal diffusivity of food gels impregnated with air bubbles. J. Food Eng. 1999, 39, 323–328. [Google Scholar] [CrossRef]

- Yin, C. Transient heating and evaporation of moving mono-component liquid fuel droplets. Appl. Therm. Eng. 2016, 104, 497–503. [Google Scholar] [CrossRef]

- Baghel, V.; Sikarwar, B.S.; Muralidhar, K. Modeling of heat transfer through a liquid droplet. Heat Mass Transf. 2019, 55, 1371–1385. [Google Scholar] [CrossRef]

- Poling, B.E.; Prausnitz, J.M.; O’Connell, J.P. The Properties of Gases and Liquids, 5th ed.; McGRAW-HILL: New York, NY, USA, 2001. [Google Scholar]

- Ferkl, P.; Toulec, M.; Laurini, E.; Pricl, S.; Fermeglia, M.; Auffarth, S.; Eling, B.; Settels, V.; Kosek, J. Multi-scale modelling of heat transfer in polyurethane foams. Chem. Eng. Sci. 2017, 172, 323–334. [Google Scholar] [CrossRef]

- Dogu, O.; Plehiers, P.P.; Van De Vijver, R.; D’Hooge, D.R.; Van Steenberge, P.H.M.; Van Geem, K.M. Distribution Changes during Thermal Degradation of Poly(styrene peroxide) by Pairing Tree-Based Kinetic Monte Carlo and Artificial Intelligence Tools. Ind. Eng. Chem. Res. 2021, 60, 3334–3353. [Google Scholar] [CrossRef]

- Dente, M.; Bozzano, G.; Faravelli, T.; Marongiu, A.; Pierucci, S.; Ranzi, E. Kinetic Modelling of Pyrolysis Processes in Gas and Condensed Phase. Adv. Chem. Eng. 2007, 32, 51–166. [Google Scholar]

- Faravelli, T.; Bozzano, G.; Colombo, M.; Ranzi, E.; Dente, M. Kinetic modeling of the thermal degradation of polyethylene and polystyrene mixtures. J. Anal. Appl. Pyrolysis 2003, 70, 761–777. [Google Scholar] [CrossRef]

- Kiran Ciliz, N.; Ekinci, E.; Snape, C.E. Pyrolysis of virgin and waste polypropylene and its mixtures with waste polyethylene and polystyrene. Waste Manag. 2004, 24, 173–181. [Google Scholar] [CrossRef] [PubMed]

- Dogu, O.; Pelucchi, M.; Van De Vijver, R.; Van Steenberge, P.H.M.; D’Hooge, D.R.; Cuoci, A.; Mehl, M.; Frassoldati, A.; Faravelli, T.; Van Geem, K.M. The chemistry of chemical recycling of solid plastic waste via pyrolysis and gasification: State-of-the-art, challenges, and future directions. Prog. Energy Combust. Sci. 2021, 84, 100901. [Google Scholar] [CrossRef]

- Vinu, R.; Broadbelt, L.J. Unraveling reaction pathways and specifying reaction kinetics for complex systems. Annu. Rev. Chem. Biomol. Eng. 2012, 3, 29–54. [Google Scholar] [CrossRef]

- Poutsma, M.L. Fundamental reactions of free radicals relevant to pyrolysis reactions. J. Anal. Appl. Pyrolysis 2000, 54, 5–35. [Google Scholar] [CrossRef]

- Materazzi, M.; Lettieri, P.; Mazzei, L.; Taylor, R.; Chapman, C. Thermodynamic modelling and evaluation of a two-stage thermal process for waste gasification. Fuel 2013, 108, 356–369. [Google Scholar] [CrossRef]

- Jarungthammachote, S.; Dutta, A. Equilibrium modeling of gasification: Gibbs free energy minimization approach and its application to spouted bed and spout-fluid bed gasifiers. Energy Convers. Manag. 2008, 49, 1345–1356. [Google Scholar] [CrossRef]

- Zainal, Z.A.; Ali, R.; Lean, C.H.; Seetharamu, K.N. Prediction of performance of a downdraft gasifier using equilibrium modeling for different biomass materials. Energy Convers. Manag. 2001, 42, 1499–1515. [Google Scholar] [CrossRef]

- Melgar, A.; Pérez, J.F.; Laget, H.; Horillo, A. Thermochemical equilibrium modelling of a gasifying process. Energy Convers. Manag. 2007, 48, 59–67. [Google Scholar] [CrossRef]

- Lee, U.; Chung, J.N.; Ingley, H.A. High-Temperature Steam Gasification of Municipal Solid Waste, Rubber, Plastic and Wood. Energy Fuels 2014, 28, 4573–4587. [Google Scholar] [CrossRef]

- Jand, N.; Brandani, V.; Foscolo, P.U. Thermodynamic Limits and Actual Product Yields and Compositions in Biomass Gasification Processes. Ind. Eng. Chem. Res. 2006, 42, 834–843. [Google Scholar] [CrossRef]

- Ranzi, E.; Dente, M.; Goldaniga, A.; Bozzano, G.; Faravelli, T. Lumping procedures in detailed kinetic modeling of gasification, pyrolysis, partial oxidation and combustion of hydrocarbon mixtures. Prog. Energy Combust. Sci. 2001, 27, 99–139. [Google Scholar] [CrossRef]

- Faravelli, T.; Pinciroli, M.; Pisano, F.; Bozzano, G.; Dente, M.; Ranzi, E. Thermal degradation of polystyrene. J. Anal. Appl. Pyrolysis 2001, 60, 103–121. [Google Scholar] [CrossRef]

- Abbas-Abadi, M.S.; Van Geem, K.M.; Fathi, M.; Bazgir, H.; Ghadiri, M. The pyrolysis of oak with polyethylene, polypropylene and polystyrene using fixed bed and stirred reactors and TGA instrument. Energy 2021, 232, 121085. [Google Scholar] [CrossRef]

- Singh, P.; Déparrois, N.; Burra, K.G.; Bhattacharya, S.; Gupta, A.K. Energy recovery from cross-linked polyethylene wastes using pyrolysis and CO2 assisted gasification. Appl. Energy 2019, 254, 113722. [Google Scholar] [CrossRef]

- Marongiu, A.; Bozzano, G.; Dente, M.; Ranzi, E.; Faravelli, T. Detailed kinetic modeling of pyrolysis of tetrabromobisphenol A. J. Anal. Appl. Pyrolysis 2007, 80, 325–345. [Google Scholar] [CrossRef]

- Westerhout, R.W.J.; Waanders, J.; Kuipers, J.A.M.; Van Swaaij, W.P.M. Kinetics of the Low-Temperature Pyrolysis of Polyethene, Polypropene, and Polystyrene Modeling, Experimental Determination, and Comparison with Literature Models and Data. Ind. Eng. Chem. Res. 1997, 36, 1955–1964. [Google Scholar] [CrossRef]

- Kashiwagi, T.; Ohlemiller, T.J. A study of oxygen effects on nonflaming transient gasification of PMMA and PE during thermal irradiation. Symp. (Int.) Combust. 1982, 19, 815–823. [Google Scholar] [CrossRef]

- Jeong, Y.-S.; Choi, Y.-K.; Kim, J.-S. Three-stage air gasification of waste polyethylene: In-situ regeneration of active carbon used as a tar removal additive. Energy 2019, 166, 335–342. [Google Scholar] [CrossRef]

- Zevenhoven, R.; Karlsson, M.; Hupa, M.; Frankenhaeuser, M. Combustion and gasification properties of plastics particles. J. Air Waste Manag. Assoc. 1997, 47, 861–870. [Google Scholar] [CrossRef]

- Xiao, R.; Jin, B.; Zhou, H.; Zhong, Z.; Zhang, M. Air gasification of polypropylene plastic waste in fluidized bed gasifier. Energy Convers. Manag. 2007, 48, 778–786. [Google Scholar] [CrossRef]

- Esmaeili, V.; Ajalli, J.; Faramarzi, A.; Abdi, M.; Gholizadeh, M. Gasification of wastes: The impact of the feedstock type and co-gasification on the formation of volatiles and char. Int. J. Energy Res. 2020, 44, 3587–3606. [Google Scholar] [CrossRef]

- Koo, J.-K.; Kim, S.-W. Reaction Kinetic Model for Optimal Pyrolysis of Plastic Wastes Mixtures. Waste Manag. Res. 1993, 11, 515–529. [Google Scholar] [CrossRef]

- Bradbury, A.G.W.; Sakai, Y.; Shafizadeh, F. A kinetic model for pyrolysis of cellulose. J. Appl. Polym. Sci. 1979, 23, 3271–3280. [Google Scholar] [CrossRef]

- Chen, S.; Meng, A.; Long, Y.; Zhou, H.; Li, Q.; Zhang, Y. TGA pyrolysis and gasification of combustible municipal solid waste. J. Energy Inst. 2015, 88, 332–343. [Google Scholar] [CrossRef]

- Wang, L.; Chai, M.; Liu, R.; Cai, J. Synergetic effects during co-pyrolysis of biomass and waste tire: A study on product distribution and reaction kinetics. Bioresour. Technol. 2018, 268, 363–370. [Google Scholar] [CrossRef] [PubMed]

- Martínez-Lera, S.; Pallarés Ranz, J. On the development of a polyolefin gasification modelling approach. Fuel 2017, 197, 518–527. [Google Scholar] [CrossRef]

- Conesa, J.A.; Font, R.; Marcilla, A.; Caballero, J.A. Kinetic model for the continuous pyrolysis of two types of polyethylene in a fluidized bed reactor. J. Anal. Appl. Pyrolysis 1997, 40–41, 419–431. [Google Scholar] [CrossRef]

- Hoffmann, A.C.; Janssen, L.P.B.M.; Prins, J. Particle segregation in fluidised binary mixtures. Chem. Eng. Sci. 1993, 48, 1583–1592. [Google Scholar] [CrossRef]

- Sommariva, S.; Grana, R.; Maffei, T.; Pierucci, S.; Ranzi, E. A kinetic approach to the mathematical model of fixed bed gasifiers. Comput. Chem. Eng. 2011, 35, 928–935. [Google Scholar] [CrossRef]

- Hla, S.S.; Lopes, R.; Roberts, D. The CO2 gasification reactivity of chars produced from Australian municipal solid waste. Fuel 2016, 185, 847–854. [Google Scholar] [CrossRef]

- Paviet, F.; Bals, O.; Antonini, G. Kinetic study of various chars steam gasification. Int. J. Chem. React. Eng. 2007, 5. [Google Scholar] [CrossRef]

- ECN.TNO. Phyllis2, Database for Biomass and Waste. Available online: https://phyllis.nl/ (accessed on 18 January 2022).

- Serranti, S.; Gargiulo, A.; Bonifazi, G. Characterization of post-consumer polyolefin wastes by hyperspectral imaging for quality control in recycling processes. Waste Manag. 2011, 31, 2217–2227. [Google Scholar] [CrossRef] [PubMed]

- McGhee, B.; Norton, F.; Snape, C.E.; Hall, P.J. The copyrolysis of poly(vinyl chloride) with cellulose derived materials as a model for municipal waste derived chars. Fuel 1995, 74, 28–31. [Google Scholar] [CrossRef]

- De Oliveira, L.P.; Hudebine, D.; Guillaume, D.; Verstraete, J.J. A Review of Kinetic Modeling Methodologies for Complex Processes. OGST–Revue d’IFP Energies Nouvelles 2016, 71, 45. [Google Scholar] [CrossRef]

- Németh, A.; Blazsó, M.; Baranyai, P.; Vidóczy, T. Thermal degradation of polyethylene modeled on tetracontane. J. Anal. Appl. Pyrolysis 2008, 81, 237–242. [Google Scholar] [CrossRef]

- Mastan, E.; Zhu, S. Method of moments: A versatile tool for deterministic modeling of polymerization kinetics. Eur. Polym. J. 2015, 68, 139–160. [Google Scholar] [CrossRef]

- Nasresfahani, A.; Hutchinson, R.A. Modeling the Distribution of Functional Groups in Semibatch Radical Copolymerization: An Accelerated Stochastic Approach. Ind. Eng. Chem. Res. 2018, 57, 9407–9419. [Google Scholar] [CrossRef]

- Vandewiele, N.M.; Van Geem, K.M.; Reyniers, M.-F.; Marin, G.B. Genesys: Kinetic model construction using chemo-informatics. Chem. Eng. J. 2012, 207–208, 526–538. [Google Scholar] [CrossRef]

- De Smit, K.; Marien, Y.W.; Van Geem, K.M.; Van Steenberge, P.H.M.; D’Hooge, D.R. Connecting polymer synthesis and chemical recycling on a chain-by-chain basis: A unified matrix-based kinetic Monte Carlo strategy. React. Chem. Eng. 2020, 5, 1909–1928. [Google Scholar] [CrossRef]

- CRECK Modeling Lab. Detailed Kinetic Mechanisms and CFD of Reacting Flows. Available online: http://creckmodeling.chem.polimi.it/ (accessed on 10 June 2021).

- Sogancioglu, M.; Yel, E.; Ahmetli, G. Pyrolysis of waste high density polyethylene (HDPE) and low density polyethylene (LDPE) plastics and production of epoxy composites with their pyrolysis chars. J. Clean. Prod. 2017, 165, 369–381. [Google Scholar] [CrossRef]

- Xu, F.; Wang, B.; Yang, D.; Qiao, Y.; Tian, Y. The steam gasification reactivity and kinetics of municipal solid waste chars derived from rapid pyrolysis. Waste Manag. 2018, 80, 64–72. [Google Scholar] [CrossRef] [PubMed]

- Ye, D.P.; Agnew, J.B.; Zhang, D.K. Gasification of a South Australian low-rank coal with carbon dioxide and steam: Kinetics and reactivity studies. Fuel 1998, 77, 1209–1219. [Google Scholar] [CrossRef]

- Murillo, R.; Navarro, M.V.; López, J.M.; García, T.; Callén, M.S.; Aylón, E.; Mastral, A.M. Activation of pyrolytic tire char with CO2: Kinetic study. J. Anal. Appl. Pyrolysis 2004, 71, 945–957. [Google Scholar] [CrossRef]

- Bhatia, S.K.; Perlmutter, D.D. A random pore model for fluid-solid reactions: I. Isothermal, kinetic control. AlChE J. 1980, 26, 379–386. [Google Scholar] [CrossRef]

- Senneca, O.; Salatino, P. A semi-detailed kinetic model of char combustion with consideration of thermal annealing. Proc. Combust. Inst. 2011, 33, 1763–1770. [Google Scholar] [CrossRef]

- Ren, Y.; Guo, G.; Liao, Z.; Yang, Y.; Sun, J.; Jiang, B.; Wang, J.; Yang, Y. Kinetic modeling with automatic reaction network generator, an application to naphtha steam cracking. Energy 2020, 207, 118204. [Google Scholar] [CrossRef]

- Froment, G.F. On fundamental kinetic equations for chemical reactions and processes. Curr. Opin. Chem. Eng. 2014, 5, 1–6. [Google Scholar] [CrossRef]

- Gao, C.W.; Allen, J.W.; Green, W.H.; West, R.H. Reaction Mechanism Generator: Automatic construction of chemical kinetic mechanisms. Comput. Phys. Commun. 2016, 203, 212–225. [Google Scholar] [CrossRef]

- Vandewiele, N.M.; Van De Vijver, R.; Van Geem, K.M.; Reyniers, M.-F.; Marin, G.B. Symmetry calculation for molecules and transition states. J. Comput. Chem. 2015, 36, 181–192. [Google Scholar] [CrossRef]

- Coley, C.W.; Green, W.H.; Jensen, K.F. RDChiral: An RDKit Wrapper for Handling Stereochemistry in Retrosynthetic Template Extraction and Application. J. Chem. Inf. Model. 2019, 59, 2529–2537. [Google Scholar] [CrossRef] [PubMed]

- Vandewiele, N.M.; Van De Vijver, R.; Carstensen, H.-H.; Van Geem, K.M.; Reyniers, M.-F.; Marin, G.B. Implementation of Stereochemistry in Automatic Kinetic Model Generation. Int. J. Chem. Kinet. 2016, 48, 755–769. [Google Scholar] [CrossRef]

- Van De Vijver, R.; Van Geem, K.M.; Marin, G.B. On-the-fly ab initio calculations toward accurate rate coefficients. Proc. Combust. Inst. 2019, 37, 283–290. [Google Scholar] [CrossRef]

- Broadbelt, L.J.; Stark, S.M.; Klein, M.T. Computer Generated Pyrolysis Modeling: On-the-Fly Generation of Species, Reactions, and Rates. Ind. Eng. Chem. Res. 1994, 33, 790–799. [Google Scholar] [CrossRef]

- Ohno, K.; Maeda, S. A scaled hypersphere search method for the topography of reaction pathways on the potential energy surface. Chem. Phys. Lett. 2004, 384, 277–282. [Google Scholar] [CrossRef]

- Van De Vijver, R.; Zádor, J. KinBot: Automated stationary point search on potential energy surfaces. Comput. Phys. Commun. 2020, 248, 106947. [Google Scholar] [CrossRef]

- Stagni, A.; Cuoci, A.; Frassoldati, A.; Faravelli, T.; Ranzi, E. Lumping and Reduction of Detailed Kinetic Schemes: An Effective Coupling. Ind. Eng. Chem. Res. 2014, 53, 9004–9016. [Google Scholar] [CrossRef]

- Huang, H.; Fairweather, M.; Griffiths, J.F.; Tomlin, A.S.; Brad, R.B. A systematic lumping approach for the reduction of comprehensive kinetic models. Proc. Combust. Inst. 2005, 30, 1309–1316. [Google Scholar] [CrossRef]

- Wang, H.; Frenklach, M. Detailed reduction of reaction mechanisms for flame modeling. Combust. Flame 1991, 87, 365–370. [Google Scholar] [CrossRef]

- Gascoin, N.; Navarro-Rodriguez, A.; Fau, G.; Gillard, P. Kinetic modelling of High Density PolyEthylene pyrolysis: Part 2. Reduction of existing detailed mechanism. Polym. Degrad. Stab. 2012, 97, 1142–1150. [Google Scholar] [CrossRef][Green Version]

- Lu, T.; Law, C.K. Linear time reduction of large kinetic mechanisms with directed relation graph: N-Heptane and iso-octane. Combust. Flame 2006, 144, 24–36. [Google Scholar] [CrossRef]

- Briceno, J.; Lemos, M.A.; Lemos, F. Kinetic analysis of the degradation of HDPE+PP polymer mixtures. Int. J. Chem. Kinet. 2021, 53, 660–674. [Google Scholar] [CrossRef]

- Tuffi, R.; D’Abramo, S.; Cafiero, L.M.; Trinca, E.; Ciprioti, S.V. Thermal behavior and pyrolytic degradation kinetics of polymeric mixtures from waste packaging plastics. eXPRESS Polym. Lett. 2018, 12, 82–99. [Google Scholar] [CrossRef]

- Richter, F.; Rein, G. The Role of Heat Transfer Limitations in Polymer Pyrolysis at the Microscale. Front. Mech. Eng. 2018, 4, 18. [Google Scholar] [CrossRef]

- Saadatkhah, N.; Carillo Garcia, A.; Ackermann, S.; Leclerc, P.; Latifi, M.; Samih, S.; Patience, G.S.; Chaouki, J. Experimental methods in chemical engineering: Thermogravimetric analysis—TGA. Can. J. Chem. Eng. 2020, 98, 34–43. [Google Scholar] [CrossRef]

- Samih, S.; Chaouki, J. Development of a fluidized bed thermogravimetric analyzer. AlChE J. 2015, 61, 84–89. [Google Scholar] [CrossRef]

- Quan, H. Design of Micro-Fluidized Beds by Experiments and Numerical Simulations: Flow Regims Diagonis and Hydrodynamic Study. Ph.D. Thesis, Ecole Centrale de Lille, Villeneuve-d′Ascq, France, 2017. [Google Scholar]

- Leclerc, P.; Doucet, J.; Chaouki, J. Development of a microwave thermogravimetric analyzer and its application on polystyrene microwave pyrolysis kinetics. J. Anal. Appl. Pyrolysis 2018, 130, 209–215. [Google Scholar] [CrossRef]

- Brems, A.; Dewil, R.; Baeyens, J.; Zhang, R. Gasification of plastic waste as waste-to-energy or waste-to-syngas recovery route. Nat. Sci. 2013, 05, 695–704. [Google Scholar] [CrossRef]

- Kishore, K.; Mohandas, K.; Annakutty, K.S. Is gasification rate controlling step in polymer ignition? Combust. Sci. Technol. 1983, 31, 183–194. [Google Scholar] [CrossRef]

- Bockhorn, H.; Hornung, A.; Hornung, U.; Jakobströer, P. Modelling of isothermal and dynamic pyrolysis of plastics considering non-homogeneous temperature distribution and detailed degradation mechanism. J. Anal. Appl. Pyrolysis 1999, 49, 53–74. [Google Scholar] [CrossRef]

- Yin, L.; Jia, Y.; Guo, X.; Chen, D.; Jin, Z. Flow behaviors and heat transfer characteristics of liquid film during the pyrolysis process of molten plastics using OpenFOAM. Int. J. Heat Mass Transf. 2019, 133, 129–136. [Google Scholar] [CrossRef]

- Simons, G.A. Char Gasification: Part I. Transport Model. Combust. Sci. Technol. 1979, 20, 107–116. [Google Scholar] [CrossRef]

- Schulze, S.; Nikrityuk, P.; Abosteif, Z.; Guhl, S.; Richter, A.; Meyer, B. Heat and mass transfer within thermogravimetric analyser: From simulation to improved estimation of kinetic data for char gasification. Fuel 2017, 187, 338–348. [Google Scholar] [CrossRef]

- Cuoci, A.; Avedisian, C.T.; Brunson, J.D.; Guo, S.; Dalili, A.; Wang, Y.; Mehl, M.; Frassoldati, A.; Seshadri, K.; Dec, J.E.; et al. Simulating combustion of a seven-component surrogate for a gasoline/ethanol blend including soot formation and comparison with experiments. Fuel 2021, 288, 119451. [Google Scholar] [CrossRef]

- Arabkhalaj, A.; Azimi, A.; Ghassemi, H.; Shahsavan Markadeh, R. A fully transient approach on evaporation of multi-component droplets. Appl. Therm. Eng. 2017, 125, 584–595. [Google Scholar] [CrossRef]

- Tanaka, S.; Kastens, S.; Fujioka, S.; Schlüter, M.; Terasaka, K. Mass transfer from freely rising microbubbles in aqueous solutions of surfactant or salt. Chem. Eng. J. 2020, 387, 121246. [Google Scholar] [CrossRef]

- Brenn, G.; Deviprasath, L.J.; Durst, F.; Fink, C. Evaporation of acoustically levitated multi-component liquid droplets. Int. J. Heat Mass Transf. 2007, 50, 5073–5086. [Google Scholar] [CrossRef]

- Mouvanal, S.; Lamiel, Q.; Lamarque, N.; Helie, J.; Burkhardt, A.; Bakshi, S.; Chatterjee, D. Evaporation of thin liquid film of single and multi-component hydrocarbon fuel from a hot plate. Int. J. Heat Mass Transf. 2019, 141, 379–389. [Google Scholar] [CrossRef]

- Tonini, S.; Cossali, G.E. A multi-component drop evaporation model based on analytical solution of Stefan–Maxwell equations. Int. J. Heat Mass Transf. 2016, 92, 184–189. [Google Scholar] [CrossRef]

- Ebrahimian, V.; Habchi, C. Towards a predictive evaporation model for multi-component hydrocarbon droplets at all pressure conditions. Int. J. Heat Mass Transf. 2011, 54, 3552–3565. [Google Scholar] [CrossRef]

- Yi, P.; Long, W.; Jia, M.; Feng, L.; Tian, J. Development of an improved hybrid multi-component vaporization model for realistic multi-component fuels. Int. J. Heat Mass Transf. 2014, 77, 173–184. [Google Scholar] [CrossRef]

- Tong, A.Y.; Sirignano, W.A. Multicomponent droplet vaporization in a high temperature gas. Combust. Flame 1986, 66, 221–235. [Google Scholar] [CrossRef]

- Sazhin, S.S.; Rybdylova, O.; Crua, C. A mathematical model for heating and evaporation of a multi-component liquid film. Int. J. Heat Mass Transf. 2018, 117, 252–260. [Google Scholar] [CrossRef]

- Samimi Abianeh, O.; Chen, C.P. A discrete multicomponent fuel evaporation model with liquid turbulence effects. Int. J. Heat Mass Transf. 2012, 55, 6897–6907. [Google Scholar] [CrossRef]

- Arri, L.E.; Amundson, N.R. An analytical study of single particle char gasification. AlChE J. 1978, 24, 72–87. [Google Scholar] [CrossRef]

- Sefiane, K.; Ward, C.A. Recent advances on thermocapillary flows and interfacial conditions during the evaporation of liquids. Adv. Colloid Interface Sci. 2007, 134–135, 201–223. [Google Scholar] [CrossRef]

- Shinjo, J.; Xia, J.; Megaritis, A.; Ganippa, L.C.; Cracknell, R.F. Modeling Temperature Distribution Inside an Emulsion Fuel Droplet Under Convective Heating: A Key to Predicting Microexplosion and Puffing. At. Sprays 2016, 26, 551–583. [Google Scholar] [CrossRef]

- Larson, R.G.; Desai, P.S. Modeling the Rheology of Polymer Melts and Solutions. Annu. Rev. Fluid Mech. 2015, 47, 47–65. [Google Scholar] [CrossRef]

- Bress, T.J.; Dowling, D.R. Particle image velocimetry in molten plastic. Polym. Eng. Sci. 2011, 51, 730–745. [Google Scholar] [CrossRef]

- Karkri, M.; Jarny, Y.; Mousseau, P. Thermal state of an incompressible pseudo-plastic fluid and Nusselt number at the interface fluid–die wall. Int. J. Therm. Sci. 2008, 47, 1284–1293. [Google Scholar] [CrossRef]

- Philippoff, W.; Gaskins, F.H. Viscosity measurements on molten polyethylene. J. Polym. Sci. 1956, 21, 205–222. [Google Scholar] [CrossRef]

- Haim, M.; Kalman, H. The effect of internal particle heat conduction on heat transfer analysis of turbulent gas–particle flow in a dilute state. Granul. Matter 2008, 10, 341–349. [Google Scholar] [CrossRef]

- Dutil, Y.; Rousse, D.R.; Salah, N.B.; Lassue, S.; Zalewski, L. A review on phase-change materials: Mathematical modeling and simulations. Renew. Sustain. Energy Rev. 2011, 15, 112–130. [Google Scholar] [CrossRef]

- Nagle, J.F.; Gujrati, P.D.; Goldstein, M. Towards better theories of polymer melting. J. Phys. Chem. 1984, 88, 4599–4608. [Google Scholar] [CrossRef]

- Chalid, M.; Fikri, A.I.; Haidar Satrio, H.; Joshua, Y.M.; Fatriansyah, J.F. An Investigation of the Melting Temperature Effect on the Rate of Solidification in Polymer using a Modified Phase Field Model. Int. J. Technol. 2017, 8, 1321. [Google Scholar] [CrossRef][Green Version]

- Zhang, R.; Fall, W.S.; Hall, K.W.; Gehring, G.A.; Zeng, X.; Ungar, G. Quasi-continuous melting of model polymer monolayers prompts reinterpretation of polymer melting. Nat. Commun. 2021, 12, 1710. [Google Scholar] [CrossRef]

- Riedlbauer, D.; Drexler, M.; Drummer, D.; Steinmann, P.; Mergheim, J. Modelling, simulation and experimental validation of heat transfer in selective laser melting of the polymeric material PA12. Comput. Mater. Sci. 2014, 93, 239–248. [Google Scholar] [CrossRef]

- Sommer, J.-U.; Luo, C. Molecular dynamics simulations of semicrystalline polymers: Crystallization, melting, and reorganization. J. Polym. Sci. Part. B Polym. Phys. 2010, 48, 2222–2232. [Google Scholar] [CrossRef]

- Takahashi, N.; Hikosaka, M.; Yamamoto, T. Computer simulation of melting of polymer crystals. Physical B 1996, 219–220, 420–422. [Google Scholar] [CrossRef]

- Lindt, J.T. Mathematical-Modeling of Melting of Polymers in a Single-Screw Extruder—A Critical-Review. Polym. Eng. Sci. 1985, 25, 585–588. [Google Scholar] [CrossRef]

- Donovan, R.C. Theoretical Melting Model for Plasticating Extruders. Polym. Eng. Sci. 1971, 11, 247–257. [Google Scholar] [CrossRef]

- Liu, H.; Luo, Y.; Zhang, G.; Chen, J.; Yang, Z.; Qu, J. Modeling of Pressure-Induced Melt Removal Melting in Vane Extruder for Polymer Processing. Adv. Polym. Tech. 2014, 33, 21452. [Google Scholar] [CrossRef]

- Celik, A.; Bonten, C.; Togni, R.; Kloss, C.; Goniva, C. A Novel Modeling Approach for Plastics Melting within a CFD-DEM Framework. Polymers 2021, 13, 227. [Google Scholar] [CrossRef] [PubMed]

- Voller, V.R.; Swaminathan, C.R.; Thomas, B.G. Fixed grid techniques for phase change problems: A review. Int. J. Numer. Methods. Eng. 1990, 30, 875–898. [Google Scholar] [CrossRef]

- He, Y.-L.; Liu, Q.; Li, Q.; Tao, W.-Q. Lattice Boltzmann methods for single-phase and solid-liquid phase-change heat transfer in porous media: A review. Int. J. Heat Mass Transf. 2019, 129, 160–197. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, X. Coupled solid-liquid phase change and thermal flow simulation by particle method. Int. Commun. Heat Mass Transf. 2020, 113, 104519. [Google Scholar] [CrossRef]

- Truex, M. Numerical Simulation of Liquid-Solid, Solid-Liquid Phase Change Using Finite Element Method in h,p,k Framework with Space-Time Variationally Consistent Integral Forms. Ph.D. Thesis, University of Kansas, Lawrence, KS, USA, 2010. [Google Scholar]

- Schawe, J.E.K.; Bergmann, E. Investigation of polymer melting by temperature modulated differential scanning calorimetry and it’s description using kinetic models. Thermochim. Acta 1997, 304–305, 179–186. [Google Scholar] [CrossRef]

- Li, Q.; Zhang, T.; Yuan, J. Numerical simulation of polymer crystal growth under flow field using a coupled phase-field and lattice Boltzmann method. Appl. Math. Comput. 2020, 387, 124302. [Google Scholar] [CrossRef]

- Ansys® Fluent, Release 18.0, Theory Guide; ANSYS, Inc.: Canonsburg, PA, USA, 2017.

- Yi, P.; Long, W.; Jia, M.; Tian, J.; Li, B. Development of a quasi-dimensional vaporization model for multi-component fuels focusing on forced convection and high temperature conditions. Int. J. Heat Mass Transf. 2016, 97, 130–145. [Google Scholar] [CrossRef]

- Bird, R.B.; Stewart, W.E.; Lightfoot, E.N. Transport Phenomena; John Wiley and Sons, Inc.: New York, NY, USA, 1960. [Google Scholar] [CrossRef]

- Frank-Kamenetskii, D.A. Diffusion and Heat Transfer in Chemical Kinetics, 2nd ed.; Plenum Press: New York, NY, USA, 1969. [Google Scholar]

- Abramzon, B.; Sirignano, W.A. Droplet vaporization model for spray combustion calculations. Int. J. Heat Mass Transf. 1989, 32, 1605–1618. [Google Scholar] [CrossRef]

- Zhang, Y.; Jia, M.; Yi, P.; Liu, H.; Xie, M. An efficient liquid film vaporization model for multi-component fuels considering thermal and mass diffusions. Appl. Therm. Eng. 2017, 112, 534–548. [Google Scholar] [CrossRef]

- Saufi, A.E.; Frassoldati, A.; Faravelli, T.; Cuoci, A. DropletSMOKE++: A comprehensive multiphase CFD framework for the evaporation of multidimensional fuel droplets. Int. J. Heat Mass Transf. 2019, 131, 836–853. [Google Scholar] [CrossRef]

- Tamim, J.; Hallett, W.L.H. A continuous thermodynamics model for multicomponent droplet vaporization. Chem. Eng. Sci. 1995, 50, 2933–2942. [Google Scholar] [CrossRef]

- Yi, P.; Zhang, H.; Yang, S. Evaluation of a non-equilibrium multi-component evaporation model for blended diesel/alcohol droplets. In Proceedings of the AIAA Scitech 2020 Forum, Orlando, FL, USA, 6–10 January 2020. [Google Scholar]

- Ju, D.; Xiao, J.; Geng, Z.; Huang, Z. Effect of mass fractions on evaporation of a multi-component droplet at dimethyl ether (DME)/n-heptane-fueled engine conditions. Fuel 2014, 118, 227–237. [Google Scholar] [CrossRef]

- Smith, J.M.; Van Ness, H.C.; Abbott, M.M.; Swihart, M.T. Introduction to Chemical Engineering Thermodynamics, 8th ed.; McGraw-Hill: New York, NY, USA, 1959. [Google Scholar]

- Fang, B.; Chen, L.; Li, G.; Wang, L. Multi-component droplet evaporation model incorporating the effects of non-ideality and thermal radiation. Int. J. Heat Mass Transf. 2019, 136, 962–971. [Google Scholar] [CrossRef]

- Govindaraju, P.B.; Ihme, M. Group contribution method for multicomponent evaporation with application to transportation fuels. Int. J. Heat Mass Transf. 2016, 102, 833–845. [Google Scholar] [CrossRef]

- Furfaro, D.; Saurel, R. Modeling droplet phase change in the presence of a multi-component gas mixture. Appl. Math. Comput. 2016, 272, 518–541. [Google Scholar] [CrossRef]

- CRECK Modeling Lab. OpenSMOKE++. Available online: https://www.opensmokepp.polimi.it/ (accessed on 2 June 2021).

- Zhu, L.-T.; Liu, Y.-X.; Luo, Z.-H. An enhanced correlation for gas-particle heat and mass transfer in packed and fluidized bed reactors. Chem. Eng. J. 2019, 374, 531–544. [Google Scholar] [CrossRef]

- Couto, N.; Silva, V.; Monteiro, E.; Teixeira, S.; Chacartegui, R.; Bouziane, K.; Brito, P.S.D.; Rouboa, A. Numerical and experimental analysis of municipal solid wastes gasification process. Appl. Therm. Eng. 2015, 78, 185–195. [Google Scholar] [CrossRef]

- Zhang, Q.; Dor, L.; Biswas, A.K.; Yang, W.; Blasiak, W. Modeling of steam plasma gasification for municipal solid waste. Fuel Process Technol. 2013, 106, 546–554. [Google Scholar] [CrossRef]

- Zhong, H.; Lan, X.; Gao, J. Numerical simulation of pitch–water slurry gasification in both downdraft single-nozzle and opposed multi-nozzle entrained-flow gasifiers: A comparative study. J. Ind. Eng. Chem. 2015, 27, 182–191. [Google Scholar] [CrossRef]

- Ranz, W.E.; Marshall, W.R., Jr. Evaporation From Drops, Part I. Chem. Eng. Prog. 1952, 48, 141–146. [Google Scholar]

- Gunn, D.J.; De Souza, J.F.C. Heat transfer and axial dispersion in packed beds. Chem. Eng. Sci. 1974, 29, 1363–1371. [Google Scholar] [CrossRef]

- Deen, N.G.; Peters, E.A.J.F.; Padding, J.T.; Kuipers, J.A.M. Review of direct numerical simulation of fluid–particle mass, momentum and heat transfer in dense gas–solid flows. Chem. Eng. Sci. 2014, 116, 710–724. [Google Scholar] [CrossRef]

- Hardy, B.; De Wilde, J.; Winckelmans, G. A penalization method for the simulation of weakly compressible reacting gas-particle flows with general boundary conditions. Comput. Fluids 2019, 190, 294–307. [Google Scholar] [CrossRef]