Analysis of Damping Characteristics of Magnetorheological Damper under Impact Load

Abstract

:1. Introduction

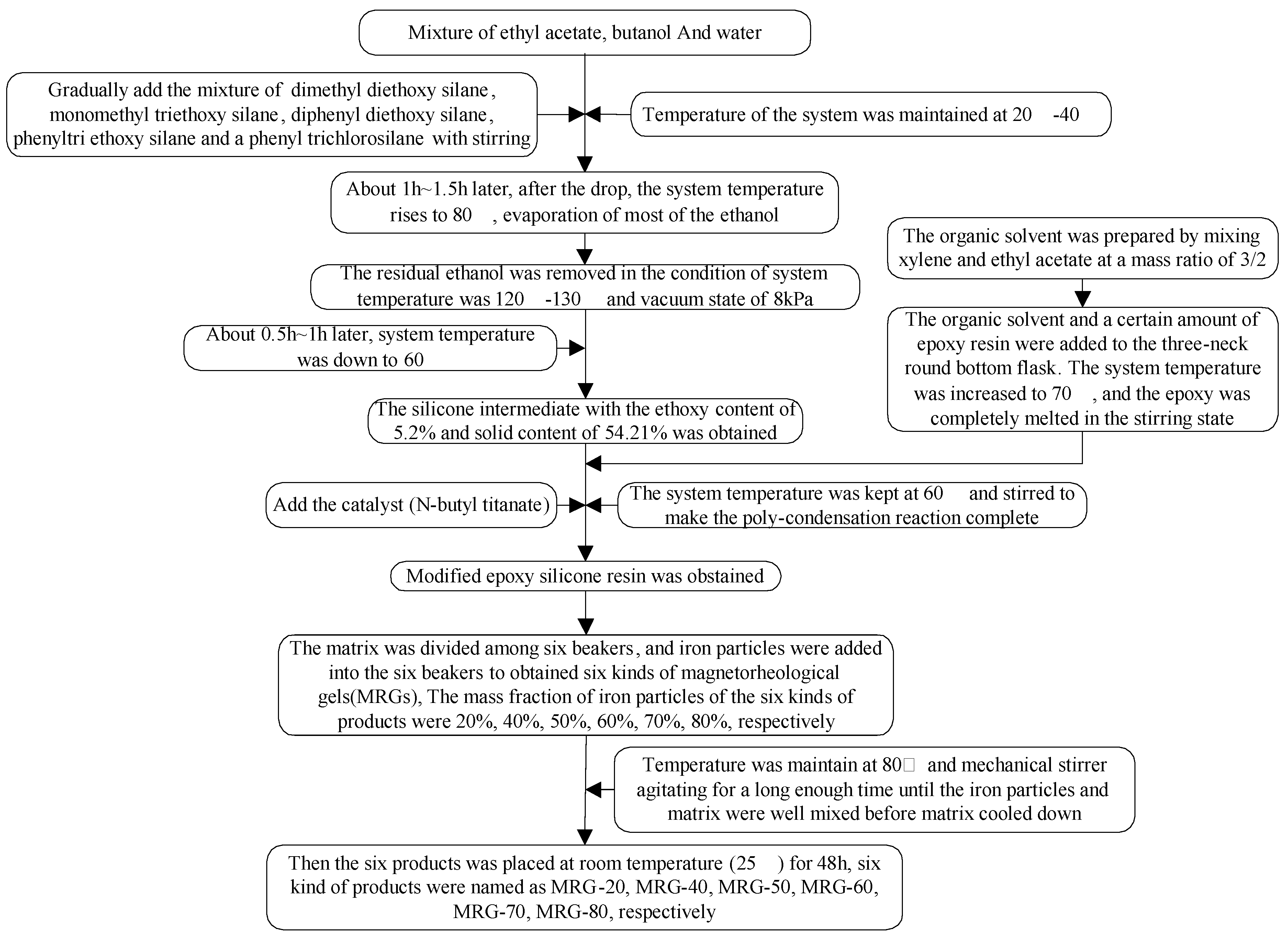

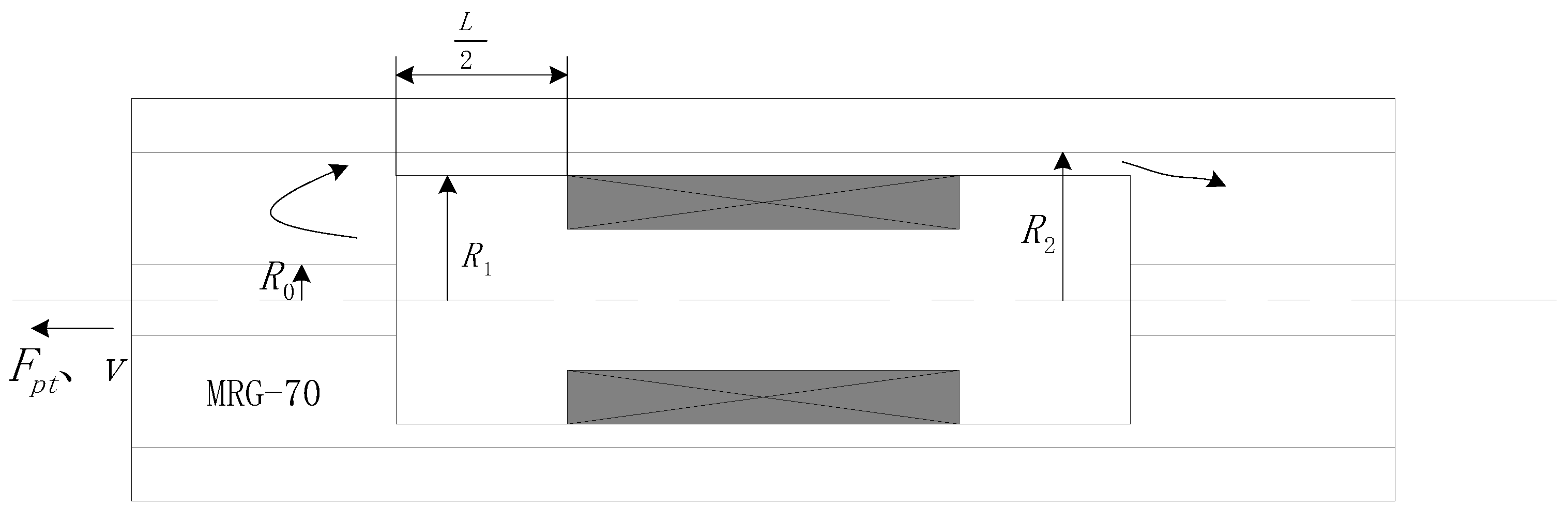

2. Sample Preparation and Model Parameter Identification

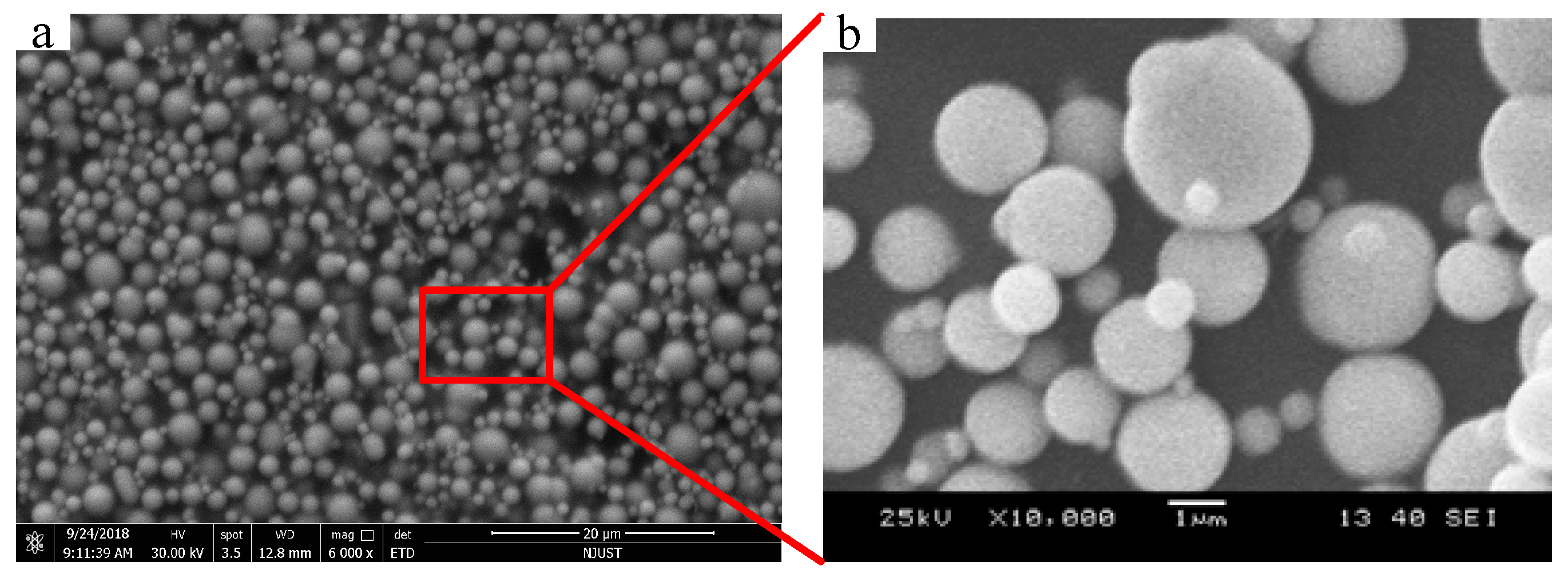

2.1. Preparation

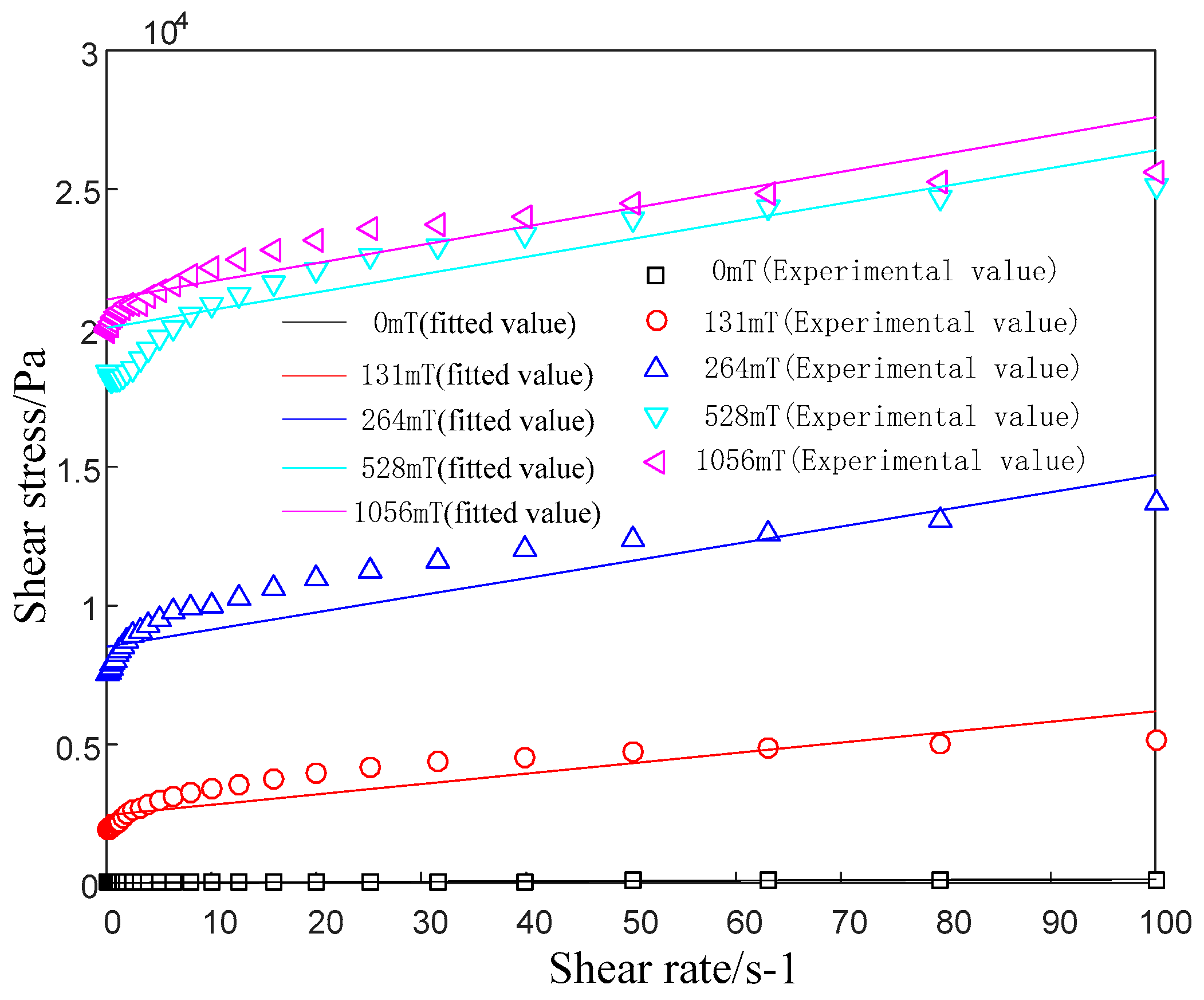

2.2. Bingham Model Parameter Identification

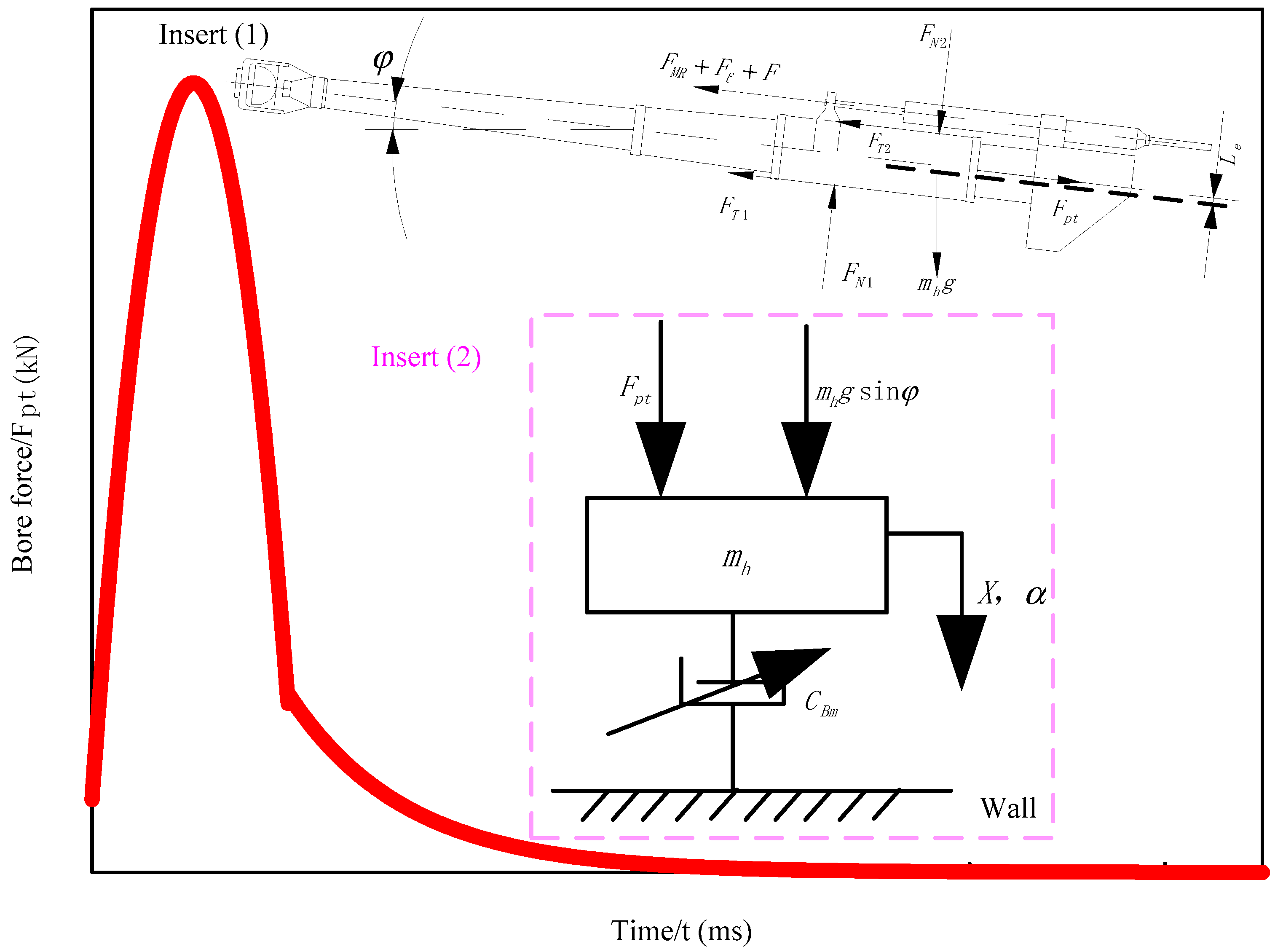

3. Dynamic Analysis for MR Damper System (Take the Anti-Recoil System of Artillery for Example)

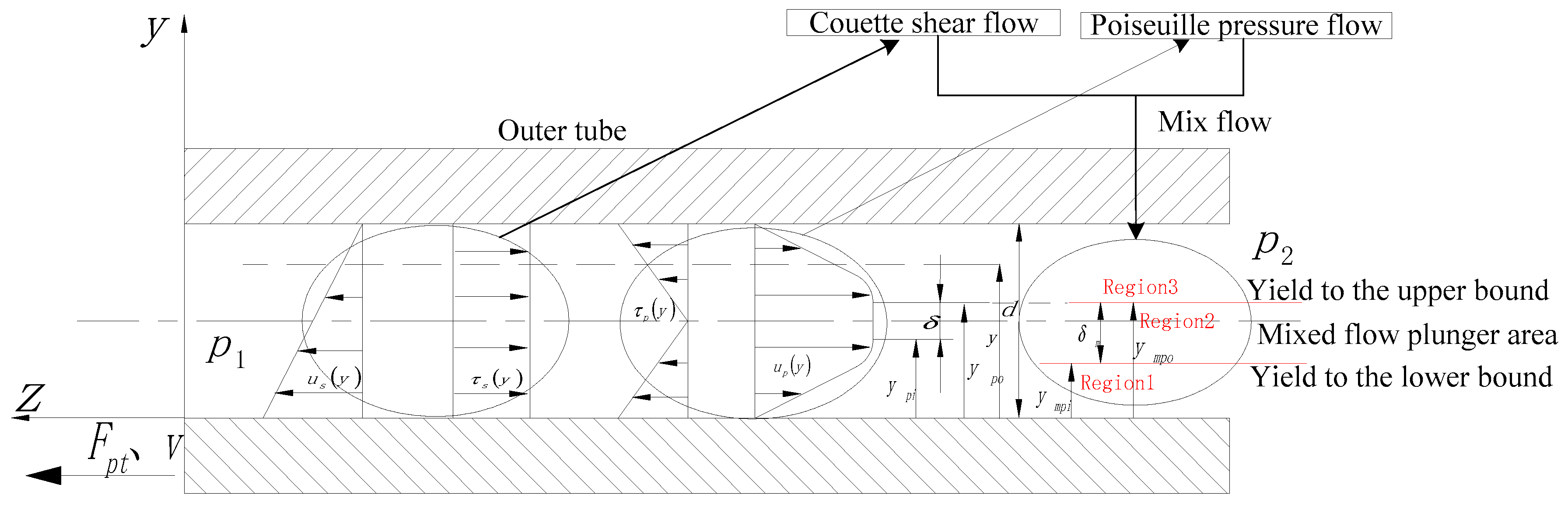

4. Analysis of the Magnetorheological Damping Coefficient

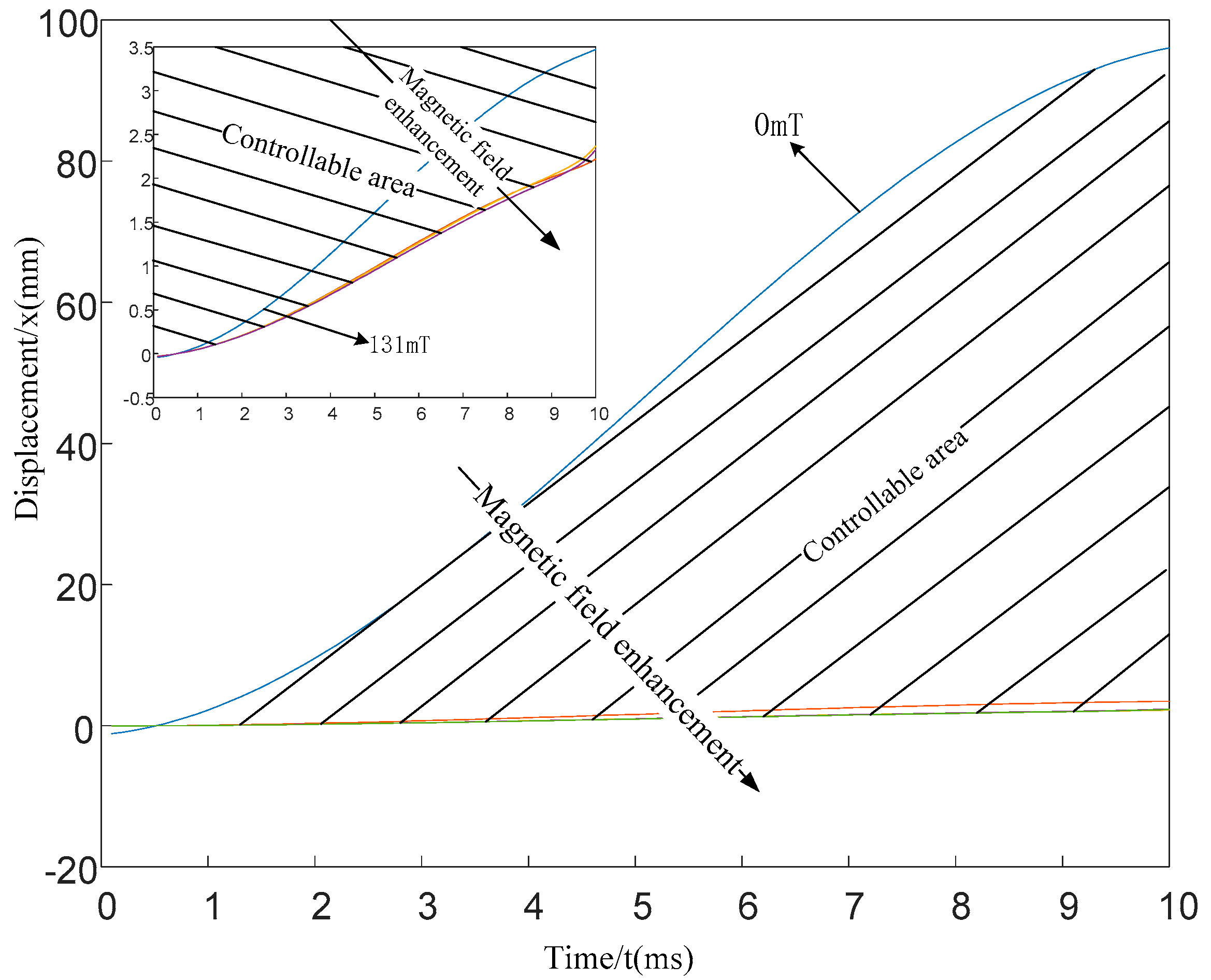

5. Theoretical Analysis of Displacement Controllable Magnetorheological Damper under Impact Environment (Take the Anti-Recoil as an Example)

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Stepanov, G.V.; Abramchuk, S.S.; Grishin, D.A.; Nikitin, L.V.; Kramarenko, E.Y.; Khokhlov, A.R. Effect of a Homogeneous Magnetic Field on the Viscoelastic Behavior of Magnetic Elastomers. Polymer 2007, 48, 488–495. [Google Scholar] [CrossRef]

- Stepanov, G.V.; Borin, D.; Raikher, Y.; Melenev, P.; Perov, N.S. Motion of ferroparticles inside the polymeric matrix in magnetoactive elastomers. J. Phys. Condens. Matter 2008, 20, 204121. [Google Scholar] [CrossRef]

- Mitsumata, T.; Honda, A.; Kanazawa, H.; Kawai, M. Magnetically Tunable Elasticity for Magnetic Hydrogels Consisting of Carrageenan and Carbonyl Iron Particles. J. Phys. Chem. B 2012, 116, 12341–12348. [Google Scholar] [CrossRef]

- Guo, F.; Cheng-Bin, D.; Guo-Jun, Y. A new magnetorheological composite gels and its controllable rheological behavior. J. Magn. Mater. Devices 2015, 46, 32–38. [Google Scholar]

- Mitsumata, T.; Ohori, S.; Chiba, N.; Kawai, M. Mika Enhancement of magnetoelastic behavior of bimodal magnetic elastomers by stress transfer via nonmagnetic particles. Soft Matter 2013, 9, 10108–10116. [Google Scholar] [CrossRef]

- Nanpo, J.; Kawai, M.; Mitsumata, T. Magnetic-field sensitivity for magnetic elastomers with various elasticities. Chem. Lett. 2016, 45, 785–786. [Google Scholar] [CrossRef]

- Plachy, T.; Rohrer, P.; Holcapkova, P. Gelatine-Coated Carbonyl Iron Particles and Their Utilization in Magnetorheological Suspensions. Materials 2021, 14, 2503. [Google Scholar] [CrossRef]

- An, H.; Sun, B.; Picken, S.; Mendes, E. Long time response of soft magnetorheological gels. J. Phys. Chem. B 2012, 116, 4702. [Google Scholar] [CrossRef]

- Zhang, G.; Wang, H.; Wang, J. Development and dynamic performance test of magnetorheological material for recoil of gun. Appl. Phys. A 2018, 124, 781. [Google Scholar] [CrossRef]

- Zhang, G.; Wang, H.; Wang, J.; Zheng, J.; Ouyang, Q. The impact of CIP content on the field-dependent dynamic viscoelastic properties of MR gels. Colloids Surf. A Physicochem. Eng. Asp. 2019, 580, 123596. [Google Scholar] [CrossRef]

- Chen, S.; Yang, J. Probing Slip Differential Heat of Magnetorheological Fluids Subjected to Shear Mode Operation and Its Effect on the Structure. Materials 2019, 12, 1860. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Yu, M.; Fu, J.; Qi, S. Investigation on the effects of doped dendritic Co particles on rheological property of magnetorheological gel. Smart Mater. Struct. 2018, 27, 105041. [Google Scholar] [CrossRef]

- Khan, M.; Pal, S. Non-adiabatic small polaron hopping and the effect of spin-polarized tunneling in electron-doped Ca0.85Nd0.15MnO3. Appl. Phys. A 2015, 119, 1443–1449. [Google Scholar] [CrossRef]

- An, H.; Picken, S.; Mendes, E. Enhanced hardening of soft self-assembled copolymer gels under homogeneous magnetic fields. Soft Matter 2010, 6, 4497–4503. [Google Scholar] [CrossRef]

- Kim, H.; Kim, H.; Kim, Y. Stiffness control of magnetorheological gels for adaptive tunable vibration absorber. Smart Mater. Struct. (Print) 2017, 26, 015016. [Google Scholar] [CrossRef]

- Ismail, M.; Ikhouane, F.; Rodellar, J. The hysteresis Bouc-Wen model, a survey. Arch. Comput. Methods Eng. 2009, 16, 161–188. [Google Scholar] [CrossRef]

- Li, Y.; Su, Z.; Luo, Y.; Wang, Y.; Luo, J.; Ji, D. Study on the Friction and Wear Properties of Magnetorheological Fluids Based on Different Lubricant Formulas. J. Supercond. Nov. Magn. 2021, 34, 943–950. [Google Scholar] [CrossRef]

- Nugroho, C.; Ubaidillah, U.; Arilasita, R.; Margono, M.; Priyambodo, B.H.; Purnama, B.; Mazlan, S.A.; Choi, S.B. The Effect of Sr-CoFe2O4 Nanoparticles with Different Particles Sized as Additives in CIP-Based Magnetorheological Fluid. Materials 2021, 14, 3684. [Google Scholar] [CrossRef]

- Pang, H.; Pei, L.; Sun, C.; Gong, X. Normal stress in magnetorheological polymer gel under large amplitude oscillatory shear. J. Rheol. 2018, 62, 1409–1418. [Google Scholar] [CrossRef]

- Yang, P.; Yu, M.; Luo, H.; Fu, J.; Qu, H.; Xie, Y. Improved rheological properties of dimorphic magnetorheological gels based on flower-like carbonyl iron particles. Appl. Surf. Sci. 2017, 416, 772–780. [Google Scholar] [CrossRef]

- An, H.; Picken, S.; Mendes, E. Direct observation of particle rearrangement during cyclic stress hardening of magnetorheological gels. Soft Matter 2012, 8, 11995–12001. [Google Scholar] [CrossRef]

- Nie, S.; Xin, D.; Ji, H.; Yin, F.L. Optimization and performance analysis of magnetorheological fluid damper considering different piston configurations. J. Intell. Mater. Syst. Struct. 2019, 30, 1045389X1982852. [Google Scholar] [CrossRef]

- Lu, J.; Gao, S.; Xiong, W.; Xu, C. Optimization of GPU parallel scheme for simulating ultrafast magnetization dynamics model. Comput. Mater. Sci. 2020, 184, 109924. [Google Scholar] [CrossRef]

- Li, Y.; Dong, D.; Wang, S.; Wu, Z.P.; Cui, C.; Li, P.G.; Li, L.H.; Xiao, J.H.; Tang, W.H. Focused ion beam fabrication and magneto-electrical transport properties of La0.6Ca0.33MnO3 nanobridge. Appl. Phys. A 2014, 115, 791–795. [Google Scholar] [CrossRef]

- Ahmadian, M.; Poynor, J. An evaluation of magneto rheological dampers for controlling gun recoil dynamics. Shock Vib. 2001, 8, 147–155. [Google Scholar] [CrossRef]

- Bajkowski, M.; Bajkowski, J. Design of the magnetorheological damper for the recoil damping of the special object 7.62 mm calibre. Mach. Dyn. Res. 2012, 36, 15–23. [Google Scholar]

- Bajkowski, M.; Makuch, A.; Lindemann, Z. Determining parameters of recoil reduction system with spring and magnetorheological damper intended for special object. Mach. Dyn. Res. 2015, 3, 065020. [Google Scholar]

- Singh, H.; Wereley, N. Optimal control of gun recoil in direct fire using magnetorheological absorbers. Smart Mater. Struct. 2014, 23, 055009. [Google Scholar] [CrossRef]

- Akiwate, D.; Gawade, S. Design and performance analysis of smart fluid damper for gun recoil system. Int. J. Adv. Mech. Eng. 2014, 4, 543–550. [Google Scholar]

- Fuchs, A.; Xin, M.; Gordaninejad, F.; Wang, X.; Hitchcock, G.H.; Gecol, H.; Evrensel, C.; Korol, G. Development and characterization of hydrocarbon polyol polyurethane and silicone magnetorheological polymeric gels. J. Appl. Polym. Sci. 2004, 92, 1176–1182. [Google Scholar] [CrossRef]

- Wilson, M.; Fuchs, A.; Gordaninejad, F. Development and characterization of magnetorheological polymer gels. J. Appl. Polym. Sci. 2002, 84, 2733–2742. [Google Scholar] [CrossRef]

- Zhang, G.; Wang, H.; Qing, O. Research on rheological properties of silicone resin-based magnetorheological glue and identification of Herschel-Bulkley model parameters. J. Hunan Univ. Nat. Sci. Ed. 2018, 45, 10. [Google Scholar]

- Becnel, A.; Hu, W.; Wereley, N. Measurement of Magnetorheological Fluid Properties at Shear Rates of up to 25,0001/s. IEEE Trans. Magn. 2012, 48, 3525–3528. [Google Scholar] [CrossRef]

- Chand, M.; Shankar, A.; Jain, K.; Pant, R.P. Improved properties of bidispersed magnetorheological fluids. RSC Adv. 2014, 4, 53960–53966. [Google Scholar]

- Ainley, L. Integrated Artillery Recoil Mechanism and Automated Handling Design for 155 mm Self-Propelled Howitzer; PACIFIC CAR AND FOUNDRY CO RENTON WA: Renton, WA, USA, 1980. [Google Scholar]

- Ristic, Z.; Ilic, S.; Davidovic, M. Defining optimal values of output parameters of the hydraulic recoil brake in the artillery weapon. Mil. Tech. Cour. 2001, 49, 580–594. [Google Scholar] [CrossRef]

- Penskii, O. Practice and theory of use of recoiling artillery cannons for the embedment of structural components. Soil Mech. Found. Eng. 2004, 41, 162–167. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, P.; Fu, J.; Zhang, X. Analysis of Anomalies in Pressure Testing of Artillery Counter-Recoil Mechanism. J. Test Meas. Technol. 2008, 22, 118–122. [Google Scholar]

- Zheng, J.; Ouyang, Q.; Li, Z.; Li, Y.; Wang, J. Experimental analysis of separately controlled multi coils on the performance of MR absorber under impact loading. J. Intell. Mater. Syst. Struct. 2016, 27, 887–897. [Google Scholar] [CrossRef]

- Lindler, J.; Wereley, N. Quasi-steady Bingham plastic analysis of an electrorheological flow mode bypass damper with piston bleed. Smart Mater. Struct. 2003, 12, 305. [Google Scholar] [CrossRef]

| Materials | Specification | Manufacturer |

|---|---|---|

| Dimethyldiethoxysilane (DDS) | 98% | Sinopharm Chemical Reagent Co., Ltd. China |

| Monomethyltriethoxysilane (MTS) | 98% | Sinopharm Chemical Reagent Co., Ltd. China |

| Diphenyldiethoxysilane | 98% | Jiangsu Sanmu Chemical Reagent Co., Ltd. China |

| Phenyldiethoxysilane (PES) | 98% | Jiangsu Sanmu Chemical Reagent Co., Ltd. China |

| Ethyl acetate | Industry | Nanjing Guochen Chemical Co., Ltd. China |

| Butanol | Industry | Nanjing Guochen Chemical Co., Ltd. China |

| water | Pure water | Nanjing Pure Water Company. China |

| Phenyltrichlorosilane | 98% | Hebei Taifeng Chemical Co., Ltd. China |

| Magnetic Field/mT | 0 | 131 | 264 | 528 | 1056 |

|---|---|---|---|---|---|

| /Pa | 6.78 | 2445.66 | 8515.72 | 20,010.39 | 21,028.84 |

| /Pa·s | 1.32 | 37.41 | 61.84 | 63.97 | 65.69 |

| Working Mode | Pressure Gradient | Boundary Conditions of Bingham Constitutive Model | ||

|---|---|---|---|---|

| Mix mode | Region2 | Region1 | Region3 | |

| Working Mode | Constitutive Model | Damping Coefficient | Bingham Coefficient |

|---|---|---|---|

| Mix flow | Bingham |

| 5 mm | 10 mm | 12 mm | 20 mm |

| Coefficient | 0 mT | 131 mT | 264 mT | 528 mT | 1056 mT |

|---|---|---|---|---|---|

| 0.13 | 3.28 | 4.15 | 4.85 | 4.91 | |

| 32.11 | 285.21 | 332.52 | 351.01 | 356.99 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, M.; Li, X.; Zhou, Z.; Zhu, Q.; Liu, B.; Chen, X.; Wang, J.; Zhang, G.; Cai, S. Analysis of Damping Characteristics of Magnetorheological Damper under Impact Load. Materials 2022, 15, 4161. https://doi.org/10.3390/ma15124161

Sun M, Li X, Zhou Z, Zhu Q, Liu B, Chen X, Wang J, Zhang G, Cai S. Analysis of Damping Characteristics of Magnetorheological Damper under Impact Load. Materials. 2022; 15(12):4161. https://doi.org/10.3390/ma15124161

Chicago/Turabian StyleSun, Min, Xiangdong Li, Zhou Zhou, Qibin Zhu, Bing Liu, Xu Chen, Jiong Wang, Guang Zhang, and Shibo Cai. 2022. "Analysis of Damping Characteristics of Magnetorheological Damper under Impact Load" Materials 15, no. 12: 4161. https://doi.org/10.3390/ma15124161

APA StyleSun, M., Li, X., Zhou, Z., Zhu, Q., Liu, B., Chen, X., Wang, J., Zhang, G., & Cai, S. (2022). Analysis of Damping Characteristics of Magnetorheological Damper under Impact Load. Materials, 15(12), 4161. https://doi.org/10.3390/ma15124161