Influence of Elbow Angle on Erosion-Corrosion of 1018 Steel for Gas–Liquid–Solid Three Phase Flow

Abstract

:1. Introduction

2. Experiment Procedure and Test Methods

3. Results and Discussion

3.1. Qualitative Paint Erosion Test

3.2. Roughness Measurements and SEM Microscopic Imaging

3.3. Mass Loss

3.4. Hardness Measurements

4. Conclusions

- In plug flow, the erosive wear increased significantly with a change in elbow angle from 60° to 90°. Compared with the 60° elbow, there was an approximately 1.8 times increase in maximum erosion rate in 90° elbows for identical flow conditions;

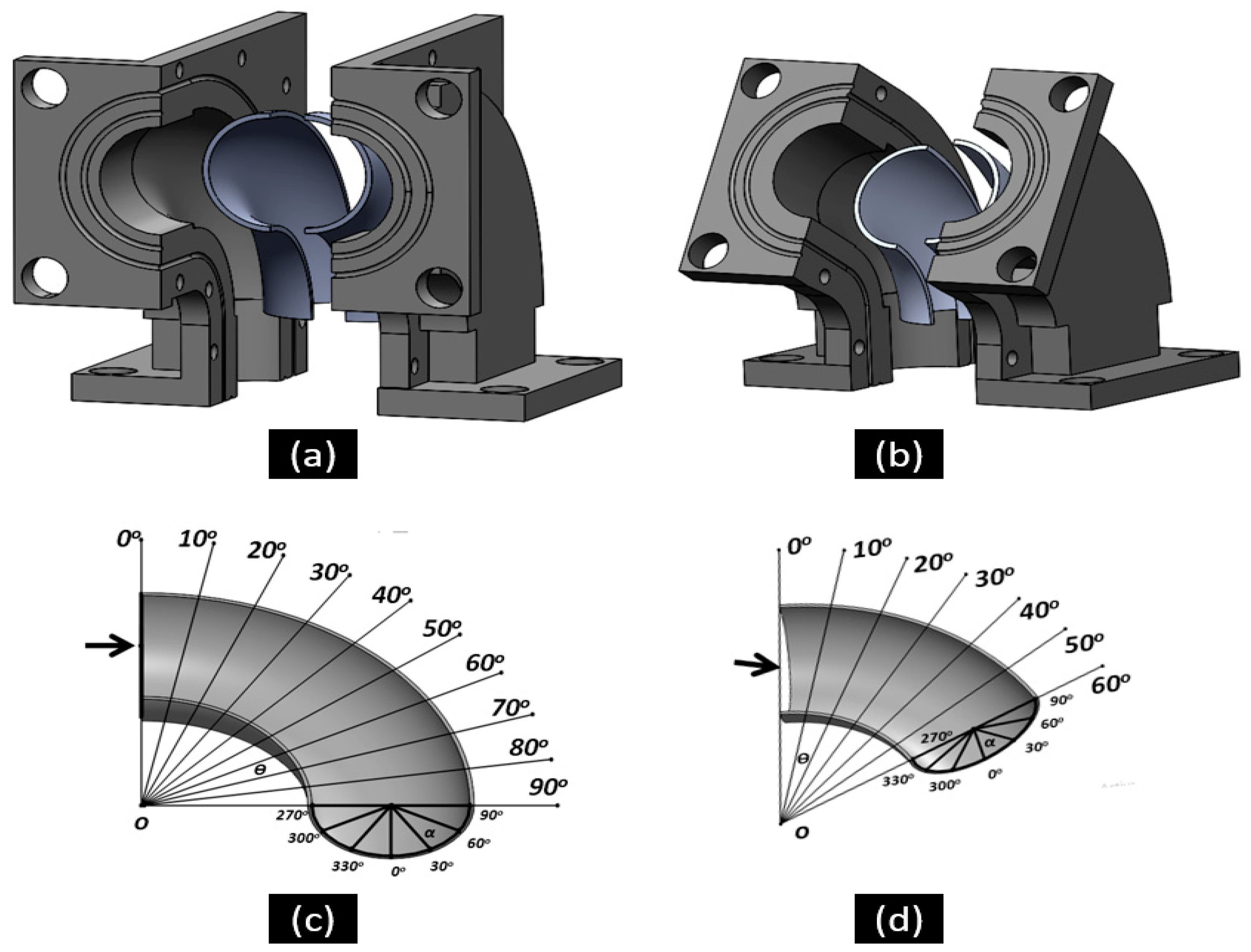

- At the top of the 90° and 60° elbows adjacent to the outlet, the erosion maximized due to the redirected flow, and the maximum silt particle impaction was identified at the outer curvature in the 50° position in the 60° elbow and the 80° position in the 90° elbow in plug flow. In the 60° elbow, the erosive wear was less because the change in the flow direction of the 60° (small angle) elbow was not as abrupt as for the 90° (wide angle) elbow;

- The arithmetic mean surfaces roughness of the samples was dramatically influenced by elbow angle. The surface roughness values and microhardness obtained showed that the surface roughness and hardness of the samples were increased on the top of the elbow compared to the bottom part at the elbow exit. The silt particle impact on the surface of the 60° and 90° elbows in the top part and the subsequent surface damage through scratching, pitting, and material removal resulted in subsequent strain hardening of the surface, which resulted in increased surface roughness and hardness;

- The microscopic study of the eroded sample showed that the primary causes of wear in the 90° elbow included pitting, ploughing, and cuttings. The microscopic images of the test specimens manifested that pitting, scratching, and indentation eventuated, which is an indication of plastic deformation due to the impact of the silt particles. The progressive effect of pitting, scratching, and indentation increased erosion in the exit of the 90° elbow pipe.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, Y.; Cao, J.; Xie, C. Research on the Wear Characteristics of a Bend Pipe with a Bump Based on the Coupled CFD-DEM. J. Mar. Sci. Eng. 2021, 9, 672. [Google Scholar] [CrossRef]

- Zhao, X.; Cao, X.; Xie, Z.; Cao, H.; Wu, C.; Bian, J. Numerical study on the particle erosion of elbows mounted in series in the gas-solid flow. J. Nat. Gas Sci. Eng. 2022, 99, 104423. [Google Scholar] [CrossRef]

- Wang, Q.; Huang, Q.; Wang, N.; Wen, Y.; Ba, X.; Sun, X.; Zhang, J.; Karimi, S.; Shirazi, S.A. An experimental and numerical study of slurry erosion behavior in a horizontal elbow and elbows in series. Eng. Fail. Anal. 2021, 130, 105779. [Google Scholar] [CrossRef]

- Wang, Q.; Ba, X.; Huang, Q.; Wang, N.; Wen, Y.; Zhang, Z.; Sun, X.; Yang, L.; Zhang, J. Modeling erosion process in elbows of petroleum pipelines using large eddy simulation. J. Pet. Sci. Eng. 2022, 211, 110216. [Google Scholar] [CrossRef]

- Khan, R.; Ya, H.H.; Pao, W.; bin Abdullah, M.Z.; Dzubir, F.A. Influence of Sand Fines Transport Velocity on Erosion-Corrosion Phenomena of Carbon Steel 90-Degree Elbow. Metals 2020, 10, 626. [Google Scholar] [CrossRef]

- Parsi, M.; Najmi, K.; Najafifard, F.; Hassani, S.; McLaury, B.S.; Shirazi, S.A. A comprehensive review of solid particle erosion modeling for oil and gas wells and pipelines applications. J. Nat. Gas Sci. Eng. 2014, 21, 850–873. [Google Scholar] [CrossRef]

- Mansouri, A.; Shirazi, S.A.; McLaury, B.S. Experimental and Numerical Investigation of the Effect of Viscosity and Particle Size on the Erosion Damage Caused by Solid Particles. In Proceedings of the ASME 2014 4th Joint US-European Fluids Engineering Division Summer Meeting collocated with the ASME 2014 12th International Conference on Nanochannels, Microchannels, and Minichannels, Chicago, IL, USA, 3 August 2014. [Google Scholar]

- Javaheri, V.; Porter, D.; Kuokkala, V.-T. Slurry erosion of steel—Review of tests, mechanisms and materials. Wear 2018, 408–409, 248–273. [Google Scholar] [CrossRef]

- Sedrez, T.A.; Rajkumar, Y.R.; Shirazi, S.A.; Khanouki, H.A.; McLaury, B.S. CFD predictions and experiments of erosion of elbows in series in liquid dominated flows. In Proceedings of the Fluids Engineering Division Summer Meeting, Montreal, QC, Canada, 15–20 July 2018; p. V003T017A001. [Google Scholar]

- Owen, J.; Ducker, E.; Huggan, M.; Ramsey, C.; Neville, A.; Barker, R. Design of an elbow for integrated gravimetric, electrochemical and acoustic emission measurements in erosion-corrosion pipe flow environments. Wear 2019, 428–429, 76–84. [Google Scholar] [CrossRef]

- Vieira, R.E.; Mansouri, A.; McLaury, B.S.; Shirazi, S.A. Experimental and computationcheckal study of erosion in elbows due to sand particles in air flow. Powder Technol. 2016, 288, 339–353. [Google Scholar] [CrossRef]

- Wang, K.; Li, X.; Wang, Y.; He, R. Numerical investigation of the erosion behavior in elbows of petroleum pipelines. Powder Technol. 2017, 314, 490–499. [Google Scholar] [CrossRef]

- Vieira, R.E.; Parsi, M.; Zahedi, P.; McLaury, B.S.; Shirazi, S.A. Sand erosion measurements under multiphase annular flow conditions in a horizontal-horizontal elbow. Powder Technol. 2017, 320, 625–636. [Google Scholar] [CrossRef]

- Naz, M.Y.; Shukrullah, S.; Noman, M.; Yaseen, M.; Naeem, M.; Sulaiman, S.A. Effect of Water-Mixed Polyvinyl Alcohol Viscosity on Wear Response of Carbon Steel Exposed to an Eroding Medium. J. Mater. Eng. Perform. 2021, 30, 2066–2073. [Google Scholar] [CrossRef]

- Cao, X.; Li, X.; Fan, Y.; Peng, W.; Xie, Z. Effect of superficial air and water velocities on the erosion of horizontal elbow in slug flow. Powder Technol. 2020, 364, 785–794. [Google Scholar] [CrossRef]

- Zahedi, P.; Parsi, M.; Asgharpour, A.; McLaury, B.S.; Shirazi, S.A. Experimental investigation of sand particle erosion in a 90° elbow in annular two-phase flows. Wear 2019, 438–439, 203048. [Google Scholar] [CrossRef]

- Khan, R.; Ya, H.H.; Pao, W.; Majid, M.A.A.; Ahmed, T.; Ahmad, A.; Alam, M.A.; Azeem, M.; Iftikhar, H. Effect of Sand Fines Concentration on the Erosion-Corrosion Mechanism of Carbon Steel 90° Elbow Pipe in Slug Flow. Materials 2020, 13, 4601. [Google Scholar] [CrossRef] [PubMed]

- Khan, R.; Ya, H.H.; Pao, W.; Khan, A. Erosion–Corrosion of 30°, 60°, and 90° Carbon Steel Elbows in a Multiphase Flow Containing Sand Particles. Materials 2019, 12, 3898. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Xu, Y.; Liu, L.; Zhou, Q.; Wang, X.; Tan, M.Y.; Huang, Y. An Overview of Major Experimental Methods and Apparatus for Measuring and Investigating Erosion-Corrosion of Ferrous-Based Steels. Metals 2020, 10, 180. [Google Scholar] [CrossRef] [Green Version]

- Elemuren, R.; Tamsaki, A.; Evitts, R.; Oguocha, I.N.A.; Kennell, G.; Gerspacher, R.; Odeshi, A. Erosion-corrosion of 90° AISI 1018 steel elbows in potash slurry: Effect of particle concentration on surface roughness. Wear 2019, 430–431, 37–49. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khan, R.; Ya, H.H.; Shah, I.; Niazi, U.M.; Ahmed, B.A.; Irfan, M.; Glowacz, A.; Pilch, Z.; Brumercik, F.; Azeem, M.; et al. Influence of Elbow Angle on Erosion-Corrosion of 1018 Steel for Gas–Liquid–Solid Three Phase Flow. Materials 2022, 15, 3721. https://doi.org/10.3390/ma15103721

Khan R, Ya HH, Shah I, Niazi UM, Ahmed BA, Irfan M, Glowacz A, Pilch Z, Brumercik F, Azeem M, et al. Influence of Elbow Angle on Erosion-Corrosion of 1018 Steel for Gas–Liquid–Solid Three Phase Flow. Materials. 2022; 15(10):3721. https://doi.org/10.3390/ma15103721

Chicago/Turabian StyleKhan, Rehan, Hamdan H. Ya, Imran Shah, Usama Muhammad Niazi, Bilal Anjum Ahmed, Muhammad Irfan, Adam Glowacz, Zbigniew Pilch, Frantisek Brumercik, Mohammad Azeem, and et al. 2022. "Influence of Elbow Angle on Erosion-Corrosion of 1018 Steel for Gas–Liquid–Solid Three Phase Flow" Materials 15, no. 10: 3721. https://doi.org/10.3390/ma15103721

APA StyleKhan, R., Ya, H. H., Shah, I., Niazi, U. M., Ahmed, B. A., Irfan, M., Glowacz, A., Pilch, Z., Brumercik, F., Azeem, M., Alam, M. A., & Ahmed, T. (2022). Influence of Elbow Angle on Erosion-Corrosion of 1018 Steel for Gas–Liquid–Solid Three Phase Flow. Materials, 15(10), 3721. https://doi.org/10.3390/ma15103721