Preparation and Characterization of Electromagnetic-Induced Rupture Microcapsules for Self-Repairing Mortars

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

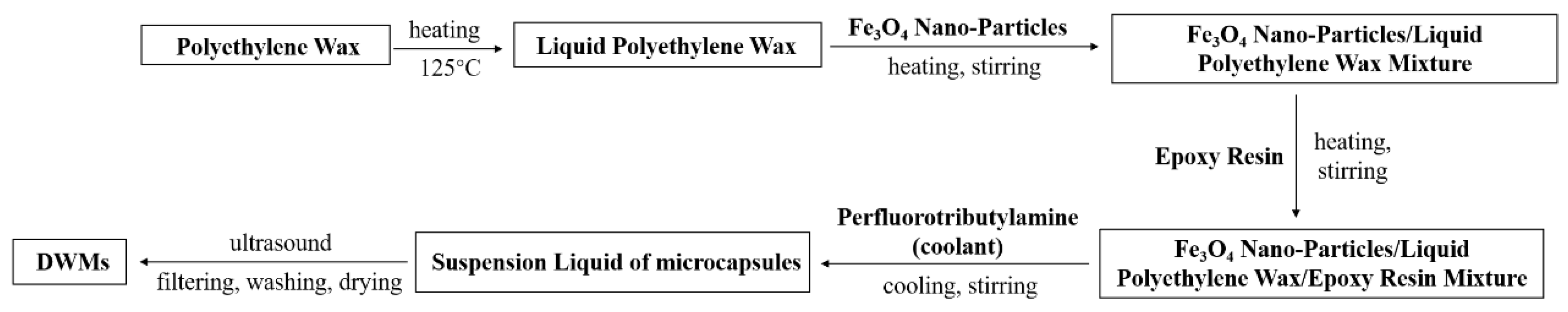

2.2. Preparation of Microcapsules

2.3. Preparation of Mortars

2.4. Measurement and Characterization

2.4.1. Core Fraction

2.4.2. Compactness of Microcapsules

2.4.3. Size Distributions

2.4.4. Morphology

2.4.5. Fourier Transform Infrared Spectroscopy (FTIR)

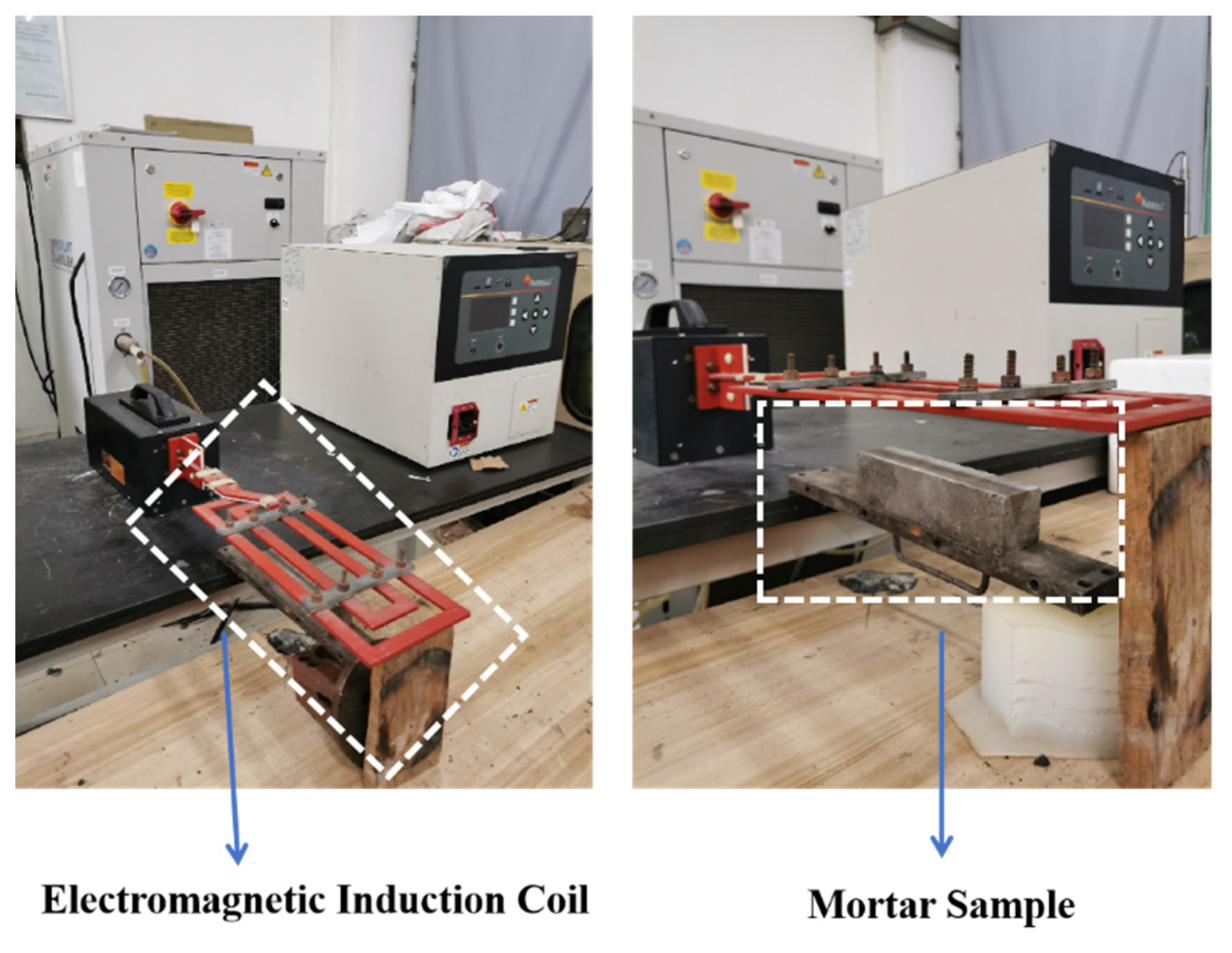

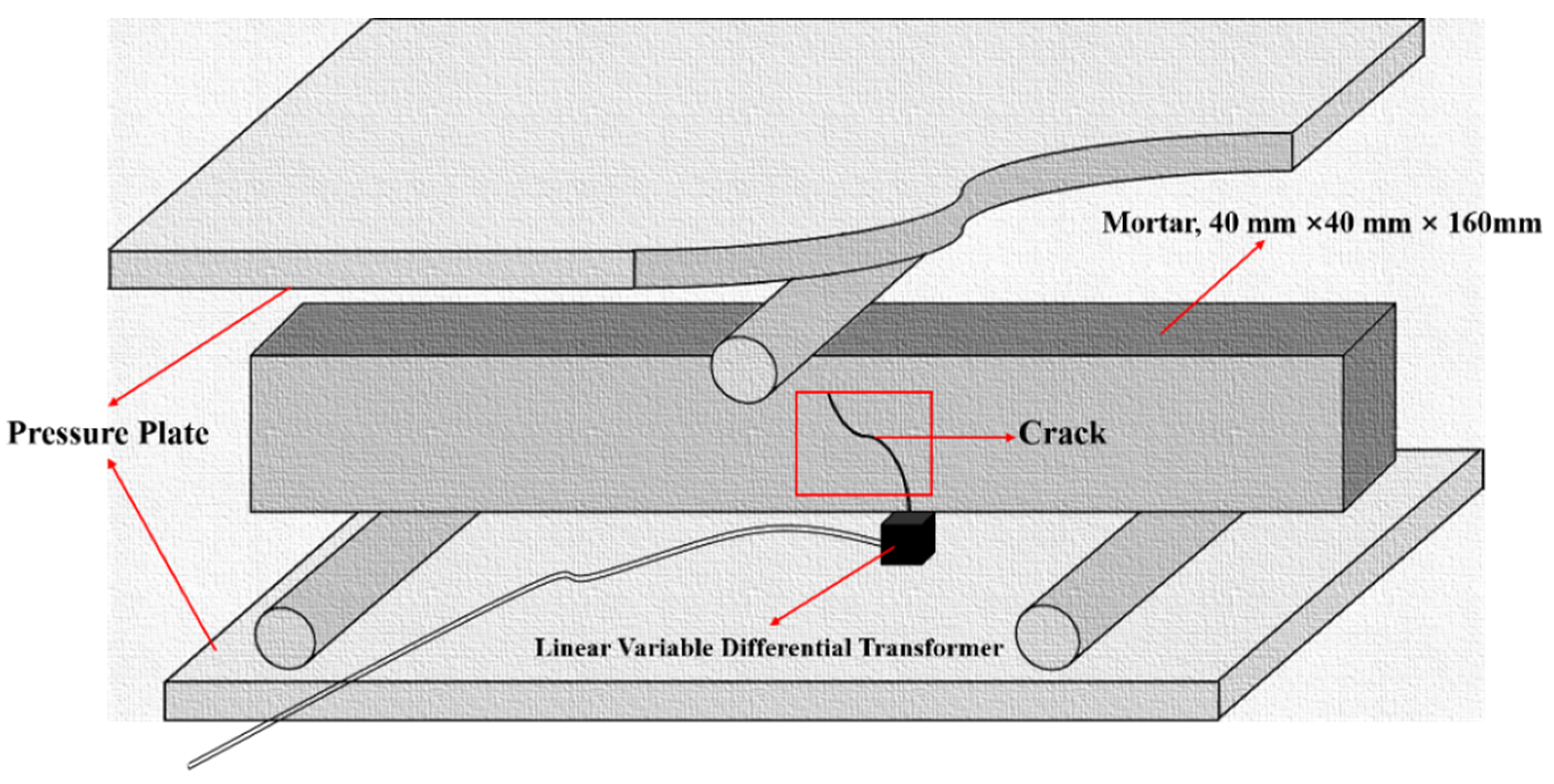

2.4.6. Self-Repairing of Pre-Damaged Mortars

2.4.7. Pore Size Distribution

2.4.8. Ultrasonic Testing

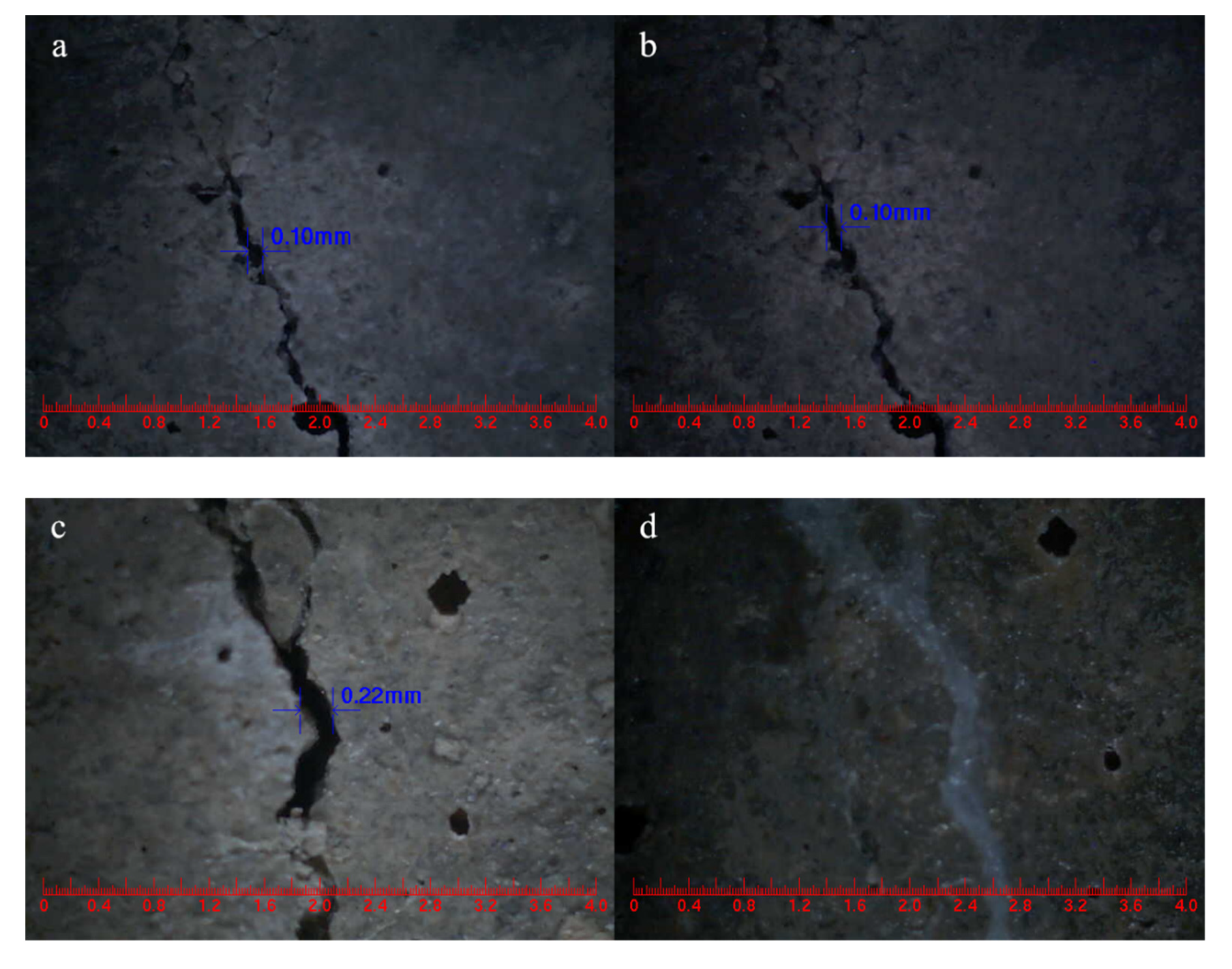

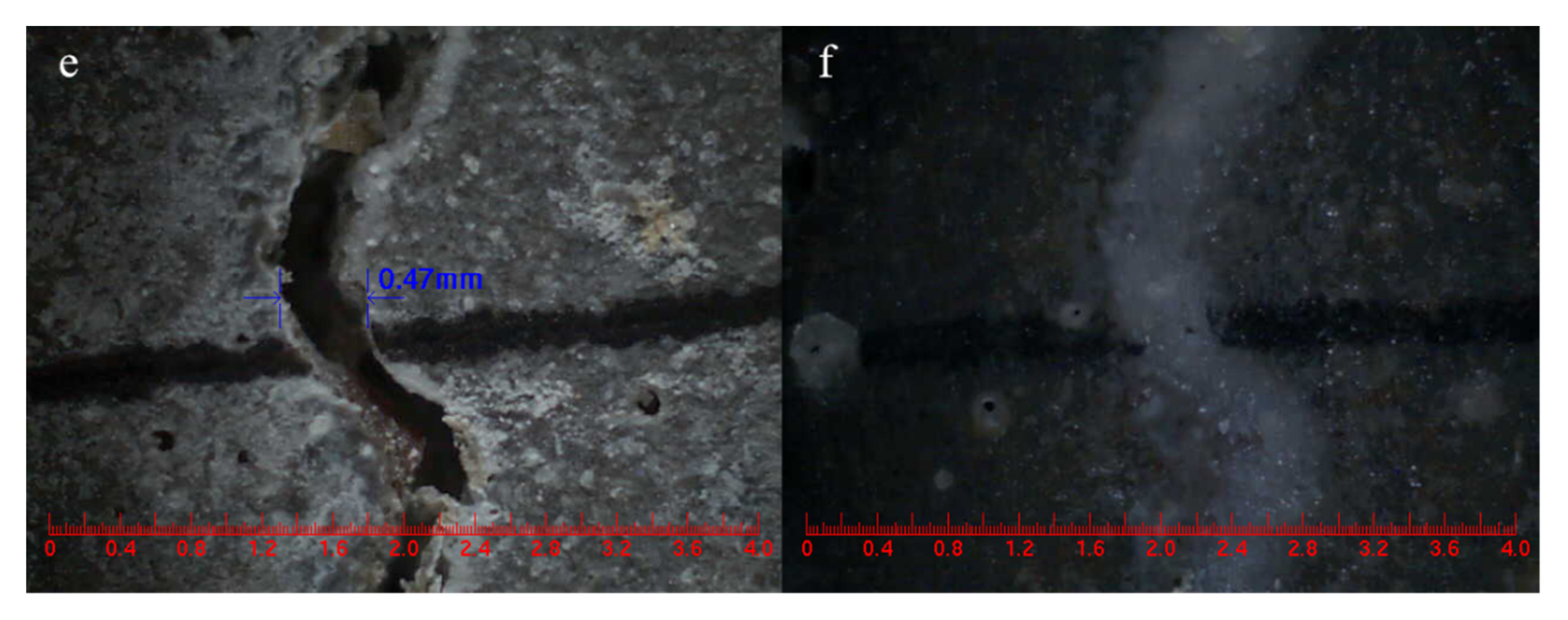

2.4.9. Surface Cracks Self-Repairing

3. Results and Discussion

3.1. Core Fraction

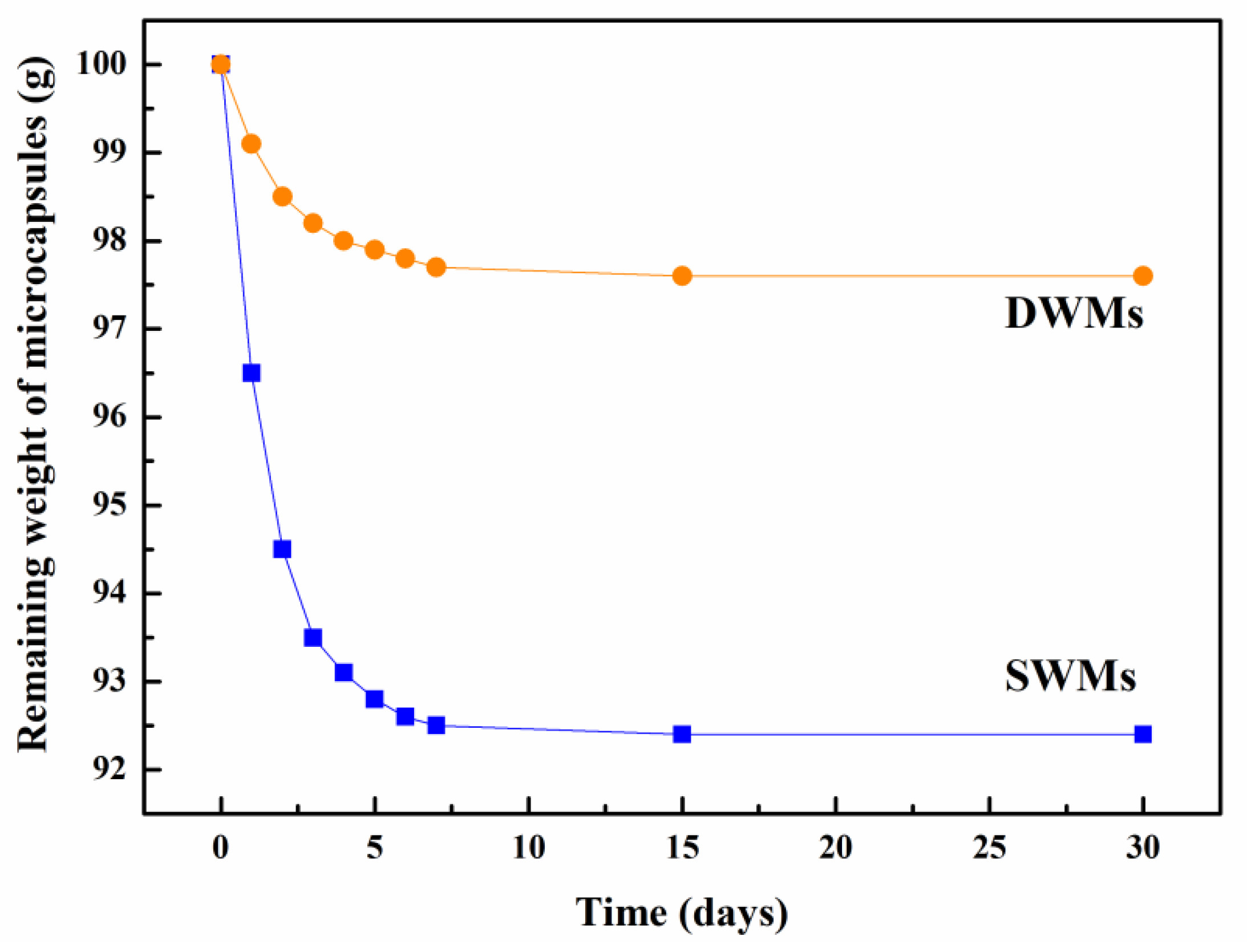

3.2. Compactness

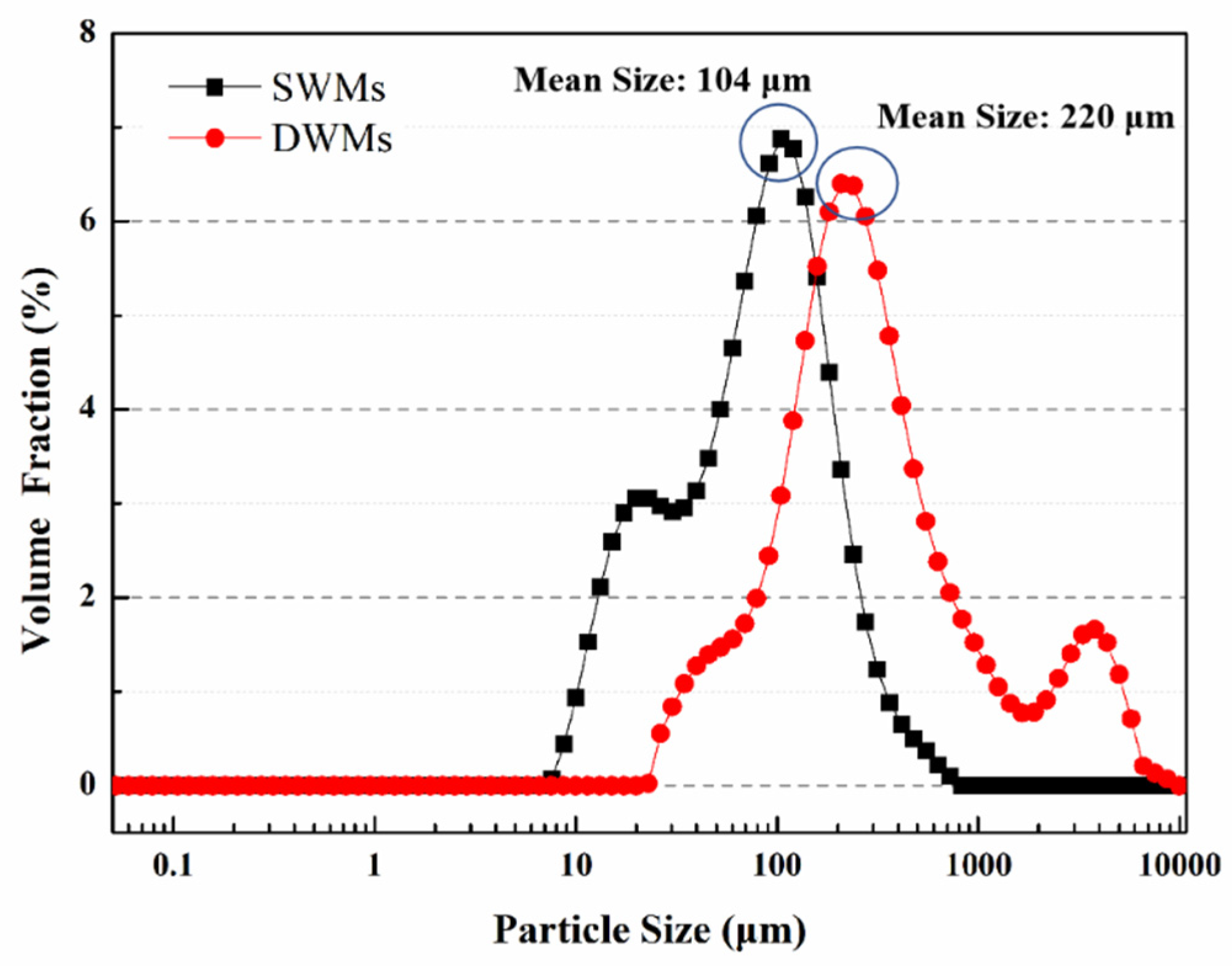

3.3. Particle Size Distributions

3.4. Morphology

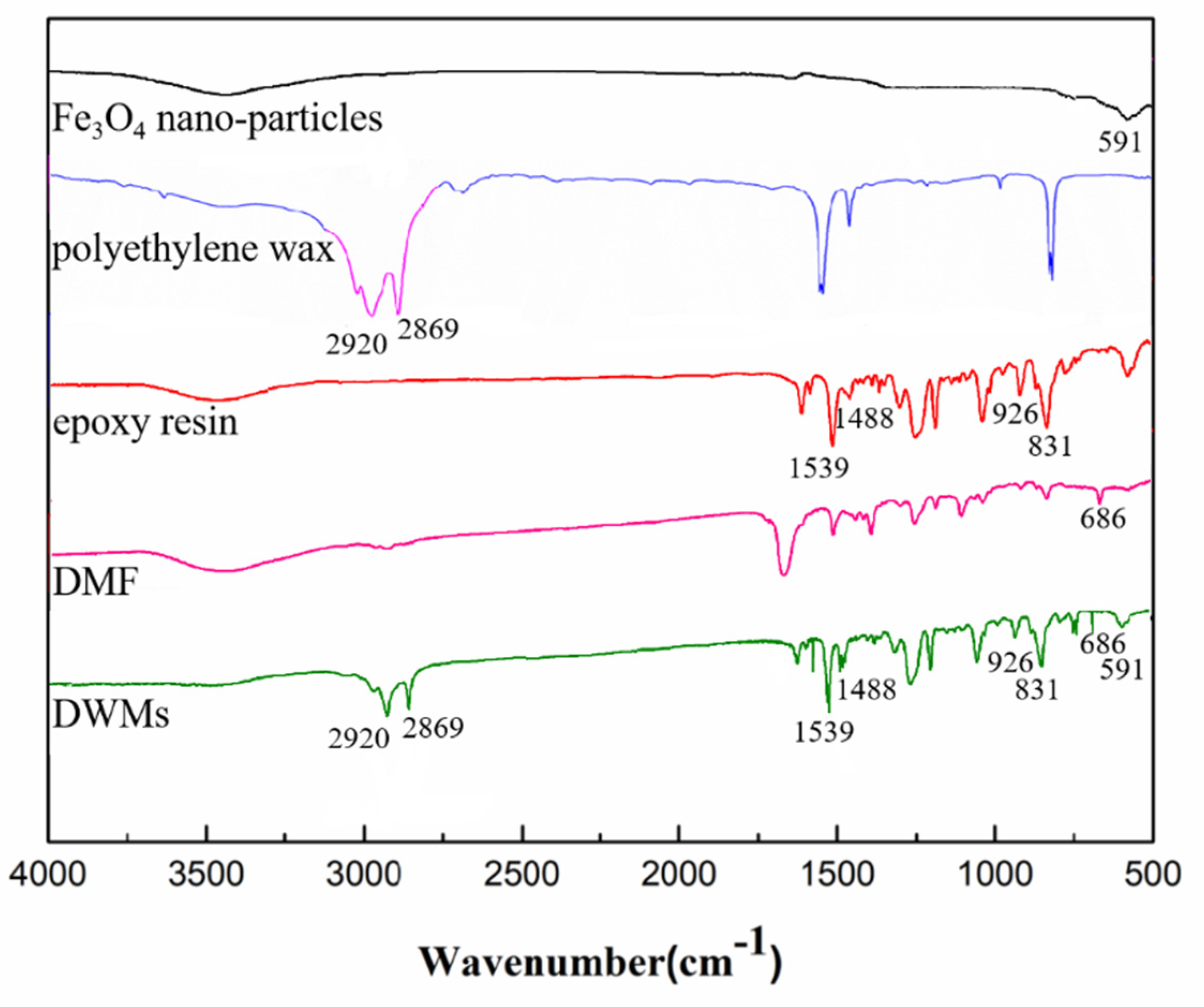

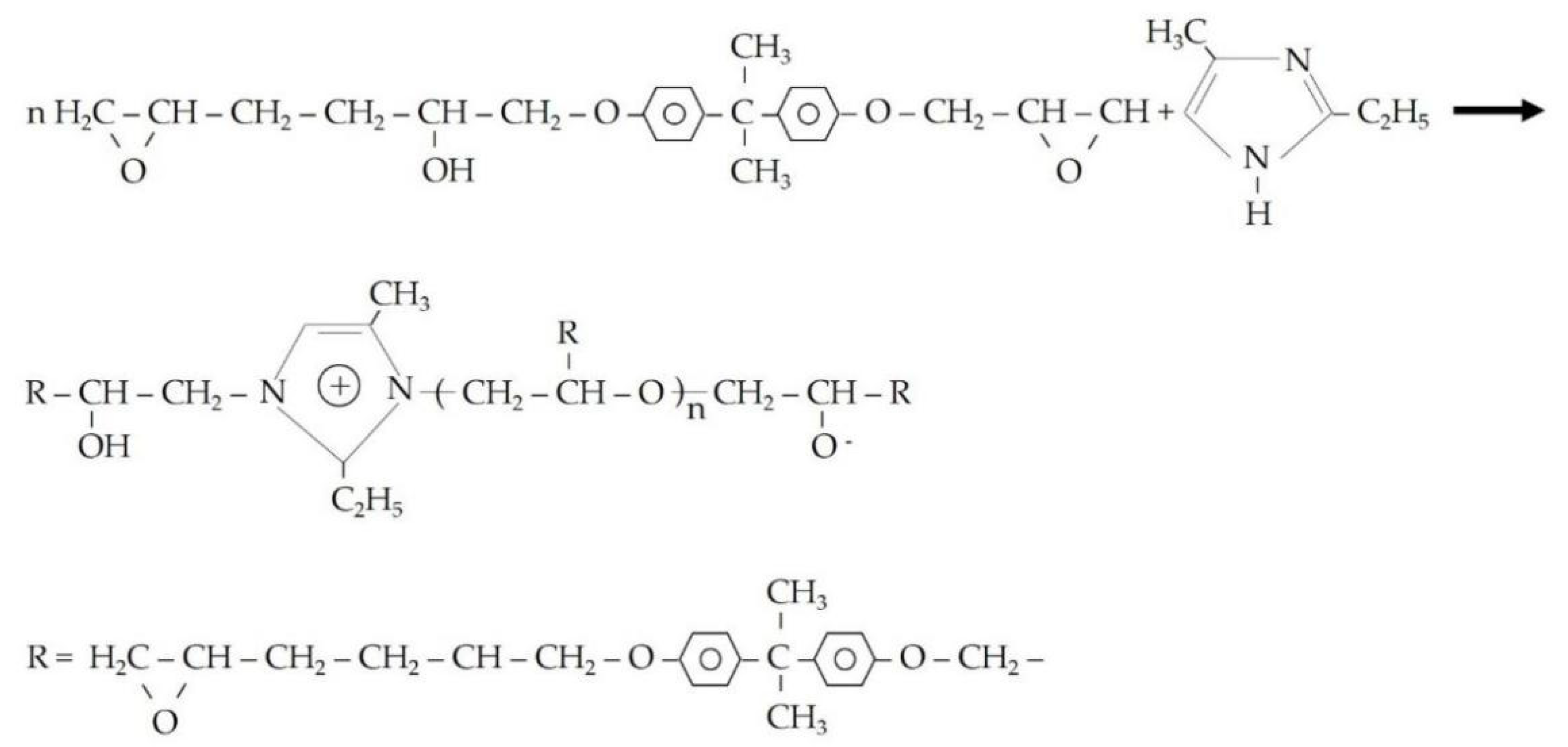

3.5. FTIR Analysis

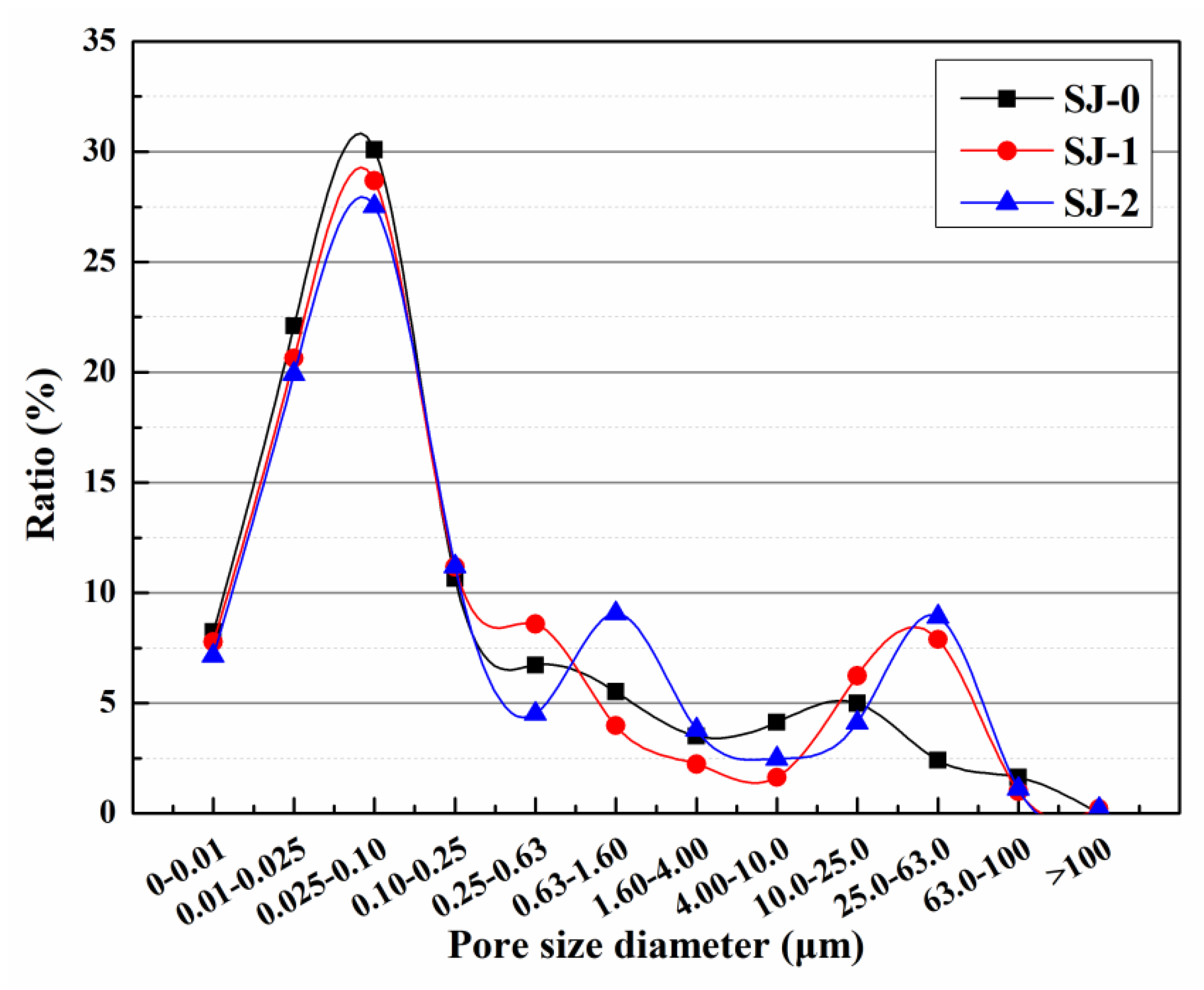

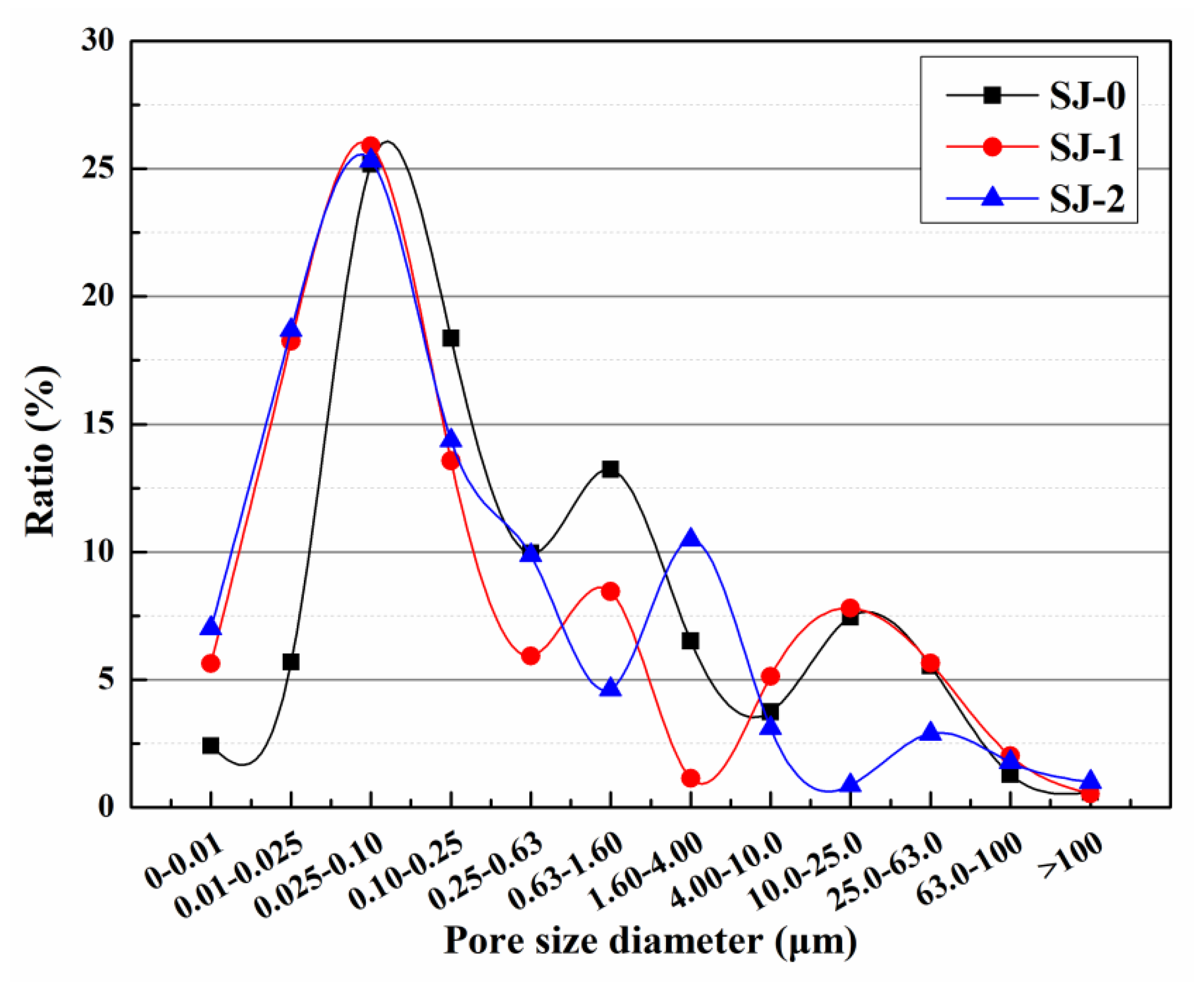

3.6. Pore Size Distribution

3.7. Flexural Strength and Compressive Strength

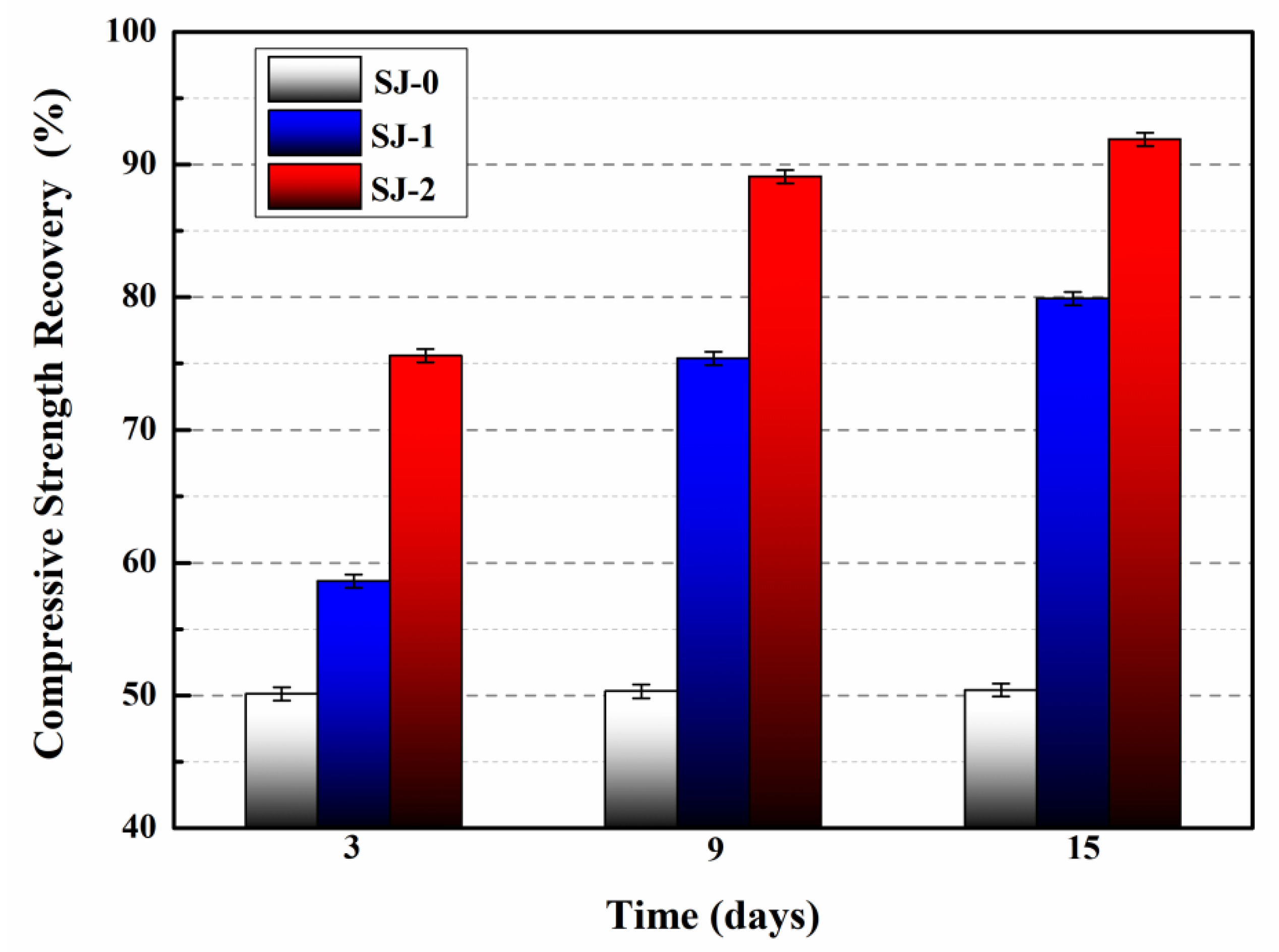

3.8. Compressive Strength Recovery

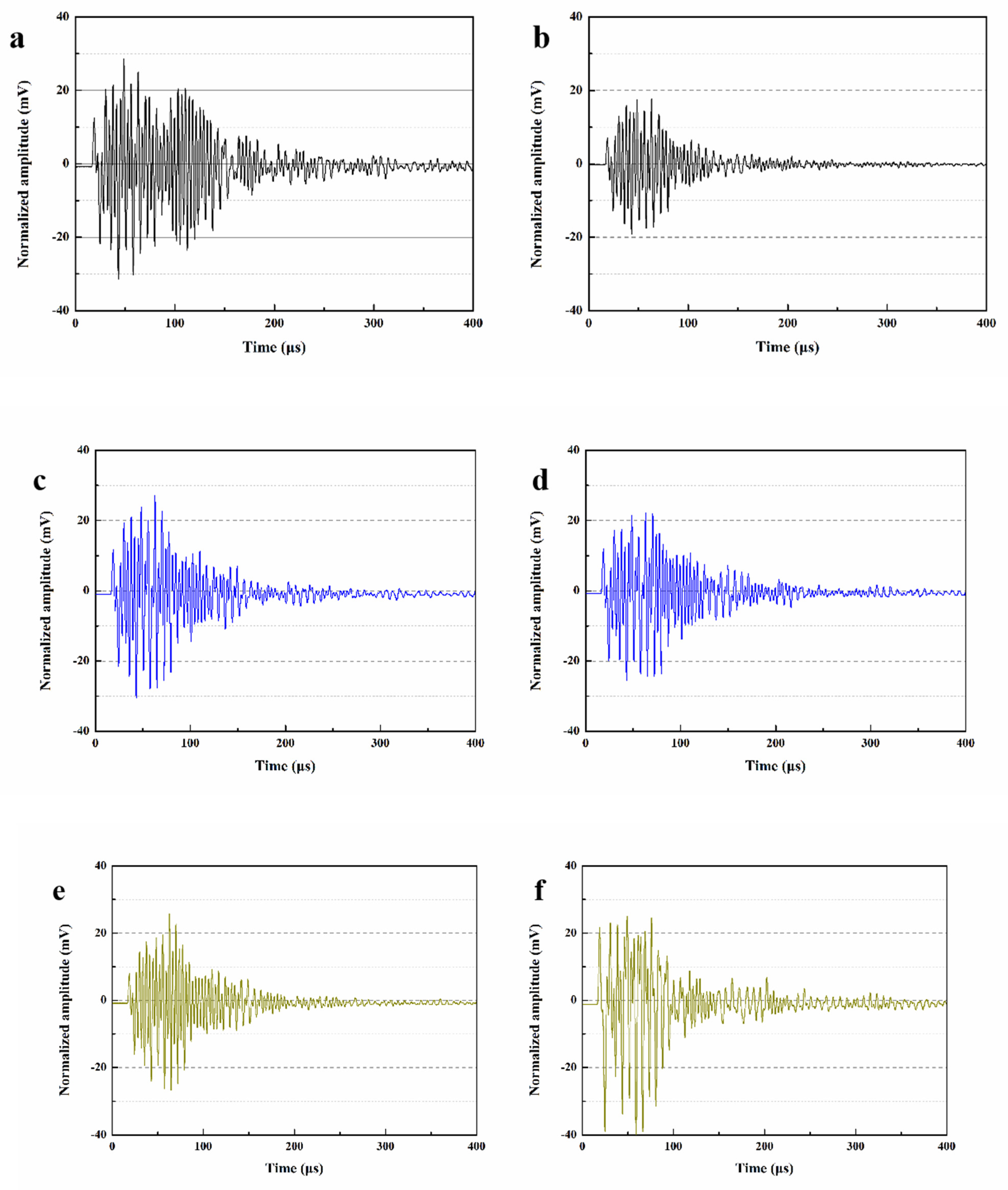

3.9. Analysis of Ultrasonic Waveform

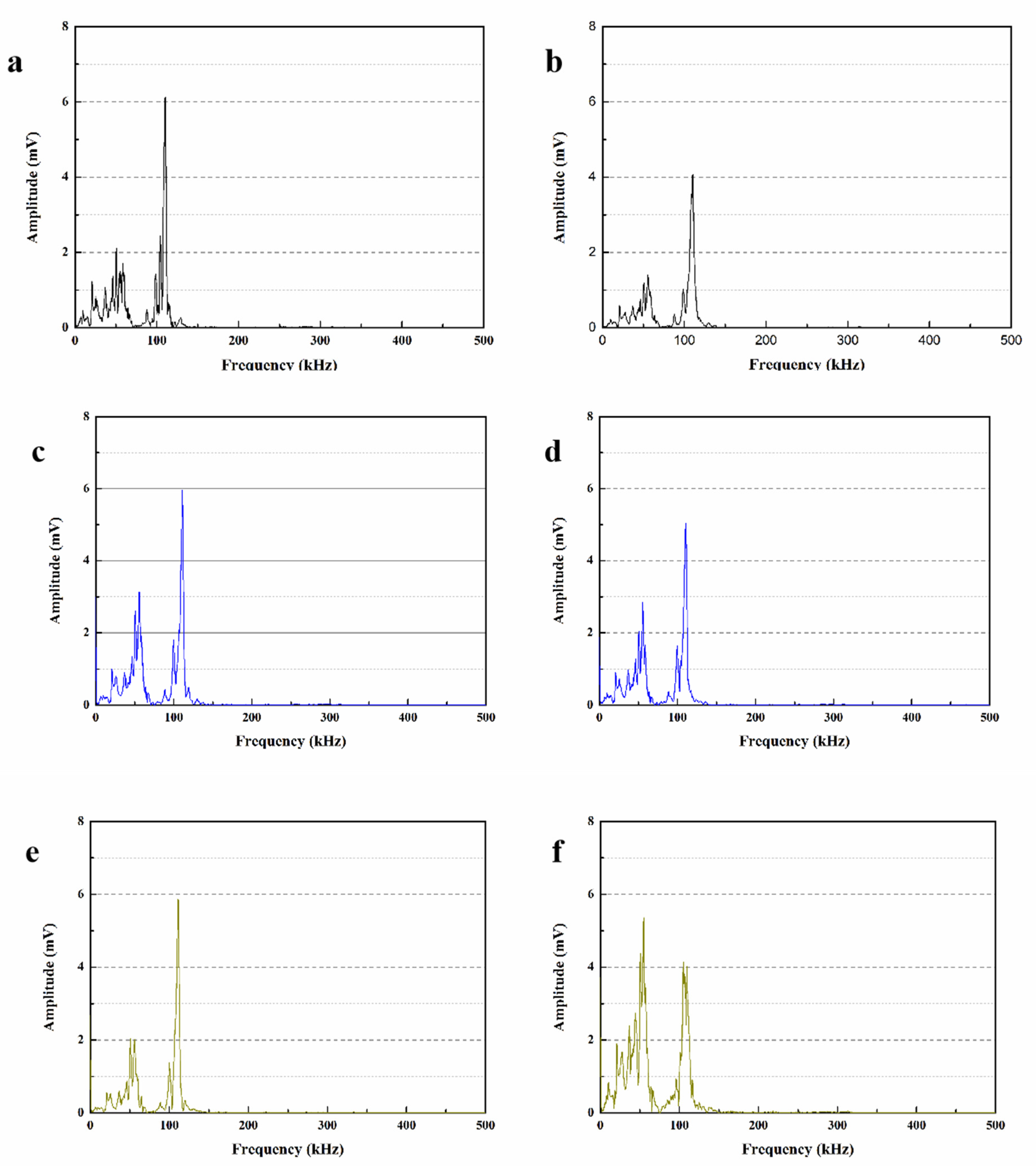

3.10. Parameters Analysis of Received Wave

3.11. Variation of Surface Cracks Repairing Ratio

3.12. Visual Crack Closure

4. Conclusions

- (1)

- It is worth noting that the core fraction, compactness, and mean particle size of DWMs were significantly higher compared to the polyethylene wax coated epoxy resin microcapsules (SWMs), which contributed to the self-repairing ability of the microcapsules. The core fraction, remaining weight (30 days), and mean size of DWMs were 72.5%, 9.6 g and 220 μm, respectively.

- (2)

- Scanning electron microscopy (SEM) showed that the DWMs were regular spherical with a rough surface, which can form a good bond with cement matrix. FTIR indicated that the epoxy resin was successfully encapsulated in the Fe3O4 nano-particles/polyethylene wax.

- (3)

- After 15 days of self-repairing, the pre-damaged mortar showed 48.97%, 91.9%, and 24.03 mV of harmful pore ratio, compressive strength recovery, and maximum amplitude, respectively. Cracks with initial widths of 0.4–0.5 mm in the mortar were self-repaired within 7 days. The results showed that the mortar containing DWMs had excellent self-repairing ability.

- (4)

- Based on the curve equations obtained from software simulations, the self-repairing of surface cracks can be predicted and monitored to calculate the crack repair ratio during the self-repairing process. This work is expected to provide new insights to address the mechanism of microcapsule rupture in self-repairing cement-based materials.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Nathaniel, O.; Sam, A.R.M.; Lim, N.H.A.S.; Adebisi, O.; Abdulkareem, M. Biogenic approach for concrete durability and sustainability using effective microorganisms: A review. Constr. Build. Mater. 2020, 261, 119664. [Google Scholar] [CrossRef]

- Wang, F.; Xie, J.; Wu, S.P.; Li, J.S.; Barbieri, D.M.; Zhang, L. Life cycle energy consumption by roads and associated interpretative analysis of sustainable policies. Renew. Sustain. Energy Rev. 2021, 141, 110823. [Google Scholar] [CrossRef]

- Owayo, A.A.; Teng, F.C.; Chen, W.C. DEM simulation of crack evolution in cement-based materials under inclined shear test. Constr. Build. Mater. 2021, 301, 124087. [Google Scholar] [CrossRef]

- Drzymała, T.; Jackiewicz-Rek, W.; Gałaj, J.; Šukys, R. Assessment of mechanical properties of high strength concrete (HSC) after exposure to high temperature. J. Civ. Eng. Manag. 2018, 24, 138–144. [Google Scholar] [CrossRef] [Green Version]

- Jackiewicz-Rek, W.; Drzymała, T.; Kuś, A.; Tomaszewski, M. Durability of high performance concrete (HPC) subject to fire temperature impact. Arch. Civ. Eng. 2016, 4, 73–93. [Google Scholar] [CrossRef] [Green Version]

- Zhang, L.V.; Nehdi, M.L.; Sumeiman, A.R.; Allaf, M.M.; Gan, M.G.; Marani, A.; Tuyan, M. Crack self-healing in bio-green concrete. Compos. Part. B Eng. 2021, 227, 109397. [Google Scholar] [CrossRef]

- Hu, J.Y.; Zhang, S.S.; Chen, E.; Li, W.G. A review on corrosion detection and protection of existing reinforced concrete (RC) structures. Constr. Build. Mater. 2022, 325, 126718. [Google Scholar] [CrossRef]

- Du, W.; Lin, R.S.; Liu, Q.T. Investigation of isophorone diisocyanate microcapsules to improve self-healing properties and sulfate resistance of concrete. Constr. Build. Mater. 2021, 300, 124438. [Google Scholar] [CrossRef]

- Ahn, E.; Kim, H.; Park, B.; Shin, M. Long-term autogenous healing and re-healing performance in concrete: Evaluation using air-coupled surface-wave method. Constr. Build. Mater. 2021, 307, 124939. [Google Scholar] [CrossRef]

- Du, W.; Liu, Q.T.; Lin, R.S.; Yu, J.Y. Influence of external environment on self-repairing ability of the cement-based materials containing paraffin/toluene-di-isocyanate microcapsules. Constr. Build. Mater. 2021, 281, 122584. [Google Scholar] [CrossRef]

- Long, W.J.; Gu, Y.; Liao, J.; Xing, F. Sustainable Design and ecological evaluation of low binder self-compacting concrete. J. Clean. Prod. 2017, 167, 317–325. [Google Scholar] [CrossRef]

- Yang, S.; Aldakheel, F.; Caggiano, A.; Wriggers, P.; Koenders, E. A Review on Cementitious Self-Healing and the Potential of Phase-Field Methods for Modeling Crack-Closing and Fracture Recovery. Materials 2020, 13, 5265. [Google Scholar] [CrossRef]

- Ziegler, F.; Masuero, A.B.; Pagnussat, D.T.; Dal Molin, D.C.C. Evaluation of internal and superfificial self-healing of cracks in concrete with crystalline admixtures. Materials 2020, 13, 4947. [Google Scholar] [CrossRef] [PubMed]

- Zheng, T.W.; Su, Y.L.; Qian, C.X.; Zhou, H.Y. Low alkali sulpho-aluminate cement encapsulated microbial spores for self-healing cement-based materials. Biochem. Eng. J. 2020, 163, 107756. [Google Scholar] [CrossRef]

- Zheng, T.W.; Su, Y.L.; Zhang, X.; Zhou, H.Y.; Qian, C.X. Effect and mechanism of encapsulation-based spores on self-healing concrete at difffferent curing ages. ACS Appl. Mater. Inter. 2020, 12, 52415–52432. [Google Scholar] [CrossRef]

- Van Tittelboom, K.; De Belie, N.; De Muynck, W.; Verstraete, W. Use of bacteria to repair cracks in concrete. Cement. Concrete. Res. 2010, 40, 157–166. [Google Scholar] [CrossRef]

- Van Tittelboom, K.; De Belie, N. Self-healing in cementitious materials—A review. Materials 2013, 6, 2182–2217. [Google Scholar] [CrossRef] [Green Version]

- Sisomphon, K.; Copuroglu, O.; Koenders, E.A.B. Self-repairing of surface cracks in mortars with expansive additive and crystalline additive. Cement. Concrete. Comp. 2012, 34, 566–574. [Google Scholar] [CrossRef]

- Roig-Flores, M.; Pirritano, F.; Serna, P.; Ferrara, L. Effect of crystalline admixtures on the self-healing capability of early-age concrete studied by means of permeability and crack closing tests. Constr. Build. Mater. 2016, 114, 447–457. [Google Scholar] [CrossRef]

- Wu, M.; Johannesson, B.; Geiker, M. A review: Self-healing in cementitious materials and engineered cementitious composite as a self-healing material. Constr. Build. Mater. 2012, 28, 571–583. [Google Scholar] [CrossRef]

- Roig-Flores, M.; Moscato, S.; Serna, P.; Ferrara, L. Self-healing capability of concrete with crystalline admixtures in different environments. Constr. Build. Mater. 2015, 86, 1–11. [Google Scholar] [CrossRef]

- Zheng, T.W.; Qian, C.X. Self-healing of later-age cracks in cement-based materials by encapsulation-based bacteria. J. Mater. Civ. Eng. 2020, 32, 04020341. [Google Scholar] [CrossRef]

- Zareie, S.; Issa, A.S.; Seethaler, R.J.; Zabihollah, A. Recent advances in the applications of shape memory alloys in civil infrastructures: A review. Structures 2020, 27, 1535–1550. [Google Scholar] [CrossRef]

- Li, W.T.; Jiang, Z.W.; Yu, Q.Q. Multiple damaging and self-healing properties of cement paste incorporating microcapsules. Constr. Build. Mater. 2020, 255, 119302. [Google Scholar] [CrossRef]

- De Belie, N.; Gruyaert, E.; Al-Tabbaa, A.; Antonaci, P.; Baera, C.; Bajare, D.; Darquennes, A.; Davies, R.; Ferrara, L.; Jefferson, T.; et al. A Review of Self-Healing Concrete for Damage Management of Structures. Adv. Mater. Interfaces 2018, 5, 1800074. [Google Scholar] [CrossRef]

- Shu, B.A.; Wu, S.P.; Dong, L.J.; Norambuena-Contreras, J.; Li, Y.Y.; Li, C.; Yang, X.; Liu, Q.T.; Wang, Q.; Wang, F.; et al. Self-healing capability of asphalt mixture containing polymeric composite fibers under acid and saline-alkali water solutions. J. Clean. Prod. 2020, 268, 122387. [Google Scholar] [CrossRef]

- White, S.R.; Sottos, N.R.; Geubelle, P.H.; Moore, J.S.; Kessler, M.R.; Sriram, S.R.; Brown, E.N.; Viswanathan, S. Autonomic healing of polymer composites. Nature 2001, 409, 794–797. [Google Scholar] [CrossRef]

- Litina, C.; Al-Tabbaa, A. First generation microcapsule-based self-healing cementitious construction repair materials. Constr. Build. Mater. 2020, 255, 119389. [Google Scholar] [CrossRef]

- Han, T.L.; Wang, X.F.; Li, D.W.; Li, D.F.; Xing, F.; Han, N.X. Impermeability characteristics of cementitious materials with self-healing based on epoxy/urea-formaldehyde microcapsules using an immersion test. Constr. Build. Mater. 2020, 259, 119782. [Google Scholar] [CrossRef]

- Tripathi, M.; Rahamtullah; Kumar, D.; Rajagopal, C.; Roy, P.K. Influence of microcapsule shell material on the mechanical behavior of epoxy composites for self-healing applications. J. Appl. Polym. Sci. 2014, 131, 40572. [Google Scholar] [CrossRef]

- Du, W.; Liu, Q.T.; Lin, R.S.; Su, X. Preparation and characterization of microcrystalline wax/epoxy resin microcapsules for self-healing of cementitious materials. Materials 2021, 14, 1725. [Google Scholar] [CrossRef] [PubMed]

- Yang, P.; Han, S.; Su, J.F.; Wang, Y.Y.; Zhang, X.L.; Han, N.X.; Li, W. Design of self-healing microcapsules containing bituminous rejuvenator with nano-CaCO3/organic composite shell: Mechanical properties, thermal stability, and compactability. Polym. Compos. 2017, 39, 1441–1451. [Google Scholar] [CrossRef]

- Du, W.; Li, E.W.; Lin, R.S. Preparation and characterization of nano-CaCO3/ceresine wax composite shell microcapsules containing E-44 epoxy resin for self-healing of cement-based materials. Nanomaterials 2022, 12, 197. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; He, J.; Li, Q.; Gao, L.; Hu, J.; Zeng, R.; Qin, J.; Wang, S.X.; Wang, Q. Self-healing of electrical damage in polymers using superparamagnetic nanoparticles. Nat. Nanotechnol. 2019, 14, 151. [Google Scholar] [CrossRef]

- Hu, S.H.; Tsai, C.H.; Liao, C.F.; Liu, D.M.; Chen, S.Y. Controlled rupture of magnetic polyelectrolyte microcapsules for drug delivery. Langmuir 2008, 24, 11811–11818. [Google Scholar] [CrossRef]

- Su, J.F.; Schlangen, E. Synthesis and physicochemical properties of high compact microcapsules containing rejuvenator applied in asphalt. Chem. Eng. J. 2012, 198–199, 289–300. [Google Scholar] [CrossRef]

- Pang, B.; Zhou, Z.H.; Hou, P.K.; Du, P.; Zhang, L.N.; Xu, H.X. Autogenous and engineered healing mechanisms of carbonated steel slag aggregate in concrete. Constr. Build. Mater. 2016, 107, 191–202. [Google Scholar] [CrossRef]

- Wu, Z.W.; Lian, H.Z. High Performance Concrete; China Railway Publishing House: Beijing, China, 1999; pp. 24–25. [Google Scholar]

- Du, W.; Liu, Q.T.; Lin, R.S. Effects of toluene-di-isocyanate microcapsules on the frost resistance and self-repairing capability of concrete under freeze-thaw cycles. J. Build. Eng. 2021, 44, 102880. [Google Scholar] [CrossRef]

- Sotiriadis, K.; Mácová, P.; Mazur, A.S.; Viani, A.; Tolstoy, P.M. Long-term thaumasite sulfate attack on portland-limestone cement concrete: A multi-technique analytical approach for assessing phase assemblage. Cement. Concrete. Res. 2020, 130, 105995. [Google Scholar] [CrossRef]

- Wang, X.F.; Xing, F.; Zhang, M. Experimental study on cementitious composites embedded with organic microcapsules. Materials 2013, 6, 4064–4081. [Google Scholar] [CrossRef]

- Xu, D.Y.; Huang, S.F.; Qin, L.; Lu, L.C.; Cheng, X. Monitoring of cement hydration reaction process based on ultrasonic technique of piezoelectric composite transducer. Constr. Build. Mater. 2012, 35, 220–226. [Google Scholar]

- Yuan, L.W.; Chen, S.S.; Wang, S.D.; Huang, Y.B.; Yang, Q.K.; Liu, S.; Wang, J.B.; Du, P.; Cheng, X.; Zhou, Z.H. Research on the improvement of concrete autogenous self-healing based on the regulation of cement particle size distribution (PSD). Materials 2019, 12, 2818. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Microcapsule | Shell Material Using by Mass Ratio | Heating Temperature | Stirring Rate | Core Material Using by Mass Ratio |

|---|---|---|---|---|

| SWMs | Polyethylene Wax, 40 | 125 °C | 900 rpm | epoxy resin, 60 |

| DWMs | Polyethylene Wax, 35; Fe3O4 nano-particles, 5 | 125 °C | 900 rpm | epoxy resin, 60 |

| Mortars | Cement | Sand | Water | Microcapsules |

|---|---|---|---|---|

| SJ-0 | 100 | 50 | 300 | 0 |

| SJ-1 | 100 | 50 | 300 | 3 (SWMs) |

| SJ-2 | 100 | 50 | 300 | 3 (DWMs) |

| Microcapsule | Core Content |

|---|---|

| SWMs | 64.9% |

| DWMs | 72.5% |

| Mortars | Flexural Strength | Compressive Strength |

|---|---|---|

| SJ-0 | 8.2 MPa | 33.4 MPa |

| SJ-1 | 7.9 MPa | 32.6 MPa |

| SJ-2 | 7.5 MPa | 30.9 MPa |

| Mortars | Widths | Fitting Line | R2 |

|---|---|---|---|

| SJ-1 | 0–0.1 mm | y = (98.26x2 + 198.6x + 99.52)/(x2 + 1.96x + 0.99) | 0.9999 |

| 0.1–0.2 mm | y = (99.22x2 + 190.9x + 91.67)/(x2 + 1.88x + 0.92) | 0.9999 | |

| 0.2–0.3 mm | y = (84.73x2 + 315.4x + 218.6)/(x2 + 12.84x + 2.24) | 0.9984 | |

| 0.3–0.4 mm | y = (1463x2 + 497,500x + 457,700)/(x2 + 4386x + 5776) | 0.9965 | |

| 0.4–0.5 mm | y = (191,800x2 + 1,028,000x + 939,000)/(x2 + 8521x + 13,530) | 0.9901 | |

| SJ-2 | 0–0.1 mm | y = (5722x + 5267)/(x2 + 55.16x + 52.77) | 0.9945 |

| 0.1–0.2 mm | y = (96.11x2 + 262.2x + 159.9)/(x2 + 2.524x + 1.604) | 0.9913 | |

| 0.2–0.3 mm | y = (138,300x2 − 2,350,000x + 2,279,000)/(x2 + 20,640x + 22,840) | 0.9913 | |

| 0.3–0.4 mm | y = (304,900x2 − 2,815,000x − 2,848,000)/(x2 − 22,230x − 28,920) | 0.9861 | |

| 0.4–0.5 mm | y = (889x + 818.2)/(x2 + 6.463x + 9.078) | 0.9945 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, E.; Du, W.; Zhuang, R.; Ba, M.; Yuan, L.; Zhang, Q.; Zhang, Y. Preparation and Characterization of Electromagnetic-Induced Rupture Microcapsules for Self-Repairing Mortars. Materials 2022, 15, 3608. https://doi.org/10.3390/ma15103608

Li E, Du W, Zhuang R, Ba M, Yuan L, Zhang Q, Zhang Y. Preparation and Characterization of Electromagnetic-Induced Rupture Microcapsules for Self-Repairing Mortars. Materials. 2022; 15(10):3608. https://doi.org/10.3390/ma15103608

Chicago/Turabian StyleLi, Erwang, Wei Du, Ronghua Zhuang, Mingfang Ba, Lianwang Yuan, Qian Zhang, and Yuepin Zhang. 2022. "Preparation and Characterization of Electromagnetic-Induced Rupture Microcapsules for Self-Repairing Mortars" Materials 15, no. 10: 3608. https://doi.org/10.3390/ma15103608

APA StyleLi, E., Du, W., Zhuang, R., Ba, M., Yuan, L., Zhang, Q., & Zhang, Y. (2022). Preparation and Characterization of Electromagnetic-Induced Rupture Microcapsules for Self-Repairing Mortars. Materials, 15(10), 3608. https://doi.org/10.3390/ma15103608