Mechanical and Durability Performance of Coconut Fiber Reinforced Concrete: A State-of-the-Art Review

Abstract

:1. Introduction

2. Physical Properties of Coconut Fibers

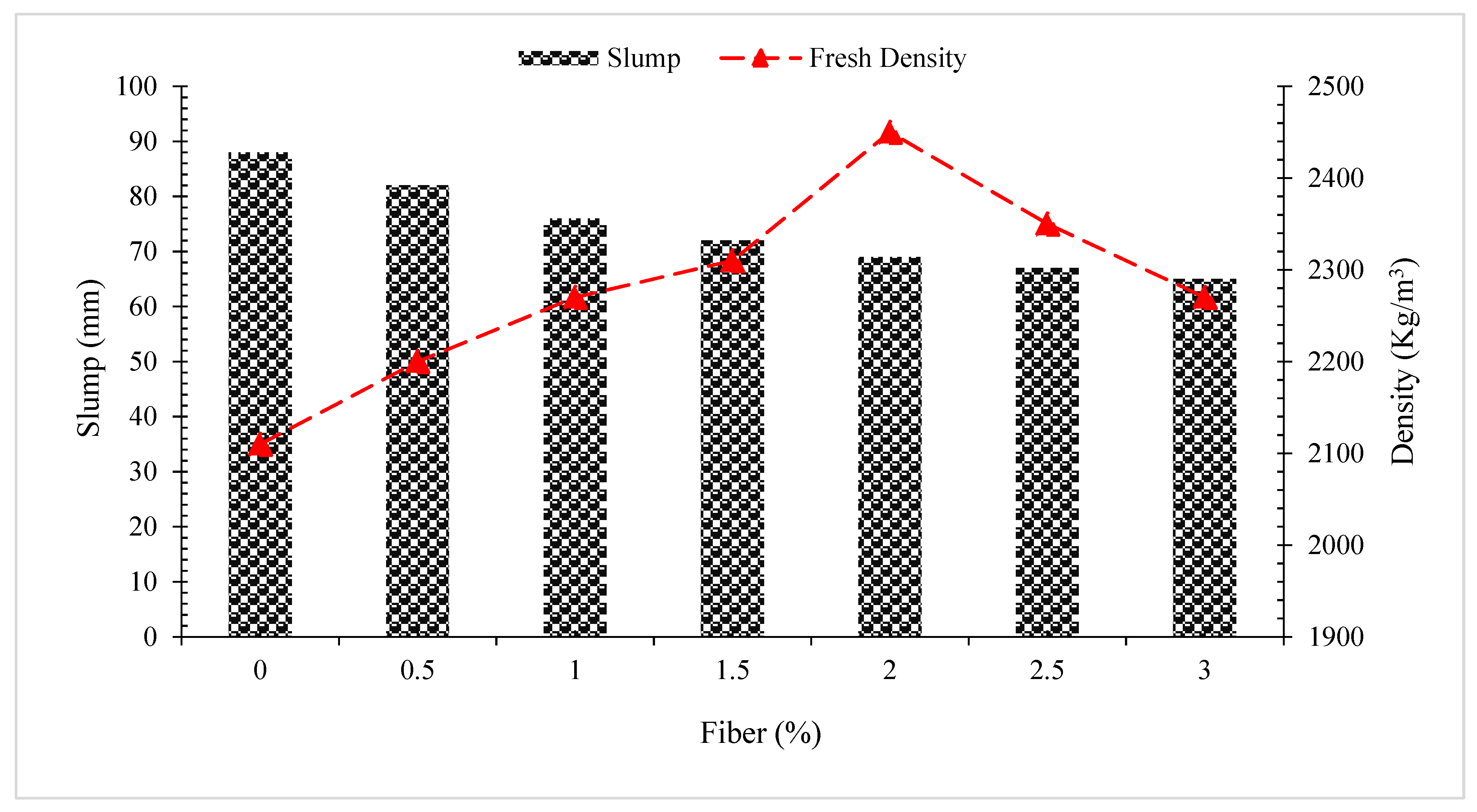

3. Fresh Properties

4. Treatment of Coconut Fibers

5. Mechanical Properties

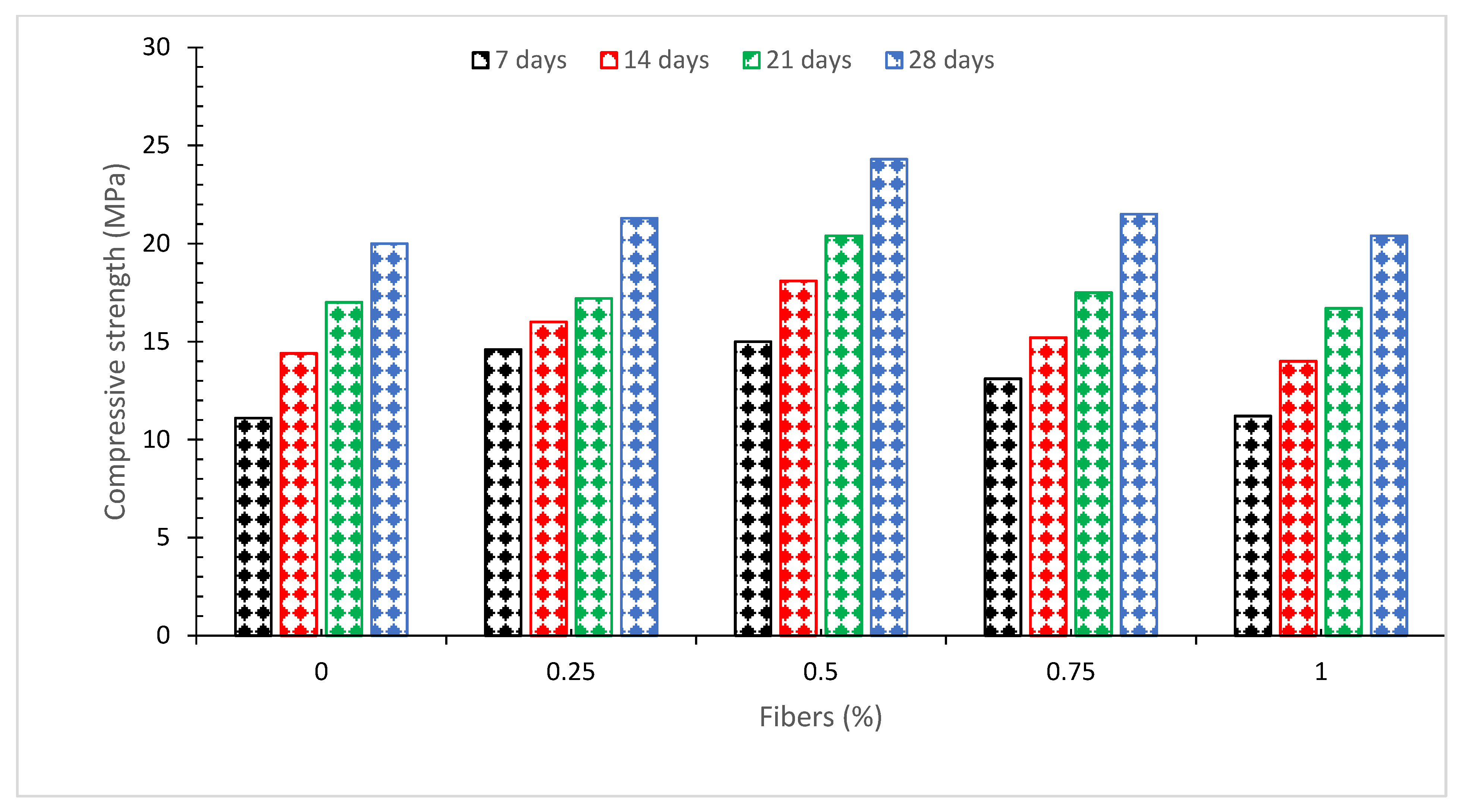

5.1. Compressive Strength

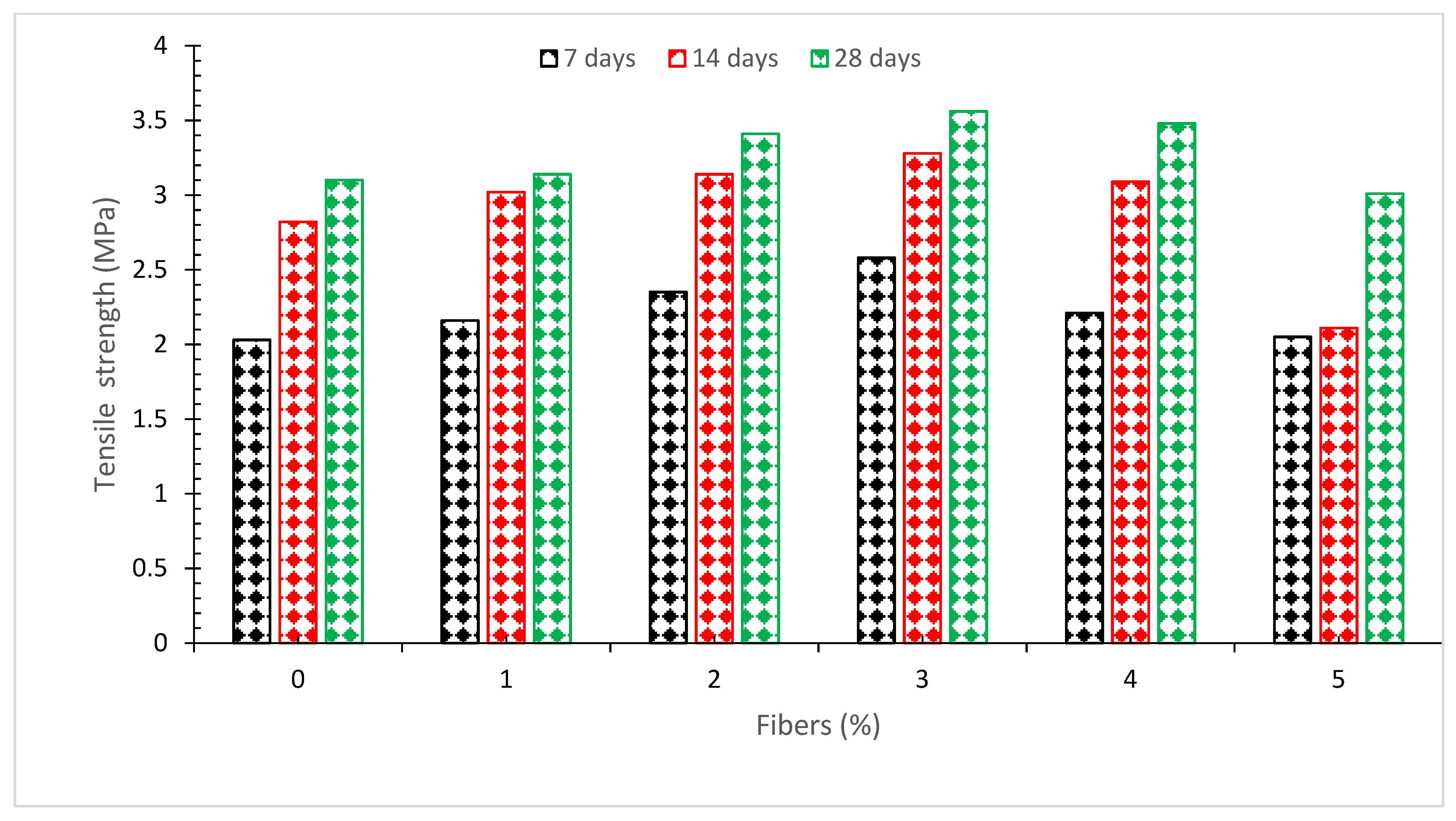

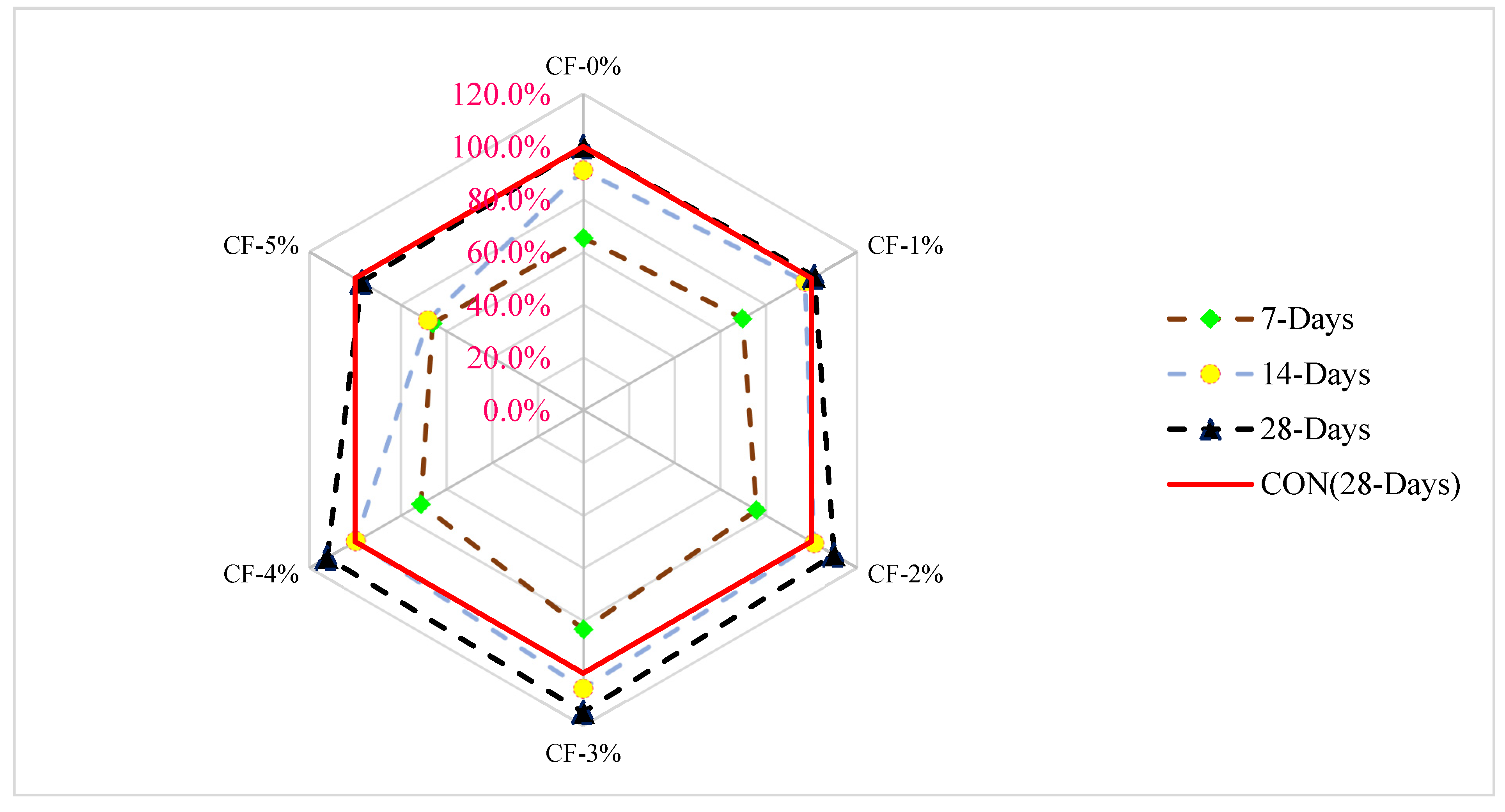

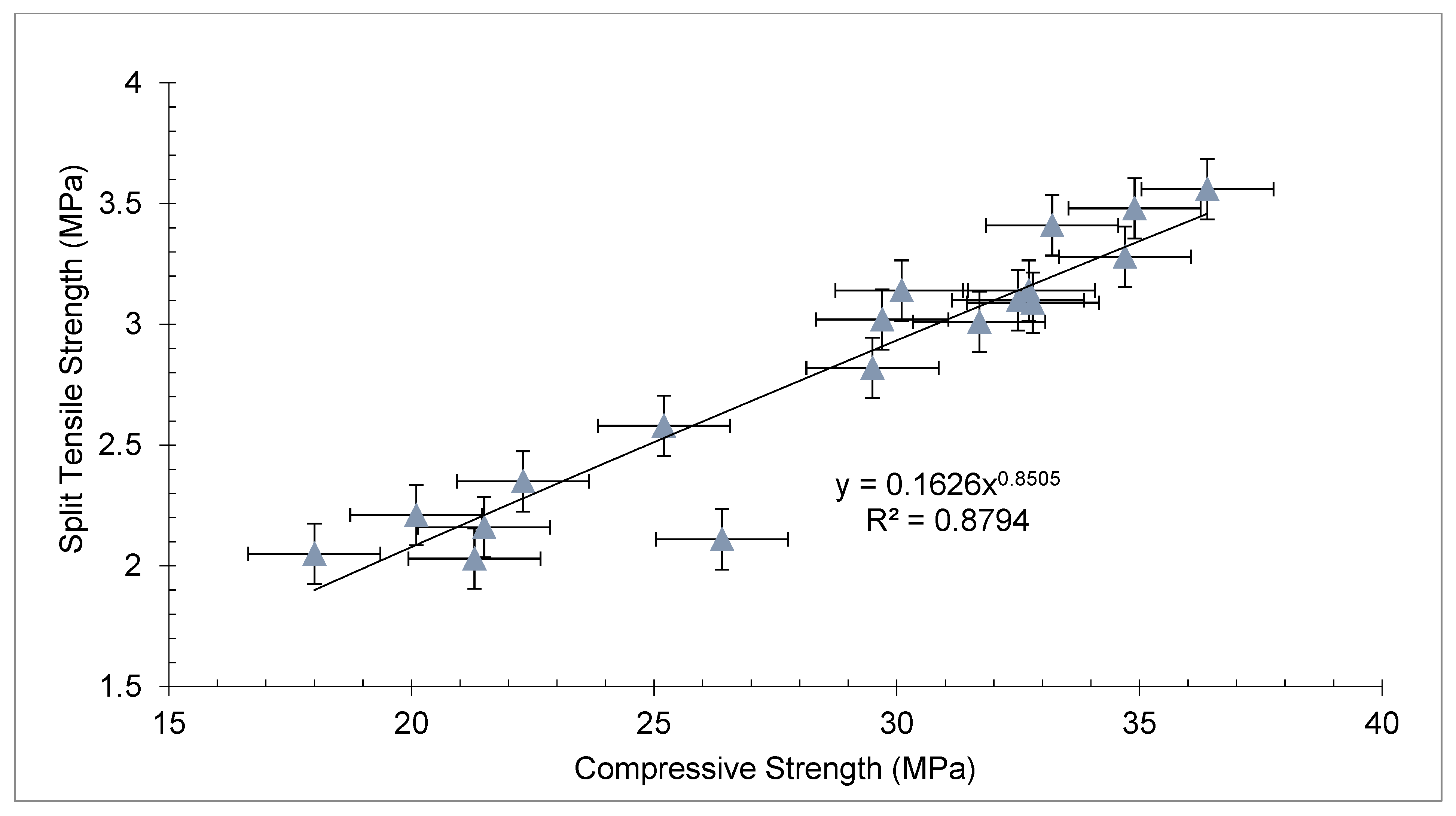

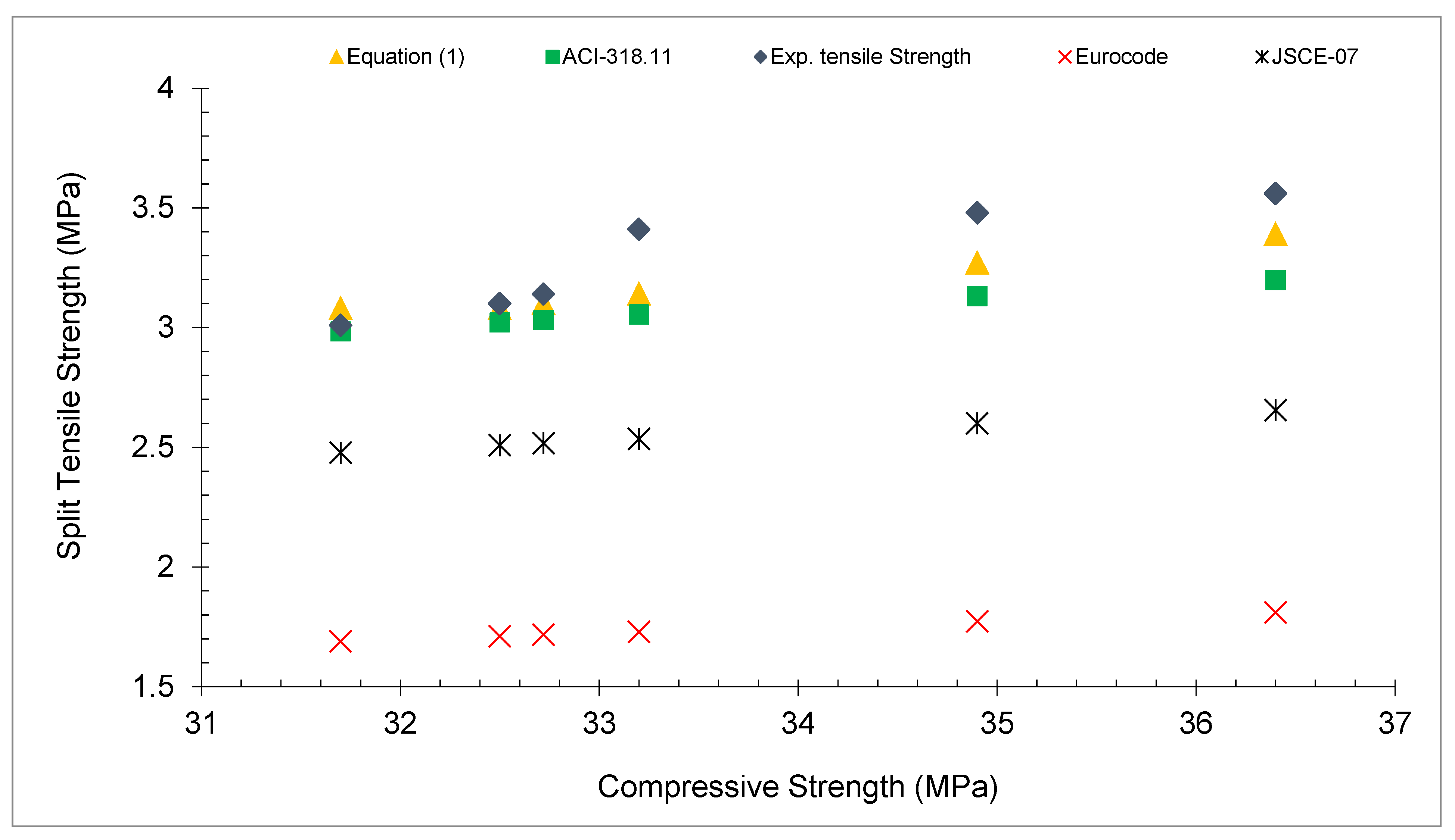

5.2. Split Tensile Strength

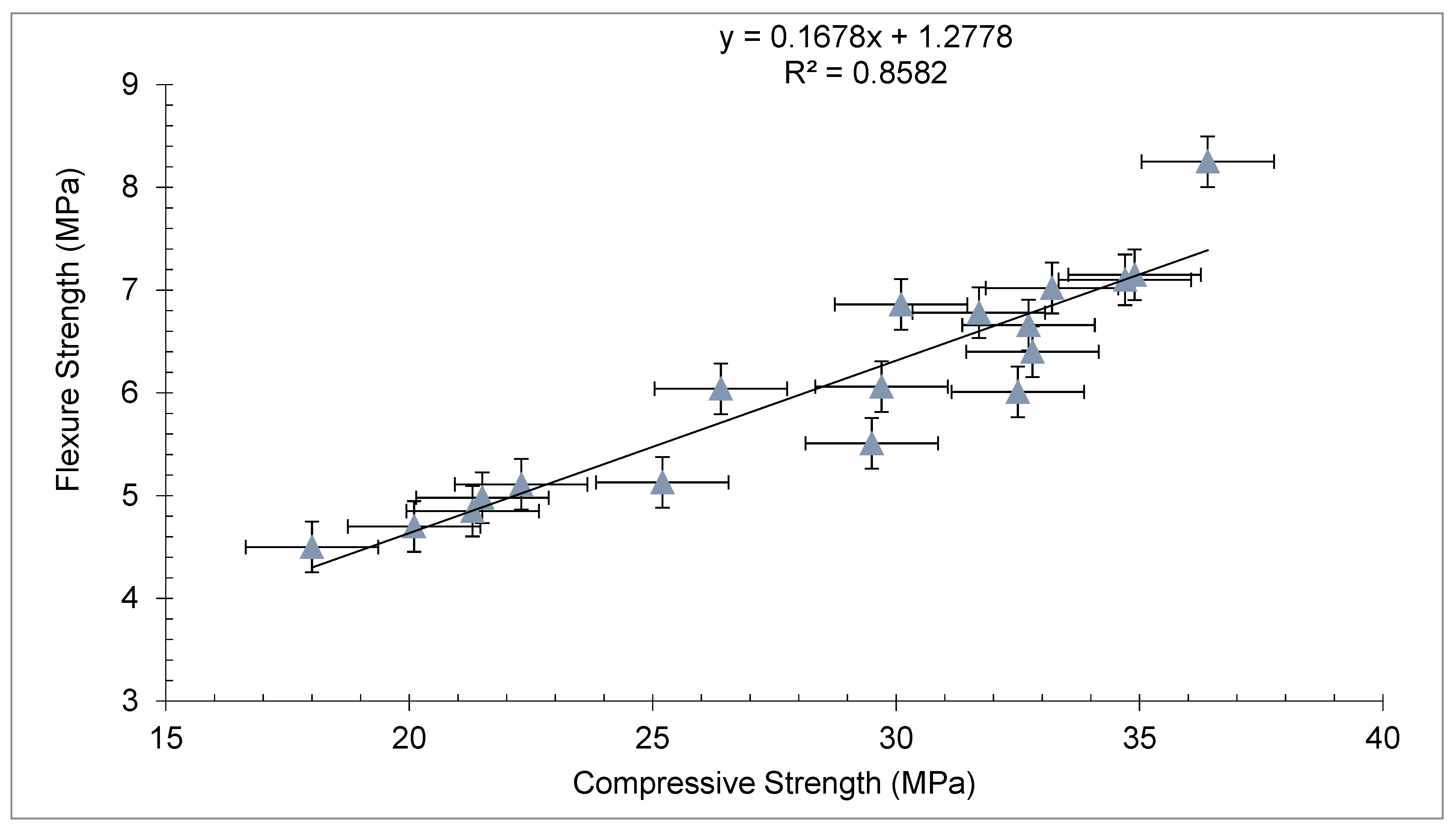

5.3. Flexure Strength

6. Durability

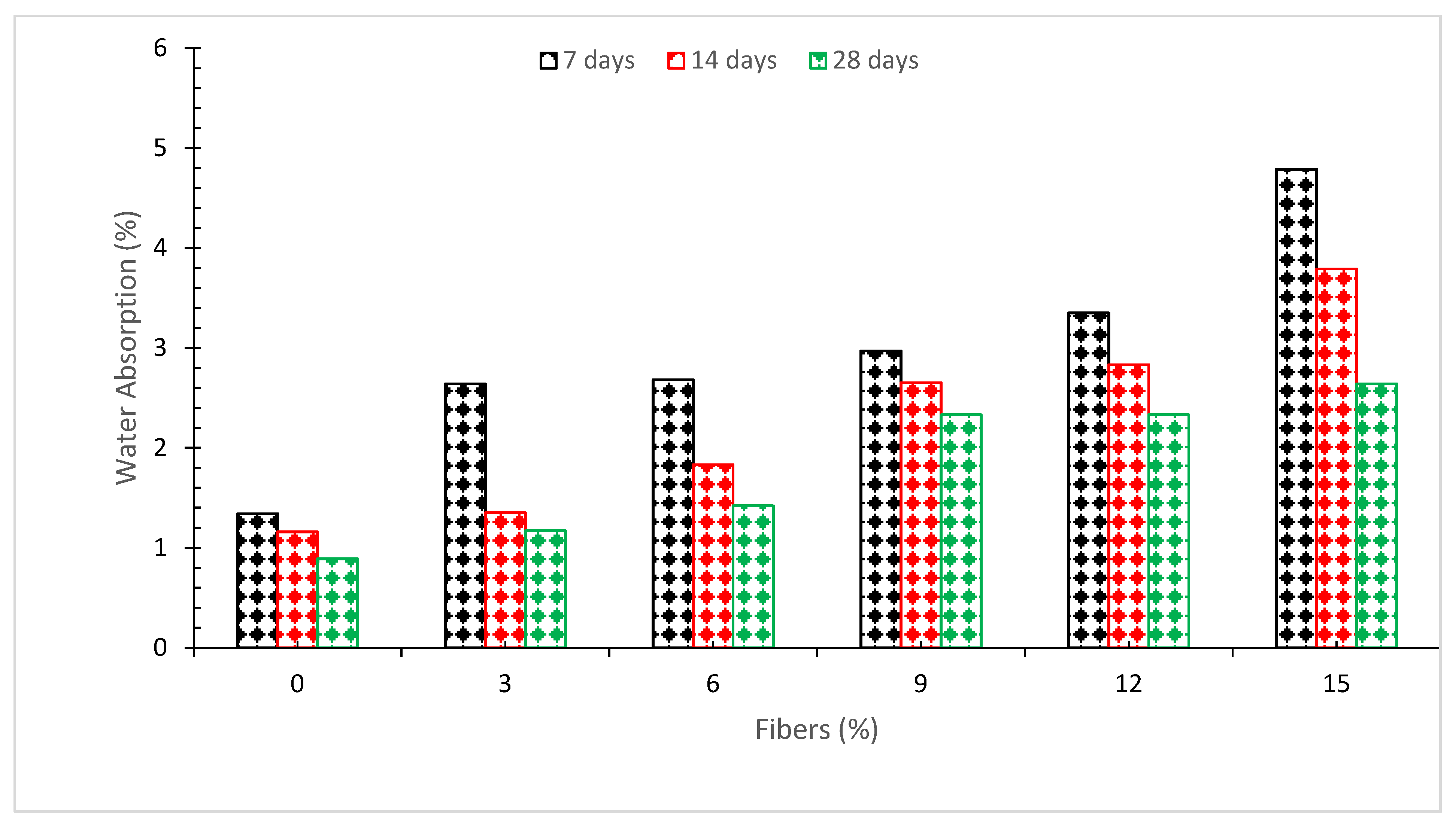

6.1. Water Absorption

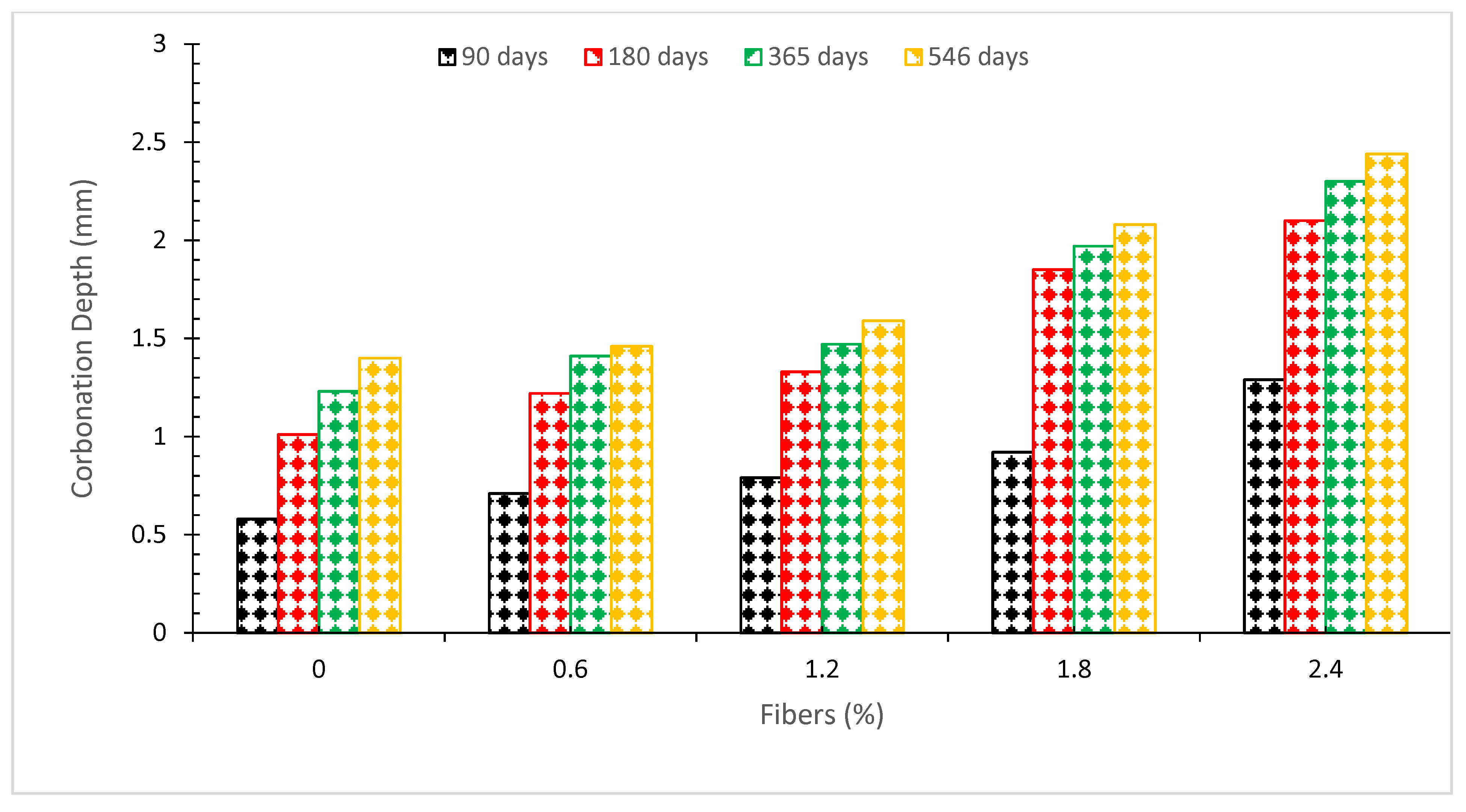

6.2. Carbonation Depth

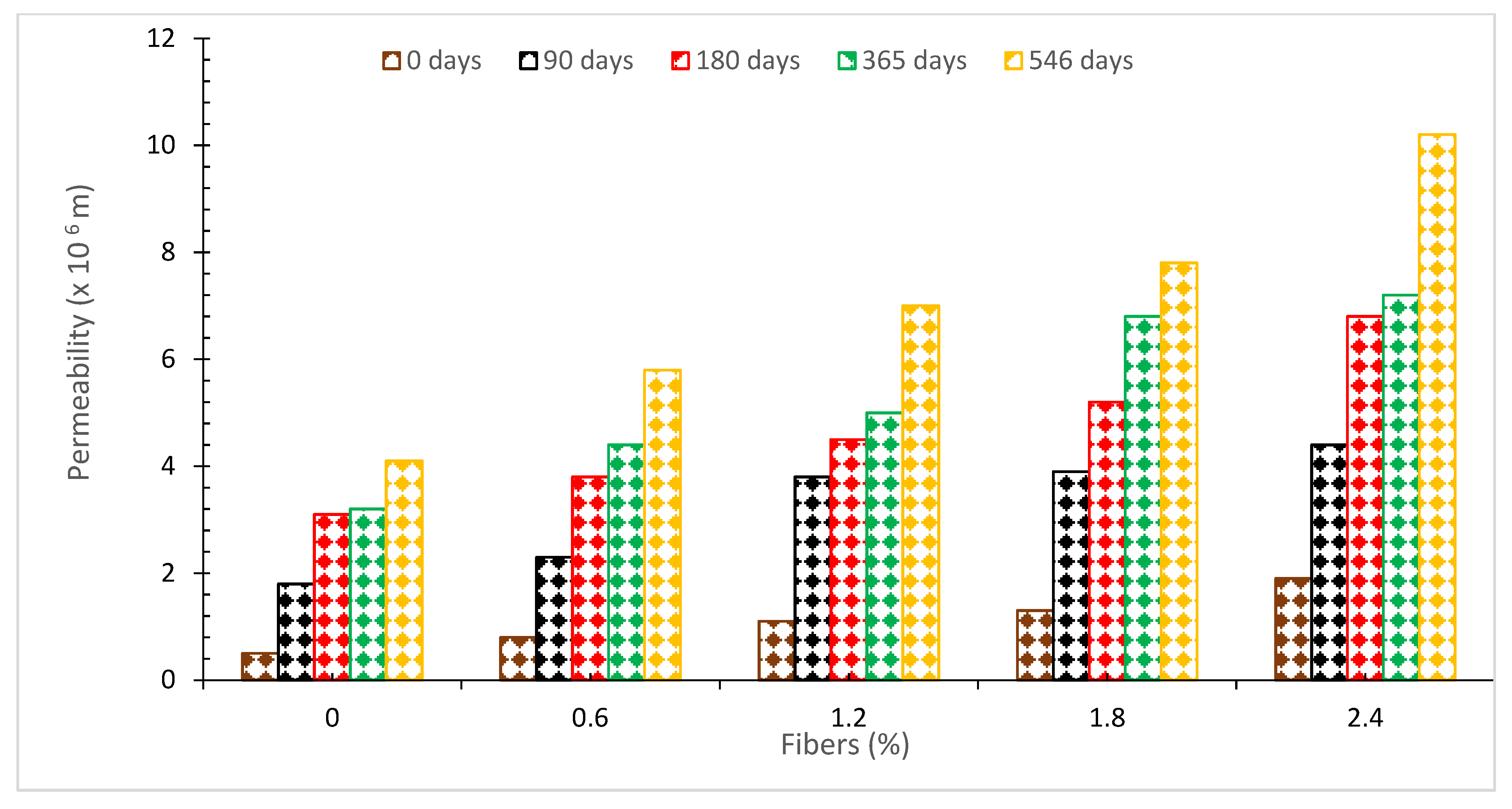

6.3. Permeability

7. Scan Electronic Microscopy (SEM)

8. Conclusions

- The flowability of concrete decreased with the addition of coconut fiber due to the larger surface area of the fiber, which enhanced the internal friction among concrete ingredients, leading to less workability. Furthermore, an increase in fresh density is observed up to 2% addition of coconut fibers.

- Mechanical characteristics such as compressive, split tensile, and flexure strength were improved up to a certain dose of coconut fiber, which depends on physical properties of fibers such as length, diameter, and aspect ratio. Furthermore, it can also be observed that coconut fibers improved flexure capacity (47%) more efficiently than compressive capacity (12%).

- Increased durability properties were also observed with the addition of coconut fibers. However, less information is available in this regard.

- The optimum dose of coconut fibers is the most important parameter for better performance of concrete, as a higher dose results in more voids in hardened concrete due to lack of workability, leading to lower mechanical and durability performance of concrete. The optimum dose of concrete varies depending on fiber length, diameter, and aspect ratio. However, the majority of researchers recommended the optimum dose of coconut fiber is from 2 to 3% by volume of cement.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sekar, A.; Kandasamy, G. Study on Durability Properties of Coconut Shell Concrete with Coconut Fiber. Buildings 2019, 9, 107. [Google Scholar] [CrossRef] [Green Version]

- Feduik, R. Reducing permeability of fiber concrete using composite binders. Spec. Top. Rev. Porous Media Int. J. 2018, 9, 79–89. [Google Scholar] [CrossRef]

- Cosgun, T. An Experimental Study of RC Beams with Varying Concrete Strength Classes Externally Strengthened with CFRP Composites. J. Eng. Fiber. Fabr. 2016, 11, 155892501601100300. [Google Scholar] [CrossRef] [Green Version]

- Yin, S.; Yu, Y.; Na, M. Flexural Properties of Load-Holding Reinforced Concrete Beams Strengthened with Textile-Reinforced Concrete under a Chloride Dry–Wet Cycle. J. Eng. Fiber. Fabr. 2019, 14, 1558925019845902. [Google Scholar] [CrossRef]

- Said, A.; Elsayed, M.; Abd El-Azim, A.; Althoey, F.; Tayeh, B.A. Using Ultra-High Performance Fiber Reinforced Concrete In Improvement Shear Strength of Reinforced Concrete Beams. Case Stud. Constr. Mater. 2022, 16, e01009. [Google Scholar] [CrossRef]

- Althoey, F. Compressive Strength Reduction of Cement Pastes Exposed to Sodium Chloride Solutions: Secondary Ettringite Formation. Constr. Build. Mater. 2021, 299, 123965. [Google Scholar] [CrossRef]

- Althoey, F.; El-Aal, A.K.A.; Shoukry, H.; Hakeem, I. Performance of Cement Mortars Containing Clay Exposed to High Temperature. Arab. J. Sci. Eng. 2021, 47, 591–599. [Google Scholar] [CrossRef]

- Althoey, F.; Farnam, Y. The Effect of Using Supplementary Cementitious Materials on Damage Development Due to the Formation of a Chemical Phase Change in Cementitious Materials Exposed to Sodium Chloride. Constr. Build. Mater. 2019, 210, 685–695. [Google Scholar] [CrossRef]

- Hasan, K.M.; Horváth, P.G.; Alpár, T. Potential Natural Fiber Polymeric Nanobiocomposites: A Review. Polymers 2020, 12, 1072. [Google Scholar] [CrossRef]

- Nizamuddin, S.; Jadhav, A.; Qureshi, S.S.; Baloch, H.A.; Siddiqui, M.T.H.; Mubarak, N.M.; Griffin, G.; Madapusi, S.; Tanksale, A.; Ahamed, M.I. Synthesis and Characterization of Polylactide/Rice Husk Hydrochar Composite. Sci. Rep. 2019, 9, 5445. [Google Scholar] [CrossRef]

- Hasan, K.M.F.; Horváth, P.G.; Alpár, T. Lignocellulosic Fiber Cement Compatibility: A State of the Art Review. J. Nat. Fibers 2021, 1–26. [Google Scholar] [CrossRef]

- Hasan, K.M.F.; Wang, H.; Mahmud, S.; Taher, M.A.; Genyang, C. Wool Functionalization through AgNPs: Coloration, Antibacterial and Wastewater Treatment. Surf. Innov. 2020, 9, 25–36. [Google Scholar] [CrossRef]

- Olatunde, O.O.; Benjakul, S.; Vongkamjan, K. Coconut Husk Extract: Antibacterial Properties and Its Application for Shelf-life Extension of Asian Sea Bass Slices. Int. J. Food Sci. Technol. 2019, 54, 810–822. [Google Scholar] [CrossRef]

- Ku, H.; Wang, H.; Pattarachaiyakoop, N.; Trada, M. A Review on the Tensile Properties of Natural Fiber Reinforced Polymer Composites. Compos. Part B Eng. 2011, 42, 856–873. [Google Scholar] [CrossRef] [Green Version]

- Ahmad, J.; Zaid, O.; Siddique, M.S.; Aslam, F.; Alabduljabbar, H.; Khedher, K.M. Mechanical and Durability Characteristics of Sustainable Coconut Fibers Reinforced Concrete with Incorporation of Marble Powder. Mater. Res. Express 2021, 8, 075505. [Google Scholar] [CrossRef]

- Kumar, G.B.R.; Kesavan, V. Study of Structural Properties Evaluation on Coconut Fiber Ash Mixed Concrete. Mater. Today Proc. 2020, 22, 811–816. [Google Scholar] [CrossRef]

- Thanushan, K.; Yogananth, Y.; Sangeeth, P.; Coonghe, J.G.; Sathiparan, N. Strength and Durability Characteristics of Coconut Fibre Reinforced Earth Cement Blocks. J. Nat. Fibers 2021, 18, 773–788. [Google Scholar] [CrossRef]

- Ohler, J.H. Modern Coconut Management; Palm Cultivation and Products. Available online: ecoport.org/ep?SearchType=earticleView&earticleId=127...2 (accessed on 20 March 2022).

- Saheb, D.N.; Jog, J.P. Natural Fiber Polymer Composites: A Review. Adv. Polym. Technol. J. Polym. Process. Inst. 1999, 18, 351–363. [Google Scholar] [CrossRef]

- Li, X.; Tabil, L.G.; Panigrahi, S.; Crerar, W.J. The Influence of Fiber Content on Properties of Injection Molded Flax Fiber-HDPE Biocomposites. In Proceedings of the 2006 ASAE Annual Meeting, Boston, MA, USA, 19–22 August 2016; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2006; p. 1. [Google Scholar]

- Elsaid, A.; Dawood, M.; Seracino, R.; Bobko, C. Mechanical Properties of Kenaf Fiber Reinforced Concrete. Constr. Build. Mater. 2011, 25, 1991–2001. [Google Scholar] [CrossRef]

- Palanisamy, E.; Ramasamy, M. Dependency of Sisal and Banana Fiber on Mechanical and Durability Properties of Polypropylene Hybrid Fiber Reinforced Concrete. J. Nat. Fibers 2020, 1–11. [Google Scholar] [CrossRef]

- Malkapuram, R.; Kumar, V.; Negi, Y.S. Recent Development in Natural Fiber Reinforced Polypropylene Composites. J. Reinf. Plast. Compos. 2009, 28, 1169–1189. [Google Scholar] [CrossRef]

- Ridha, N.; Prashant, K. Studies on Strength Properties of Coconut Fibre Concrete. Int. J. Res. Appl. Sci. Eng. Technol. 2019, 7, 404–410. [Google Scholar]

- Sathiparan, N.; Rupasinghe, M.N.; Pavithra, B.H.M. Performance of Coconut Coir Reinforced Hydraulic Cement Mortar for Surface Plastering Application. Constr. Build. Mater. 2017, 142, 23–30. [Google Scholar] [CrossRef]

- Ahmad, J.; Aslam, F.; Martinez-Garcia, R.; El Ouni, M.H.; Khedher, K.M. Performance of Sustainable Self-Compacting Fiber Reinforced Concrete with Substitution of Marble Waste (MW) and Coconut Fibers (CFs). Sci. Rep. 2021, 11, 23184. [Google Scholar] [CrossRef]

- Ali, M. Coconut Fibre: A Versatile Material and Its Applications in Engineering. J. Civ. Eng. Constr. Technol. 2011, 2, 189–197. [Google Scholar]

- Das, G.; Biswas, S. Physical, Mechanical and Water Absorption Behaviour of Coir Fiber Reinforced Epoxy Composites Filled With Al 2 O 3 Particulates. IOP Conf. Ser. Mater. Sci. Eng. 2016, 115, 012012. [Google Scholar] [CrossRef]

- Choumanidis, D.; Badogiannis, E.; Nomikos, P.; Sofianos, A. The Effect of Different Fibres on the Flexural Behaviour of Concrete Exposed to Normal and Elevated Temperatures. Constr. Build. Mater. 2016, 129, 266–277. [Google Scholar] [CrossRef]

- Asasutjarit, C.; Hirunlabh, J.; Khedari, J.; Daguenet, M.; Quenard, D. Coconut Coir Cement Board. In Proceedings of the 10DBMC International Conference on Durability of Building Materials and Components LYON [France], Lyon, France, 17–20 April 2005. [Google Scholar]

- Ede, A.N.; Aina, A.O. Effects of Coconut Husk Fibre and Polypropylene Fibre on Fire Resistance of Concrete. Int. J. Eng. Sci. Manag. 2015, 5, 171–179. [Google Scholar]

- Hutten, I.M. Handbook of Nonwoven Filter Media; Elsevier: Amsterdam, The Netherlands, 2007; ISBN 1856174417. [Google Scholar]

- Naveen, P.N.E.; Prasad, R. V Evaluation of Mechanical Properties of Coconut Coir/Bamboo Fiber Reinforced Polymer Matrix Composites. Sci. Eng. 2013, 3, 15–22. [Google Scholar]

- Amadi, A.A.; Eberemu, A.O.; Momoh, O.H. Use of Coir Fiber Reinforcement Technique to Improve Strength of Cement Kiln Dust Treated Black Cotton Soil Subgrade. Geosynth. Long Beach 2013, 223–229. Available online: https://scholar.google.com/scholar?hl=en&as_sdt=0%2C5&q=Use+of+Coir+Fiber+Reinforcement+Technique+to+Improve+Strength+of+Cement+Kiln+&btnG= (accessed on 20 March 2022).

- Bai, Y.; Liu, J.; Song, Z.; Chen, Z.; Jiang, C.; Lan, X.; Shi, X.; Bu, F.; Kanungo, D.P. Unconfined Compressive Properties of Composite Sand Stabilized with Organic Polymers and Natural Fibers. Polymers 2019, 11, 1576. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ramakrishna, G.; Sundararajan, T. Studies on the Durability of Natural Fibres and the Effect of Corroded Fibres on the Strength of Mortar. Cem. Concr. Compos. 2005, 27, 575–582. [Google Scholar] [CrossRef]

- Ramli, M.; Kwan, W.H.; Abas, N.F. Strength and Durability of Coconut-Fiber-Reinforced Concrete in Aggressive Environments. Constr. Build. Mater. 2013, 38, 554–566. [Google Scholar] [CrossRef]

- Ahmad, J.; Manan, A.; Ali, A.; Khan, M.W.; Asim, M.; Zaid, O. A Study on Mechanical and Durability Aspects of Concrete Modified with Steel Fibers (SFs). Civ. Eng. Archit. 2020, 8, 814–823. [Google Scholar] [CrossRef]

- Rumbayan, R.; Ticoalu, A. A Study into Flexural, Compressive and Tensile Strength of Coir-Concrete as Sustainable Building Material. In Proceedings of the MATEC Web of Conferences, Sibiu, Romania, 5–7 June 2019; EDP Sciences: Les Ulis, France, 2019; Volume 258, p. 1011. [Google Scholar]

- Ali, M.; Liu, A.; Sou, H.; Chouw, N. Mechanical and Dynamic Properties of Coconut Fibre Reinforced Concrete. Constr. Build. Mater. 2012, 30, 814–825. [Google Scholar] [CrossRef]

- Piérard, J.; Dooms, B.; Cauberg, N. Durability Evaluation of Different Types of UHPC. In Proceedings of the RILEM-fib-AFGC International Symposium on Ultra-High Performance Fiber-Reinforced Concrete, Marseille, France, 1–3 October 2013; pp. 275–284. [Google Scholar]

- Zhang, P.; Li, Q.; Chen, Y.; Shi, Y.; Ling, Y.-F. Durability of Steel Fiber-Reinforced Concrete Containing SiO2 Nano-Particles. Materials 2019, 12, 2184. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tadepalli, P.R.; Mo, Y.L.; Hsu, T.T.C. Mechanical Properties of Steel Fibre Concrete. Mag. Concr. Res. 2013, 65, 462–474. [Google Scholar] [CrossRef]

- da Silva, E.J.; Marques, M.L.; Velasco, F.G.; Junior, C.F.; Luzardo, F.M.; Tashima, M.M. A New Treatment for Coconut Fibers to Improve the Properties of Cement-Based Composites–Combined Effect of Natural Latex/Pozzolanic Materials. Sustain. Mater. Technol. 2017, 12, 44–51. [Google Scholar] [CrossRef] [Green Version]

- Ardanuy, M.; Claramunt, J.; Toledo Filho, R.D. Cellulosic Fiber Reinforced Cement-Based Composites: A Review of Recent Research. Constr. Build. Mater. 2015, 79, 115–128. [Google Scholar] [CrossRef] [Green Version]

- Wang, W.; Huang, G. Characterization and Utilization of Natural Coconut Fibers Composites. Mater. Des. 2009, 30, 2741–2744. [Google Scholar] [CrossRef]

- C39/C39M, A. Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. Annu. B ASTM Stand 2003. Available online: https://scholar.google.com/scholar?hl=en&as_sdt=0%2C5&q=47.%09C39%2FC39M%2C+A.+Standard+Test+Method+for+Compressive+Strength+of+Cylindrical+Concrete+Specimens.+Annu.+B+ASTM+Stand.+2003&btnG= (accessed on 20 March 2022).

- Ede, A.N.; Agbede, J.O. Use of Coconut Husk Fiber for Improved Compressive and Flexural Strength of Con-Crete. Int. J. Sci. Eng. Res. 2015, 6, 968–974. [Google Scholar]

- Usman, M.; Farooq, S.H.; Umair, M.; Hanif, A. Axial Compressive Behavior of Confined Steel Fiber Reinforced High Strength Concrete. Constr. Build. Mater. 2020, 230, 117043. [Google Scholar] [CrossRef]

- Ahmad, W.; Farooq, S.H.; Usman, M.; Khan, M.; Ahmad, A.; Aslam, F.; Al Yousef, R.; Al Abduljabbar, H.; Sufian, M. Effect of Coconut Fiber Length and Content on Properties of High Strength Concrete. Materials 2020, 13, 1075. [Google Scholar] [CrossRef] [Green Version]

- Designation, A. C496-71. Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens 1. 1976. Available online: https://www.academia.edu/34903117/Standard_Test_Method_for_Splitting_Tensile_Strength_of_Cylindrical_Concrete_Specimens_1 (accessed on 20 March 2022).

- Williamson, G.R. The Effect of Steel Fibers on the Compressive Strength of Concrete. Spec. Publ. 1974, 44, 195–208. [Google Scholar]

- Lim, J.C.; Ozbakkaloglu, T. Confinement Model for FRP-Confined High-Strength Concrete. J. Compos. Constr. 2014, 18, 4013058. [Google Scholar] [CrossRef]

- Deluce, J.R.; Vecchio, F.J. Cracking Behavior of Steel Fiber-Reinforced Concrete Members Containing Conventional Reinforcement. ACI Struct. J. 2013, 110, 481–490. [Google Scholar] [CrossRef]

- Ma, X.; Yu, J.; Kennedy, J.F. Studies on the Properties of Natural Fibers-Reinforced Thermoplastic Starch Composites. Carbohydr. Polym. 2005, 62, 19–24. [Google Scholar] [CrossRef]

- Syed, H.; Nerella, R.; Madduru, S.R.C. Role of Coconut Coir Fiber in Concrete. Mater. Today Proc. 2020, 27, 1104–1110. [Google Scholar] [CrossRef]

- Bui, H.; Sebaibi, N.; Boutouil, M.; Levacher, D. Determination and Review of Physical and Mechanical Properties of Raw and Treated Coconut Fibers for Their Recycling in Construction Materials. Fibers 2020, 8, 37. [Google Scholar] [CrossRef]

- ACI, A.C.I. 318-11: Building Code Requirements for Structural Concrete. Farmingt. Hills, MI Am. Concr. Inst. 2011. Available online: https://scholar.google.com/scholar?hl=en&as_sdt=0%2C5&q=58.%09ACI%2C+A.C.I.+318-11%3A+Building+Code+Requirements+for+Structural+Concrete.+Farmingt.+Hills%2C+MI+Am.+Concr.+Inst.+2011&btnG= (accessed on 20 March 2022).

- En, B.S. 1-1. Eurocode 2: Design of Concrete Structures–Part 1-1: General Rules and Rules for Buildings. Eur. Comm. Stand. 2004. Available online: https://scholar.google.com/scholar?hl=en&as_sdt=0%2C5&q=59.%09En%2C+B.S.+1-1.+Eurocode+2%3A+Design+of+Concrete+Structures–Part+1-1%3A+General+Rules+and+Rules+for+Buildings.+Eur.+Comm.+Stand.+2004.+&btnG= (accessed on 20 March 2022).

- Sato, R.; Sogo, S.; Kanazu, T.; Kishi, T.; Noguchi, T.; Mizobuchi, T.; Miyazawa, S. JCI Guideline for Control of Cracking of Mass Concrete. Sustain. Constr. Mater. Technol. 2008. Available online: https://scholar.google.com/scholar?hl=en&as_sdt=0%2C5&q=60.%09Sato%2C+R.%3B+Sogo%2C+S.%3B+Kanazu%2C+T.%3B+Kishi%2C+T.%3B+Noguchi%2C+T.%3B+Mizobuchi%2C+T.%3B+Miyazawa%2C+S.+JCI+Guideline+for+Control+of+Cracking+of+Mass+Concrete.+Sustain.+Constr.+Mater.+Technol.+2008.&btnG= (accessed on 20 March 2022).

- ASTM, C. Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Third-Point Loading). In Proceedings of the American Society for Testing and Materials; 2010; Volume 100, pp. 12959–19428. Available online: https://scholar.google.com/scholar?hl=en&as_sdt=0%2C5&q=61.%09ASTM%2C+C.+Standard+Test+Method+for+Flexural+Strength+of+Concrete+%28Using+Simple+Beam+with+Third-Point+Loading%29.+In+Pro-ceedings+of+the+American+Society+for+Testing+and+Materials%3B+2010%3B+Volume+100%2C+pp.+12959–19428.&btnG= (accessed on 20 March 2022).

- Kikuchi, T.; Shintani, Y.; Hirashima, T.; Kohno, M. Mechanical Properties of Steel Fiber Reinforced Concrete at High Temperature. J. Struct. Constr. Eng. 2020, 85, 169–176. [Google Scholar] [CrossRef]

- Abbass, M.; Singh, D.; Singh, G. Properties of Hybrid Geopolymer Concrete Prepared Using Rice Husk Ash, Fly Ash AND GGBS with Coconut Fiber. Mater. Today Proc. 2021, 45, 4964–4970. [Google Scholar] [CrossRef]

- Srinivas, K.; Akula, K.R.; Mahesh, V. Experimental Investigation on Lightweight Concrete by Replacing the Coarse Aggregate with Coconut Shell and Expanded Polystyene Beads and Using Polypropylene Fiber. Mater. Today Proc. 2021, 46, 838–842. [Google Scholar] [CrossRef]

- Khan, M.; Rehman, A.; Ali, M. Efficiency of Silica-Fume Content in Plain and Natural Fiber Reinforced Concrete for Concrete Road. Constr. Build. Mater. 2020, 244, 118382. [Google Scholar] [CrossRef]

- Das, S.; Sobuz, M.H.R.; Tam, V.W.Y.; Akid, A.S.M.; Sutan, N.M.; Rahman, F.M.M. Effects of Incorporating Hybrid Fibres on Rheological and Mechanical Properties of Fibre Reinforced Concrete. Constr. Build. Mater. 2020, 262, 120561. [Google Scholar] [CrossRef]

- Raj, B.; Sathyan, D.; Madhavan, M.K.; Raj, A. Mechanical and Durability Properties of Hybrid Fiber Reinforced Foam Concrete. Constr. Build. Mater. 2020, 245, 118373. [Google Scholar] [CrossRef]

- Wongsa, A.; Kunthawatwong, R.; Naenudon, S.; Sata, V.; Chindaprasirt, P. Natural Fiber Reinforced High Calcium Fly Ash Geopolymer Mortar. Constr. Build. Mater. 2020, 241, 118143. [Google Scholar] [CrossRef]

- Krishna, N.K.; Prasanth, M.; Gowtham, R.; Karthic, S.; Mini, K.M. Enhancement of Properties of Concrete Using Natural Fibers. Mater. Today Proc. 2018, 5, 23816–23823. [Google Scholar] [CrossRef]

- Hwang, C.-L.; Tran, V.-A.; Hong, J.-W.; Hsieh, Y.-C. Effects of Short Coconut Fiber on the Mechanical Properties, Plastic Cracking Behavior, and Impact Resistance of Cementitious Composites. Constr. Build. Mater. 2016, 127, 984–992. [Google Scholar] [CrossRef]

- Korniejenko, K.; Frączek, E.; Pytlak, E.; Adamski, M. Mechanical Properties of Geopolymer Composites Reinforced with Natural Fibers. Procedia Eng. 2016, 151, 388–393. [Google Scholar] [CrossRef]

- Baruah, P.; Talukdar, S. A Comparative Study of Compressive, Flexural, Tensile and Shear Strength of Concrete with Fibres of Different Origins. Indian Concr. J. 2007, 81, 17–24. [Google Scholar]

- Abdullah, A.; Jamaludin, S.B.; Noor, M.M.; Hussin, K. Composite Cement Reinforced Coconut Fiber: Physical and Mechanical Properties and Fracture Behavior. Aust. J. Basic Appl. Sci. 2011, 5, 1228–1240. [Google Scholar]

- Huang, G.; Xie, X. Experimental Study on the Effect of Nano-SiO2 to Durability in Hydraulic Concrete. Yellow River 2011, 33, 138–140. [Google Scholar]

- Guo, Y.; Pan, H.; Li, Z. Study on Carbonation of Steel-Fiber Reinforced Concrete. Concrete 2007, 29, 45–47. [Google Scholar]

- Hearn, N.; Hooton, R.D.; Mills, R.H. Pore Structure and Permeability. In Significance of Tests and Properties of Concrete and Concrete-Making Materials; ASTM International: West Conshohocken, PA, USA, 1994. [Google Scholar]

- Hearn, N.; Figg, J. Effect of Microstructural Damage on Barrier Characteristics of Concrete. In Materials Science of Concrete VI; Mindess, S., Skaln, J., Eds.; American Ceramic Society: Columbus, OH, USA, 2001. [Google Scholar]

- Savastano, H., Jr.; Agopyan, V. Transition Zone Studies of Vegetable Fibre-Cement Paste Composites. Cem. Concr. Compos. 1999, 21, 49–57. [Google Scholar] [CrossRef]

- Persson, K. Micromechanical Modelling of Wood and Fibre Properties; Lund University, Department of Mechanics and Materials: Lund, Sweden, 2000; ISBN 9178740940. [Google Scholar]

- Ahmad, J.; Zaid, O.; Shahzaib, M.; Abdullah, M.U.; Ullah, A.; Ullah, R. Mechanical Properties of Sustainable Concrete Modified by Adding Marble Slurry as Cement Substitution. AIMS Mater. Sci. 2021, 8, 343–358. [Google Scholar] [CrossRef]

- Fediuk, R. High-Strength Fibrous Concrete of Russian Far East Natural Materials. IOP Conf. Ser. Mater. Sci. Eng. 2016, 116, 012020. [Google Scholar] [CrossRef] [Green Version]

- Abdelgader, H.; Fediuk, R.; Kurpińska, M.; Elkhatib, J.; Murali, G.; Baranov, A.V.; Timokhin, R.A. Mechanical Properties of Two-Stage Concrete Modified by Silica Fume. Mag. Civ. Eng. 2019, 89, 26–38. [Google Scholar]

| Property Name | Naveen et al. [33] | Amadi et al. [34] | Bai et al. [35] | Ramakrishna et al. [36] | Ahmad et al. [15] | Ramli et al. [37] |

|---|---|---|---|---|---|---|

| Length (mm) | - | 25 | 18 | 60 to 250 | 8 to 10 | 20 to 30 |

| Diameter (mm) | - | 0.25 | 0.1 to 0.5 | 0.40 to 0.10 | 0.5 to 1.0 | 0.32 |

| Aspect Ratio | - | 100 | - | - | - | - |

| Tensile Strength (MPa) | 175 | 405 | - | 15 to 327 | - | 176 |

| Modulus (GPa) | 4 to 6 | 4 | - | - | 4.5 | 22.4 |

| Density (g/cm3) | - | - | 0.67 to 10 | - | - | - |

| Water Absorption (%) | 130 to 180 | - | - | - | - | - |

| Elongation (%) | 30 | - | - | 75 | 25 | - |

| Coating | Solution | Details |

|---|---|---|

| Silica fume | Water | Coconut fibers were immersed in a deionized water solution for 60 min while being constantly agitated. Following that, the fibers were put in a receiver that was filled with silica fume to dry. The coconut fiber began to get covered with a thin coating of silica fume on its surface as the process progressed. |

| Silica fume | Latex | The same silica water treatment technique is followed, with the exception that the deionized water solution is replaced with a natural latex solution at a concentration of 1 percent. |

| Metakaolin | Water | The identical silica water treatment process is applied, with the exception that silica fume is used in place of metakaolin instead of the latter. |

| Metakaolin | Latex | The metakaolin water treatment technique is the same as before, with the exception that metakaolin is used instead of silica fume. |

| Nil | Nil | Using natural coconut fiber (that has not been treated) and incorporating it into the cementitious matrix for the fabrication of specimens for the durability test |

| Experimental Compressive Strength (MPa) | Equation (1) | ACI-318.11 [58] | Eurocode [59] | JSCE-07 [60] | Experimental Split Tensile Strength (MPa) |

|---|---|---|---|---|---|

| 32.5 | 3.08 | 3.02 | 1.71 | 2.50 | 3.1 |

| 32.72 | 3.10 | 3.03 | 1.71 | 2.51 | 3.14 |

| 33.2 | 3.14 | 3.05 | 1.72 | 2.53 | 3.41 |

| 36.4 | 3.39 | 3.19 | 1.80 | 2.65 | 3.56 |

| 34.9 | 3.27 | 3.13 | 1.77 | 2.59 | 3.48 |

| 31.7 | 3.08 | 2.98 | 1.68 | 2.47 | 3.01 |

| Author/ Reference | Percentage of Replacement | Compression Strength (MPa) | Flexure Strength (MPa) | Split Tensile Strength (MPa) |

|---|---|---|---|---|

| Abbass et al. [63] | 0 0.1 0.2 0.3 0.4 0.5 0.6 | 36 38 38 36.5 35 33.5 30 | 4.8 5.2 5.4 4.98 4.85 4.75 4.50 | 3.61 3.70 3.90 3.85 3.60 3.50 3.30 |

| Srinivas et al. [64] | 0 0.5 1 1.5 | 8.0 8.66 9.93 4.75 | 6.33 3.23 3.82 2.80 | 2.95 0.87 0.95 0.92 |

| Kumar et al. [16] | 0 CF%:5 CF ASH%:15 | 22.3 19.53 34.87 | 6.73 5.27 5.33 | 1.28 2.39 1.378 |

| Khan et al. [65] | Silica Fume:CF 0:2 5:2 10: 2 15: 2 20: 2 | 27.2 27.5 28.8 32.4 26.6 | 6.2 6.6 7.8 8.3 4.7 | 3.0 3.4 3.5 3.6 2.9 |

| Das et al. [66] | Steel fiber:CF 0:0 1:2 1:4 1:6 | 19.26 20.42 18.58 17.66 | 3.94 492 4.02 3.56 | 3.62 4.32 3.76 2.98 |

| Raj et al. [67] | 0 0.3 0.4 0.5 | 9.5 11.5 8.0 7.5 | 1.4 1.7 1.2 1.1 | 3.50 3.48 2.45 2.10 |

| Wongsa et al. [68] | 0 0.5 0.75 1 | 31 33 28 25 | 3.2 5.3 6.2 6.7 | 1.8 2.1 2.2 2.4 |

| Krishna et al. [69] | 0 0.5 1 1.5 2 | 37.5 35 47.5 51 41.75 | - | - |

| Sathiparan et al. [25] | 0.000 0.125 0.250 0.500 0.750 | 2.8 2.83 2.86 2.75 2.62 | 1 1.12 1.14 1.15 0.84 | - |

| Hwang et al. [70] | 0 1 2.5 4 | 65 50 48 40 | 5.2 5.5 6.4 7.5 | - |

| Korniejenko et al. [71] | Control Coir fibers (1%) Cotton fibers (1%) Raffia fibers (1%) Sisal fibers (1%) | 24.78 31.36 28.42 13.66 25.16 | 5.55 5.25 5.85 3.05 5.90 | - |

| Ali et al. [40] | Length (2.5 cm:5 cm:7.5 cm) 1:1:1 2: 2:2 3: 3:3 5: 5:5 | 42:43.5:37 41:42.5:33.5 40:38:31.5 36.5:36:00 | - | 3.85:4.3:4.35 3.80:4.30:4.20 3.35:4.25:4.00 3.5:3.75:0.00 |

| Baruah et al. [72] | 0 0.5 1.0 1.5 2.0 | 21.42 21.70 22.74 25.10 24.35 | - | 2.88 3.02 3.18 3.37 3.54 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmad, J.; Majdi, A.; Al-Fakih, A.; Deifalla, A.F.; Althoey, F.; El Ouni, M.H.; El-Shorbagy, M.A. Mechanical and Durability Performance of Coconut Fiber Reinforced Concrete: A State-of-the-Art Review. Materials 2022, 15, 3601. https://doi.org/10.3390/ma15103601

Ahmad J, Majdi A, Al-Fakih A, Deifalla AF, Althoey F, El Ouni MH, El-Shorbagy MA. Mechanical and Durability Performance of Coconut Fiber Reinforced Concrete: A State-of-the-Art Review. Materials. 2022; 15(10):3601. https://doi.org/10.3390/ma15103601

Chicago/Turabian StyleAhmad, Jawad, Ali Majdi, Amin Al-Fakih, Ahmed Farouk Deifalla, Fadi Althoey, Mohamed Hechmi El Ouni, and Mohammed A. El-Shorbagy. 2022. "Mechanical and Durability Performance of Coconut Fiber Reinforced Concrete: A State-of-the-Art Review" Materials 15, no. 10: 3601. https://doi.org/10.3390/ma15103601

APA StyleAhmad, J., Majdi, A., Al-Fakih, A., Deifalla, A. F., Althoey, F., El Ouni, M. H., & El-Shorbagy, M. A. (2022). Mechanical and Durability Performance of Coconut Fiber Reinforced Concrete: A State-of-the-Art Review. Materials, 15(10), 3601. https://doi.org/10.3390/ma15103601