Influence of Diamond Grain Size on the Basic Properties of WC-Co/Diamond Composites Used in Tools for Wood-Based Materials Machining

Abstract

:1. Introduction

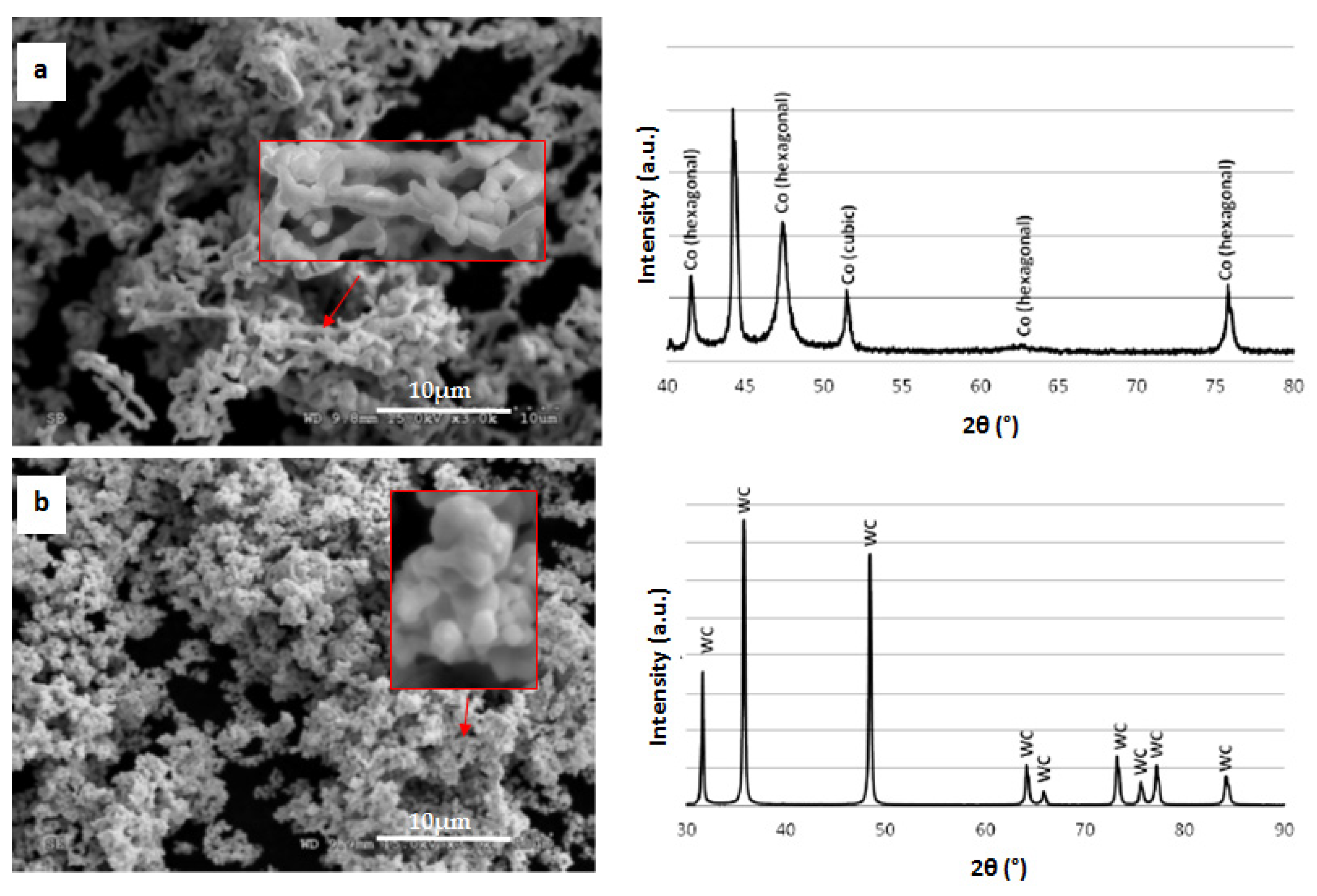

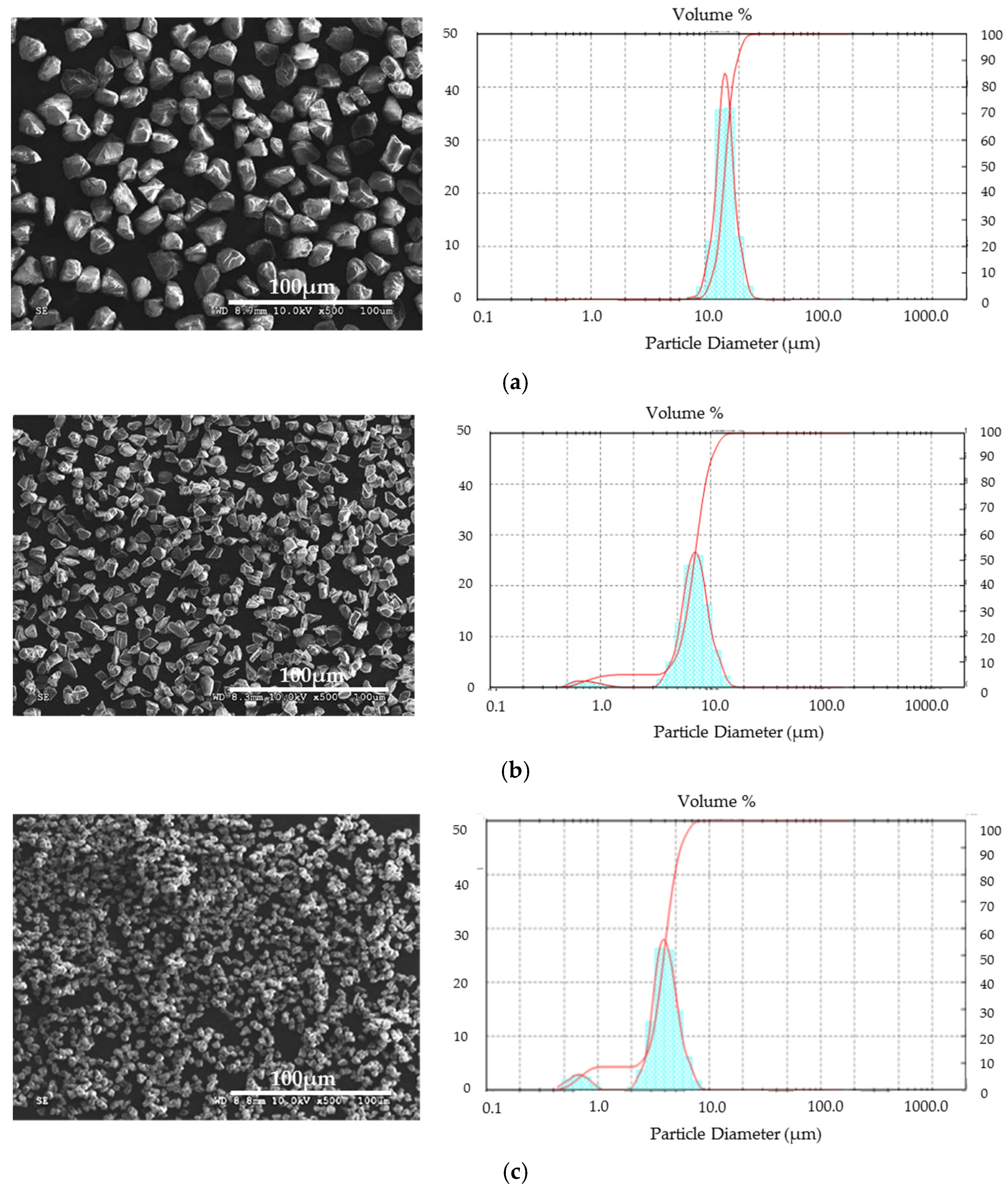

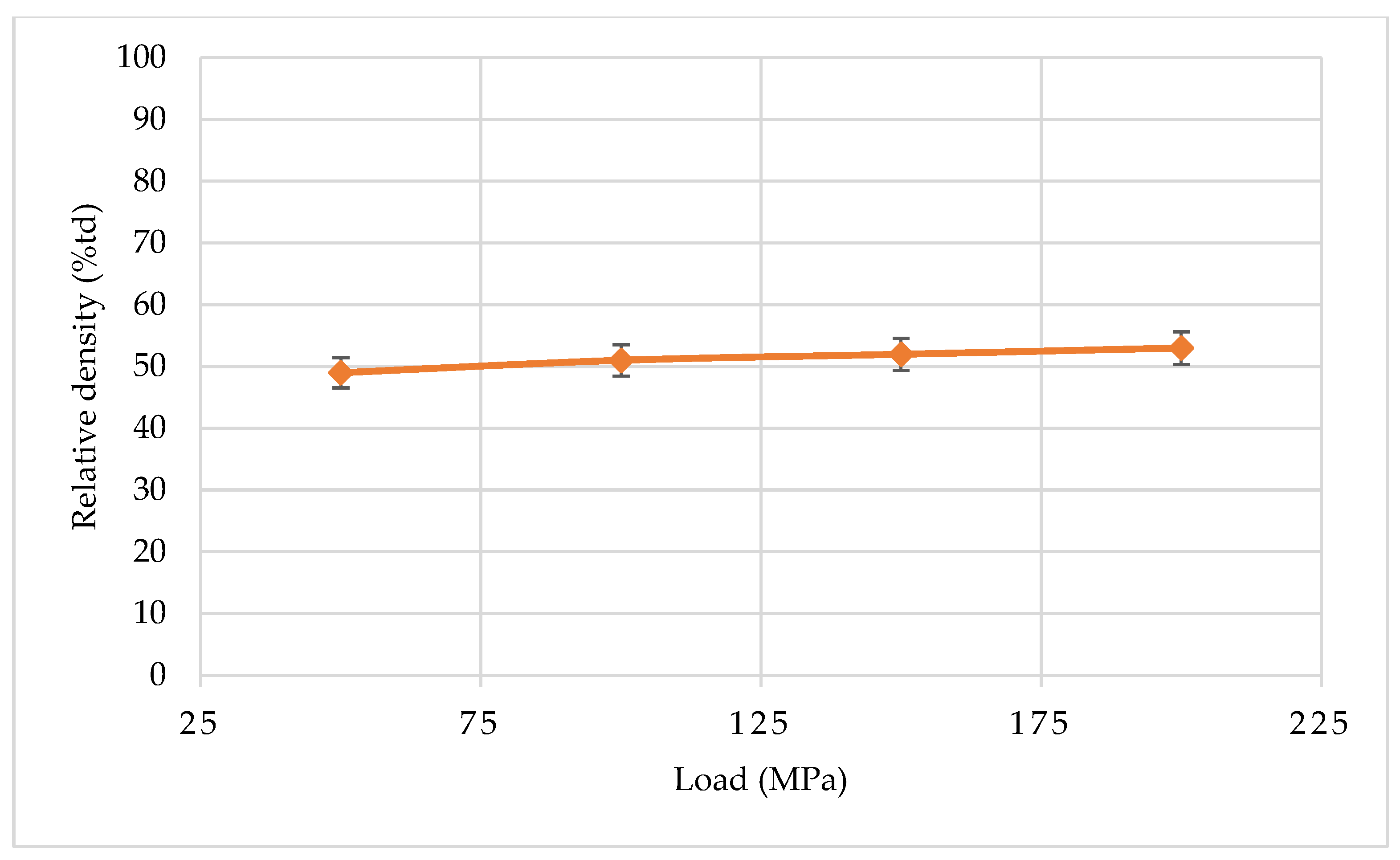

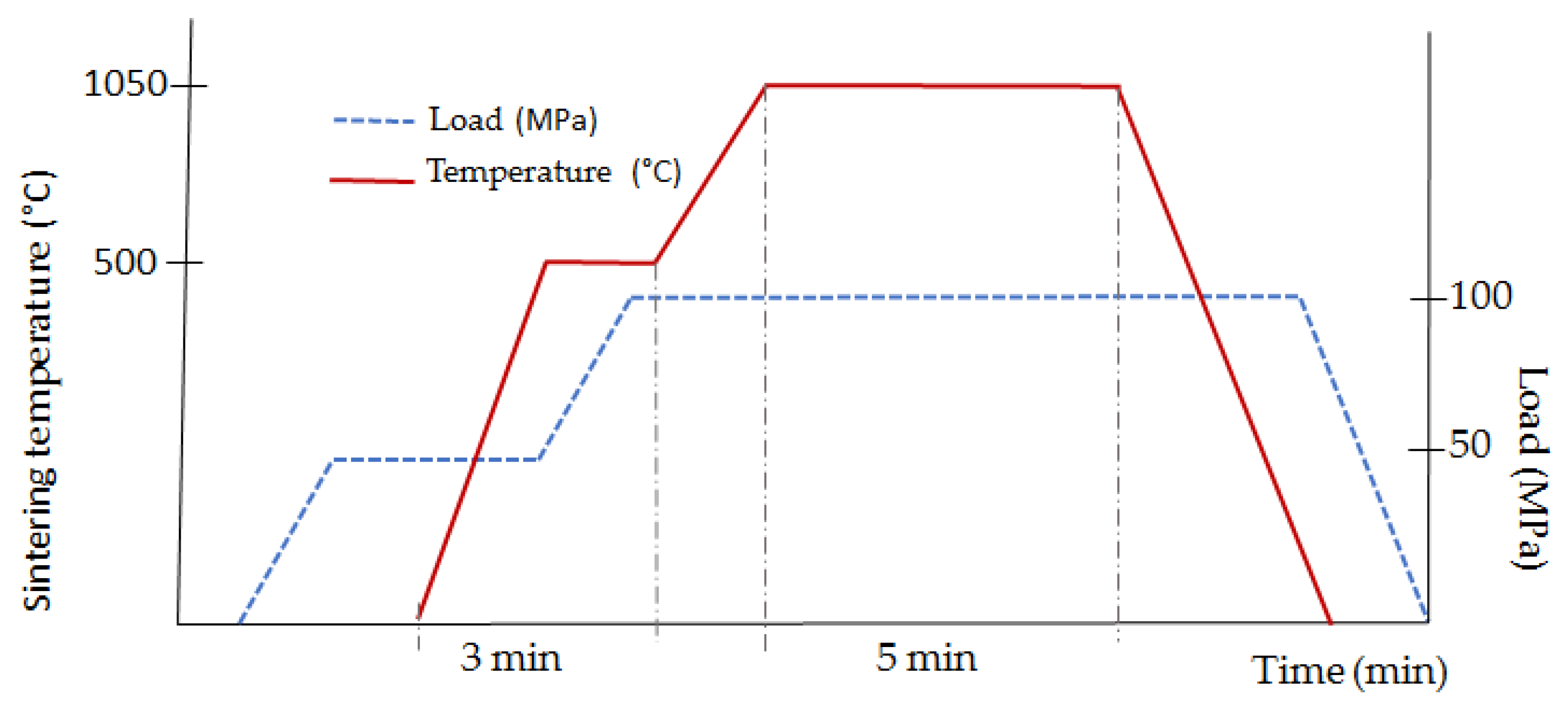

2. Materials and Methods

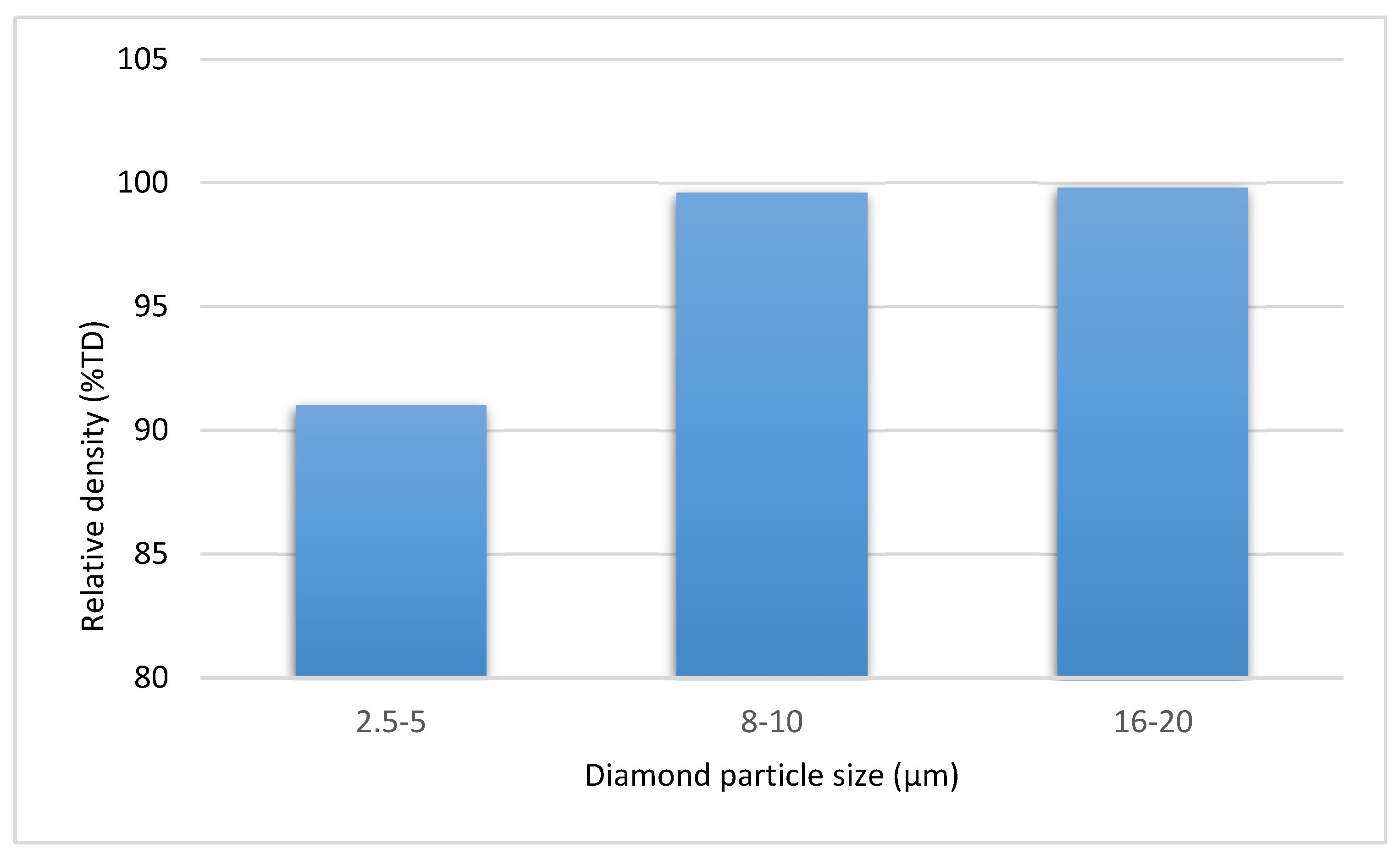

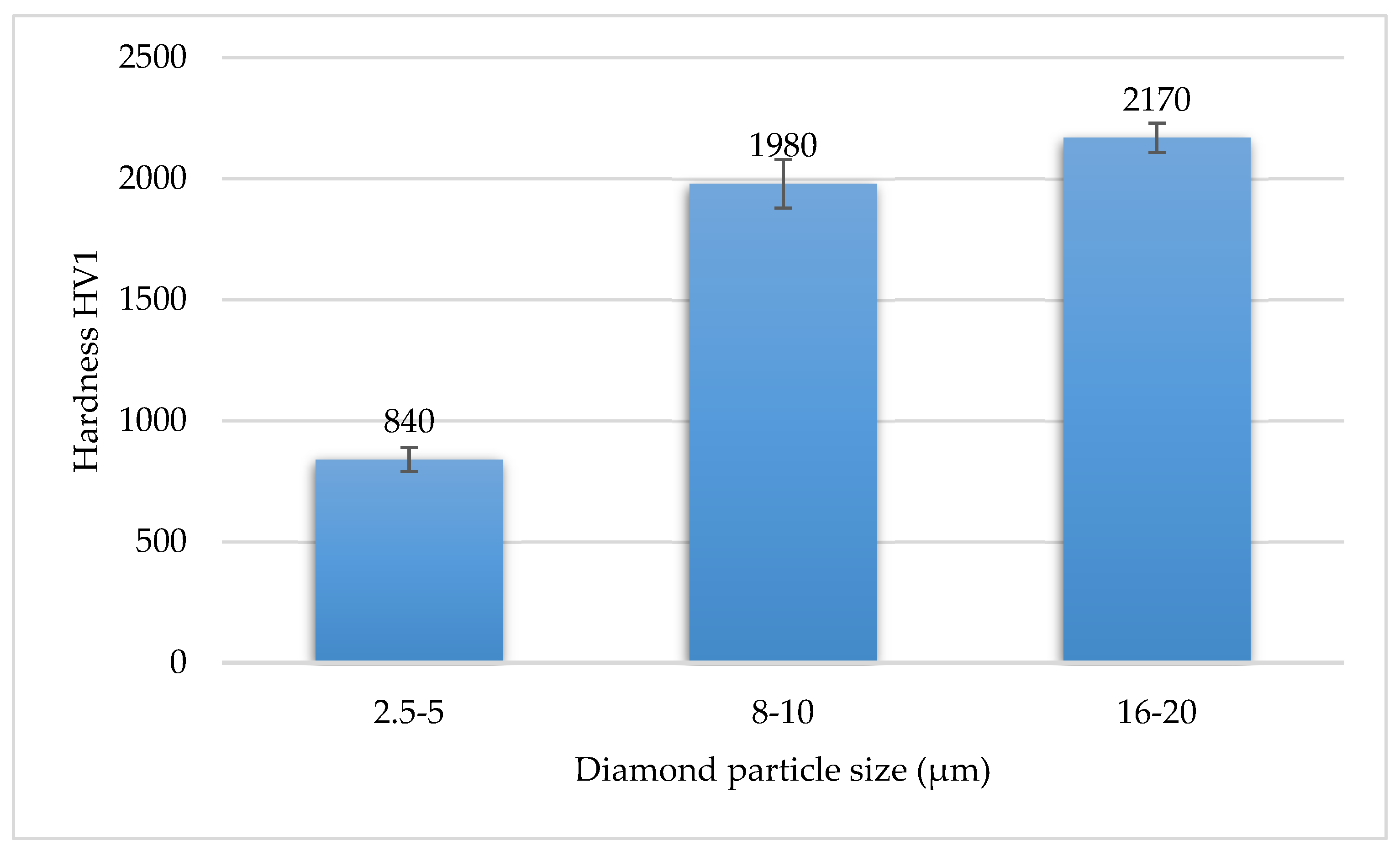

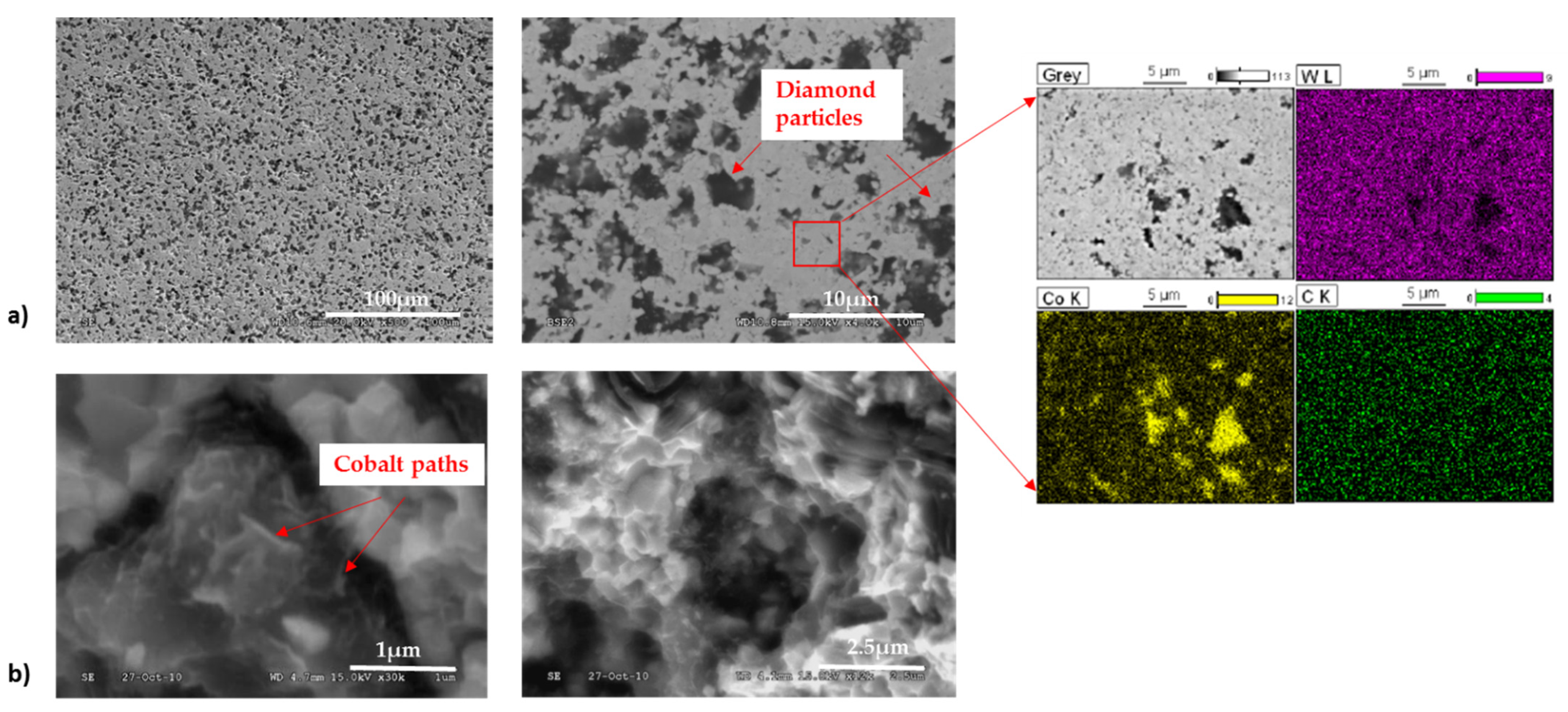

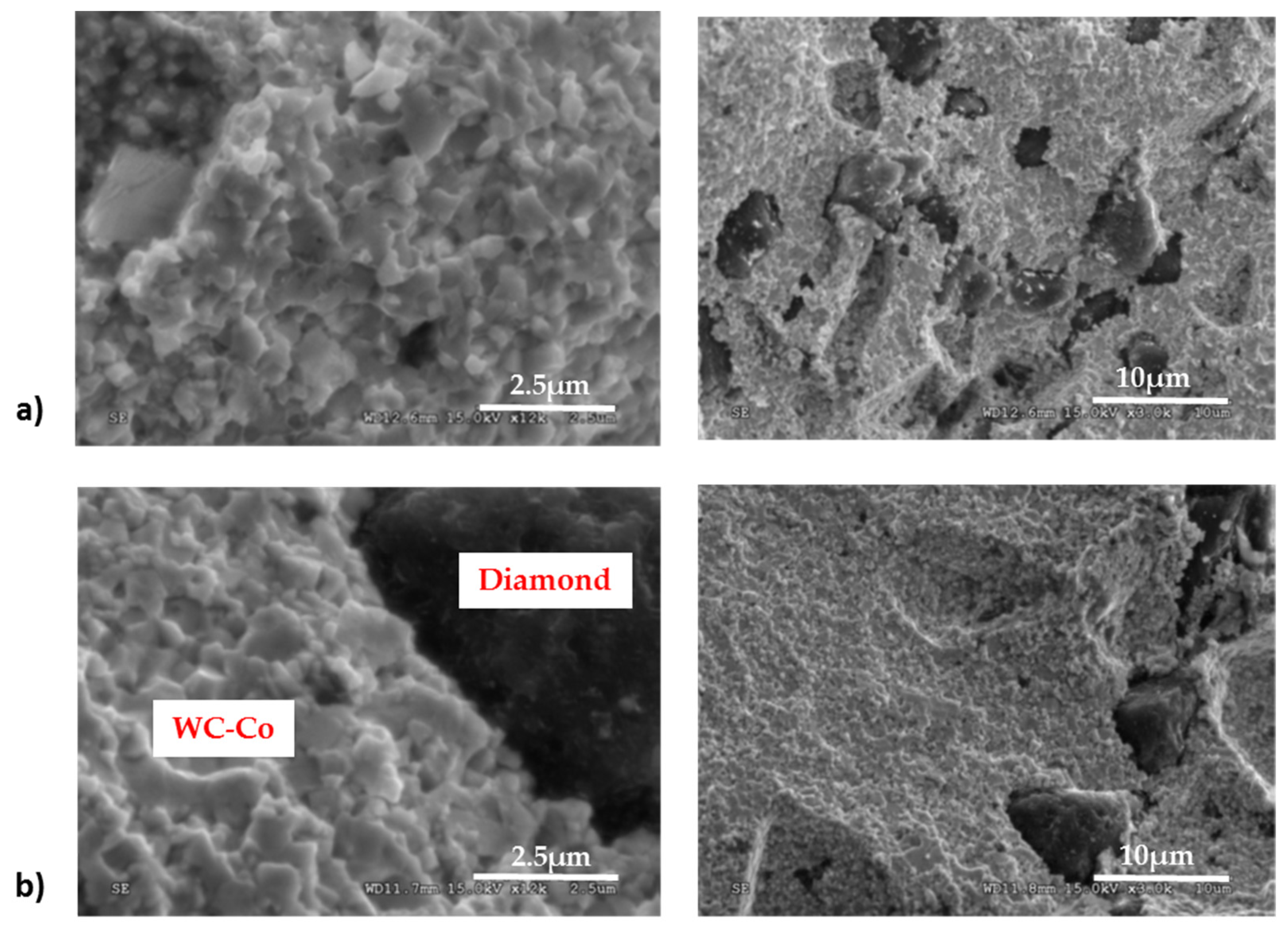

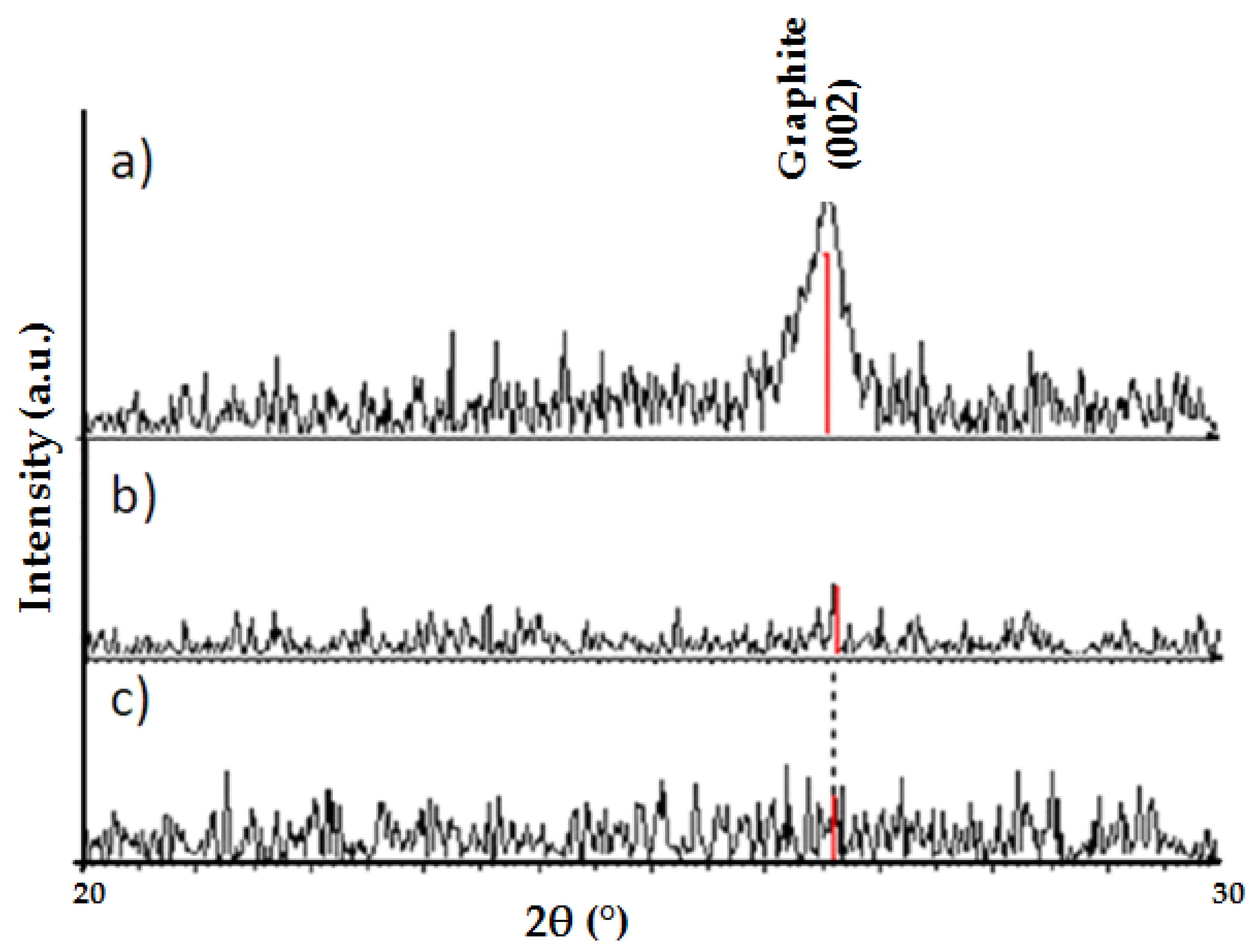

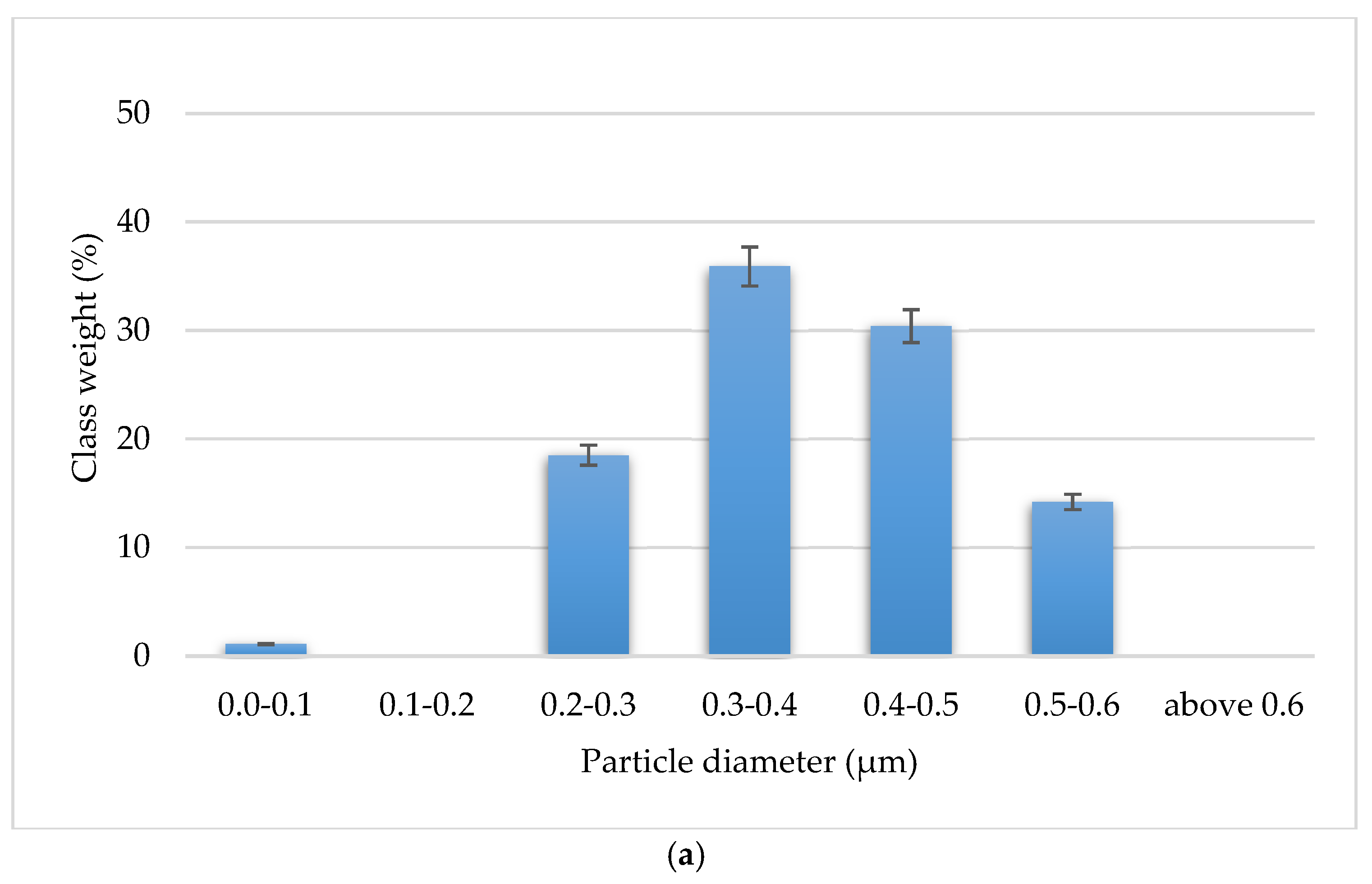

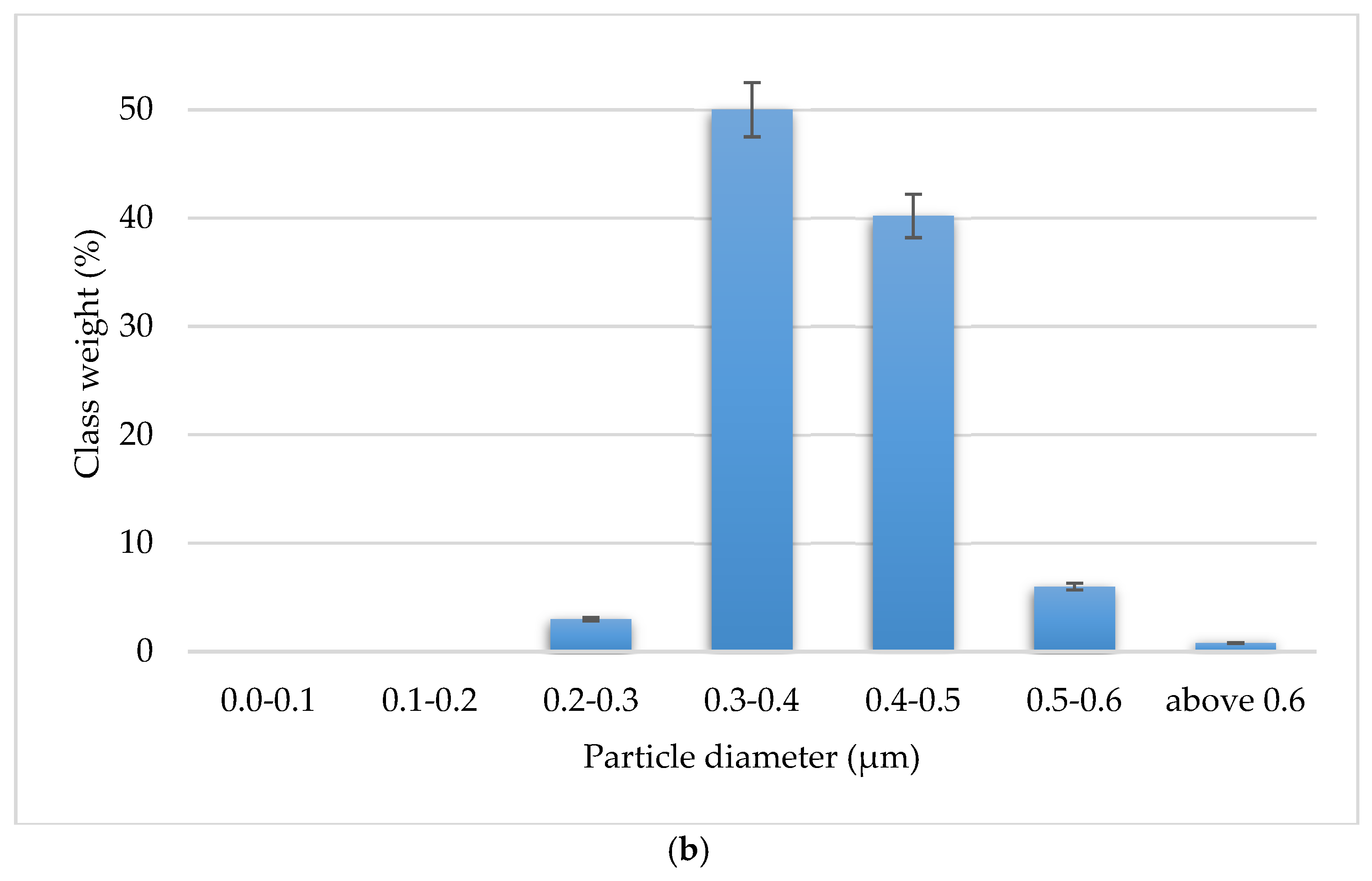

3. Results

4. Summary

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hao, T.; Du, J.; Su, G.; Zhang, P.; Sun, Y.; Zhang, J. Mechanical and cutting performance of cemented carbide tools with Cr/x/DLC composite coatings. Int. J. Adv. Manuf. Technol. 2020, 106, 5241–5254. [Google Scholar] [CrossRef]

- Parihar, R.S.; Setti, S.G.; Sahu, R.K. Preliminary investigation on development of functionally graded cemented tungsten carbide with solid lubricant via ball milling and spark plasma sintering. J. Compos. Mater. 2018, 52, 1363–1377. [Google Scholar] [CrossRef]

- Denkena, B.; Michaelis, A.; Herrmann, M.; Pötschke, J.; Krödel, A.; Vornberger, A.; Picker, T. Influence of tool material properties on the wear behavior of cemented carbide tools with rounded cutting edges. Wear 2020, 456, 203395. [Google Scholar] [CrossRef]

- Bushlya, V.; Johansson, D.; Lenrick, F.; Ståhl, J.-E.; Schultheiss, F. Wear mechanisms of uncoated and coated cemented carbide tools in machining lead-free silicon brass. Wear 2017, 376, 143–151. [Google Scholar] [CrossRef] [Green Version]

- Yehia, H.M. Microstructure, physical, and mechanical properties of the Cu/(WC-TiC-Co) nano-composites by the electroless coating and powder metallurgy technique. J. Compos. Mater. 2019, 53, 1963–1971. [Google Scholar] [CrossRef]

- Zhou, W.; Lin, J.; Feng, F.; Ma, Y.; Zha, H.; Ji, W.; Jiang, E.; Cai, Z.; Feng, P. Performance improvement of carbide cutting tool for Ti6Al4V alloys using electromagnetic treatment. Int. J. Adv. Manuf. Technol. 2021, 113, 1547–1560. [Google Scholar] [CrossRef]

- Sidorov, S.A.; Lobachevskii, Y.P.; Khoroshenkov, V.K.; Akhmedova, T.S.; Vorob’Ev, D.A. Wear and breakage resistance of hard alloy coatings strengthened with tungsten carbide. Metallurgist 2018, 61, 1023–1028. [Google Scholar] [CrossRef]

- Chayeuski, V.V.; Zhylinski, V.V.; Rudak, P.V.; Rusalsky, D.P.; Višniakov, N.; Černašėjus, O. Characteristics of ZrC/Ni-UDD coatings for a tungsten carbide cutting tool. Appl. Surf. Sci. 2018, 446, 18–26. [Google Scholar] [CrossRef]

- Gajrani, K.K.; Suresh, S.; Sankar, M.R. Environmental friendly hard machining performance of uncoated and MoS2 coated mechanical micro-textured tungsten carbide cutting tools. Tribol. Int. 2018, 125, 141–155. [Google Scholar] [CrossRef]

- Wilkowski, J.; Barlak, M.; Werner, Z.; Zagórski, J.; Czarniak, P.; Podziewski, P.; Szymanowski, K. Lifetime improvement and the cutting forces in nitrogen-implanted drills during wood-based material machining. Wood Fiber Sci. 2019, 51, 209–220. [Google Scholar] [CrossRef] [Green Version]

- Morozow, D.; Barlak, M.; Werner, Z.; Pisarek, M.; Konarski, P.; Zagórski, J.; Rucki, M.; Chałko, L.; Łagodziński, M.; Narojczyk, J.; et al. Wear Resistance Improvement of Cemented Tungsten Carbide Deep-Hole Drills after Ion Implantation. Materials 2021, 14, 239. [Google Scholar] [CrossRef]

- Wachowicz, J.; Michalski, A. Synthesis and properties of WCCo/diamond composite for uses as tool material for wood-based material machining. Compos. Interfaces 2020, 28, 735–747. [Google Scholar] [CrossRef]

- Wojciechowski, S.; Talar, R.; Zawadzki, P.; Wieczorowski, M. Evaluation of physical indicators and tool wear during grooving of spheroidal cast iron with a novel WCCo/cBN (BNDCC) inserts. Wear 2020, 454, 203301. [Google Scholar] [CrossRef]

- Wachowicz, J.; Truszkowski, T.; Rosiński, M.; Ossowski, M.; Skrabalak, G.; Cyrankowski, M. Tribological Properties of WCCo/cBNComposites Produced by Pulse Plasma Sintering. Arch. Metall. Mater. 2018, 63, 1763–1768. [Google Scholar]

- Bondarenko, M.O.; Davidenko, S.A. The Effect of Doping on the Structure and Properties of the Diamond–(WC–Co) Composite Material. Review. J. Superhard Mater. 2020, 42, 287–293. [Google Scholar] [CrossRef]

- Bakoń, A.; Szymański, A. Practical Uses of Diamond; Polish Scientific Publihers PWN: Warszawa, Poland, 1993. [Google Scholar]

- Uspenskaya, K.C.; Tormashev, U.N.; Fedoceev, D.V. Oxidization and graphitization of diamond in condition of low pressure atmosphere. J. Phys. Chem. 1982, 56, 495–496. [Google Scholar]

- Fedoseev, D.V.; Buhovets, V.L.; Vnukov, S.P. Surfacial graphitization of diamond at high temperatures. Surface 1980, 1, 92–99. [Google Scholar]

- Shao, W.Z.; Ivanov, V.V.; Zhen, L.; Cui, Y.S.; Wang, Y. A study on graphitization of diamond in copper–diamond composite materials. Mater. Lett. 2004, 58, 146–149. [Google Scholar] [CrossRef]

- Qian, J.; Pantea, C.; Huang, J.; Zerda, T.W.; Zhao, Y. Graphitization of diamond powders of different sizes at high pressure–high temperature. Carbon 2004, 42, 2691. [Google Scholar] [CrossRef]

- Rahman, A.A.; Frangeskou, A.C.; Kim, M.S.; Bose, S.; Morley, G.W.; Barker, P.F. Burning and graphitization of optically levitated nanodiamonds in vuum. Sci. Rep. 2016, 6, 21633. [Google Scholar] [CrossRef] [Green Version]

- Xu, N.S.; Chen, J.; Deng, S.Z. Effect of heat treatment on theproperties of nano-diamond under oxygen and argon ambient. Diam. Relat. Mater. 2002, 11, 249–256. [Google Scholar] [CrossRef]

- De Oliveira, L.J.; Cabral, S.C.; Filgueira, M. Study hot pressed Fe-diamond composites graphitization. Int. J. Refract. Met. Hard Mater. 2012, 35, 228–234. [Google Scholar] [CrossRef]

- Moriguchi, H.; Tsuduki, K.; Ikegaya, A.; Miyamoto, Y.; Morisada, Y. Sintering behavior and properties of diamond/cemented carbides. Int. J. Refract. Met. Hard Mater. 2007, 25, 237. [Google Scholar] [CrossRef]

- Shi, X.L.; Shao, G.Q.; Duan, X.L.; Xiong, Z.; Yang, H. The effect of tungsten Buffet layer on the stability of diamond with tungsten carbide-cobalt nanocomposite powder during spark plasma sintering. Diam. Relat. Mater. 2006, 15, 1643. [Google Scholar] [CrossRef]

- Michalski, A.; Siemiaszko, D. Nanocrystalline cemented carbides sintered by the pulse plasma method. Int. J. Refract. Met. Hard Mater. 2007, 25, 153–158. [Google Scholar] [CrossRef]

- Rosinski, M.; Ciupinski, L.; Grzonka, J.; Michalski, A.; Kurzydlowski, K. Synthesis and characterization of the diamond/copper composites produced by the pulse plasma sintering (PPS) method. Diam. Relat. Mater. 2012, 27, 29–35. [Google Scholar] [CrossRef]

- Cavaliere, P.; Sadeghi, B.; Shabani, A. Spark plasma sintering: Process fundamentals. In Spark Plasma Sintering of Materials; Springer: Cham, Switzerland, 2019; pp. 3–20. [Google Scholar]

- Hu, Z.Y.; Zhang, Z.H.; Cheng, X.W.; Wang, F.C.; Zhang, Y.F.; Li, S.L. A review of multi-physical fields induced phenomena and effects in spark plasma sintering: Fundamentals and applications. Mater. Des. 2020, 191, 108662. [Google Scholar] [CrossRef]

- Chaim, R. Densification mechanisms in spark plasma sintering of nanocrystalline ceramics. Mater. Sci. Eng. A 2007, 443, 25–32. [Google Scholar] [CrossRef]

- Song, X.; Liu, X.; Zhang, J. Neck formation and self-adjusting mechanism of neck growth of conducting powders in spark plasma sintering. J. Am. Ceram. Soc. 2006, 89, 494–500. [Google Scholar] [CrossRef]

- Rosiński, M.; Wachowicz, J.; Ziętala, M.; Michalski, A. Właściwości kompozytu WCCo spiekanego metodą PPS. Mater. Ceram. 2012, 64, 319–323. [Google Scholar]

- Rosinski, M.; Wachowicz, J.; Plocinski, T.; Truszkowski, T.; Michalski, A. Properties of WCCO/diamond composites produced by PPS method intended for drill bits for machining of building stones. In Innovative Processing and Manufacturing of Advanced Ceramics and Composites II; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2014; p. 181. [Google Scholar]

- Lisovsky, A.F.; Bondarenko, N. The role of interphase and contact surfaces in the formations of structures and properties of diamond-(WC-Co) composites. A review. J. Superhard Mater. 2014, 36, 145–155. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wachowicz, J.; Wilkowski, J. Influence of Diamond Grain Size on the Basic Properties of WC-Co/Diamond Composites Used in Tools for Wood-Based Materials Machining. Materials 2022, 15, 3569. https://doi.org/10.3390/ma15103569

Wachowicz J, Wilkowski J. Influence of Diamond Grain Size on the Basic Properties of WC-Co/Diamond Composites Used in Tools for Wood-Based Materials Machining. Materials. 2022; 15(10):3569. https://doi.org/10.3390/ma15103569

Chicago/Turabian StyleWachowicz, Joanna, and Jacek Wilkowski. 2022. "Influence of Diamond Grain Size on the Basic Properties of WC-Co/Diamond Composites Used in Tools for Wood-Based Materials Machining" Materials 15, no. 10: 3569. https://doi.org/10.3390/ma15103569

APA StyleWachowicz, J., & Wilkowski, J. (2022). Influence of Diamond Grain Size on the Basic Properties of WC-Co/Diamond Composites Used in Tools for Wood-Based Materials Machining. Materials, 15(10), 3569. https://doi.org/10.3390/ma15103569