Effect of PET Size, Content and Mixing Process on the Rheological Characteristics of Flexible Pavement

Abstract

1. Introduction

2. Materials and Methods

2.1. Bitumen

2.2. Polyethylene Terephthalate Plastics Fiber

2.3. Selection and Mixing Mechanism of PET-Modified Asphalt Binder

2.4. Preparation of PET Modified Binder for Consistency Test

2.5. Sample Preparation of PET Modified Binder for Rheological Test

2.6. Rheological Characterization of Asphalt Binder

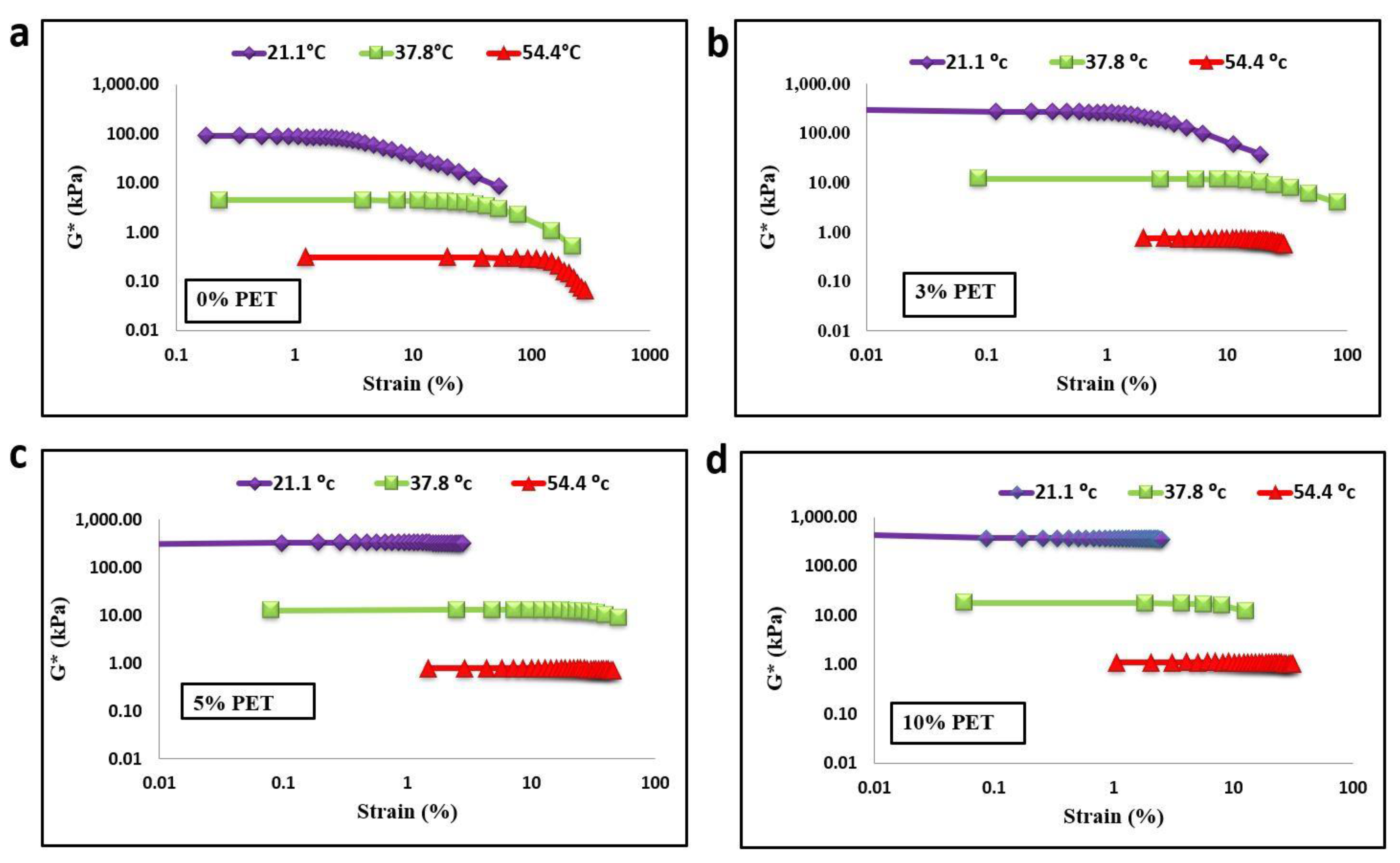

2.6.1. Amplitude Sweep Test Result

2.6.2. PG Determination

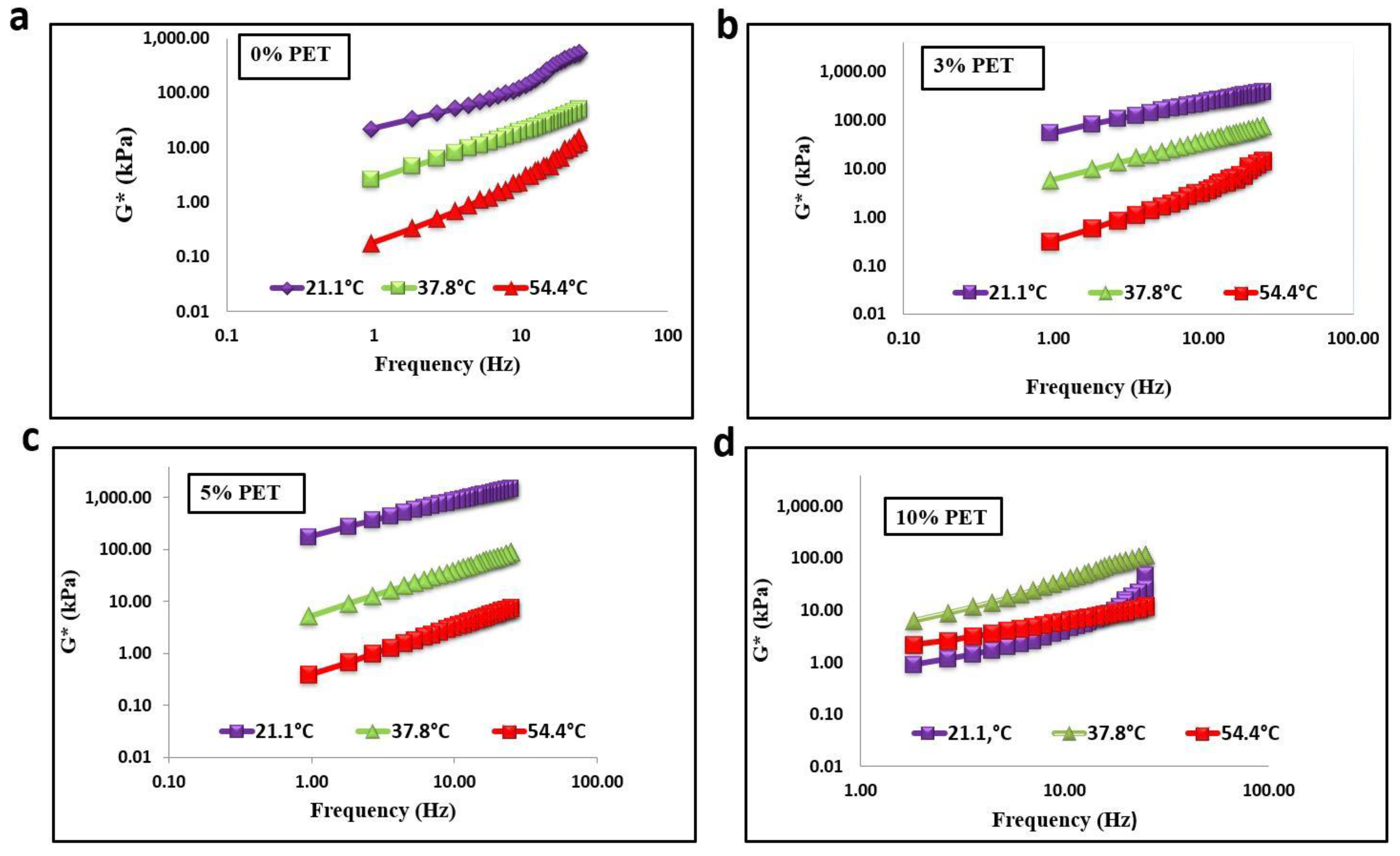

2.6.3. Frequency Sweep Test

3. Results

3.1. Convection Test Result

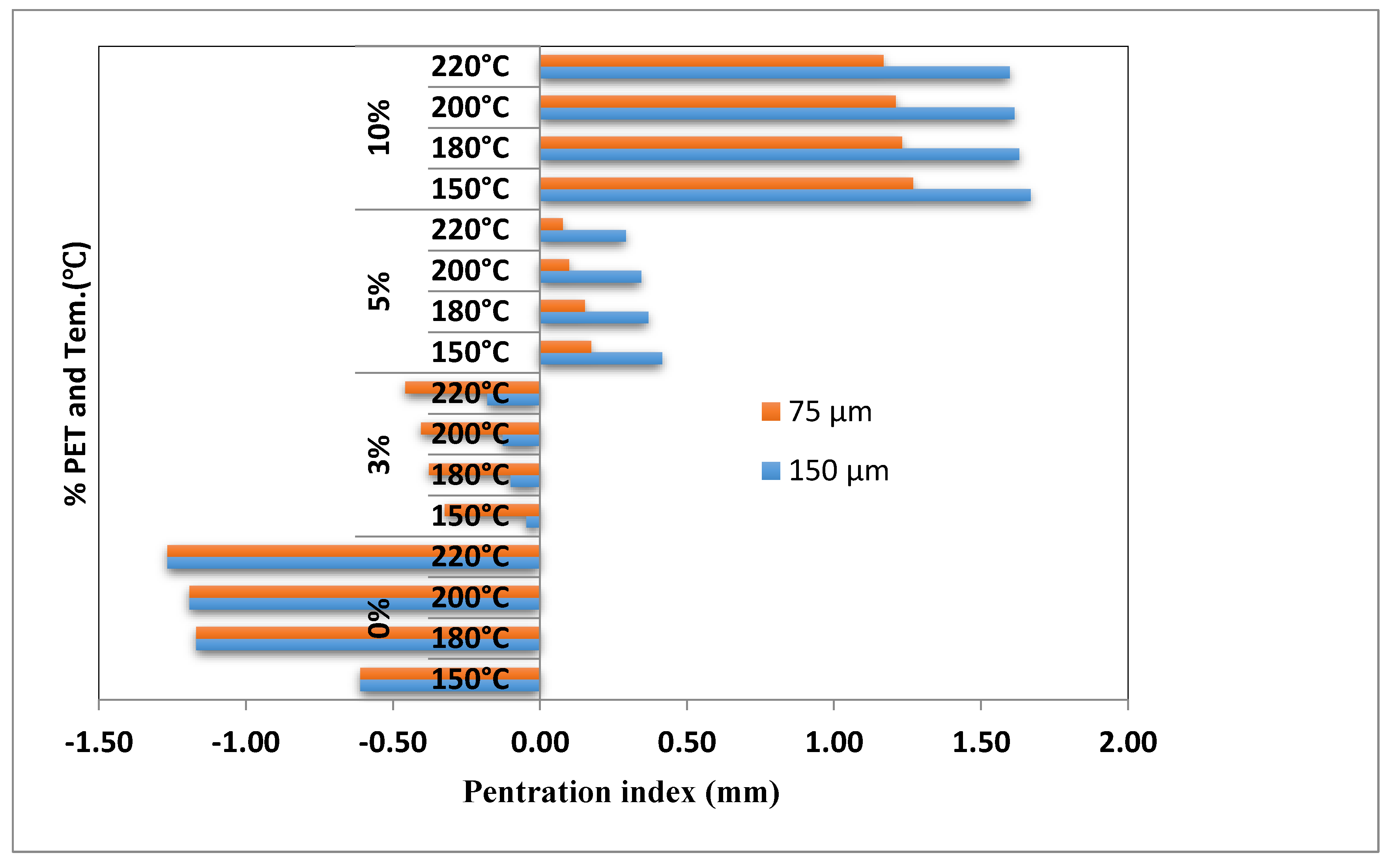

3.1.1. Effect of Size and Content of PET on PI Value

3.1.2. Effect of Mix Process on Physical Properties of Asphalt Binder

3.1.3. Effect of Mixing Temperature on Physical Properties of Asphalt Binder

3.2. Rheological Properties of Rubberized Bitumen

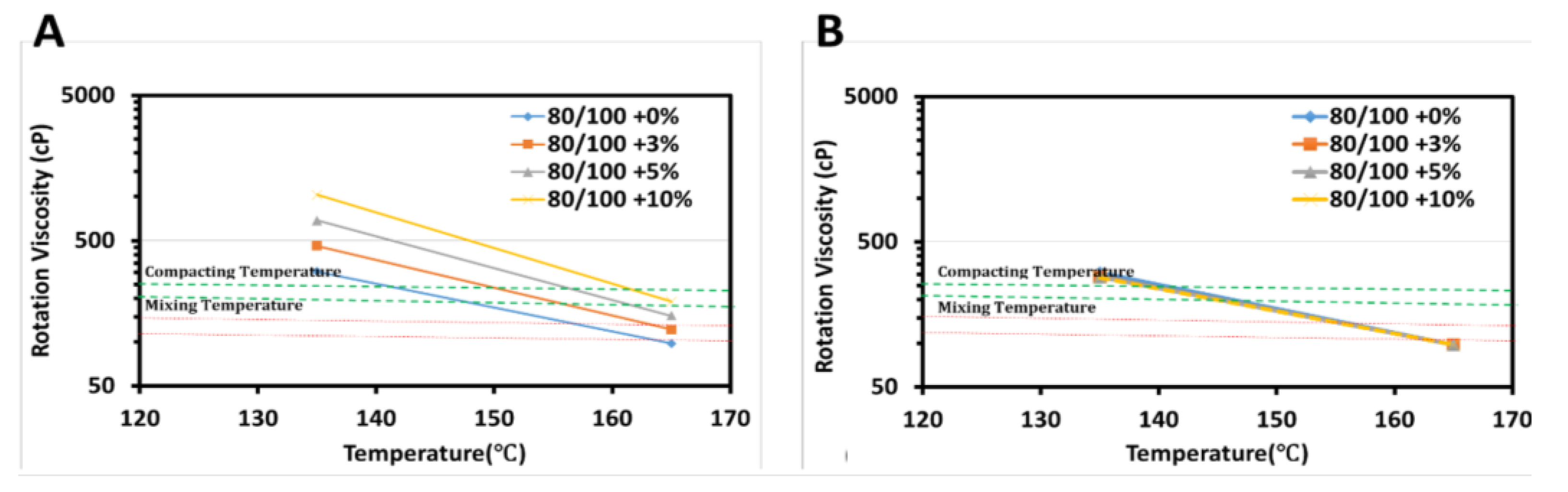

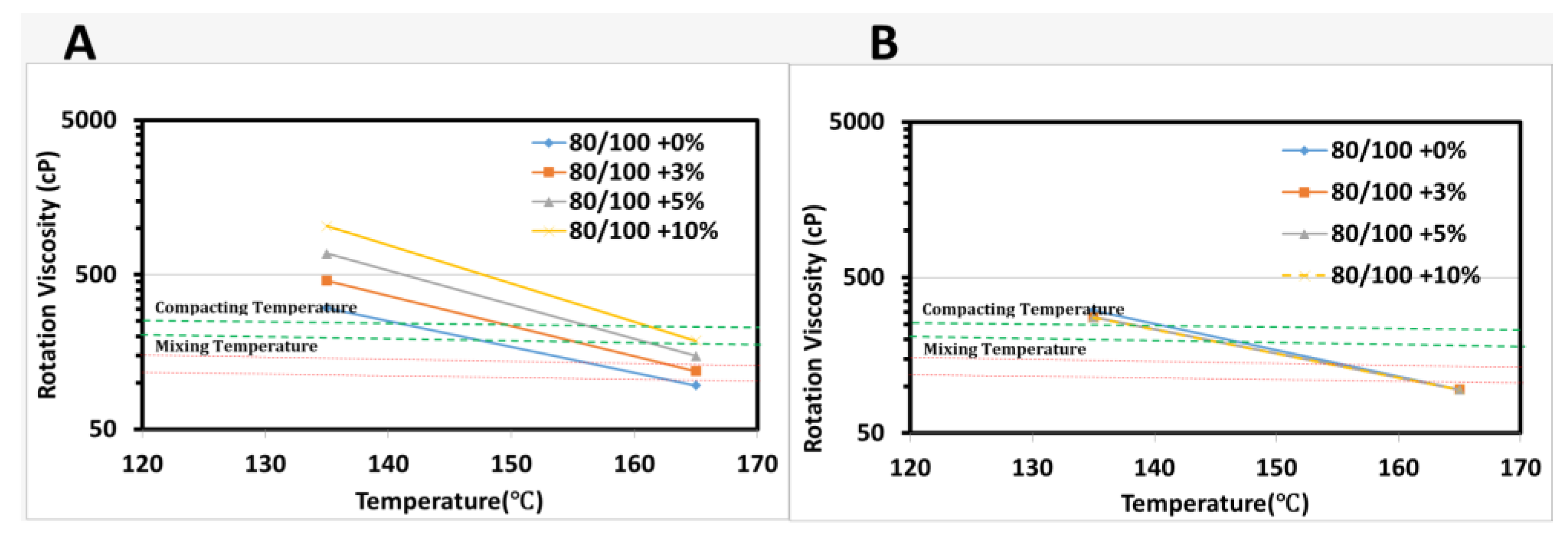

3.2.1. Effect of Mix Process Technique on Viscosity of PET Modified Asphalt Binder

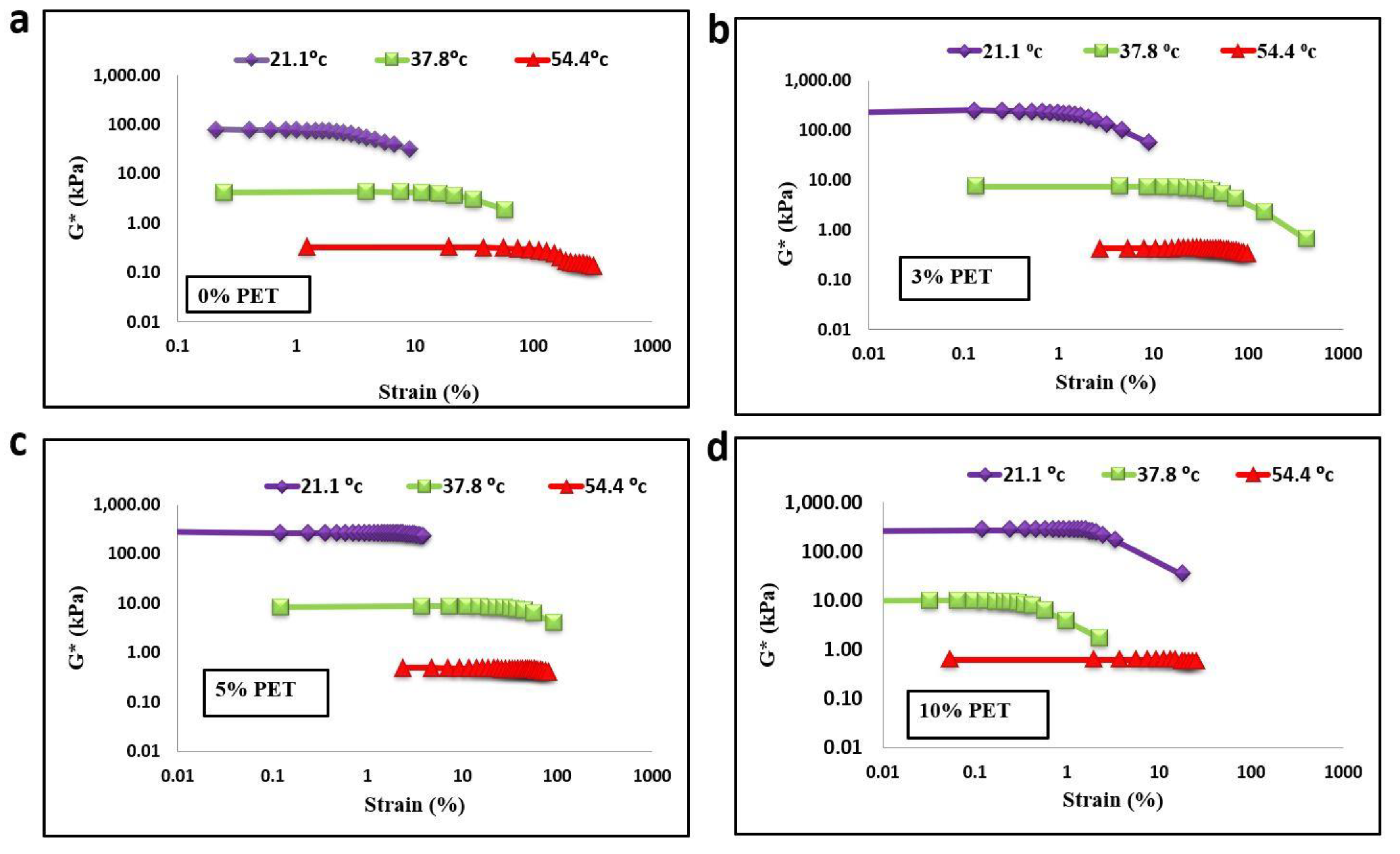

3.2.2. Effect of PET Content, Temperature, and Aging on Binder LVER

3.2.3. PG Determination

3.2.4. Frequency Sweep Test

3.2.5. Master Curves of Complex Shear Modulus

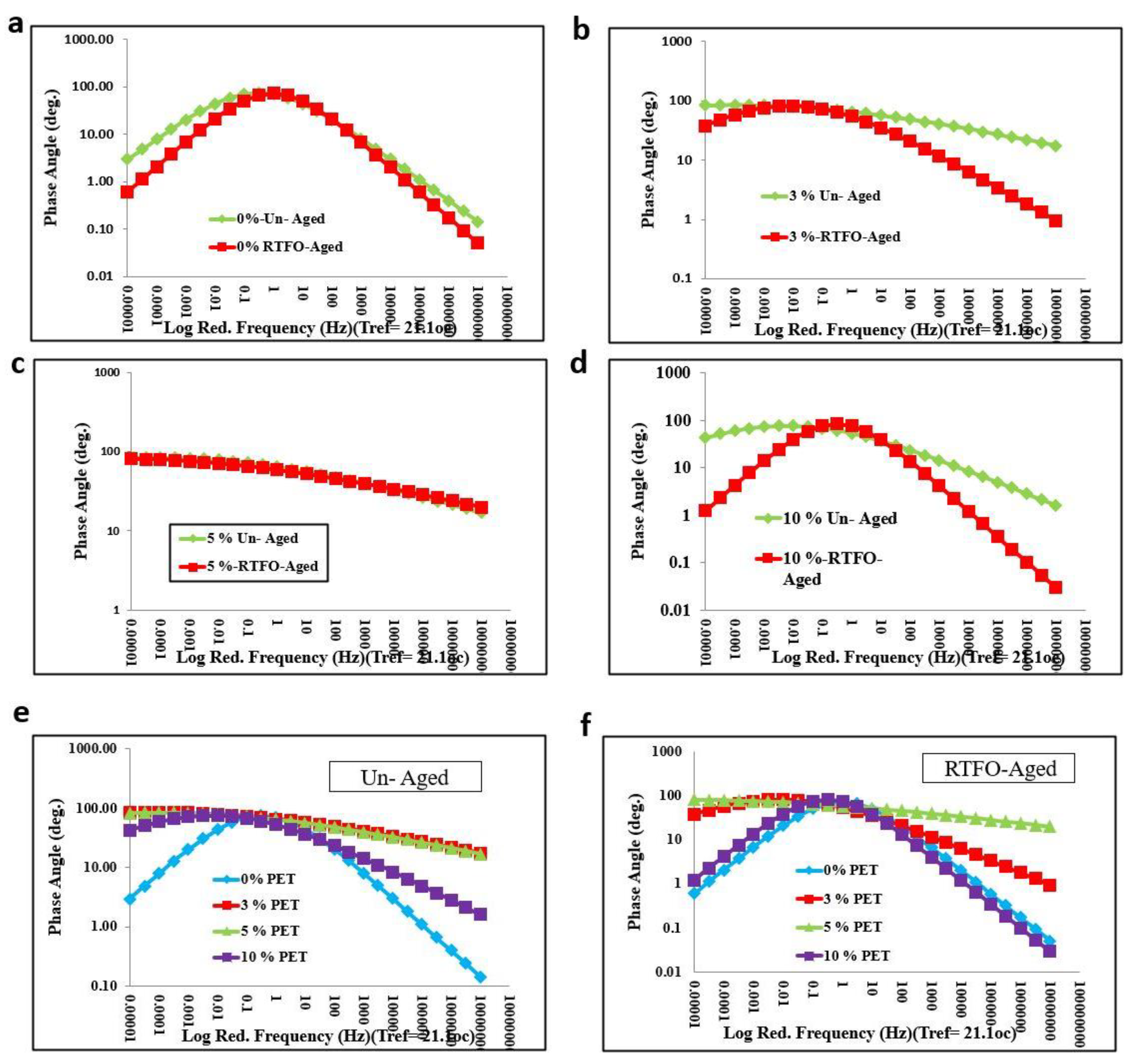

3.2.6. Master Curves of Phase Angle

4. Conclusions

- The properties of bitumen, such as penetration and softening point, were improved with the addition of the waste plastic PET fiber as compared to the baseline binder. The content and size of PET in bitumen had a significant effect, dramatically increasing the softening and decreasing the penetration value. Increasing the size of PET from 75 to 150 µm led the PI value to increase up to 31%, while the baseline bitumen accelerated four-fold when the PET content increased from 0% to 10%. The increase in the size and amount of PET increased softening point due to the blending of temperature effect and physical mix. The decrease in penetration value occurred as PET made the bitumen stiffer. This led the bitumen to have a higher PI value. A Higher PI value, in turn, implies the improvement of temperature susceptibility, which makes higher resistance to temperature crack and deformation.

- Rather than the blending temperature, the PET content and size had a pronounced effect on the penetration value and the softening point, while a constant ductility value was obtained. At constant 150 °C, a variation in PETcontent from 0% to 10% of bitumen resulted in a decline of the penetration and ductility values of the binder from 96 to 85 mm and 100 to 78 cm, respectively. The softening point increased from 46 to 56.6 °C when increasing the PET content from 0% to 10%. Utilizing PET particles improved the high-temperature susceptibility of the binder.

- The viscosity of baseline bitumen was 306 and 98 cP under 135 and 165 °C, which was less viscose than when 10% PET was incorporated into bitumen, reaching 1032 and 19 cP. Thus, adding 10% of PET increased the viscosity value three times the baseline bitumen under 135 °C. The viscosity value declined four times when the temperature increased from 135 to 165 °C at 10% PET.

- Modifiers had a greater effect at high temperatures than at low temperatures. PG results reveal that when 10% PET was added to the baseline bitumen, the PG value upgraded from PG 58 to PG 64. Additionally, compared to unaged and RTFO aged PG values, the PG value of RTFO aged was softer (not susceptible to hardening) than the unaged binders. The modifier significantly improved the shear stiffness and decreased phase angle (increase elastic modules) at low frequency and high temperature than at high frequency. With the help of PET additive, increasing the stiffness and elastic modulus of the binder the pavement performance was improved against this distress.

Author Contributions

Funding

Conflicts of Interest

References

- Zhang, Y.; Leng, Z. Quantification of bituminous mortar aging and its application in raveling evaluation of porous asphalt wearing courses. Mater. Des. 2017, 119, 1–11. [Google Scholar] [CrossRef]

- Zhang, Y.; van de Ven, M.; Molenaar, A.; Wu, S. Preventive maintenance of porous asphalt concrete using surface treatment technology. Mater. Des. 2016, 99, 262–272. [Google Scholar] [CrossRef]

- Fadil, H.; Jelagin, D.; Larsson, P.L.; Partl, M.N. Measurement of the visco-elastic properties of asphalt mortar and its components with indentation tests. Road Mater. Pavement Des. 2019, 20, S797–S811. [Google Scholar] [CrossRef]

- Wang, X.; Guo, H.; Yang, B.; Chang, X.; Wan, C.; Wang, Z. Aging characteristics of bitumen from different bituminous pavement structures in service. Materials 2019, 12, 530. [Google Scholar] [CrossRef] [PubMed]

- Ghavibazoo, A.; Abdelrahman, M.; Ragab, M. Evaluation of oxidization of crumb rubber–modified asphalt during short-term aging. J. Transp. Res. Board 2015, 2505, 84–91. [Google Scholar] [CrossRef]

- Kumbargeri, Y.S.; Biligiri, K.P. Understanding aging behavior of conventional asphalt binders used in India. Transp. Res. Procedia 2016, 17, 282–290. [Google Scholar] [CrossRef]

- Huang, S.C.; Zeng, M. Characterization of aging effect on rheological properties of asphalt-filler systems. Int. J. Pavement Eng. 2014, 8, 213–223. [Google Scholar] [CrossRef]

- Zhang, F.; Li, J.; Yaseen, M.; Han, M.; Yin, Y.; Yang, S. Preparation methods and performance of modified asphalt using rubber–plastic alloy and its compounds. J. Mater. Civ. Eng. 2018, 30, 04018163. [Google Scholar] [CrossRef]

- Fang, C.; Wu, C.; Yu, R.; Zhang, Z.; Zhang, M.; Zhou, S. Aging properties and mechanism of the modified asphalt by packaging waste polyethylene and waste rubber powder. Polym. Adv. Technol. 2013, 24, 51–55. [Google Scholar] [CrossRef]

- Qin, Q.; Schabron, J.F.; Boysen, R.B.; Farrar, M.J. Field aging effect on chemistry and rheology of asphalt binders and rheological predictions for field aging. Fuel 2014, 121, 86–94. [Google Scholar] [CrossRef]

- Rahmani, H.; Shirmohammadi, H.; Hamedi, G.H. Effect of asphalt binder aging on thermodynamic parameters and its relationship with moisture sensitivity of asphalt mixes. J. Mater. Civ. Eng. 2018, 30, 04018278. [Google Scholar] [CrossRef]

- Cong, P.; Chen, S.; Yu, J.; Wu, S. Effects of aging on the properties of modified asphalt binder with flame retardants. Constr. Build. Mater. 2010, 24, 2554–2558. [Google Scholar] [CrossRef]

- Zhang, H.; Xu, G.; Chen, X.; Wang, R.; Shen, K. Effect of long-term laboratory aging on rheological properties and cracking resistance of polymer-modified asphalt binders at intermediate and low-temperature range. Constr. Build. Mater. 2019, 226, 767–777. [Google Scholar] [CrossRef]

- Sarker, M.; Rashid, M.M. Thermal degradation of poly (ethylene terephthalate) waste soft drinks bottles and low-density polyethylene grocery bags. Int. J. Sustain. Energy Environ. 2013, 1, 78–86. [Google Scholar]

- Zohoori, M.; Ghani, A. Municipal solid waste management challenges and problems for cities in low-income and developing countries. Int. J. Sci. Eng. Appl. 2017, 6, 39–48. [Google Scholar] [CrossRef]

- Gedefaw, M. Assessing the current status of solid waste management of Gondar Town, Ethiopia. Int. J. Sci. Technol. Res. 2015, 4, 28–36. [Google Scholar]

- Erasu, D.; Feye, T.; Kiros, A.; Balew, A. Municipal solid waste generation and disposal in Robe town, Ethiopia. J. Air Waste Manag. Assoc. 2018, 68, 1391–1397. [Google Scholar] [CrossRef]

- Ling, T.; Lu, Y.; Zhang, Z.; Li, C.; Oeser, M. Value-added application of waste rubber and waste plastic in asphalt binder as a multifunctional additive. Materials 2019, 12, 1280. [Google Scholar] [CrossRef]

- Shu, B.; Wu, S.; Pang, L.; Javilla, B. The utilization of multiple-walled carbon nanotubes in polymer-modified bitumen. Materials 2017, 10, 416. [Google Scholar] [CrossRef]

- Wang, H.; Liu, X.; Apostolidis, P.; Scarpas, T. Rheological behavior and its chemical interpretation of crumb rubber modified asphalt containing warm-mix additives. Transp. Res. Rec. 2018, 2672, 337–348. [Google Scholar] [CrossRef]

- Ren, S.; Liu, X.; Fan, W.; Wang, H.; Erkens, S. Rheological properties, compatibility, and storage stability of SBS latex-modified asphalt. Materials 2019, 12, 3683. [Google Scholar] [CrossRef]

- Nasr, D.; Pakshir, A.H. Rheology and storage stability of modified binders with waste polymers composites. Road Mater. Pavement Des. 2017, 20, 773–792. [Google Scholar] [CrossRef]

- Brasileiro, L.; Moreno-Navarro, F.; Tauste-Martínez, R.; Matos, J.; Rubio-Gámez, M.D. Reclaimed polymers as asphalt binder modifiers for more sustainable roads: A review. Sustainability 2019, 11, 646. [Google Scholar] [CrossRef]

- Wang, H.; Liu, X.; Apostolidis, P.; Scarpas, T. Non-Newtonian behaviors of crumb rubber-modified bituminous binders. Appl. Sci. 2018, 8, 1760. [Google Scholar] [CrossRef]

- Leng, Z.; Padhan, R.K.; Sreeram, A. Production of a sustainable paving material through chemical recycling of waste PET into crumb rubber modified asphalt. J. Clean. Prod. 2018, 180, 682–688. [Google Scholar] [CrossRef]

- Bary, E.A.; Farag, R.K.; Ragab, A.A.; Abdel-monem, R.M.; Abo-shanab, Z.L.; Saleh, A.M. Green asphalt construction with improved stability and dynamic mechanical properties. Polym. Bull. 2020, 77, 1729–1747. [Google Scholar] [CrossRef]

- Sangiorgi, C.; Eskandarsefat, S.; Tataranni, P.; Simone, A.; Vignali, V.; Lantieri, C.; Dondi, G. A Complete laboratory assessment of crumb rubber porous asphalt. Constr. Build. Mater. 2017, 132, 500–507. [Google Scholar] [CrossRef]

- Cheng, Y.; Chai, C.; Liang, C.; Chen, Y. Mechanical performance of warm-mixed porous asphalt mixture with steel slag and crumb-rubber–SBS modified bitumen for seasonal frozen regions. Materials 2019, 12, 857. [Google Scholar] [CrossRef]

- Eskandarsefat, S.; Dondi, G.; Sangiorgi, C. Recycled and rubberized SMA modified mixtures: A comparison between polymer modified bitumen and modified fibres. Constr. Build. Mater. 2019, 202, 681–691. [Google Scholar] [CrossRef]

- Lee, S.J.; Akisetty, C.K.; Amirkhanian, S.N. The effect of crumb rubber modifier (CRM) on the performance properties of rubberized binders in HMA pavements. Constr. Build. Mater. 2008, 22, 1368–1376. [Google Scholar] [CrossRef]

- Fang, C.Q.; Zhang, M.Y.; Yu, R.E.; Liu, X.L. Effect of preparation temperature on the aging properties of waste polyethylene modified asphalt. J. Mater. Sci. Technol. 2015, 31, 320–324. [Google Scholar] [CrossRef]

- Gürü, M.; Çubuk, M.K.; Arslan, D.; Farzanian, S.A.; Bilici, I. An approach to the usage of polyethylene terephthalate (PET) waste as a roadway pavement material. J. Hazard. Mater. 2014, 279, 302–310. [Google Scholar] [CrossRef]

- Fuentes-Audén, C.; Sandoval, J.A.; Jerez, A.; Navarro, F.J.; Martínez-Boza, F.J.; Partal, P.; Gallegos, C. Evaluation of thermal and mechanical properties of recycled polyethylene modified bitumen. Polym. Test. 2008, 27, 1005–1012. [Google Scholar] [CrossRef]

- Behl, A.; Sharma, G.; Kumar, G. A sustainable approach: Utilization of waste PVC in asphalting of roads. Constr. Build. Mater. 2014, 54, 113–117. [Google Scholar] [CrossRef]

- Rahman, M.N.; Ahmeduzzaman, M.; Sobhan, M.A.; Ahmed, T.U. Performance evaluation of waste polyethylene and PVC on hot asphalt mixtures. Am. J. Civ. Eng. Arch. 2013, 1, 97–102. [Google Scholar]

- Lyons, K.R.; Putman, B.J. Laboratory evaluation of stabilizing methods for porous asphalt mixtures. Constr. Build. Mater. 2013, 49, 772–780. [Google Scholar] [CrossRef]

- Ji, J.; Yao, H.; Liu, L.; You, Z.; Yang, X.; Suo, Z.; Zhai, P. Adhesion evaluation of asphalt-aggregate interface using surface free energy method. Appl. Sci. 2017, 7, 156. [Google Scholar] [CrossRef]

- Chu, L.; Tang, B.; Fwa, T. Evaluation of functional characteristics of laboratory mix design of porous pavement materials. Constr. Build. Mater. 2018, 191, 281–289. [Google Scholar] [CrossRef]

- Calandra, P.; Caputo, P.; De Santo, M.P.; Todaro, L.; Liveri, V.T.; Rossi, C.O. Effect of additives on the structural organization of asphaltene aggregates in bitumen. Constr. Build. Mater. 2019, 199, 288–297. [Google Scholar] [CrossRef]

- Martinho, F.C.G.; Picado-Santo, L.G.; Capitão, S.D. Feasibility assessment of the use of recycled aggregates for asphalt mixtures. Sustainability 2018, 10, 1737. [Google Scholar] [CrossRef]

- Fernandes, S.; Peralta, J.; Oliveira, J.R.; Williams, R.C.; Silva, H.M. Improving asphalt mixture performance by partially replacing bitumen with waste motor oil and elastomer modifiers. Appl. Sci. 2017, 7, 794. [Google Scholar] [CrossRef]

- Rahman, W.M.; Omardin, M.A. Characterization of recycled polyethylene terephthalate as partial fine aggregate replacement properties and behavior of asphalt mixtures for road pavements. Arpn J. Eng. Appl. Sci. 2016, 11, 3755–3758. [Google Scholar]

- Dalhat, M.A.; Al-Abdul Wahhab, H.I. Performance of recycled plastic waste modified asphalt binder in Saudi Arabia. Int. J. Pavement Eng. 2015, 18, 349–357. [Google Scholar] [CrossRef]

- Khan, I.M.; Kabir, S.; Alhussain, M.A.; Almansoor, F.F. Asphalt design using recycled plastic and crumb-rubber waste for sustainable pavement construction. Int. Conf. Sustain. Des. Eng. Constr. 2016, 145, 1557–1564. [Google Scholar] [CrossRef]

- Addissie, H.; Gebissa, A.; Tsegaye, M. Rheological properties of plastic modified bitumen for sub-tropical areas of Ethiopia. Am. J. Civ. Eng. Archit. 2018, 6, 223–235. [Google Scholar]

- Movilla-Quesada, D.; Raposeiras, A.C.; Olavarría, J. Effects of recycled polyethylene terephthalate (PET) on the stiffness of hot asphalt mixtures. Adv. Civ. Eng. 2019, 2019, 6969826. [Google Scholar] [CrossRef]

- Taherkhani, H.; Arshadi, M.R. Investigating the effects of using waste rubber and polyethylene terephthalate (PET) on mechanical properties of asphalt concrete. Int. J. Environ. Sci. Dev. 2018, 9, 316–321. [Google Scholar] [CrossRef][Green Version]

- Moghaddam, T.B.; Karim, M.R.; Syammaun, T. Dynamic properties of stone mastic asphalt mixtures containing waste plastic bottles. Constr. Build. Mater. 2012, 34, 236–242. [Google Scholar] [CrossRef]

- Maharaj, C.; Maharaj, R.; Maynard, J. The effect of polyethylene terephthalate particle size and concentration on the properties of asphalt and bitumen as an additive. Prog. Rubber Plast. Recycl. Technol. 2015, 31, 1–23. [Google Scholar] [CrossRef]

- Abdullah, M.E.; Ahmad, N.A.; Jaya, R.P.; Hassan, N.A.; Yaacob, H.; Hainin, M.R. Effects of waste plastic on the physical and rheological properties of bitumen. In Proceedings of the 5th International Conference on Nanomaterials and Materials Engineering, Paris, France, 1–3 April 2017. [Google Scholar]

- Thi, N.B.D.; Kumar, G.; Lin, C.Y. An overview of food waste management in developing countries: Current status and future perspective. J. Environ. Manag. 2015, 157, 220–229. [Google Scholar] [CrossRef]

- Hunter, R.N.; Self, A.; Read, J. The Shell Bitumen Handbook, 6th ed.; Shell International Petroleum Company Ltd.: London, UK, 2013; ISBN 978-0-7277-5837-8. [Google Scholar]

- Habib, N.Z.; Kamaruddin, I.; Napiah, M.; Tan, I.M. Effect of mixing process on polypropylene modified bituminous concrete mix properties. Int. J. Civ. Environ. Eng. 2011, 5, 477–482. [Google Scholar]

- Geçkil, T. Physical, chemical, microstructural and rheological properties of reactive terpolymer modifified bitumen. Materials 2019, 12, 921. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, M.S.; Fareed, M. Characterization of bitumen mixed with plastic waste. Int. J. Transp. Eng. 2015, 3, 2. [Google Scholar]

- Abu Abdo, A.M.; Khater, M.E. Enhancing rutting resistance of asphalt binder by adding plastic waste. Civ. Environ. Eng. Res. 2018, 5, 1452472. [Google Scholar] [CrossRef]

- Suresh, B.; Venkat Rao, N. Determination of physical and rehological properties of bitumen mixed with waste plastic. Int. J. Civ. Eng. Technol. (IJCIET) 2018, 9, 985–990. [Google Scholar]

- Kasanagh, S.H.; Ahmedzade, P.; Fainleib, A.; Gunay, T. Investigation of physical properties of asphalt binder modified by recycled polyethylene and ground tire rubber. Int. Sch. Sci. Res. Innov. 2018, 12, 599–603. [Google Scholar]

| Tests | Results | Applicable Standard | Specification AASHTO M82 |

|---|---|---|---|

| Penetration,100 g 5 sec at 25 °C | 86 | AASHTO T 49 | 80–100 |

| Ductility, 5 cm/min, cm | 100+ | AASHTO T 51 | min, 100 |

| Specific Gravity of Asphalt, (g/mL) | 1023 | AASHTO T 228-06 | 1010–1050 |

| Solubility in Trichlorethylene, % | 99.8% | AASHTO T 44 | min, 99.5 |

| Loss On Heating | 0.2% | AASHTO T 47 | max, 0.2% |

| Softening Point | 46.0 °C | AASHTO T 53 | 45–52 °C |

| Flash Point | 588.2 0F | AASHTO T 48 | min, 232 °C |

| Water Content | - | AASHTO T 55 | max, 0.2% |

| Penetration of Residue | 88.4 | ASTM D5-IP49 | min, 53 |

| Ductility of Residue | 100+ | AASHTO T 51 | min, 75 |

| Property | Result | ASTM Standard |

|---|---|---|

| density | 0.9185 gm/cm3 | D1,505,792 |

| Melting point | 265 °C | D3418 |

| Thermal conductivity | 0.15 to 0.24 W m−1 K−1 | |

| Chemical unit | (CH2−CH2−)−n | |

| Flexural modules | 0.203 GPa | D790 |

| Tensile strength | 10.11 N/mm3 | D638 |

| % of PET and Binder | Waste Plastic Pet Size | |||||

|---|---|---|---|---|---|---|

| (150 μm) | (75 μm) | |||||

| Av. Pen. @25 °C in mm | Av. Soft. °C | PI Value B/n [−1+1] 0.1 mm | Av. Pen. @25 °C in mm | Av. Soft. °C | PI Value B/n [−1+1] 0.1 mm | |

| 0% | 96 | 46 | −0.6110 | 96 | 46 | −0.6110 |

| 3% | 95 | 48 | −0.0454 | 95.5 | 47 | −0.3235 |

| +5% | 92 | 50 | 0.4163 | 93 | 49 | 0.1735 |

| +10% | 85 | 56 | 1.6687 | 87 | 54 | 1.2692 |

| % PET | Av. Pen@25 °C in mm | Av. Soft. °C | Ductility (cm) | |||

|---|---|---|---|---|---|---|

| Dry Mix Process | ||||||

| (150 µm) | (75 µm) | (150 µm) | (75 µm) | (150 µm) | (75 µm) | |

| 0% | 96 | 96 | 46 | 46 | 100 | 100 |

| 3% | 95 | 95.5 | 48 | 47 | 89 | 90 |

| 5% | 92 | 93 | 50 | 49 | 85 | 85 |

| 10% | 85 | 87 | 56 | 54 | 75 | 78 |

| Wet Mix Process | ||||||

| 0% | 96 | 95.5 | 46 | 45 | 100 | 100 |

| 3% | 96 | 95.5 | 46 | 45 | 100 | 100 |

| 5% | 96 | 95.5 | 46 | 45 | 100 | 100 |

| 10% | 96 | 95.5 | 46 | 45 | 100 | 100 |

| Aging Status | PET % | Test Temp °C | G* (Pa) (×102) | δ(o) | G*/sin delta @10rad/sec. Pa (×102) | PG Pass Fail Tem (°C) | PG |

|---|---|---|---|---|---|---|---|

| Super-pave Spec. Limit (kPa) > 1.0 kPa | |||||||

| Un-aged | 0 | 58 | 14.9 | 85.7 | 14.9 | 61.7 | PG 58-xx |

| 64 | 7.7 | 86.8 | 7.7 | ||||

| 70 | 4.6 | 86.1 | 4.6 | ||||

| 3 | 58 | 23.7 | 88.0 | 23.7 | 64.9 | PG 64-xx | |

| 64 | 10.7 | 88.7 | 10.7 | ||||

| 70 | 4.9 | 88.8 | 4.9 | ||||

| 5 | 58 | 27.2 | 87.7 | 27.3 | 65.7 | PG 64-xx | |

| 64 | 12.2 | 88.4 | 12.3 | ||||

| 70 | 5.8 | 88.4 | 5.8 | ||||

| 10 | 58 | 34.7 | 87.1 | 34.8 | 67.1 | PG 64-xx | |

| 64 | 14.7 | 87.7 | 14.7 | ||||

| 70 | 7.0 | 87.7 | 7.0 | ||||

| Super-pave Spec. Limit (kPa) > 2.2 kPa | |||||||

| RTFO-aged | 0 | 58 | 26.3 | 84.7 | 26.3 | 59.3 | PG 58-xx |

| 64 | 11.7 | 86.4 | 11.7 | ||||

| 3 | 58 | 39.6 | 85.9 | 39.7 | 62.3 | PG 58-xx | |

| 64 | 17.3 | 87.0 | 17.3 | ||||

| 5 | 58 | 45.4 | 86.3 | 45.5 | 63.2 | PG 58-xx | |

| 64 | 19.5 | 87.3 | 19.5 | ||||

| 10 | 58 | 14.5 | 85.0 | 14.5 | 66.5 | PG 64-xx | |

| 64 | 29.2 | 84.5 | 29.3 | ||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mahdi, T.W.; Senadheera, S.; Ghebrab, T. Effect of PET Size, Content and Mixing Process on the Rheological Characteristics of Flexible Pavement. Materials 2022, 15, 3565. https://doi.org/10.3390/ma15103565

Mahdi TW, Senadheera S, Ghebrab T. Effect of PET Size, Content and Mixing Process on the Rheological Characteristics of Flexible Pavement. Materials. 2022; 15(10):3565. https://doi.org/10.3390/ma15103565

Chicago/Turabian StyleMahdi, Teyba Wedajo, Sanjaya Senadheera, and Tewodros Ghebrab. 2022. "Effect of PET Size, Content and Mixing Process on the Rheological Characteristics of Flexible Pavement" Materials 15, no. 10: 3565. https://doi.org/10.3390/ma15103565

APA StyleMahdi, T. W., Senadheera, S., & Ghebrab, T. (2022). Effect of PET Size, Content and Mixing Process on the Rheological Characteristics of Flexible Pavement. Materials, 15(10), 3565. https://doi.org/10.3390/ma15103565